Pump having a pressure compensated annular volume

a technology of annular volume and pump, which is applied in the field of pumps, can solve the problems of limited ability of each individual pump stage in itself to deliver pressure increase, long existing construction, and short service life of the entire pump, so as to reduce the wear resulting from any sand production and facilitate the operation of the pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

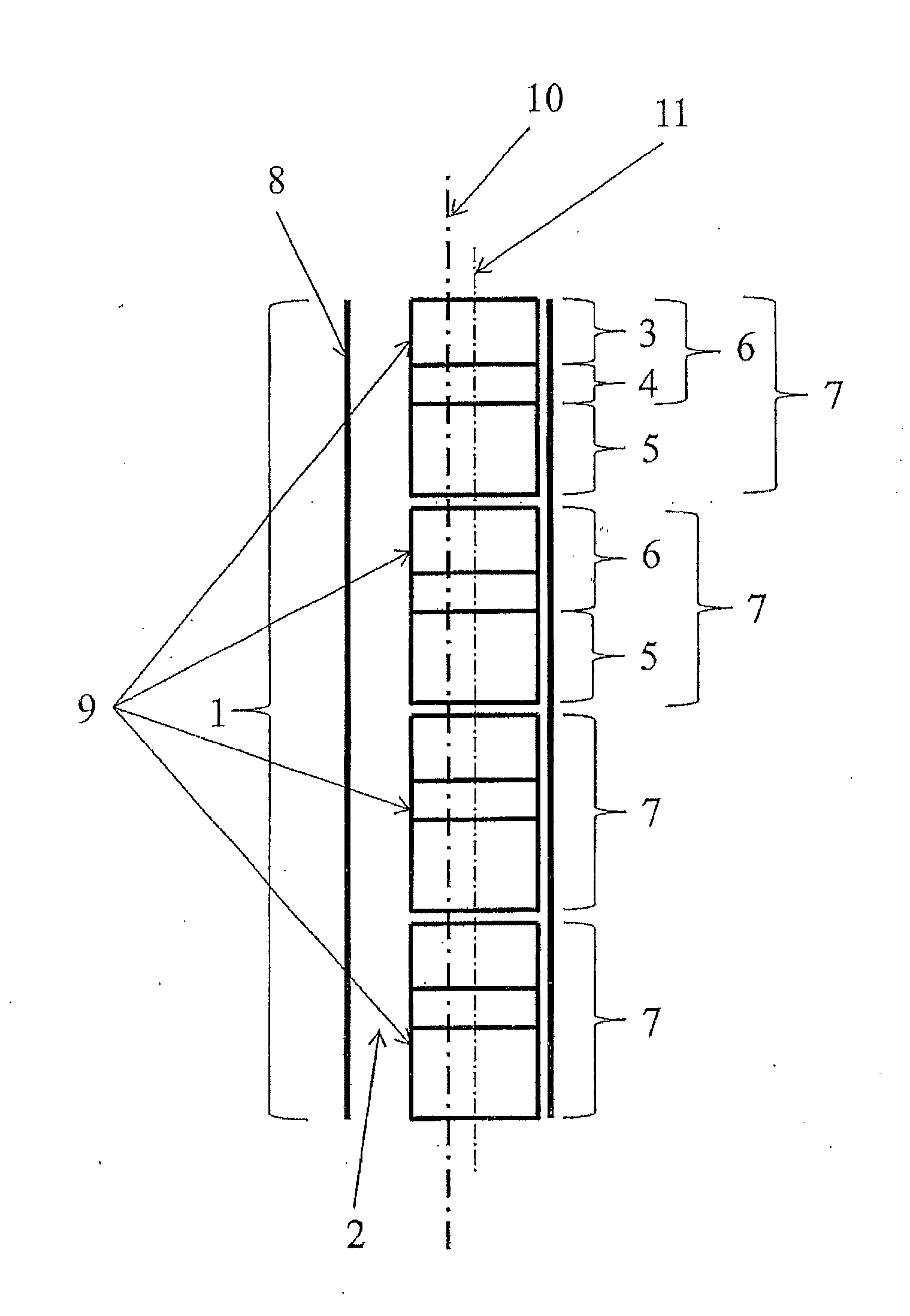

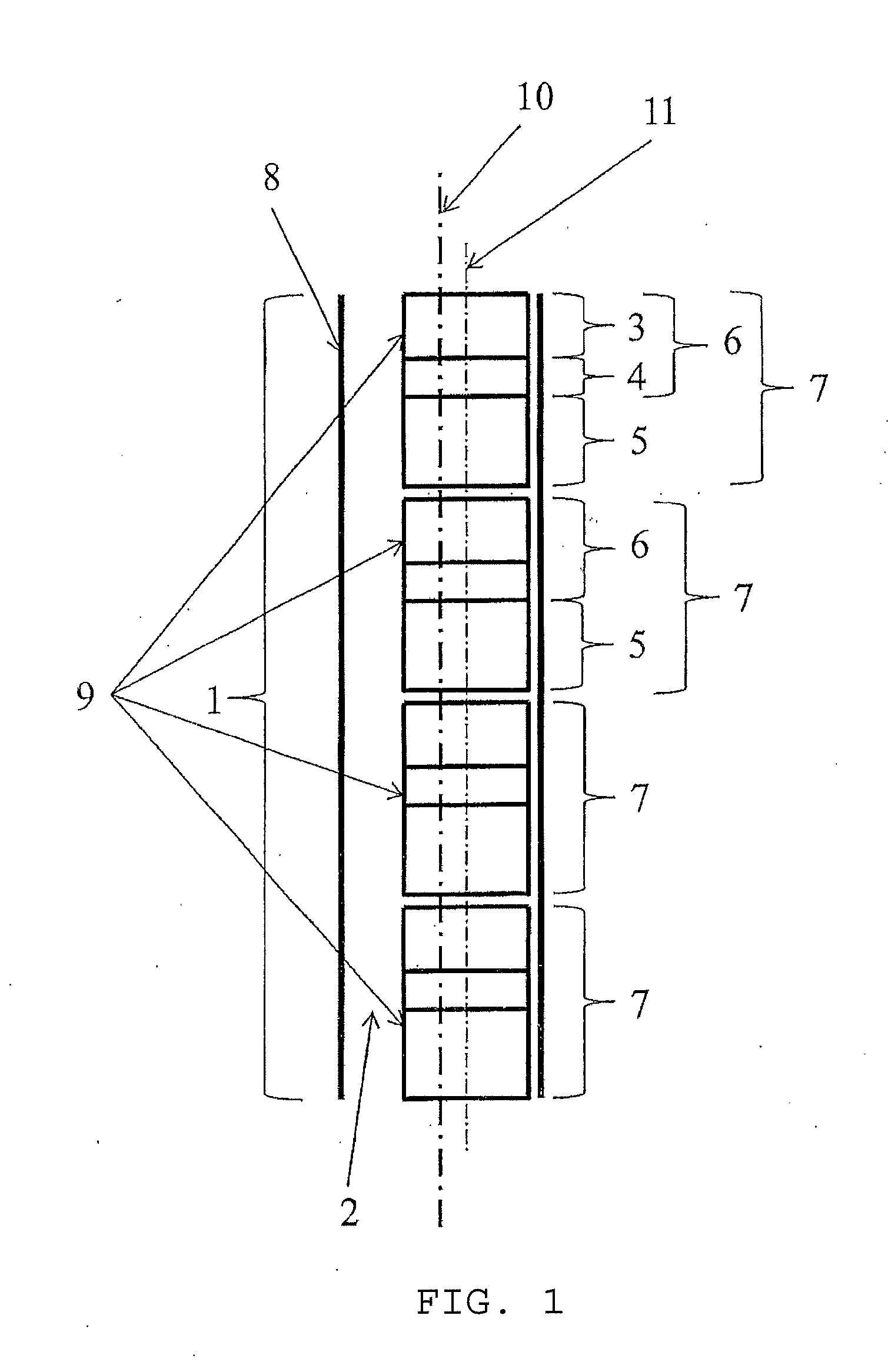

[0046]FIG. 1 illustrates a principle drawing of a pump section 1 where the pump steps 7 with inner casings 9 and a centre line 11 are located radially displaced, asymmetrical relative to a centre line 10 of the pump section 1. An annular volume 2 is thereby formed between the outer casing 8 in the pump section 1 and the inner casings 9 in the pump steps 7. The asymmetry is illustrated by the centre line 10 of the pump section 1 being displaced to the left of the common centre line 11 of the pump steps 7. FIG. 1 also shows that the four pump steps 7 each consist of a motor 5 and pump stage 6. It can also be seen in the figure that it is precisely in this embodiment illustrated here that each pump step 7 only has one pump stage 6. A pump stage 6 consists of an impeller 4 and a diffuser 3. The well fluid which has to be lifted to the surface will flow internally in each pump step 7.

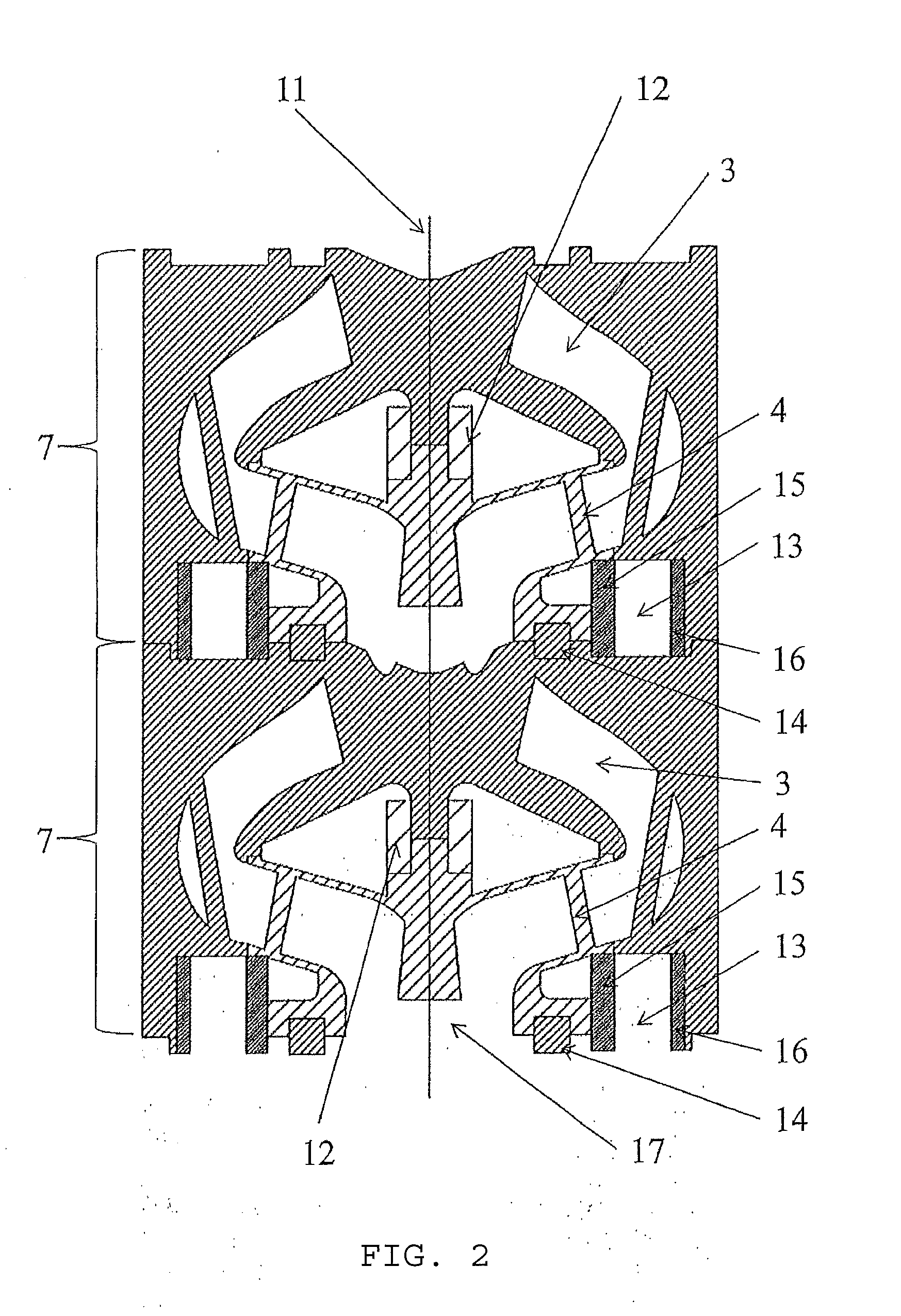

[0047]FIG. 2 illustrates an embodiment of two pump steps 7, both of which in this embodiment contain a pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com