Novel casting aluminium alloy and preparation method thereof

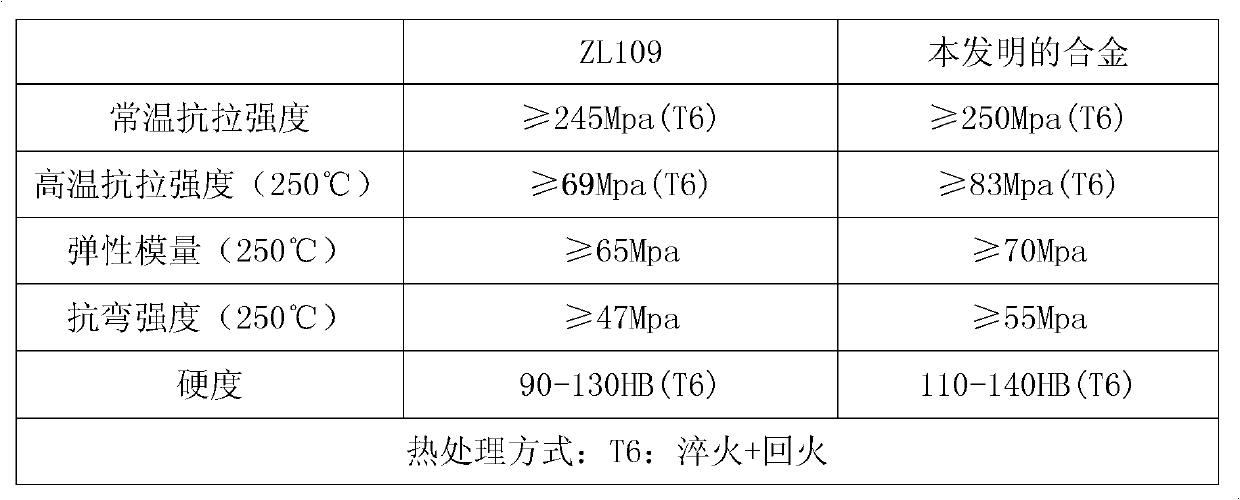

A casting aluminum alloy, a new type of technology, applied in the field of new casting aluminum alloy and its preparation, can solve the problem of poor comprehensive performance such as low service life, high temperature tensile strength, elastic modulus thermal conductivity, linear expansion rate hardness, etc., engine piston work Performance limitations and other issues, to achieve the effects of prolonging service life, improving comprehensive mechanical properties, and improving high-temperature thermal fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

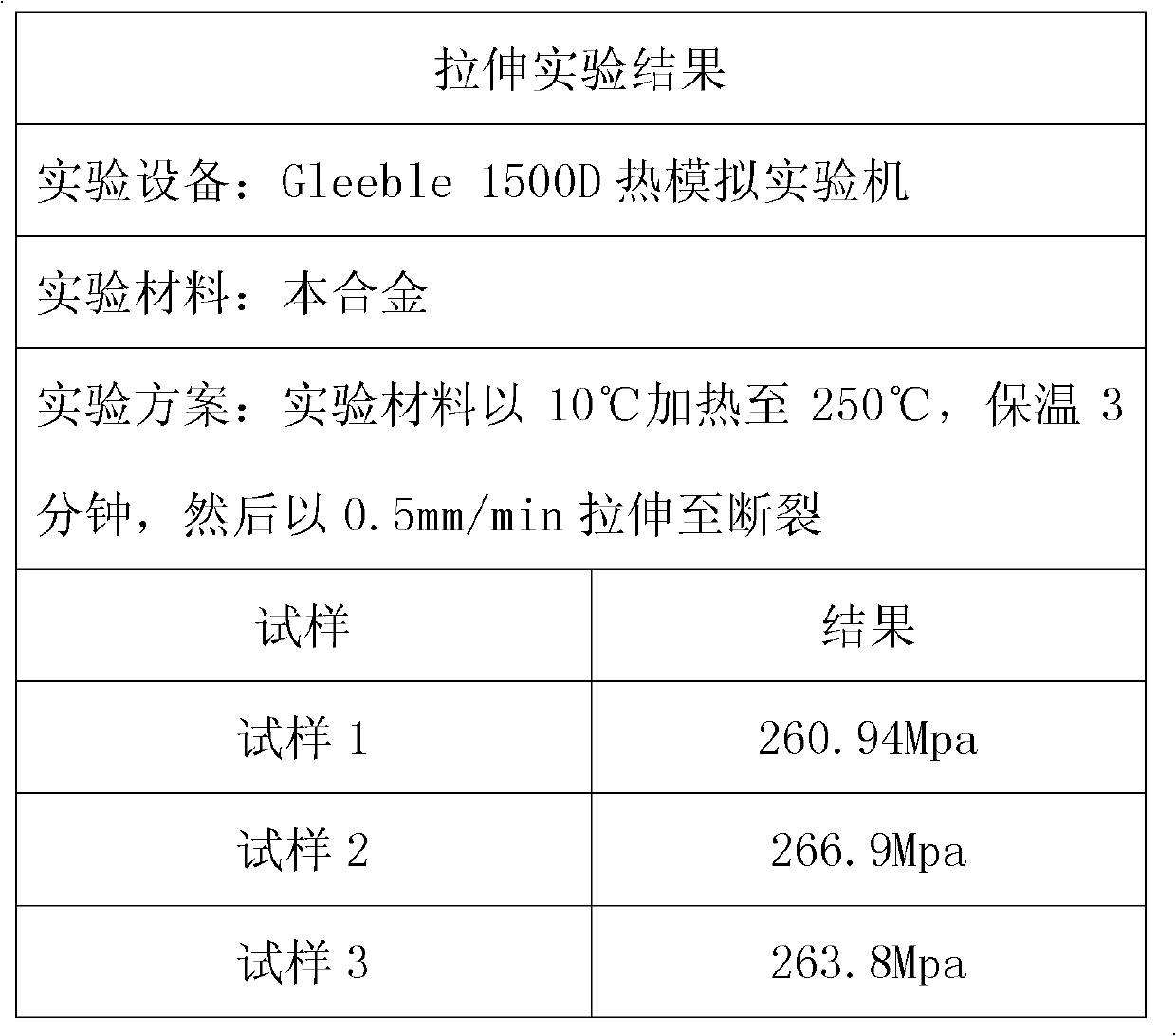

Examples

Embodiment 1

[0018] Embodiment 1: The novel casting aluminum alloy of this embodiment comprises by weight percentage: 11% of Si, 4% of Cu, 0.5% of Mg, 3.5% of Ni, 0.08% of Ti and 0.2% of V, and the rest are Aluminum ingot; wherein, the aluminum ingot brand is Al99.50.

[0019] The preparation method of the novel casting aluminum alloy is: comprise the following steps:

[0020] a. After drying the smelting furnace, put 400 kg of copper and 350 kg of nickel into the smelting furnace, and continue to heat up until the copper and nickel are melted;

[0021] b. Add aluminum ingots: put in 4036 kg of aluminum ingots first, continue heating, and then add 4036 kg of aluminum ingots after melting;

[0022] c. When the aluminum ingot is completely melted to a molten state, add 1100 kg of silicon particles and stir to make the surface of the silicon particles completely cover the molten aluminum;

[0023] d. Heating to raise the temperature, control the furnace temperature at 900°C, when the melt t...

Embodiment 2

[0028] Embodiment 2: The novel casting aluminum alloy of this embodiment comprises by weight percentage: 13% Si, 2% Cu, 1.2% Mg, 2% Ni, 0.18% Ti and 0.1% V, and the rest are Aluminum ingots. Among them, the grade of aluminum ingot is Al99.50.

[0029] The preparation method of the novel casting aluminum alloy is: comprise the following steps:

[0030] a. After the smelting furnace is dried, put 200 kg of copper and 200 kg of nickel into the smelting furnace, and continue to heat up until the copper and nickel are melted;

[0031] b. Add aluminum ingots: put in 4076 kg of aluminum ingots first, continue heating, and then add 4076 kg of aluminum ingots after melting;

[0032] c. When the aluminum ingot is completely melted to a molten state, add 1300 kg of silicon particles and stir to make the surface of the silicon particles completely cover the molten aluminum;

[0033] d. Heating to raise the temperature, control the furnace temperature at 850°C, when the melt turns orang...

Embodiment 3

[0039] Embodiment 3: The novel casting aluminum alloy of this embodiment comprises by weight percentage: 12% of Si, 3% of Cu, 0.8% of Mg, 3% of Ni, 0.12 of Ti and 0.15% of V, and the rest is aluminum ingot. Among them, the grade of aluminum ingot is Al99.50.

[0040] The preparation method of the novel casting aluminum alloy is: comprise the following steps:

[0041] a. After drying the smelting furnace, put 300 kg of copper and 300 kg of nickel into the smelting furnace, and continue to heat up until the copper and nickel are melted;

[0042] b. Adding aluminum ingots: first put in 4046.5 kg of aluminum ingots, continue heating, and then add 4046.5 kg of aluminum ingots after melting;

[0043] c. When the aluminum ingot is completely melted to a molten state, add 1200 kg of silicon particles and stir to make the surface of the silicon particles completely cover the molten aluminum;

[0044] d. Heating to raise the temperature, control the furnace temperature at 880°C, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com