Device and method for realizing premixed jet flow continuous jetting

A spraying device and pre-mixing technology, which is applied in the direction of abrasive feeding device, abrasive spraying machine tool, abrasive, etc., can solve the problems of long-term, continuous, and large-flow usage occasions that are unacceptable, and achieve good use value and improve Effects of continuous injection time, jet flow stability, and maintenance cost improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

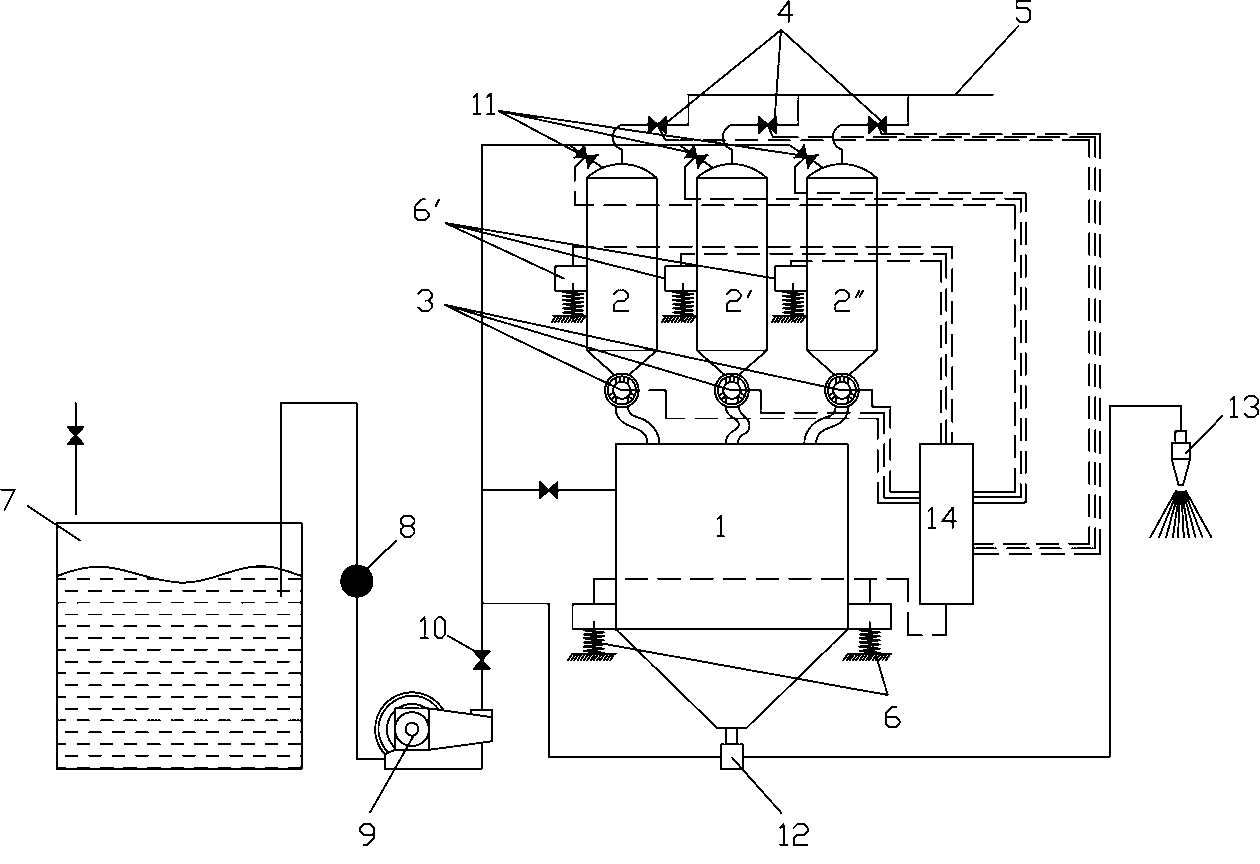

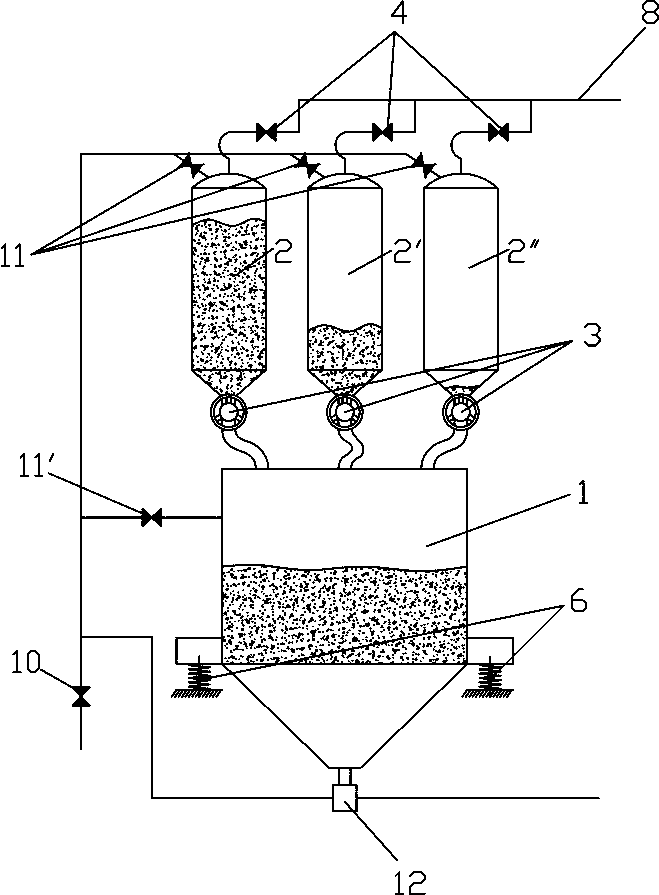

[0031] see Figure 1 ~ Figure 2 , the present invention realizes an embodiment of the pre-mixed jet continuous spraying device, which includes a main tank 1 for storing mortar; three sub-tanks 2, 2', 2 " for temporarily storing mortar, passing through pipelines respectively 1. The high-pressure sand valve 3 is connected to the inlet of the main tank 1; the inlets of the sub-tanks 2, 2', and 2" are respectively connected to a mortar supply pipeline 5 through pipelines and corresponding low-pressure sand valves 4; four sets of weight measuring devices 6 , 6', respectively set in the main tank 1 and three sub-tanks 2, 2', 2"; the pool or water tank 7, the outlet pipeline is equipped with a filter 8, a booster pump 9, a control valve 10, and passes through several sub-tanks respectively The pipelines are connected to the sub-tanks 2, 2', 2" and the main tank 1, and high-pressure water valves 11 and 11' are respectively set in each sub-pipeline; a sand mixer 12, the inlet end of wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com