Ultra-fine crystal aluminum alloy used for preparing pipe fitting

An aluminum alloy, ultra-fine grain technology, applied in the field of alloy materials, can solve the problems of reducing hardness, strength and corrosion resistance, and achieve the effect of improving machinability, tensile properties and processing characteristics, and balancing comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

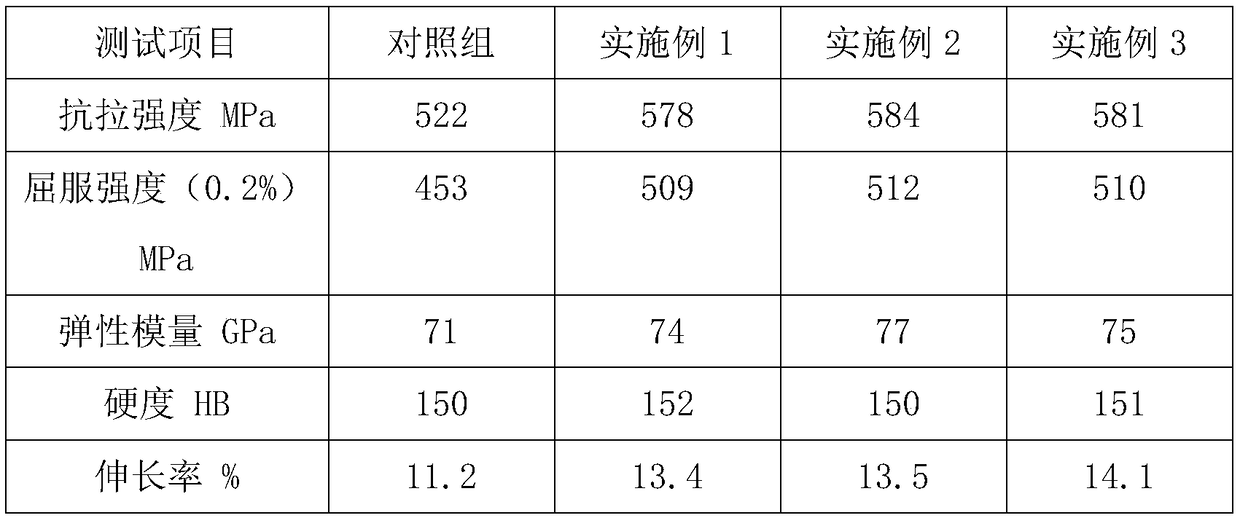

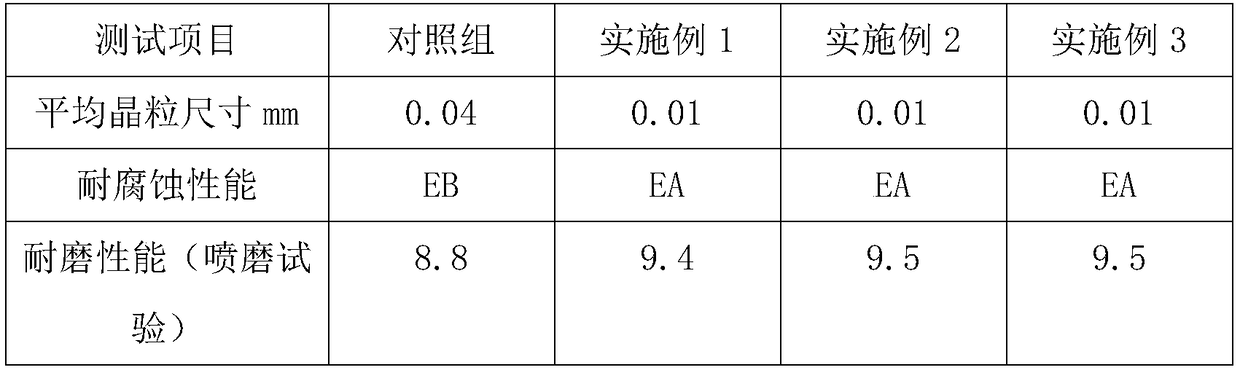

Examples

Embodiment 1

[0039] An ultra-fine-grained aluminum alloy used in the preparation of pipe fittings. The raw material components of the aluminum alloy include 0.3wt% crystal phase modifier and 99.7wt% 7075 aluminum alloy; wherein, the 7075 aluminum alloy contains the following elements in mass percentage: Zn: 5.25%; Mg: 2.78%; Cu: 1.25%; Si: 0.13%; Fe: 0.15%; Cr: 0.09%; Zr: 0.08%, Mn: 0.05%; Ti: 0.02%; unavoidable impurities.

[0040] The preparation method of the ultrafine-grained aluminum alloy provided in this embodiment includes the following steps:

[0041] (1) Add the 7075 aluminum alloy with the above element composition into the melting furnace, heat the aluminum ingot to 720°C, add the aluminum covering agent when the aluminum ingot starts to melt, and put the crystal phase modifier into the melting furnace when the aluminum ingot is completely melted At the bottom of the aluminum melt in the furnace, raise the furnace temperature to 830°C, electromagnetically stir and heat-preserv...

Embodiment 2

[0048] An ultra-fine-grained aluminum alloy used in the preparation of pipe fittings. The raw material components of the aluminum alloy include 0.5wt% crystal phase regulator and 99.5wt% 7075 aluminum alloy; wherein, the 7075 aluminum alloy contains the following elements in mass percentage: Zn: 6.58%; Mg: 2.88%; Cu: 2.14%; Si: 0.17%; Fe: 0.22%; Cr: 0.16%; Zr: 0.15%, Mn: 0.07%; Ti: 0.03%; unavoidable impurities.

[0049] The preparation method of the ultrafine-grained aluminum alloy provided in this embodiment includes the following steps:

[0050] (1) Add the 7075 aluminum alloy with the above element composition into the melting furnace, heat the aluminum ingot to 760°C, add the aluminum covering agent when the aluminum ingot starts to melt, and put the crystal phase modifier into the melting furnace when the aluminum ingot is completely melted At the bottom of the aluminum melt in the furnace, raise the furnace temperature to 860°C, electromagnetically stir and heat-preser...

Embodiment 3

[0057] An ultra-fine-grained aluminum alloy used in the preparation of pipe fittings. The raw material components of the aluminum alloy include 0.4wt% crystal phase regulator and 99.6wt% 7075 aluminum alloy; wherein, the 7075 aluminum alloy contains the following elements by mass percentage: Zn: 6.15%; Mg: 2.82%; Cu: 1.60%; Si: 0.15%; Fe: 0.19%; Cr: 0.13%; Zr: 0.12%, Mn: 0.06%; Ti: 0.03%; unavoidable impurities.

[0058] The preparation method of the ultrafine-grained aluminum alloy provided in this embodiment includes the following steps:

[0059] (1) Add the 7075 aluminum alloy with the above element composition into the melting furnace, heat the aluminum ingot to 740°C, add the aluminum covering agent when the aluminum ingot starts to melt, and put the crystal phase modifier into the melting furnace when the aluminum ingot is completely melted At the bottom of the aluminum melt in the furnace, raise the furnace temperature to 850°C, electromagnetically stir and heat-preser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com