Patents

Literature

124results about How to "Increase reduction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

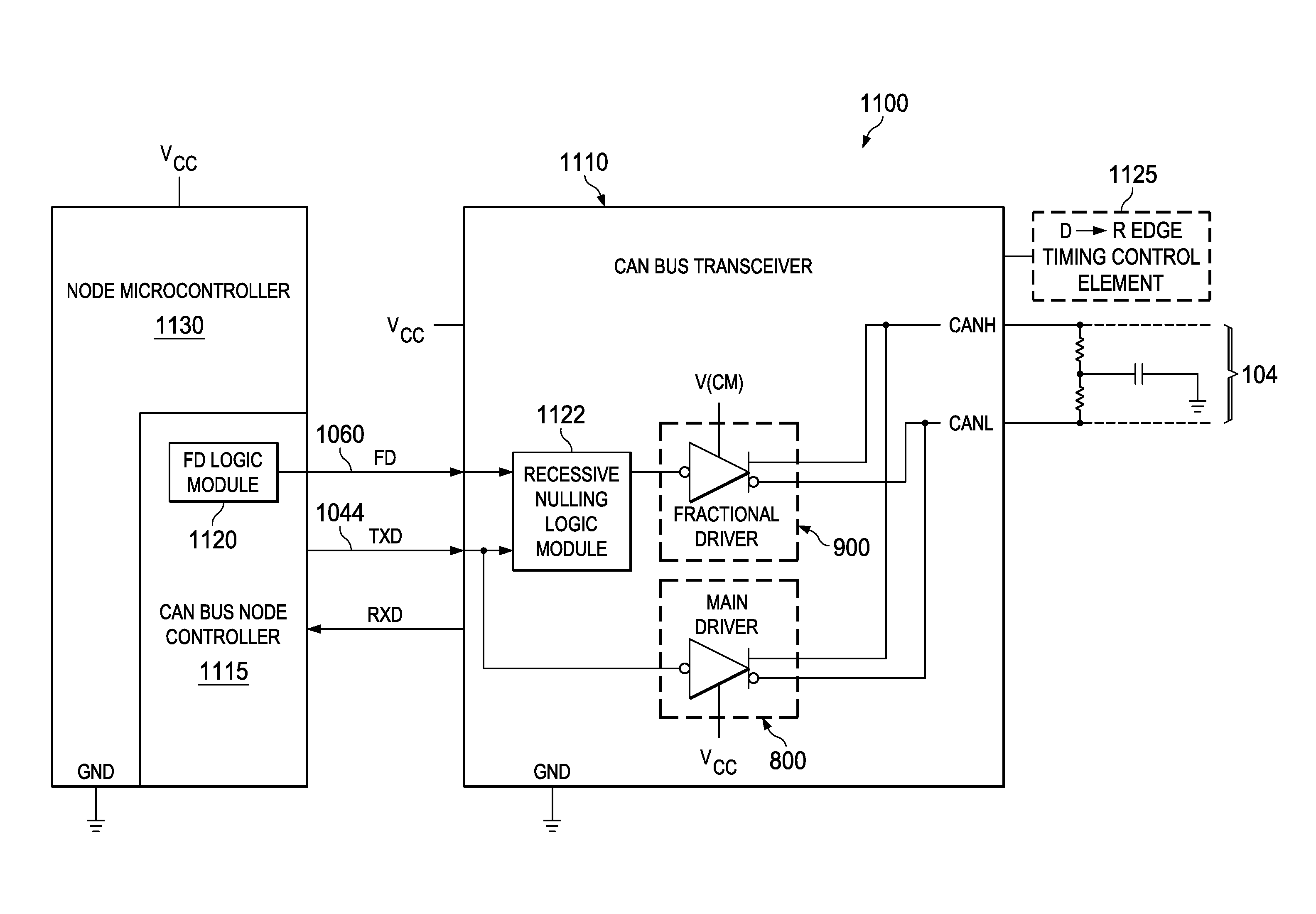

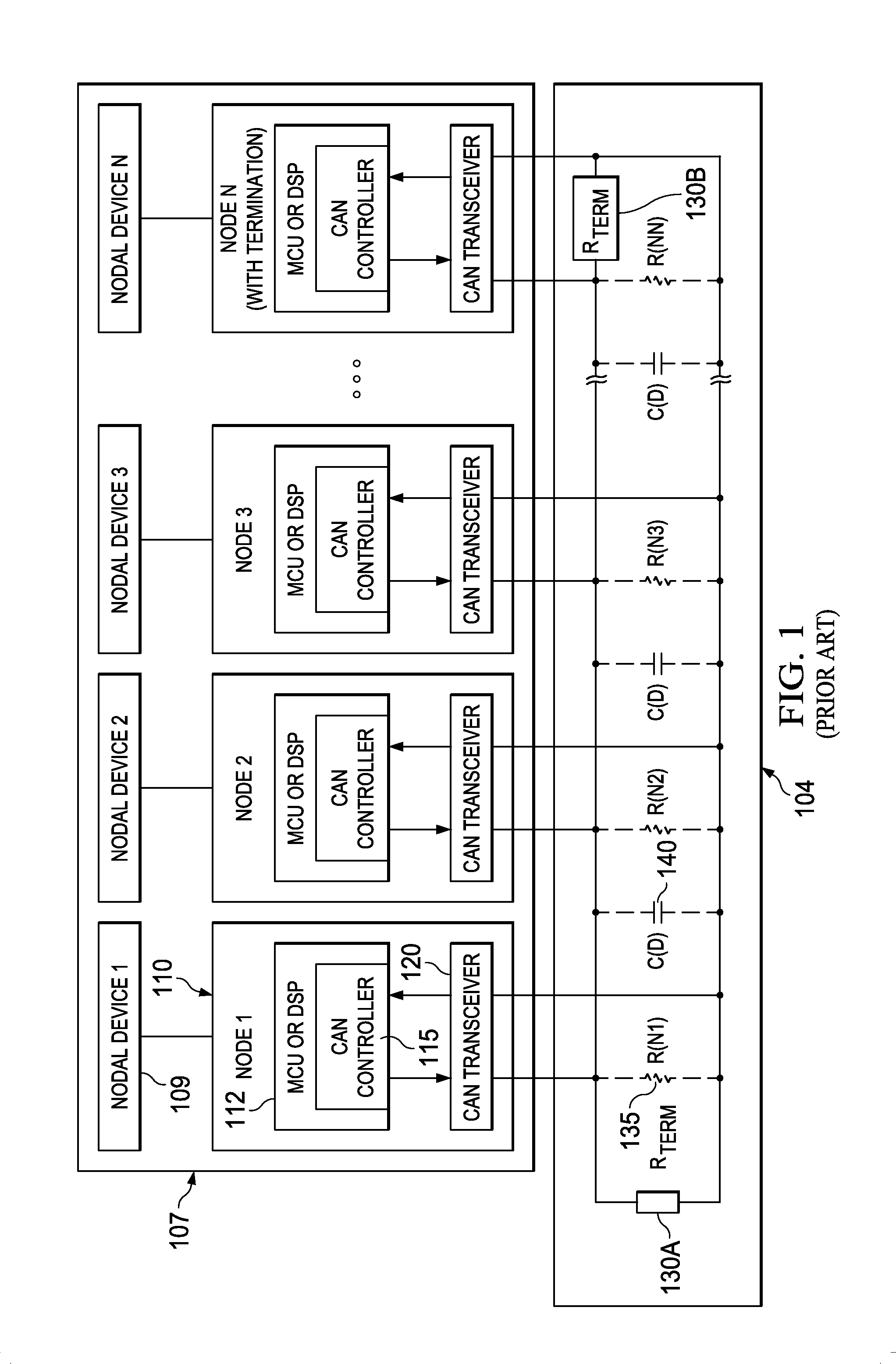

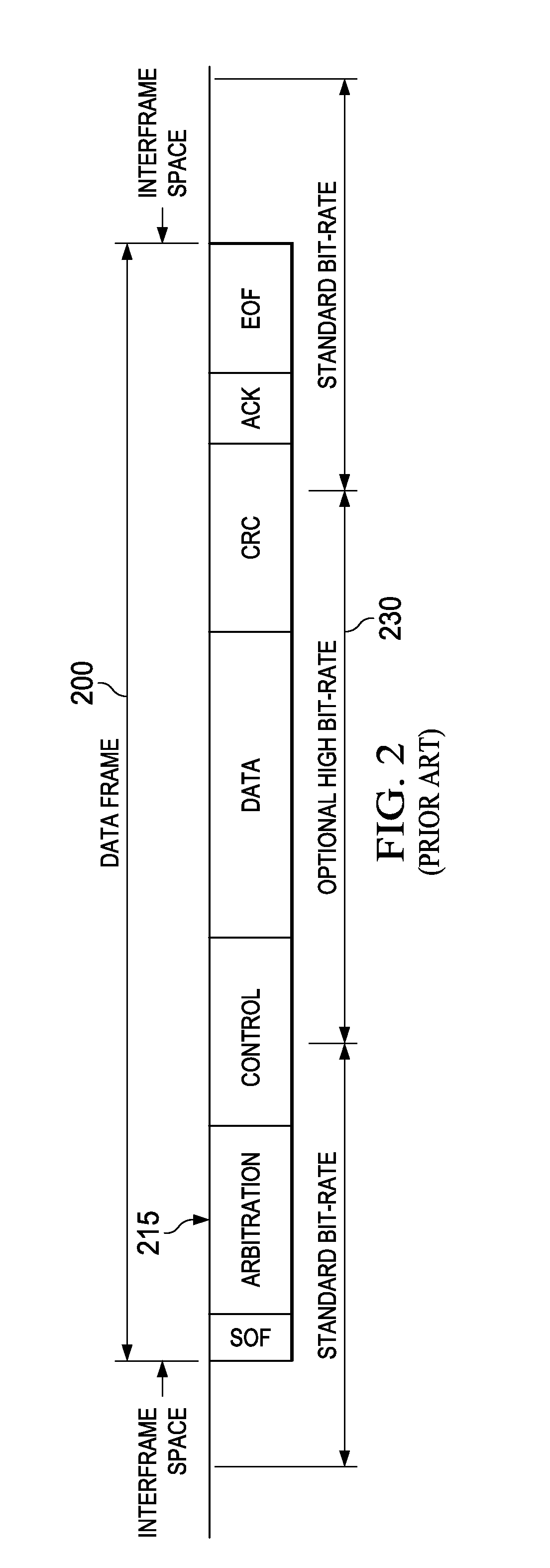

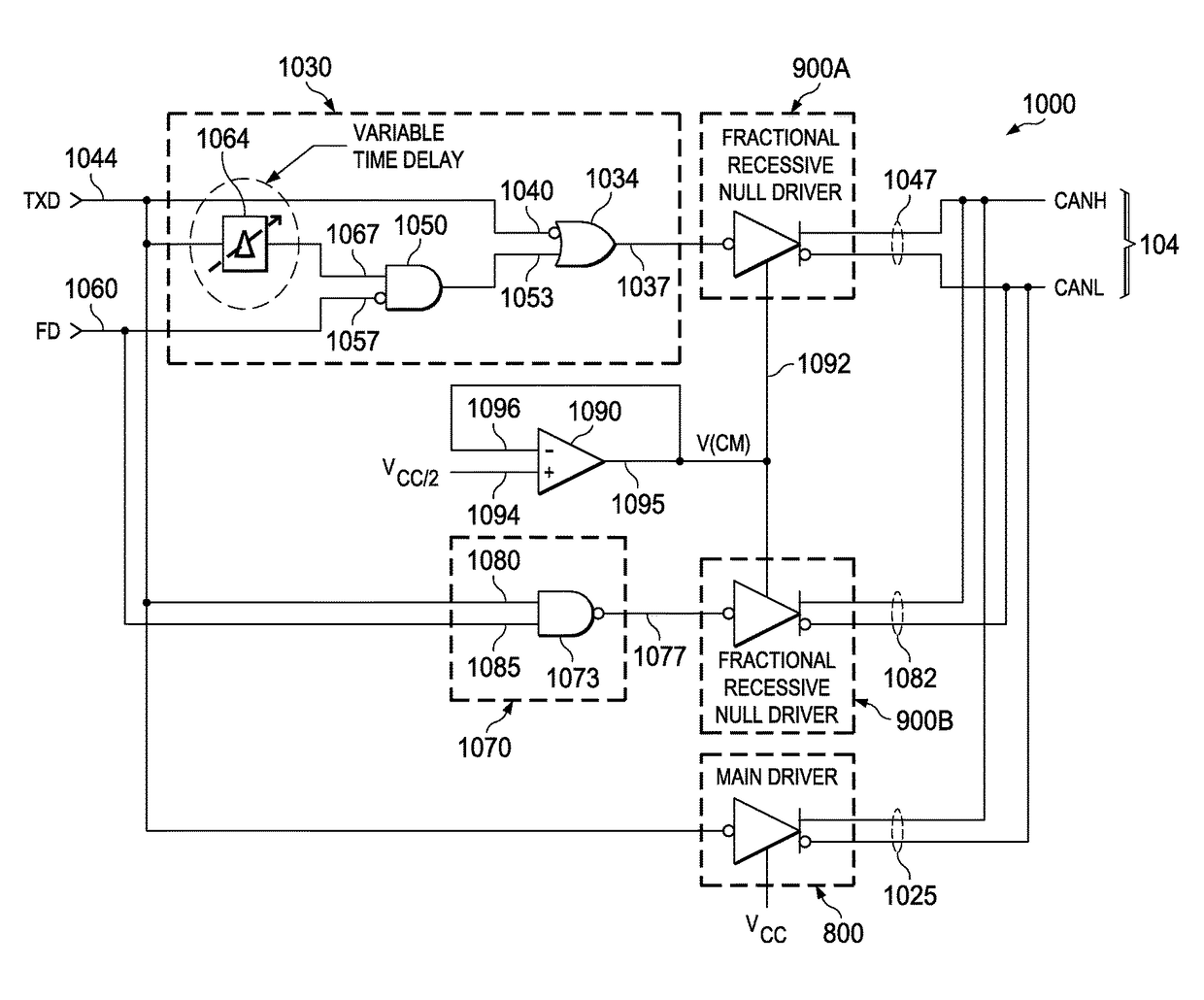

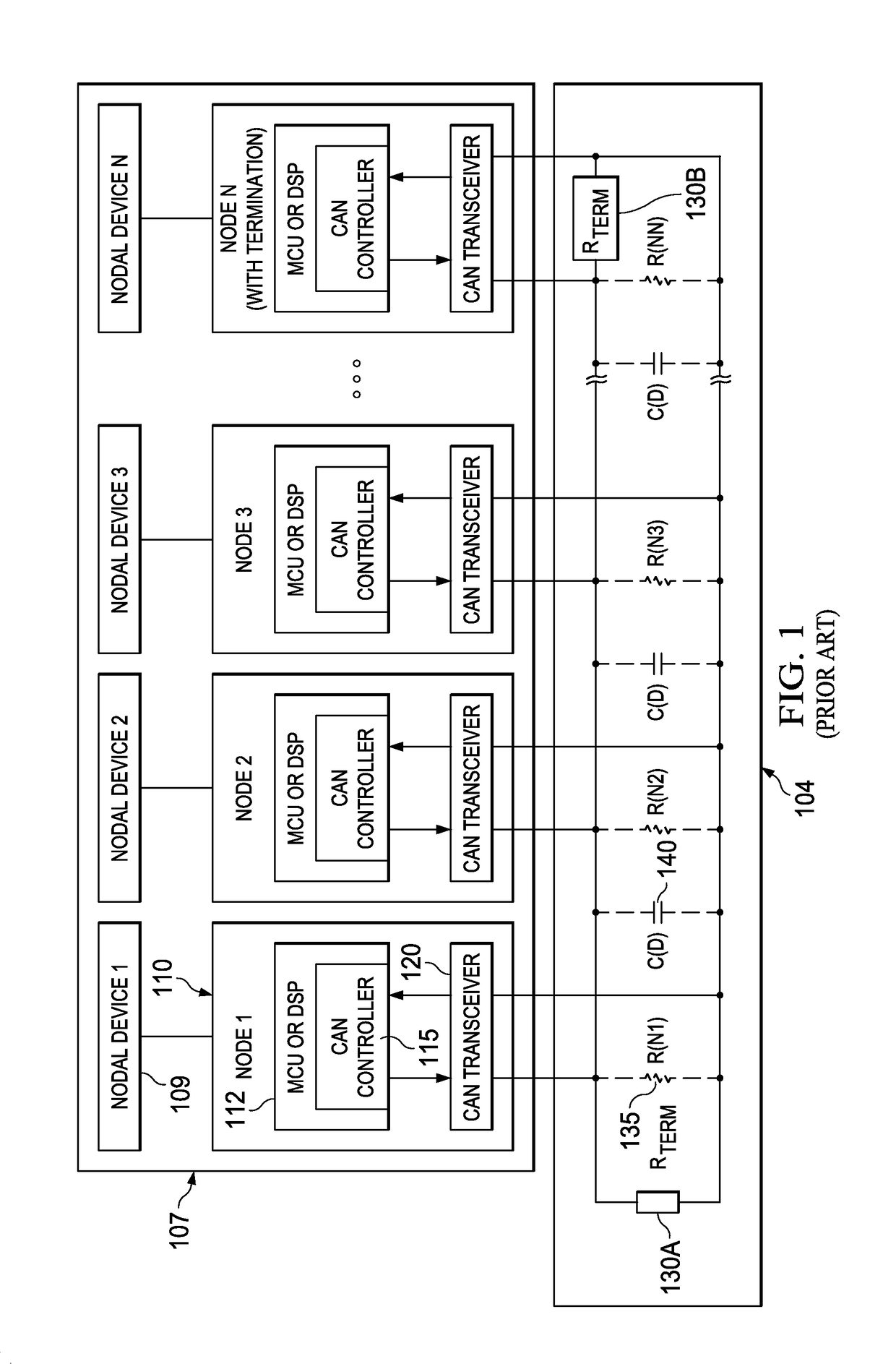

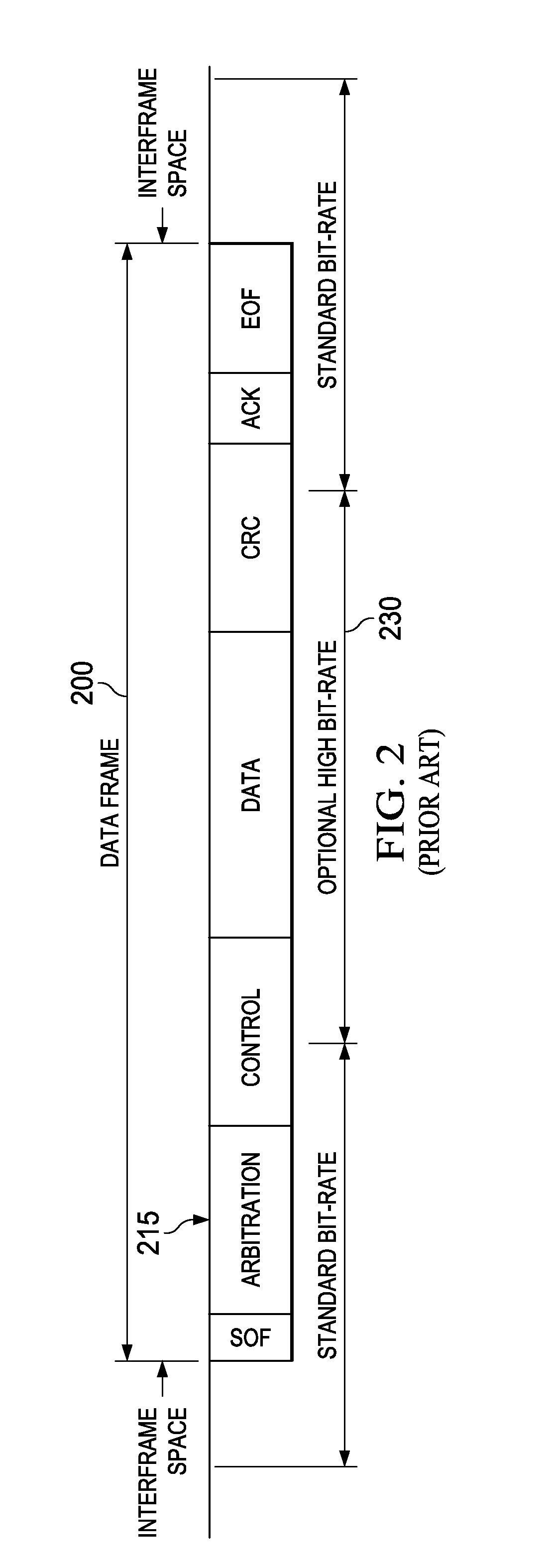

Can bus edge timing control apparatus, systems and methods

ActiveUS20140156893A1Easy dischargeSacrificing integrityData switching networksElectric digital data processingArea networkEngineering

Structures and methods herein insert one or more parallel “recessive nulling” driver impedances across a controller area network (CAN) bus starting at the time of a dominant-to-recessive data bit transition and extending for a selected recessive nulling time period. Doing so increases a rate of decay of a CAN bus dominant-to-recessive differential signal waveform, permits a shortened recessive bit time period, and allows for increased CAN bus bandwidth. Various modes of operation are applicable to various CAN bus node topologies. Recessive nulling may be applied to only the beginning portion of a recessive bit following a dominant bit (“LRN mode”) or to the entire recessive bit time (“HRN mode”). And, some embodiments may apply LRN operations to some recessive CAN frame bits and HRN operations to others.

Owner:TEXAS INSTR INC

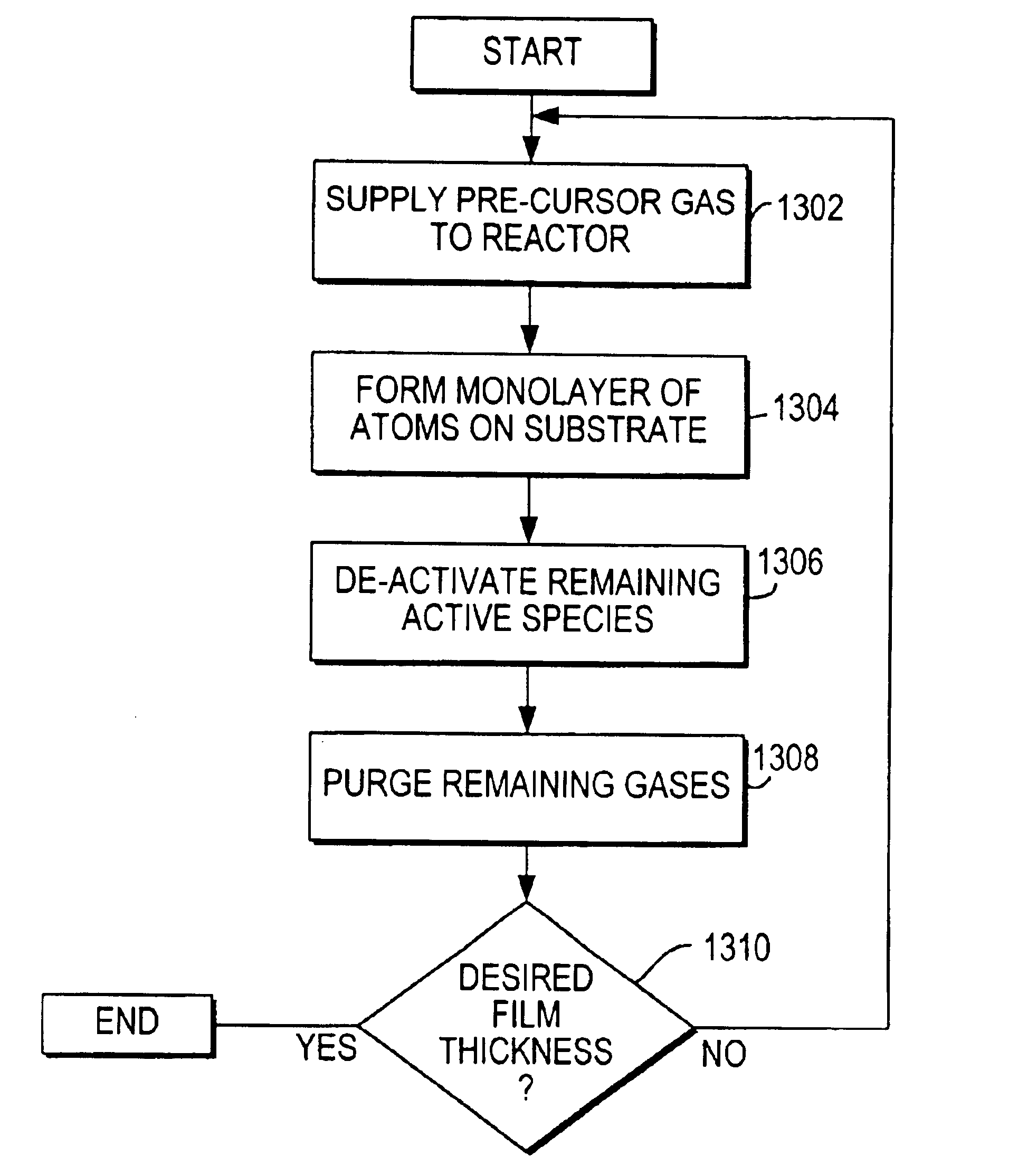

Insitu post atomic layer deposition destruction of active species

InactiveUS6844260B2Reduced purge timeImprove throughputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasAtomic layer deposition

Systems and methods for insitu post atomic layer deposition (ALD) destruction of active species are provided. ALD processes deposit multiple atomic layers on a substrate. Pre-cursor gases typically enter a reactor and react with the substrate resulting in a monolayer of atoms. After the remaining gas is purged from the reactor, a second pre-cursor gas enters the reactor and the process is repeated. The active species of some pre-cursor gases do not readily purge from the reactor, thus increasing purge time and decreasing throughput. A high-temperature surface placed in the reactor downstream from the substrate substantially destroys the active species insitu. Substantially destroying the active species allows the reactor to be readily purged, increasing throughput.

Owner:MICRON TECH INC

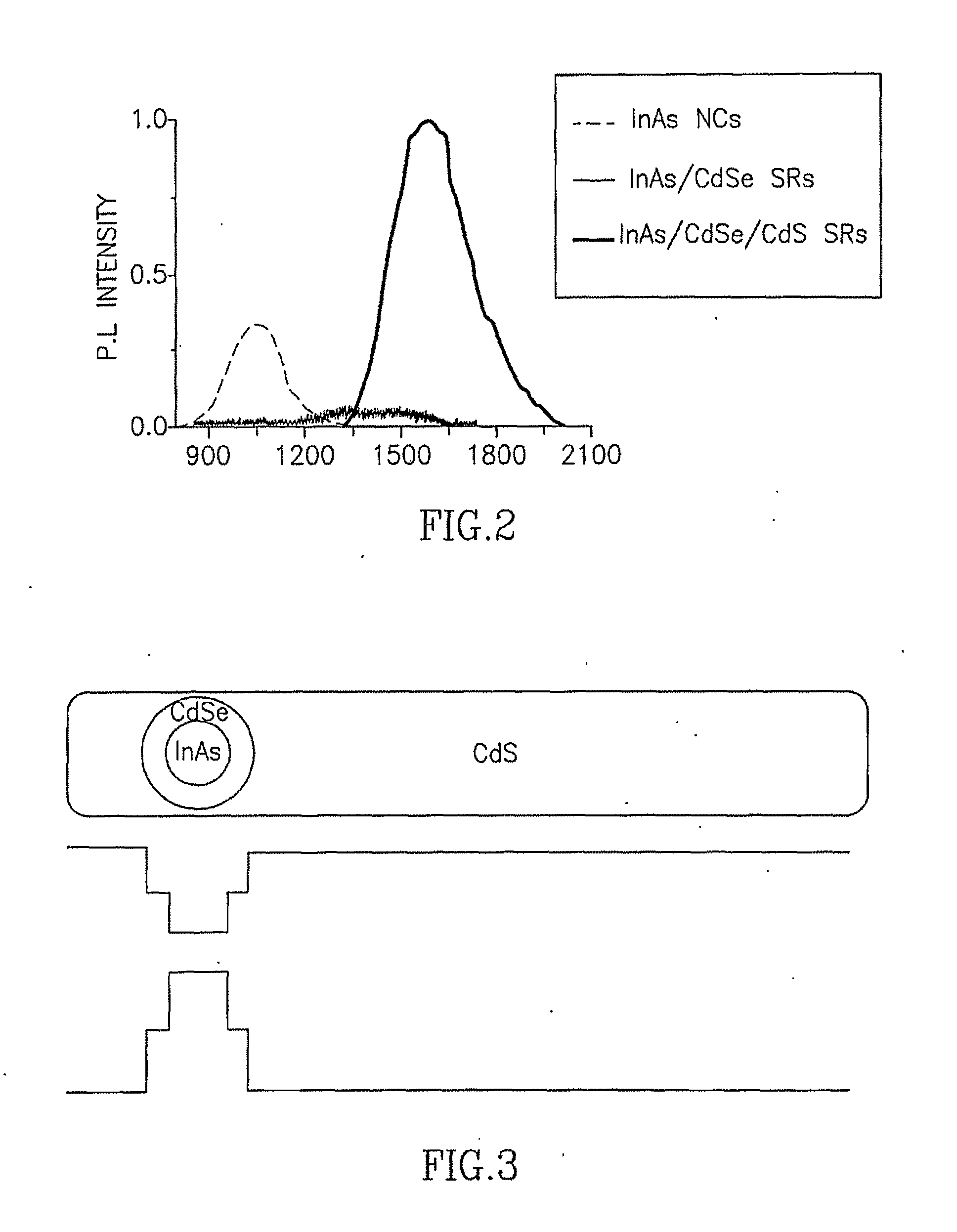

Anistropic semiconductor nanoparticles

InactiveUS20130115455A1Low fluorescence quantum efficiencyReduces electron-hole overlapLiquid surface applicatorsConductive materialEngineeringSemiconductor Nanoparticles

The present invention provides seeded rod (SR) nanostructure systems including an elongated structure embedded with a seed structure being a core / shell structure or a single-material rod element. The SR systems disclosed herein are suitable for use in a variety of electronic and optical devices.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

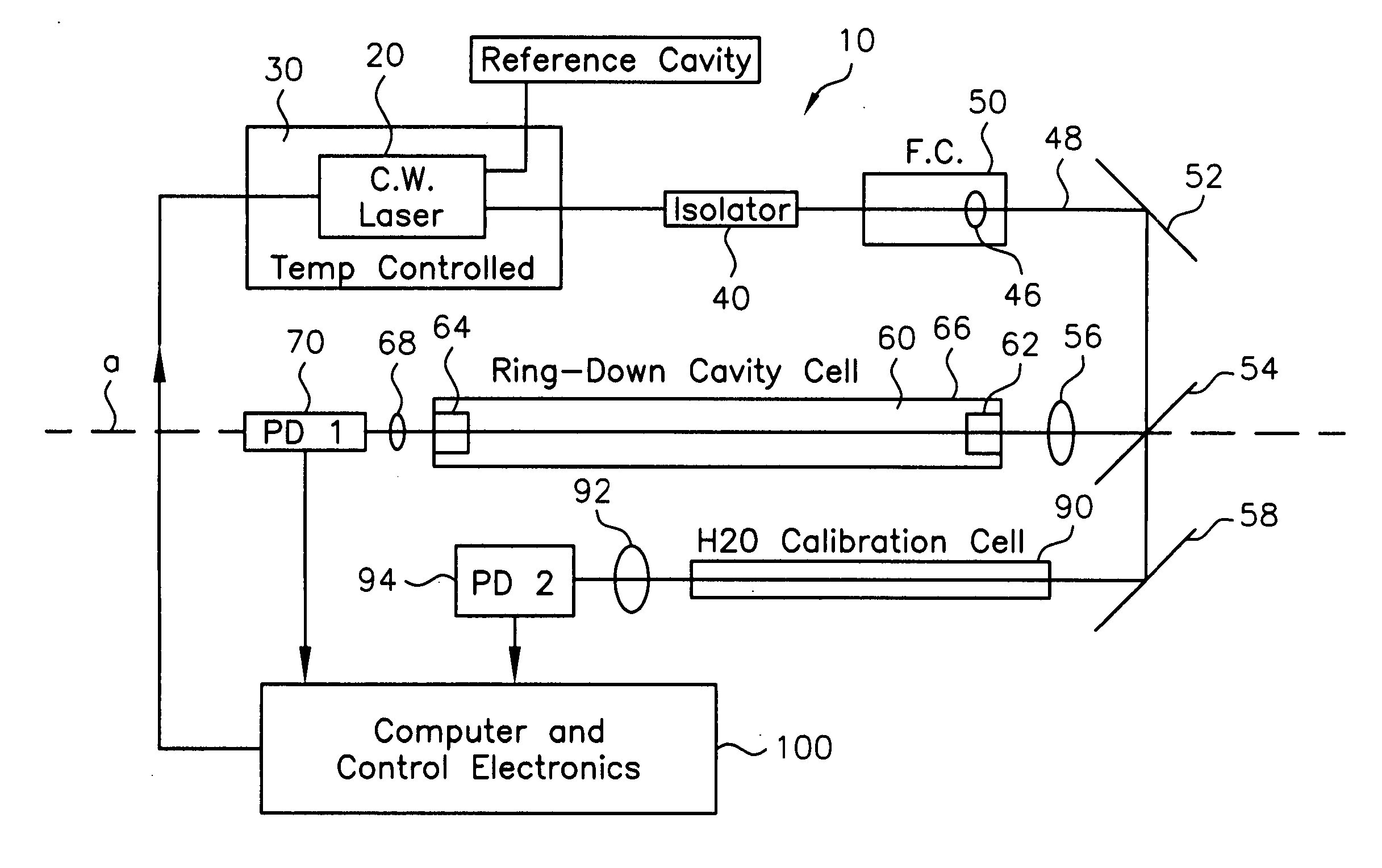

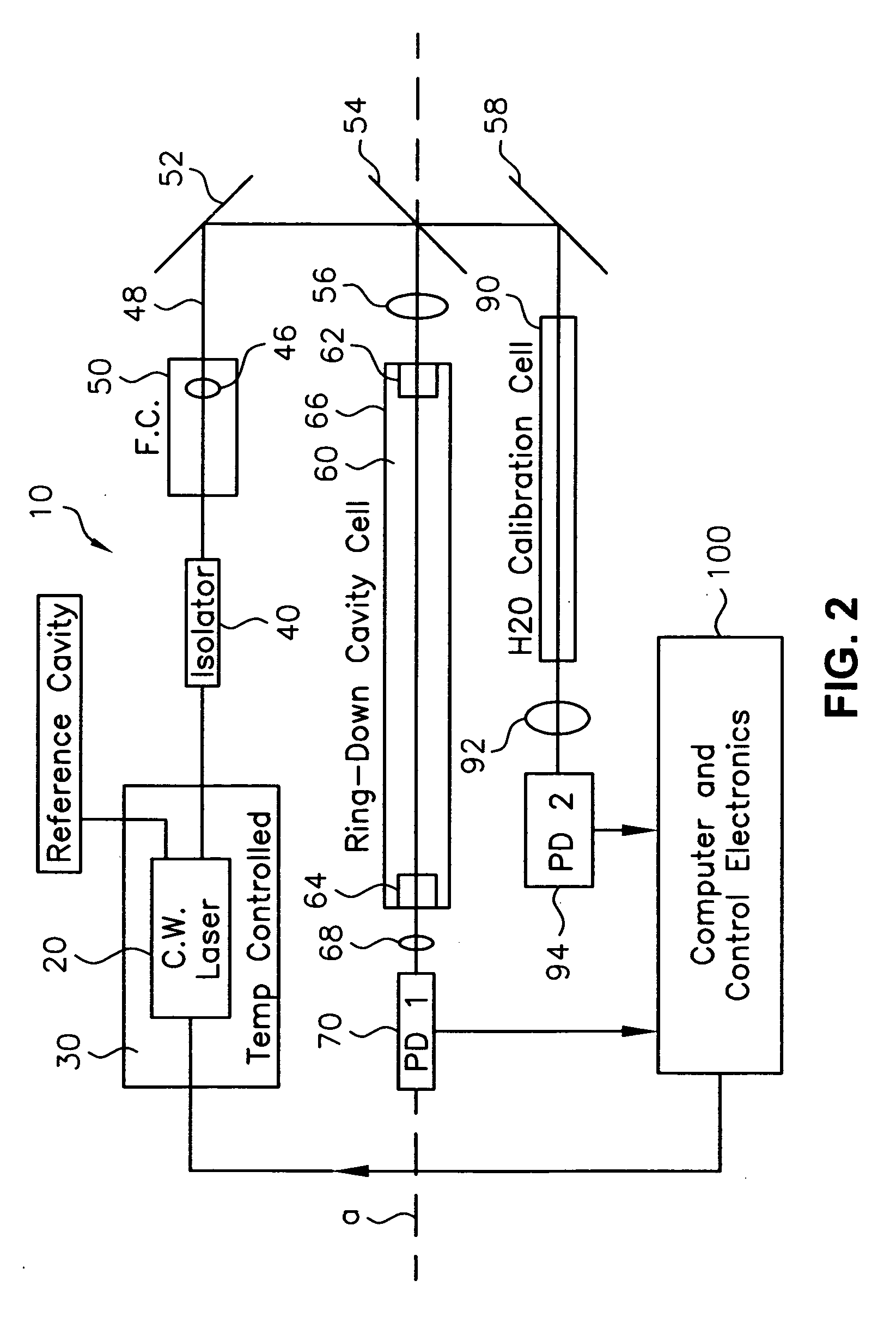

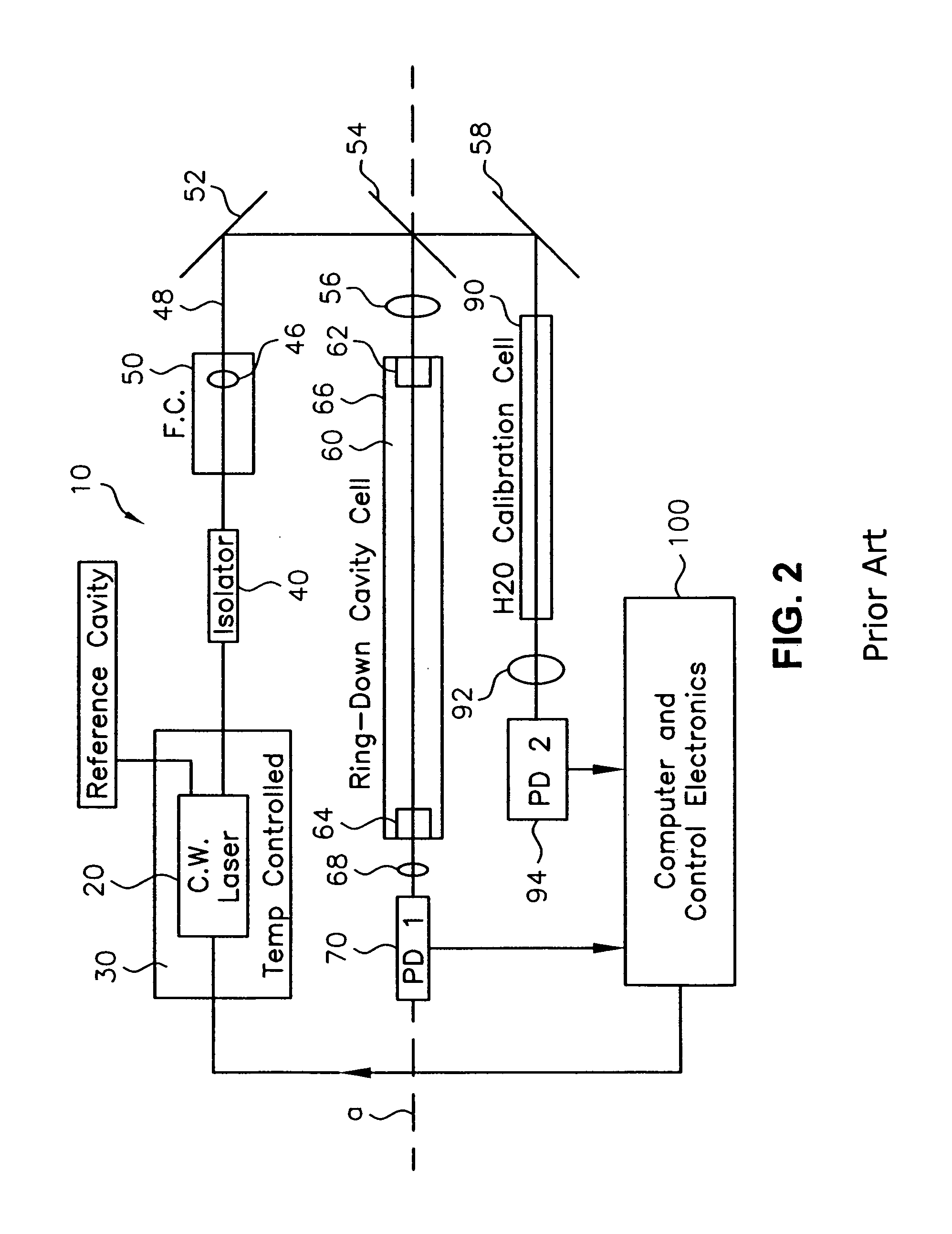

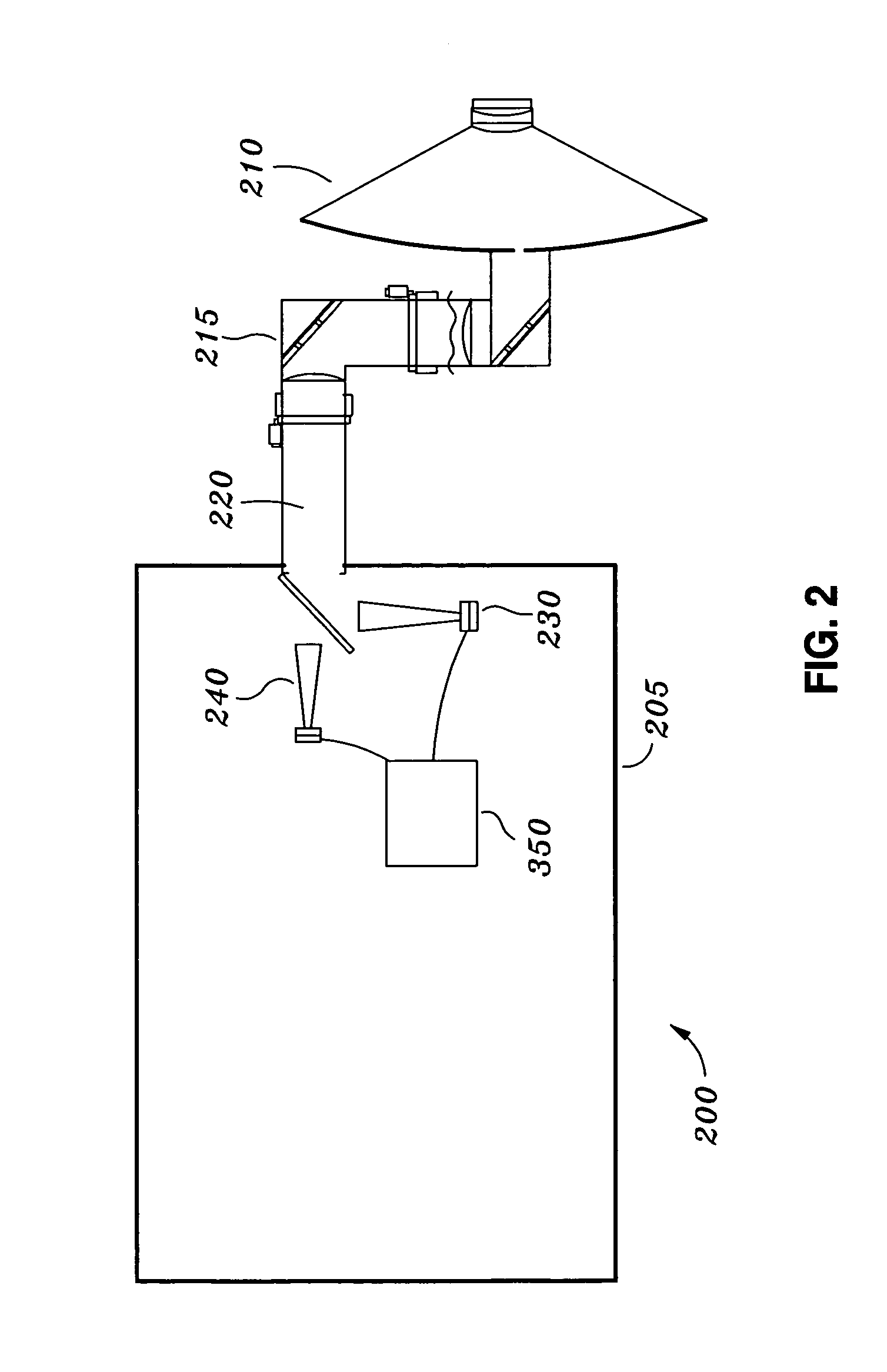

Apparatus for enhanced evanescent field exposure in an optical fiber resonator for spectroscopic detection and measurement of trace species

InactiveUS20060183241A1Increase reduction rateIncrease exposureAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorFiberRing down

Owner:THE TRUSTEES FOR PRINCETON UNIV

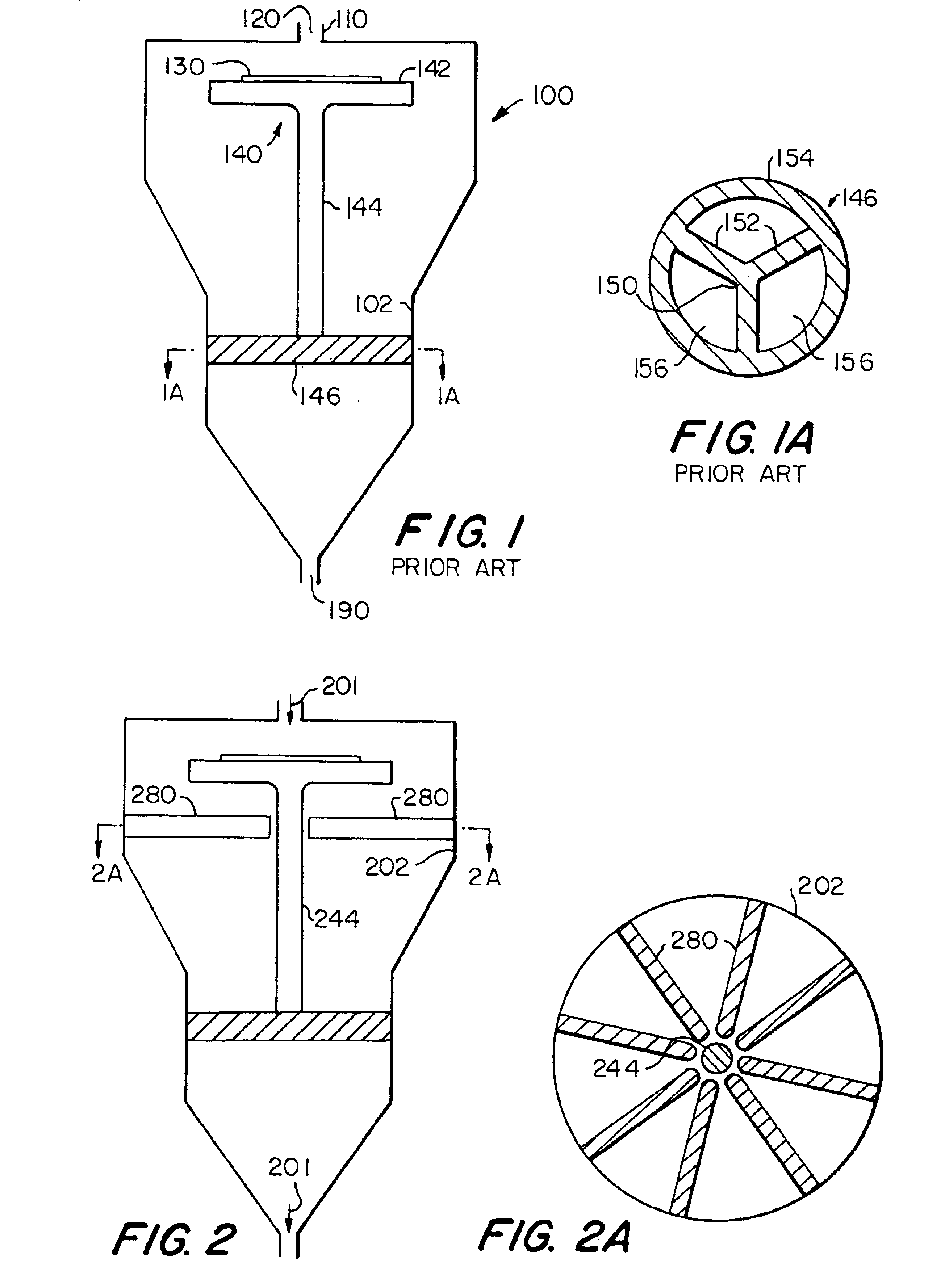

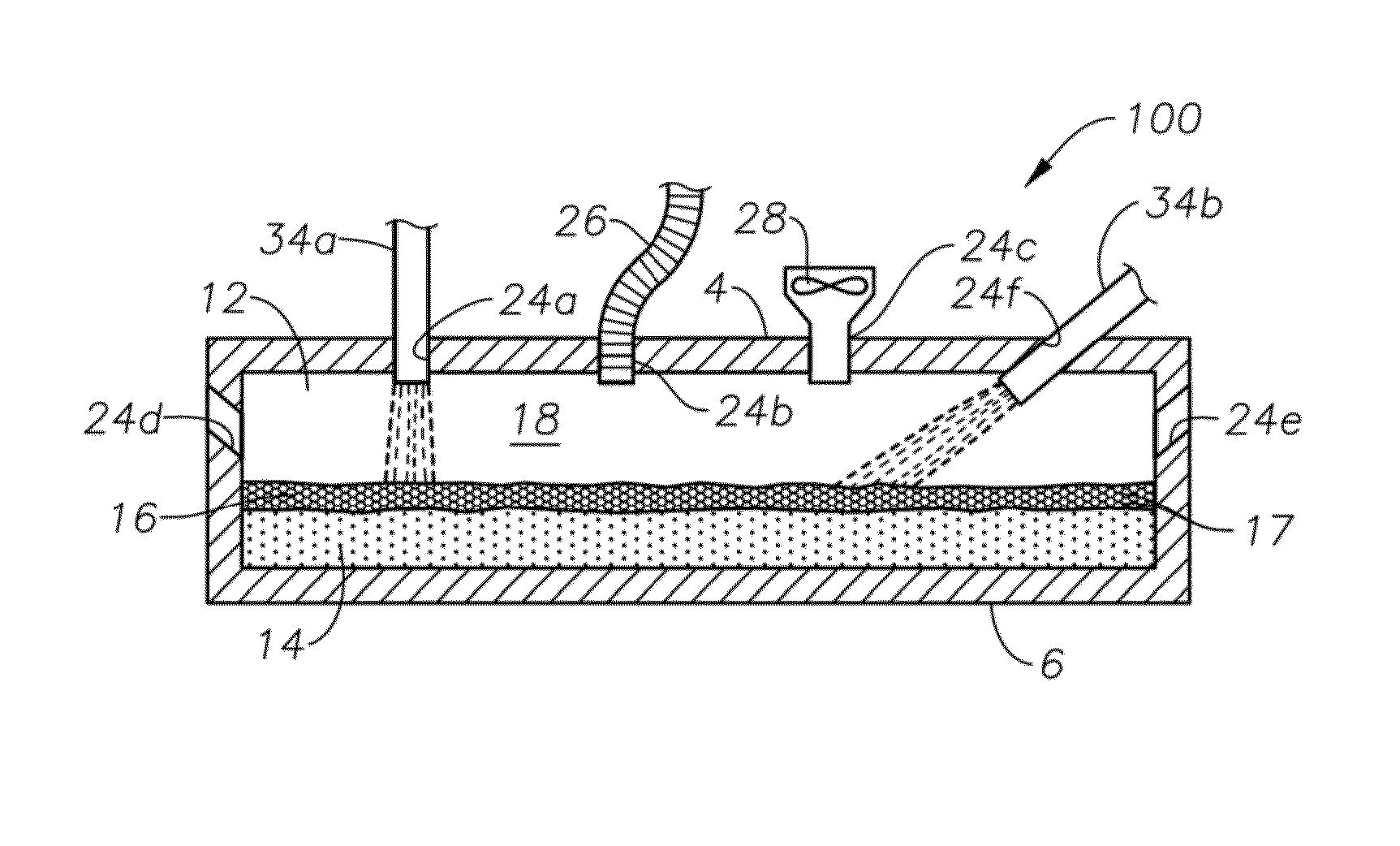

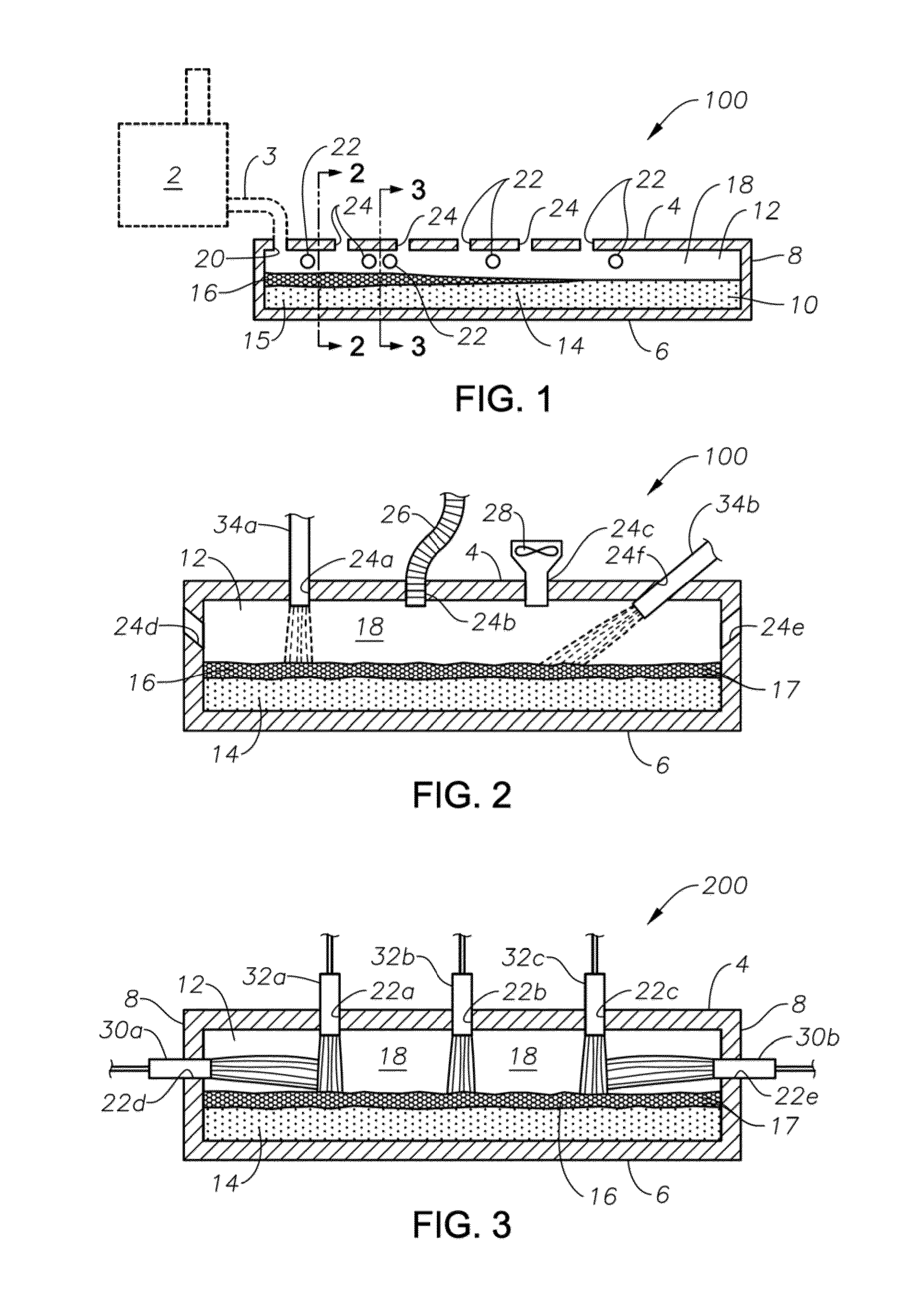

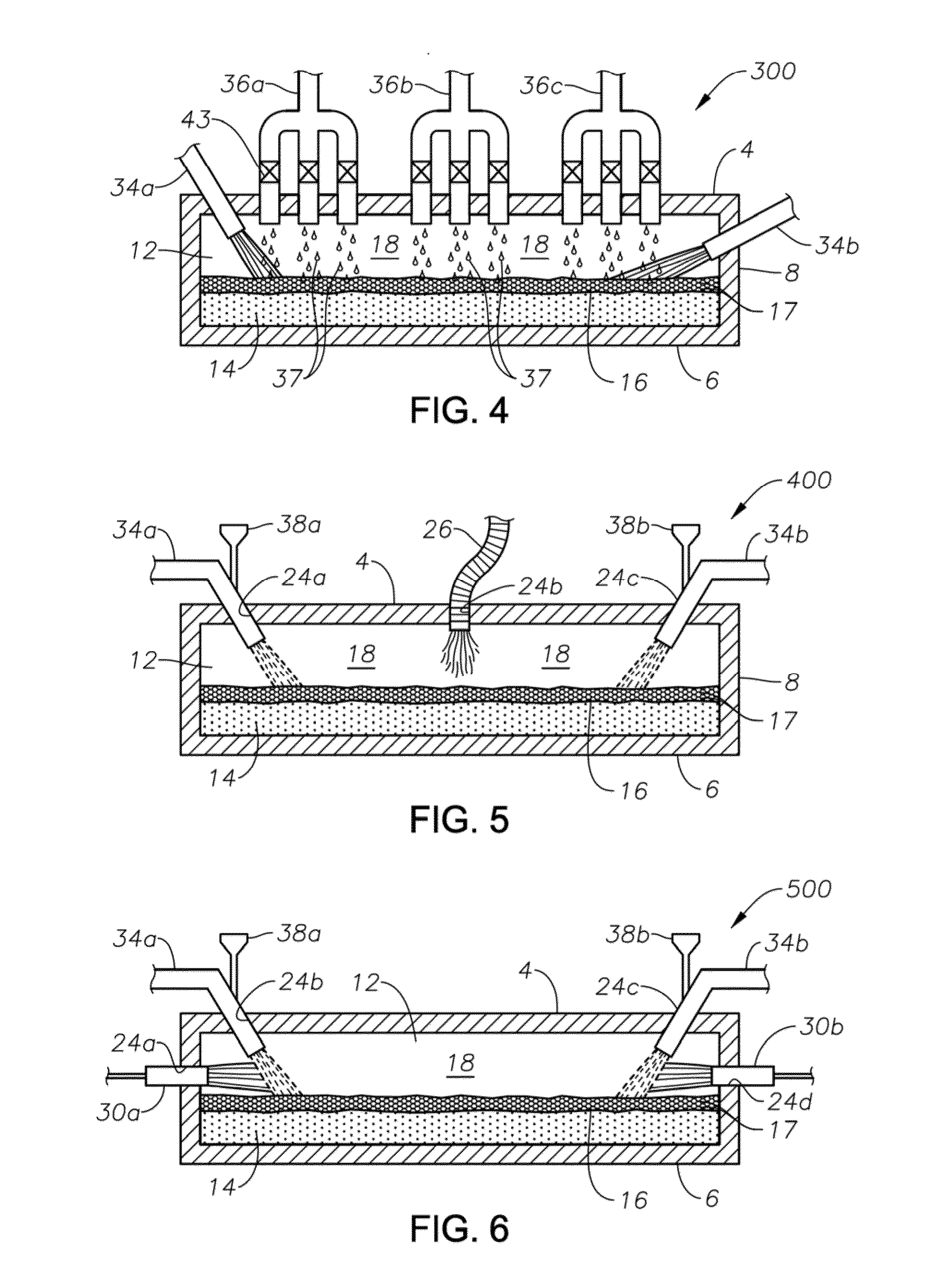

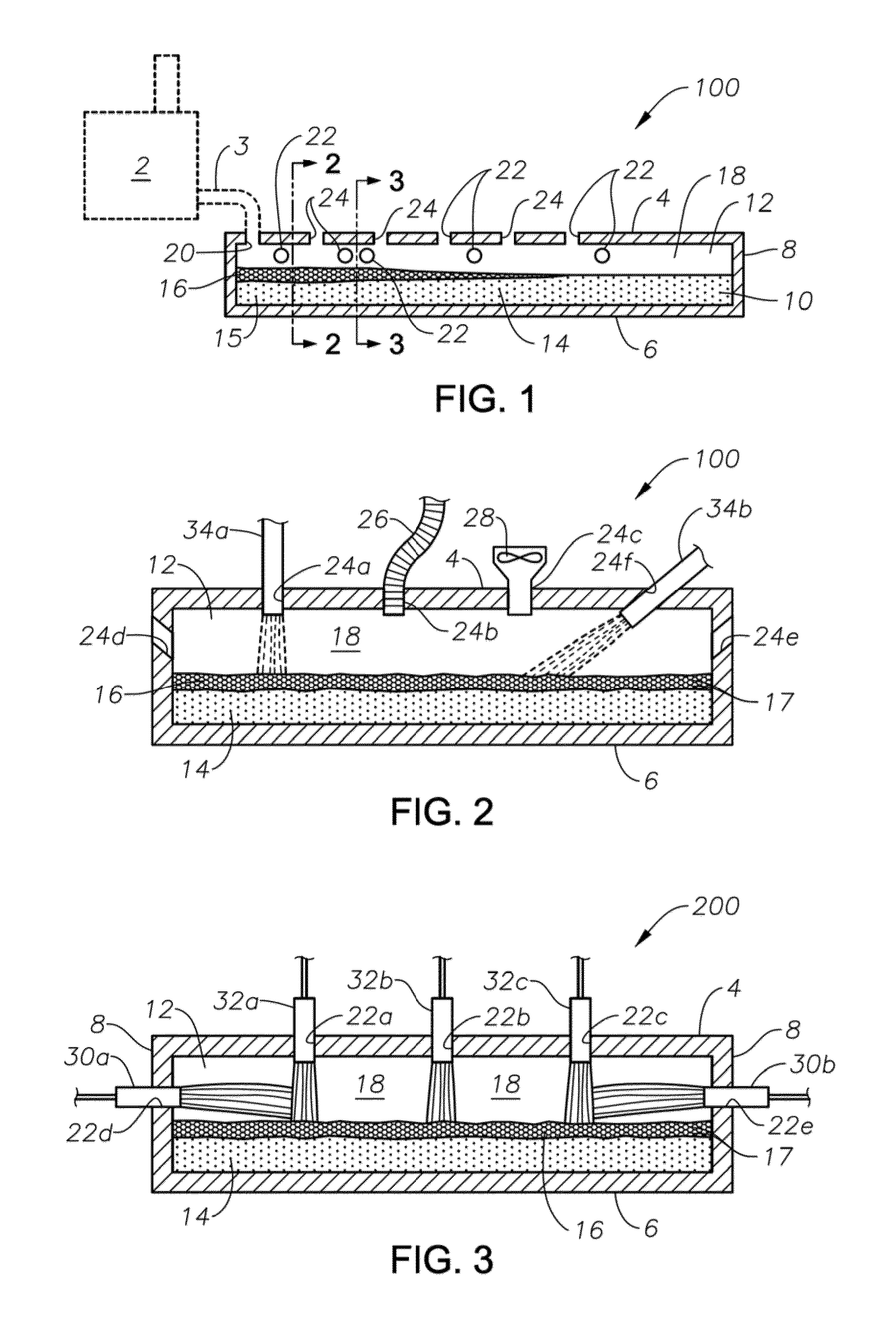

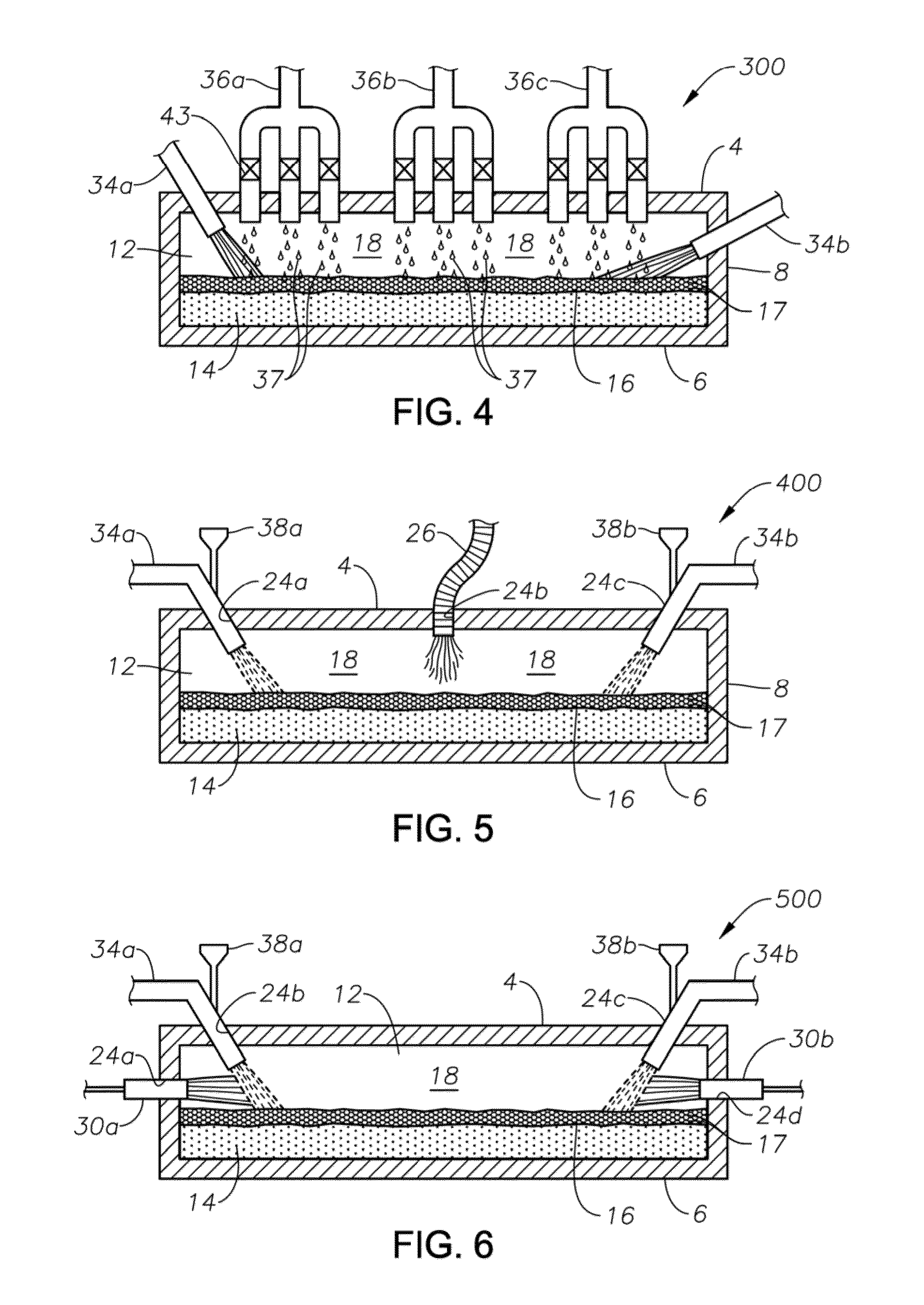

Methods and systems for controlling bubble size and bubble decay rate in foamed glass produced by a submerged combustion melter

ActiveUS20140090421A1Increase reduction rateGlass furnace apparatusGlass melting apparatusCombustionGaseous atmosphere

Methods and systems for controlling bubble size and bubble decay rate of glass foams formed during submerged combustion melting. Flowing a molten mass of foamed glass comprising molten glass and bubbles entrained therein into an apparatus downstream of a submerged combustion melter. The downstream apparatus has a floor, a roof, and a sidewall structure connecting the floor and roof. The foamed glass has glass foam of glass foam bubbles on its top surface, and the downstream apparatus defines a space for a gaseous atmosphere above and in contact with the glass foam. The downstream apparatus includes heating components to heat or maintain temperature of the foamed glass. Adjusting composition of the atmosphere above the glass foam, and / or contacting the foam with a liquid or solid composition controls bubble size of the glass foam bubbles, and / or foam decay rate.

Owner:JOHNS MANVILLE CORP

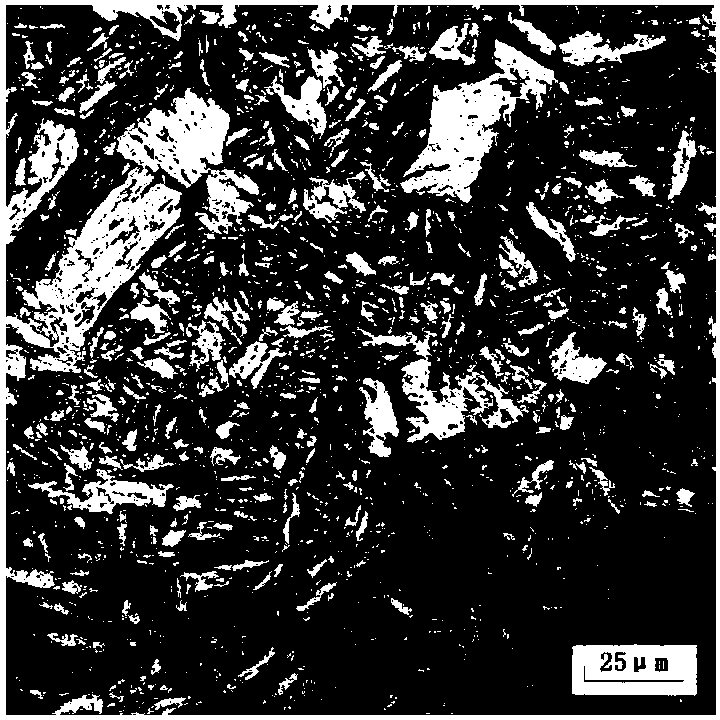

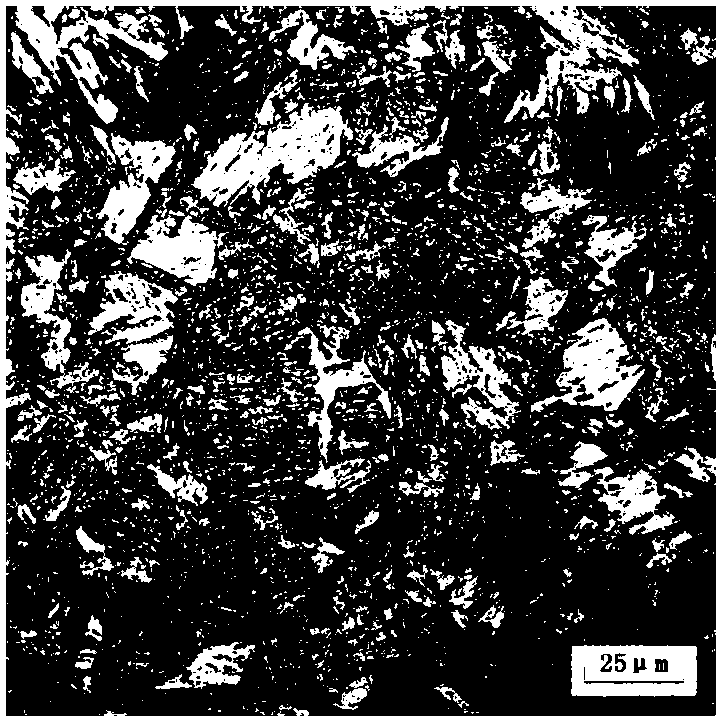

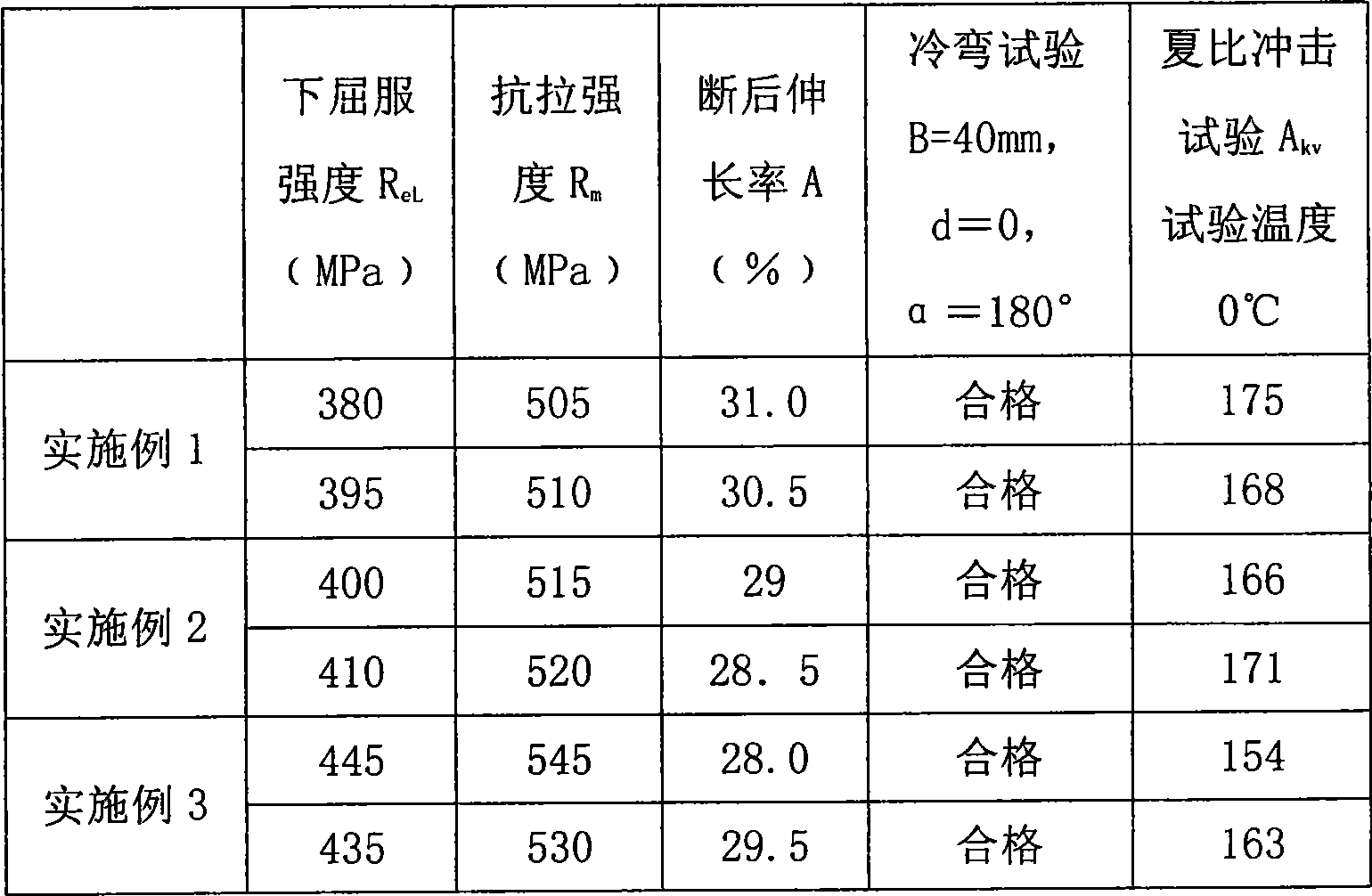

690MPa thick steel plate for ocean engineering and manufacturing method of steel plate

The invention discloses 690MPa thick steel plate for ocean engineering and a manufacturing method of the 690MPa thick steel plate, and belongs to the technical field of steel for the ocean engineering. The steel plate comprises the following chemical components: 0.08-0.15% of C, 0.10-0.30% of Si, 1.0-1.50% of Mn, 0.03-0.04% of Alt, 0.02-0.06% of Nb, 0.03-0.06% of V, 0.010-0.02% of Ti, 0.1-0.5% of Mo, 0.5-1.6% of Ni, 0.1-0.4% of Cu, 0.4-1.2% of Cr, less than 0.01% of P, less than 0.005% of S, less than or equal to 0.12% of Nb+V+Ti, 0.0005-0.0017% of B, and the balance of Fe and inevitable impurities. Quenching temperature and tempering temperature are controlled strictly; the thickness of the produced steel plate is 50-120mm; and the microstructure of the steel plate is tempered sorbite and a little tempered bainite. The steel plate and the manufacturing method have the advantages that the lamellar tearing resistance and low temperature toughness are ensured; uniformity of the thick steel plate in the thickness direction is ensured; and the production cost is reduced.

Owner:SHOUGANG CORPORATION

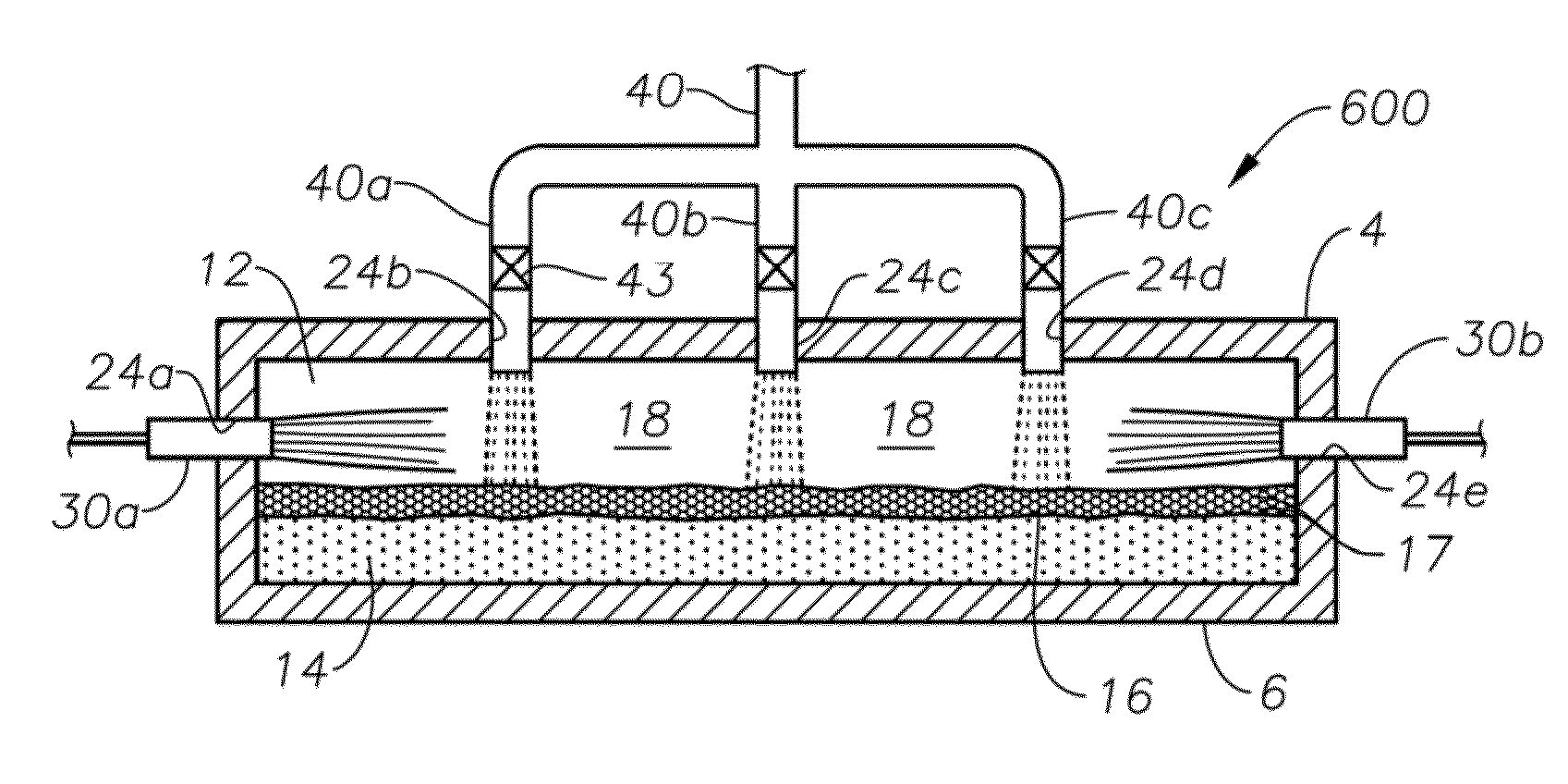

Methods and systems for controlling bubble size and bubble decay rate in foamed glass produced by a submerged combustion melter

ActiveUS8991215B2Increase reduction rateGlass furnace apparatusGlass melting apparatusCombustionGaseous atmosphere

Methods and systems for controlling bubble size and bubble decay rate of glass foams formed during submerged combustion melting. Flowing a molten mass of foamed glass comprising molten glass and bubbles entrained therein into an apparatus downstream of a submerged combustion melter. The downstream apparatus has a floor, a roof, and a sidewall structure connecting the floor and roof. The foamed glass has glass foam of glass foam bubbles on its top surface, and the downstream apparatus defines a space for a gaseous atmosphere above and in contact with the glass foam. The downstream apparatus includes heating components to heat or maintain temperature of the foamed glass. Adjusting composition of the atmosphere above the glass foam, and / or contacting the foam with a liquid or solid composition controls bubble size of the glass foam bubbles, and / or foam decay rate.

Owner:JOHNS MANVILLE CORP

CAN bus edge timing control for dominant-to-recessive transitions

ActiveUS9606948B2Easy dischargeSacrificing integrityData switching networksElectric digital data processingNODALArea network

Structures and methods herein insert one or more parallel “recessive nulling” driver impedances across a controller area network (CAN) bus starting at the time of a dominant-to-recessive data bit transition and extending for a selected recessive nulling time period. Doing so increases a rate of decay of a CAN bus dominant-to-recessive differential signal waveform, permits a shortened recessive bit time period, and allows for increased CAN bus bandwidth. Various modes of operation are applicable to various CAN bus node topologies. Recessive nulling may be applied to only the beginning portion of a recessive bit following a dominant bit (“LRN mode”) or to the entire recessive bit time (“HRN mode”). And, some embodiments may apply LRN operations to some recessive CAN frame bits and HRN operations to others.

Owner:TEXAS INSTR INC

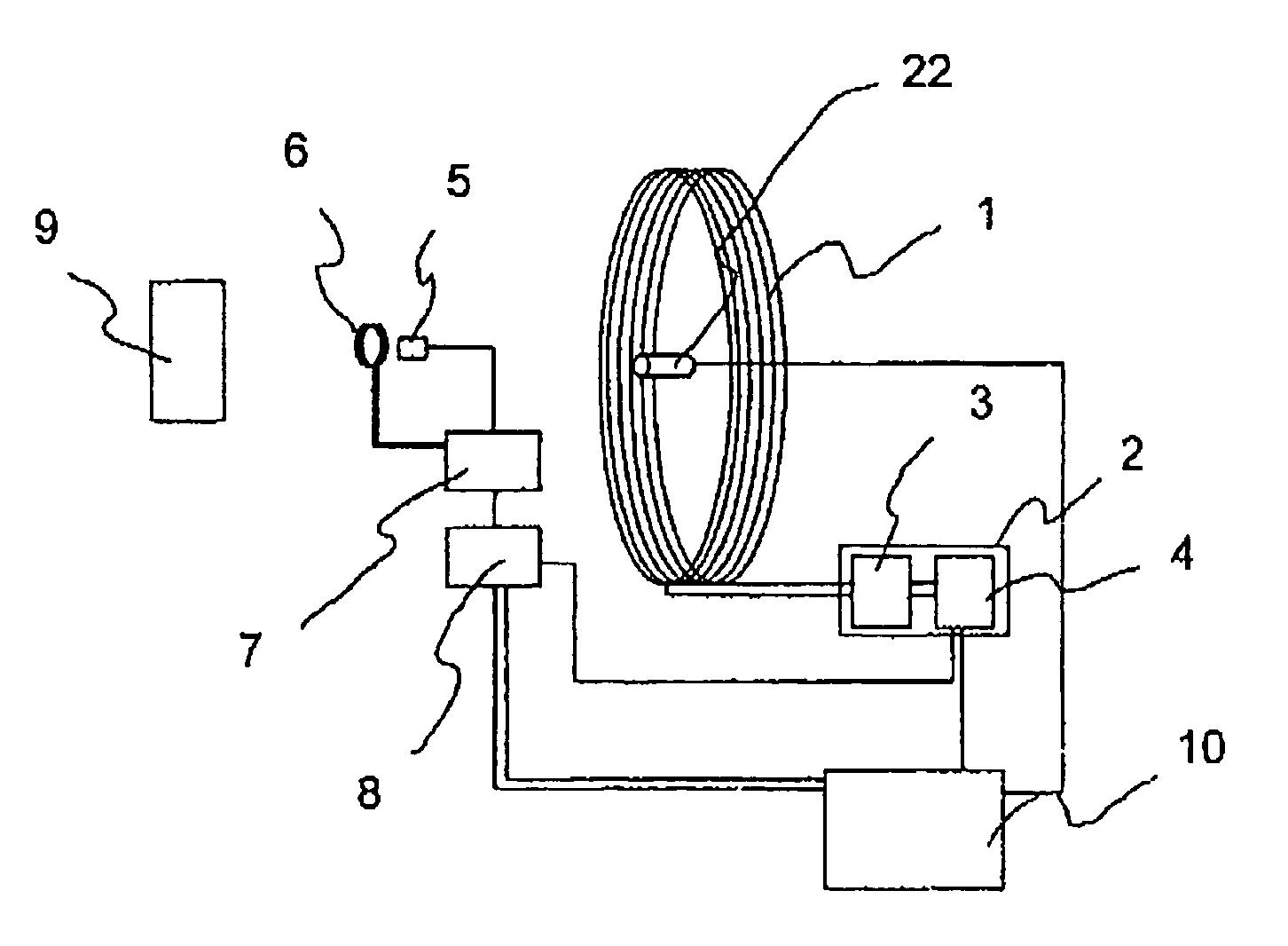

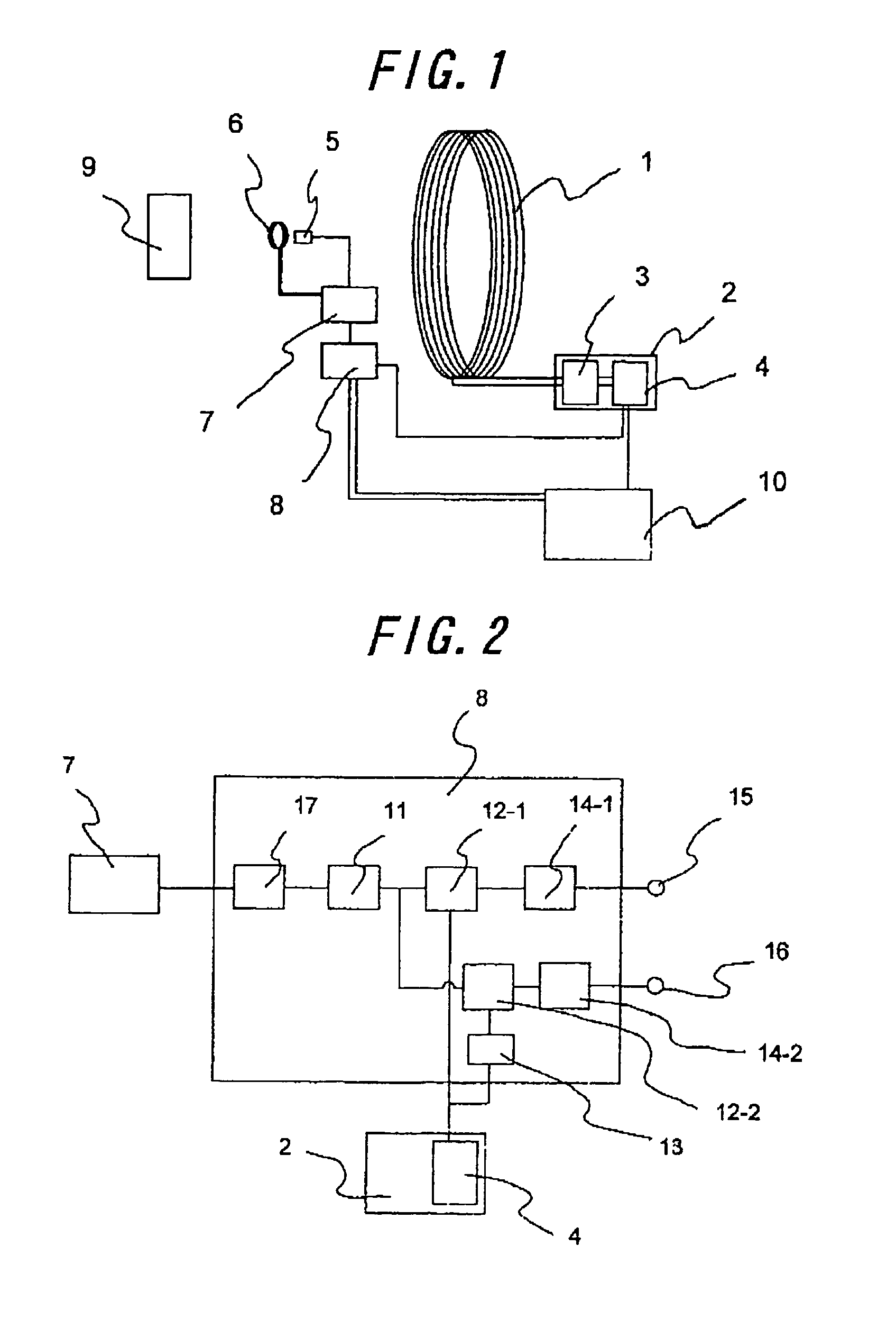

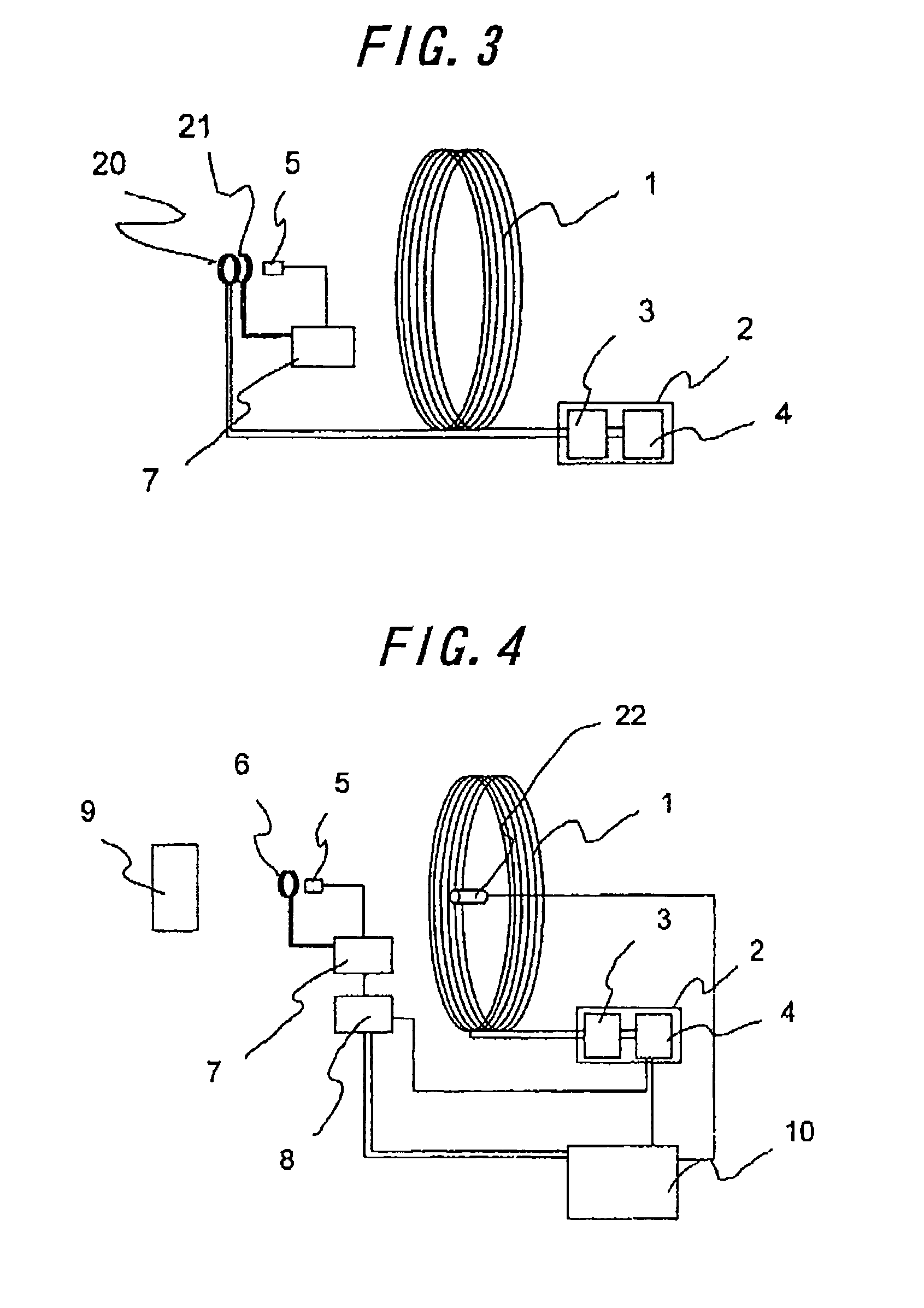

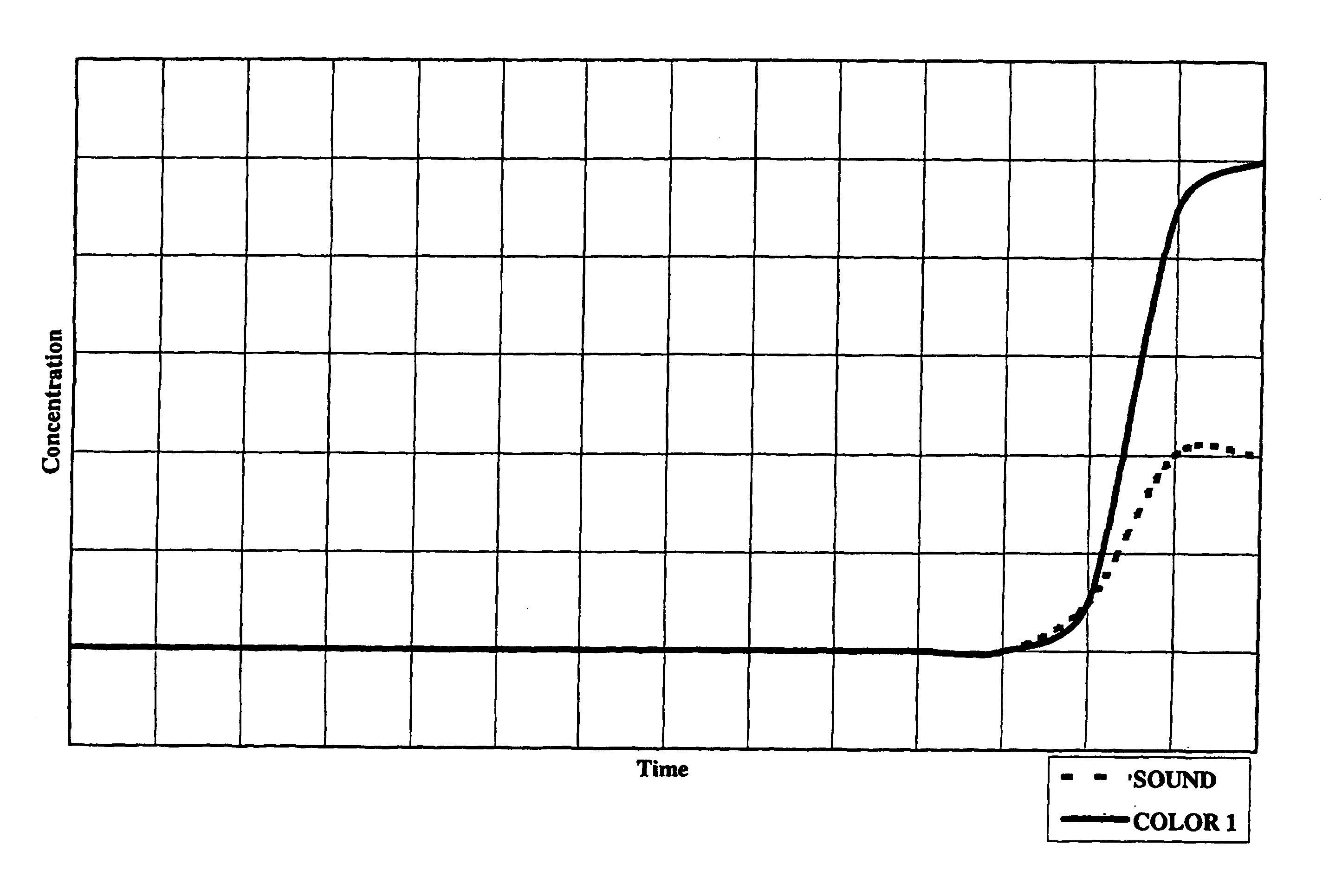

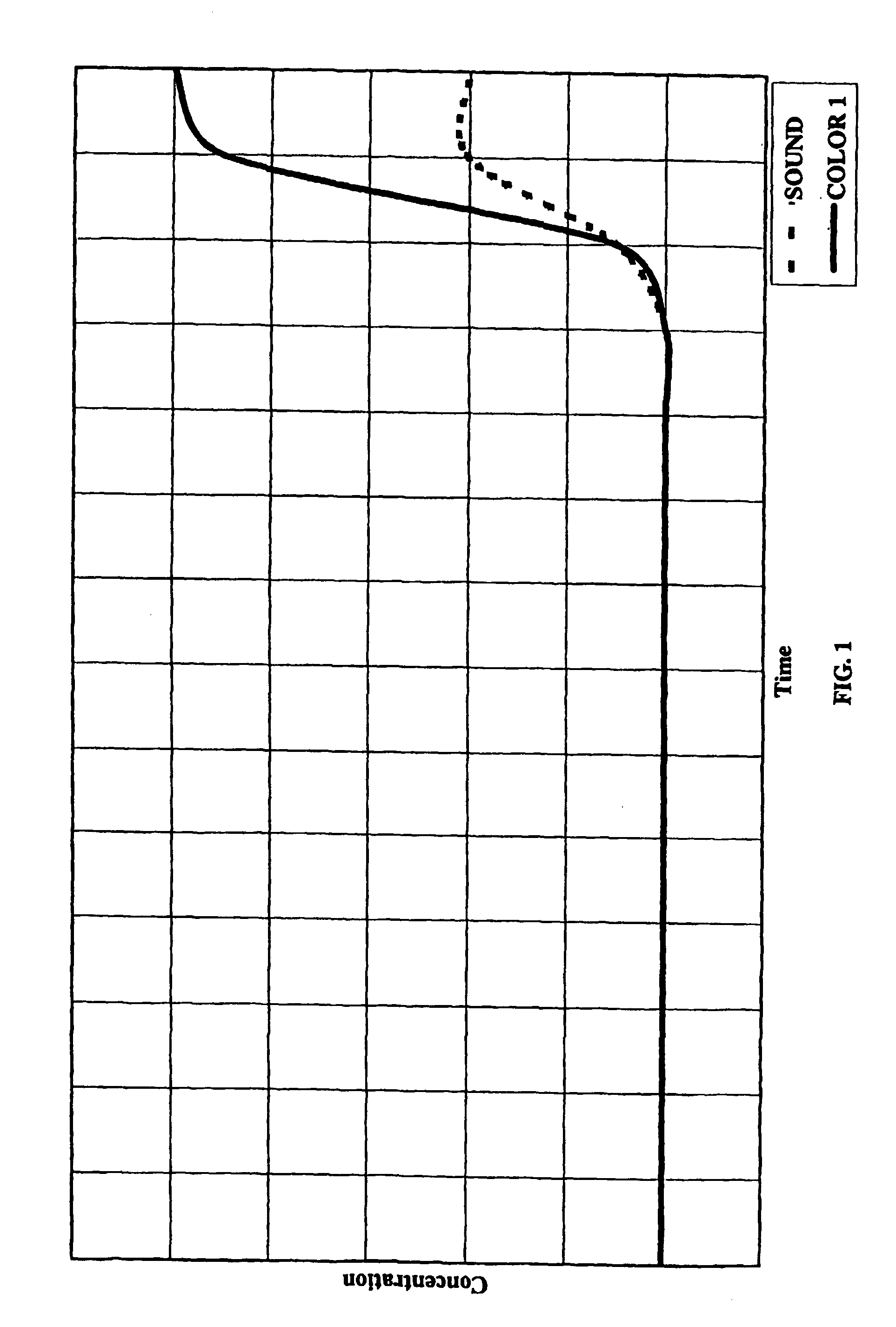

Magnetic detecting device and material identifying device

InactiveUS7525308B2Good removal effectReduce areaMagnetic property measurementsElectric/magnetic detectionAudio power amplifierPhase change

The present invention discloses a magnetic detecting device comprising an apply coil 1 for generating an alternate magnetic field of variable frequency and a power source 2 for the apply coil; a magnetic sensor 5 for detecting a change in the magnetic field induced by a test object 9 placed at a distance from a surface of said apply coil and toward said test object, said magnetic sensor being provided with a cancel coil 6 for canceling a magnetic field generated at the position of the magnetic sensor by a direct magnetic field and / or said apply coil; a measurement circuit 7 for the magnetic sensor for measuring a detection signal of said magnetic sensor; a lock-in amplifier circuit 8 for detecting an output of said measurement circuit for the magnetic sensor into two signals having the same frequency as that of said apply coil and phases different from each other by 90 degrees; and an analysis means 10 for analyzing a phase change of the output of said magnetic sensor 5 using an output signal from said lock-in amplifier circuit 8.

Owner:UNIV OKAYAMA

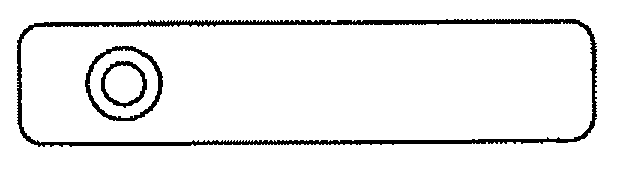

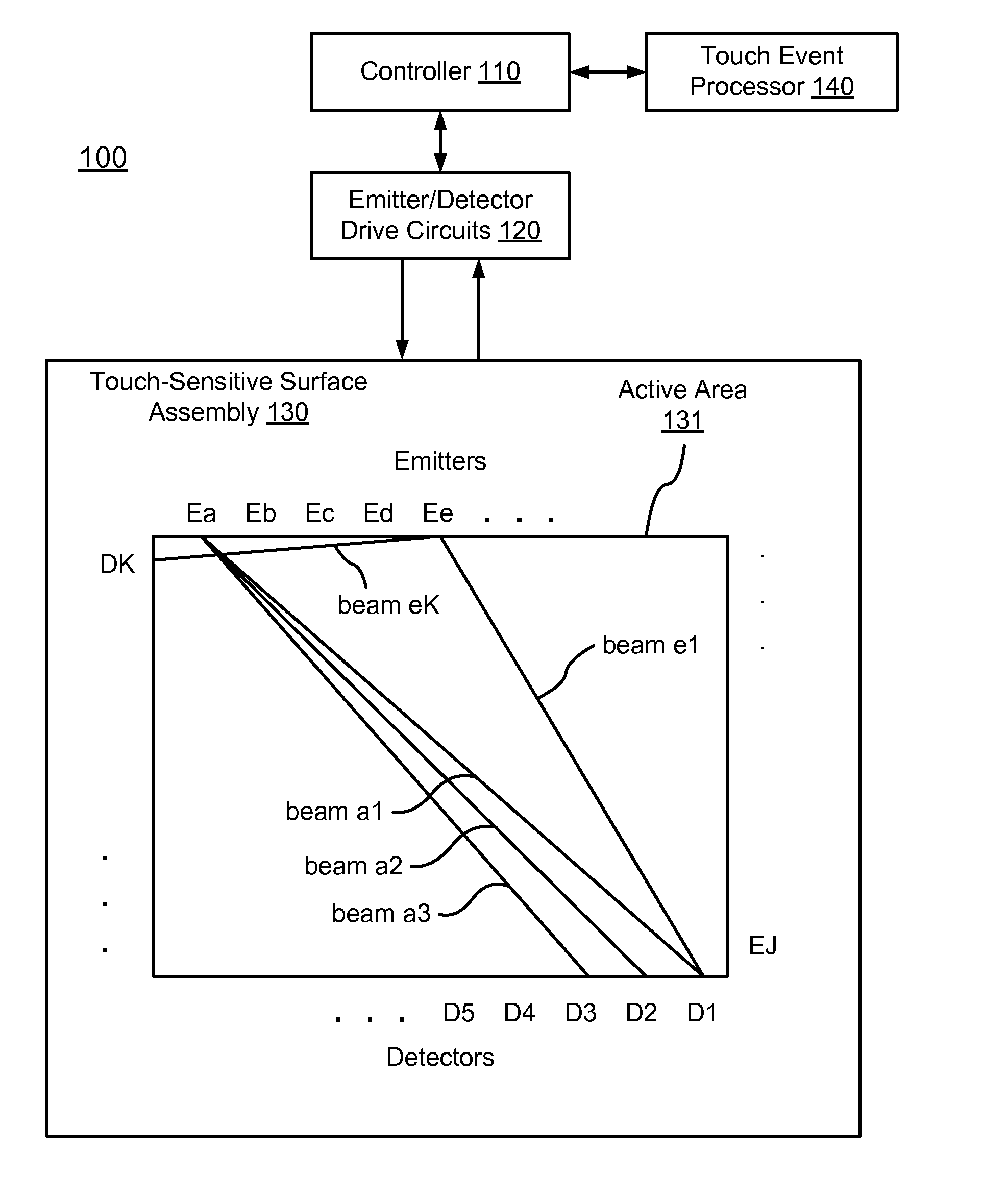

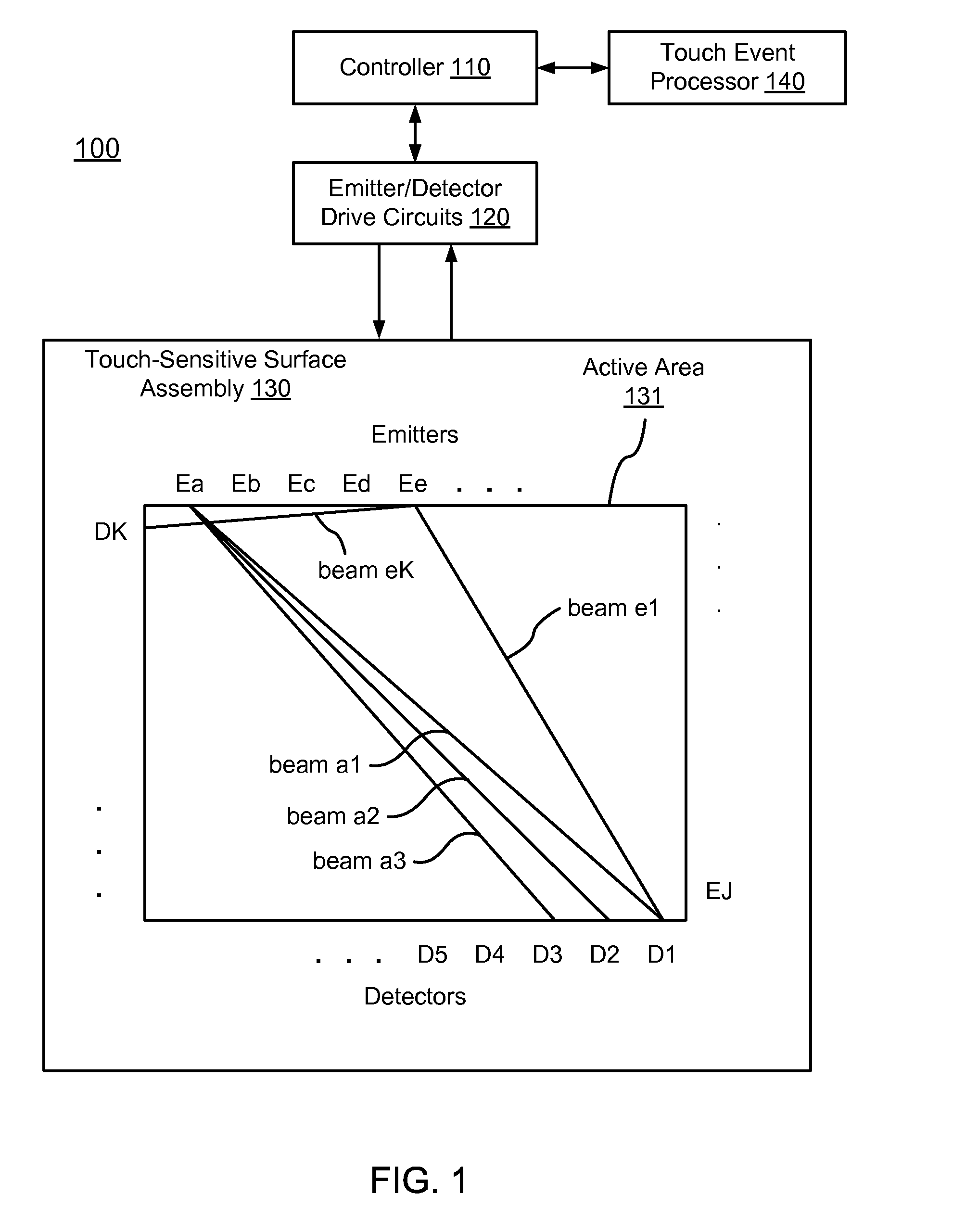

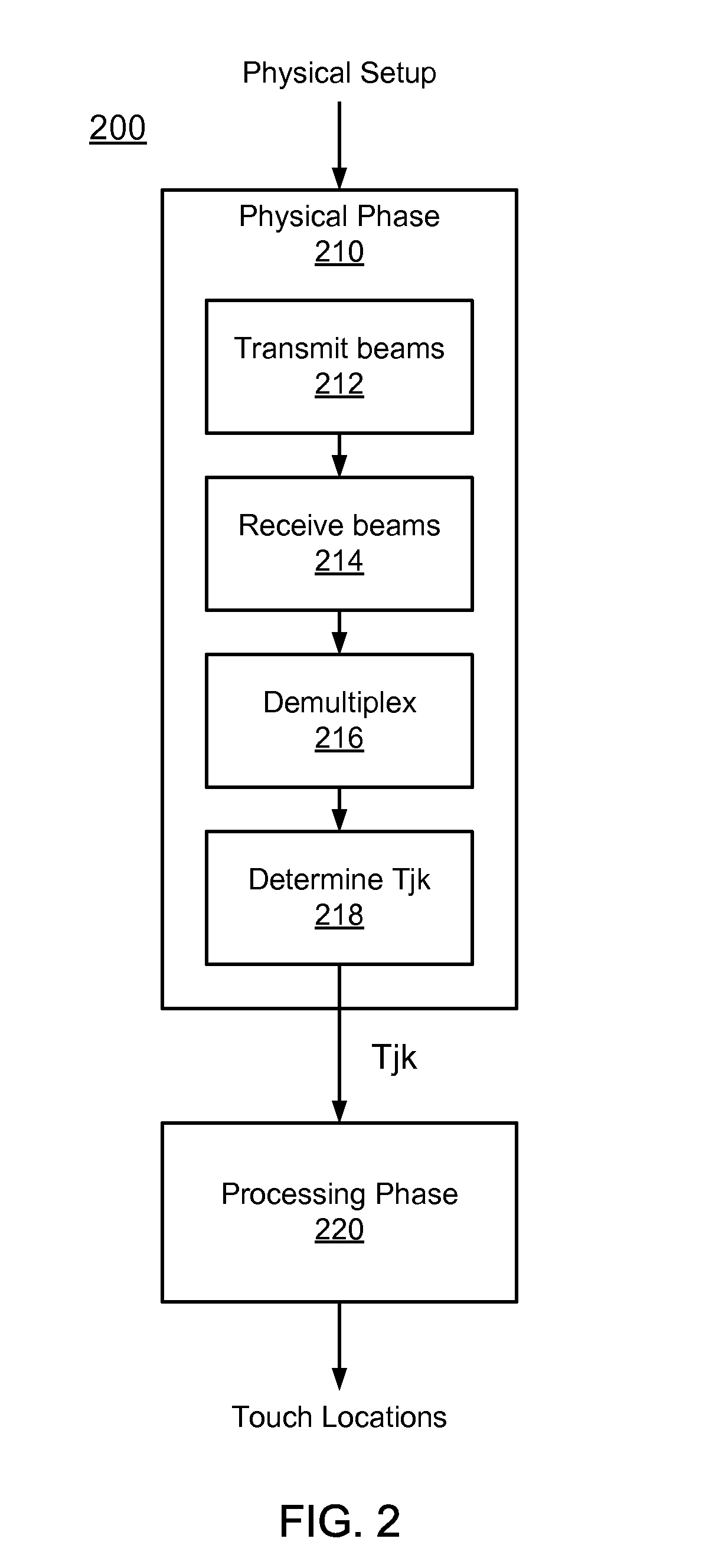

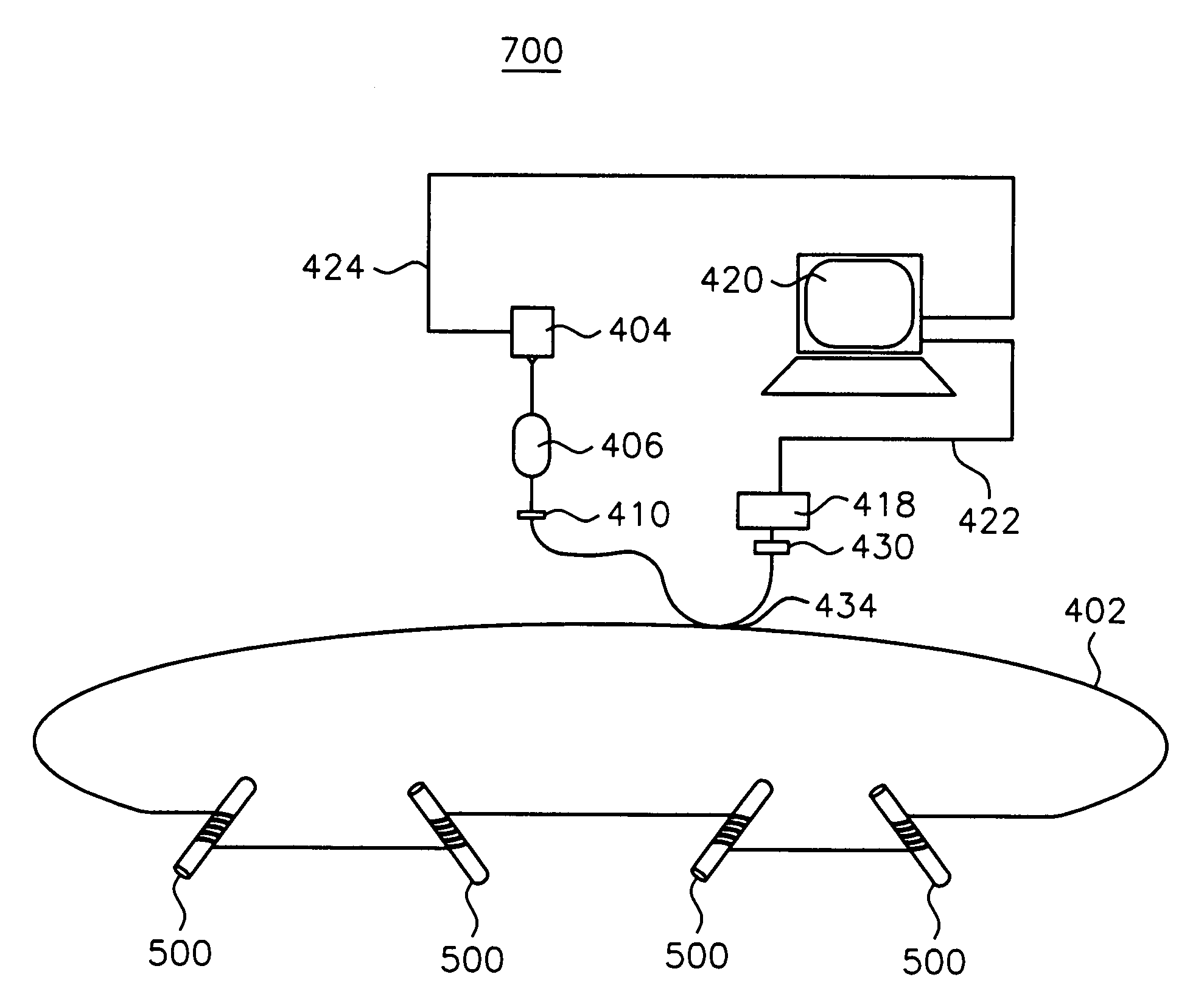

Instrument Detection with an Optical Touch Sensitive Device

ActiveUS20160062549A1Increase reduction rateVarious kindsDigital data processing detailsInput/output processes for data processingMultiplexingTotal internal reflection

An optical touch-sensitive device detects touch events caused by instruments (e.g., pens, styluses) and distinguishes these events from touch events caused by fingers. In some embodiments, different instruments can also be distinguished. The optical touch-sensitive device includes multiple emitters and detectors. Each emitter produces optical beams which are received by the detectors. The optical beams preferably are multiplexed in a manner so that many optical beams can be received by a detector simultaneously. Touch events disturb the optical beams, for example due to frustrated total internal reflection. Information indicating which optical beams have been disturbed is analyzed to detect one or more touch events. The analysis also distinguishes instrument touch events from finger touch events.

Owner:BEECHROCK LTD

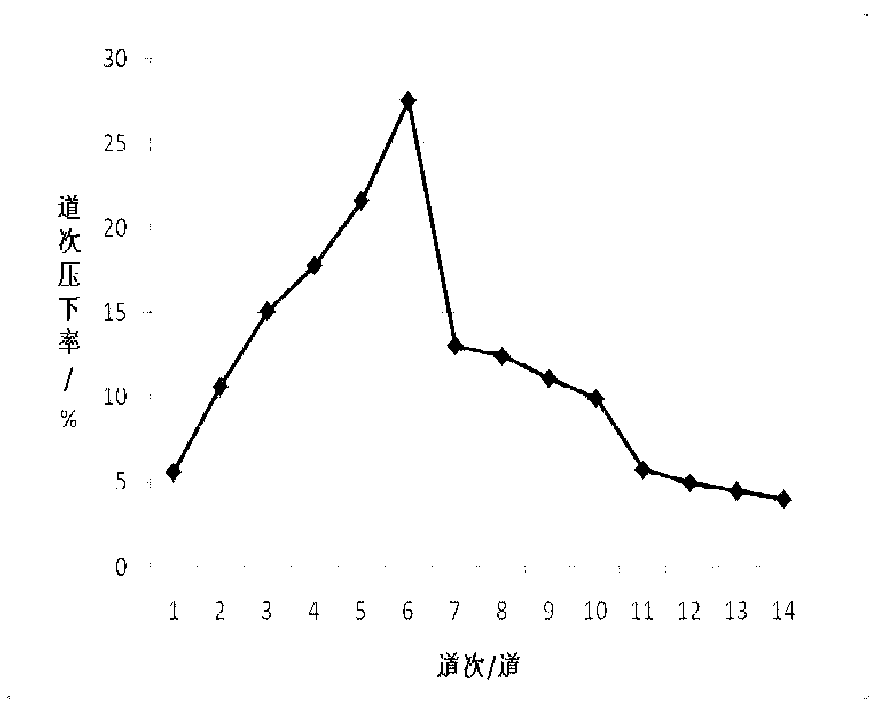

Novel method for controlling plate shape of heavy and medium plate mill

InactiveCN101811141AMeet the finishing temperatureIncrease reduction rateProfile control deviceSheet steelWave shape

The invention discloses a novel method for controlling the plate shape of a heavy and medium plate mill. The last milling pass in the method is a planishing pass for reducing head warping, head knocking and wave shape of a steel plate; the speed of the planishing pass is controlled to be between 1.0 and 3.0 m / s; the roll gap is 1 to 5 mm larger than the thickness of a finished product; and the milling force is between 200 and 600 tons. The roll gap of the planishing pass can be adjusted according to the conditions of the plate shape and the milling force. The product produced by the method can avoid the defects of head warping, head knocking, tongue shape, wave shape and the like of the steel plate; the thickness of the steel plate meets the requirements of tolerance; and the method further improves mechanical properties of the steel plate, reduces alloy elements, saves production cost and improves economic benefit of enterprises.

Owner:NANJING IRON & STEEL CO LTD

Method for rolling thick specification low-alloy structure steel plate by using middle and thin plate blank

InactiveCN101148735AIncreasing the thicknessIncrease reduction rateRoll mill control devicesMetal rolling arrangementsChemical compositionMaterials science

The present invention relates to production of structural low alloy steel plate, and is especially process of producing high strength hot rolled coiled sheet of 16-20 mm thickness with continuous cast billet of 150-170 mm thickness. The steel has chemical composition comprising C 0.15-0.20 wt%, Si 0.20-0.40 wt%, Mn 1.40-1.60 wt%, S not more than 0.030 wt%, P not more than 0.030 wt%, and Fe and impurity for the rest. The production process includes the steps of controlled heating, rough rolling, finish rolling, cooling, etc. and the produced hot rolled coiled sheet has simple composition, low cost, high tensile strength, high yield strength, high elongation, high impact toughness, high cold bending performance, good welding performance and other features.

Owner:LAIWU IRON & STEEL GRP

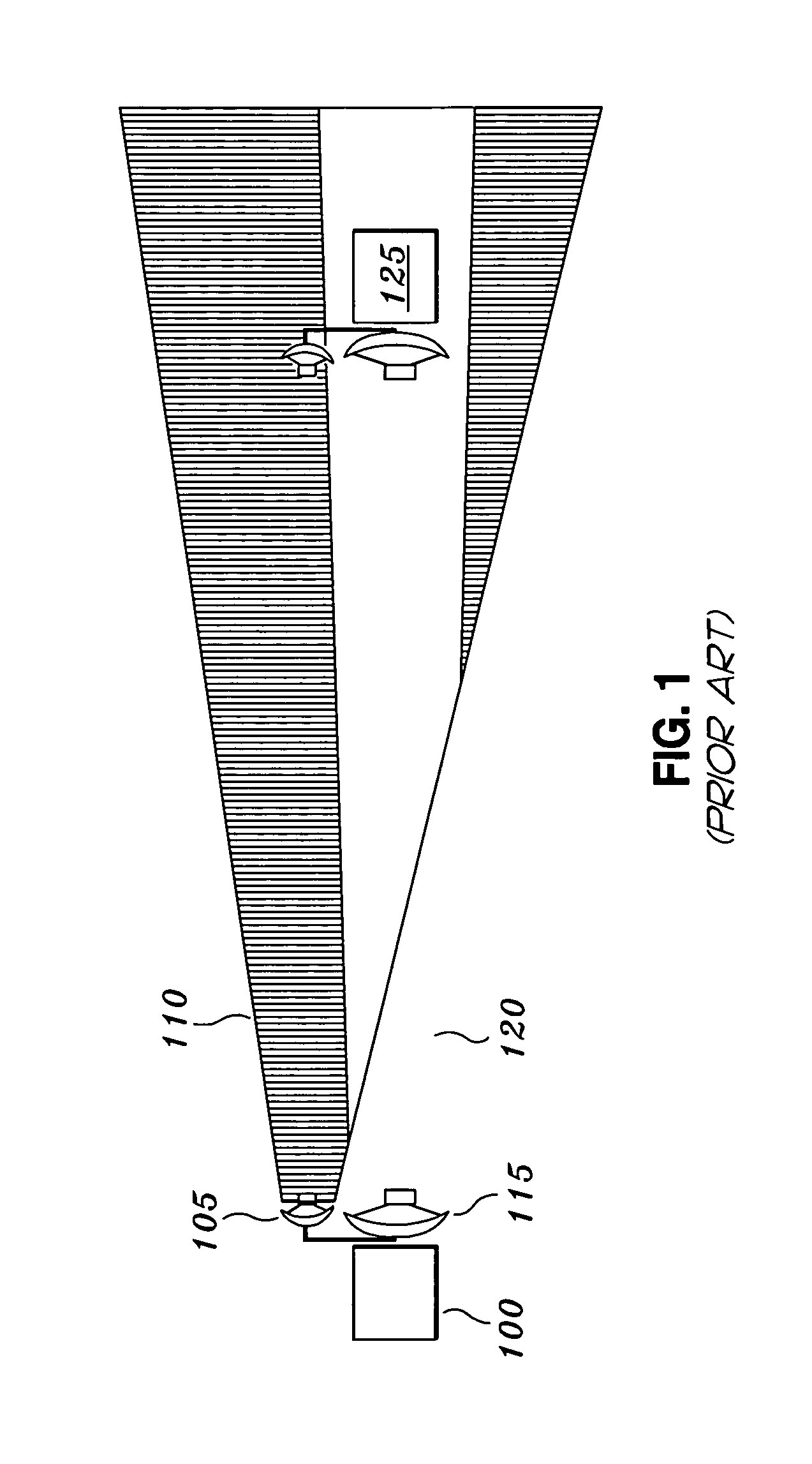

Fiber-optic based cavity ring-down spectroscopy apparatus

InactiveUS7046362B2Increase exposureIncrease penetration depthRadiation pyrometryMaterial analysis by observing effect on chemical indicatorFiberRing down

An apparatus for detection and measurement of trace species in a gas or liquid sample. A ring down cell formed from a fiber optic ring is exposed to the sample gas or liquid. A coherent source emits radiation into the fiber optic ring, which in turn is received at an output thereof. The fiber optic ring has a portion thereof, between the input and output, exposed to the sample gas or sample liquid. A processor is coupled to the receiver and determines the level of trace species in the gas or liquid sample based on the rate of decay of the radiation within the fiber optic ring.

Owner:THE TRUSTEES FOR PRINCETON UNIV

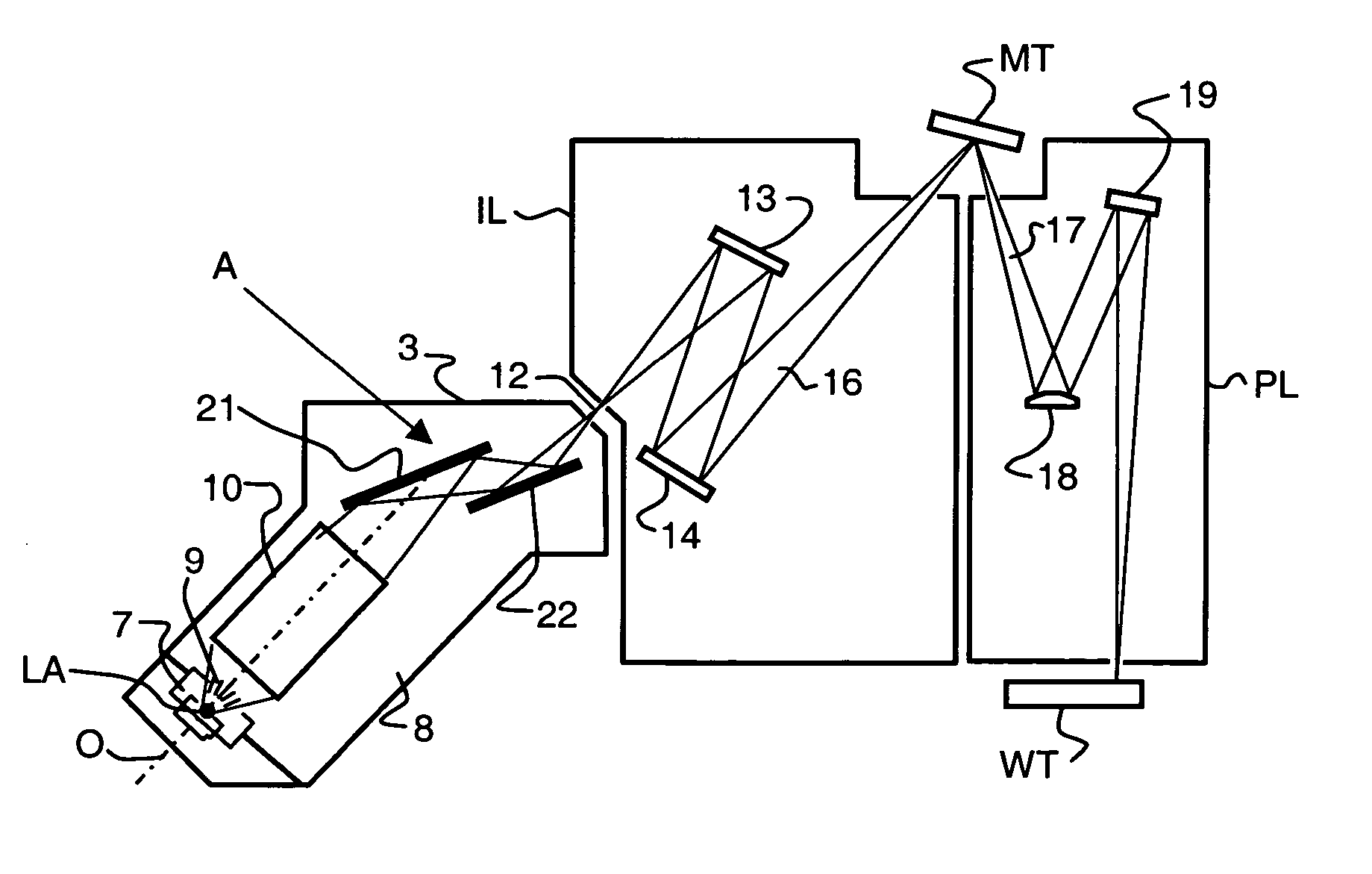

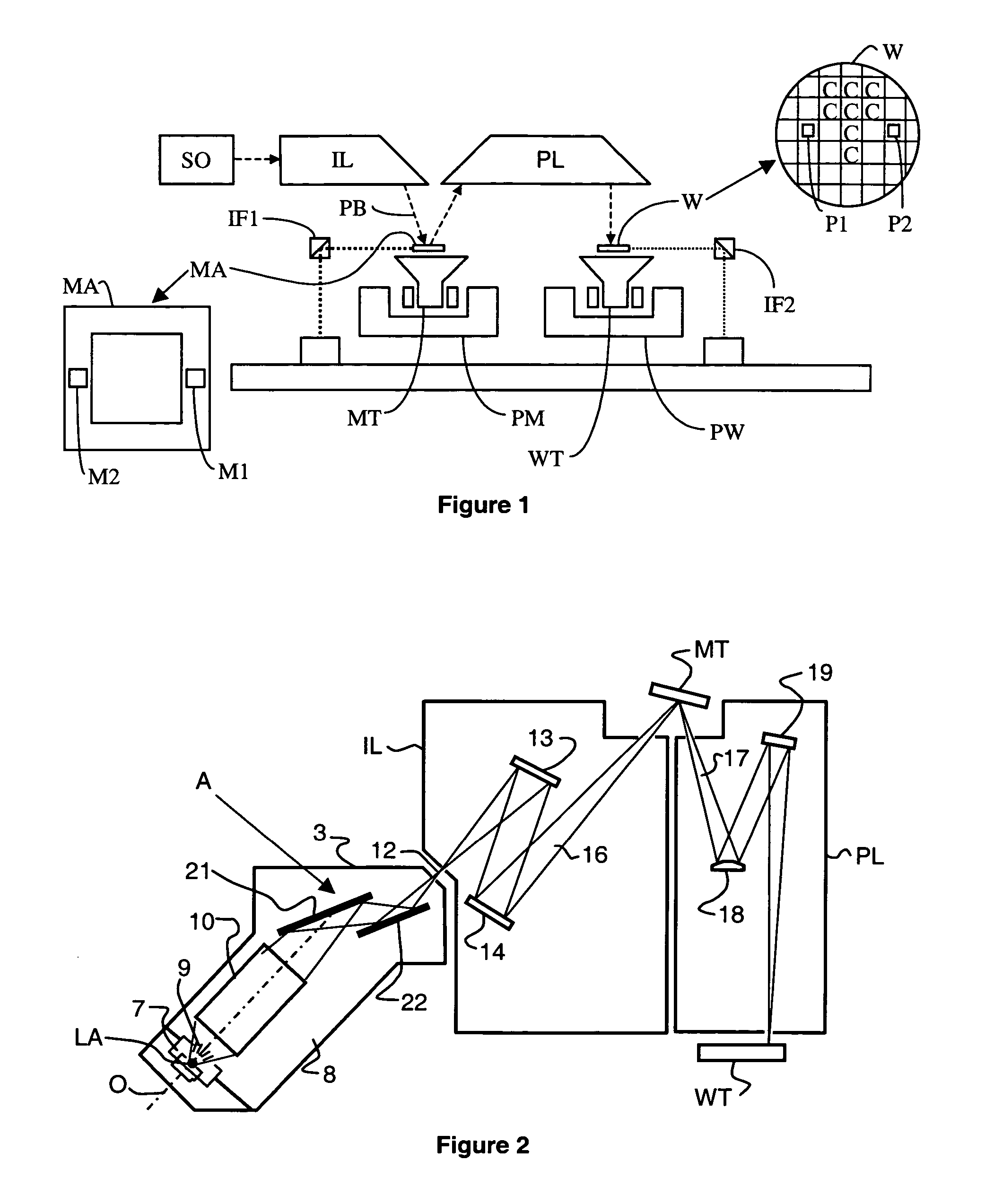

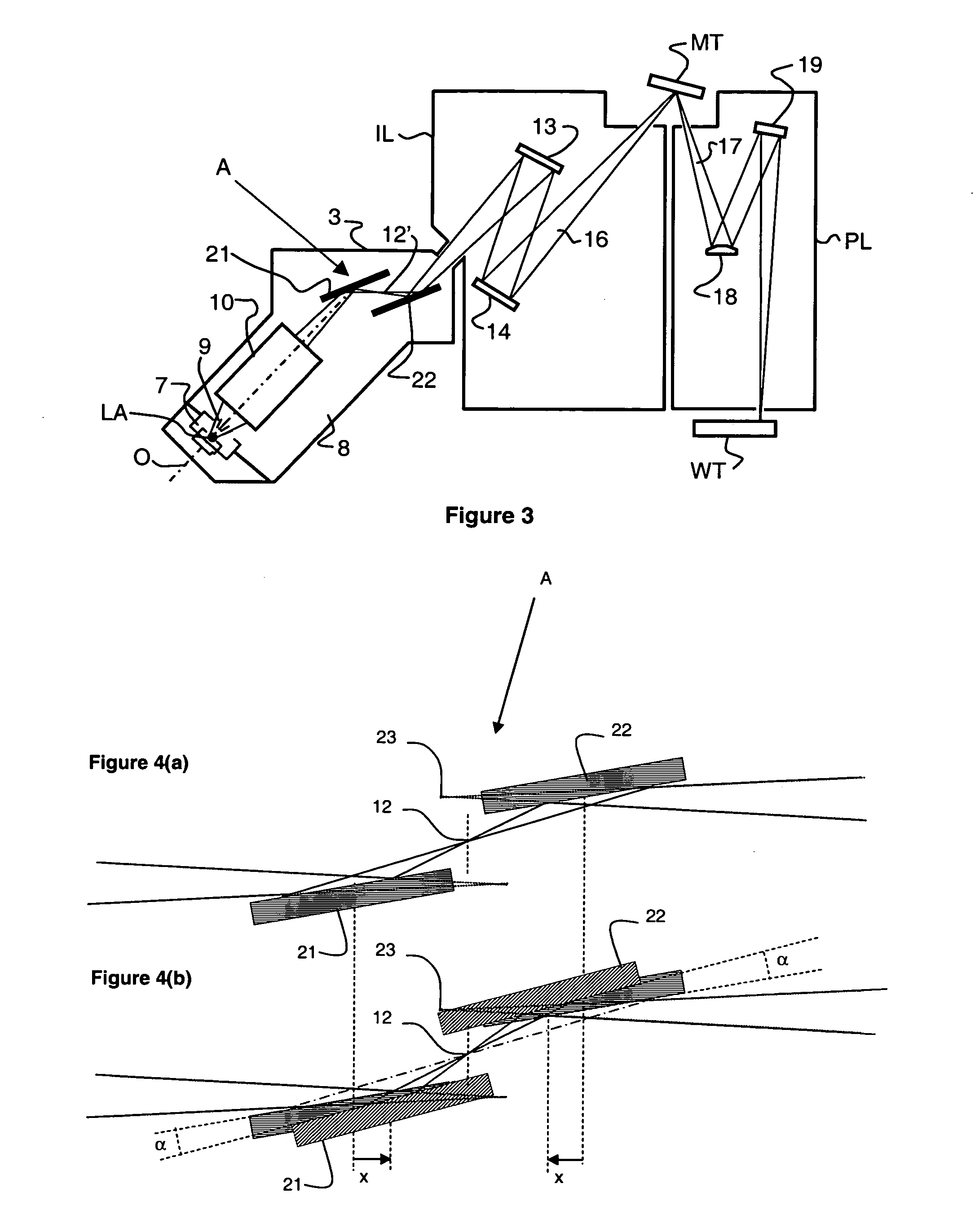

Lithographic apparatus, device manufacturing method and variable attenuator

InactiveUS20050206869A1Easy to controlImprove throughputSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusAngle of incidenceLight beam

A lithographic apparatus includes an illumination system for providing a projection beam of radiation, a support structure for supporting patterning structure for imparting a pattern to the projection beam, a substrate table for holding a wafer and a projection system for projecting the patterned beam onto a target portion of the wafer. In order to permit control of the radiation dose at the wafer so that the throughput of wafers can be optimised, a variable attenuator is provided to vary the intensity of the projection beam while not changing the position of the beam. The variable attenuator comprises two parallel mirrors positioned such that an input beam of radiation is incident on a first of the mirrors by which it is reflected towards a second of the mirrors by which the beam is reflected to produce an output beam of radiation of required intensity for input to the illumination system, and a tilting mechanism for tilting the mirrors such that the mirrors remain parallel to one another and the angles of incidence of the beams on the mirrors are changed so as to vary the intensity of the output beam. This allows the intensity of the projection beam to be varied continuously without changing the position of the beam, whether the input beam is converging, diverging or parallel.

Owner:ASML NETHERLANDS BV

Thick specification hot-rolled steel sheet for roll forming high intensity metal sheet pile and manufacturing technology

ActiveCN101451216AAvoid formingMeet demanding requirementsTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention relates to a high strength hot rolled plate and a production process thereof, in particular to a heavy gauge hot rolled steel plate for a roll bending forming high strength steel plate pile and a production process thereof. The invention mainly solves the technical problems of inadequate thickness, and lowcold bending performance and absorbed-in-fracture energy in the prior high strength heavy gauge steel plate. The technical proposal comprises: the heavy gauge hot rolled steel plate for the roll bending forming high strength steel plate pile comprises the following chemical components by weight percentage: 0.08 to 0.15 percent of C, 0.10 to 0.40 percent of Si, 0.30 to 0.90 percent of Mn, 0.020 to 0.040 percent of Nb, 0.010 to 0.030 percent of Ti, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S, and the balance being Fe. The microscopic structures can be fine grain ferrites, and pearlitic structures plus a small amount of bainite structures which are dispersed; the grain size level is 11 to 14; and the banded structure level is less than 0.5. The high strength hot rolled plate is mainly used for producing the steel plate pile.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

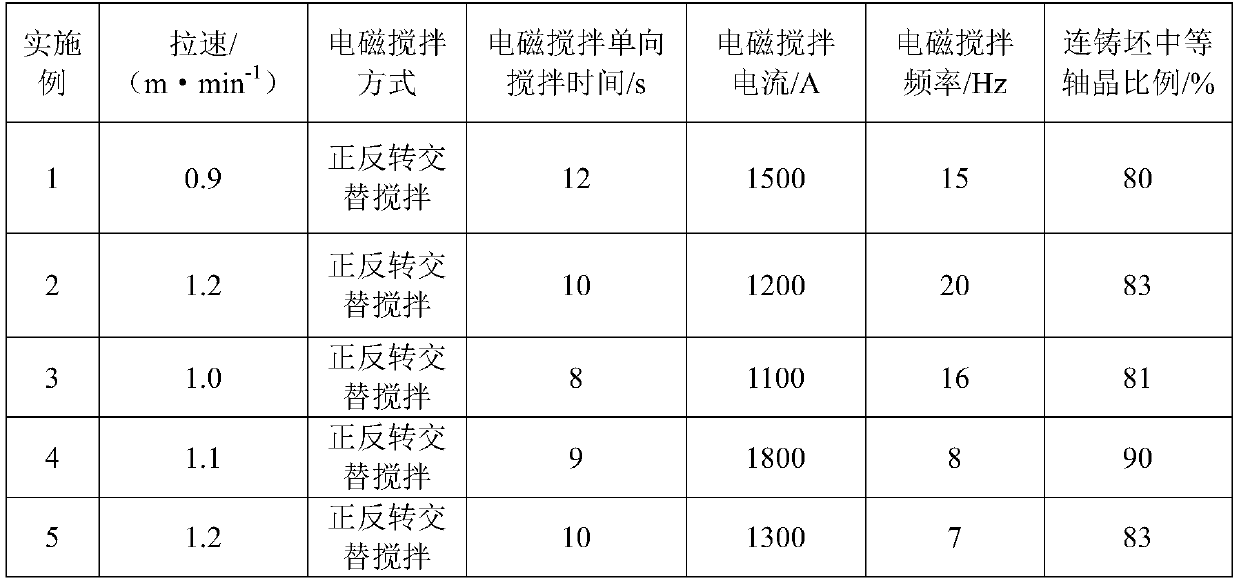

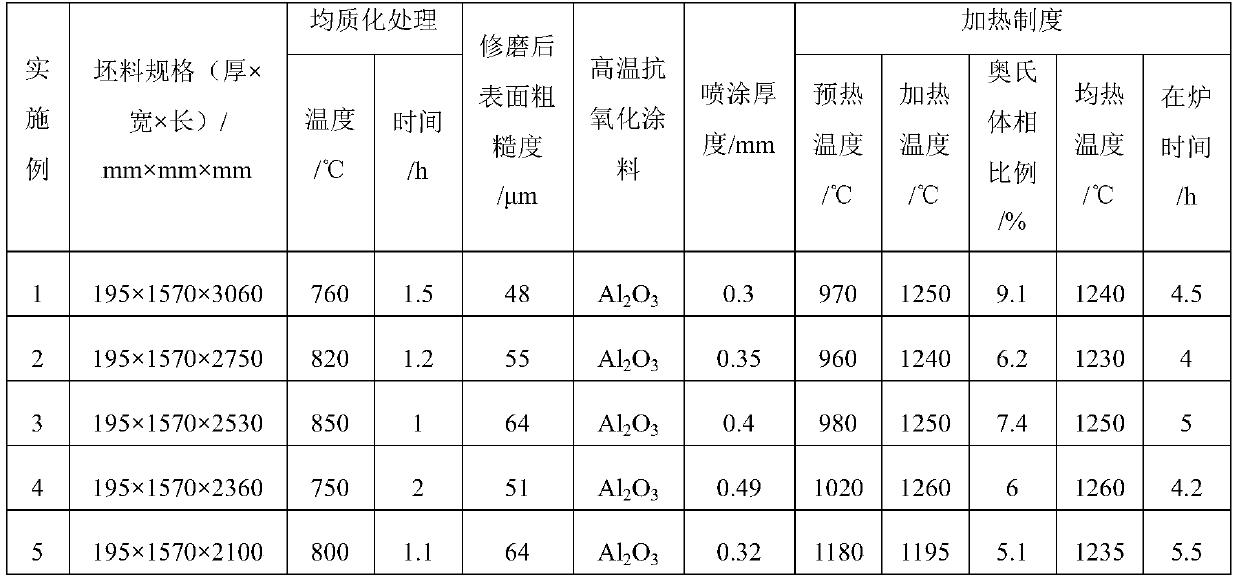

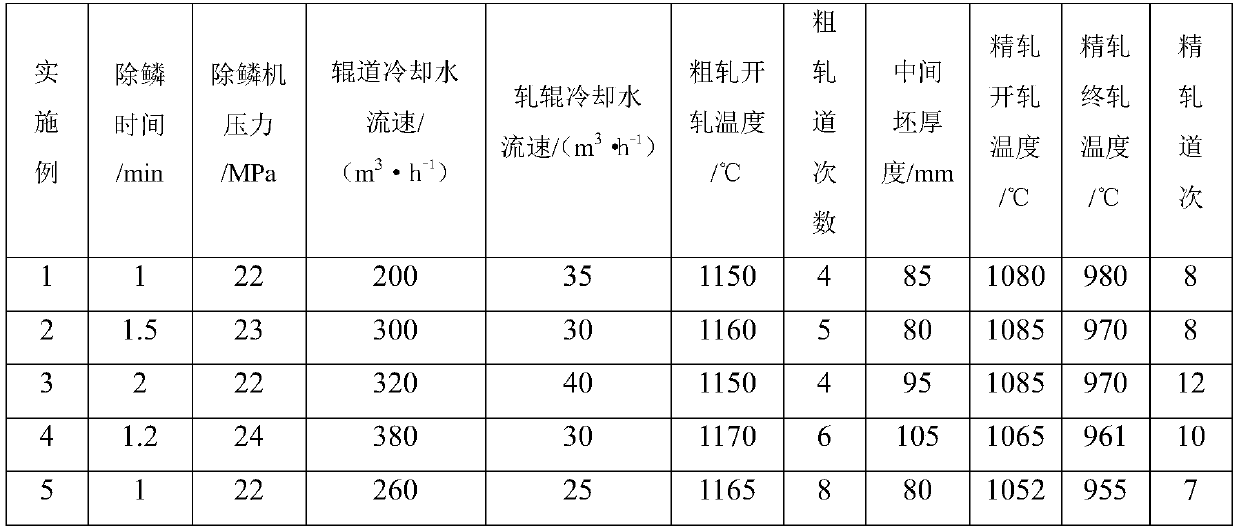

Method for eliminating surface cracks of ultra-wide ferrite stainless steel middle-thick plate

ActiveCN110438414AIncrease equiaxed crystal ratioShorten the forming intervalProcess efficiency improvementWork heating devicesSingle passThick plate

The invention discloses a method for eliminating surface cracks of an ultra-wide ferrite stainless steel middle-thick plate. The proportion of the medium axis crystal of a continuous cast blank is notlower than 75%; the homogenization temperature of the cast blank is 750-850 DEG C, the duration in the furnace is 1-2 hours, and water cooling is carried out to the room temperature; the surface roughness Ra of the cast blank after grinding is less than or equal to 70 microns, and high-temperature antioxidant coating is sprayed; the cast blank is processed by a preheating section, a heating section and a soaking section in sequence, and then is discharged from the furnace; the temperature of the preheating section is 950-1180 DEG C, the temperature of the heating section is 1180-1260 DEG C, the temperature of the soaking section is 1220-1250 DEG C, and the furnace time is 4-5.5 hours; the rough rolling temperature is larger than or equal to 1150 DEG C; the finish rolling temperature is larger than or equal to 1150 DEG C, the final rolling temperature is larger than or equal to 950 DEG C, the rolling single-pass pressing rate is less than or equal to 20%, the annealing temperature is 750-880 DEG C, the furnace time is 2-5 min / mm, and air cooling is carried out. The product width is 2500-4000 mm and the thickness is 8-30 mm. The rejection rate of the surface cracks is reduced from 6% or above to 0.5% or below.

Owner:ANGANG STEEL CO LTD

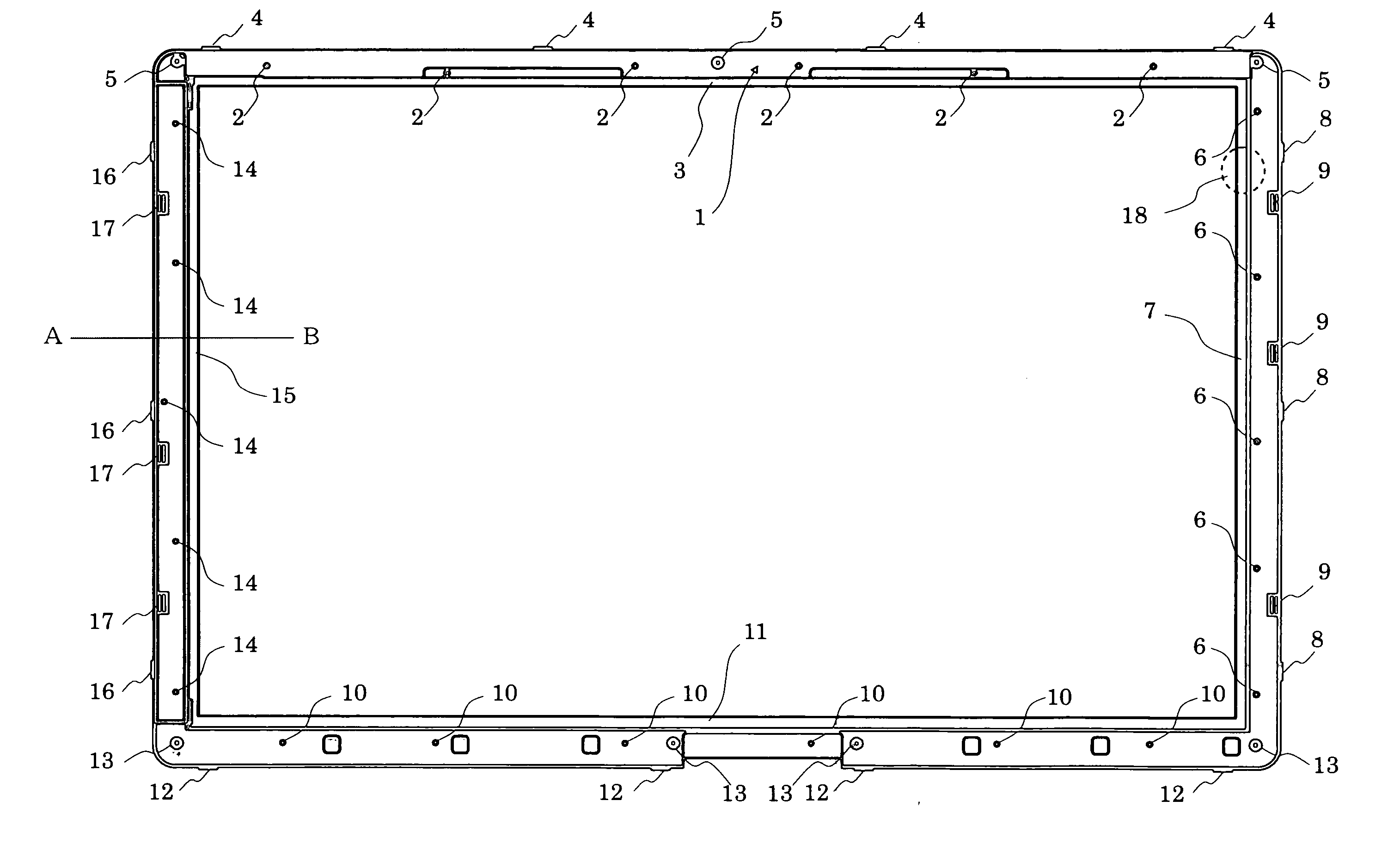

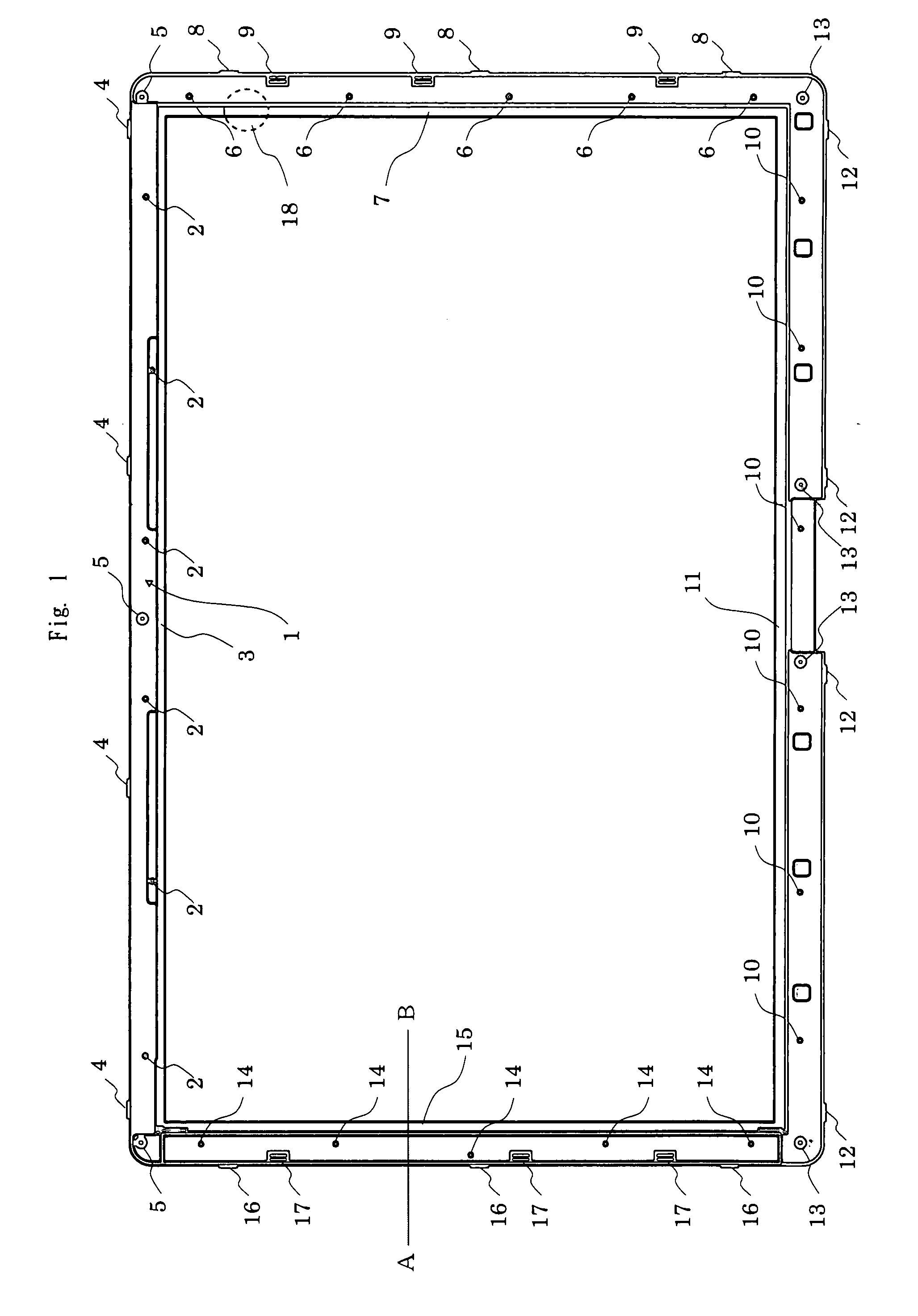

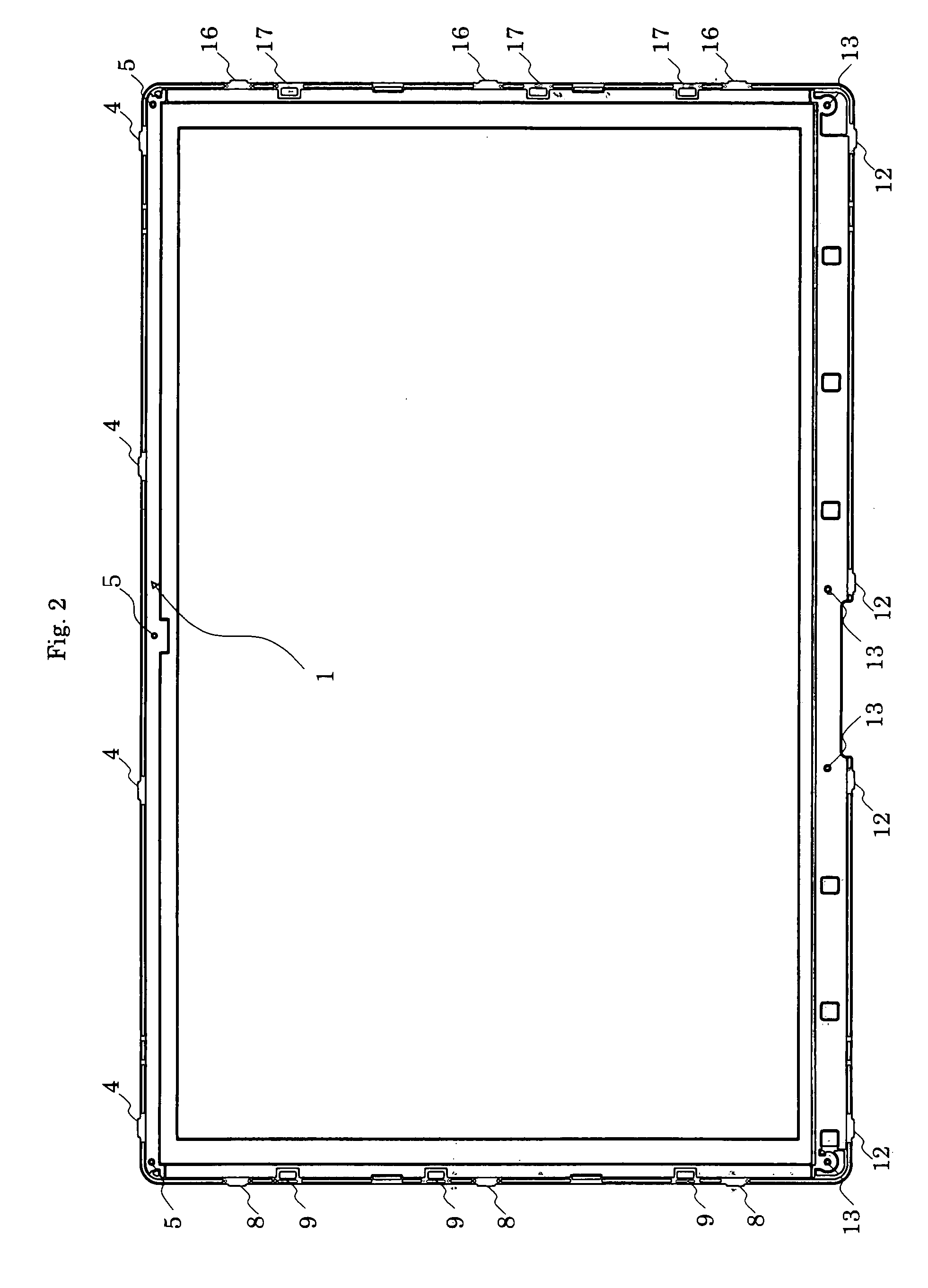

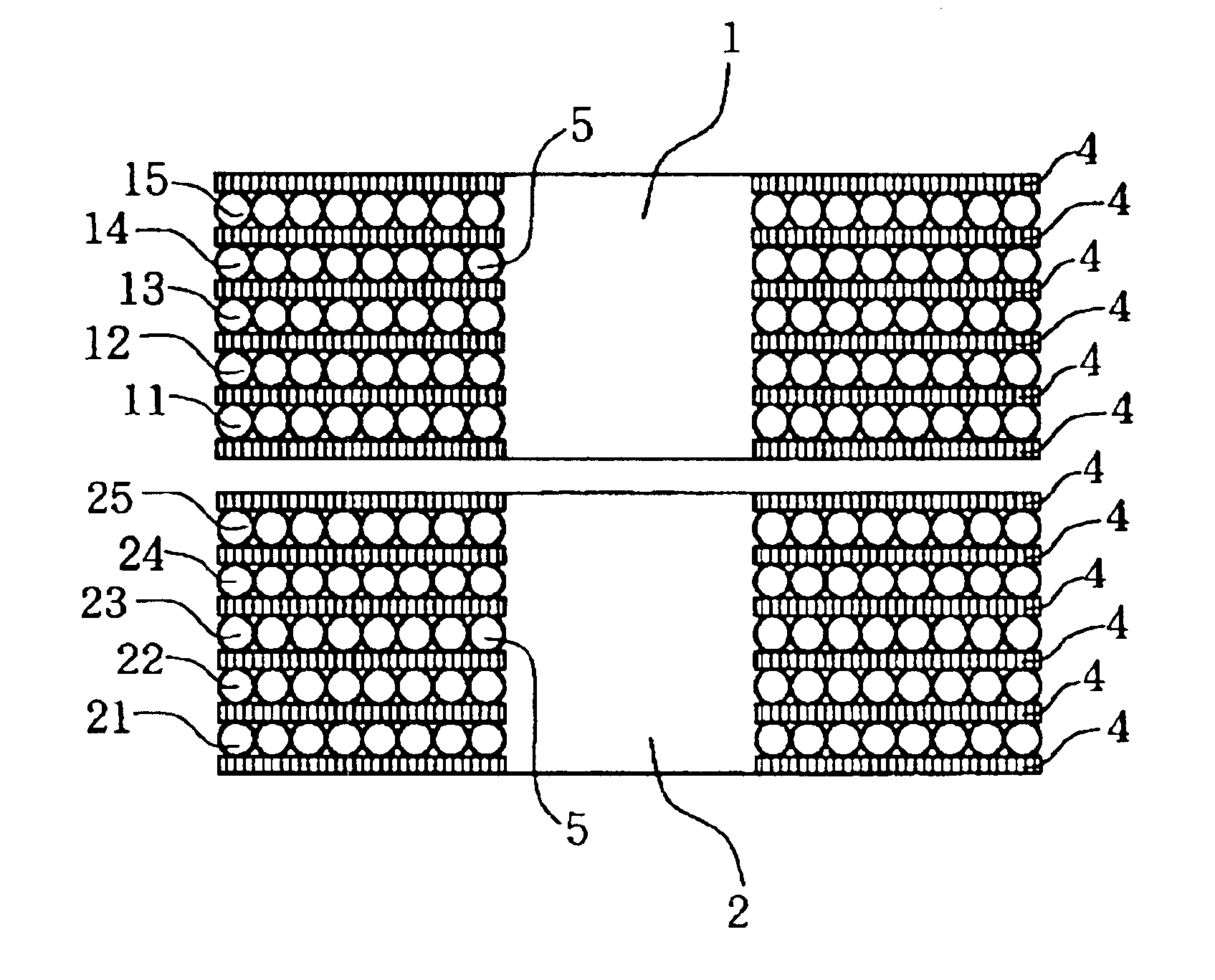

Resin Composition and Flat Panel Display Fixing Frame

InactiveUS20070257401A1Increase fraction defectiveIncrease probabilitySpecial tyresWater/sewage treatment by flocculation/precipitationFlat panel displayMuscovite

The object of the present invention are to provide a resin composition suitable for use in a flat panel display fixing frame having a snap fit structure, which comprises a filler and has stiffness and flame retardancy and a flat panel display fixing frame. There are provided the resin composition comprising (i) an aromatic polycarbonate resin (component A), (ii) at least one lamellar silicate mineral (component B) selected from the group consisting of talc having an average particle diameter of 0.5 to 9 μm (component B-1) and muscovite mica having an average particle diameter of 0.5 to 50 μm (component B-2), (iii) a fluorine-containing dripping preventing agent (component C), and (iv) an organic sulfonic acid alkali (earth) metal salt (component D) in a specific ratio, and is used in a flat panel display fixing frame having at least one snap-fit projection, hole or groove, and a flat panel display fixing frame comprising the composition in the present invention.

Owner:TEIJIN CHEM LTD

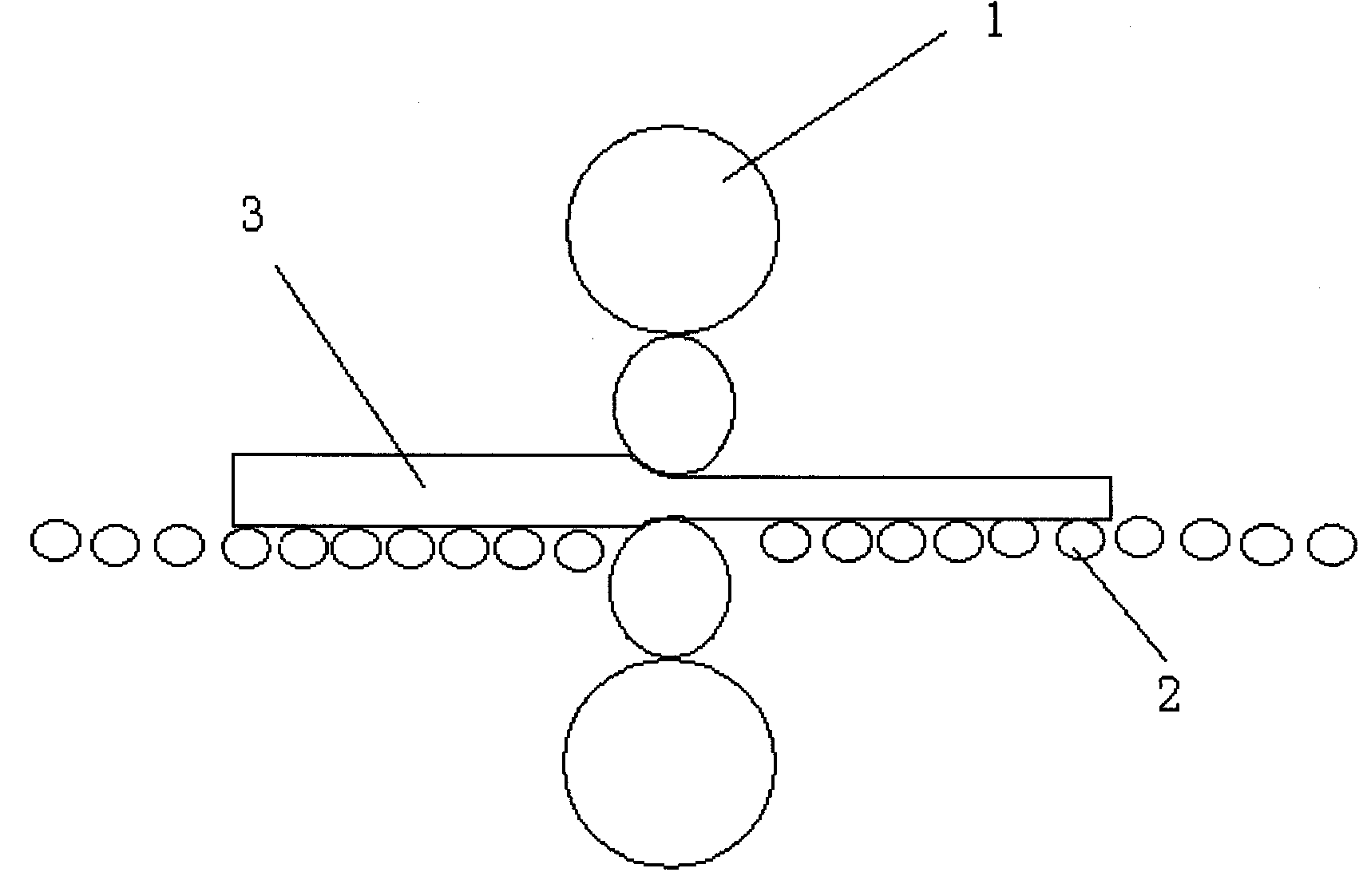

Isolation transformers

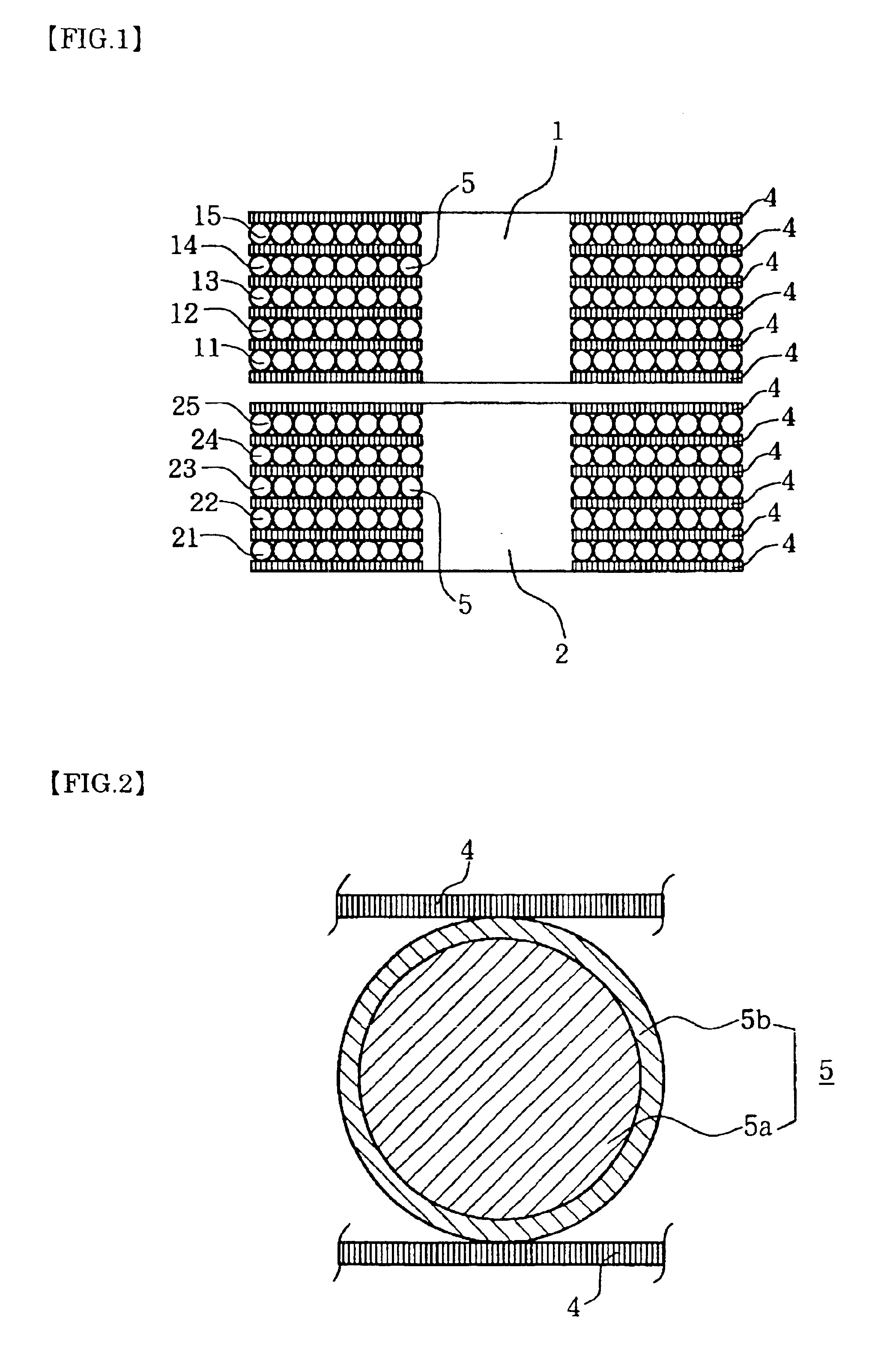

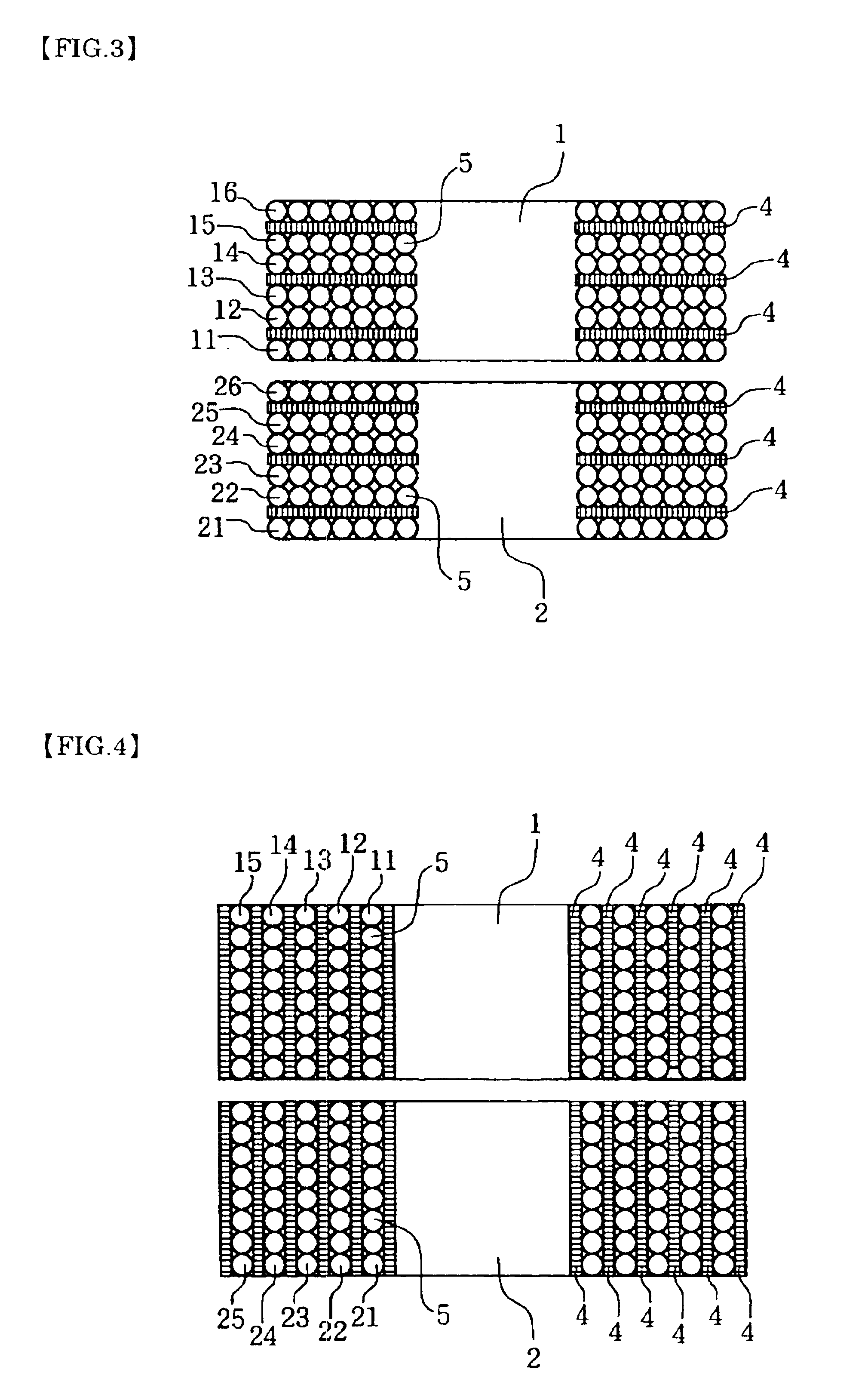

InactiveUS6888436B1Increase reduction rateImprove reliabilityTransformers/inductances casingsTransformers/inductances coils/windings/connectionsDistribution transformerCopper wire

The issue to be resolved by the present invention is to provide isolation transformers with high noise attenuation rates as well as high reliability, in the high-frequency region above a few MHz, by sufficiently suppressing the amplitudes of noise attenuation characteristic curves, which are irregular, saw-tooth shaped waves with crests and troughs of various sizes, of multi-layer, multi-winding transformers.An isolation transformer comprised by a multi-layer, multi-winding primary coil 1, a multi-layer, multi-winding secondary coil 2, and a core that forms a magnetic path between the aforementioned primary coil and the aforementioned secondary coil, functions as an isolation transformer to resolve the aforementioned issue by changing the coil layers of one or both of the coils formed by winding an insulated, covered, copper-wire 5 to a multi-layer, multi-winding coil, into which a number of short-circuit rings 4 made of conducting films are inserted and layered.The planer configuration of the aforementioned conducting short-circuit rings 4 is made approximately identical to that of the neighboring coil-layers, and their thickness is made approximately identical to or less than the skin depth of the induced current generated by the skin effect in the high-frequency region, in which resonances should be suppressed.

Owner:K K DENKEN SEIKI INST

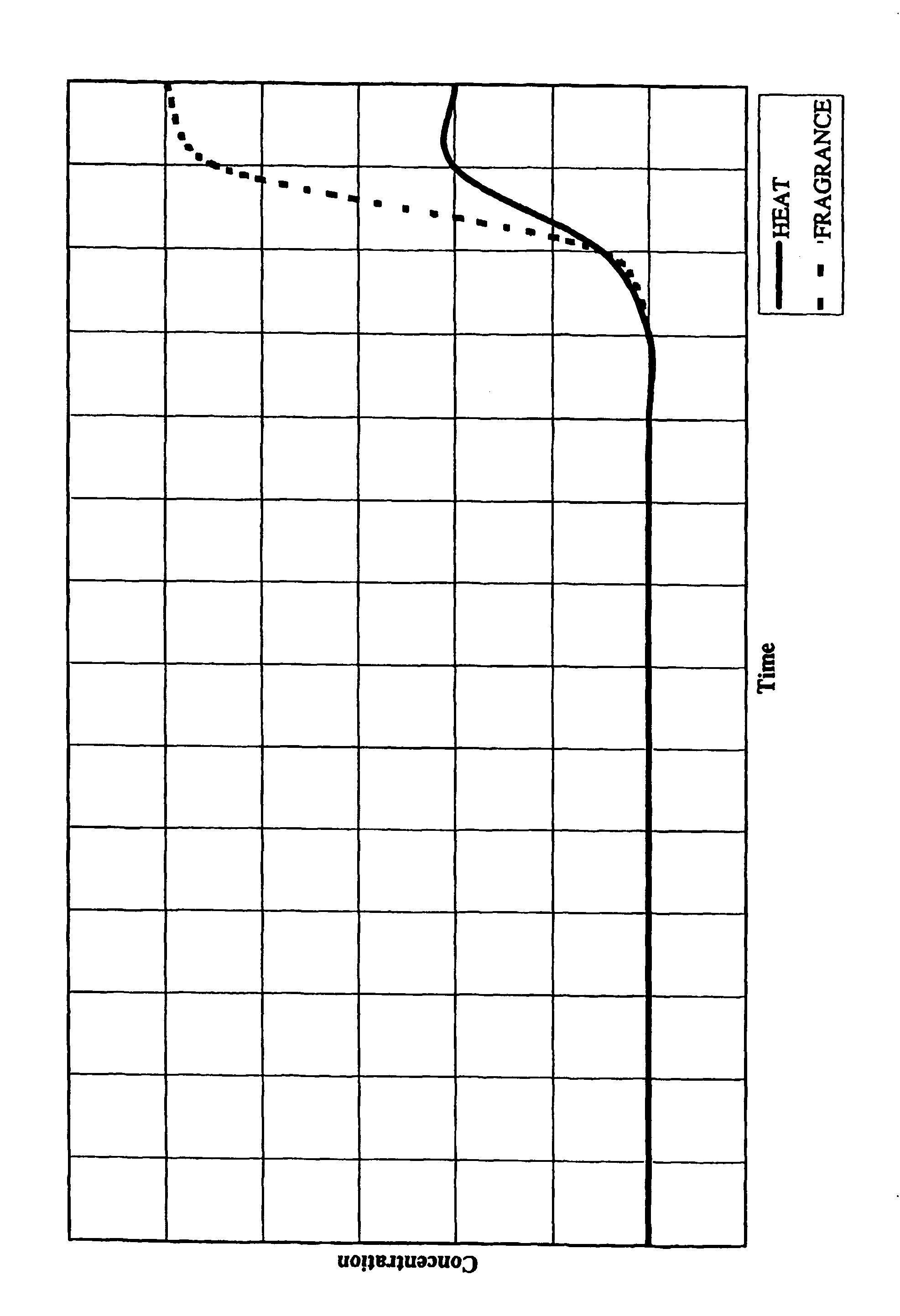

Aqueous activated components conveyed in a non-aqueous carrier system

InactiveUS20060058206A1Reduce bacteria countIncrease reduction rateCosmetic preparationsHair cosmeticsCarrier systemChemistry

Generally, compositions that provide, either individually or in combination, aqueous activated components conveyed in a non-aqueous carrier system, perceivable sensorial indicia of discrete event occurrence, or perceivable sensorial reinforcers to provide sensorial incentives or sensorial disincentives, to encourage or discourage, attainment of discrete event occurrence.

Owner:CDC INVESTMENTS LLLP

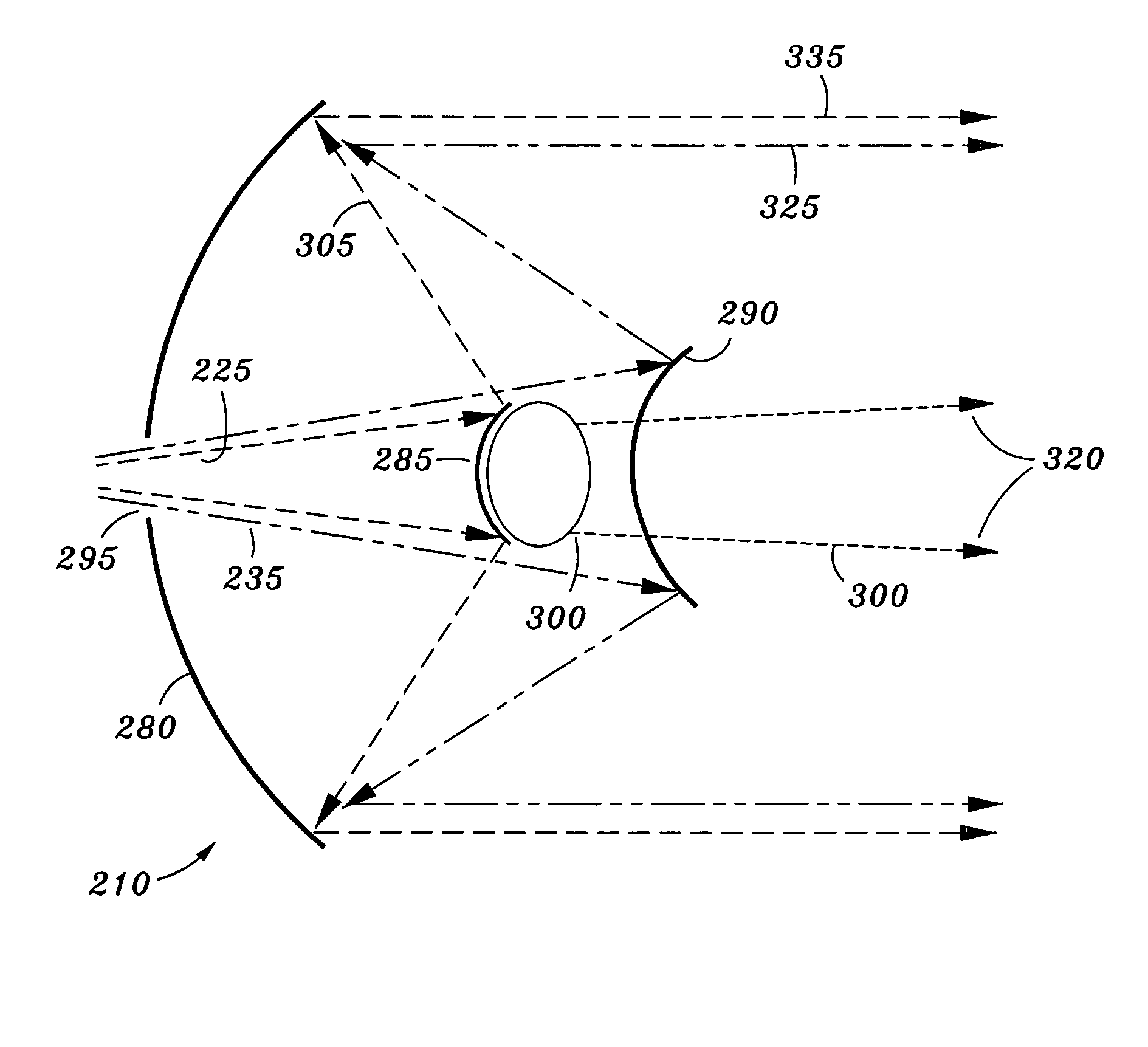

Dual-frequency-illuminating reflector

ActiveUS6965351B1Light weightCheap manufacturingSimultaneous aerial operationsAntenna adaptation in movable bodiesDual frequencyLight beam

An illuminating reflector system is provided for transmitting first and second frequency bands for satellite and terrestrial communications. The illuminating reflector includes a first reflector configured to transmit a first portion of the first frequency band in an dispersed beam, to reflect a second portion of the first frequency band, and to transmit the second frequency band; a second reflector configured to reflect the second frequency band received from the first reflector; and a primary reflector configured to receive the second portion of the first frequency band reflected from the first reflector, to receive the second frequency band reflected from the second reflector, and to reflect the second portion of the first frequency band and the second frequency band in a substantially collimated beam.

Owner:LOCKHEED MARTIN CORP

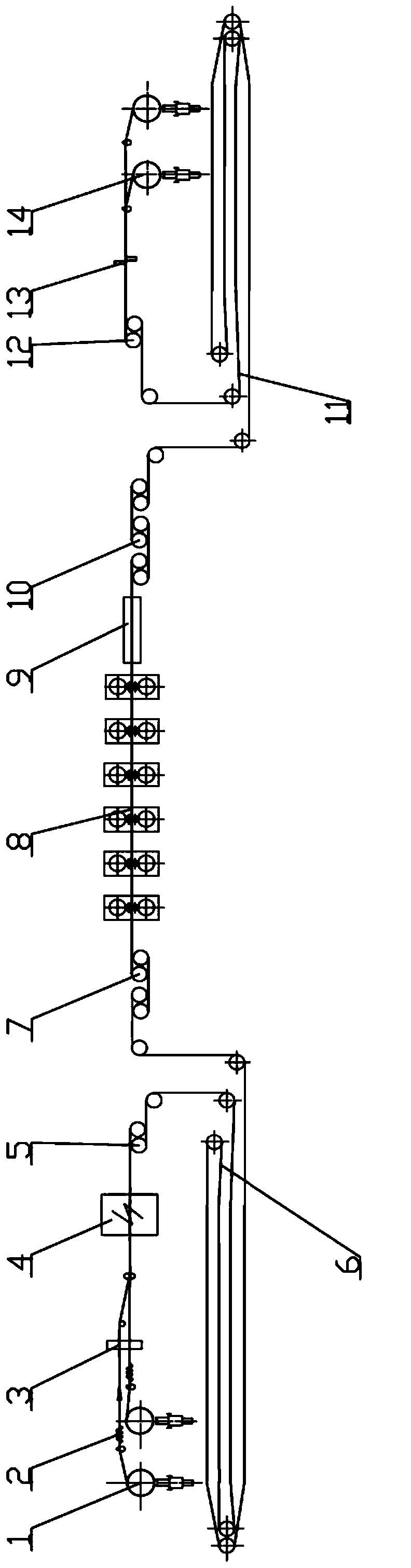

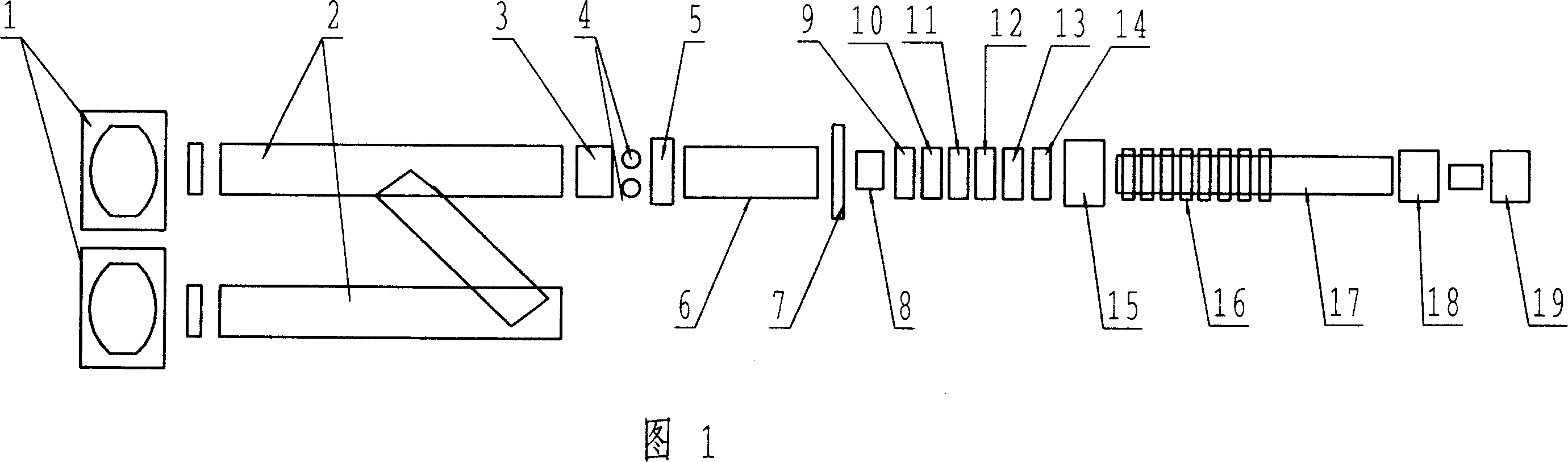

Novel stainless steel cold continuous rolling technology and unit thereof

InactiveCN103722011ASolve bottlenecksIncrease reduction rateMetal rolling arrangementsEngineeringContinuous rolling

A novel stainless steel cold continuous rolling technology unit comprises an uncoiling machine, a straightening machine, a hydraulic shear, a welding machine, a first tension roller, a continuous rolling unit, an outlet loop, a fourth tension roller, a slitting shear and a coiling machine. The uncoiling machine, the straightening machine, the hydraulic shear, the welding machine, the first tension roller, the continuous rolling unit, the outlet loop, the fourth tension roller, the slitting shear and the coiling machine are sequentially connected. The novel stainless steel cold continuous rolling technology unit is characterized in that an inlet loop and a second tension roller set are additionally arranged between the first tension roller and the continuous rolling unit, a cleaning and drying unit, a third tension roller set and the outlet loop are sequentially connected and additionally arranged between the continuous rolling unit and the fourth tension roller, the continuous rolling unit can be arranged in the mode that a plurality of rack four-roller continuous rolling units are connected in series, small-diameter rollers are adopted in the continuous rolling unit, and the continuous rolling unit is driven by supporting rollers in a centralized mode. By the adoption of the technical scheme, some small-scale enterprises can produce stainless steel cold rolling strips by using a common four-roller or six-roller rolling machine instead of twenty-roller and eighteen-roller rolling machines which are high in investment cost and maintenance cost, and therefore the production cost is greatly reduced.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

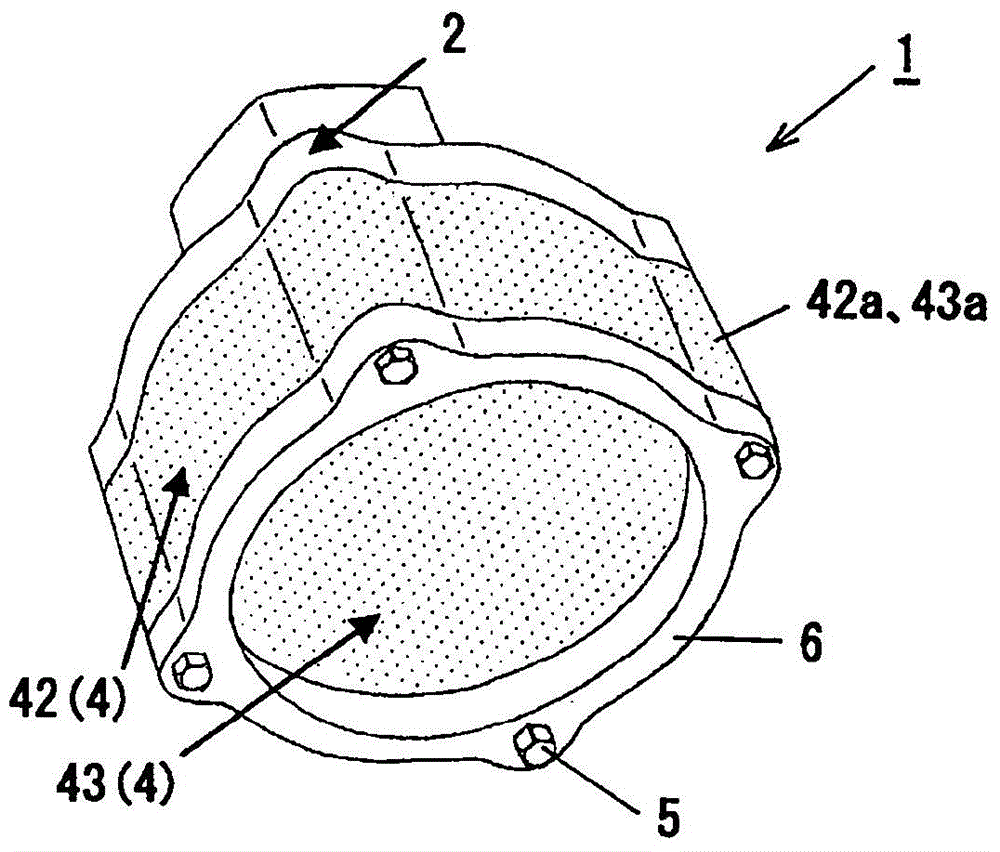

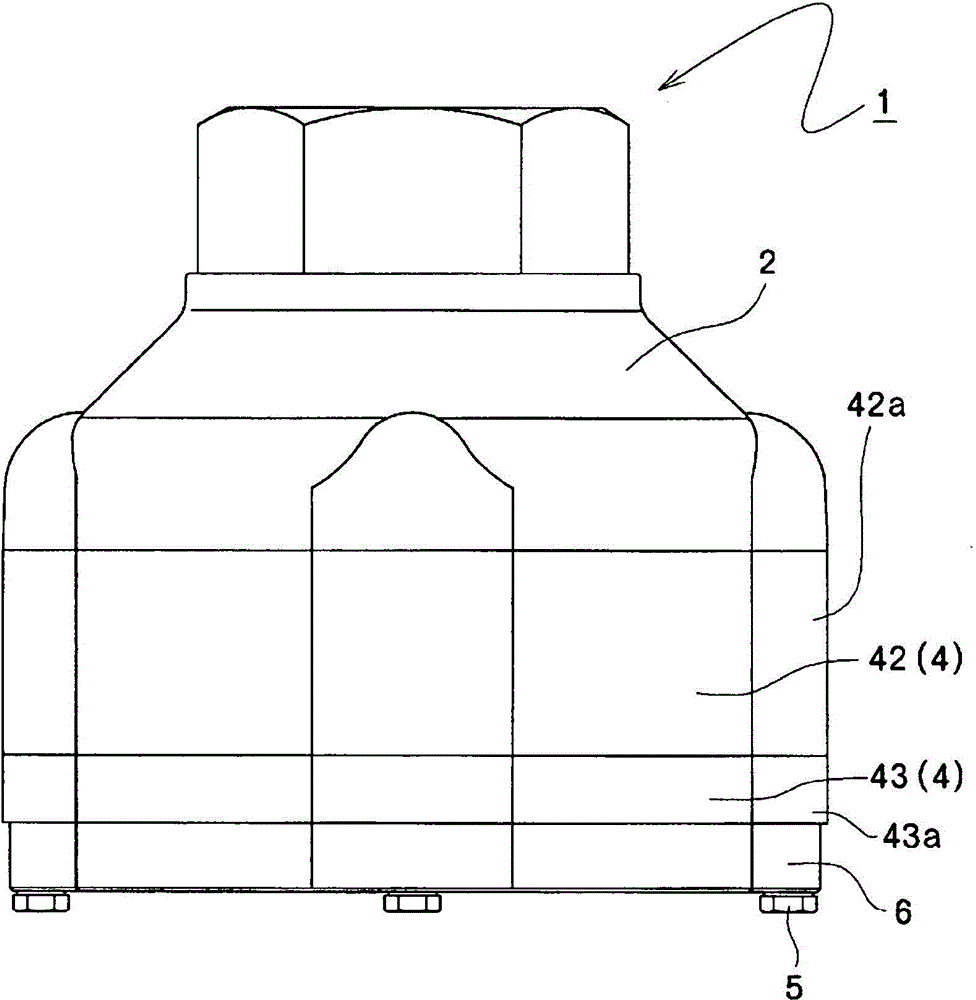

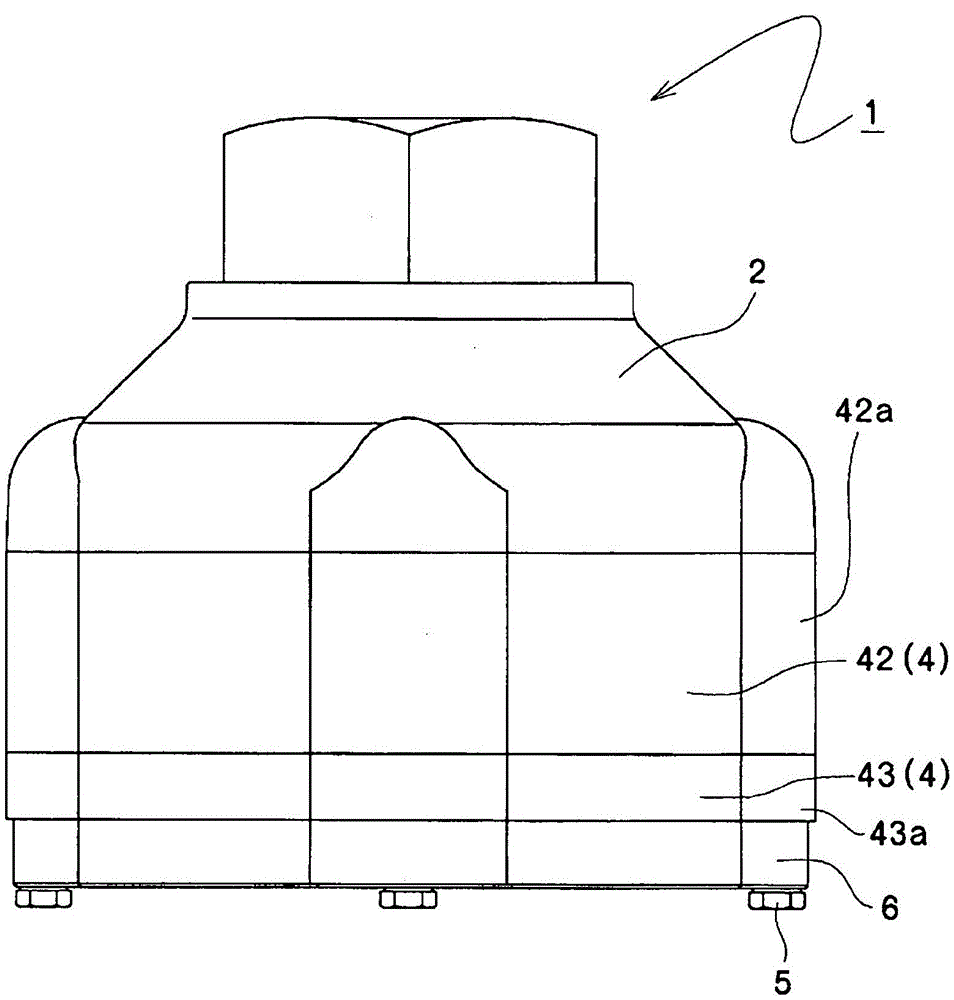

Spray head for gaseous fire extinguishing equipment having silencing function

ActiveCN104159642AReduce supportImprove the noise reduction rateSpray nozzlesFire rescueAtmospheric airFire extinguisher

[Problem] To present an injection head for gas-type fire exchanger using an injection head of a small size, capable of enhancing the noise reduction rate, and lowering the injection reaction of the fire-extinguishing gas applied to the injection head at the time of release of the fire-extinguishing gas. [Solving Means] An injection head 1 having silencing means installed for releasing a fire-extinguishing gas in a fire-extinguishing area in the gas type fire extinguisher using a fire-extinguishing gas, in which the silencing means includes silencing members 4 of block shapes made of a porous material capable of passing a gas disposed at an outlet of the orifice 31, and a one-side end face of the silencing member 4 is disposed in contact with the injector head main body 2, and a peripheral face and an other-side end face of the silencing member 4 are opened to the atmosphere except for the portion contacting with a ring member 6 for fixing the silencing member 4 to the injection head main body 2 by way of a bolt 5.

Owner:KOATSU CO LTD

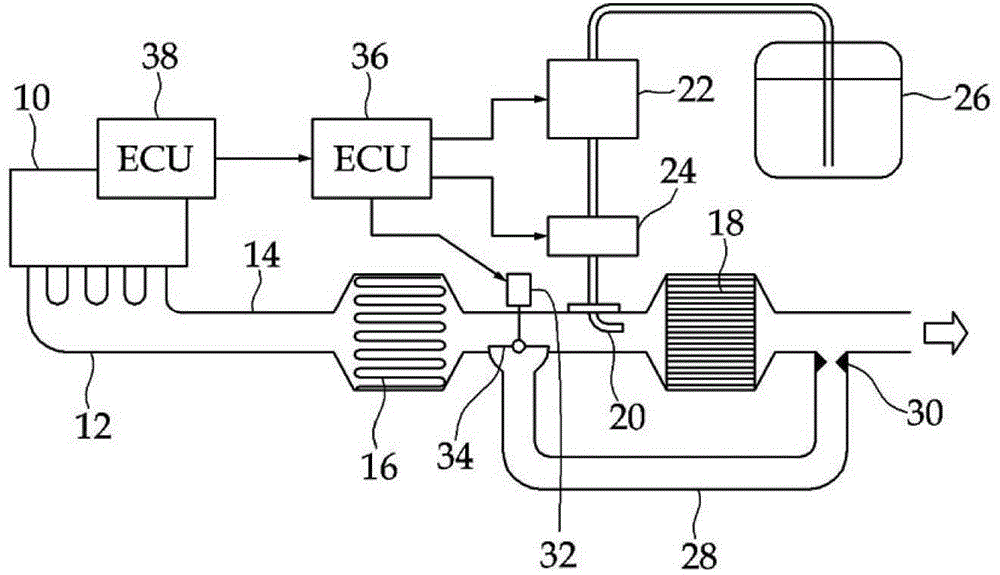

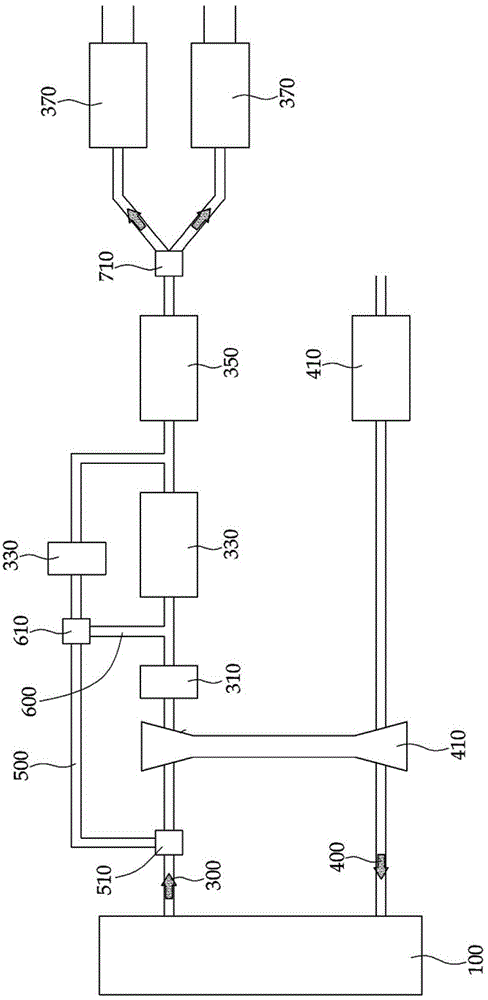

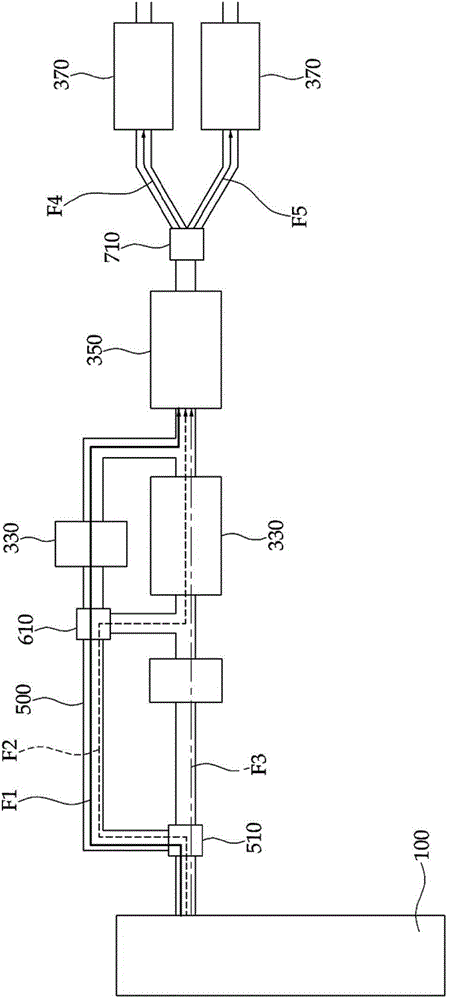

Post-processing system apparatus and control method

InactiveCN104081015AIncrease reduction ratePrevent crystallizationGas treatmentInternal combustion piston enginesEnvironmental engineeringNitrogen oxide

Owner:DOOSAN INFRACORE CO LTD

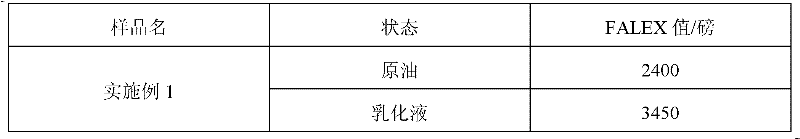

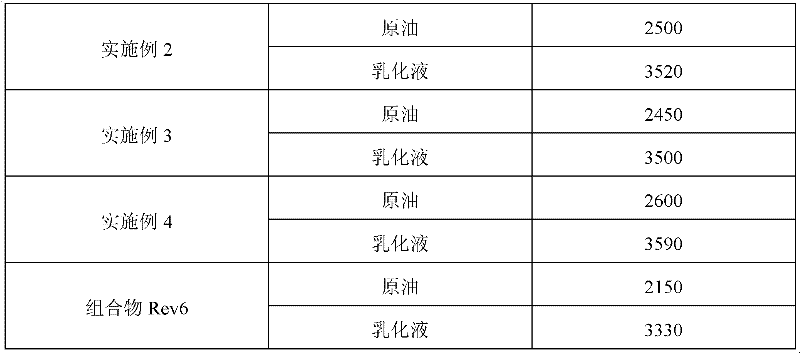

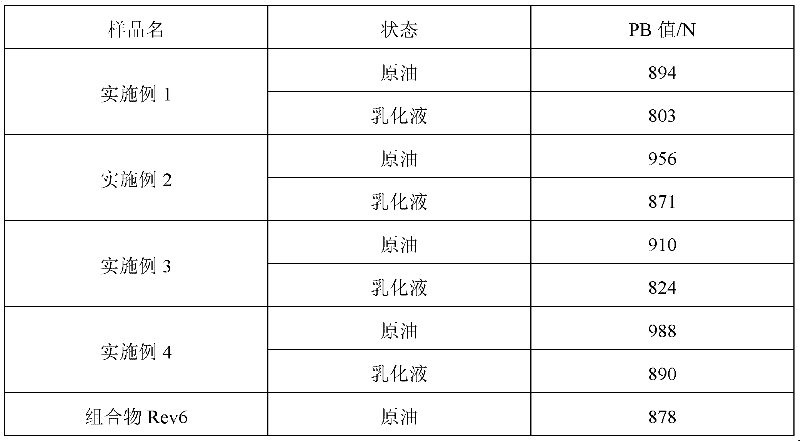

Rolling oil composition for double frame reversible rolling mill

InactiveCN102492528AImprove the lubrication effectGood spreadabilityLubricant compositionLow speedPhosphoric acid

The invention discloses a rolling oil composition for a double frame reversible rolling mill. The rolling oil composition comprises, by weight, 70-95% of a polyol ester oiliness agent, 0-5% of a polyphosphate extreme pressure antiwear agent, 0.1-10% of a thioether extreme pressure antiwear agent, 0.1-5% of a metal deactivator, 0.1-3% of a free radical inhibitor, 0.1-15% of a fatty alcohol polyether surfactant, and 0.1-20% of a polysorbitol nonionic surfactant. The rolling oil composition, which specially aims at specific technological conditions of the double frame reversible rolling mill, such as characteristics of large reduction rate, much very thin plate production and the like, has good fluid lubrication, boundary lubrication and extreme pressure lubrication performances, has a wide mixed lubrication area window, and provides excellent lubrication performances during low speed rolling and high speed rolling, is suitable for rolling of high strength steels and large deflection requirements, and simultaneously has a good cleaning property.

Owner:SHANDONG IRON & STEEL CO LTD

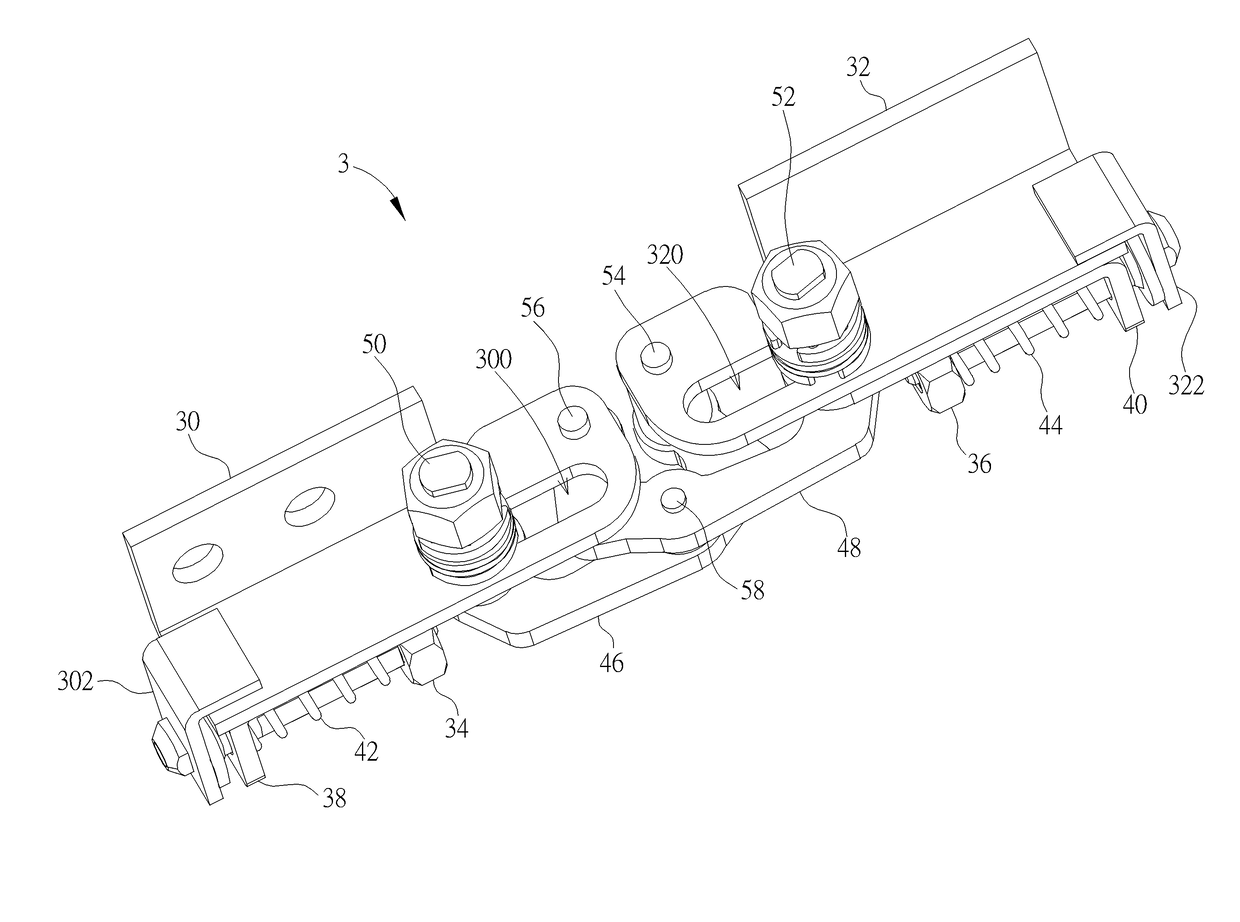

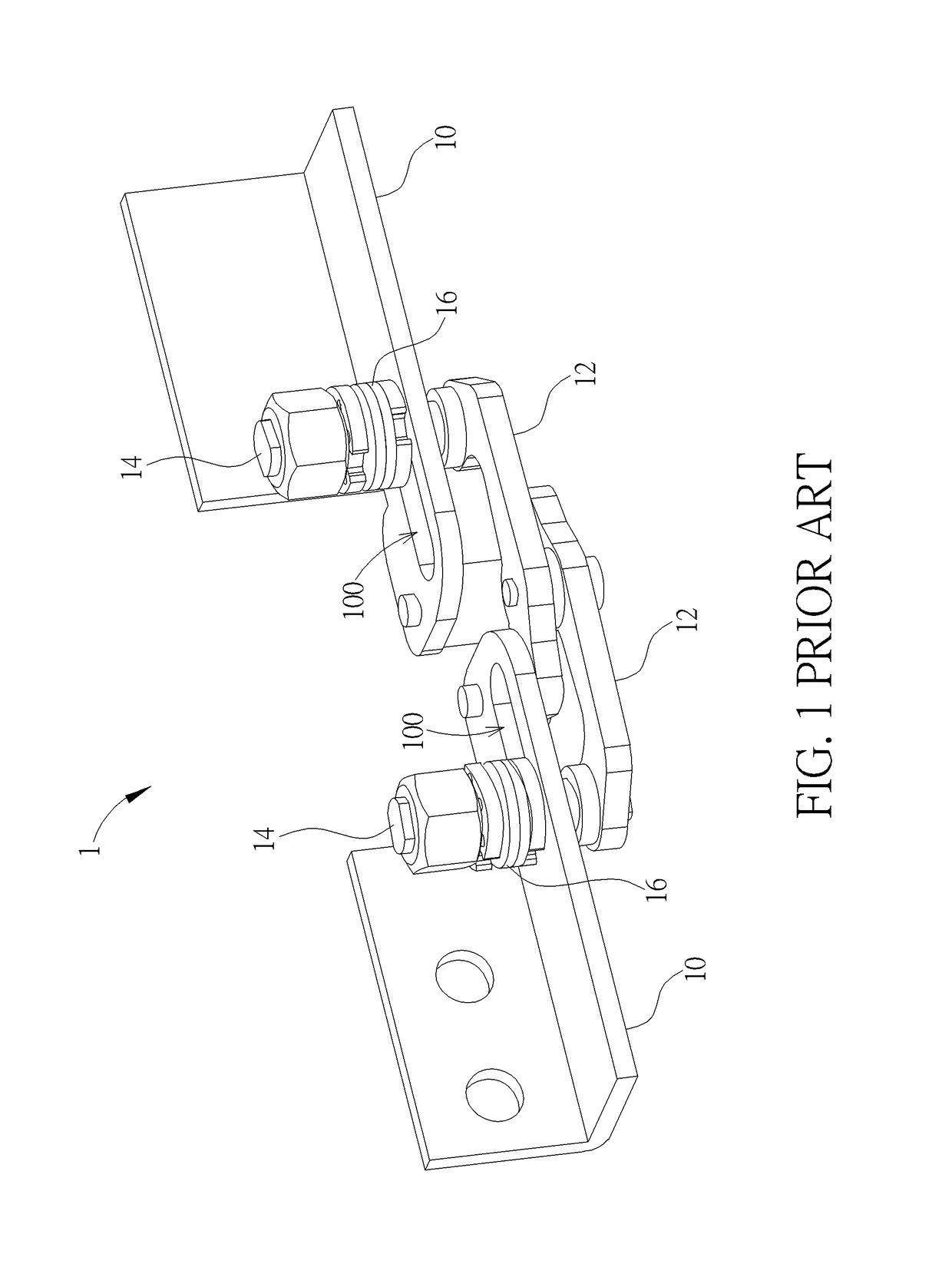

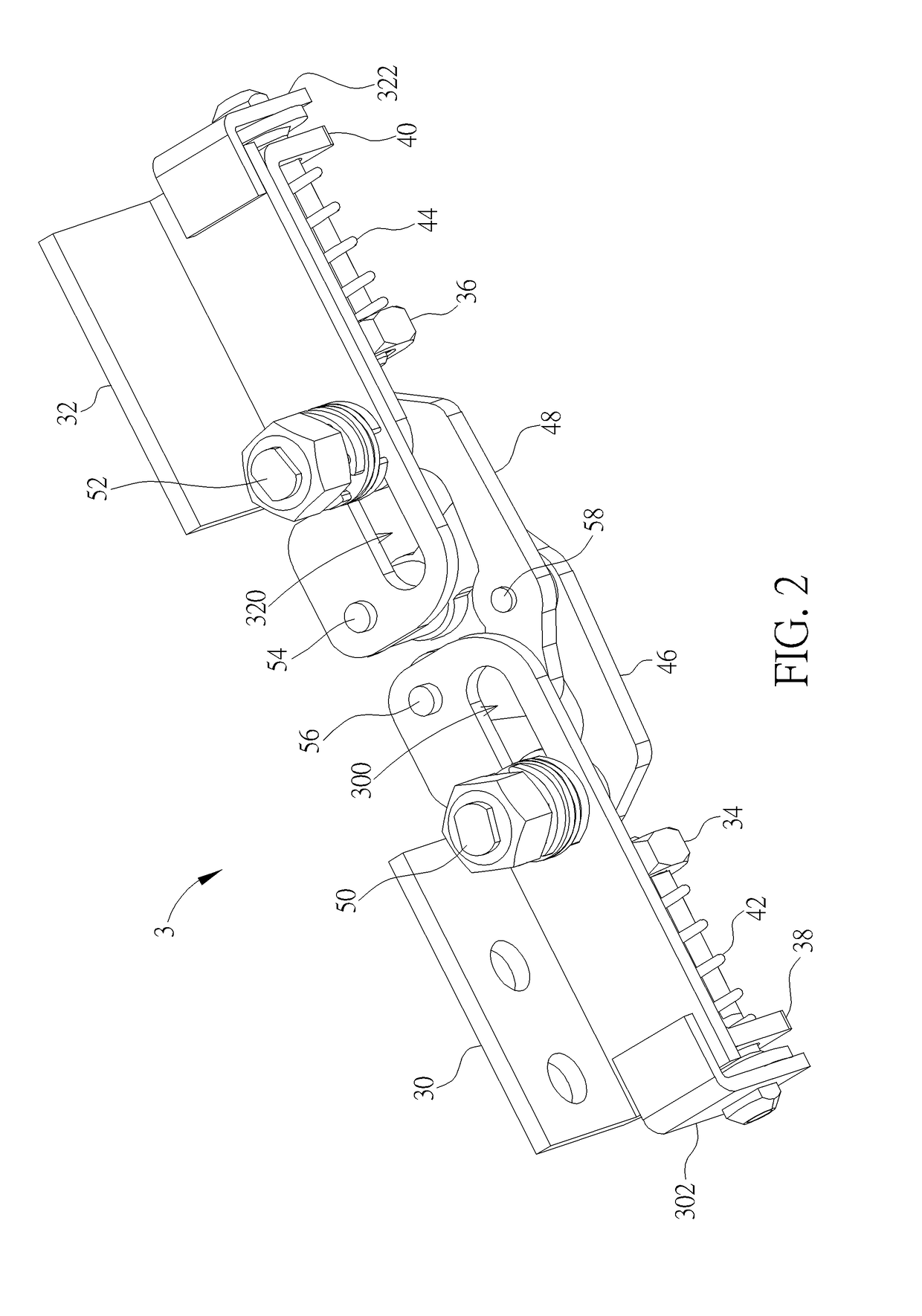

Electronic device and hinge structure

ActiveUS10100970B1Increase reduction rateProlong lifeDigital data processing detailsCasings/cabinets/drawers detailsComputer engineering

Owner:ACER INC

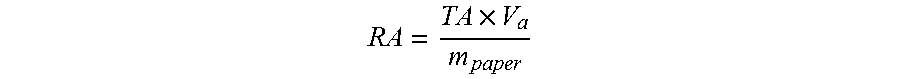

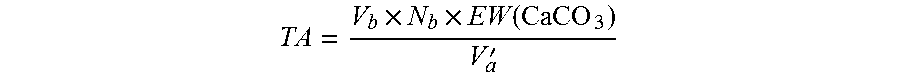

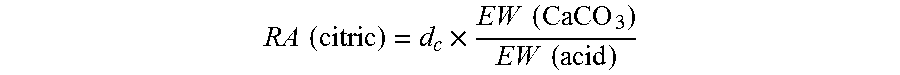

Method for producing paper

ActiveUS20170314204A1Improve strength performanceEasy to operatePaper coatingReinforcing agents additionSlurryWater soluble

A method for manufacturing paper is disclosed. A pulp slurry is produced, a paper sheet is formed from the slurry, an aldehyde functionalized polymer or polymers in combination with at least one additional strength additive is added to the slurry before and / or after sheet formation, and a water soluble acid is added on the paper sheet.

Owner:KEMIRA OY

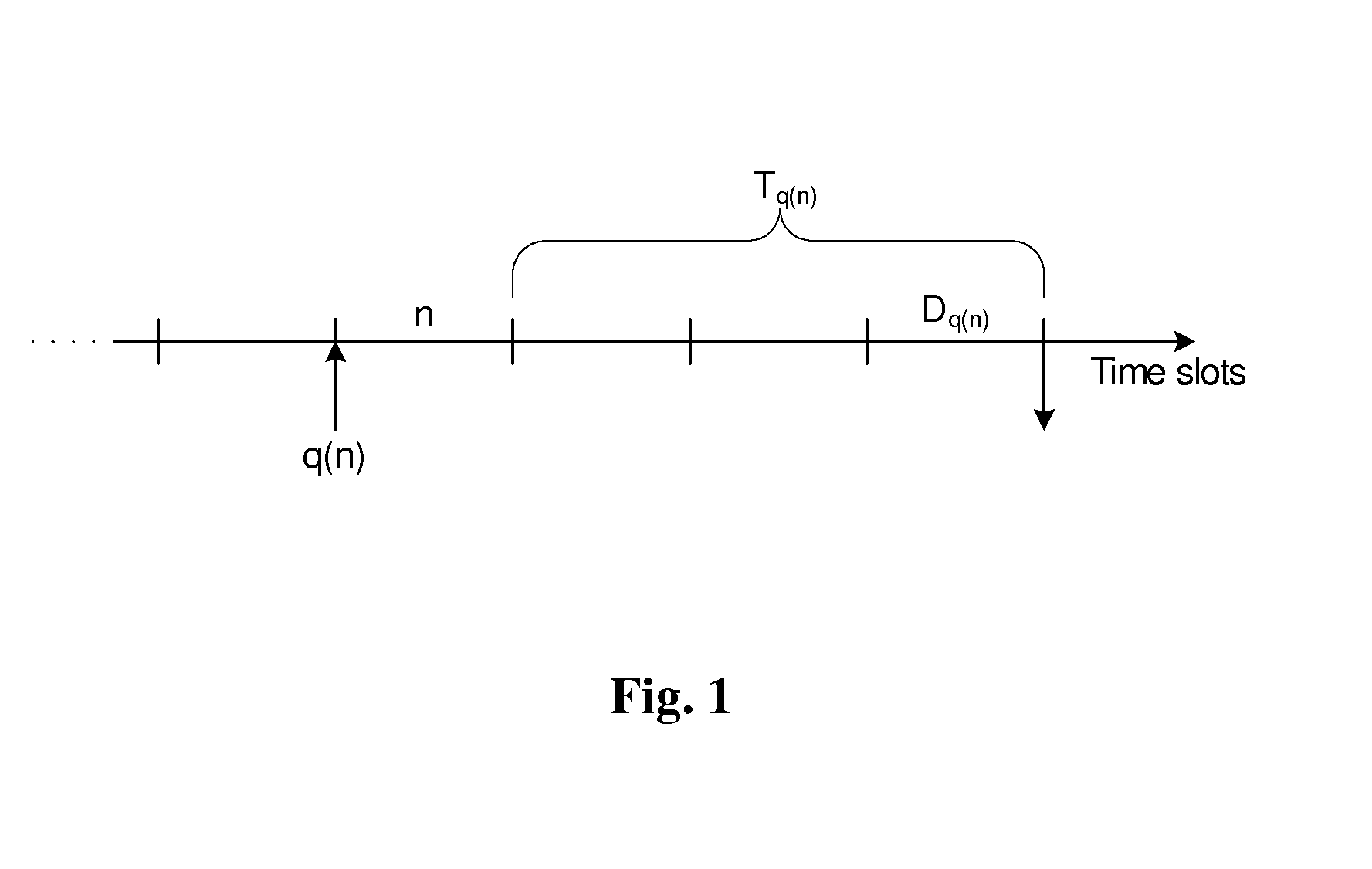

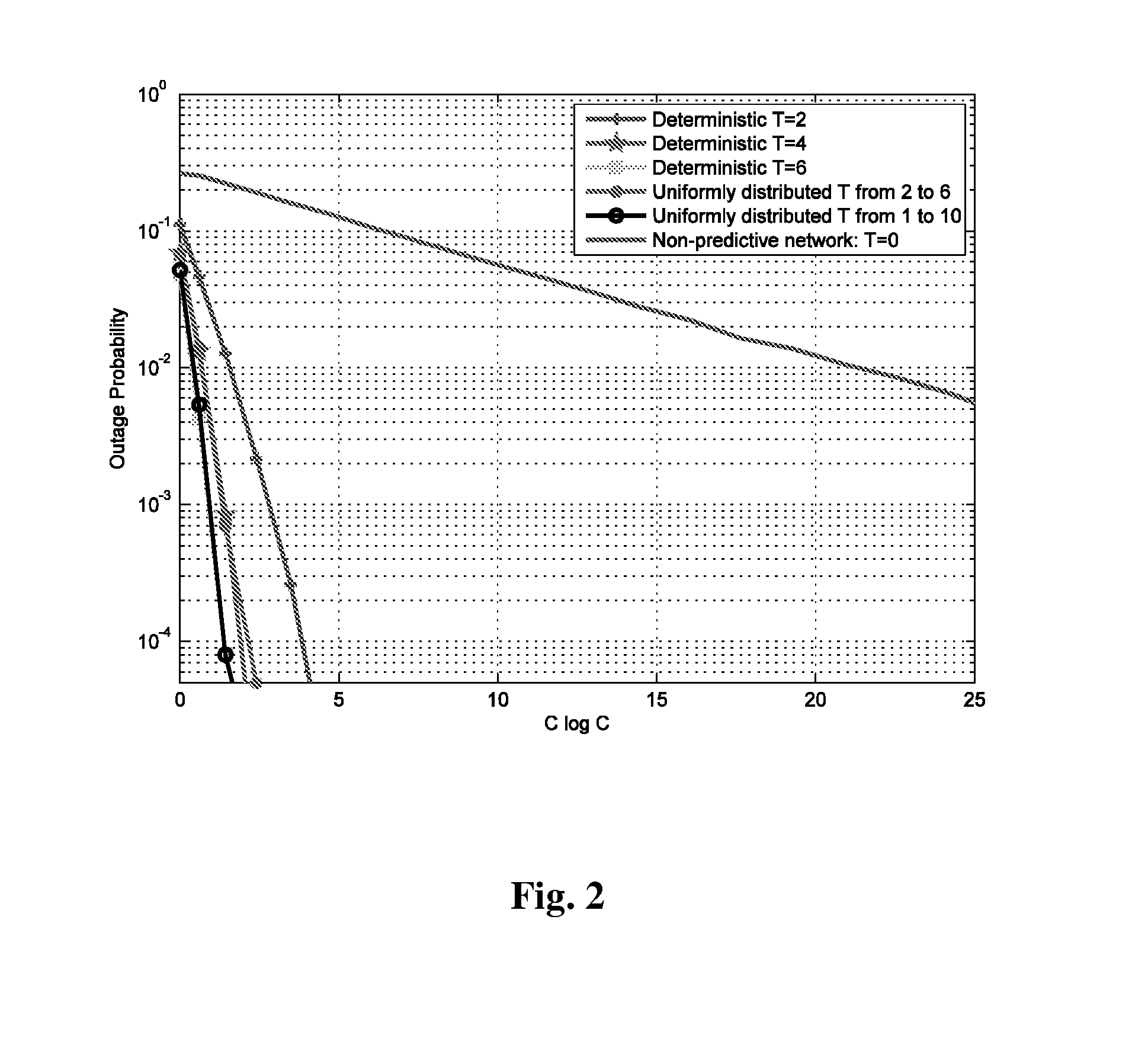

System and method for proactive resource allocation

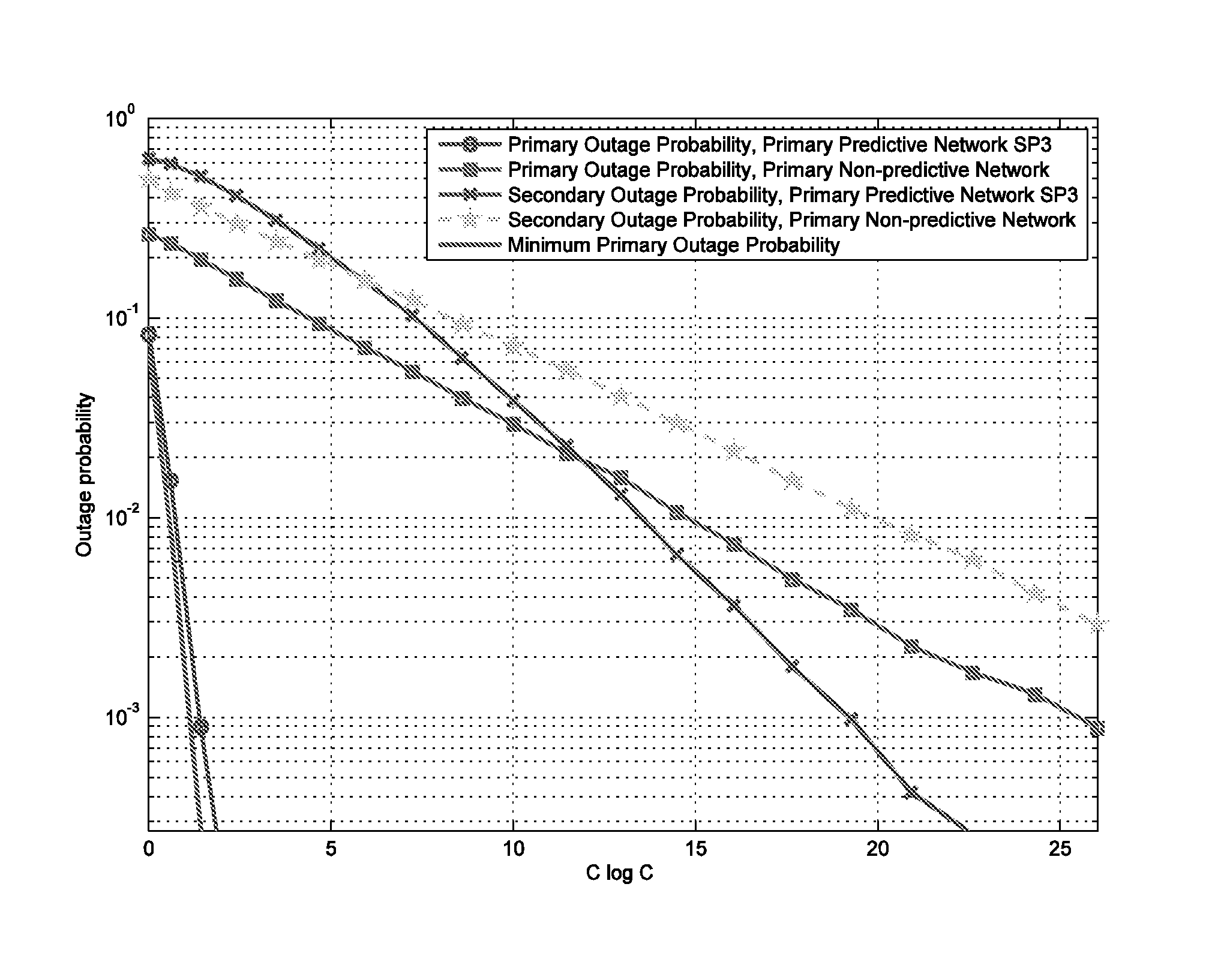

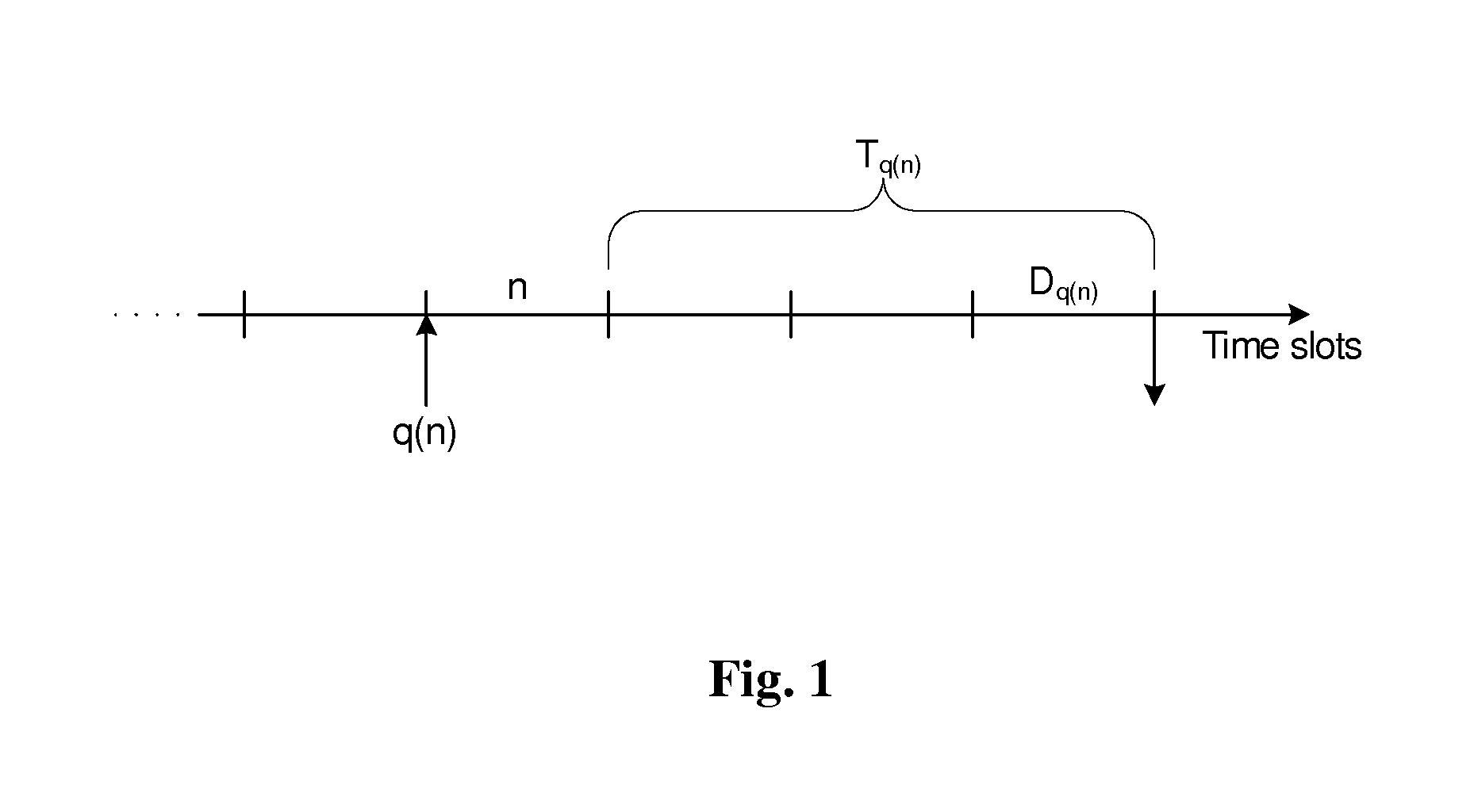

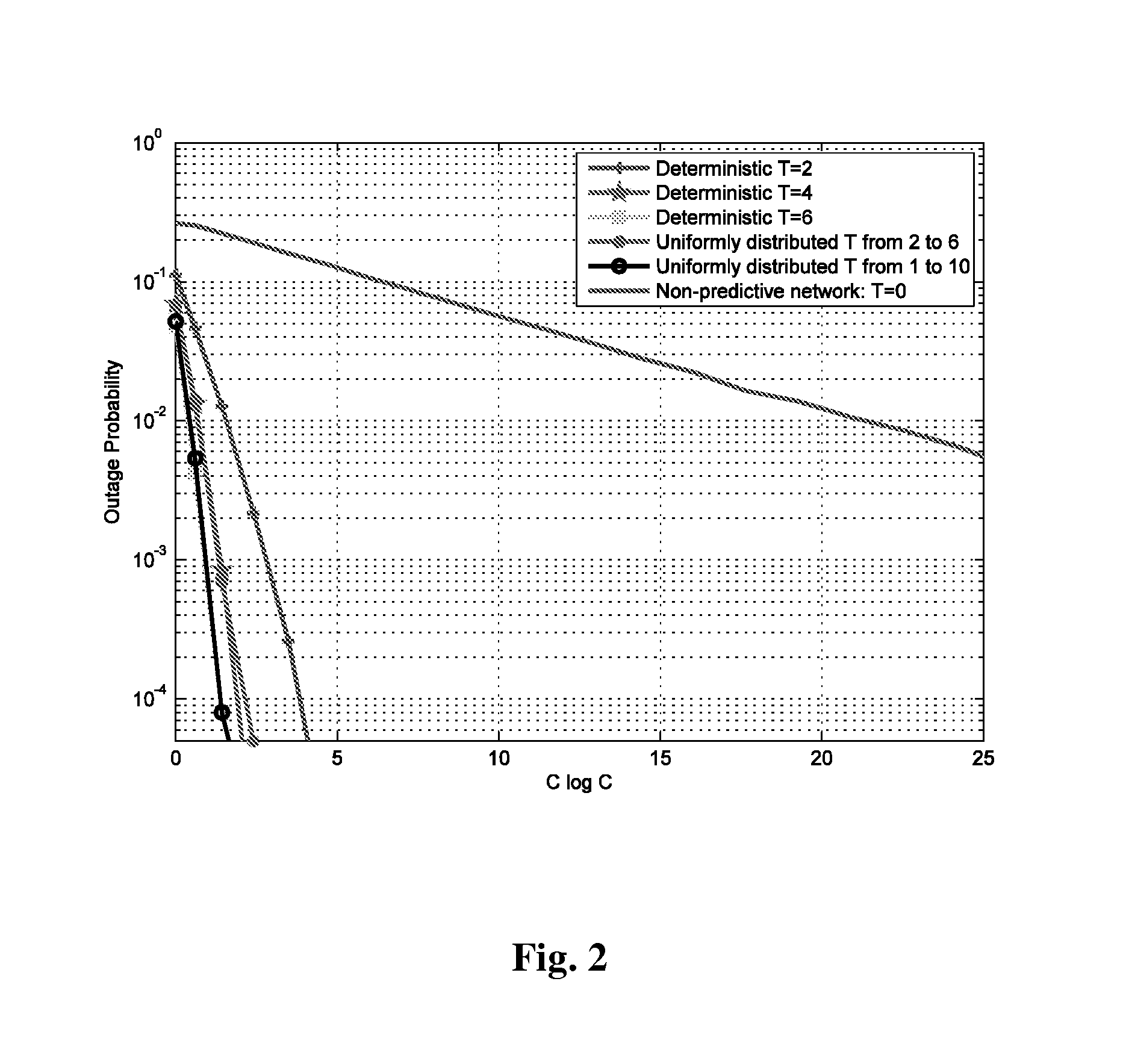

ActiveUS9531522B2Attenuation bandwidthReduce rateNetwork traffic/resource managementRadio transmission for post communicationLarge deviations theoryInternet traffic

A system and method for allocating resources in a network is disclosed. The system and method comprises a proactive resource allocation framework in which the predictability of user behavior is exploited to balance the network traffic over time and to reduce the bandwidth required to achieve a given blocking / outage probability. The disclosed proactive resource allocation framework avoids limitations associated with off-peak demand and achieves a significant reduction in the peak to average demand ratio without relying on out of network users. It is based on a model in which smart devices are assumed to predict the arrival of new requests and submit them to the network T time slots in advance. Using tools from large deviation theory, the resulting prediction diversity gain is quantified to establish that the decay rate of the outage event probabilities increases linearly with the prediction duration T.

Owner:OHIO STATE INNOVATION FOUND

System and method for proactive resource allocation

ActiveUS20140016575A1Attenuation bandwidthReduction in peak to average demand ratioNetwork traffic/resource managementRadio transmissionLarge deviations theoryPredictability

A system and method for allocating resources in a network is disclosed. The system and method comprises a proactive resource allocation framework in which the predictability of user behavior is exploited to balance the network traffic over time and to reduce the bandwidth required to achieve a given blocking / outage probability. The disclosed proactive resource allocation framework avoids limitations associated with off-peak demand and achieves a significant reduction in the peak to average demand ratio without relying on out of network users. It is based on a model in which smart devices are assumed to predict the arrival of new requests and submit them to the network T time slots in advance. Using tools from large deviation theory, the resulting prediction diversity gain is quantified to establish that the decay rate of the outage event probabilities increases linearly with the prediction duration T.

Owner:OHIO STATE INNOVATION FOUND

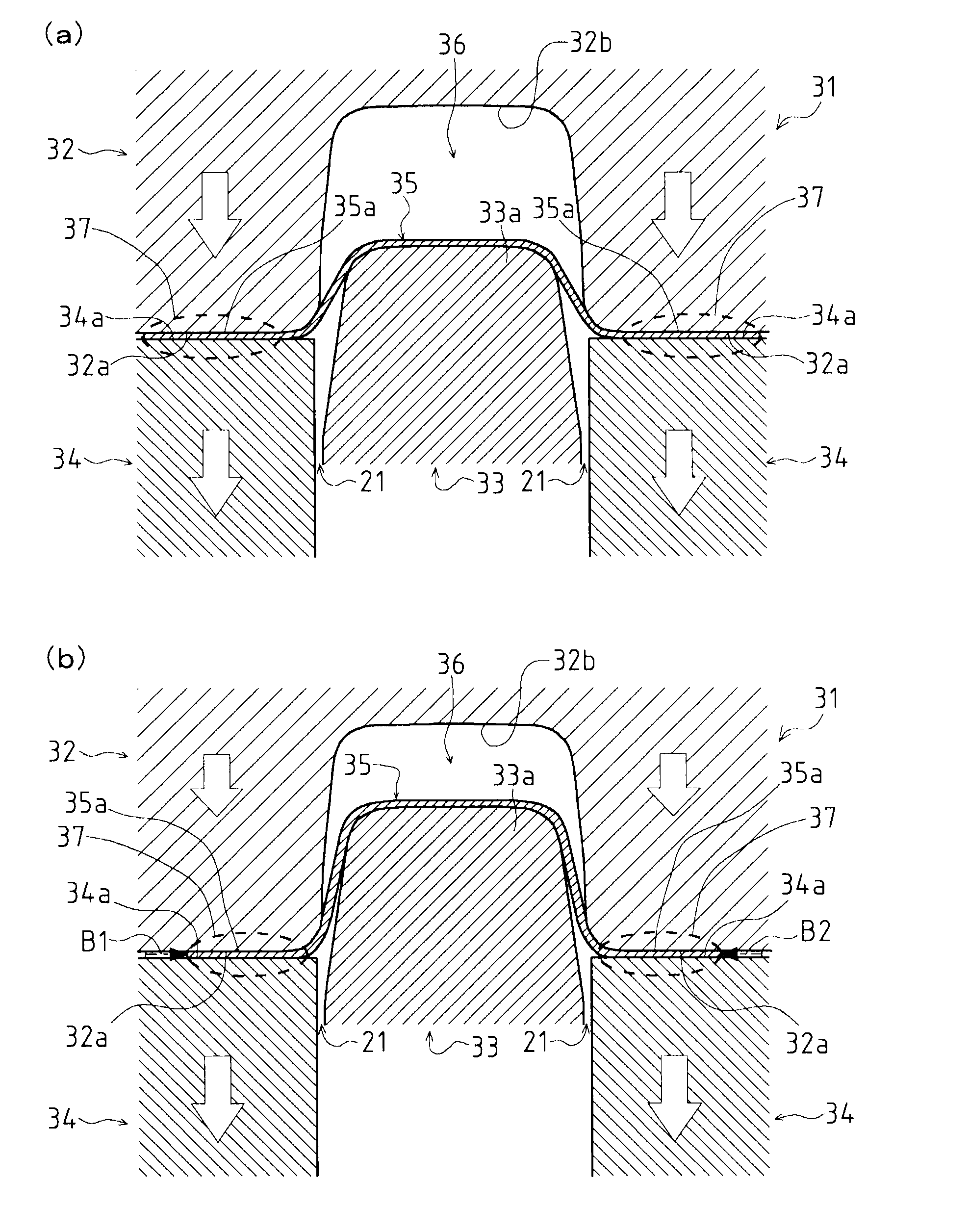

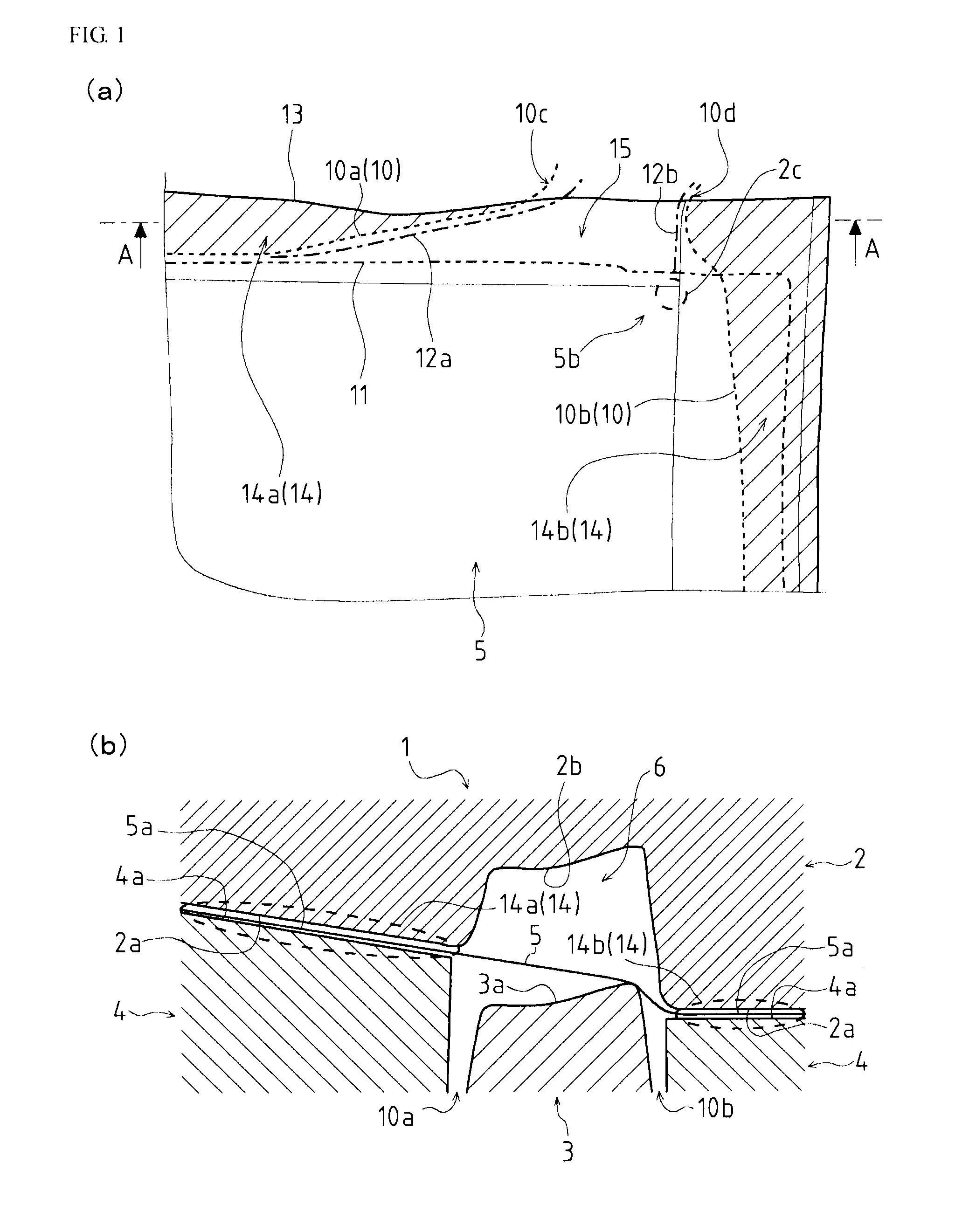

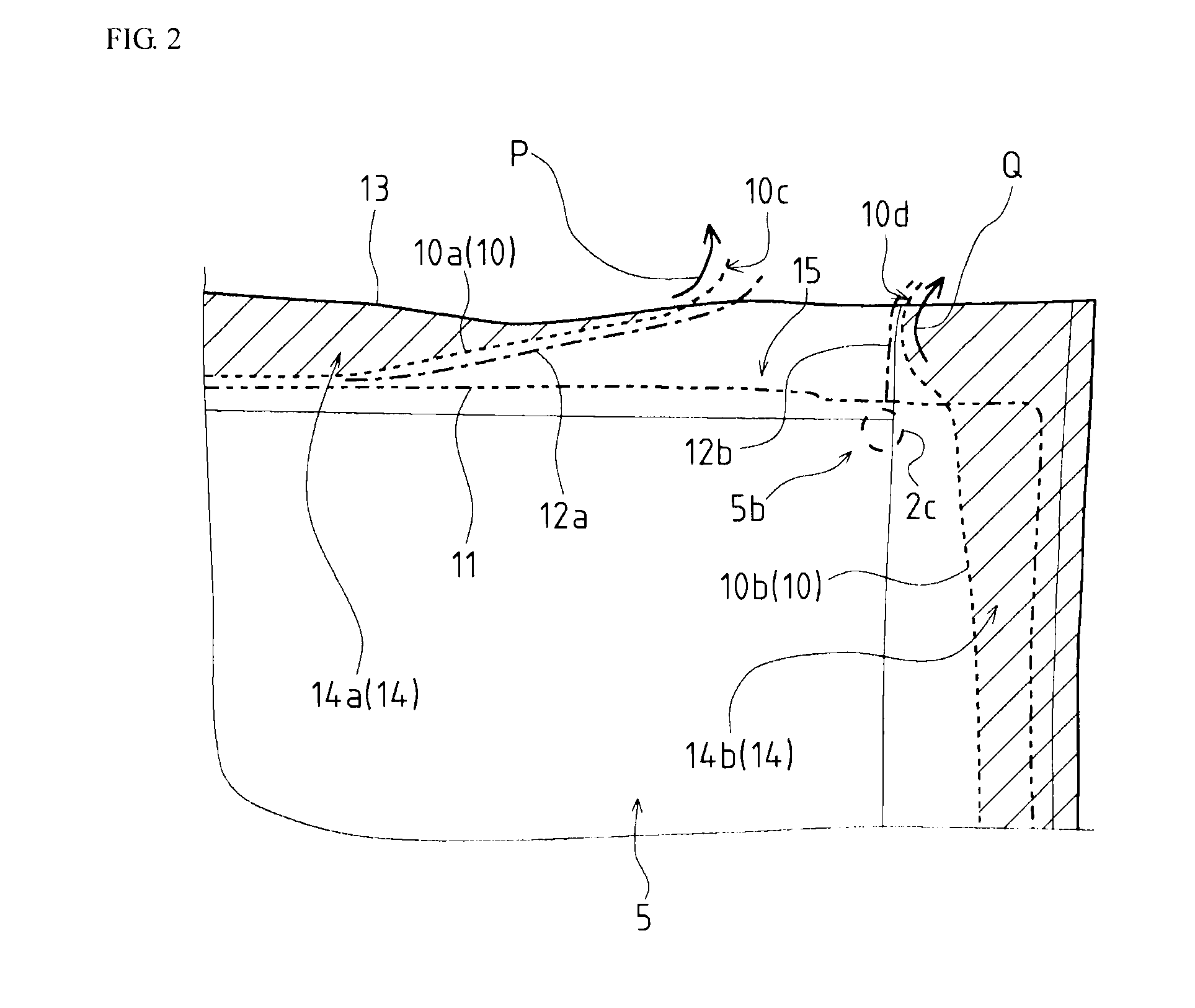

Press-molding mold, and press-molding method

Provided are a press-molding mold, in which cracks and wrinkles to be formed at the corner portions of a press-molded article are reduced regardless of the depth of the drawing, and a press-molding method using that mold. The press-molding mold (1) comprises a die (2) having a recess (2b) and a wrinkle holding face (2a) formed around the recess (2b), a punch (3) having a protrusion (3a) matching the recess (2b), and a blank holder (4) having a cushion face (4a) matching the wrinkle holding face (2a). In the press-molding mold (1), the wrinkle holding face (2a) and the cushion face (4a) form a clamping portion (14), by which a material member (5) is clamped for the press-molding operation. The clamping portion (14) of the press-molding mold (1) is divided by an opening portion (15) communicating with a corner recess (2c) of the recess (2b), into a first clamping portion (14a) and a second clamping portion (14b), by which the material member (5) is clamped.

Owner:TOYOTA JIDOSHA KK

Technique for CSP sheet billet production line cold rolling feeding

InactiveCN1927485AAvoid generatingImprove stamping effectRoll force/gap control deviceTemperature control deviceTemperature controlProduction line

The invention relates to a method for cold rolling material feeding of CSP sheet product line. Wherein, it comprises temperature control rule and deformation control rule; and the improved temperature rule comprises the outlet steel temperature of heating furnace is 1045-1062Deg. C, the final rolling temperature is 860-880Deg. C, the coiling temperature is 625-635Deg. C, and the compress rate of rough roller is 48.5-50.3%. The invention via lots of comparison tests can fine optimized coiling temperature and compress rate, to low-temperature coil at 630Deg. C and improve the compress rate of R1 rough roller. And it can obtain normal ferrite and pearlite, without additive, to reduce the yield strength of steel band.

Owner:HEBEI IRON AND STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com