Preparation method of TiAl3 enhanced aluminum-based composite material

A composite material and a technology for reinforcing aluminum matrix, which is applied in the field of preparation of aluminum matrix composite materials, can solve problems such as hindering development and occurrence of macrosegregation, and achieve the effects of convenient operation, uniform distribution and low process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

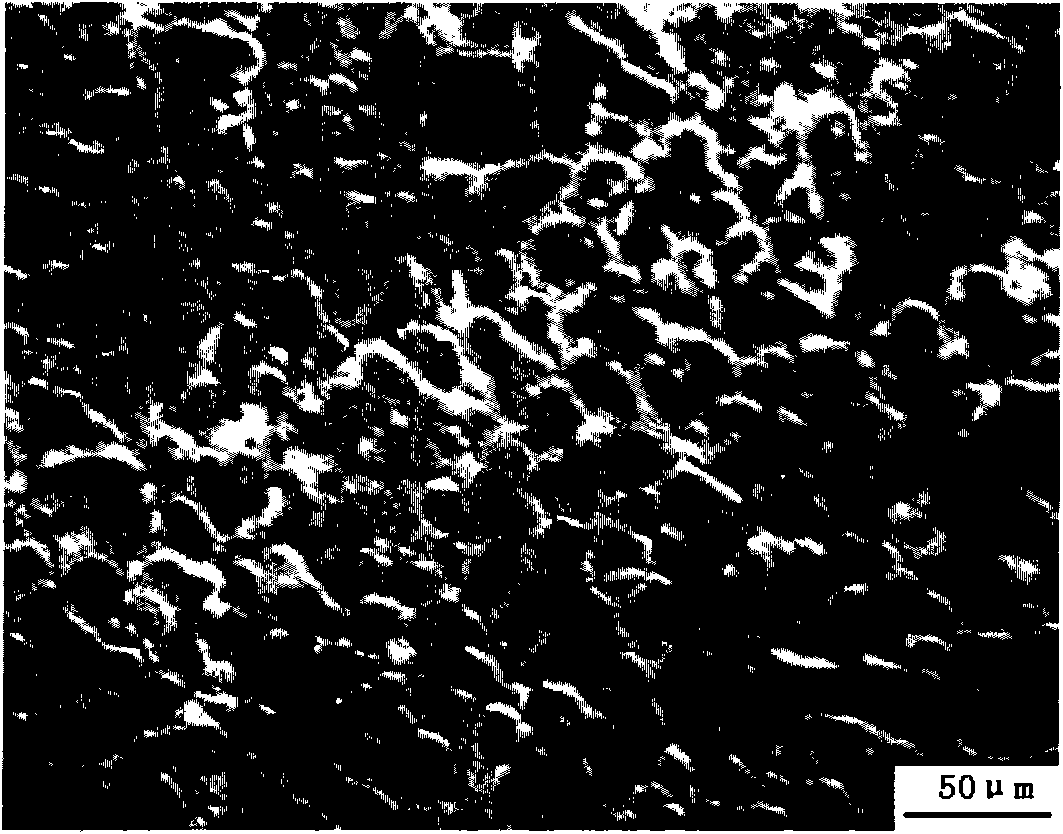

[0010] First cryolite powder (Na 3 AlF 6 ) and titanium powder (Ti) were uniformly mixed and dried at a mass ratio of 0.5:1; the 7075 aluminum alloy was heated and melted in a graphite crucible, and at a temperature of 830°C, the above-mentioned mixed powder was mixed according to the ratio of titanium to 7075 aluminum alloy Add 1wt.% of the mass number to the 7075 aluminum alloy melt, and then extend the ultrasonic horn into the aluminum alloy melt. Under the condition of ultrasonic power of 800W, ultrasonic for 20min; the temperature of the melt is lowered to 740°C , and then continue to sonicate for 4 minutes, pour into the metal model, and take samples after cooling.

Embodiment 2

[0012] First cryolite powder (Na 3 AlF 6 ) and titanium powder (Ti) were uniformly mixed and dried at a mass ratio of 0.5:1; the 7075 aluminum alloy was heated and melted in a graphite crucible; Add 2wt.% of the mass number to the 7075 aluminum alloy melt, and then extend the ultrasonic horn into the aluminum alloy melt. Under the condition of ultrasonic power of 800W, ultrasonic for 25min; the temperature of the melt is lowered to 750°C , and then continue to sonicate for 4 minutes, pour into the metal model, and take samples after cooling.

Embodiment 3

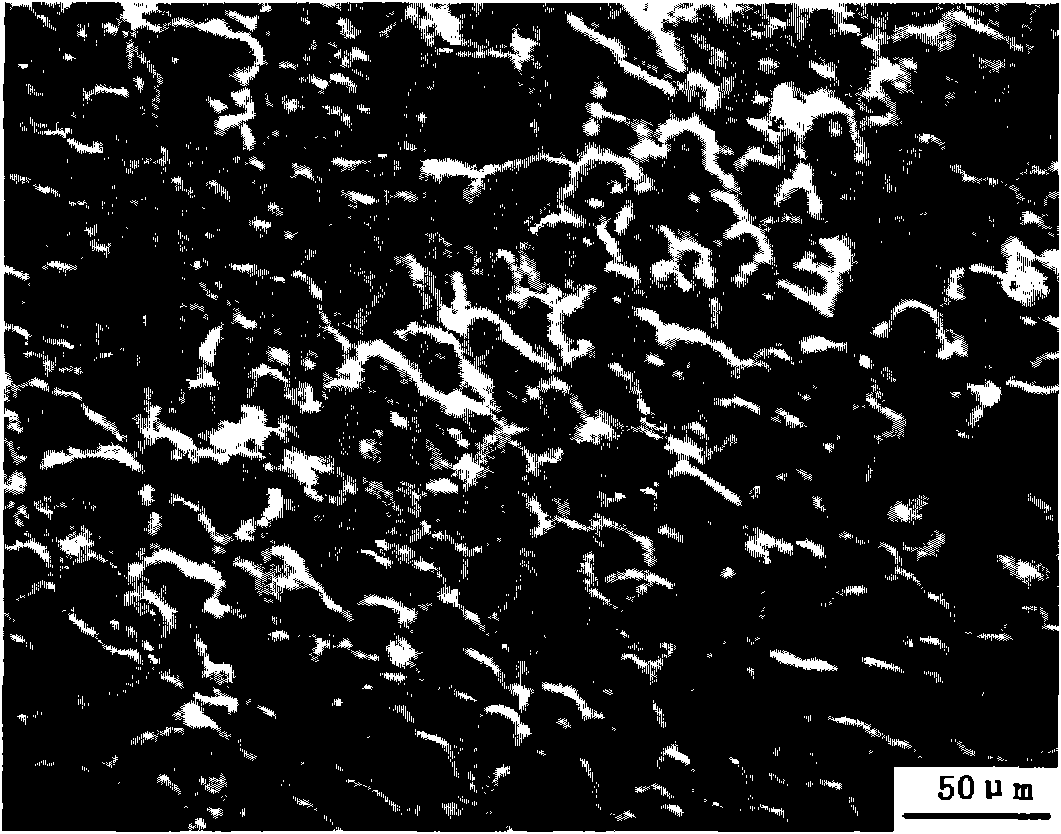

[0014] First cryolite powder (Na 3 A1F 6 ) and titanium powder (Ti) according to the mass ratio of 1:1, uniformly mixed and dried; put the 7075 aluminum alloy into the graphite crucible to heat and melt, and at a temperature of 850°C, mix the above mixed powder according to the ratio of titanium to 7075 aluminum alloy Add 4wt.% of the mass number to the 7075 aluminum alloy melt, and then extend the ultrasonic horn into the aluminum alloy melt. Under the condition of ultrasonic power of 1000W, ultrasonic for 30min; the temperature of the melt is lowered to 760°C , and then continue to sonicate for 4 minutes, pour into the metal model, and take samples after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com