Preparation method for multi-scale precipitation of heterogeneous aluminum alloy bars

An aluminum alloy material and aluminum alloy technology, which is applied in the field of aging treatment to prepare multi-scale precipitated Al/7075Al heterogeneous bars, can solve the problems of low production efficiency and inability to prepare bars with heterogeneous structures, and achieve high production efficiency, The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Select pure aluminum and 7075 aluminum alloy metal thin rods with a length of 1.2m, treat the surface, remove oil stains and oxide films, and polish until the bright metal is exposed.

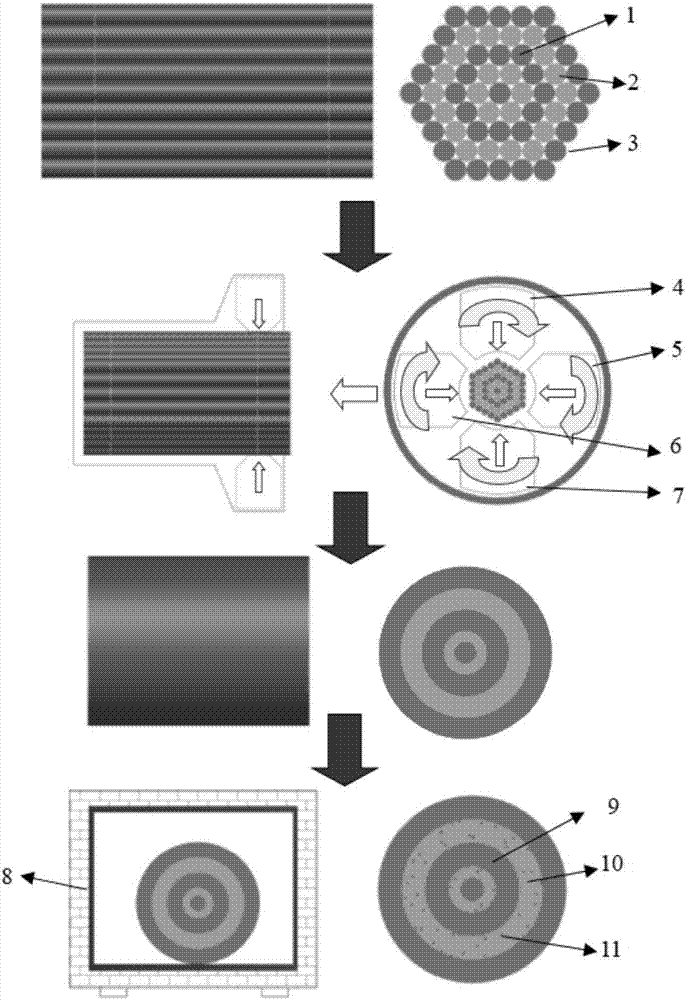

[0028] (2) two kinds of thin metal rods processed according to figure 1 In the mixed arrangement shown, since the diameter of the mold used for the first pass is 20 mm, the cross-sectional diameter of the metal rod after mixing is about 20 mm to ensure that the metal blank can be inserted into the mold cavity. In order to prevent the thin metal rods from loosening, the ends of the blanks are bound and fixed with Al wires.

[0029] (3) Put the thin metal rod blank into the rotary forging machine for large deformation processing. The feeding speed is controlled at about 5m / min. When the cross-sectional diameter of the blank reaches the diameter of the next mold (18mm), replace the next mold and repeat the above operations , until a good bond is formed between the metals.

[0030] (4)...

Embodiment 2

[0033] (1) Select pure aluminum and 7075 aluminum alloy metal thin rods with a length of 1.2m, treat the surface, remove oil stains and oxide films, and polish until the bright metal is exposed.

[0034] (2) two kinds of thin metal rods processed according to figure 1 In the mixed arrangement shown, since the diameter of the mold used for the first pass is 20 mm, the cross-sectional diameter of the metal rod after mixing is about 20 mm to ensure that the metal blank can be inserted into the mold cavity. In order to prevent the thin metal rods from loosening, the ends of the blanks are bound and fixed with Al wires.

[0035] (3) Put the thin metal rod blank into the rotary forging machine for large deformation processing. The feeding speed is controlled at about 5m / min. When the cross-sectional diameter of the blank reaches the diameter of the next mold (18mm), replace the next mold and repeat the above operations , until a good bond is formed between the metals.

[0036] (4)...

Embodiment 3

[0039] (1) Select pure aluminum and 7075 aluminum alloy metal thin rods with a length of 1.2m, treat the surface, remove oil stains and oxide films, and polish until the bright metal is exposed.

[0040] (2) two kinds of thin metal rods processed according to figure 1In the mixed arrangement shown, since the first pass uses a mold diameter of 30mm, the cross-sectional diameter of the metal rod after mixing is about 30mm, ensuring that the metal blank can be inserted into the mold cavity. In order to prevent the thin metal rods from loosening, the ends of the blanks are bound and fixed with Al wires.

[0041] (3) Put the thin metal rod blank into the rotary forging machine for large deformation processing, and the feeding speed is controlled at about 5m / min. When the cross-sectional diameter of the blank reaches the diameter of the next mold (28mm), replace the next mold and repeat the above operations , until a good bond is formed between the metals.

[0042] (4) Take out th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com