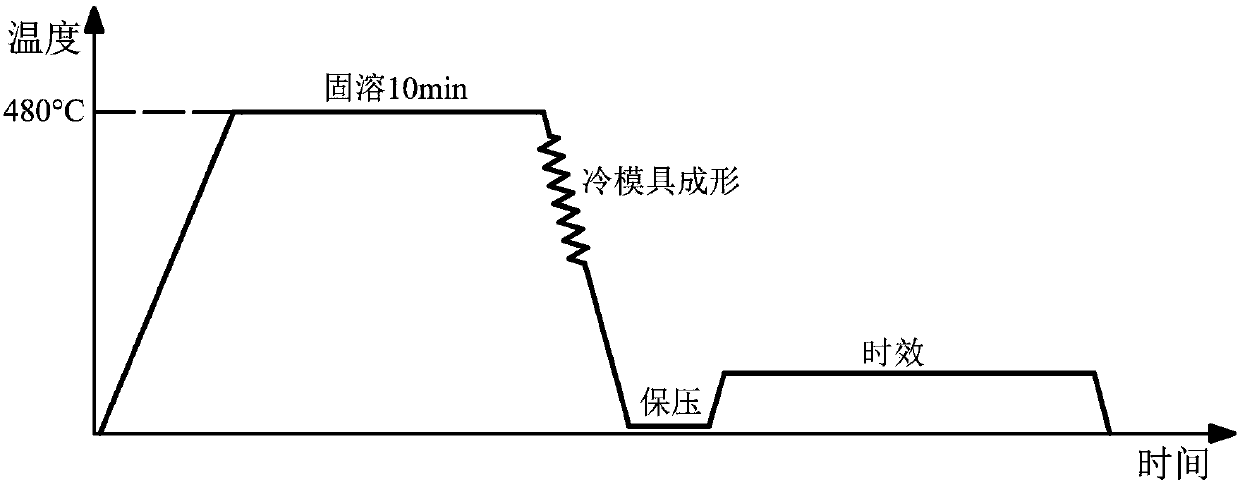

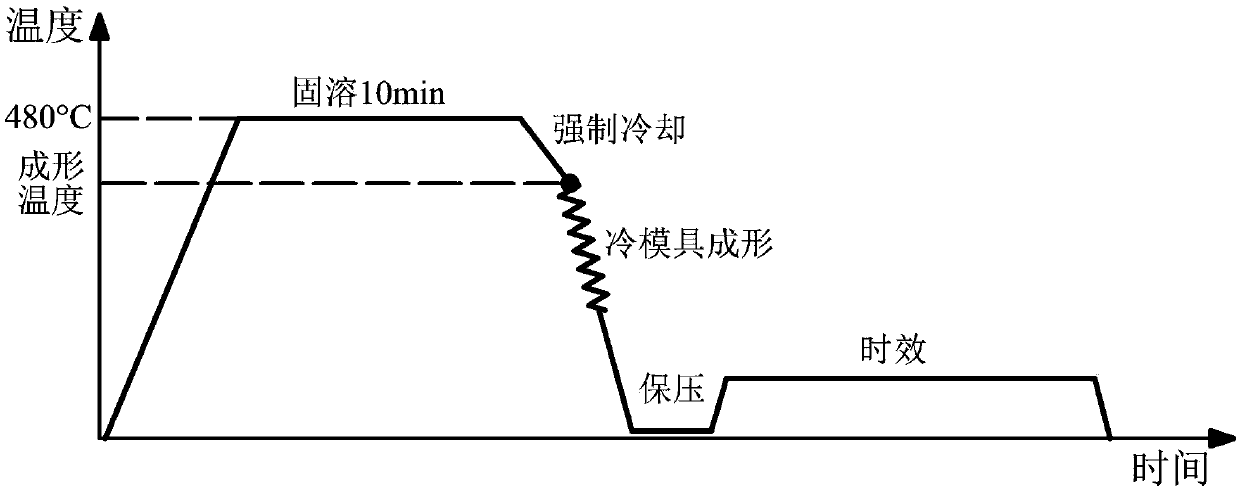

Heat treatment method for improving hot punching moldability of 7075 aluminum alloy

A heat treatment method and hot stamping forming technology are applied in the field of plastic forming processing of metal materials to achieve the effect of improving thinning rate and thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

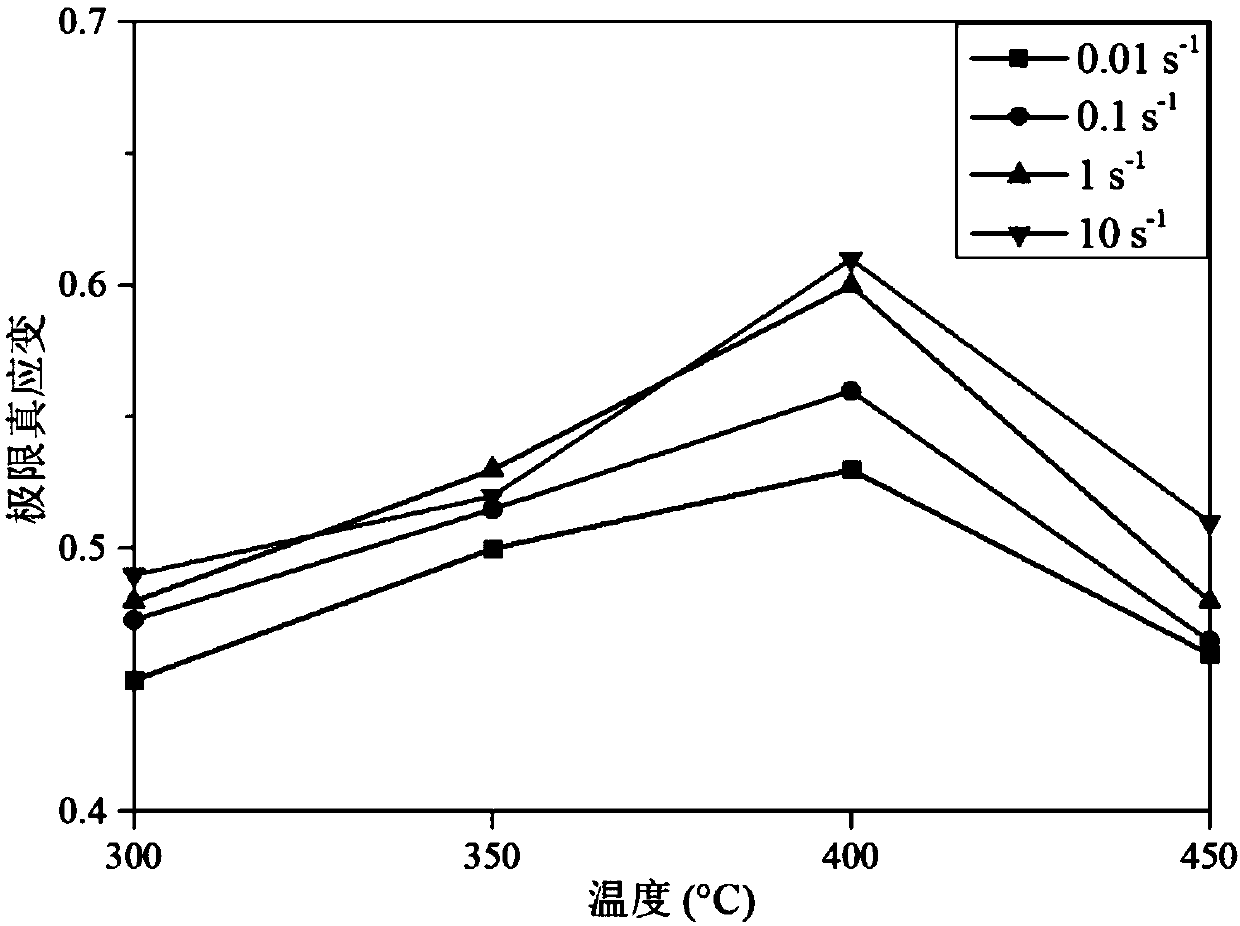

[0024] The effect of deformation temperature on the plastic elongation of 7075 aluminum alloy material was studied by experiments. The experimental conditions were as follows: the 7075 aluminum alloy sheet with a thickness of 2 mm was subjected to solution treatment, the solution temperature was 480 ° C, and the solution time was 10 minutes. Cool the sheet after solid solution to different temperatures (300°C, 350°C, 400°C, 450°C) at a cooling rate of 50°C / s, and at different strain rates (0.01s -1 , 0.1s -1 、1s -1 and 10s -1 ) for isothermal stretching to obtain the effect of deformation temperature on the plastic elongation of the material, such as image 3 As shown, the 7075 aluminum alloy sheet has the best plastic elongation at 400 °C.

[0025] The effect of cooling rate on the tensile strength of 7075 aluminum alloy material was studied by experiments. The experimental conditions were: the 7075 aluminum alloy sheet with a thickness of 2 mm was subjected to solution tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com