Method and process flow for recovering organic matter component from organic exhaust gas

A technology for emitting gas and organic matter, applied in the field of recovering organic matter components, can solve the problems of waste of resources, environment, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] It is equivalent to 19kg of gasoline discharged into the atmosphere by each gas station every day.

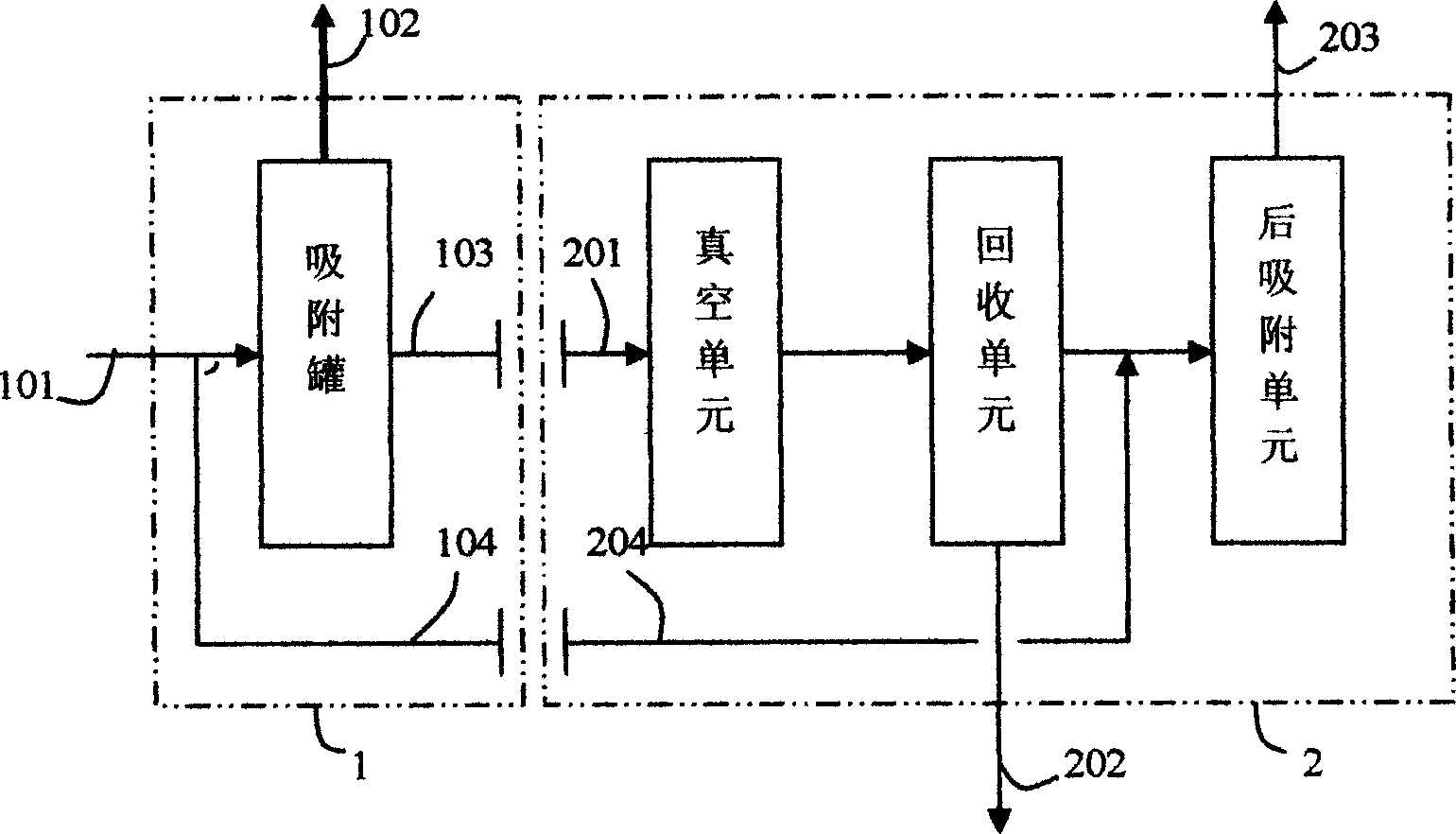

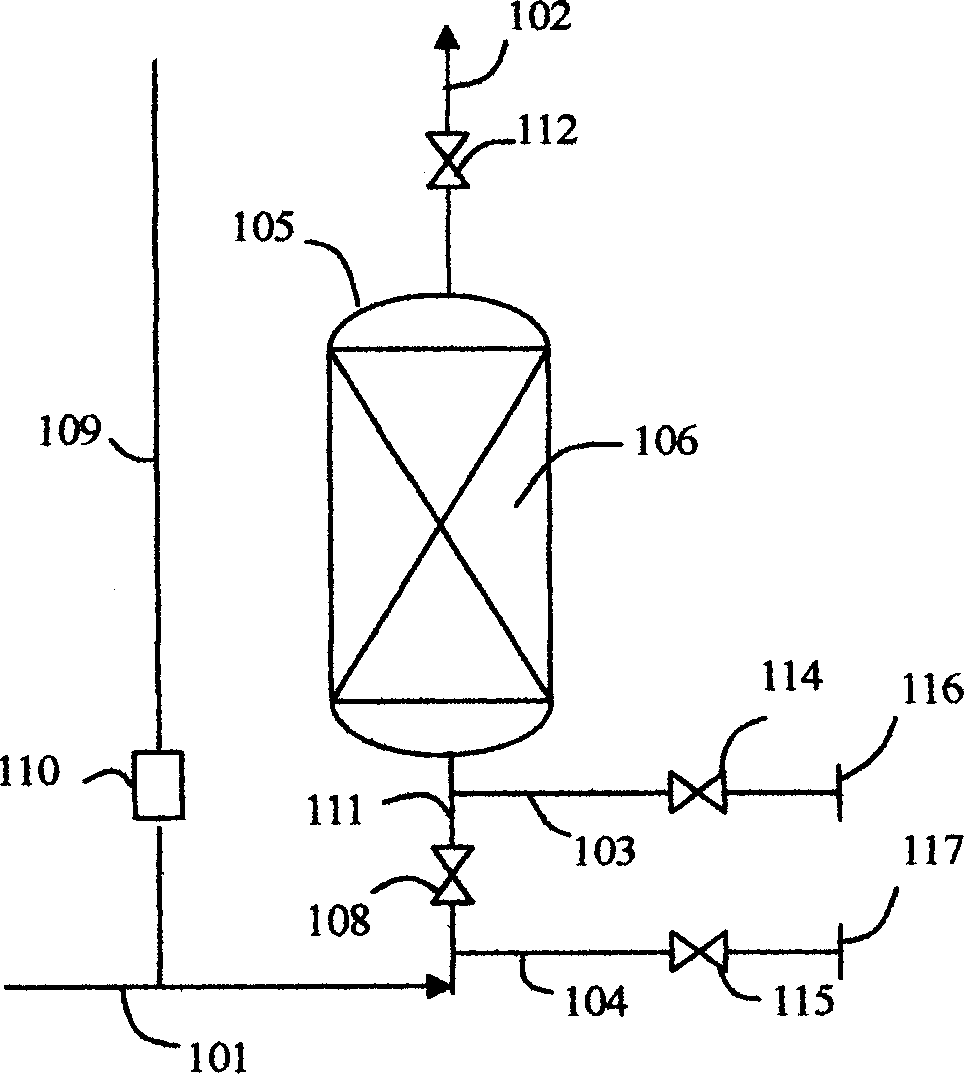

[0060] One adsorption tank is installed in each gas station, and each adsorption tank is filled with 3m 3 Activated carbon is used as an adsorbent, and the oil gas (equivalent to organic matter emission gas) discharged from the underground oil tank is introduced into the adsorption tank. After adsorption, the concentration of organic matter in the clean tail gas discharged after adsorption is less than 10mg / l, and each adsorption tank is regenerated every 5 days on average. The process flow of the on-site part is as follows: figure 2 shown.

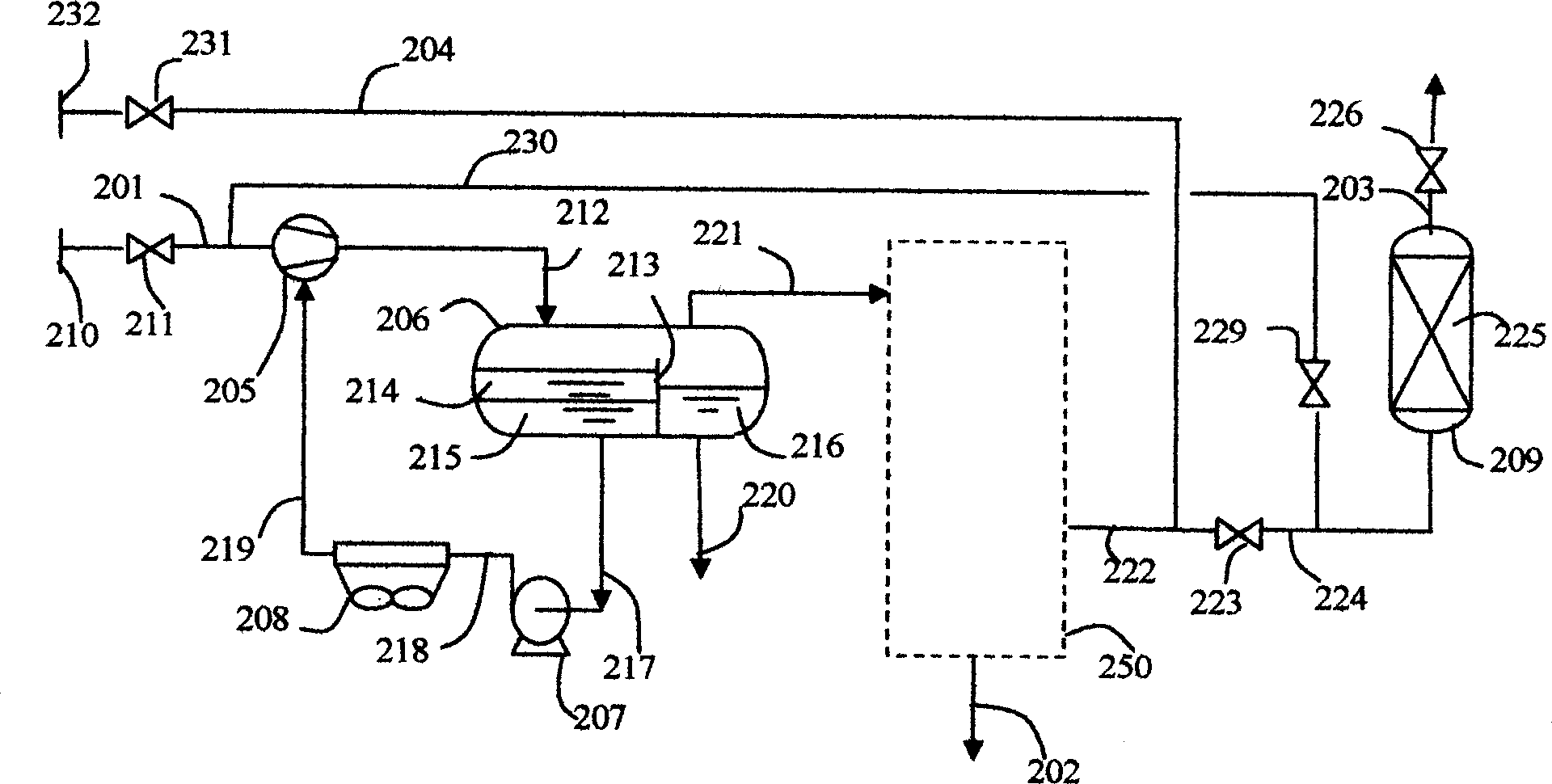

[0061] The mobile regeneration recovery machine is vehicle-mounted, and each mobile regeneration recovery machine completes the regeneration of adsorption tanks of 6 gas stations every day on average, and can provide services for 30 gas stations. The process of mobile recycling machine is as follows: image 3 and Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com