7075 aluminium alloy profile on line quenching method

An aluminum alloy profile, aluminum alloy technology, applied in other manufacturing equipment/tools, manufacturing tools and other directions, can solve the problems of energy consumption, high management cost, low production efficiency, long production process, etc., to reduce production costs and improve production. Efficient and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

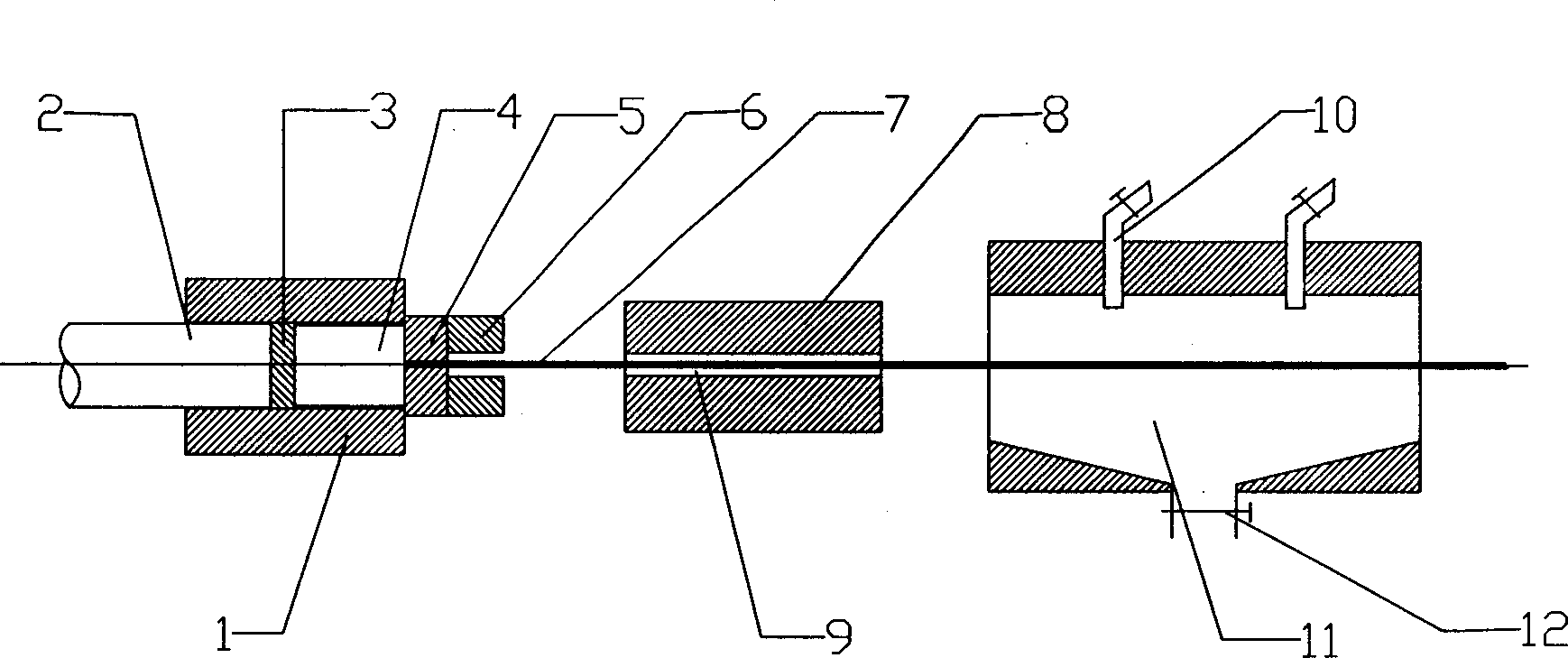

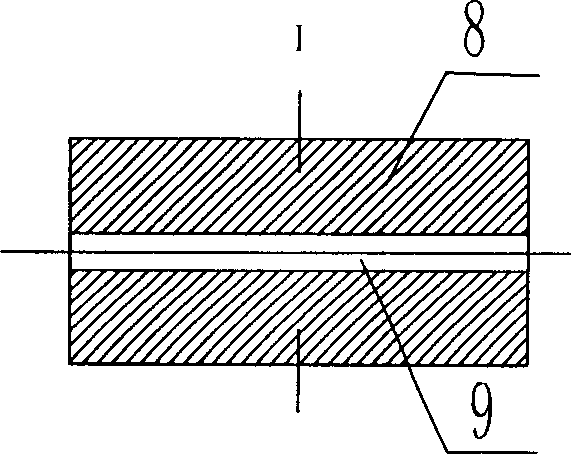

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] A method for on-line quenching of 7075 aluminum alloy profiles, the method comprising the following steps:

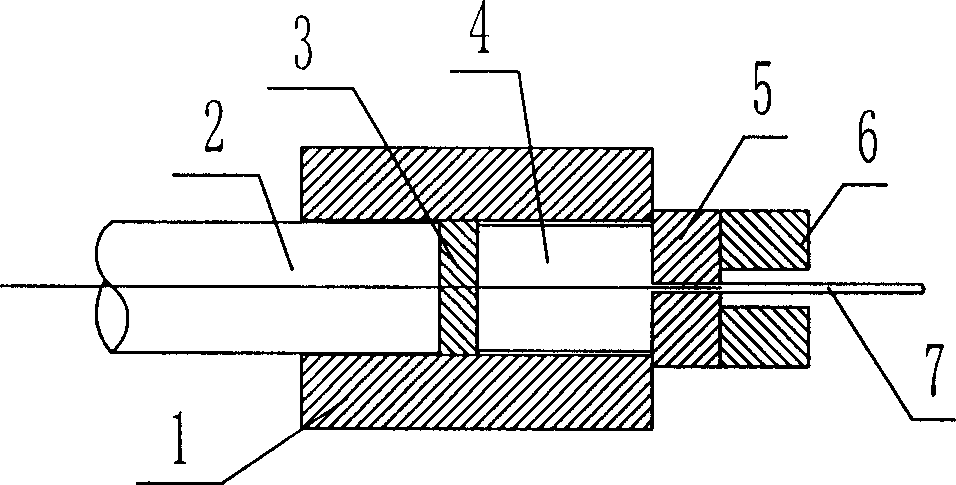

[0028] 1. Firstly melt and cast pure aluminum, pure magnesium, zinc and other raw materials into extrusion cylinder 1 with diameter ratio (see figure 2 ) with a 7075 aluminum alloy cast rod 4 with an inner diameter smaller than 1 to 2mm, and homogenize the 7075 aluminum alloy cast rod 4 in a homogenizing furnace, the homogenization treatment temperature is set at 320°C to 440°C, and the holding time is 10~18h (hour);

[0029] 2. Preheating the extrusion die 5, the preheating temperature is 320°C-420°C, the temperature of the extrusion cylinder 1 is set at 330°C-430°C, and the preheating temperature of the 7075 aluminum alloy casting rod 4 is 330°C-380°C; choose The tonnage of the extrusion machine is 1800T, and the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com