Novel stainless steel cold continuous rolling technology and unit thereof

A cold continuous rolling mill, stainless steel technology, applied in metal rolling and other directions, can solve the problems of increasing production cost, high investment cost and high maintenance cost, and achieve the effect of reducing production cost, large investment cost and high maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

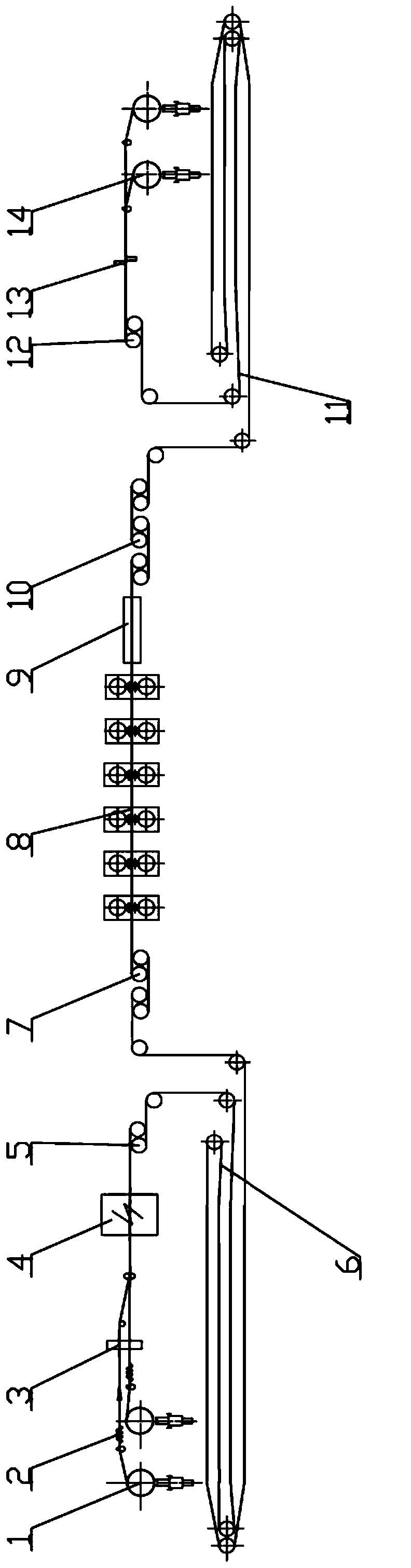

[0012] The technical scheme of the present invention will be further explained below in conjunction with the accompanying drawings: This unit adopts the process mode of full continuous endless rolling. Welding to achieve continuous production, the continuous rolling unit is in the form of six stands and four rollers in series. There are loopers at the entrance and exit of the continuous rolling unit to ensure that the rolling mill does not stop when welding at the entrance and slitting at the exit. Tension rollers are installed at the entrance and exit of the continuous rolling mill to increase the tension at the entrance and exit of the continuous rolling mill. At the same time, large tension is also used between the racks to increase the pass reduction rate of the rolling mill. In order to avoid the residual emulsion on the strip surface at the exit of the rolling mill from slipping the tension roller at the exit of the rolling mill, a cleaning and drying unit is installed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com