Patents

Literature

208results about How to "Increase investment cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

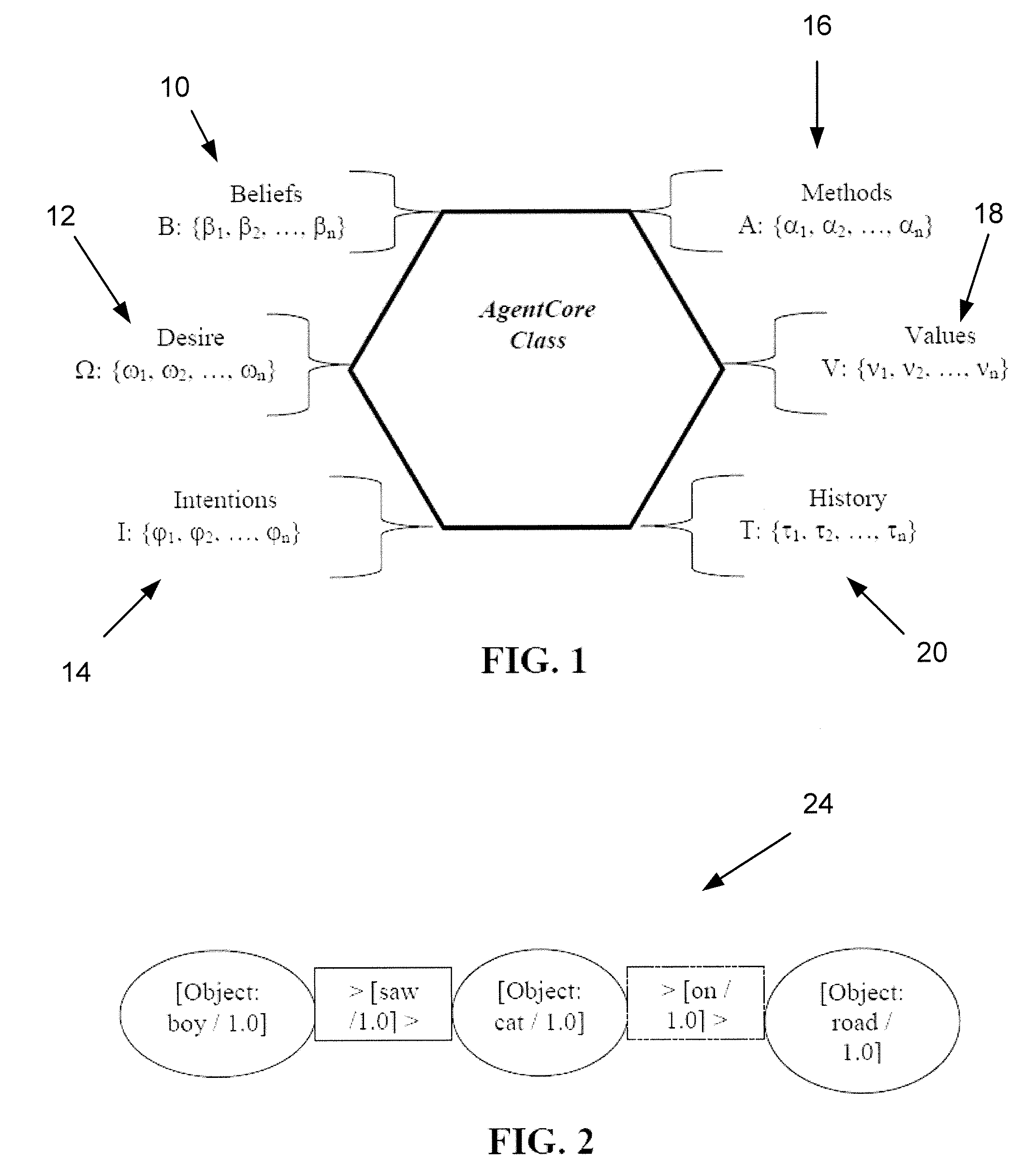

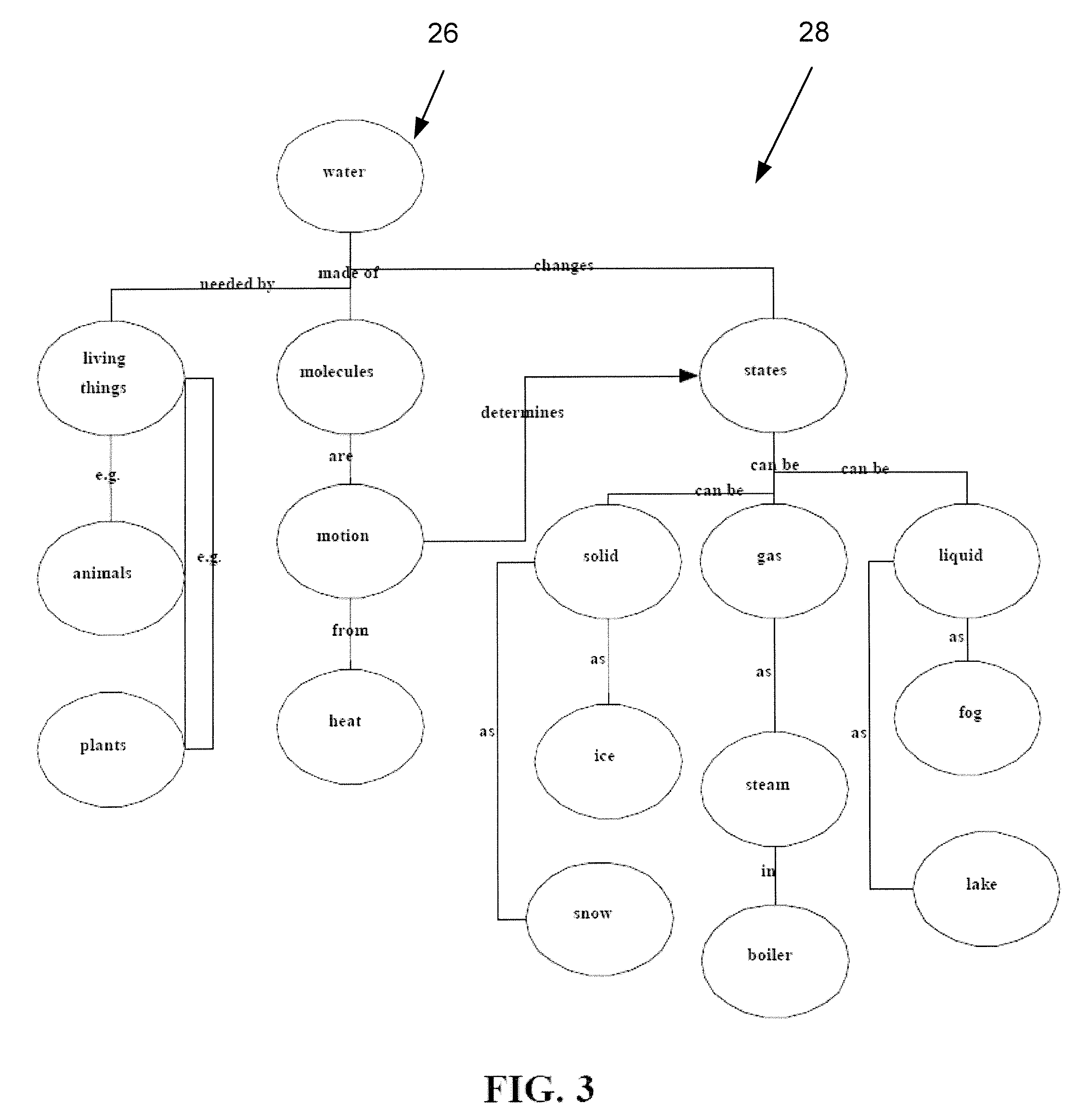

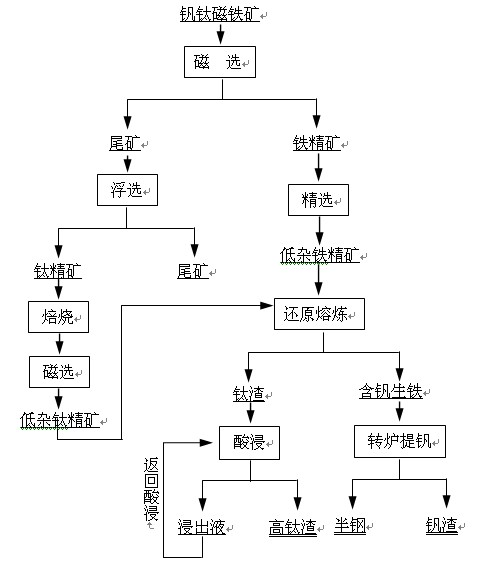

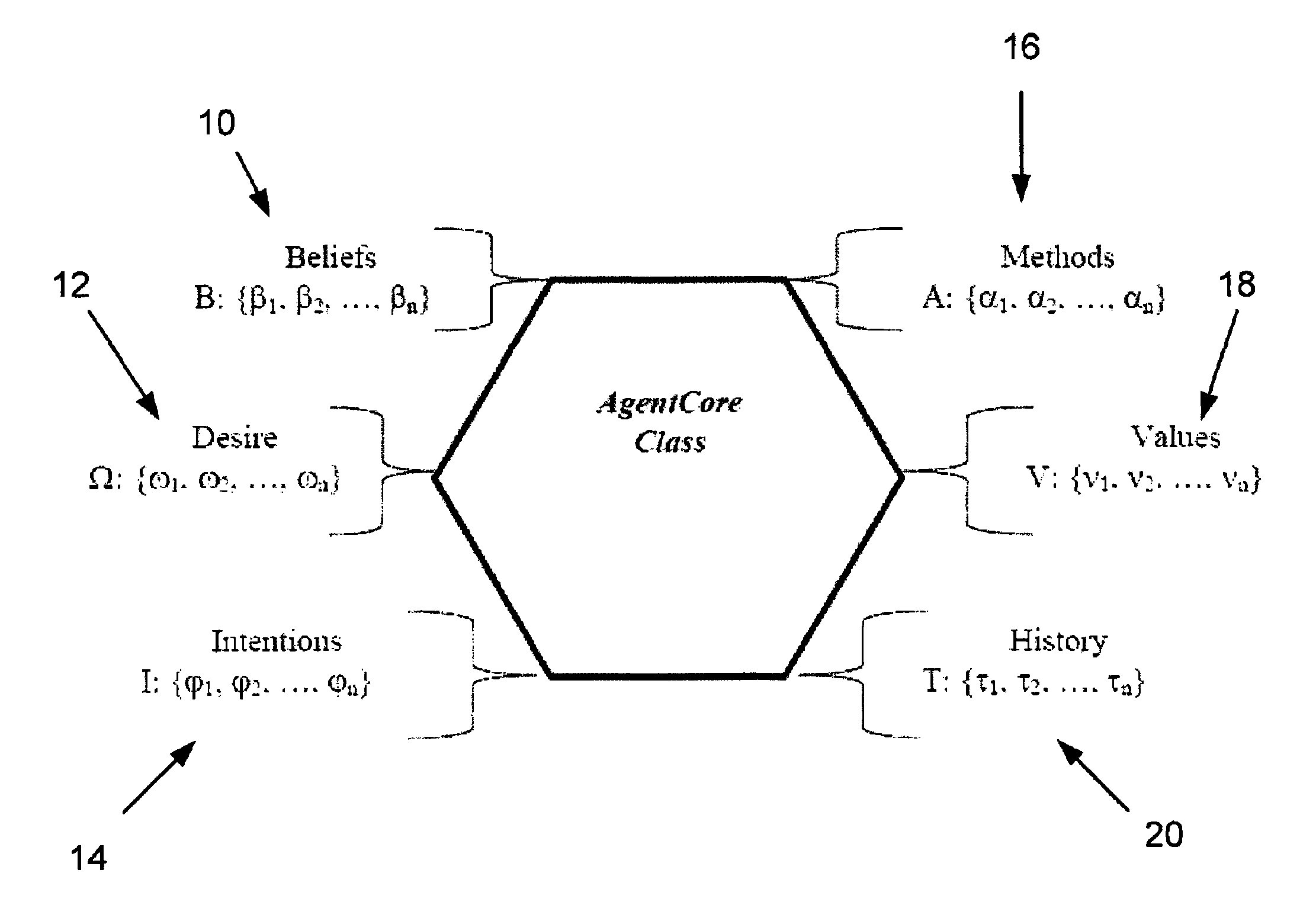

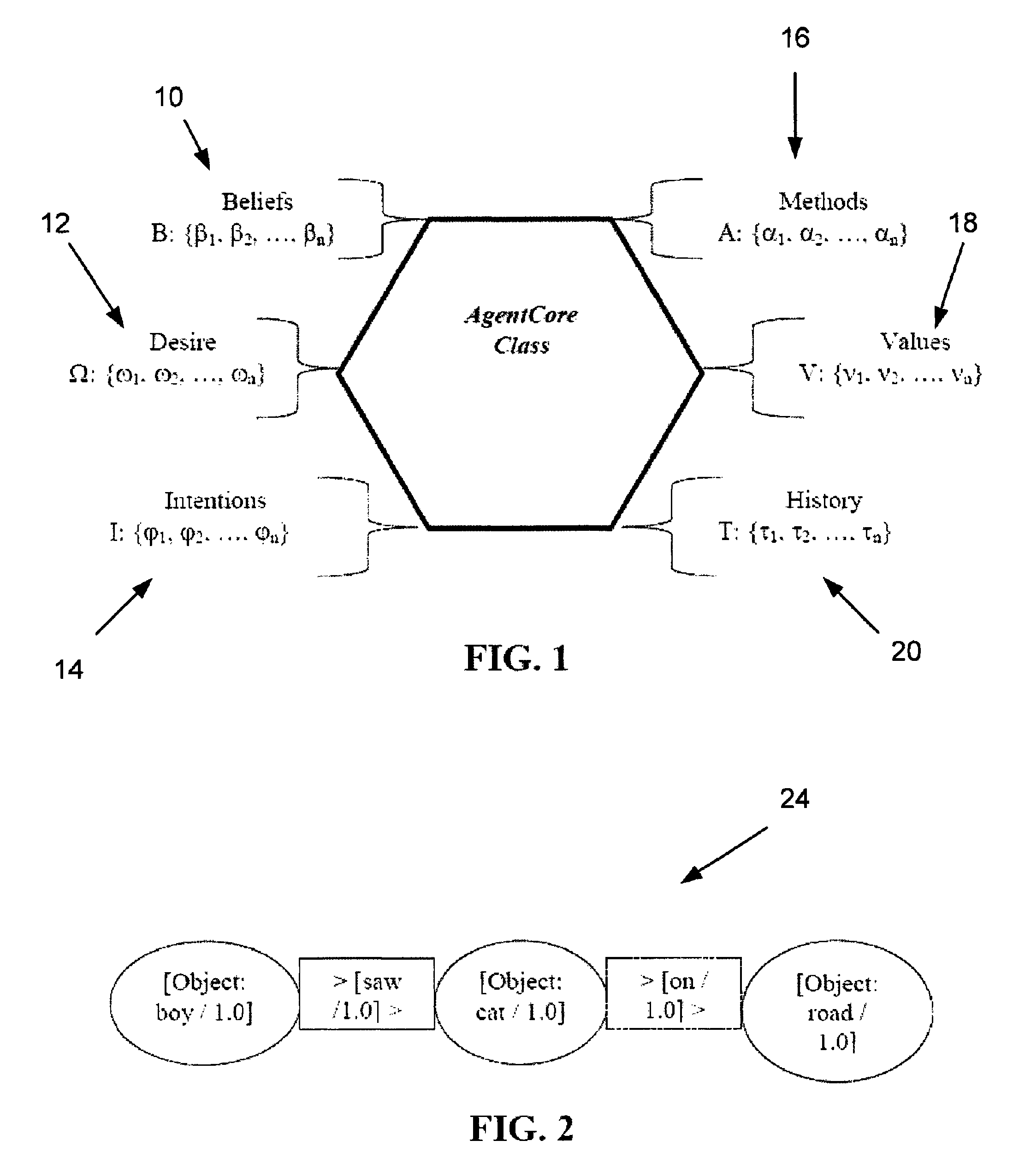

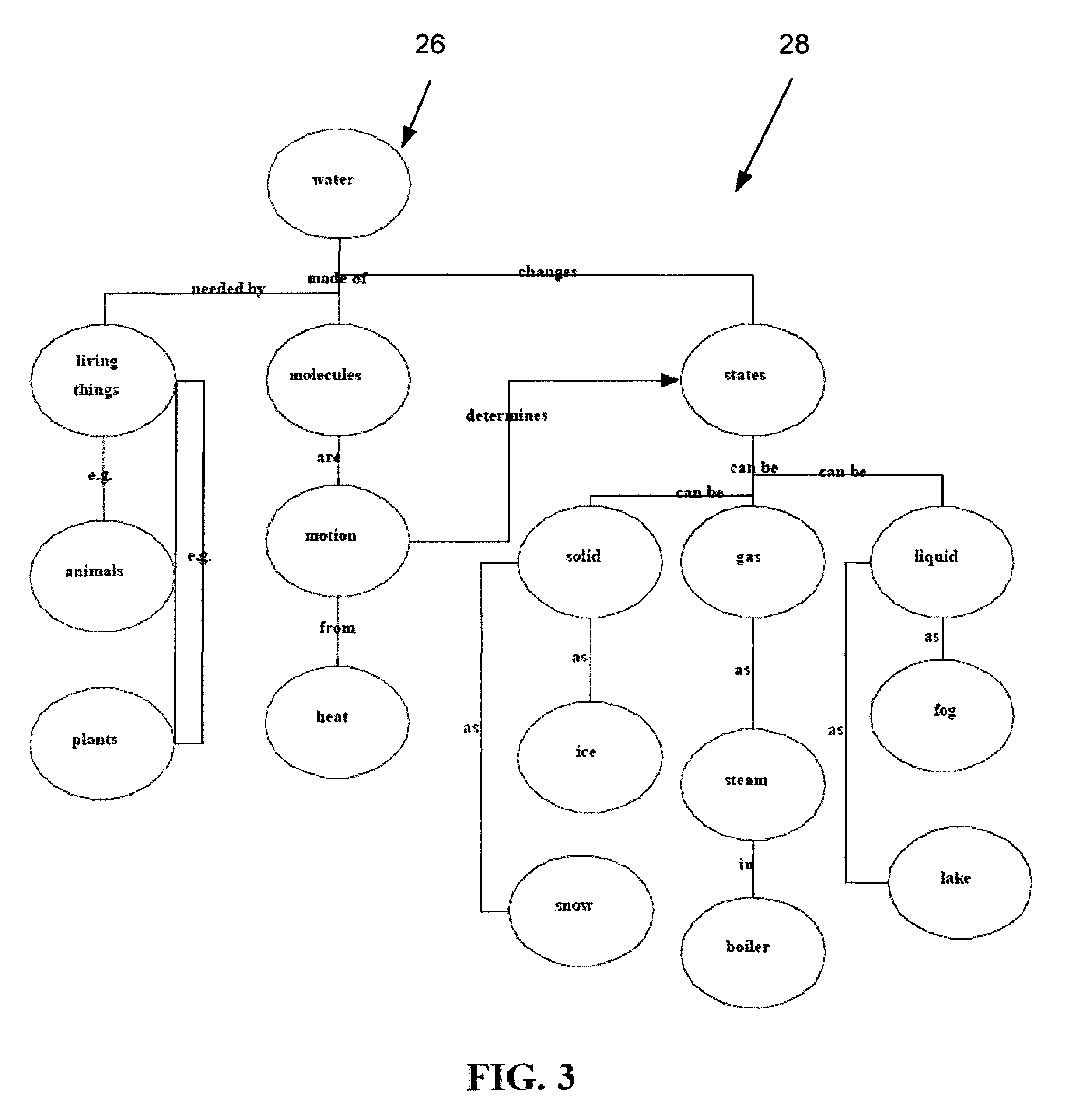

Knowledge Discovery Agent System and Method

ActiveUS20070203693A1Maximizes rangeFacilitate communicationWeb data indexingNatural language data processingUnstructured dataConditional probability

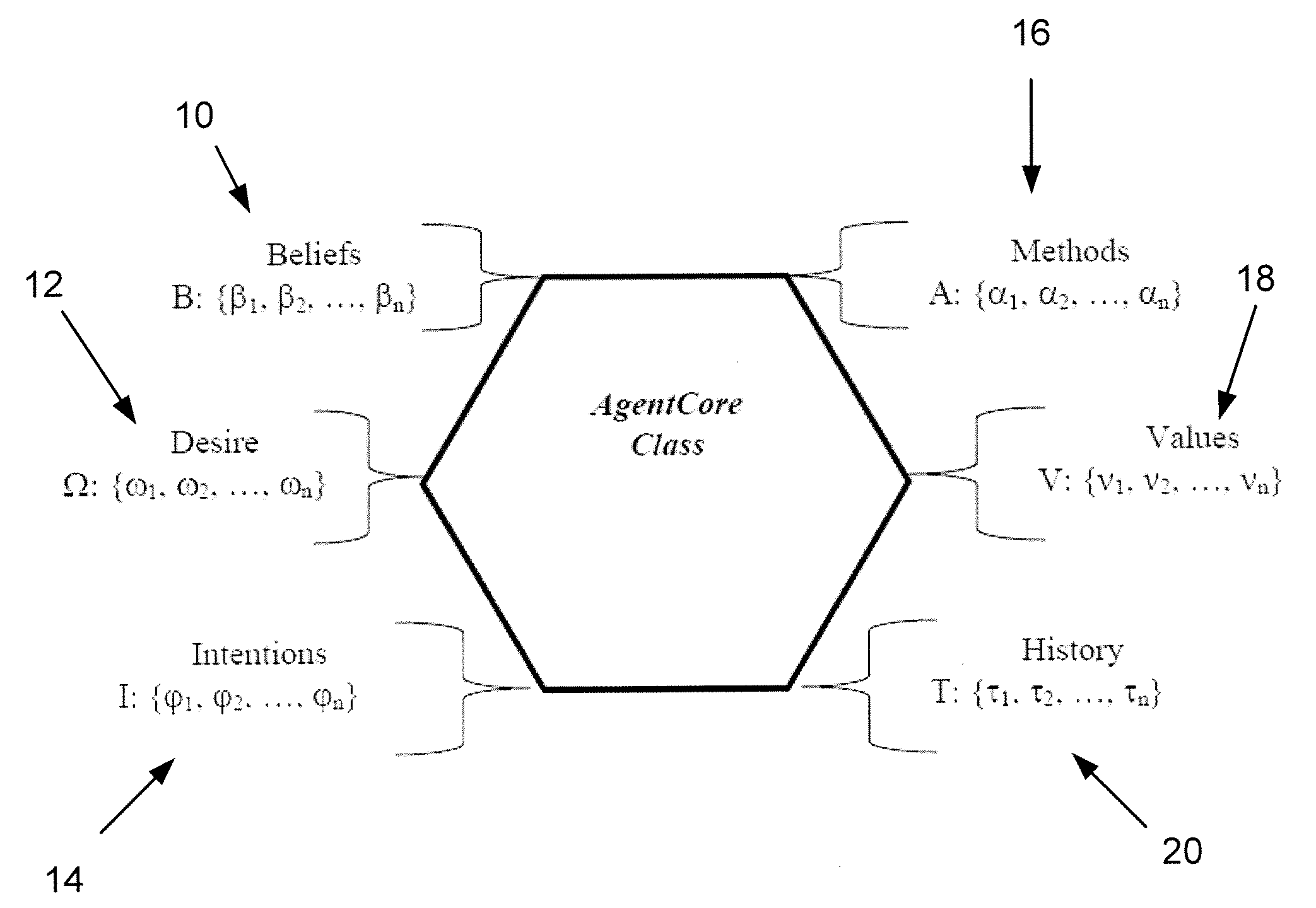

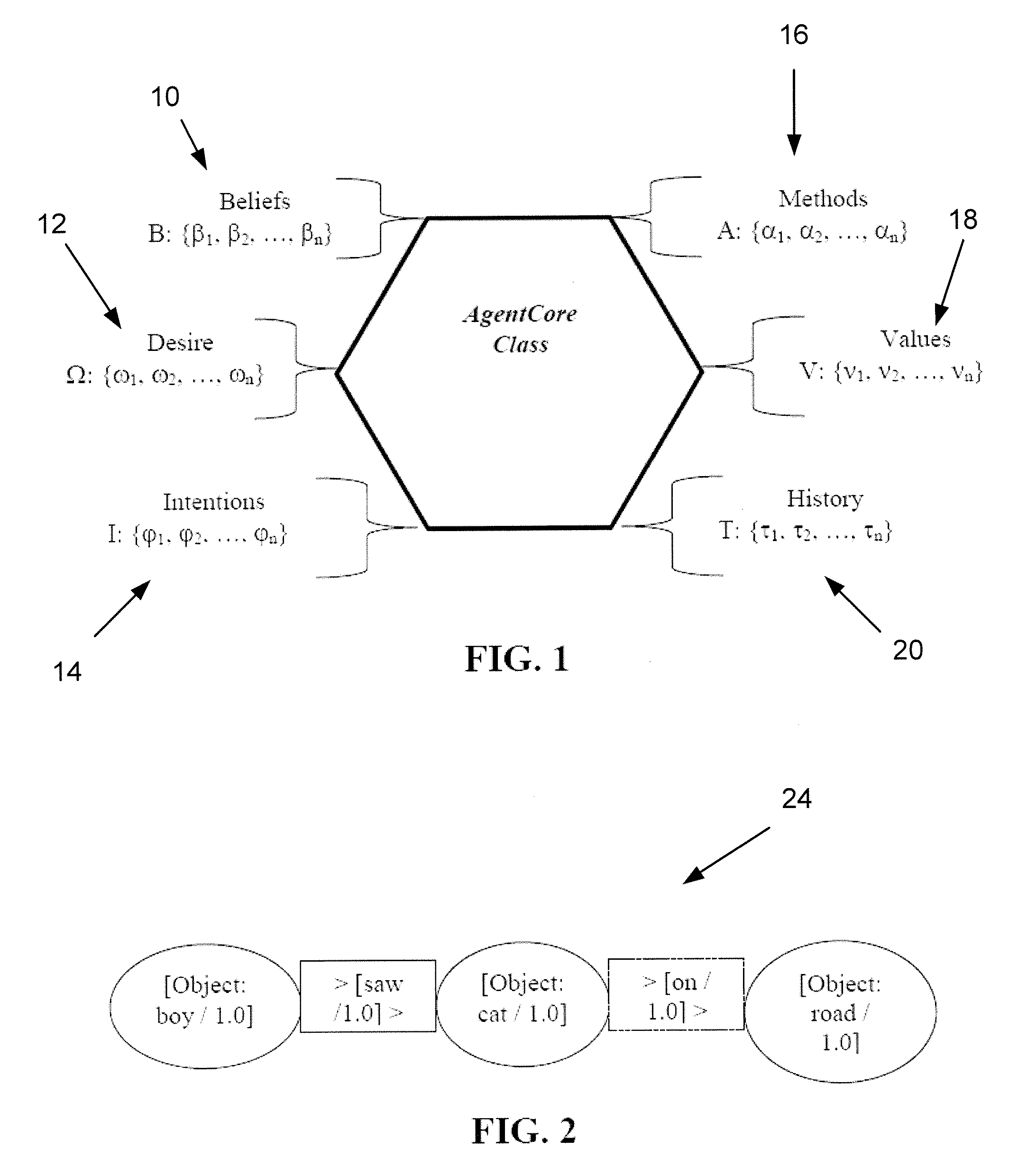

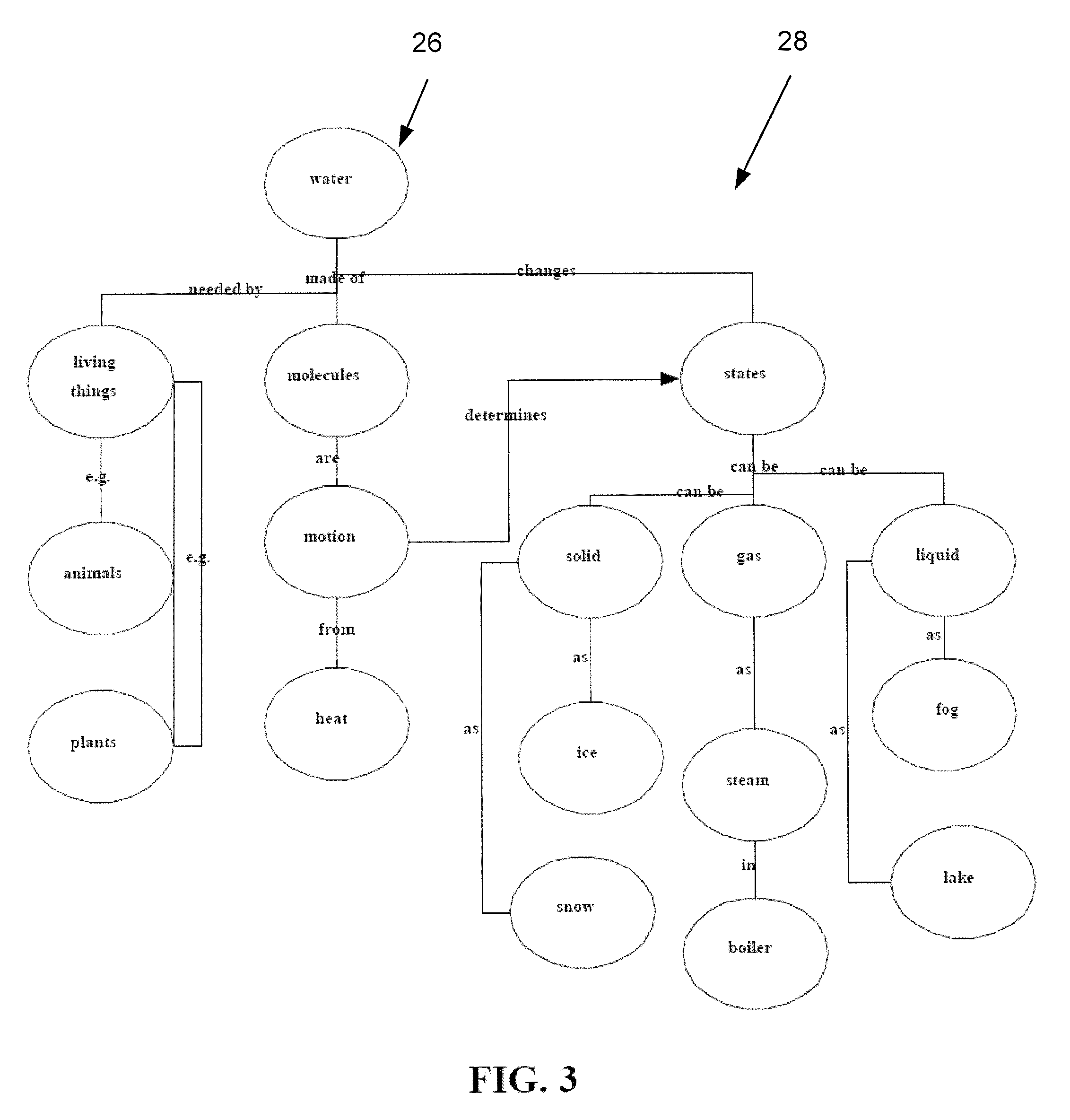

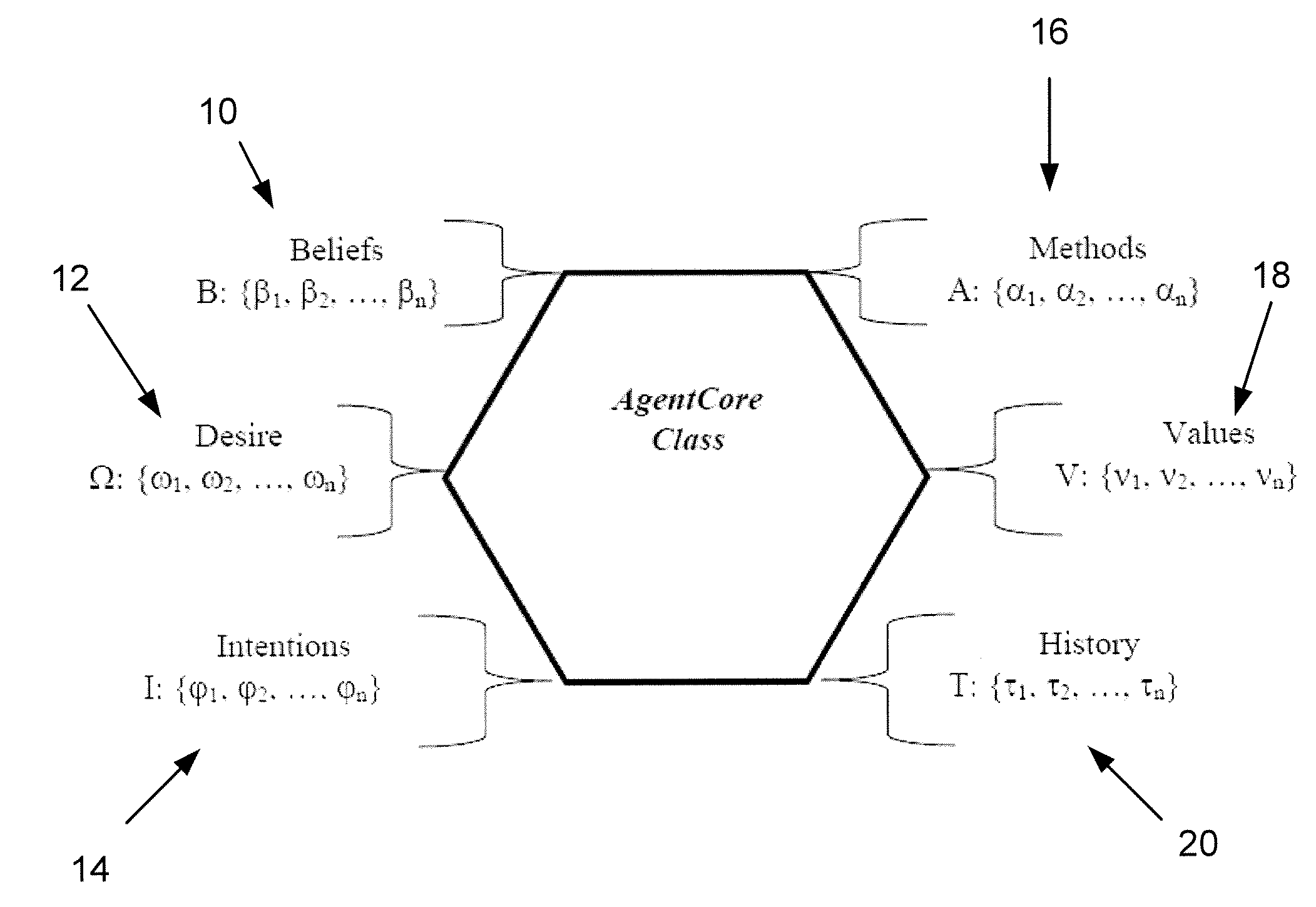

A system and method for processing information in unstructured or structured form, comprising a computer running in a distributed network with one or more data agents. Associations of natural language artifacts may be learned from natural language artifacts in unstructured data sources, and semantic and syntactic relationships may be learned in structured data sources, using grouping based on a criteria of shared features that are dynamically determined without the use of a priori classifications, by employing conditional probability constraints.

Owner:DIGITAL REASONING SYST

Knowledge discovery agent system and method

ActiveUS7249117B2Facilitate communicationMaximizes rangeChaos modelsNon-linear system modelsUnstructured dataConditional probability

A system and method for processing information in unstructured or structured form, comprising a computer running in a distributed network with one or more data agents. Associations of natural language artifacts may be learned from natural language artifacts in unstructured data sources, and semantic and syntactic relationships may be learned in structured data sources, using grouping based on a criteria of shared features that are dynamically determined without the use of a priori classifications, by employing conditional probability constraints.

Owner:DIGITAL REASONING SYST

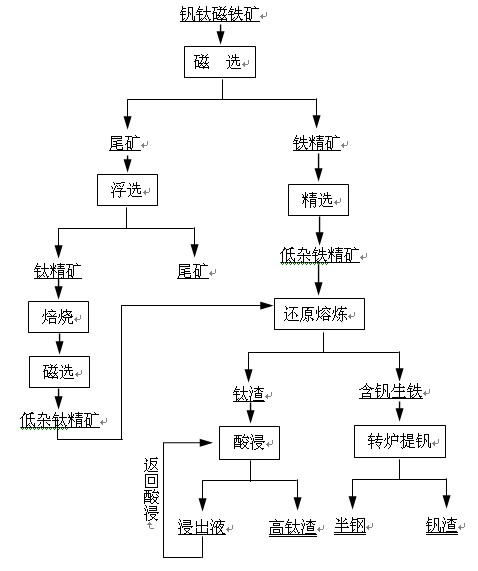

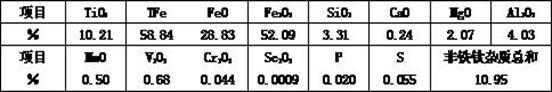

Method for separating vanadium-titanium magnetite to extract iron, vanadium and titanium

InactiveCN102179292AHigh technical difficultyIncrease processing costWet separationSmelting processMagnetite

The invention discloses a method for separating vanadium-titanium magnetite to extract iron, vanadium and titanium, comprising the following steps of: magnetically selecting raw magnetite, that is, acquiring iron-vanadium concentrate and tail magnetite after performing magnetic selection on the vanadium-titanium magnetite; sorting titanium concentrate from the tail magnetite, that is, acquiring the titanium concentrate after performing floating selection on the obtained tail magnetite; roasting and magnetically selecting the titanium concentrate, that is, performing enriched-titanium impurity-removing magnetic selection after roasting the titanium concentrate; finely selecting the iron-vanadium concentrate, that is, performing the magnetic selection and fine section again on the iron-vanadium concentrate obtained from magnetic selection; reducing and smelting, that is, mixing the titanium concentrate obtained from the impurity-removing process with the iron concentrate according to the beneficiation yield, adding in a reducer and soda ash to perform reduced iron and vanadium smelting process; purifying vanadium slag, that is, removing the impurity of the vanadium slag obtained by reducing and smelting by using the acidic dipping to obtain the high-quality titanium slag product with the content of TiO2 larger than 92%; and extracting vanadium from pig iron, that is, performing vanadium extraction by converter blowing on the vanadium-containing pig iron obtained by reducing and smelting to obtain the semi-steel and vanadium slag. The method not only improves the utilization ratio of titanium, iron and vanadium but also obtains the high-titanium slag product with the content of TiO2 larger than 92% so as to widen the application field of titanium.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

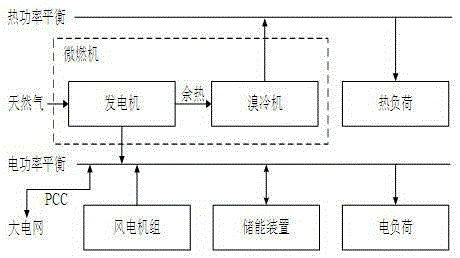

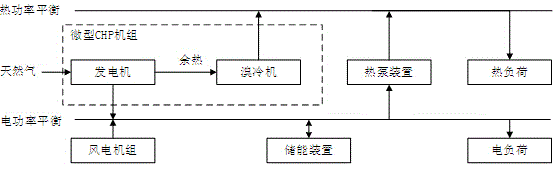

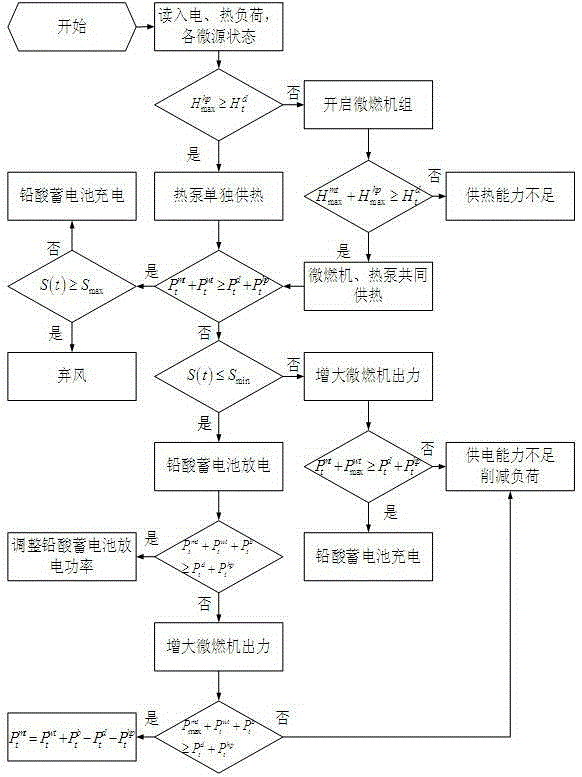

Capacity optimization configuration method for combined heat and power generation micro grid containing heat pump

ActiveCN105337303AReduce consumptionReduce configuration capacityGenetic modelsSingle network parallel feeding arrangementsCogenerationEngineering

The invention discloses a capacity optimization configuration method for a combined heat and power generation micro grid containing a heat pump. The method comprises a step 1 of establishing a micro-grid system model; a step 2 of introducing a heat pump into a combined heat and power generation micro grid and establishing an operation strategy of the combined heat and power generation micro grid containing the heat pump; a step 3 of establishing a capacity optimization configuration model of the combined heat and power generation micro grid containing the heat pump; a step 4 of solving the capacity optimization configuration model of the combined heat and power generation micro grid containing the heat pump by using a genetic algorithm. The method solves a problem that combined heat and power generation micro grid capacity optimization configuration in the prior art is not performed in the aspects of decreasing conventional energy sources, reducing wasted wind, and increasing system economic benefit so that a conventional system is high in using cost and poor in economic benefit.

Owner:POWER GRID PLANNING RES INST OF GUIZHOU POWER GRID CO LTD +1

Trough-dish combined solar thermal power generation system with fixed focus

InactiveCN101825072AImprove power generation efficiencyRealize cascade heatingFrom solar energySolar heat devicesElectronic systemsSolar field

The invention discloses a trough-dish combined solar thermal power generation system with a fixed focus and relates to a solar thermal power generation technology. The system comprises a trough type heat-collecting and heat-storing subsystem, a dish type heat-collecting and heat-storing subsystem and a power generation subsystem, wherein the trough type heat-collecting and heat-storing subsystem and the dish type heat-collecting and heat-storing subsystem are separately connected with the power generation subsystem; and the low temperature heat exchanger of the trough type heat-collecting and heat-storing subsystem is connected with the high temperature heat exchanger of the dish type heat-collecting and heat-storing subsystem. A parabolic dish reflecting mirror contains one dish or two dishes which can perform single-spindle automatic tracking and the focus, namely the receiver is fixed, thus facilitating the heating and heat insulation of large flow high temperature fluid. The invention adopts a trough type solar field with low investment cost to heat the low temperature section of the working medium and a dish type solar field to heat the high temperature section of the working medium, thus reducing the investment of the electric power plant under the premise of ensuring high generating efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

Knowledge discovery agent system and method

ActiveUS8015143B2Facilitate communicationMaximizes rangeChaos modelsNon-linear system modelsTechnical standardUnstructured data

A system and method for processing information in unstructured or structured form, comprising a computer running in a distributed network with one or more data agents. Associations of natural language artifacts may be learned from natural language artifacts in unstructured data sources, and semantic and syntactic relationships may be learned in structured data sources, using grouping based on a criteria of shared features that are dynamically determined without the use of a priori classifications, by employing conditional probability constraints.

Owner:DIGITAL REASONING SYST

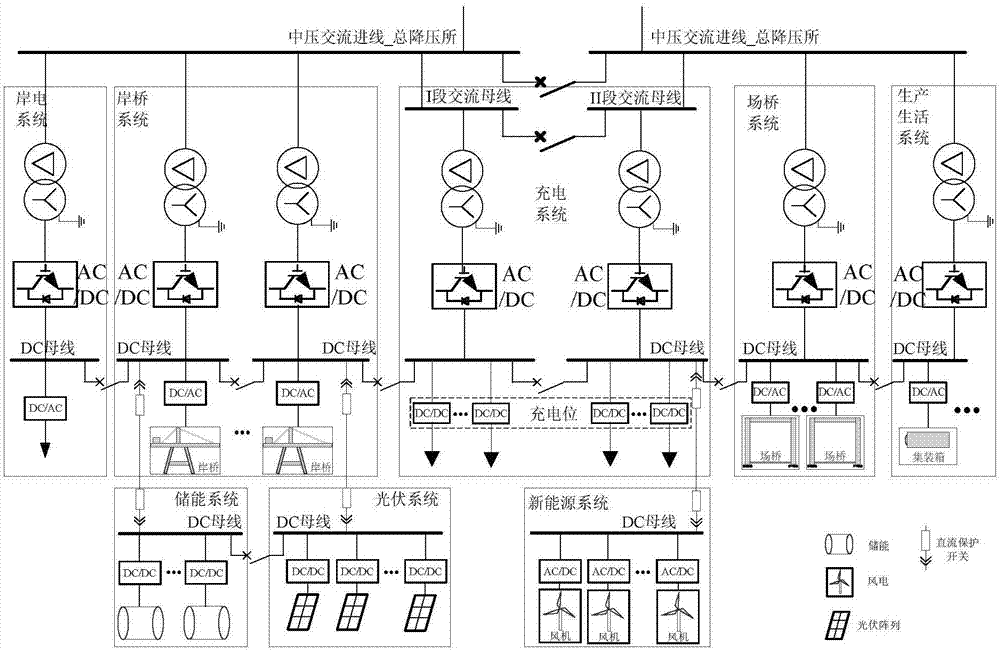

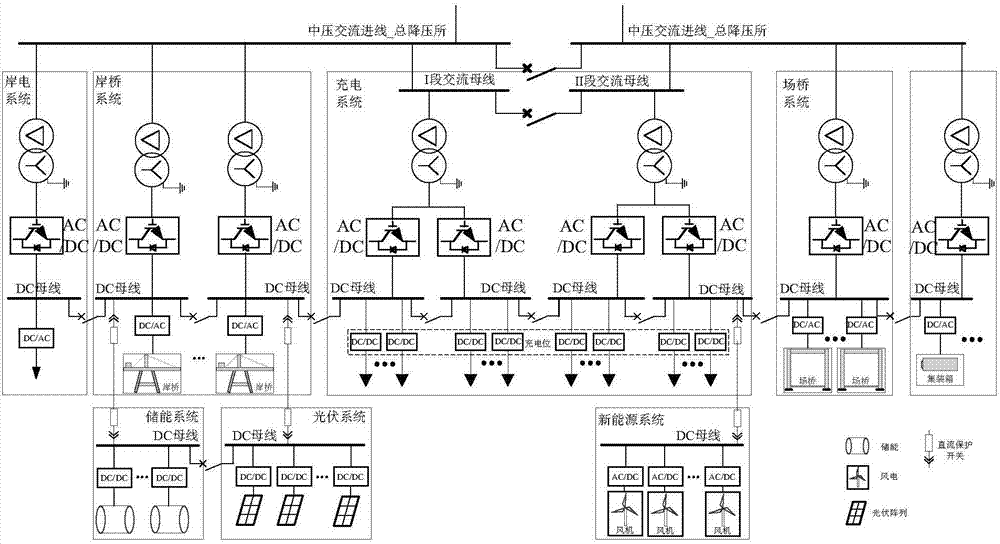

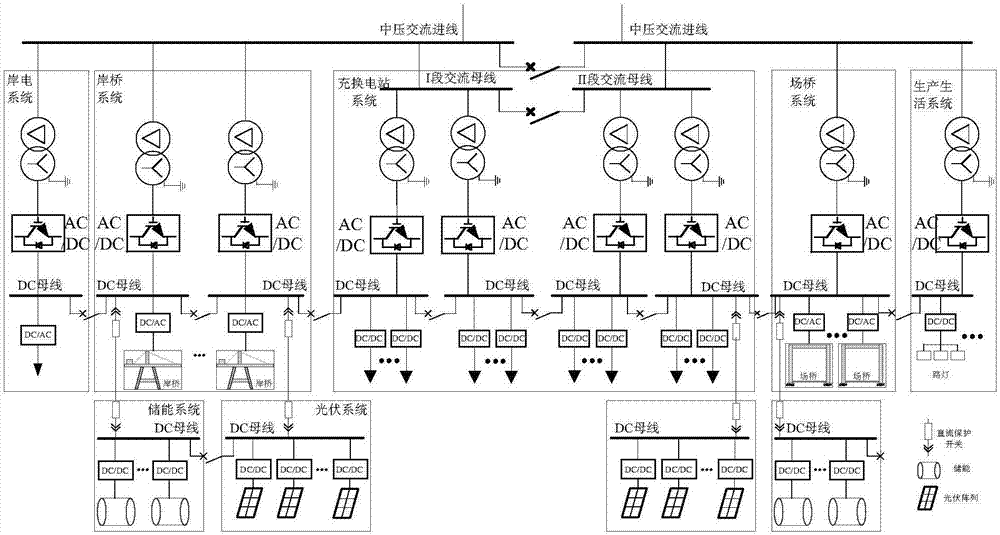

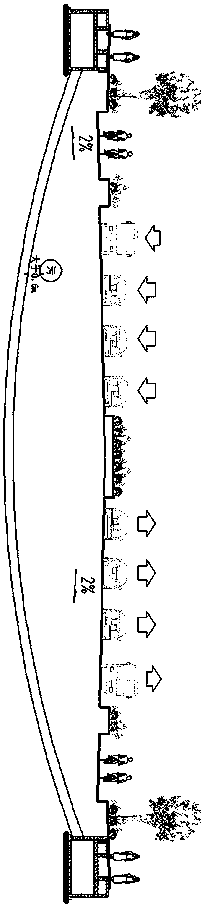

Alternating-direct current series-parallel port distribution network and comprehensive dispatching control method thereof

PendingCN107394831ADesign capacity and cost reductionIncrease flexibilitySingle network parallel feeding arrangementsDc source parallel operationDc converterDistribution transformer

The invention discloses an alternating-direct current series-parallel port distribution network and a comprehensive dispatching control method thereof, and belongs to the field of port distribution power and distribution network automation. The distribution network comprises a general step-down station, a branch substation or a switch-on / switch-off station and various distribution subsystems; a multi-channel feeder of the general step-down station provides alternating current power for the various distribution subsystems through the branch substation or the switch-on / switch-off station; each distribution subsystem comprises a shore electronic system, a shore bridge subsystem, a field bridge subsystem, a power charging and converting station subsystem for electric port trailers, a new energy subsystem and a production life subsystem; each distribution subsystem utilizes an alternating current distribution transformer and an AC / DC converter to construct a direct current bus of the distribution subsystem, and the direct current buses of the distribution subsystems are in direct current interconnection through direct current interconnection protection switches; each distribution subsystem is internally provided with multiple sections of direct current buses, and the multiple sections of direct current buses are in direct current interconnection through direct current interconnection protection switches. According to the alternating-direct current series-parallel port distribution network and the comprehensive dispatching control method thereof, the optimal power supply and comprehensive dispatching control of the port distribution network can be achieved.

Owner:STATE GRID CORP OF CHINA +2

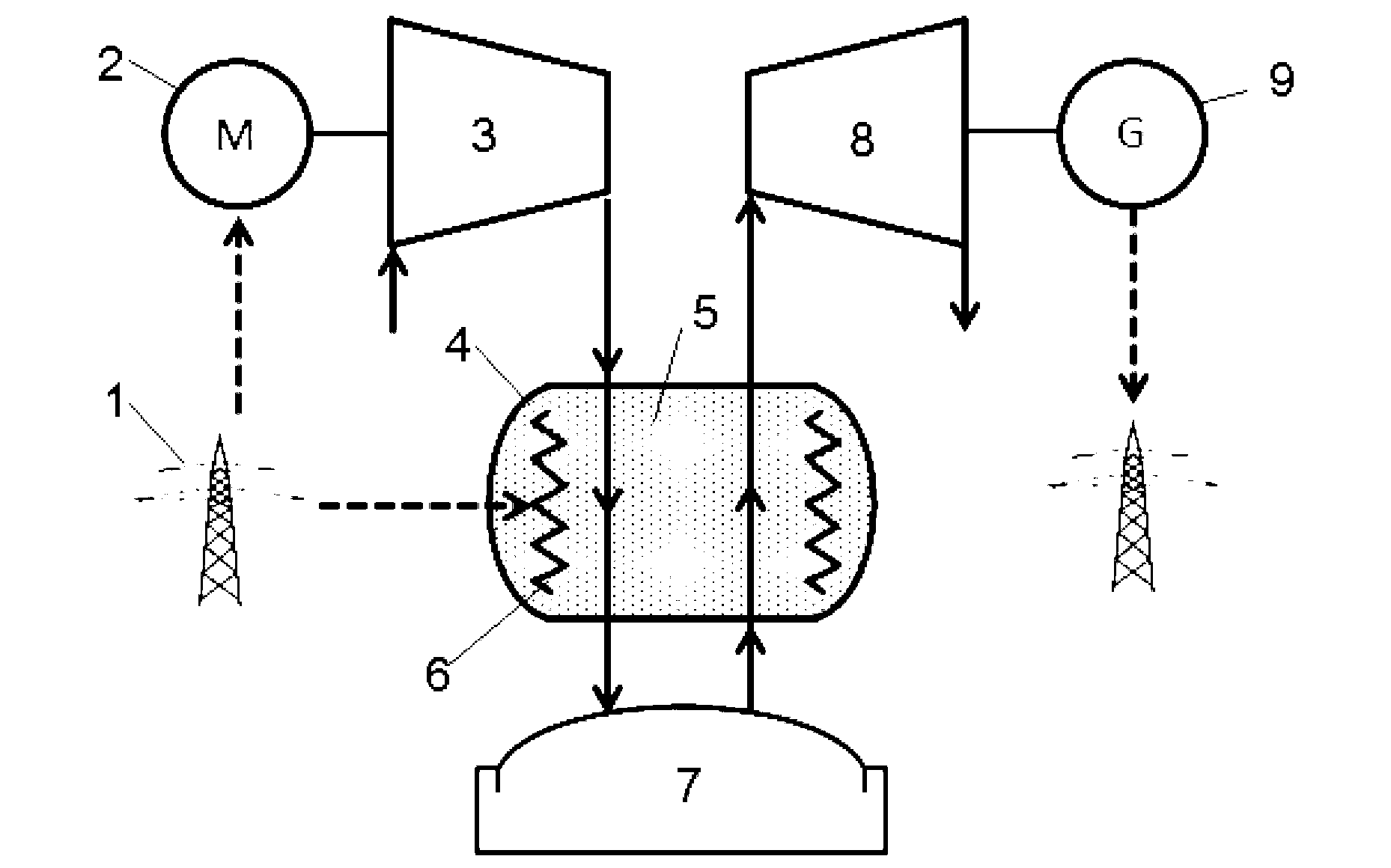

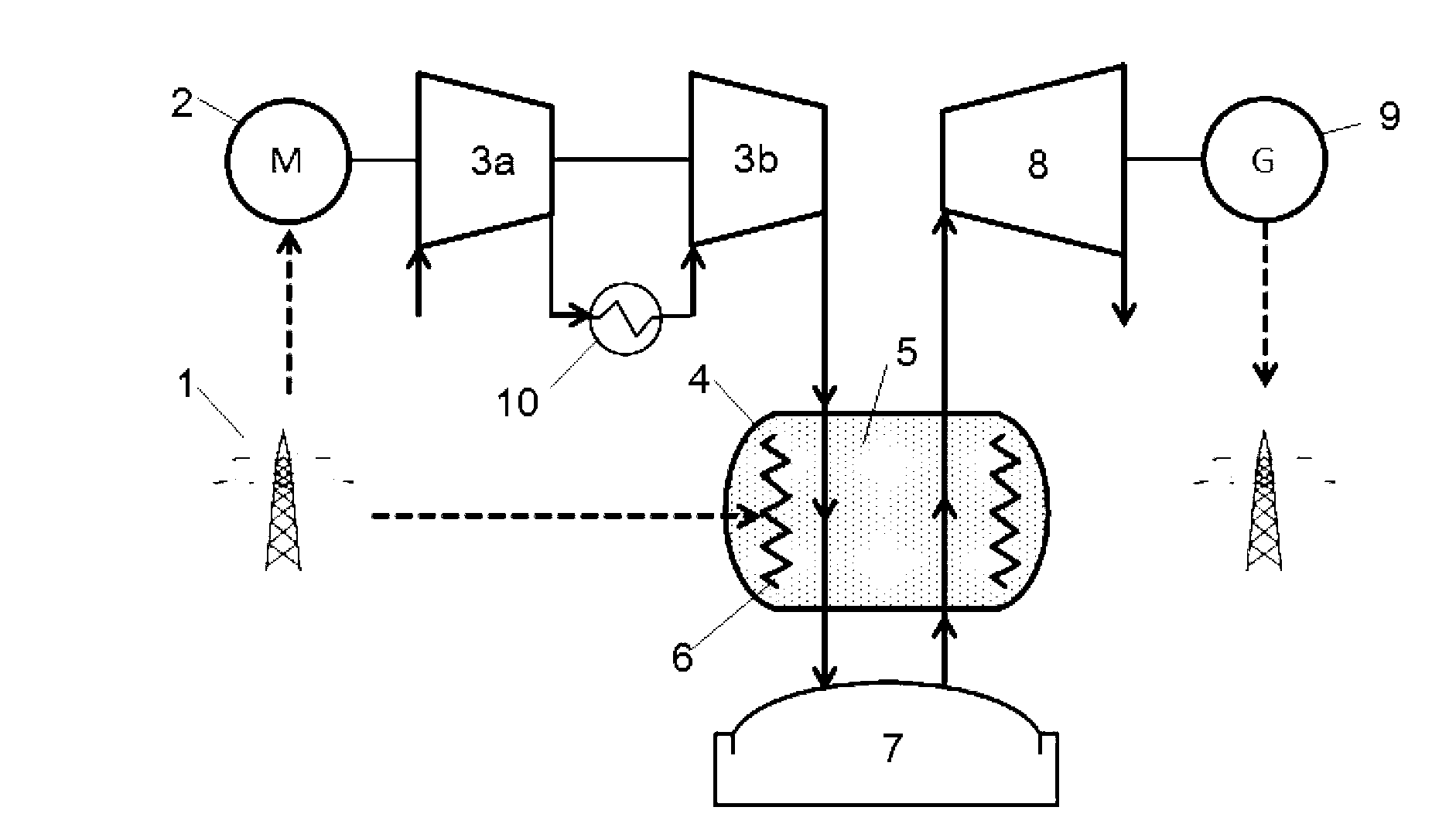

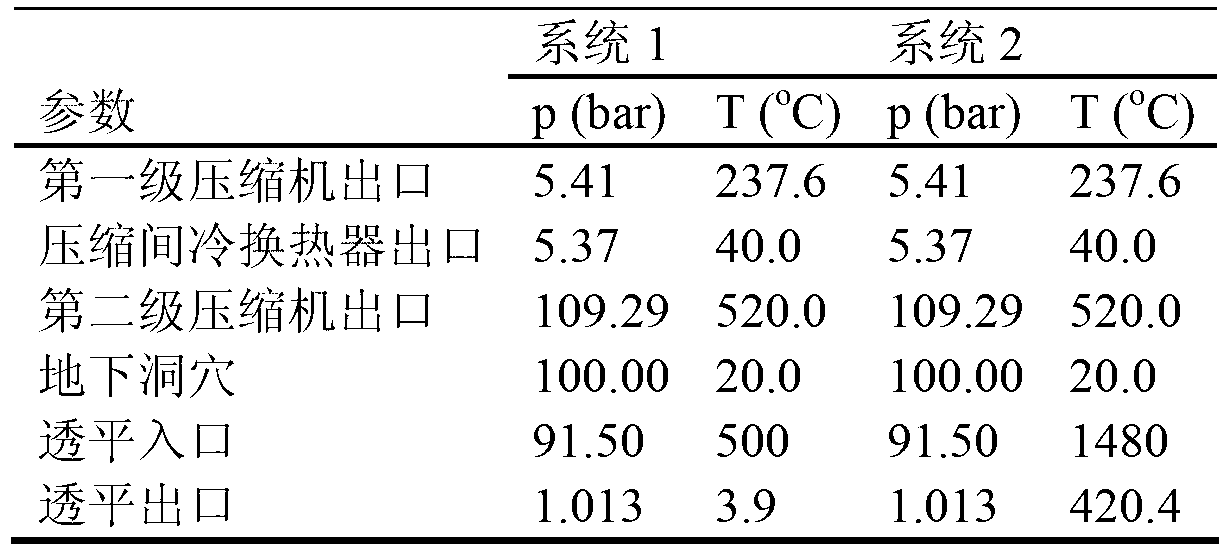

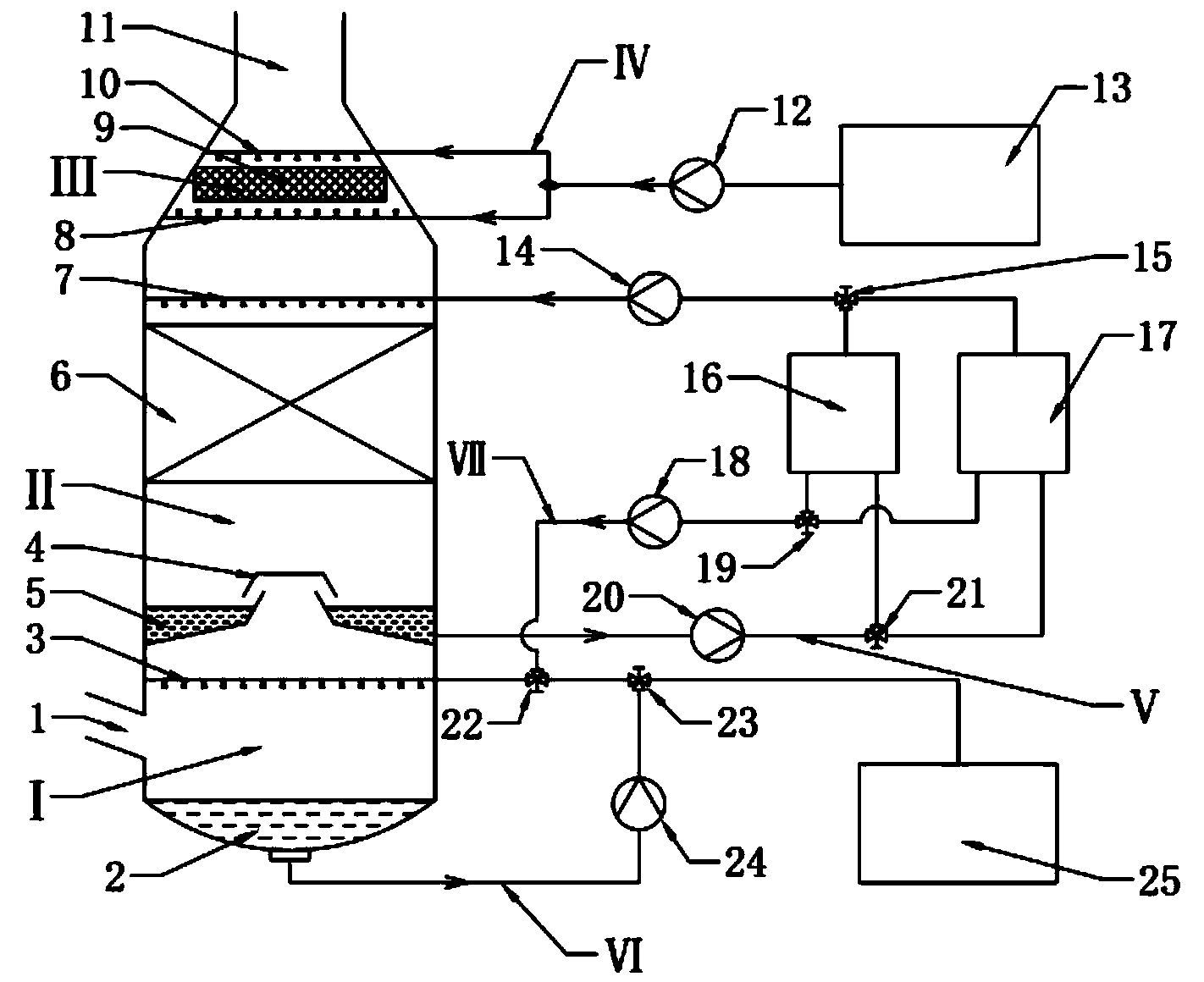

Method and system for accumulating energy by compressed air and heat accumulation medium simultaneously

ActiveCN103225598AIncrease storage capacityLow investment costPiston pumpsPump installationsElectricityEngineering

The invention relates to a method and a system for accumulating energy by compressed air and heat accumulation medium simultaneously, and belongs to the field of compressed air energy accumulating. The system comprises a motor, an air compressor, an air storage device, a heat accumulation tin, a turbine and an electric generator. The system comprises the following principles: solid heat accumulation medium and electrical heating elements are arranged in the heat accumulation tin; when the system is charged in off-peak hour period, air is compressed by the air compressor and exchanges heat with the solid heat accumulation medium in the heat accumulation tin; the heat exchanged air is stored in the air accumulation device; the heat exchanged solid heat accumulation medium is heated continuously by using the electrical heating elements; when the system discharges in peak hour period, the accumulated air is released, and enters the turbine to work after absorbing the heat from the solid heat accumulation medium; and the electric generator is driven by the turbine to generate electricity. Compared with the conventional adiabatic compression air energy accumulating system, the system has the advantages that the memory capacity is greatly increased; the unit capacity investment cost is reduced; the system only needs to adopt a one-stage heat accumulation tin and a one-stage turbine; and the system complex degree is low.

Owner:TSINGHUA UNIV

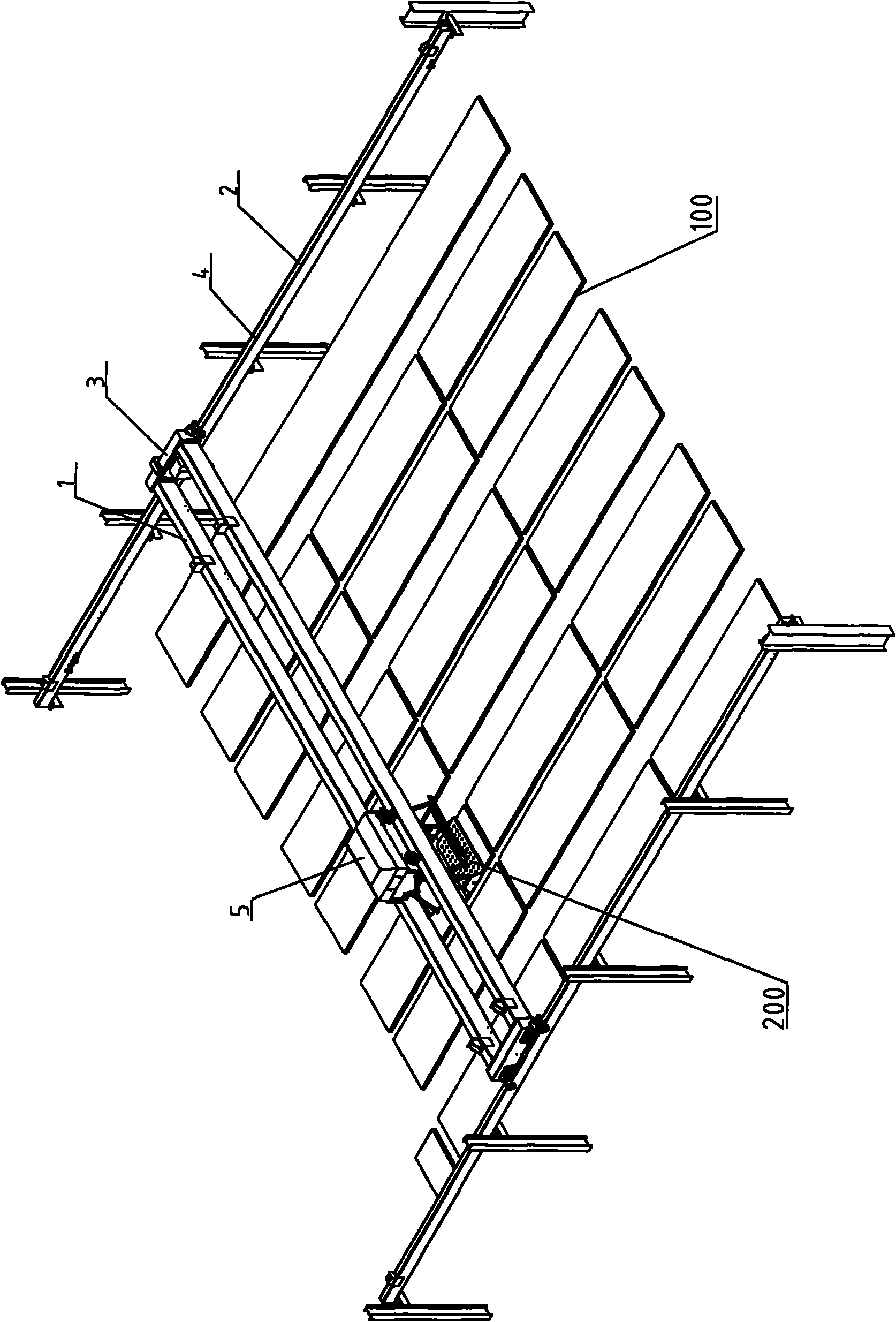

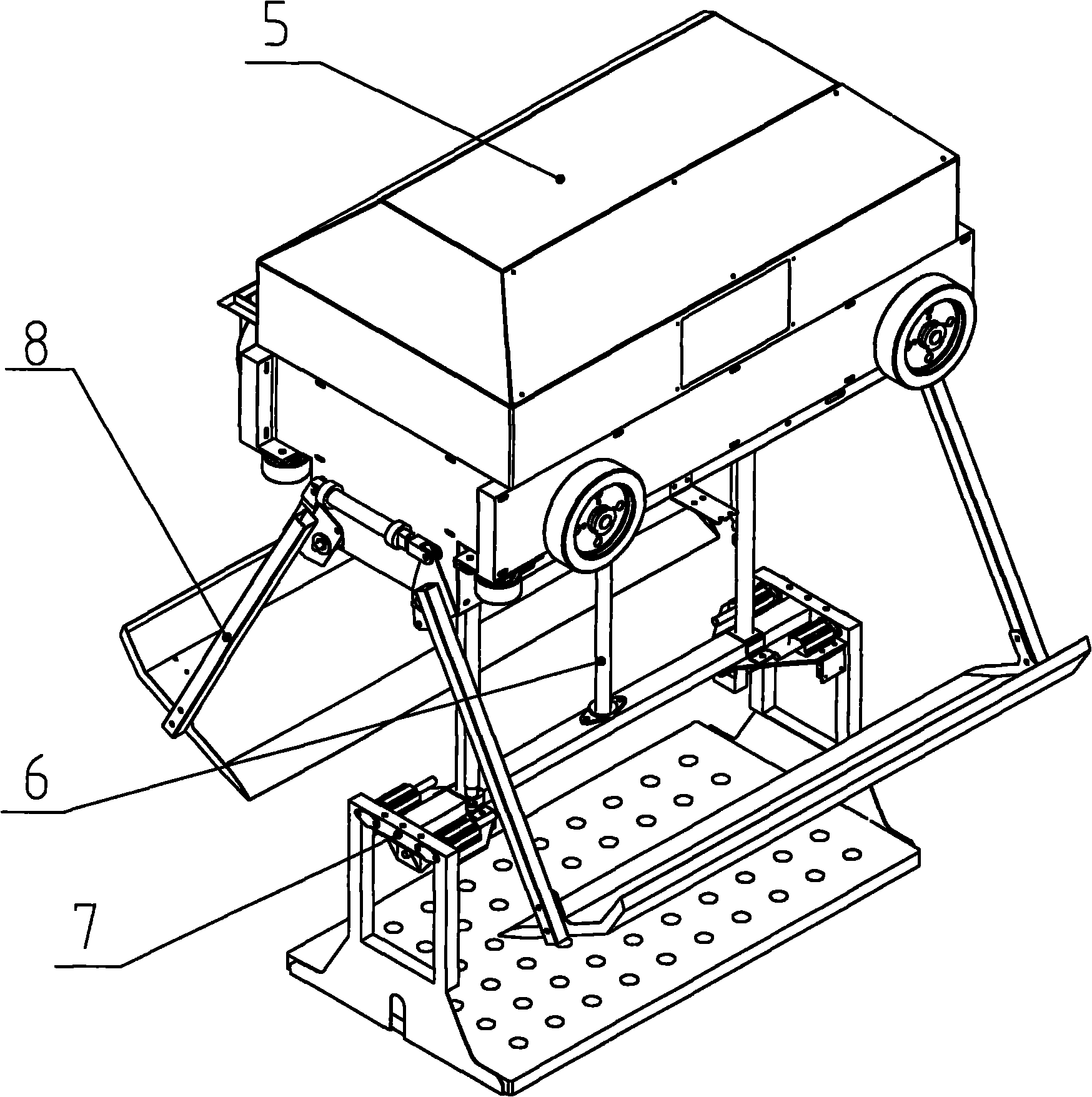

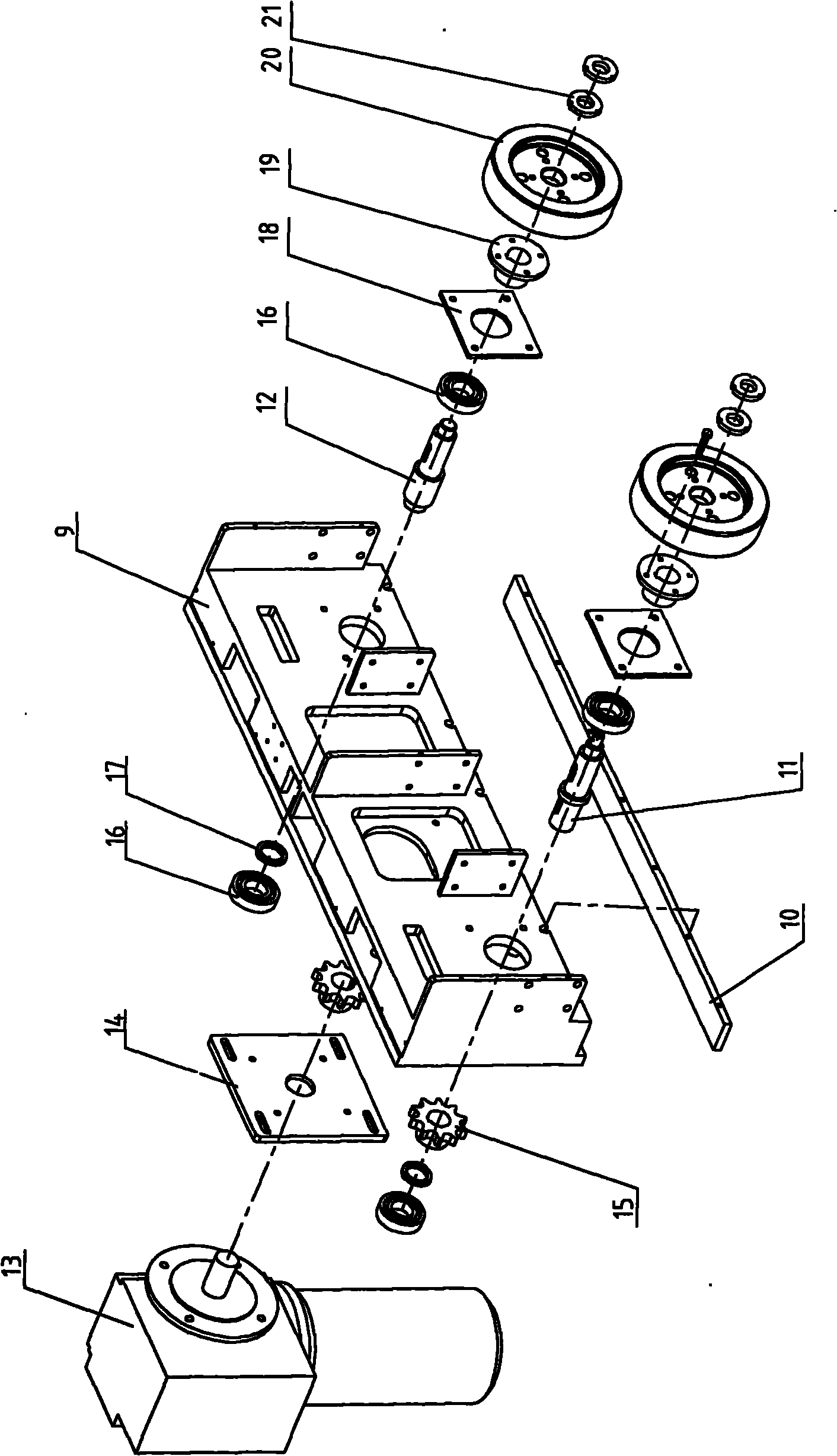

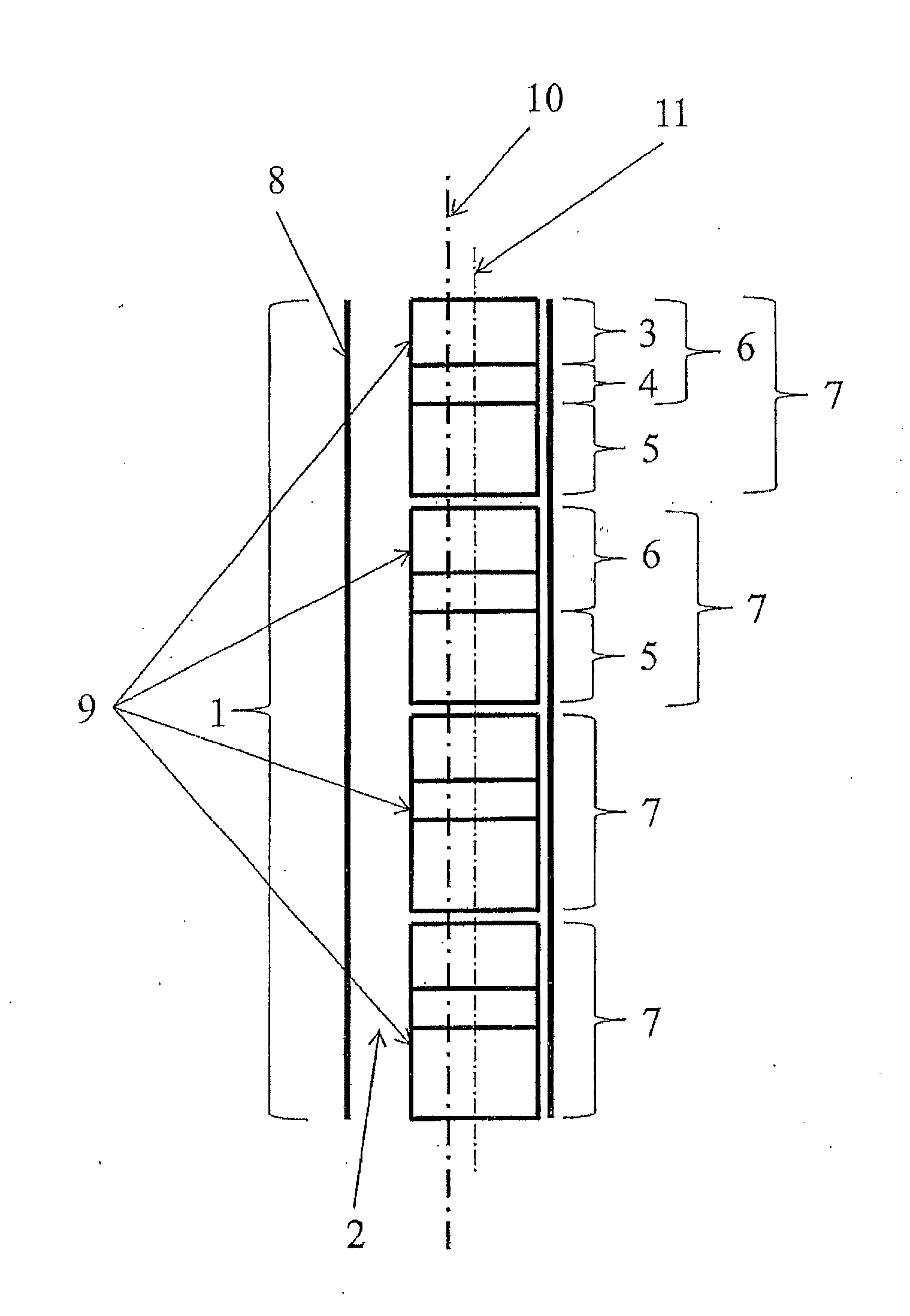

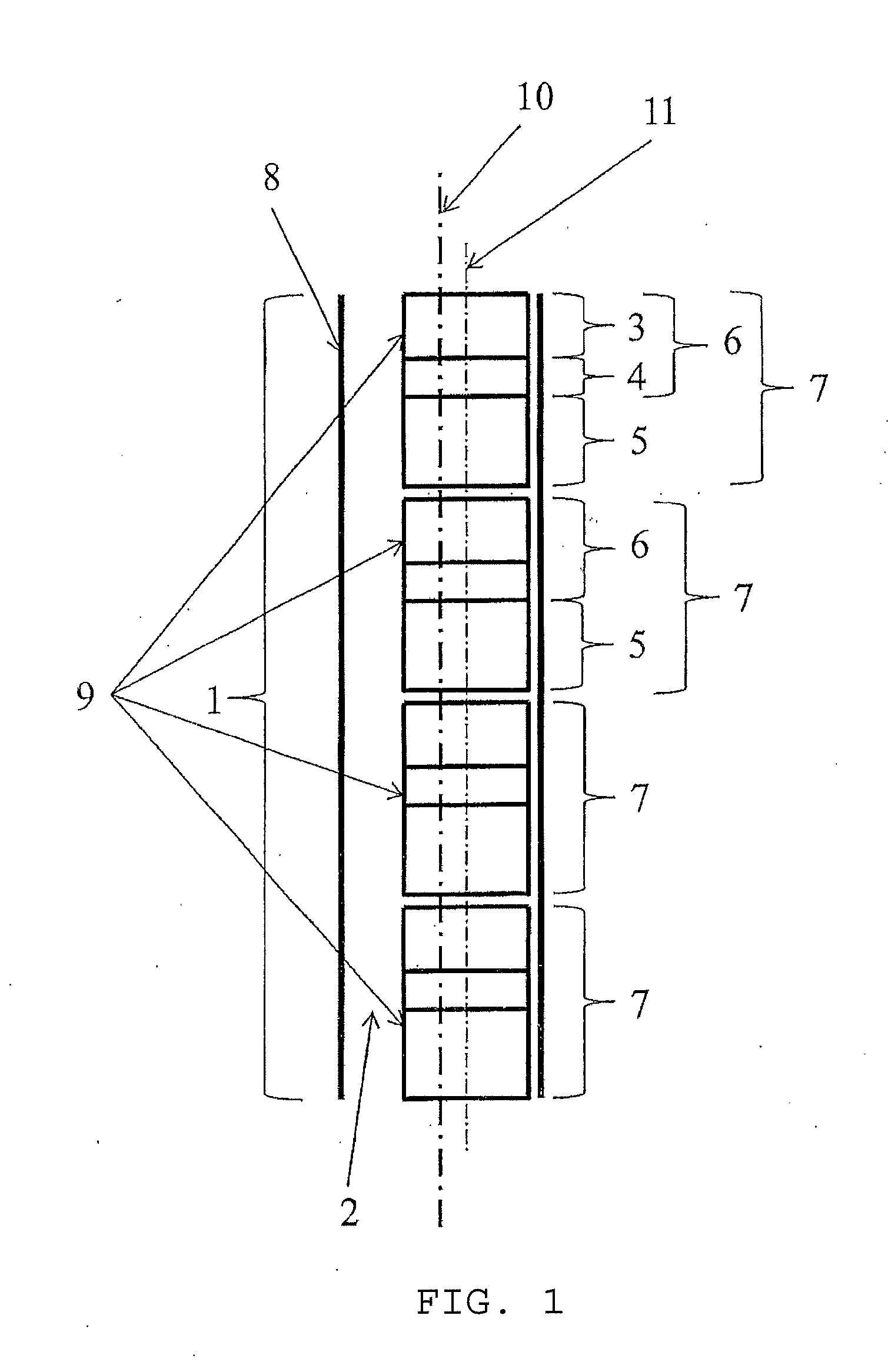

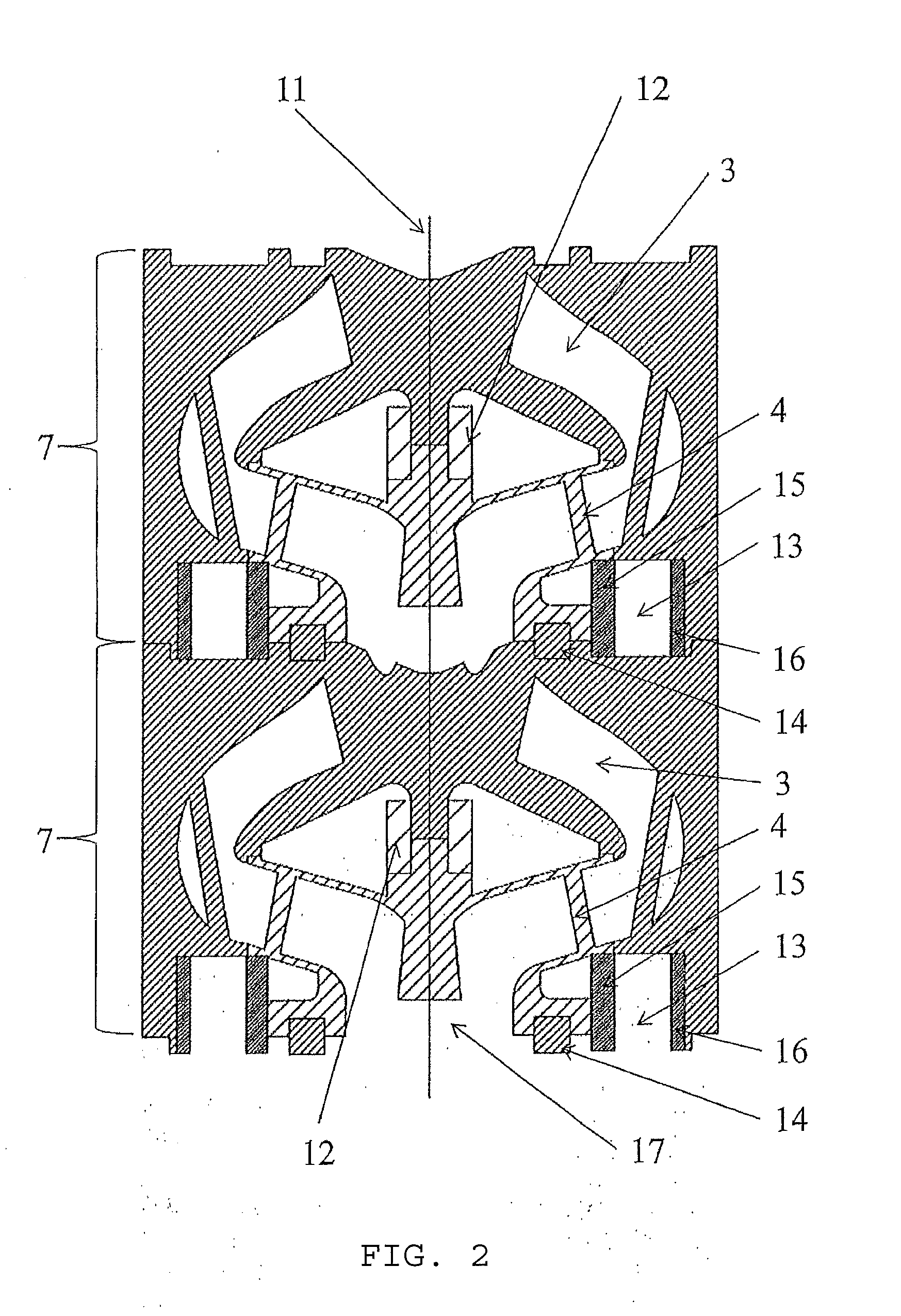

Conveying device for plug transplantation

ActiveCN101792064AIncrease the effective use areaIncrease profitCultivating equipmentsConveyor partsWheel driveSprocket

The invention relates to a conveying device for plug transplantation, which comprises stationary rails, two movable rails and a mobile car device, wherein the stationary rail is respectively erected at the two sides of a whole seedling bed in a greenhouse, and the two movable rails bestride the two stationary rails; the movable rail consists of two sprocket wheel driving devices, and the same sides of the two movable rails are respectively fixed on a pair of movable rail moving devices; the movable rail moving devices are erected on the stationary rails and can move along the stationary rails, and the mobile car device is arranged on sprocket wheels of the two movable rails; the lower part of the mobile car device is connected with a pneumatic lifting device, and the output end of the pneumatic lifting device is connected with a pneumatic gripping device; a pneumatic protecting device is arranged below the mobile car device, and at least one of a movable rail movement detecting deviceand a mobile car detecting device is assembled; and sensors for detecting and positioning are assembled on the pneumatic lifting device, the pneumatic gripping device and the pneumatic protecting device. The invention aims to reduce the labor intensity of workers, reduce the number of the workers, improve the utilization rate of greenhouse space, and increase the number of plugs in the existing greenhouse area to increase yield.

Owner:BEIJING KINGPENG INT HI TECH CORP

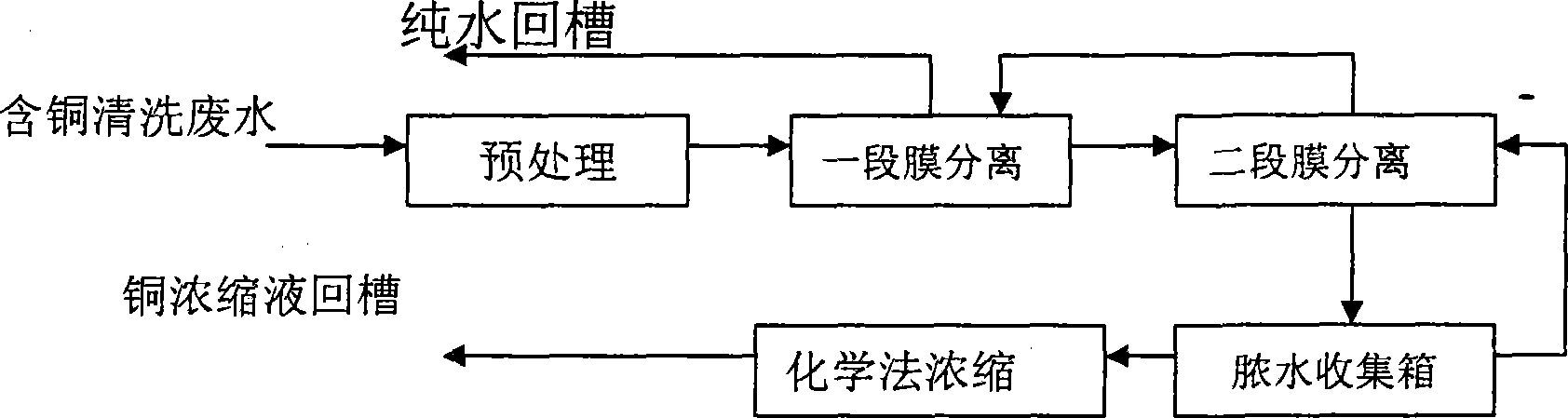

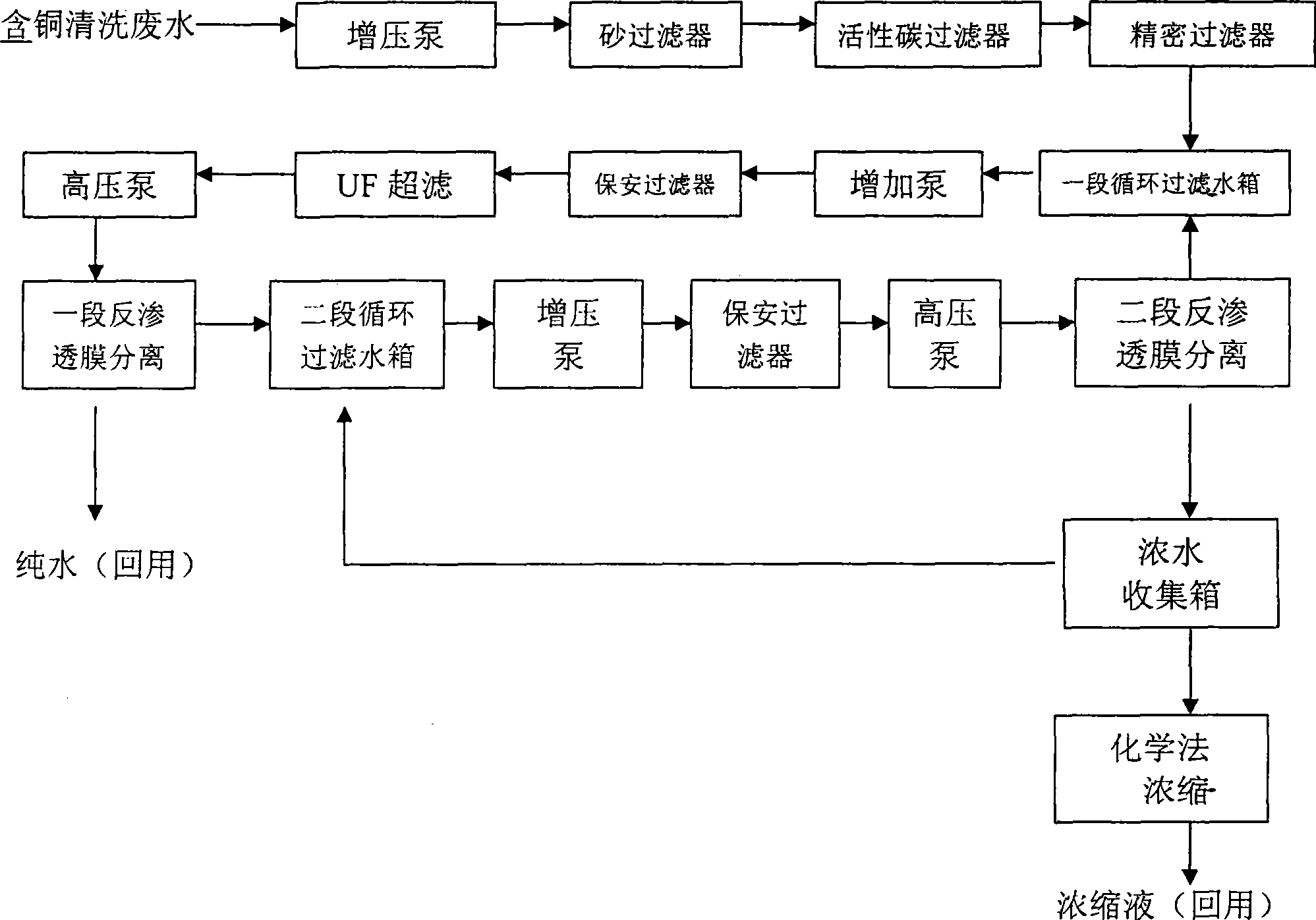

Method for recovering cupric ion from copper plating cleaning fluid

ActiveCN101418463AIncrease investment costThe method is simple and economicalCellsCopper platingDecomposition

The invention discloses a method for recovering copper ions in copper-plating cleaning solution. The method comprises the following steps of filtration pretreatment, first-stage cyclic separation, second-stage cyclic separation and chemical concentration. The method which adopts a membrane cyclic separation technique plus a chemical concentration method realizes the decomposition, concentration and complete on-line recycling of electroplating waste liquid, realizes real zero emission, is very simple and economical, and solves the problem of the industrialization of an electroplating waste liquid treatment zero-emission technique from research experiments to practical application.

Owner:NANJING YUANQUAN TECH CO LTD

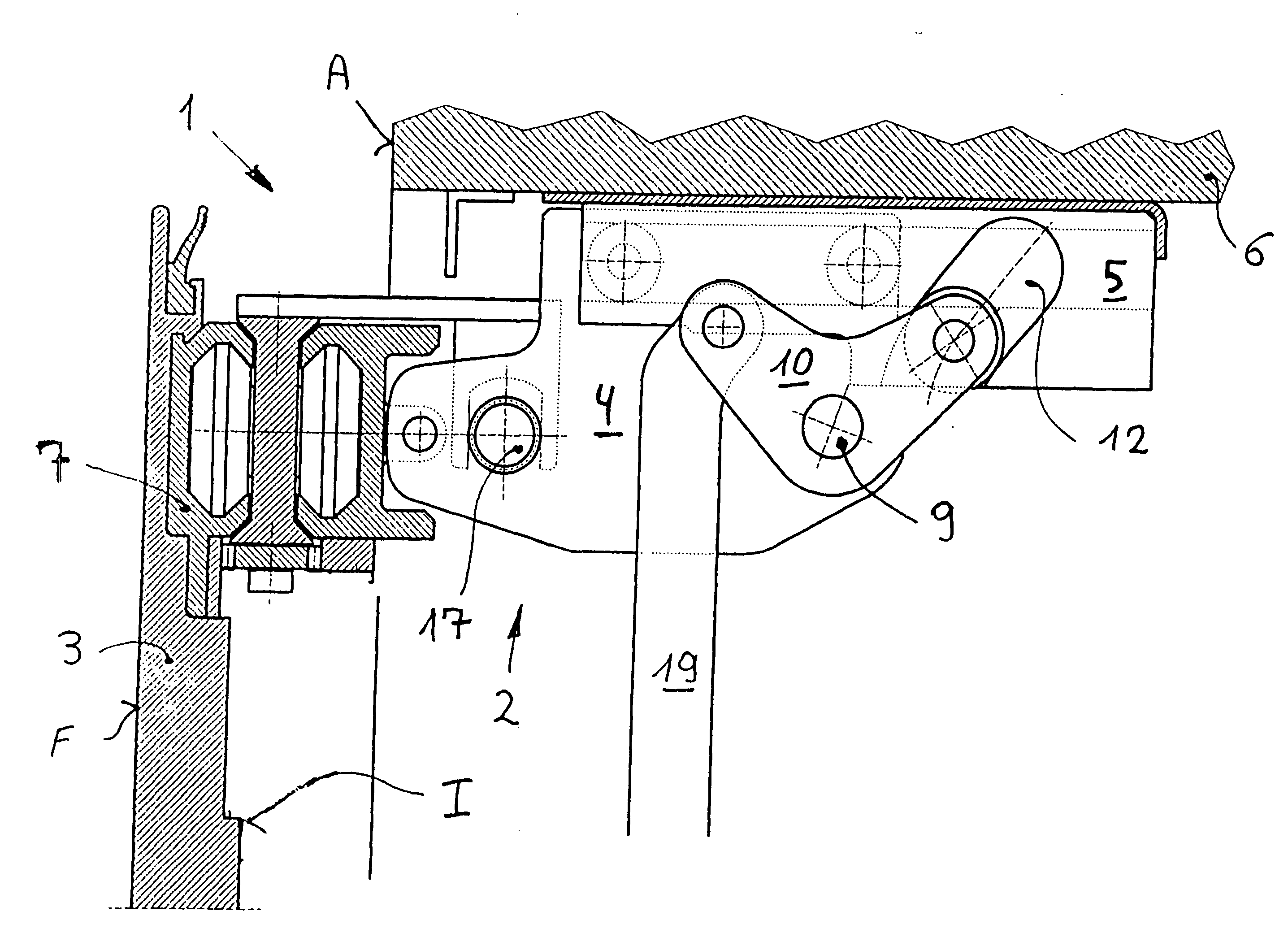

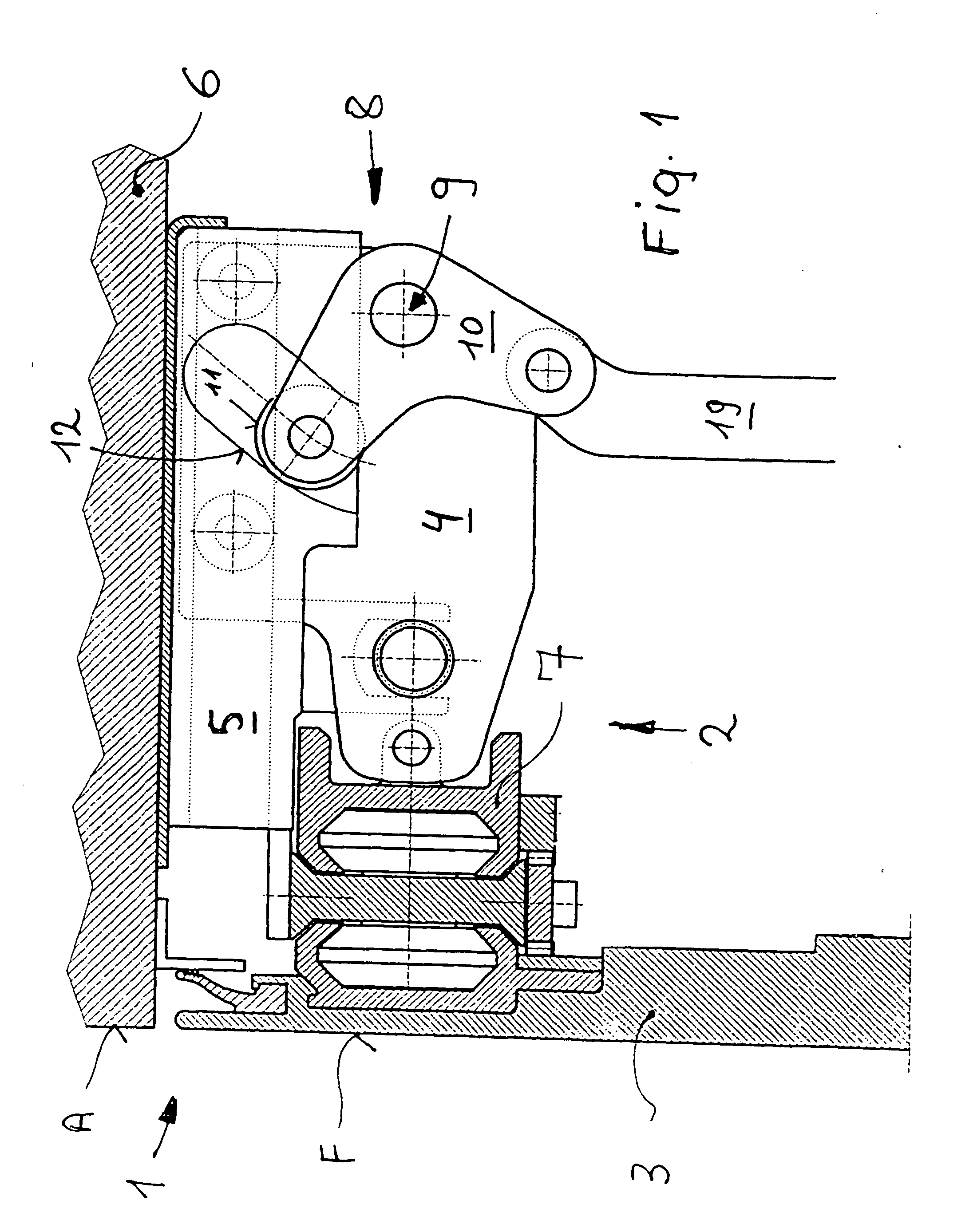

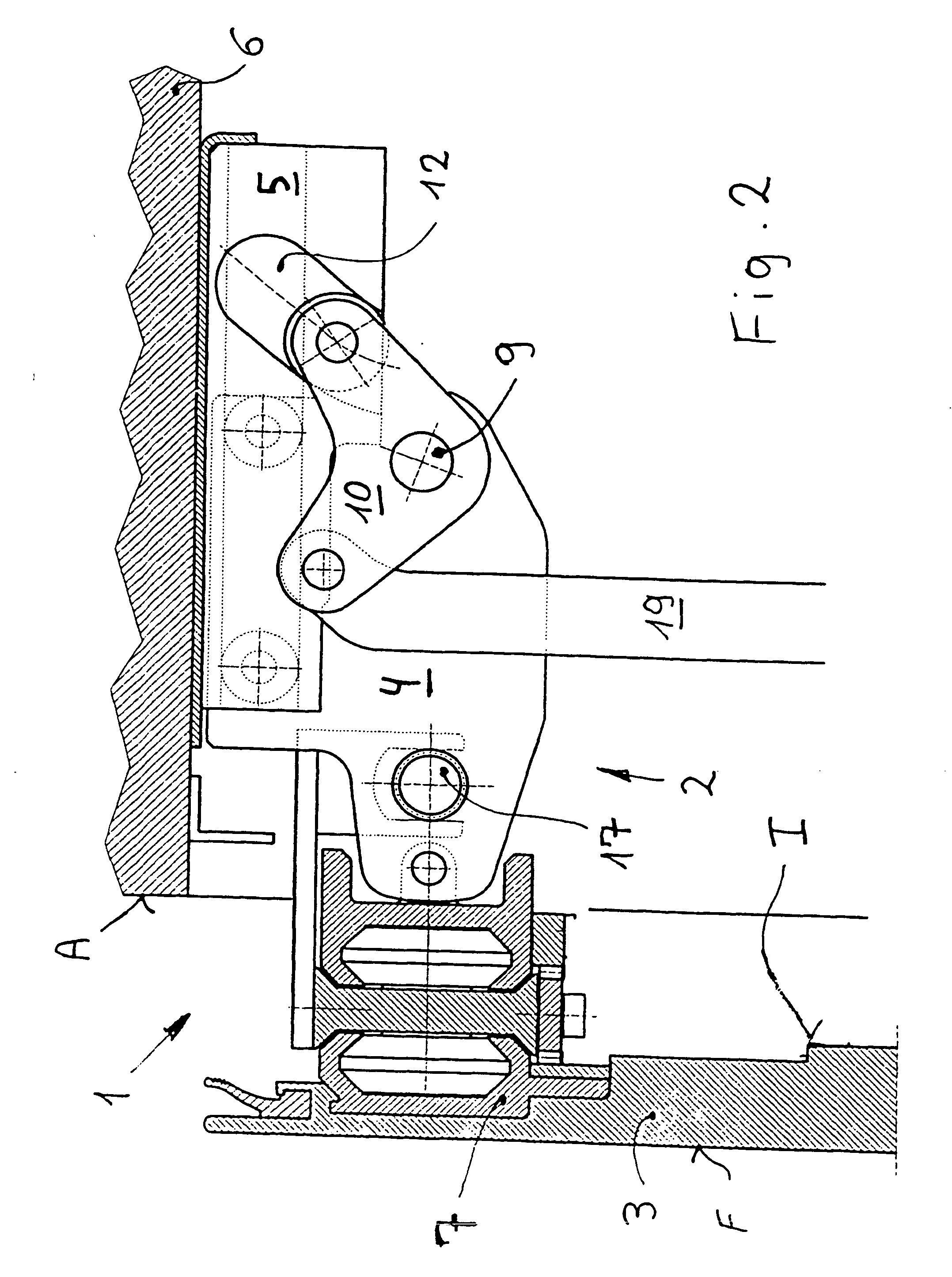

Pivoting sliding door for vehicles

InactiveUS20060225356A1Increase investment costIncrease spacePower-operated mechanismHingesEngineeringMechanical engineering

Owner:KNORR BREMSE GMBH

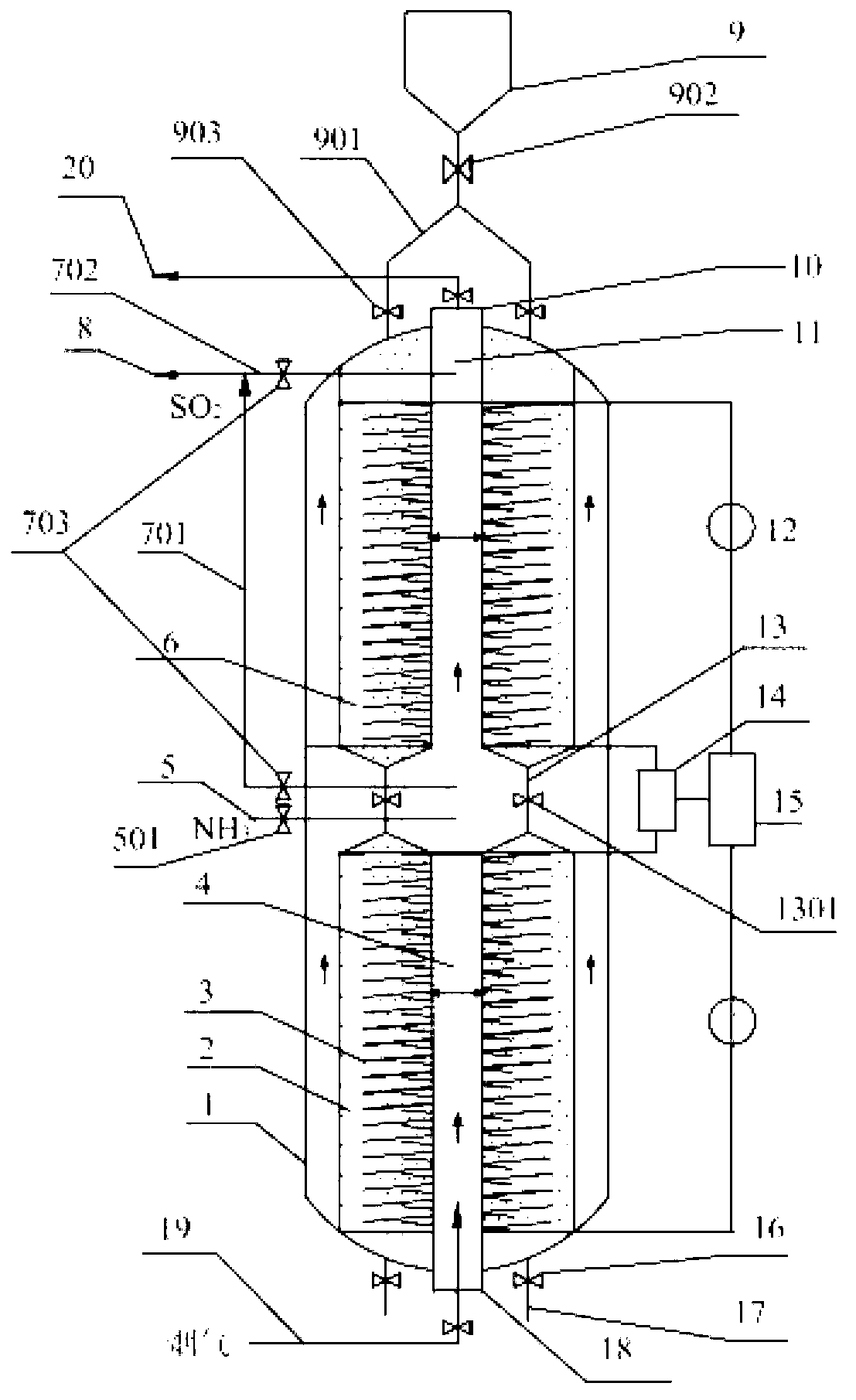

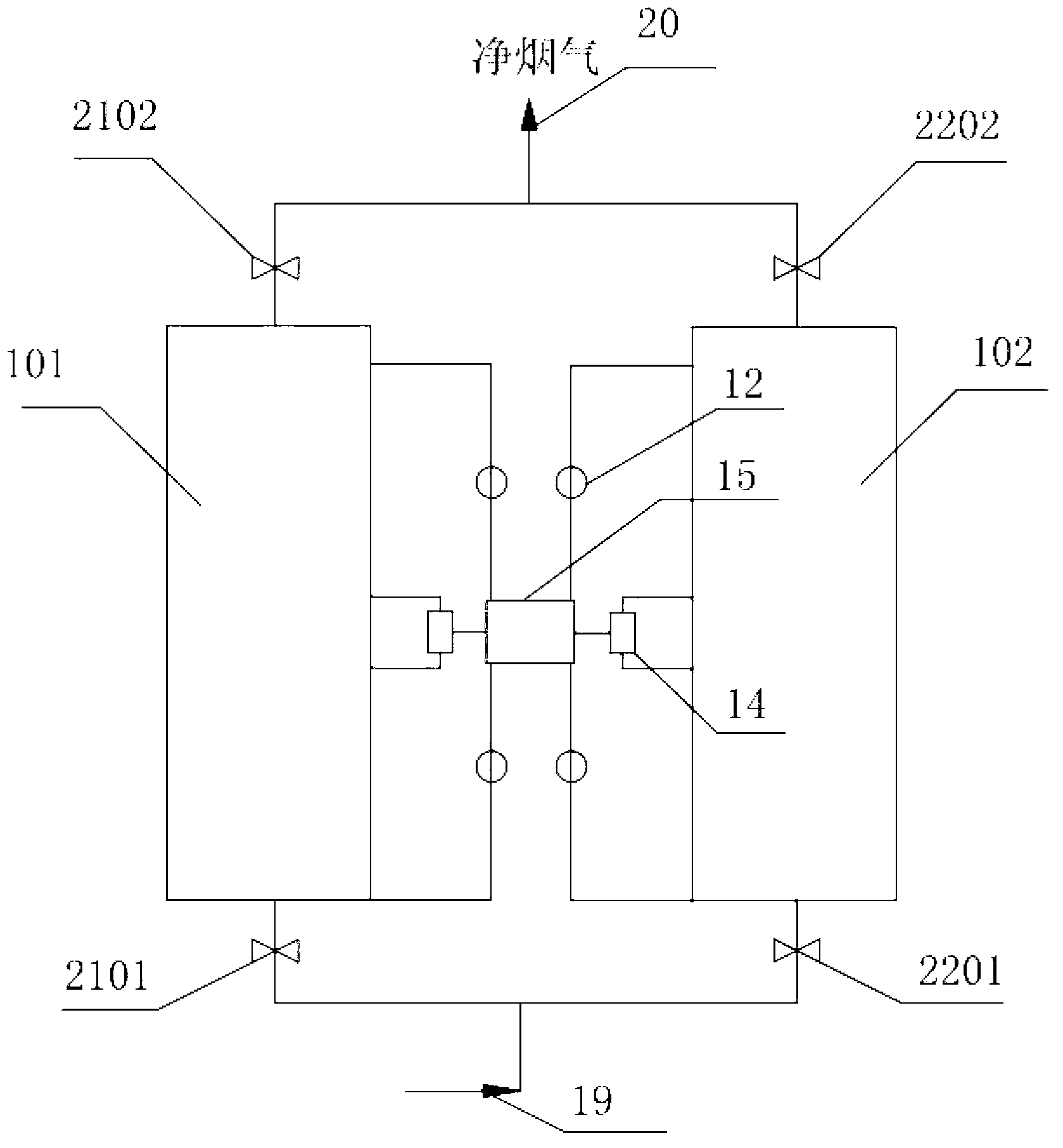

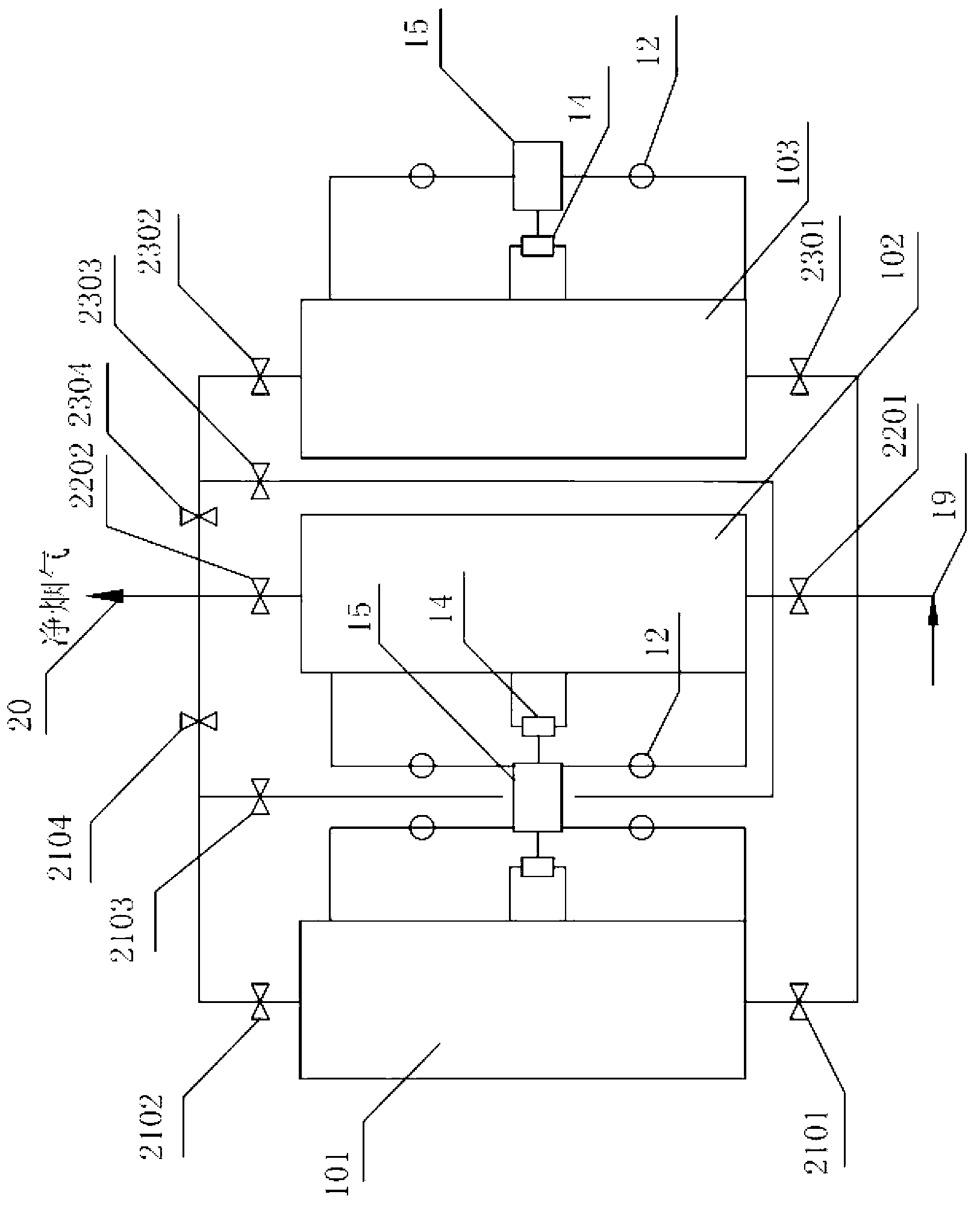

Flue gas cleaning system capable of switching pollutant desorption technology and adsorbent regeneration technology and method thereof

ActiveCN103007679AIncrease investment costNot easy to repairDispersed particle separationFlue gasDesorption

The invention provides a flue gas cleaning system capable of switching a pollutant desorption technology and an adsorbent regeneration technology. The system comprises two or more fixed bed reactors, a regenerative heating device which is used for adsorbent regeneration, and a to-be-cleaned flue gas valve and a flue gas cleaning valve which are used for controlling switching between the pollutant desorption technology and the adsorbent regeneration technology, wherein each of the fixed bed reactor is internally provided with a central tube connected with a flue gas inlet, as well as a first adsorption layer and a second adsorption layer which are used for cleaning flue gas and arranged on the outer side of the central tube; and the upper end of the central tube is connected with a flue gas outlet. The invention further discloses a flue gas cleaning method using the system. The system can be used for performing the flue gas pollutant desorption technology and the adsorbent regeneration technology in one fixed bed reactor, and achieve the switching between the pollutant desorption technology and the adsorbent regeneration technology in the different fixed bed reactors.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

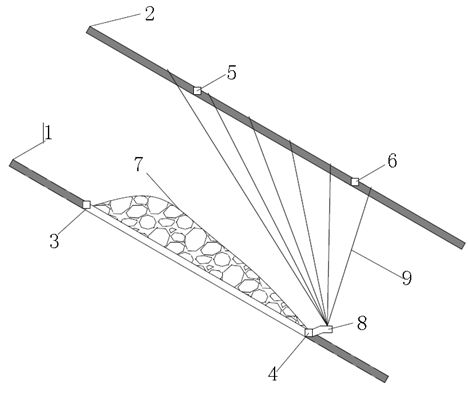

Method for pumping gas of protected layer by layer penetration and hole drilling on high-position drilling fields of protecting layer machinery tunnel

ActiveCN102644476ALarge amount of workIncrease investment costGas removalSealing/packingProtection layerPetroleum engineering

Provided is a method for pumping gas of a protected layer by layer penetration and hole drilling on high-position drilling fields of a protecting layer machinery tunnel. The high-position drilling fields are arranged in the protecting layer machinery tunnel at intervals, a plurality of layer-penetration drilled holes which are in three rows and penetrate through the protected layer are arranged towards the protected layer in each high-position drilling field, and after hole drilling in each high-position drilling field is finished, the holes are sealed, and a gas pumping pipe is connected to pump the gas. The method is suitable for gas exploiting in a protected layer exploiting technology, the gas of a protected layer can be pre-pumped prior to exploiting of a protecting layer, and the pressure-releasing gas of the protected layer is pumped after the protecting layer is exploited. The method is simple, can reduce construction cost, shortens exploiting cycle, eliminates potential safety hazards, and facilitates safety management.

Owner:CHINA UNIV OF MINING & TECH

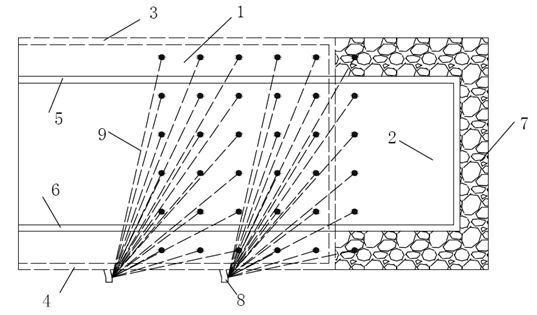

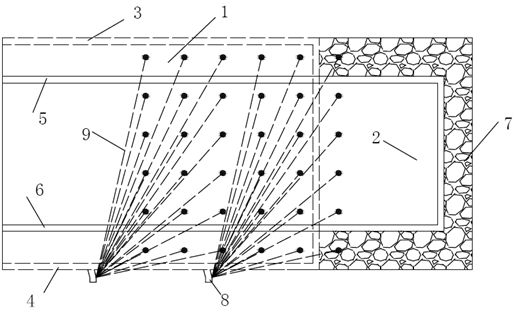

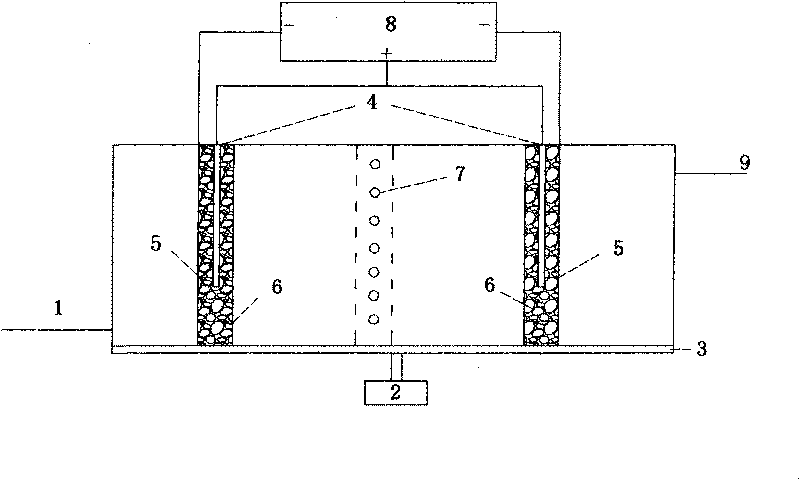

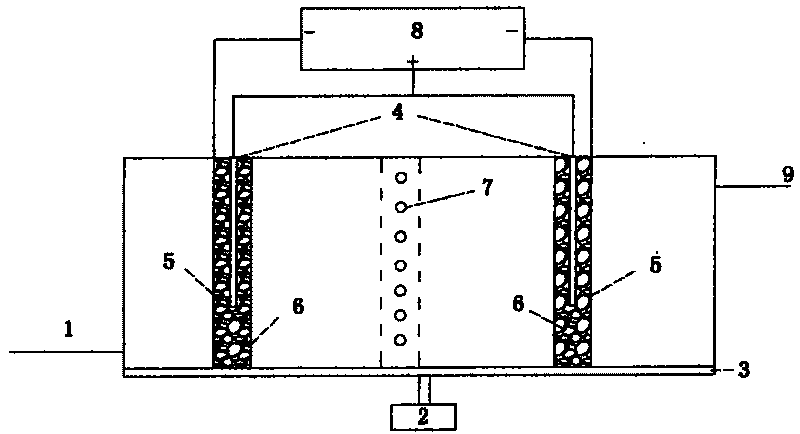

Optic-electronics integrated device for treating organic wastewater through catalytic oxidation

InactiveCN101691262AReduce recombination rateImprove photocatalytic efficiencyWater/sewage treatment by irradiationMultistage water/sewage treatmentCatalytic oxidationOxygen

The invention discloses an optic-electronics integrated device for treating organic wastewater through catalytic oxidation, which is characterized in that: a water inlet pipe (1), an aeration device (2), an air dispersion plate (3), an anode (4), a cathode (5), a catalyst filler (6), a light source system (7), a direct-current power supply (8) and a water outlet pipe (9); in the electrocatalysis aspect, a negative electrode is a stainless steel screen, a catalyst is filled in the screen, and a positive electrode (4) is a silicon carbide rod; in the photocatalysis aspect, an ultraviolet lamp system is adopted to serve as the light source system (7); persistent organic wastewater enters the optic-electronics integrated device through the water inlet pipe (1) for photoelectrocatalysis treatment; the aeration device (2) is opened to aerate the persistent organic wastewater through the air dispersion plate (3) so as to supplement oxygen to facilitate oxidation and fully stir the persistent organic wastewater to make the treated wastewater even; the waste water stays for 1 to 4 hours in the device; and water after the treatment is discharged through the water outlet pipe (9).

Owner:CHINA NAT OFFSHORE OIL CORP +1

Pump having a pressure compensated annular volume

ActiveUS20130236341A1Reduce pressureReduce riskPump componentsFlexible member pumpsEngineeringMechanical engineering

A pump and pump section, where the pump section has a centre line and where the pump section comprises at least one pump step,the pump step has a centre line and each pump step comprises a motor and one or more pump stages, and wherethe pump comprises an outer casing enclosing one or more inner casings,the outer casing forms an enclosure round the pump section and has a larger diameter then the inner casings, andthe inner casings form an enclosure round the at least one pump step,and where the centre line of the pump section is displaced relative to the centre line of the pump steps, thereby forming an annulus between the outer casing and the inner casing.

Owner:NORALI

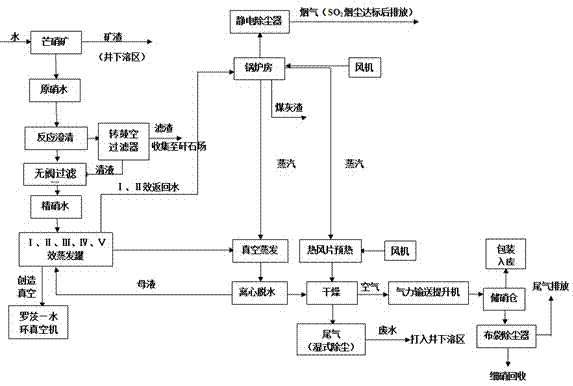

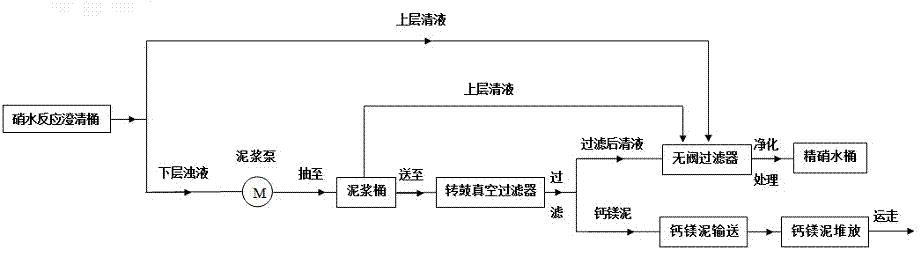

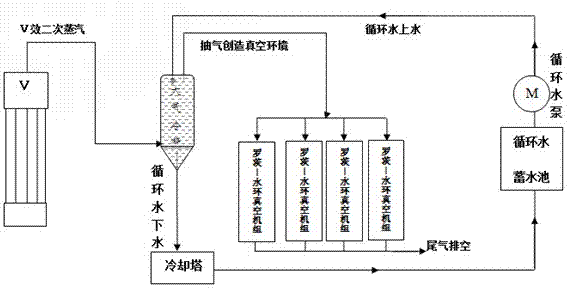

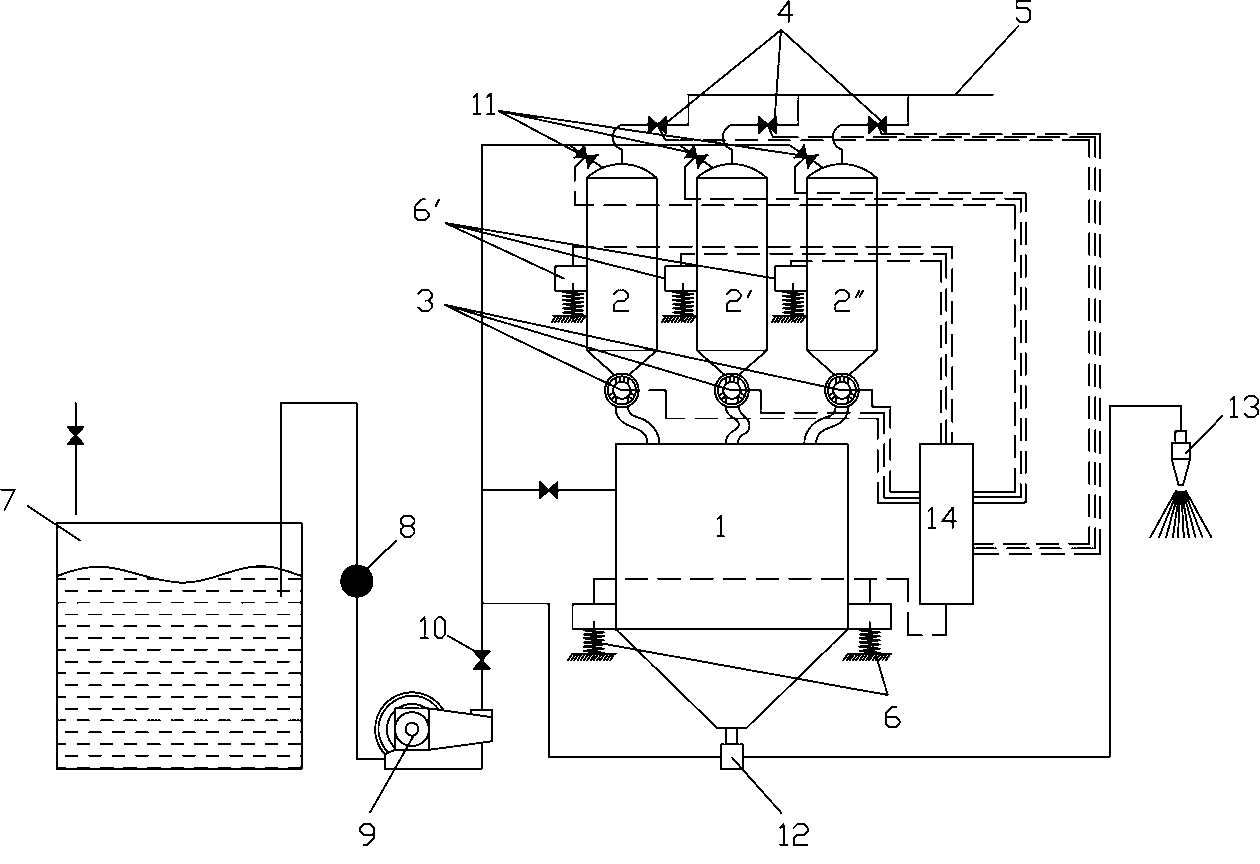

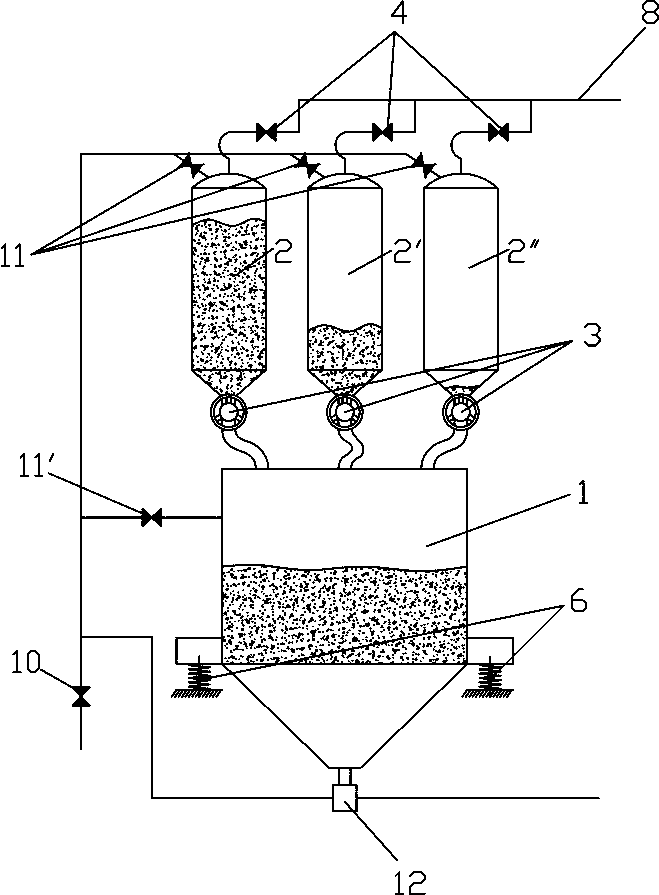

Anhydrous sodium sulfate preparation method and anhydrous sodium sulfate preparation apparatus

InactiveCN103086403AReduce environmental pollutionEffective recyclingAlkali metal sulfites/sulfatesMultiple-effect evaporatorAir drying

The invention discloses an anhydrous sodium sulfate preparation method and an anhydrous sodium sulfate preparation apparatus, and belongs to the anhydrous sodium sulfate preparation field. The method sequentially comprises the following steps: processing a raw sodium sulfate solution to prepare a fine sodium sulfate solution; dehydrating the fine sodium sulfate solution to prepare dry sodium sulfate; and processing the dry sodium sulfate to prepare finished sodium sulfate. The preparation apparatus comprises a nitrate solution reaction clarifier, a slurry clarifier, a non-valve filter, a rotary drum vacuum filter, a fine sodium sulfate solution storage device, a steam generation device, a multiple-effect evaporator, a centrifuge, an atmospheric condenser, a cooling tower, a cycle water pump, a Roots water ring vacuum set, a hot air drying device, a convey device, a pneumatic elevator, a nitrate storage bin and a cloth bag deduster. According to the invention, the sodium sulfate solution refining efficiency is high, the sodium sulfate solution quality is good, and the sodium sulfate solution is fully recycled; and the heat energy utilization rate in the production process is high, the production energy consumption is low, and the finished sodium sulfate has a fast convey speed and a high output.

Owner:四川省洪雅青衣江元明粉有限公司

Device and method for realizing premixed jet flow continuous jetting

ActiveCN102848323AImprove continuous injection time and jet stabilityEnergy Loss ImprovementAbrasive feedersAbrasive blasting machinesStreamflowHigh pressure

The invention relates to a device and a method for realizing premixed jet flow continuous jetting. The device comprises at least one main tank; at least two sub-tanks connected with an inlet end of the main tank via a pipeline and a high pressure sand valve, respectively; a mortar supply pipeline connected with inlet ends of the sub-tanks via the pipeline and a low pressure sand valve; at least three sets of weight measurers arranged at the main tank and sub-tanks, respectively; a water pool or water tank having its outlet pipeline arranged with a filter, a booster pump and a control valve, wherein the filter, booster pump and control valve are connected with the main tank and each sub-tank via sub-pipelines, and the sub-pipeline is arranged therein with a high pressure water valve; a sand mixer having its inlet end connected with the water tank and an outlet of the main tank, respectively, and its outlet connected with a nozzle; and a controller electrically connected with the low pressure sand valve, high pressure sand valve and weight measurers, respectively. Through function distribution of the main tank and multiple sub-tanks, the invention realizes sand supply of each sub-tank to the main tank in turn, mortar in the main tank is always maintained in a reasonable range, and the mixing point is arranged at bottom of the main tank, thus, stable, long-time and large-flow mortar supply of premixed jet flow is realized.

Owner:BAOSHAN IRON & STEEL CO LTD

Novel stainless steel cold continuous rolling technology and unit thereof

InactiveCN103722011ASolve bottlenecksIncrease reduction rateMetal rolling arrangementsEngineeringContinuous rolling

A novel stainless steel cold continuous rolling technology unit comprises an uncoiling machine, a straightening machine, a hydraulic shear, a welding machine, a first tension roller, a continuous rolling unit, an outlet loop, a fourth tension roller, a slitting shear and a coiling machine. The uncoiling machine, the straightening machine, the hydraulic shear, the welding machine, the first tension roller, the continuous rolling unit, the outlet loop, the fourth tension roller, the slitting shear and the coiling machine are sequentially connected. The novel stainless steel cold continuous rolling technology unit is characterized in that an inlet loop and a second tension roller set are additionally arranged between the first tension roller and the continuous rolling unit, a cleaning and drying unit, a third tension roller set and the outlet loop are sequentially connected and additionally arranged between the continuous rolling unit and the fourth tension roller, the continuous rolling unit can be arranged in the mode that a plurality of rack four-roller continuous rolling units are connected in series, small-diameter rollers are adopted in the continuous rolling unit, and the continuous rolling unit is driven by supporting rollers in a centralized mode. By the adoption of the technical scheme, some small-scale enterprises can produce stainless steel cold rolling strips by using a common four-roller or six-roller rolling machine instead of twenty-roller and eighteen-roller rolling machines which are high in investment cost and maintenance cost, and therefore the production cost is greatly reduced.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

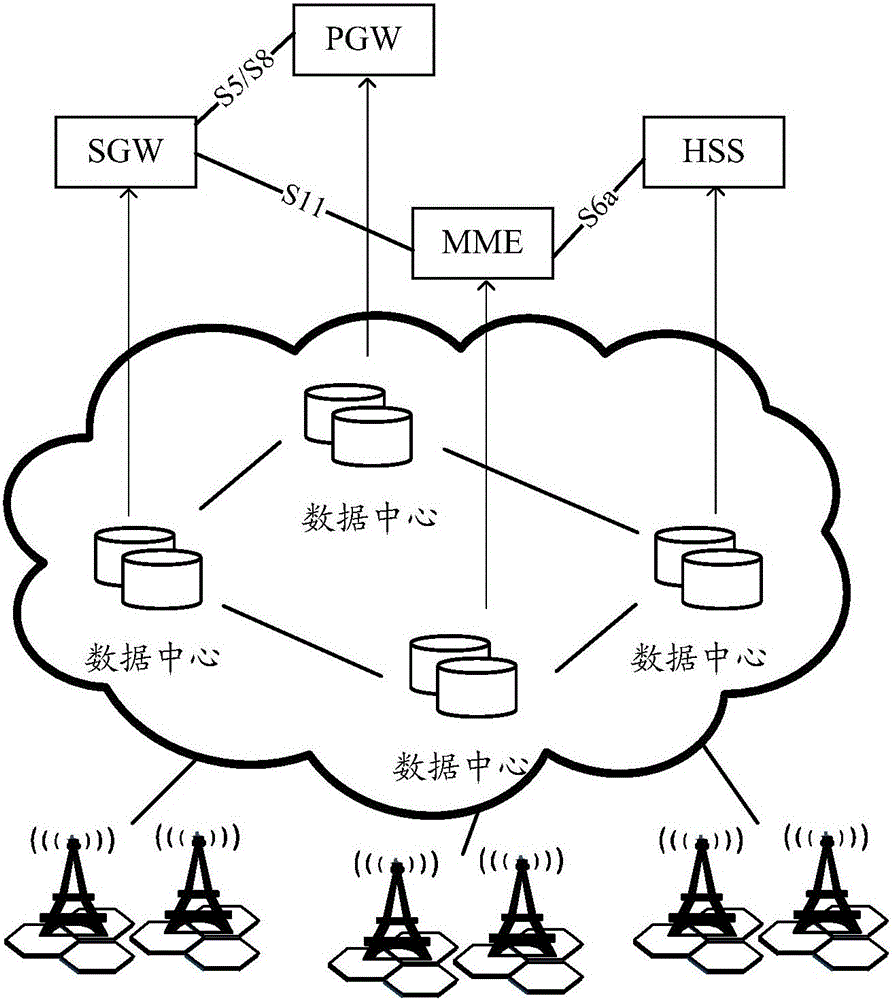

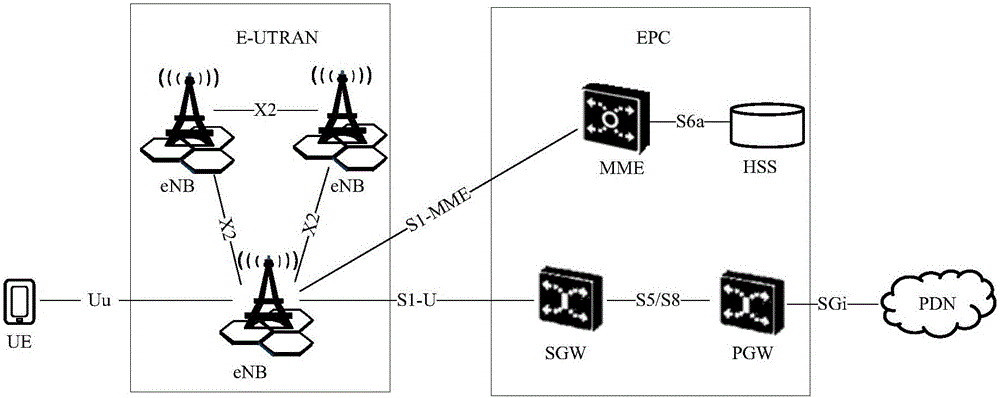

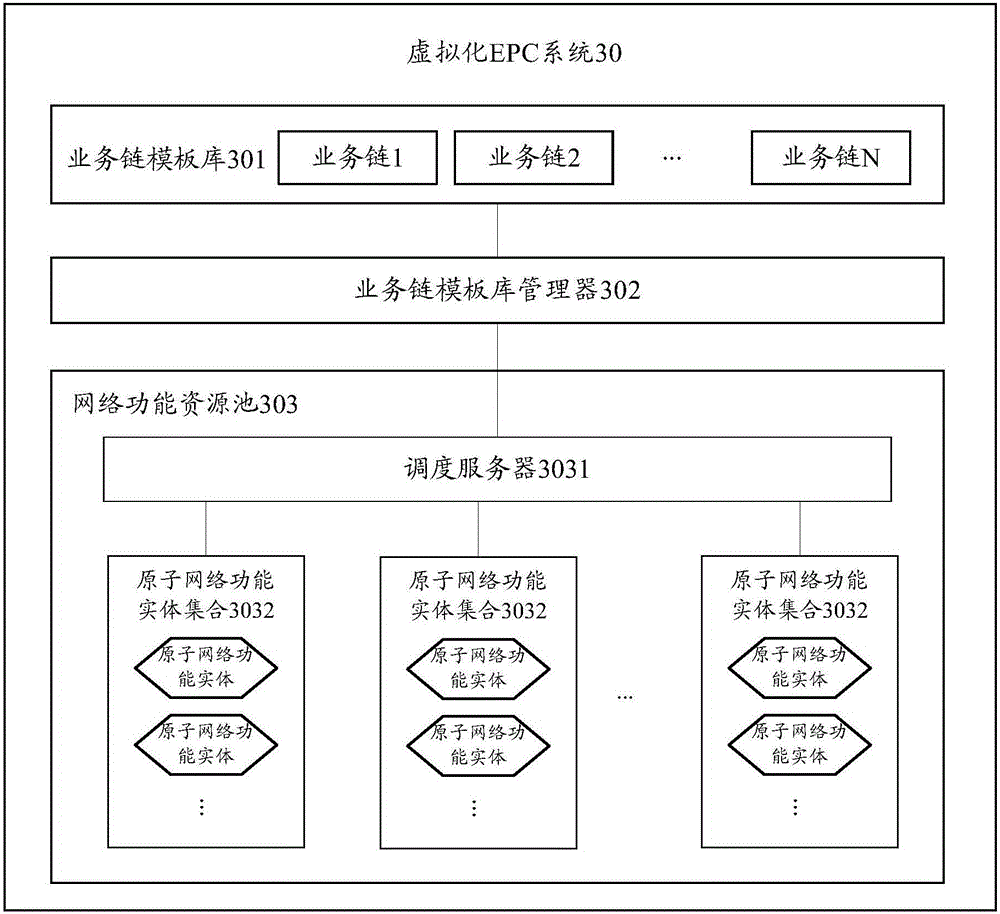

Virtualization EPC (Evolved Packet Core) system and service instantiation method

ActiveCN105847035AIncreased investment and maintenance costsImprove clarityData switching networksVirtualizationResource pool

The embodiment of this invention provides a virtualization EPC (Evolved Packet Core) system and a service instantiation method, can improve the definition of a service process and reduce the investment and maintenance cost. The system comprises a service chain template library, a network function resource pool and a service chain template library manager; the service chain template library comprises N service chain templates; each service chain template describes a service process; the service process comprises at least one service function point for realizing the service, and circulation relationships among the service functions; the network function resource pool comprises L atom network function entity sets and a dispatch service; each atom network function entity set is used for realizing a network function; the service chain template library manager is used for receiving service request information and determining the service chain template matched with the service; the dispatch server is used for determining the instantiation service of the atom network function entity of corresponding service chain template. The virtualization EPC system and the service instantiation method are applicable to the technical field of communication.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

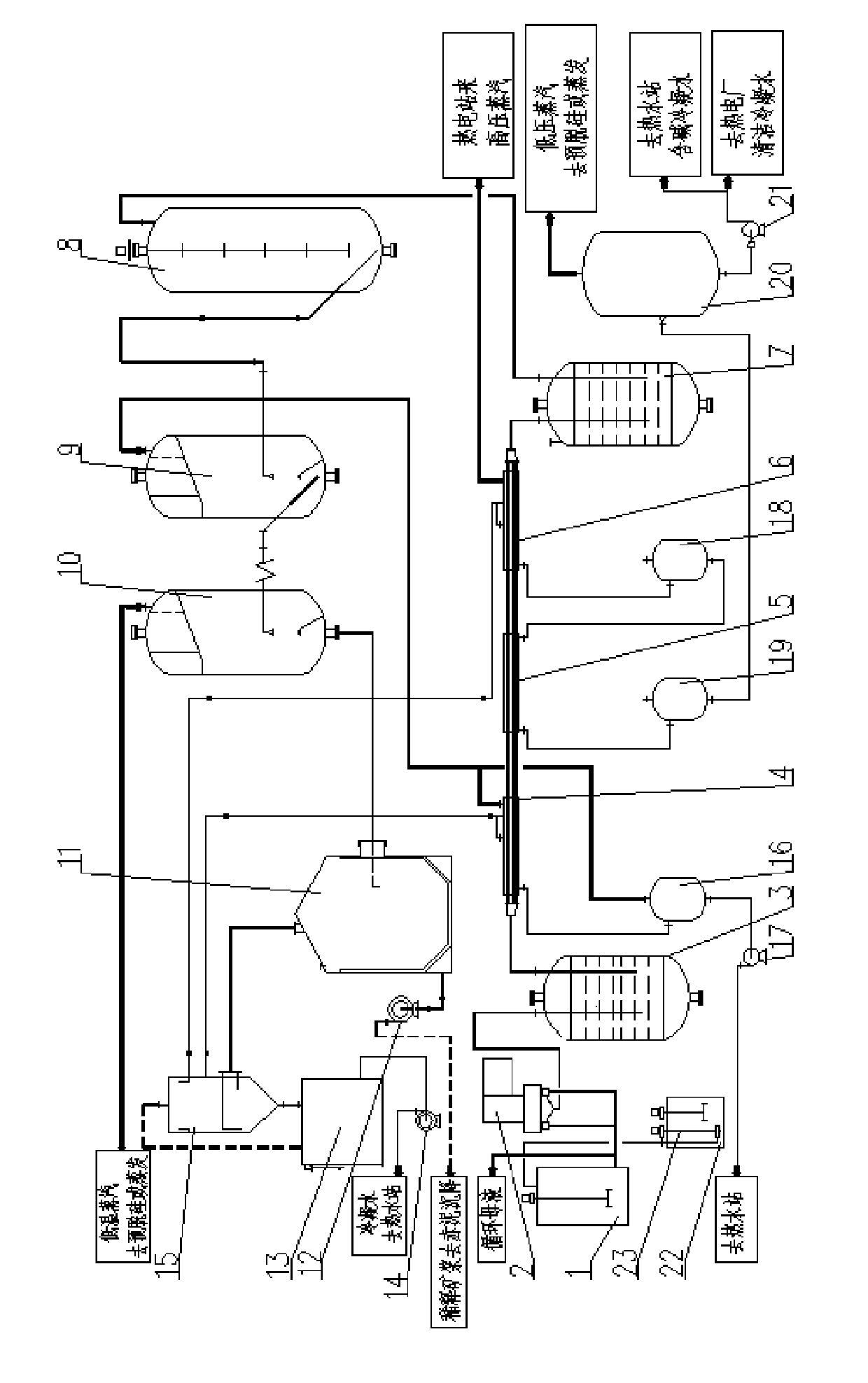

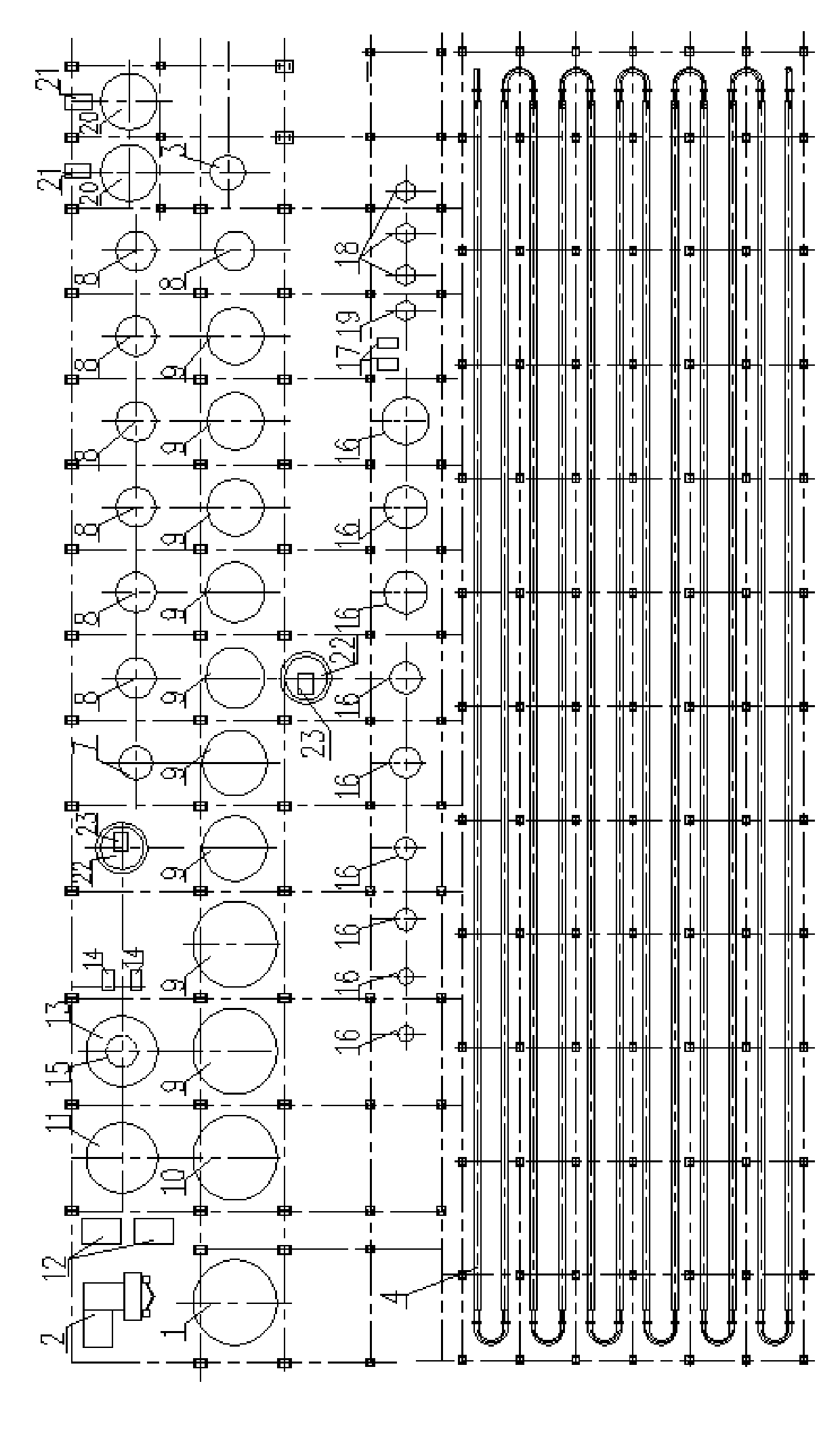

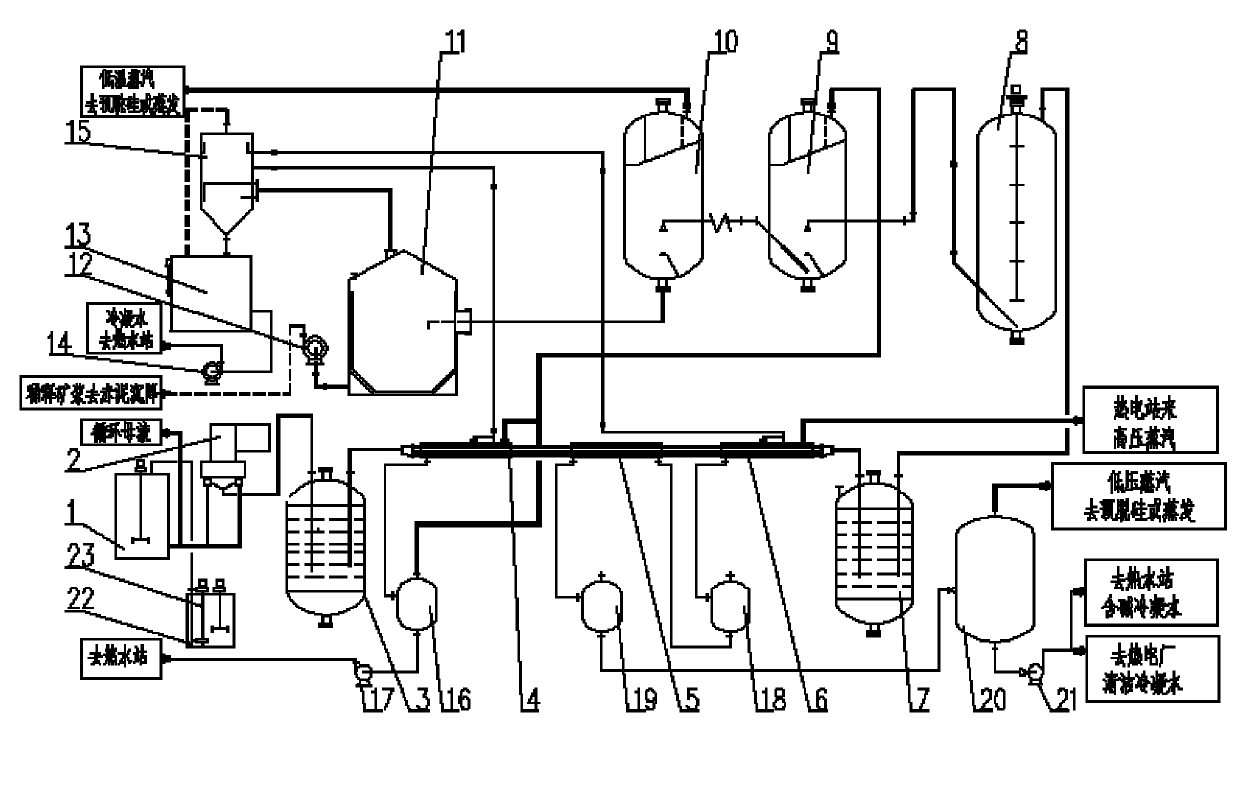

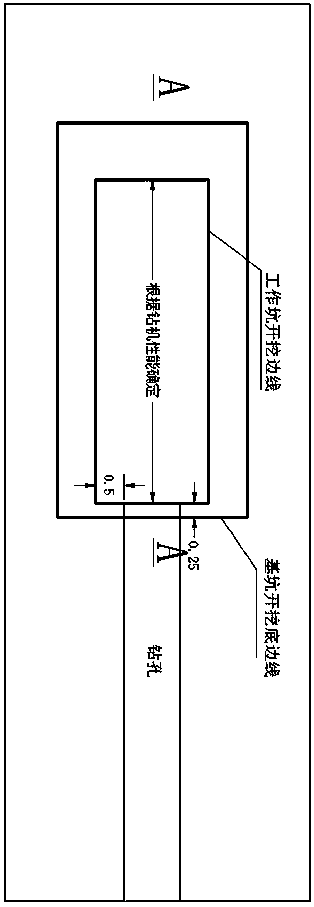

Dissolving-out process for large-sized pipeline remaining tank of diasporite bauxite ore

InactiveCN101767806ALarge pulp capacityImprove heat utilizationAluminium oxides/hydroxidesBoehmiteMother liquor

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

Non-excavation directional drilling construction method for municipal pipeline

InactiveCN109027420AImprove laying directionAdd depthPipe laying and repairEngineeringStructural engineering

The invention discloses a non-excavation directional drilling construction method for a municipal pipeline. The non-excavation directional drilling construction method for the municipal pipeline is mainly suitable for carrying out laying construction when various pipelines cross rivers, roads, buildings and other obstacles and an open excavation manner cannot be applied; the laying pipe diameter is 50 to 600mm; and the laying distance is 50 to 200m. The construction process comprises the steps of preparing for construction; designing a trace; staking out in survey; constructing a working pit;positioning and debugging a directional drilling machine; preparing a slurry; drilling a guiding hole; chambering step by step; welding and reinforcing a pipeline, and pulling back the pipeline; constructing an inspection well; and backfilling a foundation pit. According to the construction method provided by the invention, without influencing the original physiognomy, road traffic, river running,and greening vegetation, the penetration problem caused by the existence of a complete building at the original design pipeline excavation section is quickly solved, so that the construction land isreduced, the construction period is shortened, the construction efficiency is improved, the personnel investment is reduced, the investment cost is saved, and the laying direction, the laying depth and the laying accuracy of the pipeline are improved.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

Double-loop desulfurization device for ship

ActiveCN103894053AIncrease investment costReduce the amount of lyeUsing liquid separation agentDouble loopOperational stability

The invention aims to provide a double-loop desulfurization device for a ship. A conventional alkaline liquor spraying loop is divided into a high-pH-value alkaline liquor loop and a low-pH-value alkaline liquor loop, the waste gas of a ship power device is washed and desulfurized in sequence, and the utilization rate of alkaline liquor is improved by arranging a connection pipeline. The double-loop desulfurization device comprises a pipeline part consisting of a demisting cleaning pipeline IV, the high-pH-value alkaline liquor loop V and the low-pH-value alkaline liquor loop VI, wherein a washing tower is connected with the pipeline and is correspondingly divided into three parts namely a demisting area III, a high-pH-value alkaline liquor spraying area II and a low-pH-value alkaline liquor spraying area I from top to bottom. The waste gas of the ship flows upstream and passes through the three spraying areas, so that SOx and fine particles in the waste gas are effectively removed. The double-loop desulfurization device is compact in structure and easy to operate, the desulfurization efficiency can be effectively improved, and the operation stability is improved; moreover, the device is environment-friendly and energy-saving, and the using quantity of chemical additives can be reduced.

Owner:HARBIN ENG UNIV

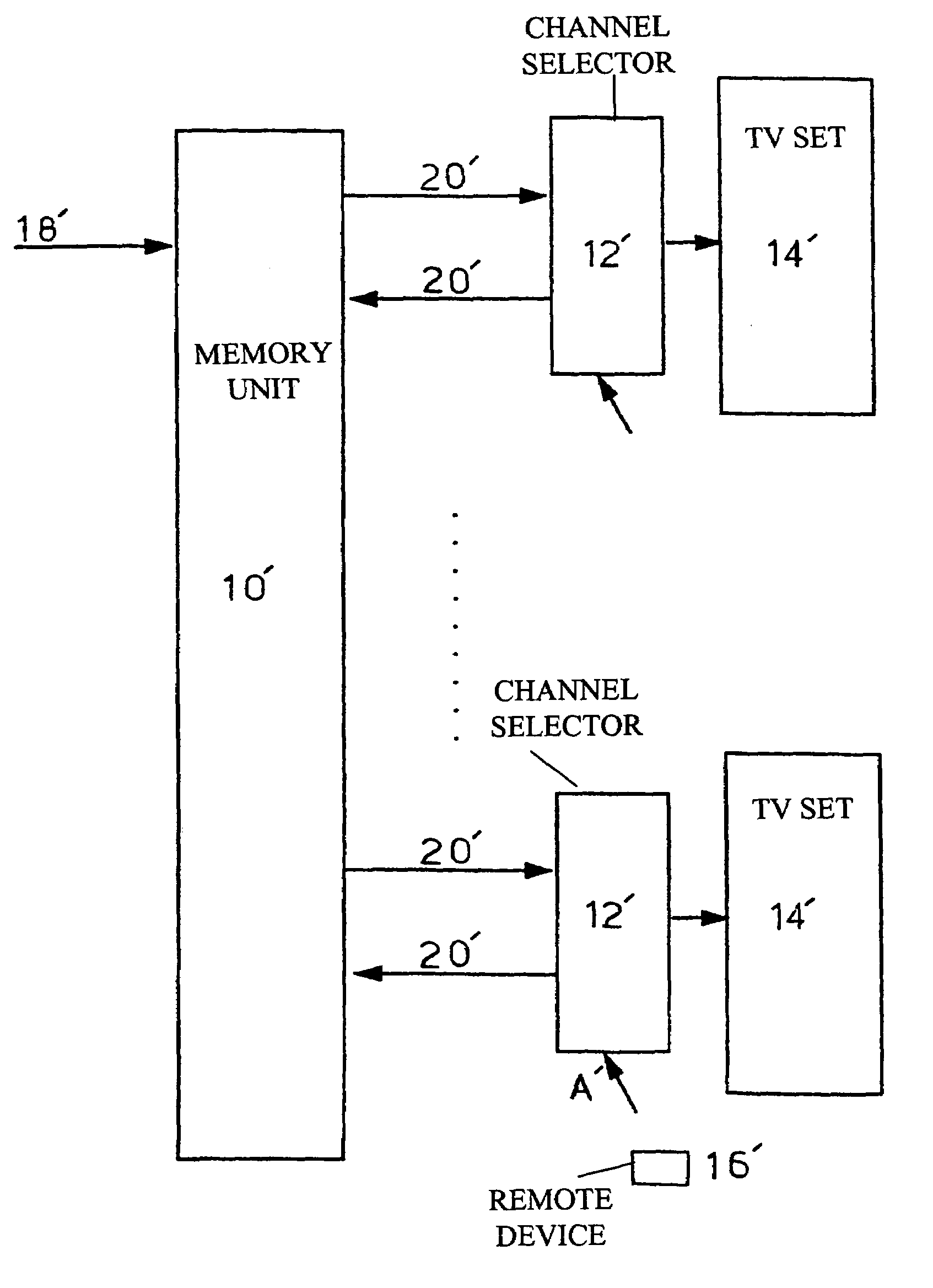

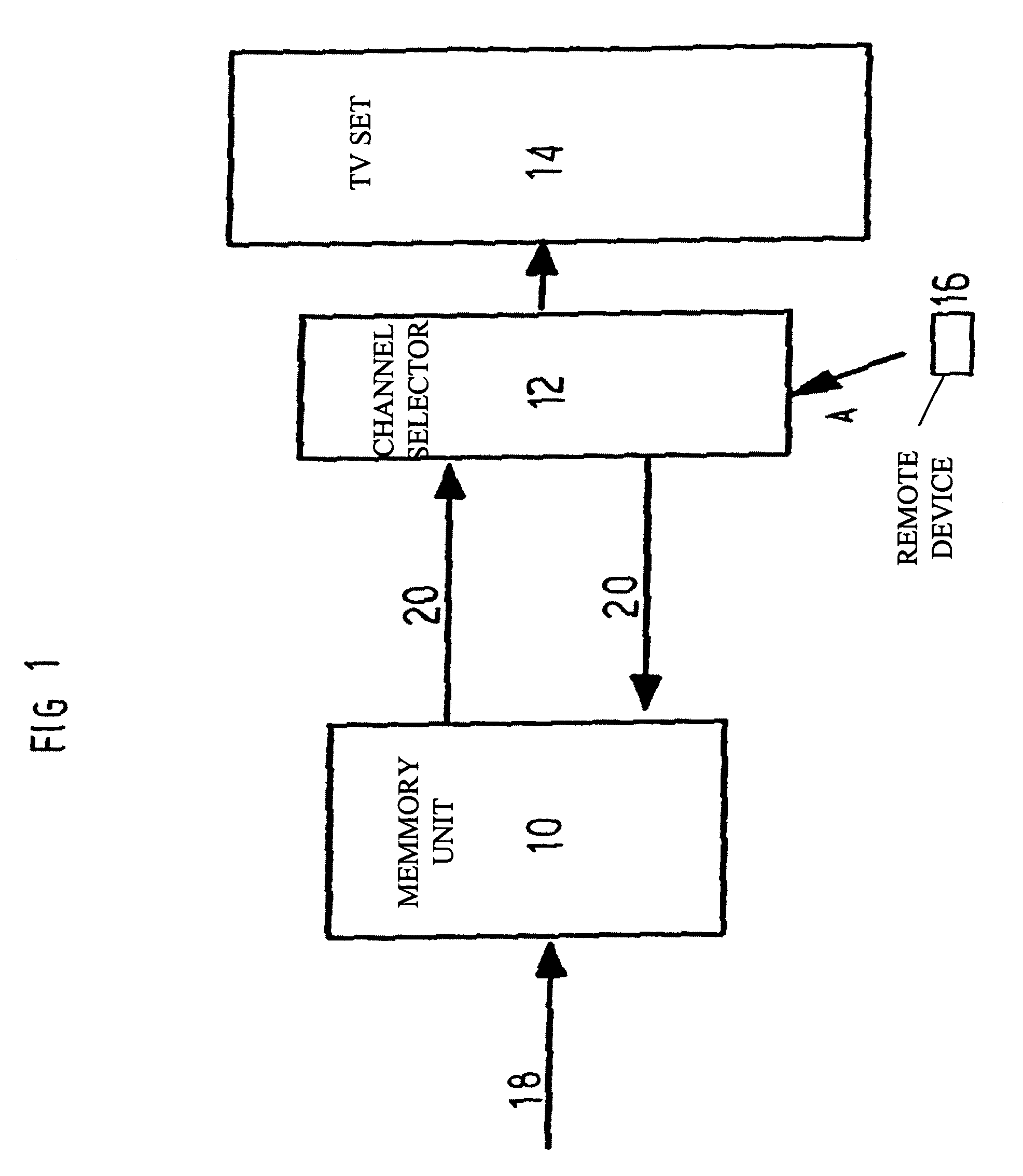

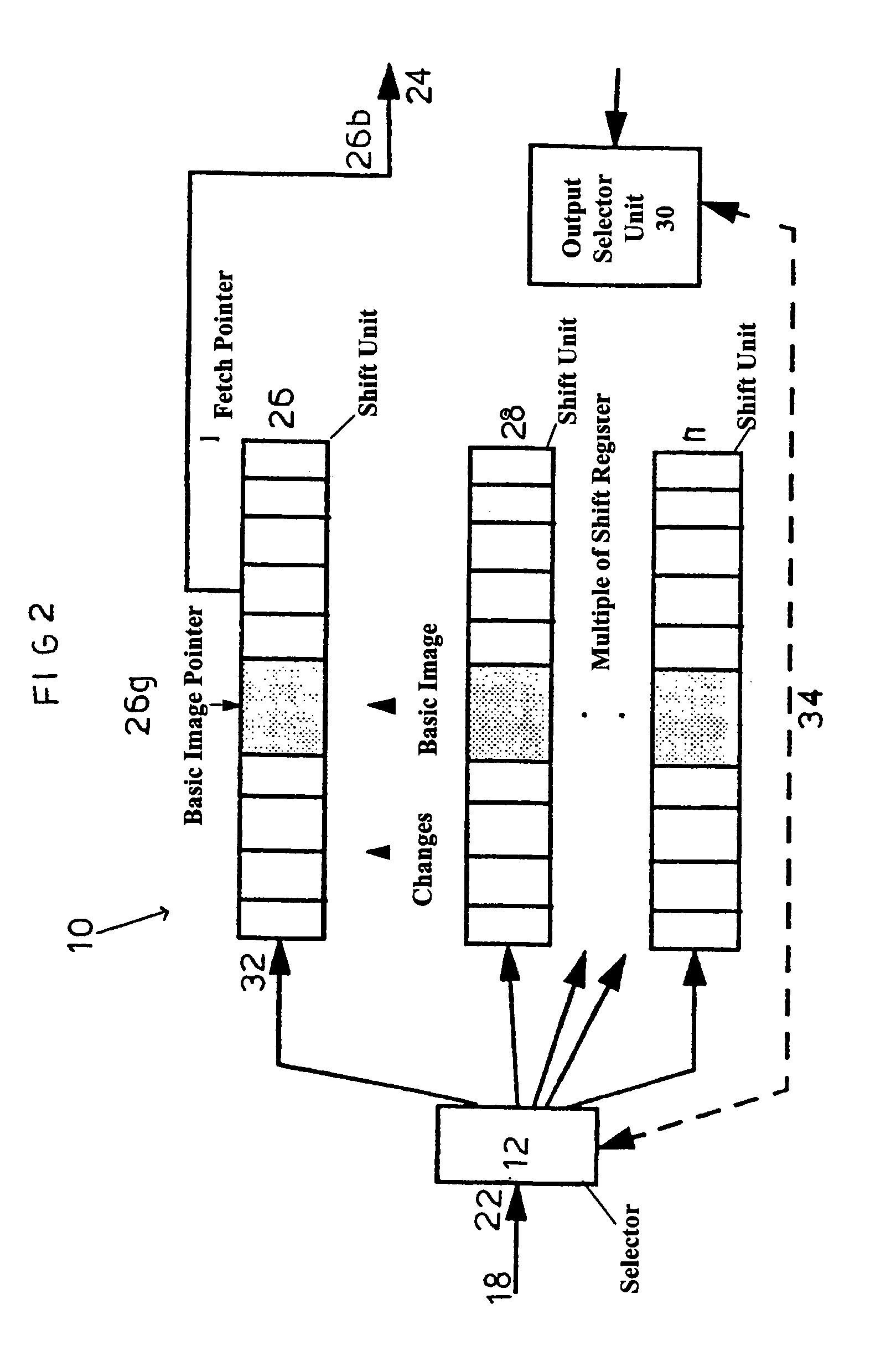

Device for changing channels in a digital television reception system

InactiveUS6950151B1Quick changeEasy constructionTelevision system detailsColor television detailsShift registerTelecommunications link

A device for changing channels in a digital TV reception system including an image display unit is presented. A communication link is connected to a memory unit that has two-way coupling with the channel selector of the image display unit. The memory unit is arranged to continuously store in the respective shift register of the memory unit a sequence of information, corresponding to at least one complete digital basic image and modifications between it and a next basic image, from several TV channels. A basic image pointer is associated with each shift unit of the memory unit, the basic image pointer continuously specifying a position of the basic image in the shift register associated with each shift unit, such that the selected TV channel after decompression is accessible for display on the screen by means of a control unit through the channel selector and the memory unit.

Owner:OMICRON CETI

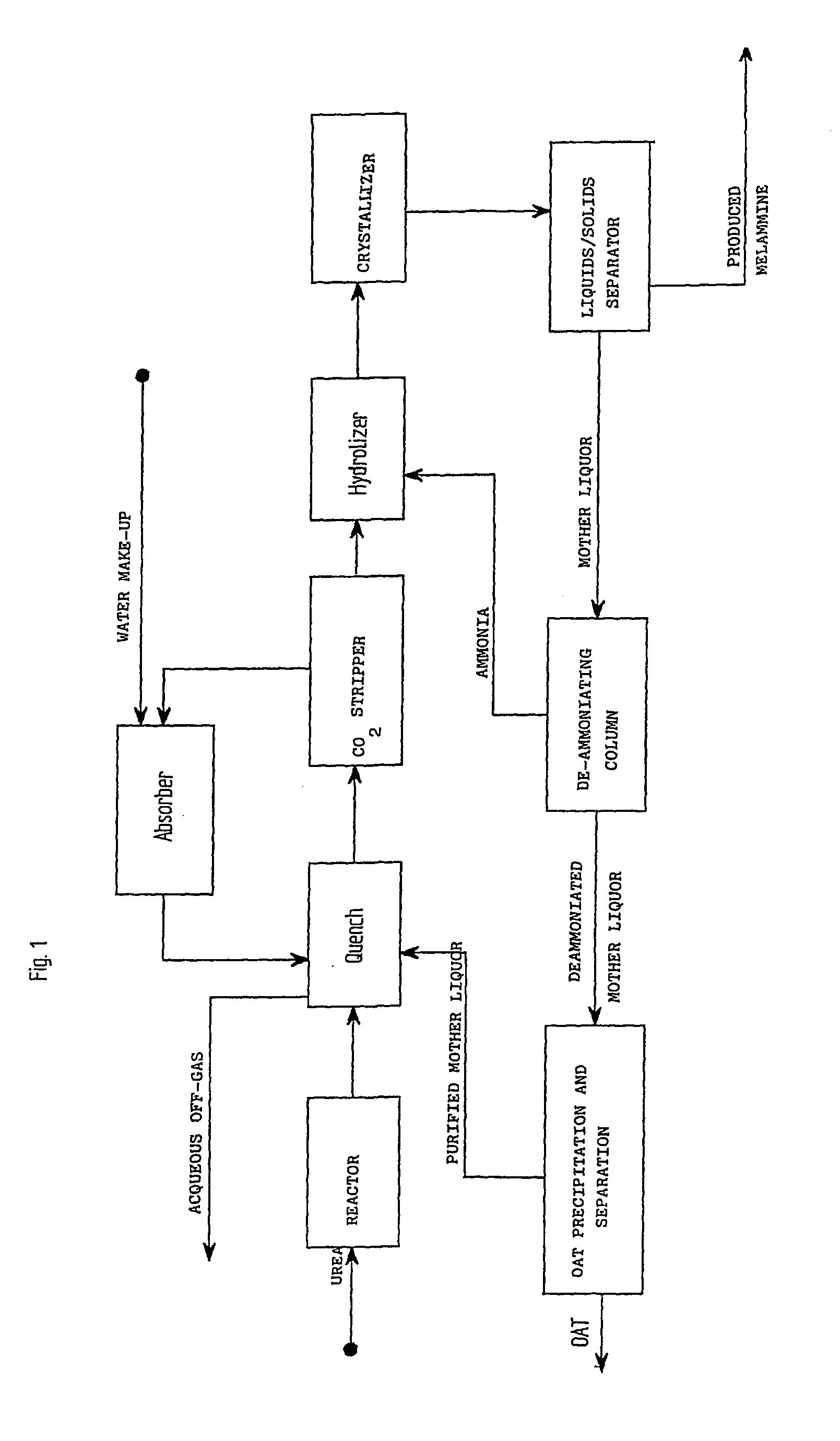

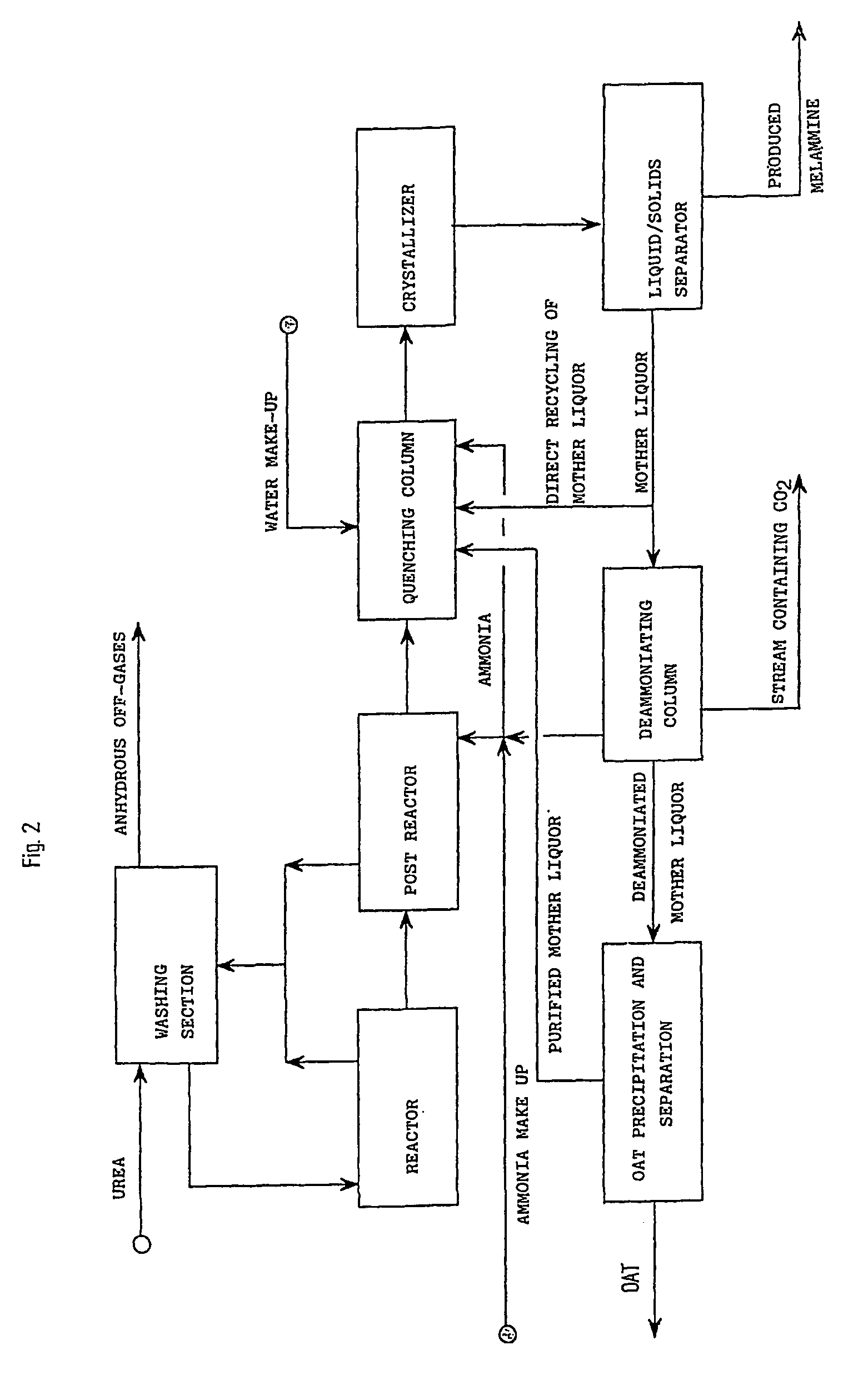

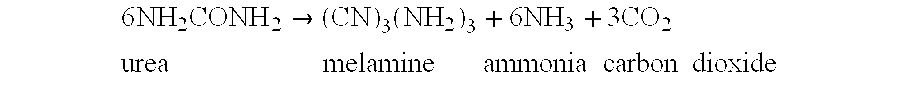

Procedure for the production of high-purity melamine with high yields

InactiveUS7125992B2Number of process step be reduceIncrease stream factor and investment costOrganic chemistryQuenchingUrea

A process for the production of high-purity melamine by pyrolysis of urea at high pressure, wherein the liquid phase output from the pyrolysis reactor is sent to a downstream post-reactor, and wherein the anhydrous gaseous phase from the pyrolysis reactor and from the post-reactor are subjected to washing with molten urea for the recovery of the melamine. The purified liquid exiting the post-reactor is treated in a quenching column, in order to eliminate polycondensates, while the quenching column output is cooled. A high purity melamine is then separated by crystallization from a mother liquor, the greater part of which is recycled to the quenching column, thereby enabling a costless recovery of ammonia and melamine. The remaining mother liquor is treated for the separation of oxidized products of pyrolysis and is then sent back to the quenching column, thereby realizing the complete recovery of the melamine.

Owner:EUROTECNICA MELAMINE AG

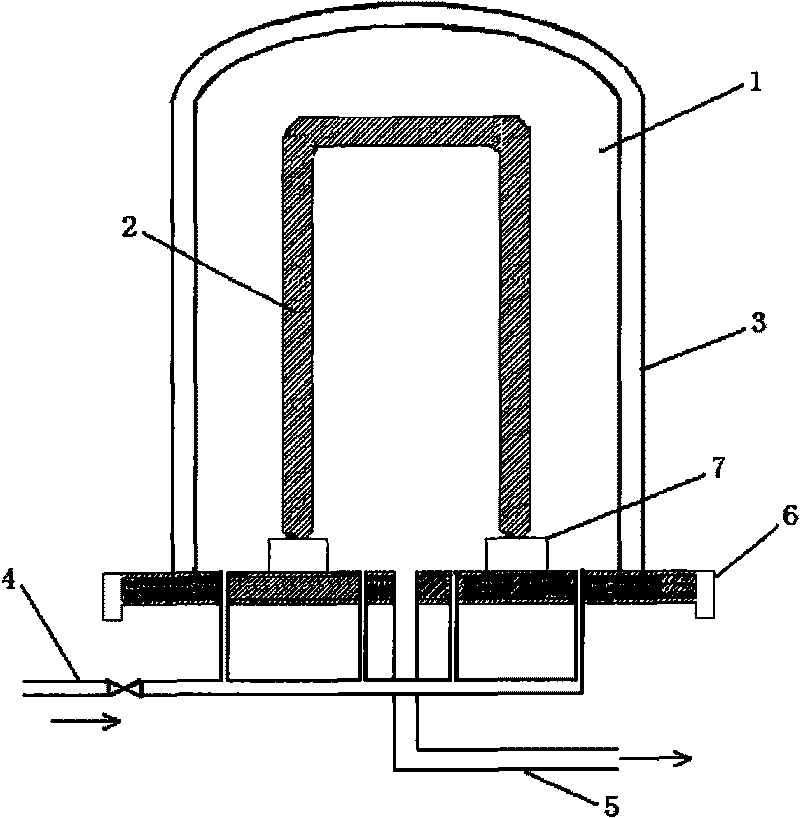

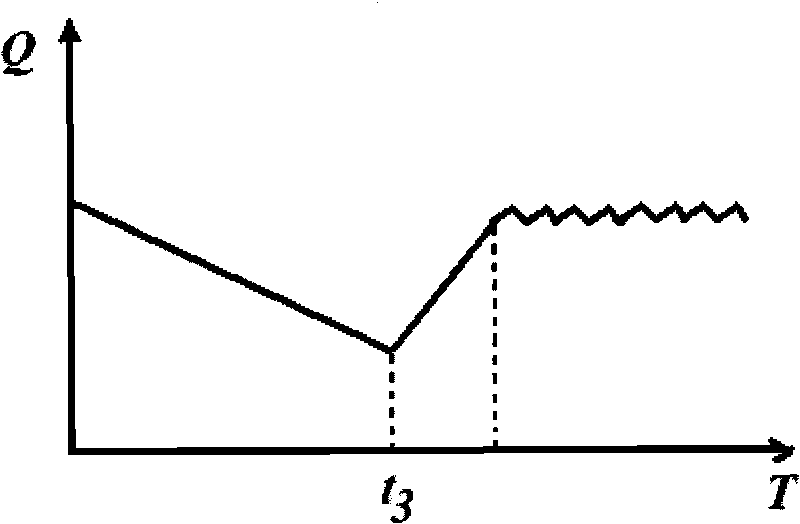

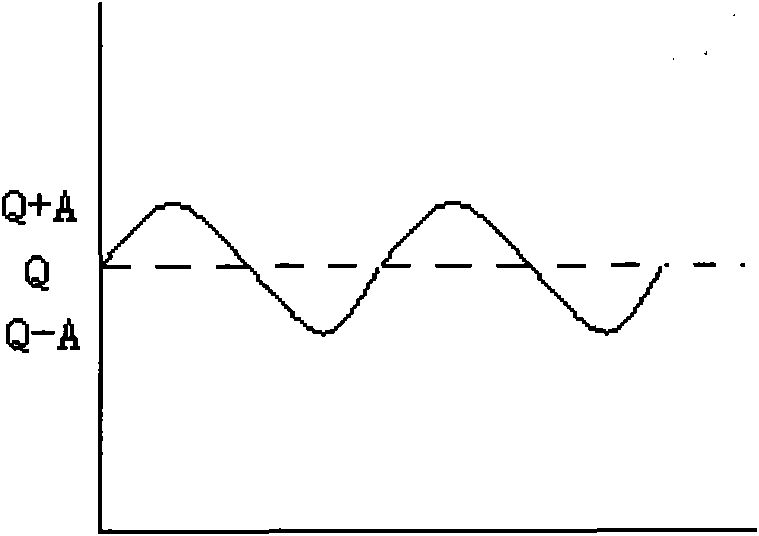

Method for producing polysilicon rod

InactiveCN101717087AAvoid equipment investment costs and equipment modification costsIncrease maintenance costSiliconChemistryPower consumption

The invention relates to a method for producing a polysilicon rod, which produces the polysilicon rod by continuously introducing a mixed gas which consists of hydrogen and a silicon containing gas and serves as a raw material gas to a reactor, and reacting the raw material gas in the reactor. The method for producing the polysilicon rod comprises the following steps: enabling the molar ratio Q of the hydrogen to the silicon containing gas to satisfy a specific relational expression by regulating the gas input M of the hydrogen serving as the raw material gas, and / or regulating the gas input N of the silicon containing gas serving as the raw material gas; and when the diameter of the polysilicon rod grows to 85 to 100 mm, enabling the Q value to fluctuate in an amplitude A. The method for producing the polysilicon rod of the invention improves the conversion per pass of trichlorosilane in a reduction process, and simultaneously, reduces the direct power consumption for the reduction of the trichlorosilane and effectively reduces the production cost of the polysilicon rod.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

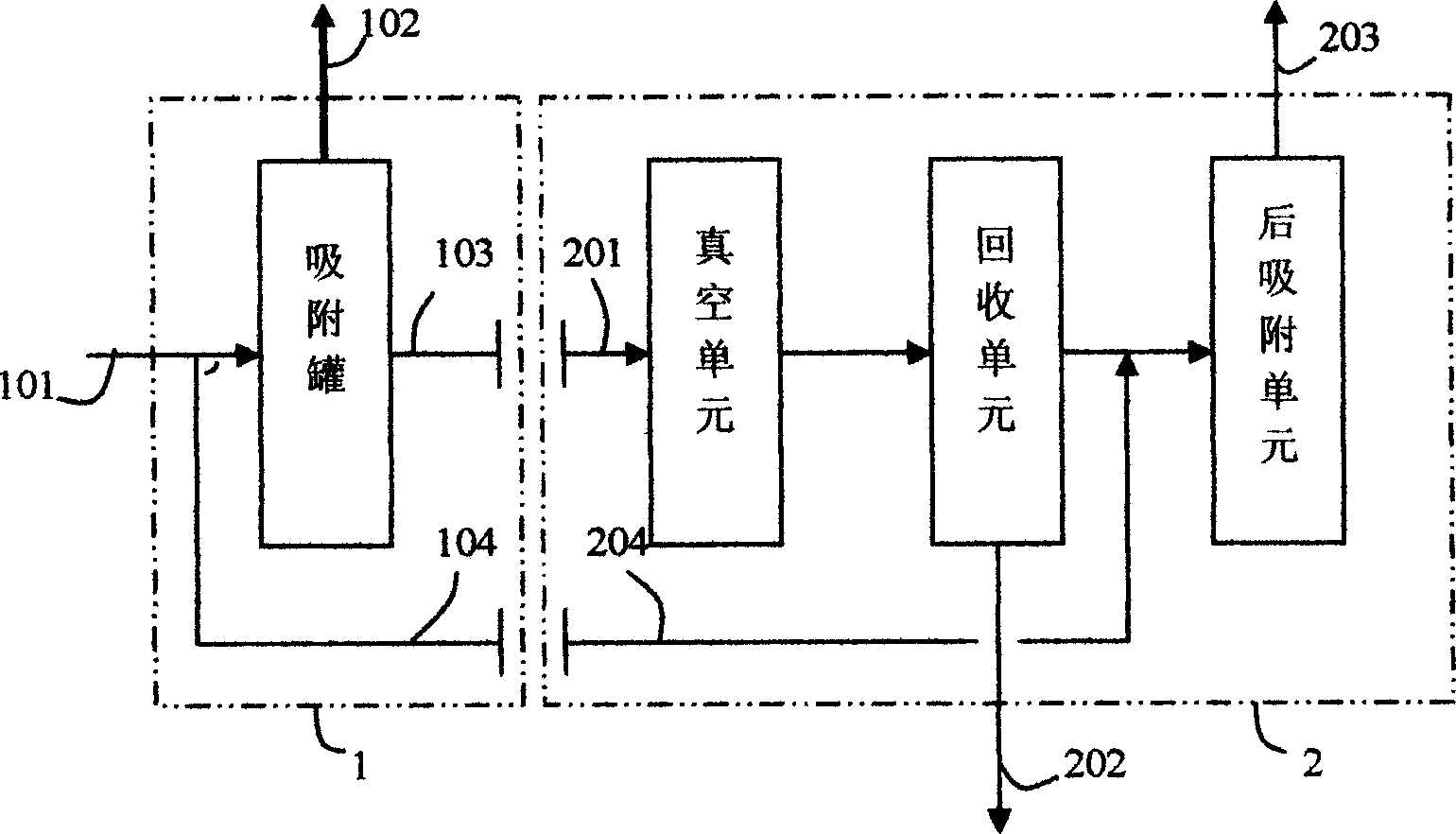

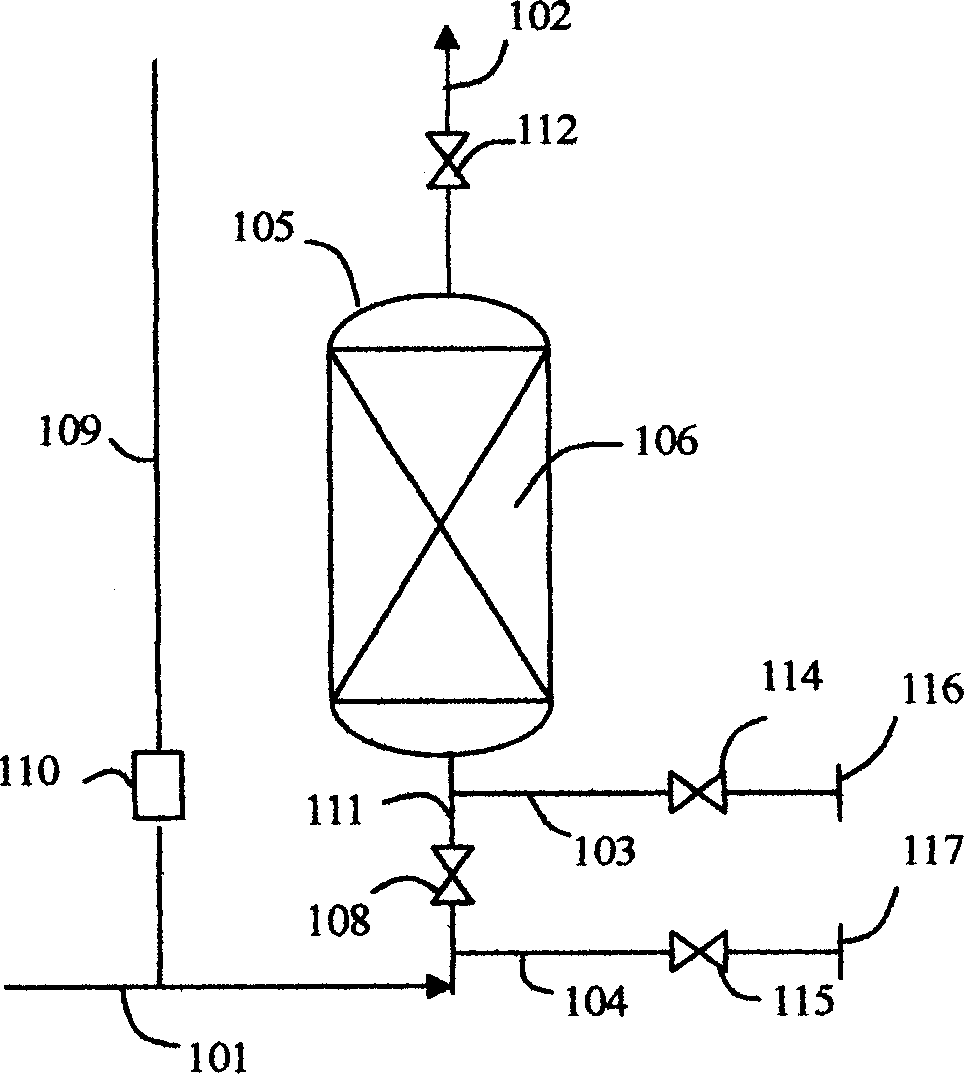

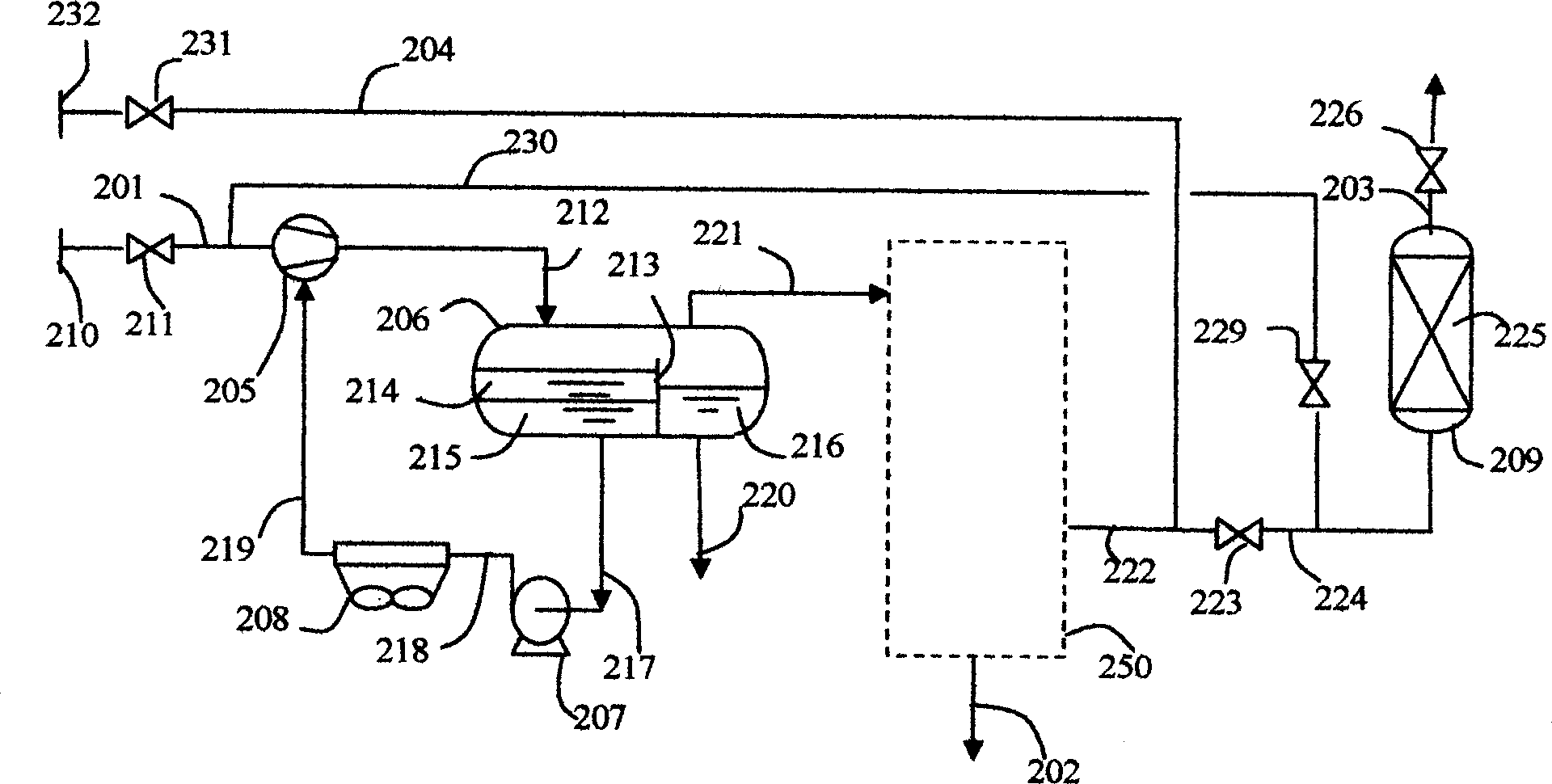

Method and process flow for recovering organic matter component from organic exhaust gas

InactiveCN1748835ARaise the condensation temperatureIncrease condensing pressureDispersed particle separationSorbentAtmospheric air

The process of recovering organic matter component from exhaust organic gas is suitable for the conditions of relatively small exhaust amount to be recovered and treated, relatively high flow and concentration fluctuation, and dispersed exhaust source. The recovering and treating system includes site parts and movable part. The site parts are set in the gas exhaust sites to accept exhausted gas and adsorb the organic component onto the adsorbent. The movable part may be used to desorb and regenerate saturated absorbent and collect desorbed organic component for several site parts.

Owner:宁波海曙洁源气体处理工程有限公司

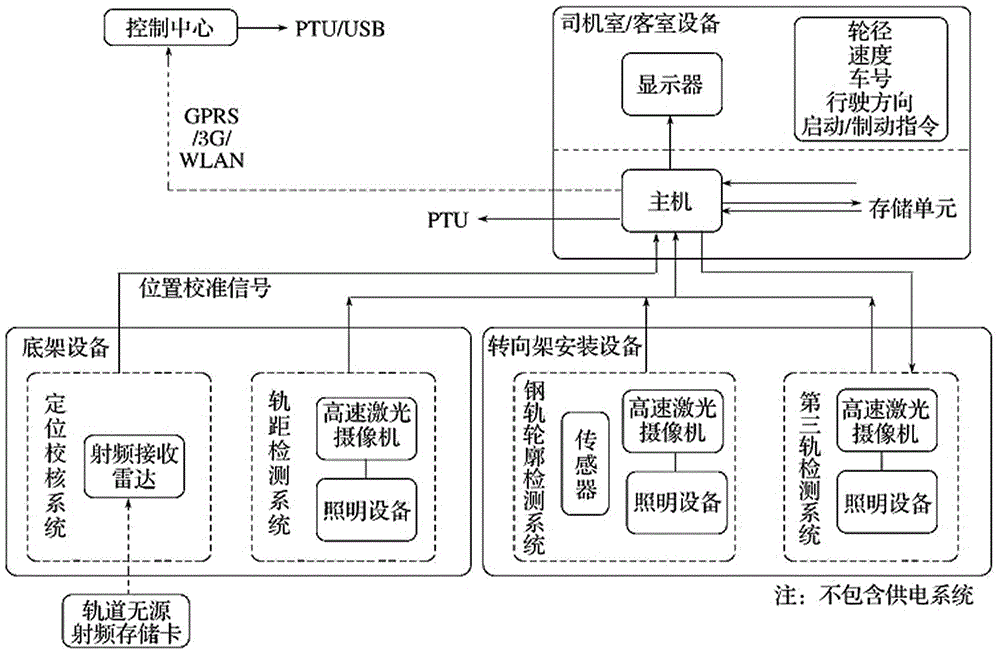

Urban rail vehicle vehicle-mounted automatic rail detection device

InactiveCN106809247AEasy to detectReduce workloadRailway auxillary equipmentRailway profile gaugesInformation processingBogie

The present invention is a vehicle-mounted automatic track detection device for urban rail vehicles, which can greatly reduce the workload of construction workers and the utilization rate of large-scale detection equipment; the present invention consists of a track detection and line inspection system, a gauge detection system, a rail profile detection system, The third rail detection system, train positioning system and other systems constitute. The entire detection system consists of three parts: chassis and bogie suspension equipment, including power supply, lighting, camera, laser, ultrasonic and other systems; computer information processing system in the passenger room (usually placed under the passenger seat); driver's cab or control system. Center display system. The automatic track detection system mainly detects the status of the track, the third rail and other accessories of the track. Generally choose to install the automatic track detection system on 2~3 trains in the operating fleet, complete the detection of the track system during the daily passenger operation of the train, and send the detection results to the ground control center (OCC).

Owner:田荣侠

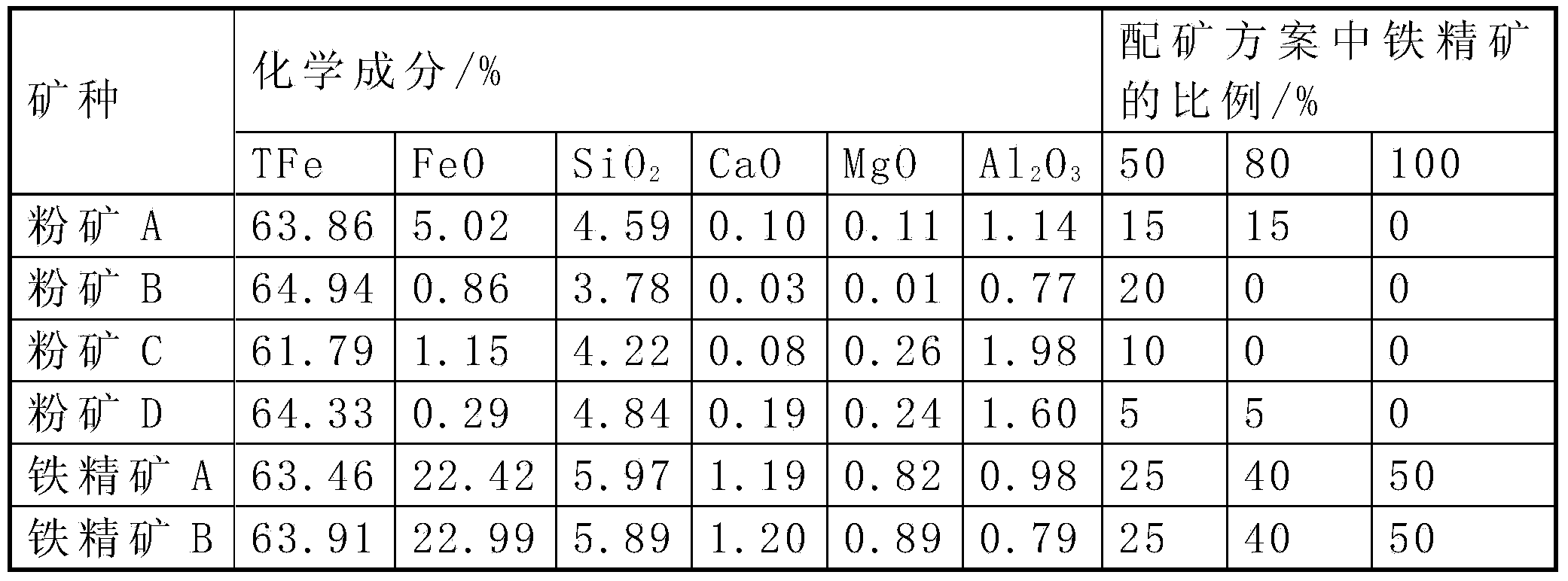

Method for strengthening sintering of high-proportion iron ore concentrate

The invention discloses a method for strengthening sintering of high-proportion iron ore concentrate. The sintering raw material is divided into two materials and then palletized. The first material comprises a part of the iron ore concentrate, quick lime and coke powder separated from the sintering raw material, first-stage palletizing is carried out on the first material, then second-stage palletizing is carried out on the first material and the second material, and the second material comprises a part of the iron ore concentrate, quick lime, coke powder, ore fines, lime stone, dolomite and return fines. By distributing the concentrate, the quick lime and the coke powder in the two materials reasonably, the purposes of palletizing strengthening and sintering mineralizing are achieved. For sintering of an iron mine with the iron ore concentrate accounting for 50-70 percent of the total mass of the iron core, after the strengthening technology is utilized, the utilization factor of a sintering machine is improved by 0.05-0.3t / (m<2>.h), the sinter yield is improved by 1-4 percent, the drum strength is improved by 0.5-4 percent, and the output index and the quality index of sintering of the high-proportion iron ore concentrate are improved.

Owner:CENT SOUTH UNIV

Desulfurization process of blast furnace gas

InactiveCN110129102AAchieve recyclingAdvanced technologyGas treatmentDispersed particle separationMolecular sieveDesorption

The invention discloses a desulfurization process of a blast furnace gas, which comprises the following steps: 1) preparing two same adsorption towers filled with molecular sieve resin, denoted as anadsorption tower A and an adsorption tower B; 2) introducing the cooled blast furnace gas into the adsorption tower A for adsorption, when the sulfur content of gas at the outlet of the adsorption tower A is more than 5 mg / m<3>, switching the blast furnace gas into an adsorption tower B for continuous adsorption, and stopping the operation of the adsorption tower A at the same time; 3) guiding outand heating a small amount of completely desulfurized coal gas, introducing the desulfurized coal gas into the adsorption tower A for high-temperature desorption regeneration, treating the gas afterthe high-temperature desorption regeneration through a recovery process of a sulfur-containing compound, and cooling the regenerated adsorption tower A for later use; and 4) alternately using the regenerated adsorption tower A and the adsorption tower B so as to complete continuous removal of the sulfur-containing compounds in the blast furnace gas. The method disclosed by the invention can realize recycling of sulfur resources, and is low in equipment investment and low in operation cost.

Owner:CHINA NAT AIR SEPARATION ENG CO LTD

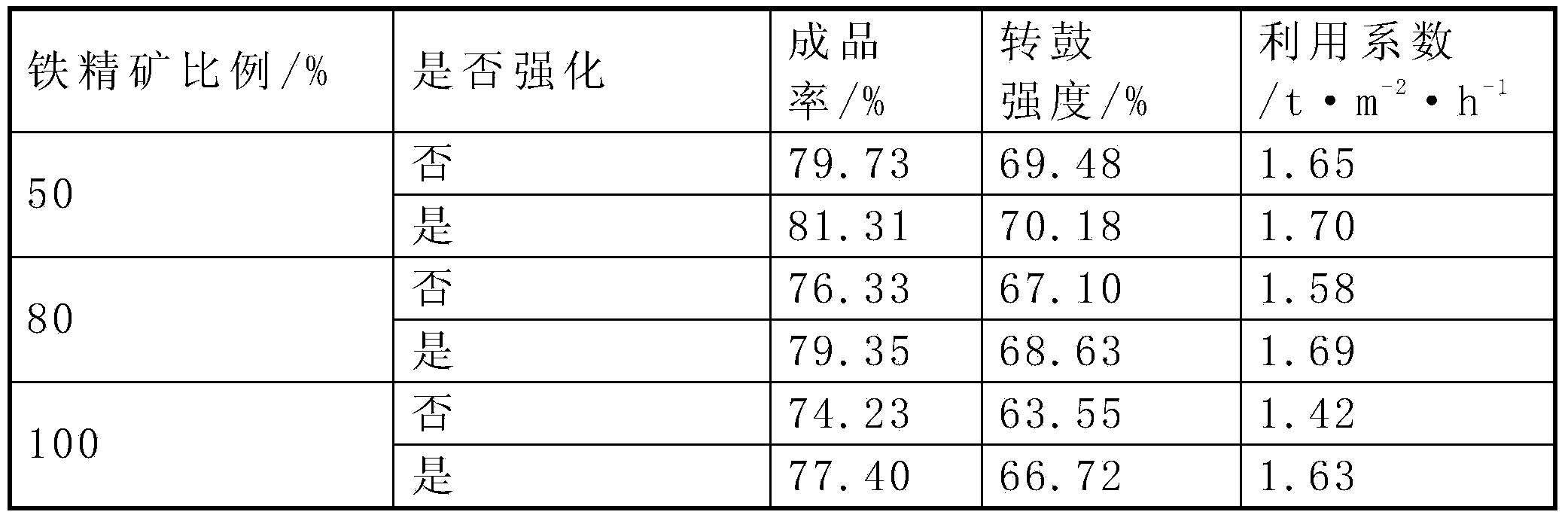

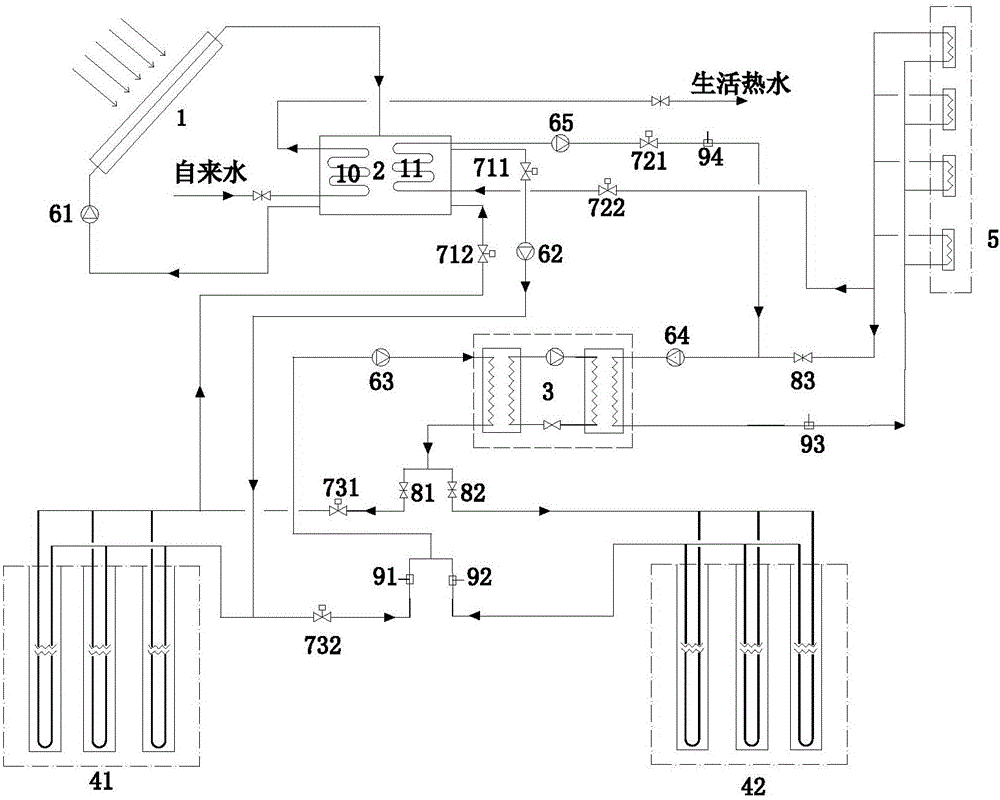

Solar energy-ground source heat pump coupling type energy supply system provided with two buried pipe groups

ActiveCN106196714AAchieve thermal balanceSolve solar heat storage across seasonsSolar heating energyHeat pumpsCouplingEnergy supply

The invention relates to a solar energy-ground source heat pump coupling type energy supply system provided with two buried pipe groups. The solar energy-ground source heat pump coupling type energy supply system provided with the two buried pipe groups is characterized in that the energy supply system comprises a solar heat collector, a heat-storage water tank, a ground source heat pump unit, the first buried pipe group, the second buried pipe group, a building tail end device, a heat-collection circulating water pump, a heat-storage circulating water pump, a ground source side circulating water pump, a first heat-storage control valve, a second heat-storage control valve, a first ground source side control valve, a second ground source side control valve, a first pipe group flow regulation valve, a second pipe group flow regulation valve, a first pipe group heat meter and a second group pipe heat meter; the solar heat collector is sequentially connected with the heat-storage water tank and the heat-collection circulating water pump through pipelines, namely a heat collection cycle is formed, and hot water generated by solar energy is collected; and the hot water outflow end of the heat-storage water tank is sequentially connected with the first heat-storage control valve, the heat-storage circulating water pump, the first buried pipe group, the second heat-storage control valve and the backflow end of the heat-storage water tank through pipelines, so that a heat storage cycle is formed.

Owner:河北泓宇能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com