Laminar compound aluminium alloy material with high intensity and preparation thereof

An aluminum alloy material, high-strength layer technology, applied in metal rolling, metal processing equipment, metal layered products, etc., can solve the problem of many process links, general tensile strength of 6009 alloy, affecting the improvement of the overall performance of the composite sheet, etc. problem, to achieve the effect of broad application prospects, good promotion and application prospects, and relaxation of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but the implementation of the present invention is not limited thereto.

[0025] 1. Casting:

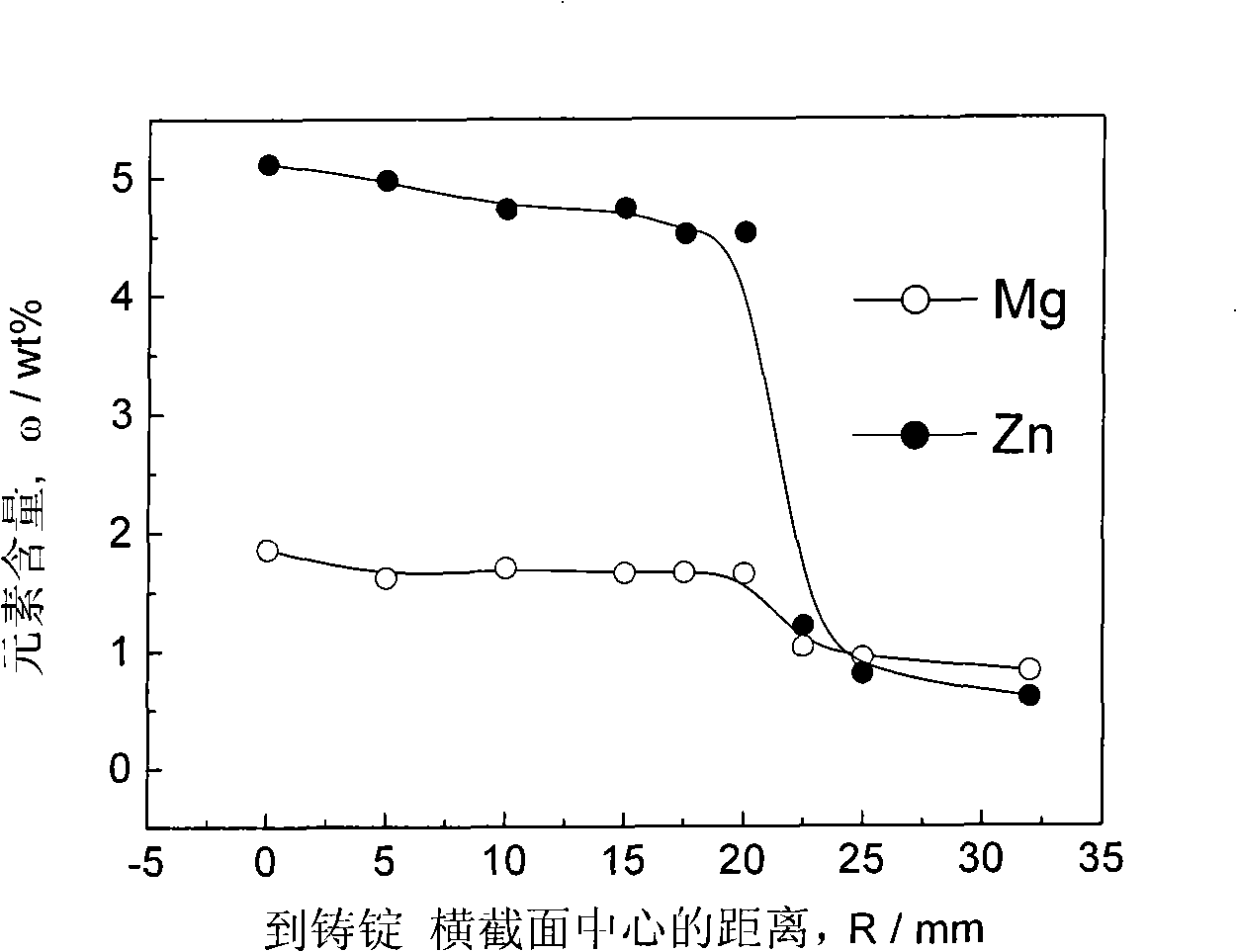

[0026] Adopt raw material industrial pure aluminum, industrial pure magnesium, industrial pure zinc, industrial chromium agent, Al-25% Si master alloy, Al-20% Mn master alloy and Al-50% Cu master alloy (weight percentage) to smelt 6009 alloy and respectively 7075 alloy. The outer layer is a corrosion-resistant aluminum alloy 6009 aluminum alloy with excellent formability. The high-strength and tough aluminum alloy has a composition (weight percentage) range of: Al-5.1-6.1Zn-2.0-3.0Mg-1.2-2.0Cu-0.16-0.3Cr, wherein the composition of the 7075 alloy is the upper limit of the composition of the alloy. Composite castings were prepared on a double-strand casting semi-continuous casting device. In order to obtain gradient composite castings without casting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com