Fast 7075 aluminium alloy shape extruding process

An aluminum alloy profile and extrusion method technology, which is applied in the field of non-ferrous metal processing, can solve the problems of uneven deformation structure, low extrusion speed, and increase in profile temperature, and achieves prevention of periodic extrusion cracks, uniform cooling, and prevention of fracture. or the effect of fuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 7075 aluminum alloy profiles rapid extrusion method, the steps of the method are as follows:

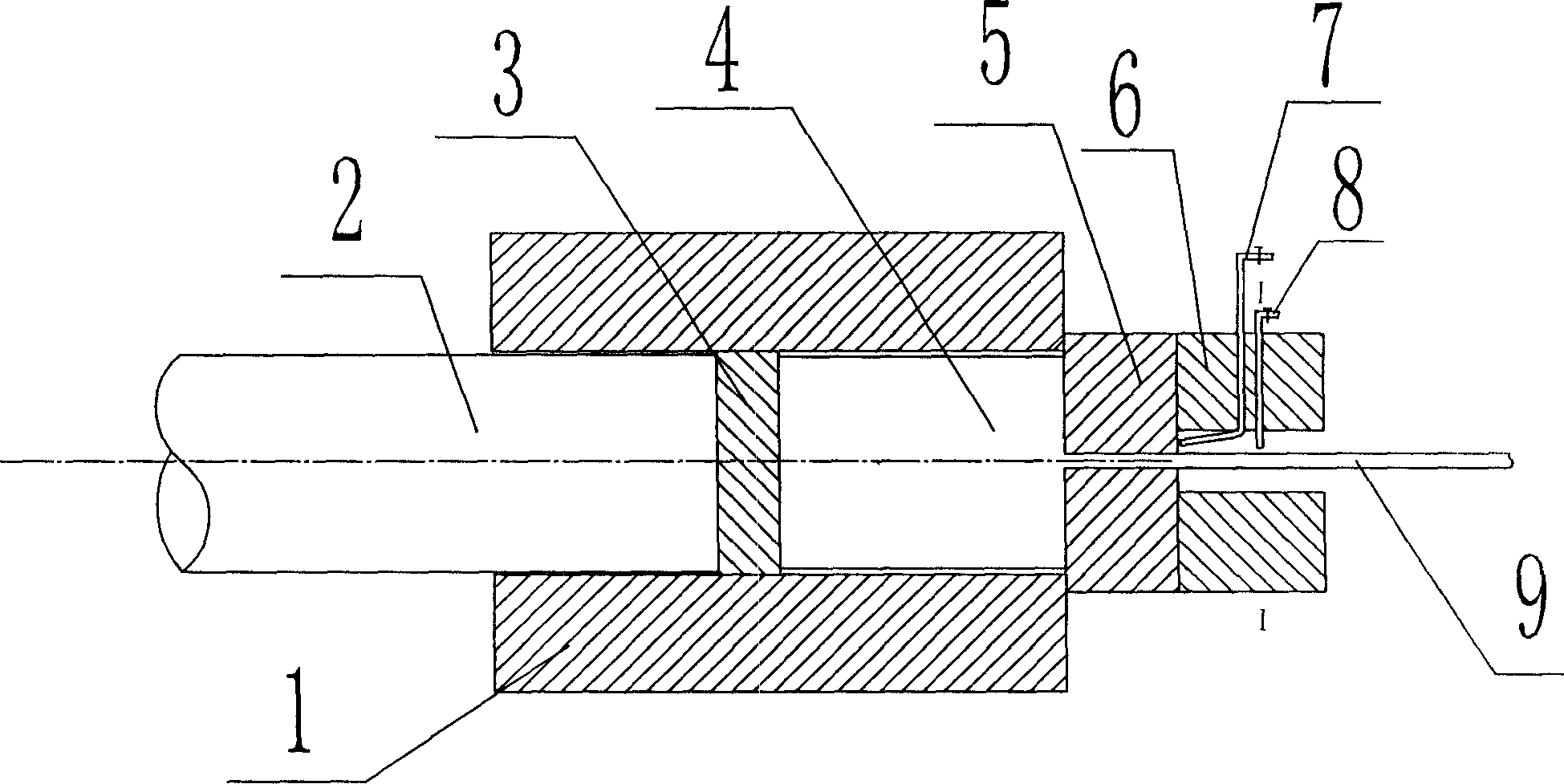

[0024] 1. First design the cross-sectional view of the 7075 aluminum alloy profile product, then design and manufacture the extrusion die 5 and the extrusion die pad 6, etc. according to the profile cross-sectional view, and reserve a place to install the cooling medium intake pipe, and select a 2200-ton extrusion machine; The ratio is 26;

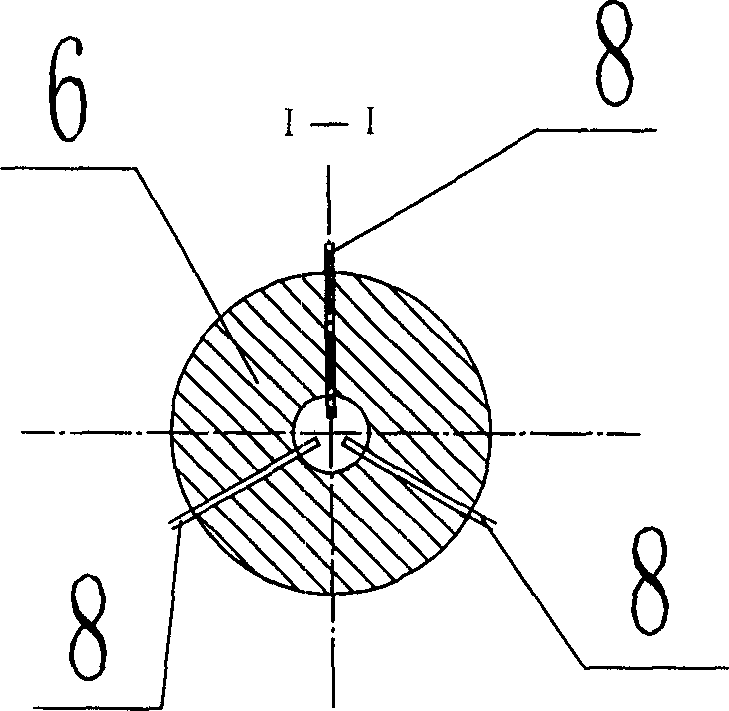

[0025] 2. The section shape of the profile is circular with a diameter of 32mm. There are 4 intake pipes for cooling, one of which is used to cool the extrusion die; the other three are used to cool the extruded profile at the exit of the die, and the three are symmetrically distributed at 120° to each other, such as figure 2 shown;

[0026] 3. According to the composition requirements of 7075 aluminum alloy, melt and cast 7075 aluminum alloy cast rod 4 with a diameter 1-2 mm smaller than that of extrusion cylinder 1, perform homogeniza...

Embodiment 2

[0032] Except that the cooling medium used in cooling the extrusion die and extrusion profile in step 5 is changed to "the medium for cooling the extrusion die is bottled liquid nitrogen, and the medium for cooling the extrusion profile is bottled nitrogen" and the section of the profile can be respectively Change to one of square, rectangle or other geometric shapes, the rest are the same as the steps of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com