Patents

Literature

108results about How to "Not easy to repair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

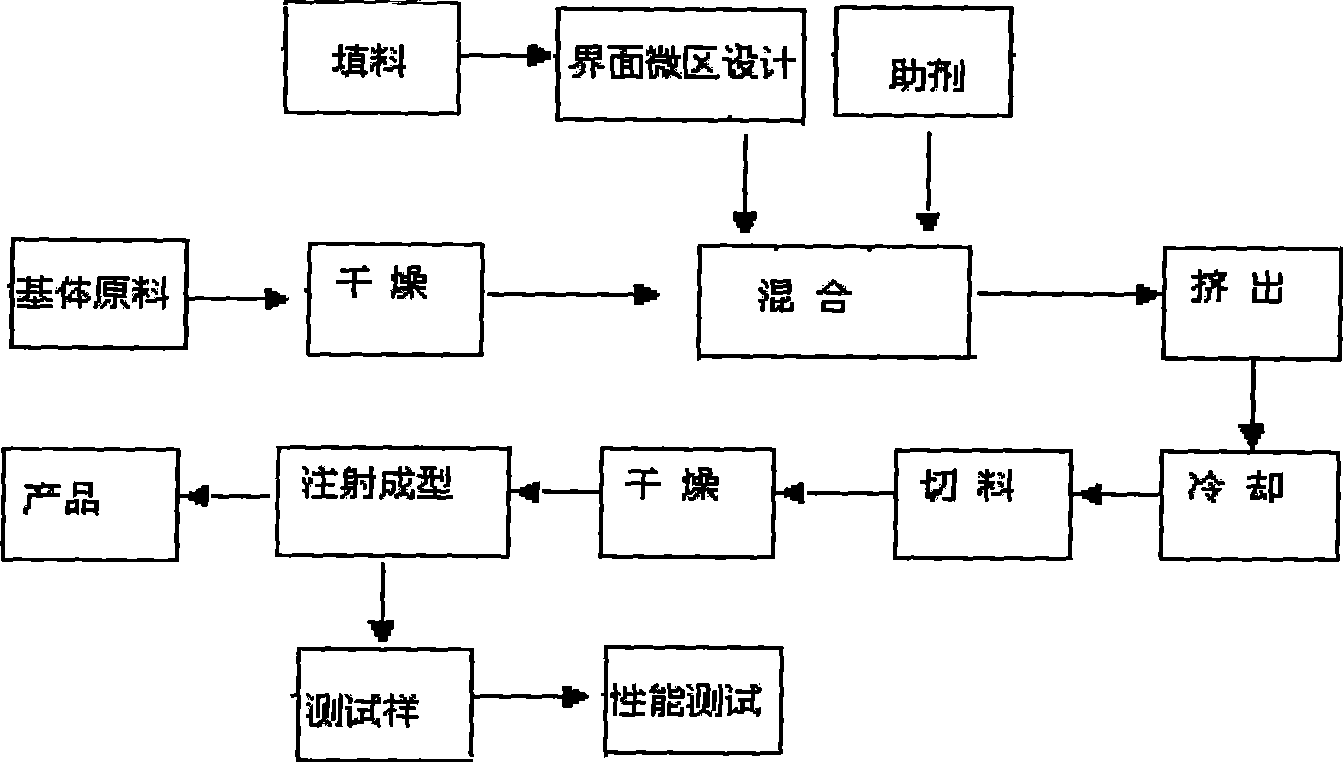

High performance polymer base composite material for support roller and preparation method

InactiveCN101423665AMeet the requirements for preparing idlersImprove corrosion resistanceGlass fiberAntistatic agent

The invention discloses a high performance polymer based composite material for carrier rollers and a method for preparing the same. The composite material comprises the following components in proportion: 50 to 80 percent of polycaprolactam, 5 to 30 percent of glass fiber, 0 to 30 percent of ceramic powder, 2 to 10 percent of lubricant, 1 to 15 percent of fire retarding agent, 0.05 to 1 percent of antistatic agent and 0.05 to 0.5 percent of anti-ageing agent; and, the adding amount of surface active is 5 percent of the weight of the ceramic powder. The composite material has the advantages of high strength, wearing resistance, high temperature resistance, electrostatic resistance, fire resistance, anti-ageing, environmental protection and the like.

Owner:CENT SOUTH UNIV +1

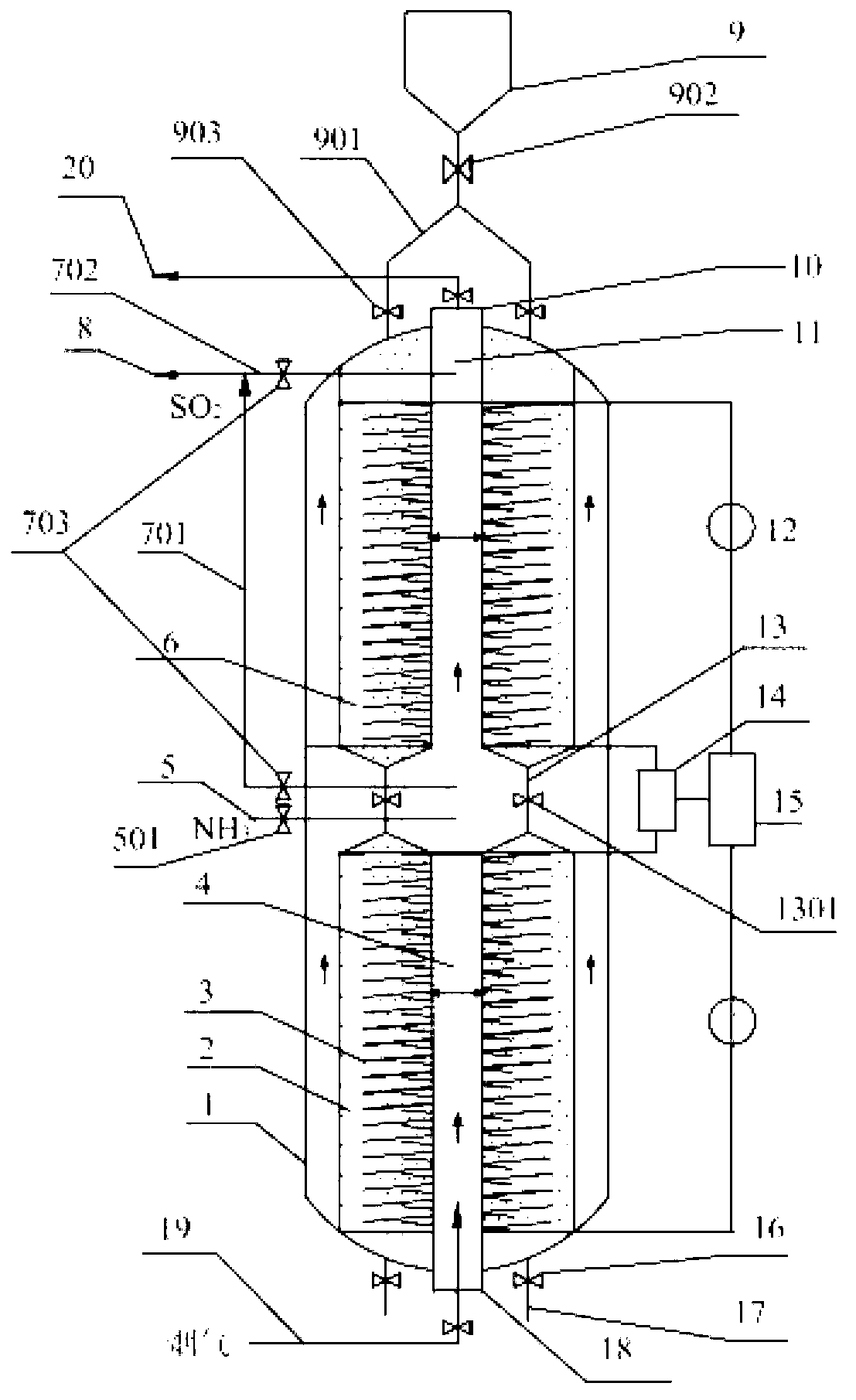

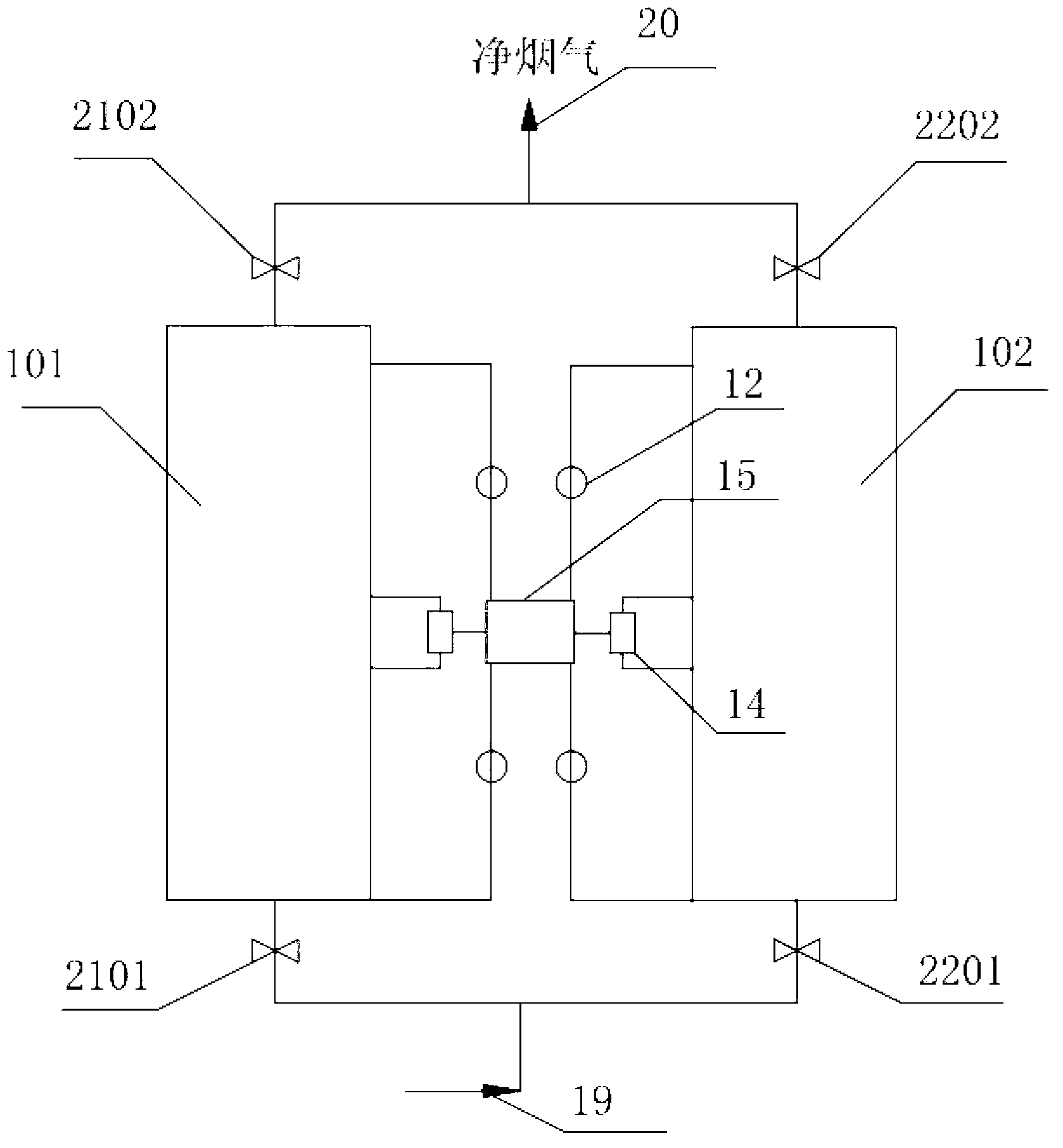

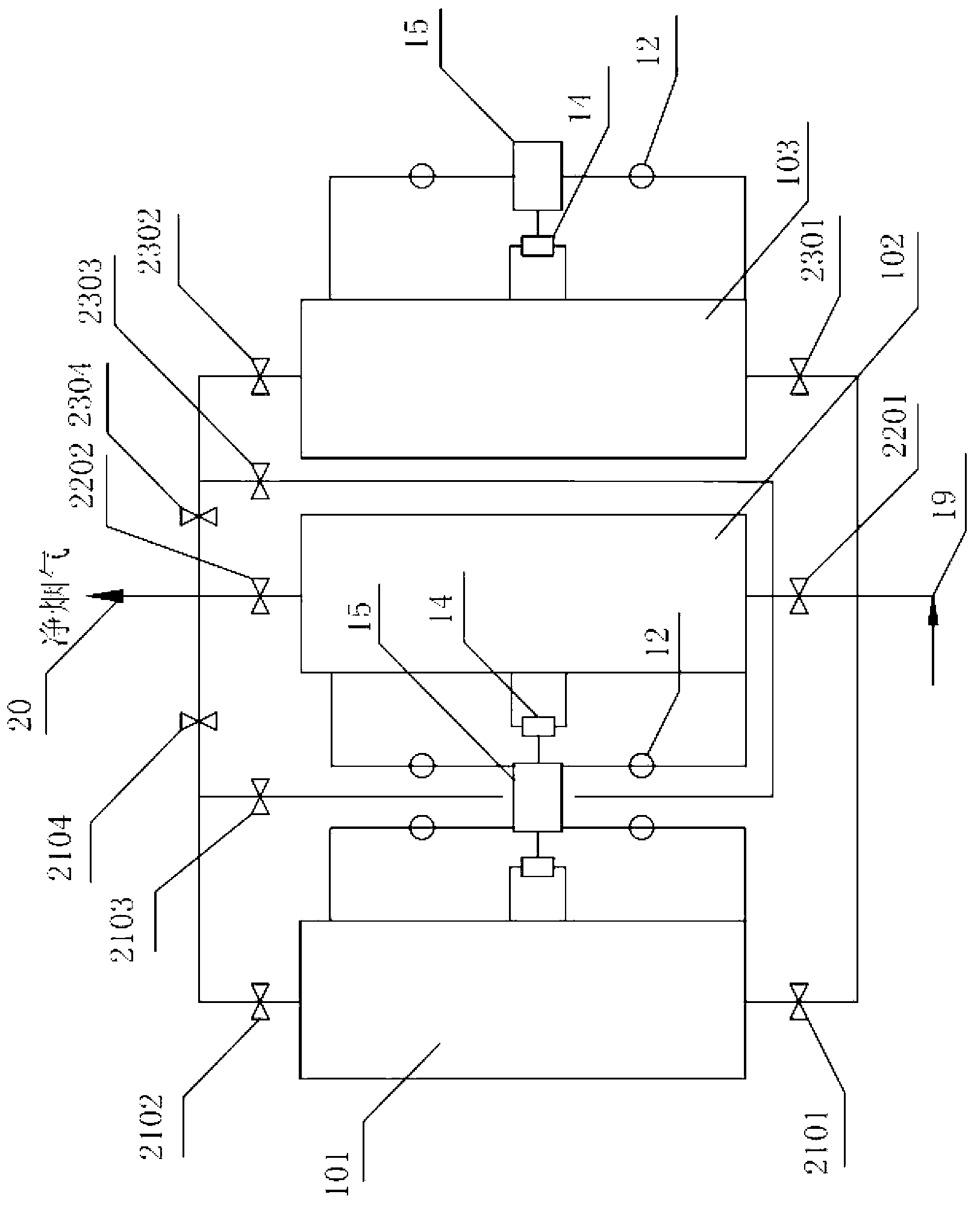

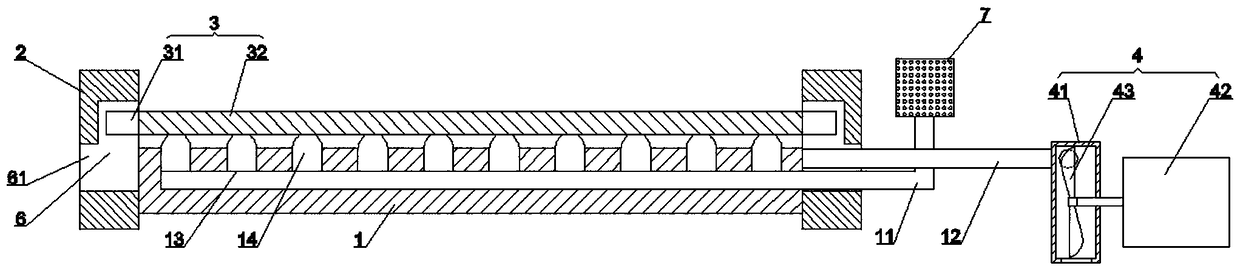

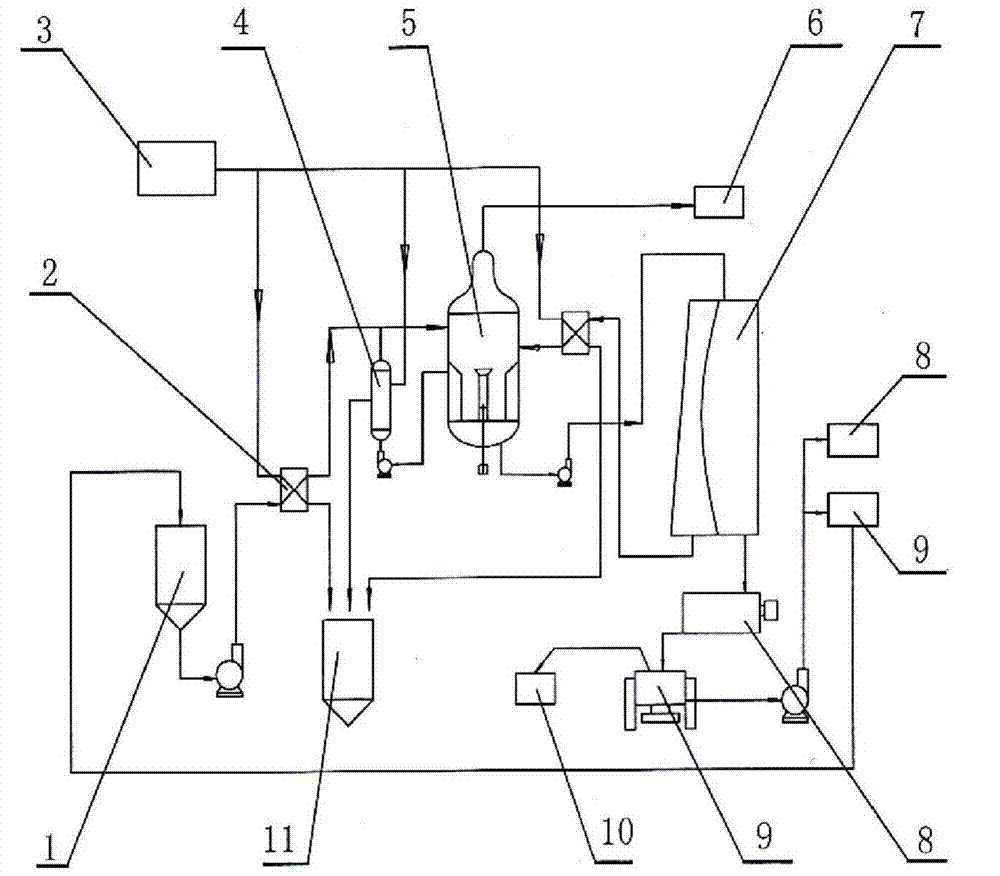

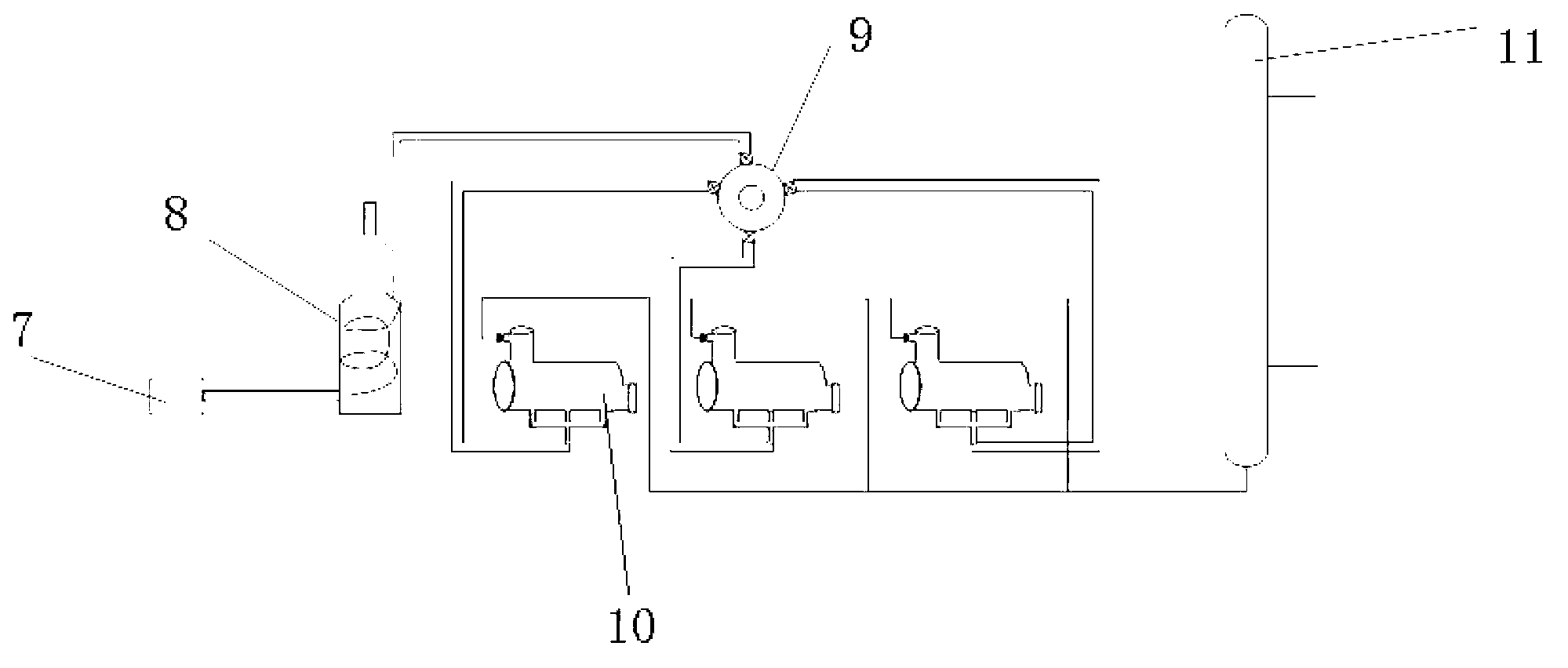

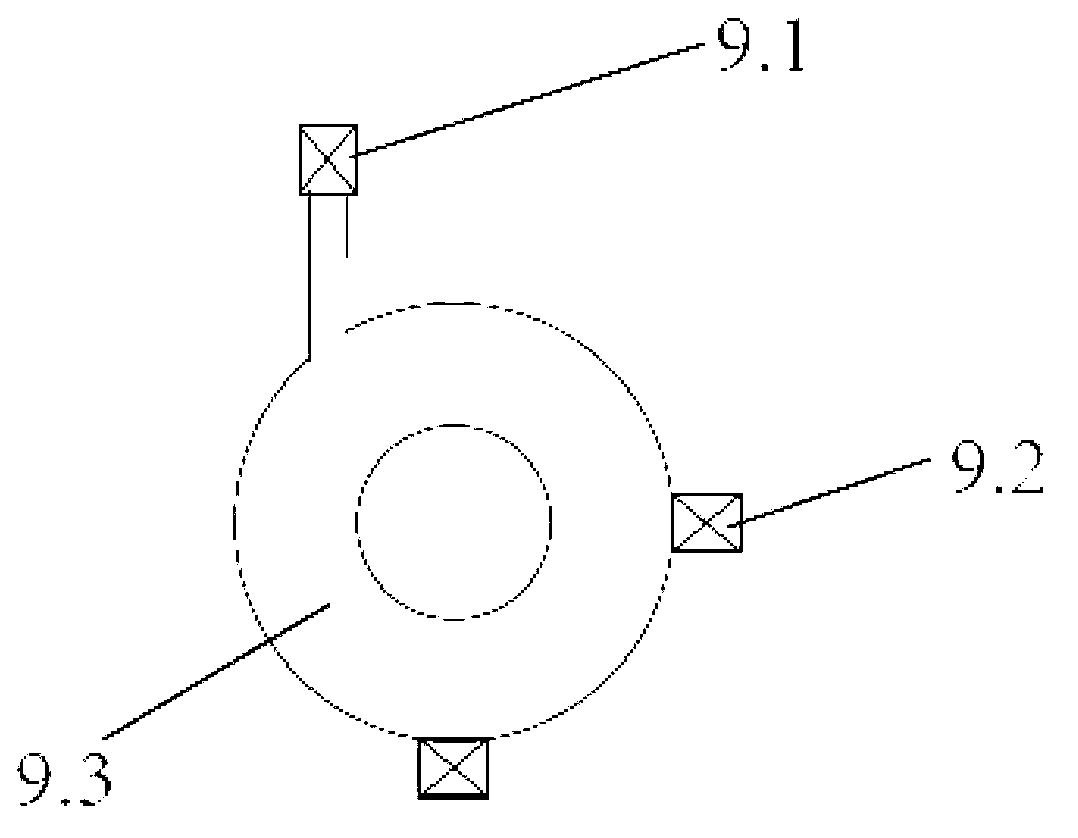

Flue gas cleaning system capable of switching pollutant desorption technology and adsorbent regeneration technology and method thereof

ActiveCN103007679AIncrease investment costNot easy to repairDispersed particle separationFlue gasDesorption

The invention provides a flue gas cleaning system capable of switching a pollutant desorption technology and an adsorbent regeneration technology. The system comprises two or more fixed bed reactors, a regenerative heating device which is used for adsorbent regeneration, and a to-be-cleaned flue gas valve and a flue gas cleaning valve which are used for controlling switching between the pollutant desorption technology and the adsorbent regeneration technology, wherein each of the fixed bed reactor is internally provided with a central tube connected with a flue gas inlet, as well as a first adsorption layer and a second adsorption layer which are used for cleaning flue gas and arranged on the outer side of the central tube; and the upper end of the central tube is connected with a flue gas outlet. The invention further discloses a flue gas cleaning method using the system. The system can be used for performing the flue gas pollutant desorption technology and the adsorbent regeneration technology in one fixed bed reactor, and achieve the switching between the pollutant desorption technology and the adsorbent regeneration technology in the different fixed bed reactors.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

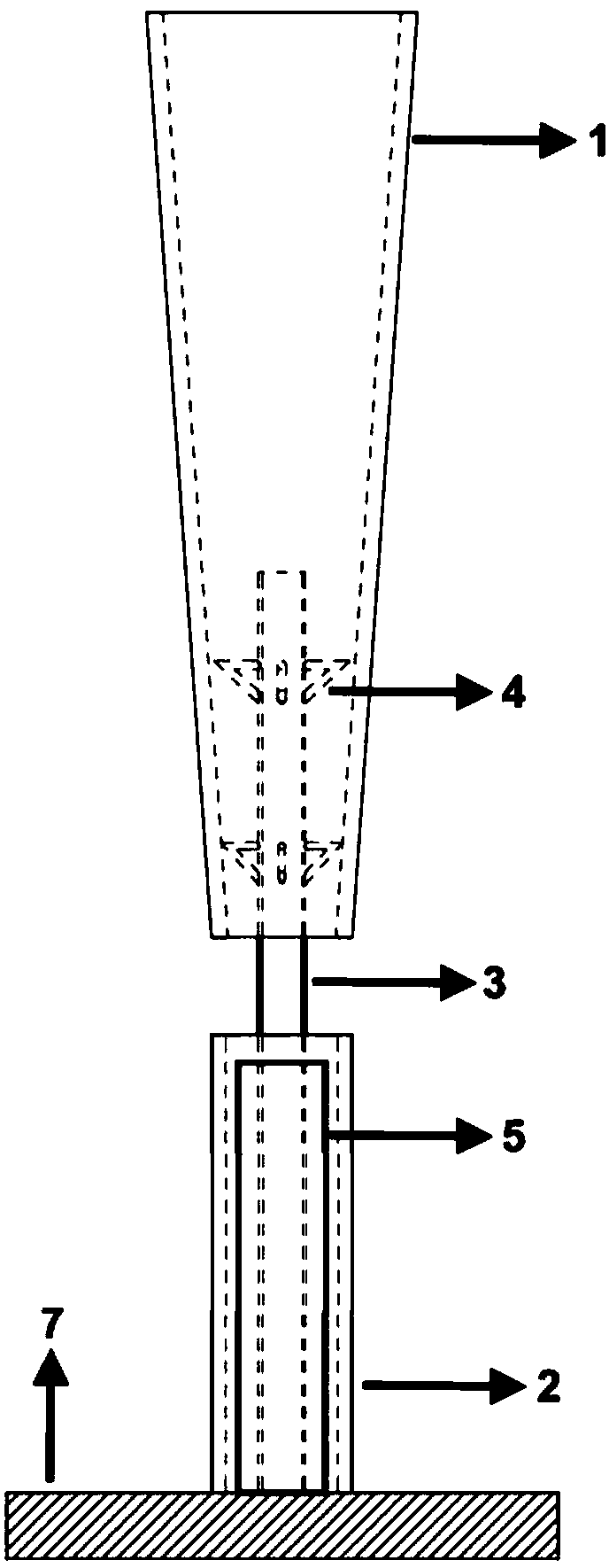

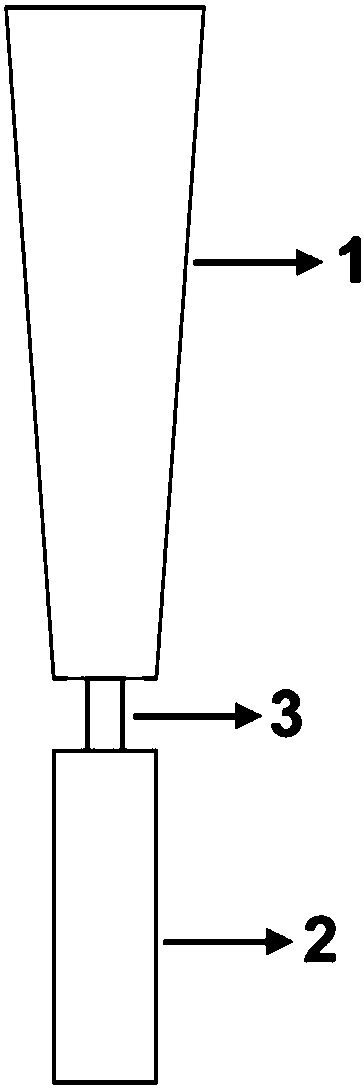

Blade-free wind power generation device based on vortex vibration theory and electromagnetic induction theory

PendingCN108278180ALarge windward sideEnhanced vortex effectWind motor combinationsMachines/enginesEngineeringFan blade

The invention discloses a blade-free wind power generation device based on a vortex vibration theory and an electromagnetic induction theory. The blade-free wind power generation device comprises a hollow thin-wall cylinder, wherein the hollow thin-wall cylinder is in an inverted circular truncated cone shape. The hollow thin-wall cylinder is installed on a connecting rod through a fixing device,the hollow thin-wall cylinder and the connecting rod are installed in an erected mode, and the bottom of the connecting rod is fixed to a foundation. A permanent magnet which synchronously swings along with the connecting rod sleeves the connecting rod located at the bottom of the hollow thin-wall cylinder. A plurality of closed electromagnetic induction coils are laid outside the permanent magnet, and when the permanent magnet synchronously swings along with the connecting rod, magnetic induction lines of the permanent magnet alternately cut the electromagnetic induction coils to generate thecurrent. By the adoption of the blade-free wind power generation device based on the vortex vibration theory and the electromagnetic induction theory, no conventional fan blades are required, a magnetic field is generated by the use of vortex vibration to conduct cutting, and then electric energy is formed; and the wind load in any wind direction can be received, and the situation that an additional device is needed to guide the wind direction so as to obtain the maximum wind energy is not required.

Owner:杭州科以才成科技有限公司

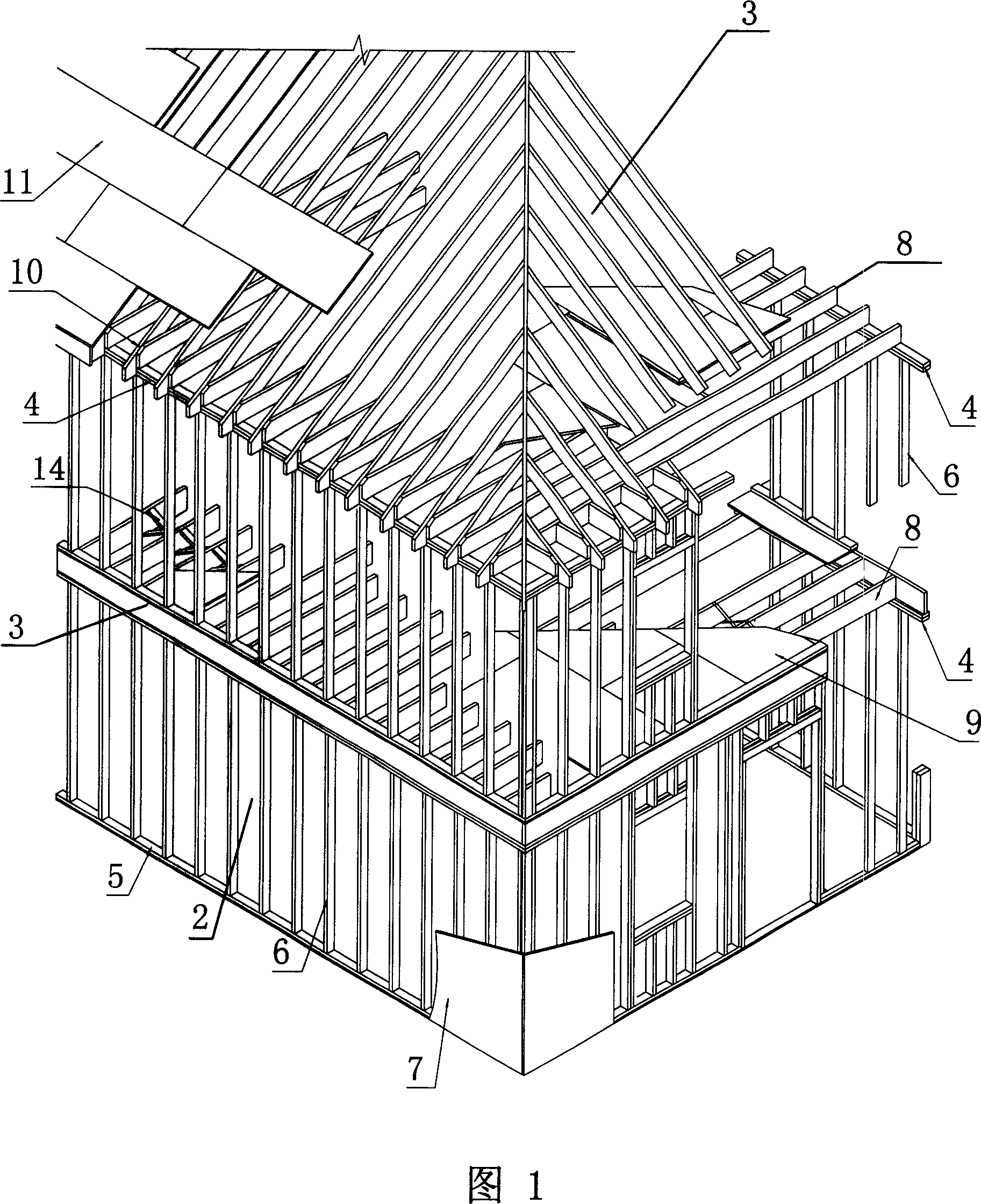

Bamboo residential building

InactiveCN1963056AShorten the growth cycleIncrease productionBuilding constructionsDwelling buildingReinforced concreteJoist

The invention discloses a bamboo domestic architecture; it includes foundation, walls, floor and roof one by one from the bottom to the top. Said foundation is bamboo concrete or armored concrete structure, the wall and the floor components use bamboo component or bamboo and wood assembly, the perimeter of floor is supported by the wall, the bamboo component of said walls comprises of beam, bottom beam, wall pillar installed between the beam and the bottom beam as well as the wall surface which covers the outside of wall pillar. The bamboo component of said floor comprises of many floor joists and floor surface using bamboo as base material, the floor joist is placed on the beam and the floor surface is placed on the floor joist. The invention is a simple, low cost, small construction difficulties, short construction period, better environmental protection and bamboo domestic architecture.

Owner:湖南博世安新技术有限公司

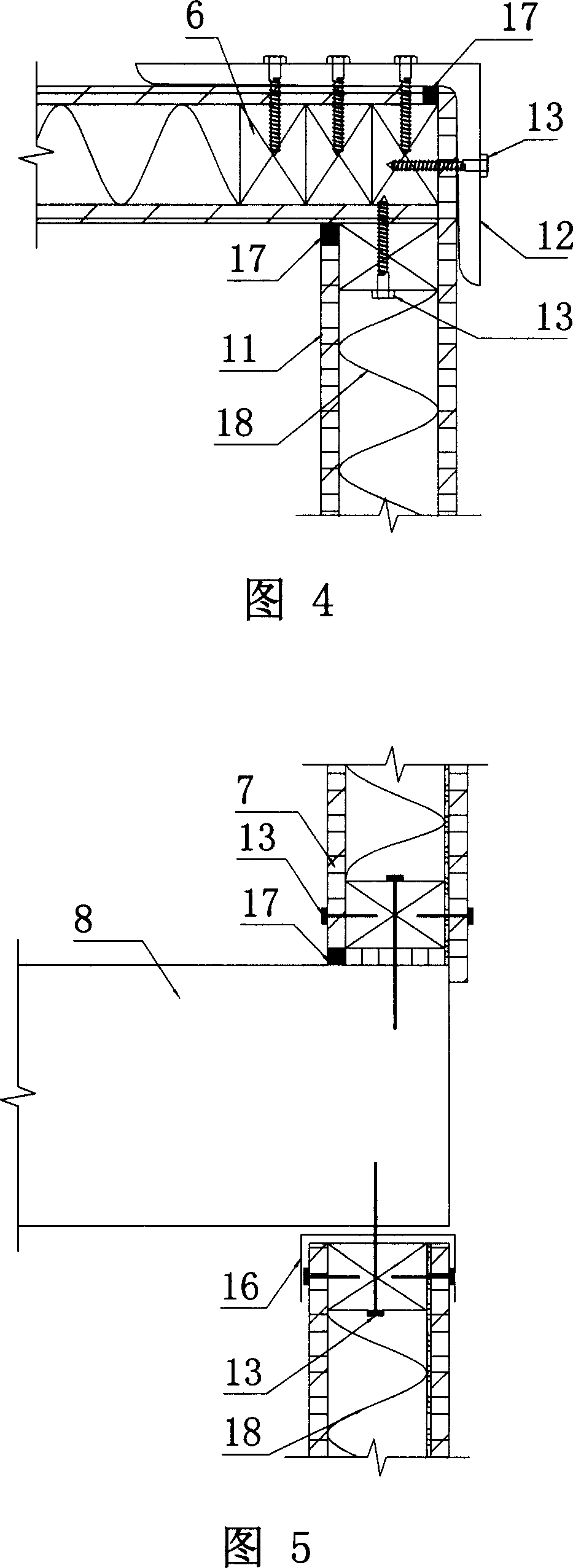

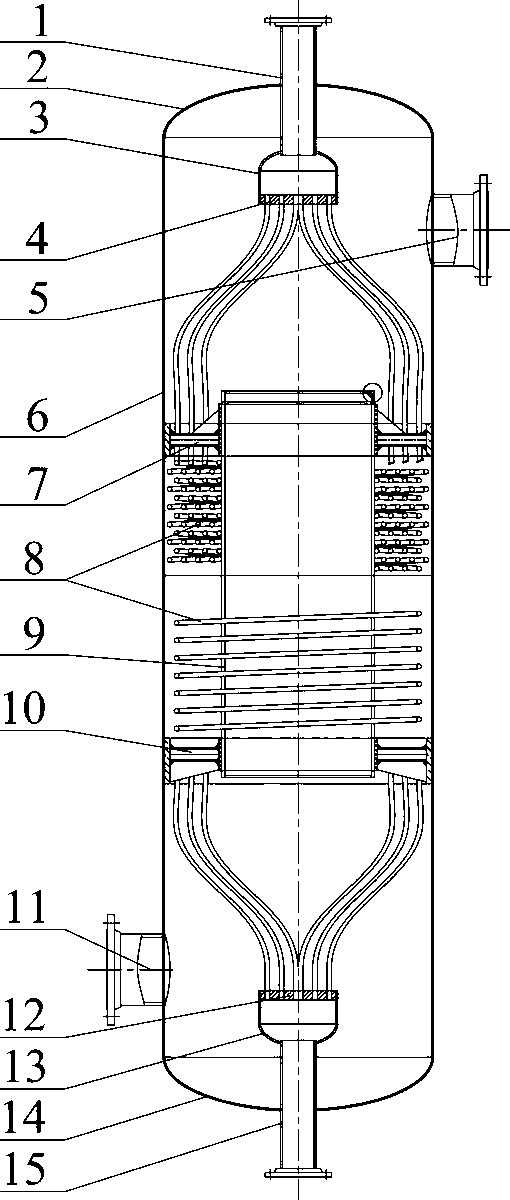

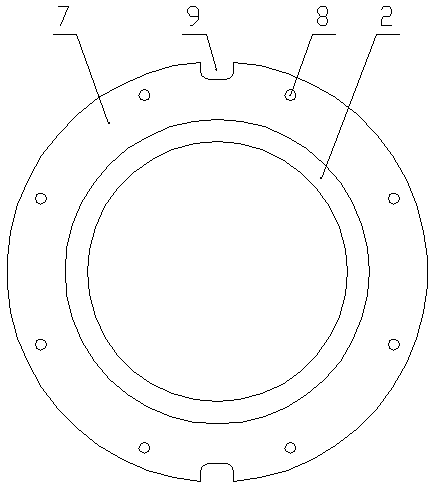

Self-flushing and self-blowing water-gas two-purpose rotational flow filter

InactiveCN102728120AExtend effective water filtration timeExtend your lifeDispersed particle filtrationStationary filtering element filtersRotational flowElectric power

The invention belongs to the field of water and gas treatment devices and particularly relates to a self-flushing and self-blowing water-gas two-purpose rotational flow filter, which is used for circulating water and gas treatment for factories of steel smelting, iron smelting, steel rolling and sintering and the like of a metallurgical enterprise, and is also used for the circulating water and gas treatment for industries of buildings, mining, electric power and the like. The self-flushing and self-blowing water-gas two-purpose rotational flow filter comprises a cylinder body comprising three parts including a separating filtering cavity, a water drainage cavity and a dirt storage cavity; the separating filtering cavity is provided with an inlet pipe; the water drainage cavity is provided with an outlet pipe; the lower part of the dirt storage cavity is provided with a dirt discharge valve; and an inverted-conical filtering net is arranged between the separating filtering cavity and the water drainage cavity. The self-flushing and self-blowing water-gas two-purpose rotational flow filter has the characteristics of being simple in structure, reasonable in design, strong in adaptability, not easy to be plugged, reliable in running, and simple and convenient to maintain.

Owner:北京五一环保科技股份有限公司

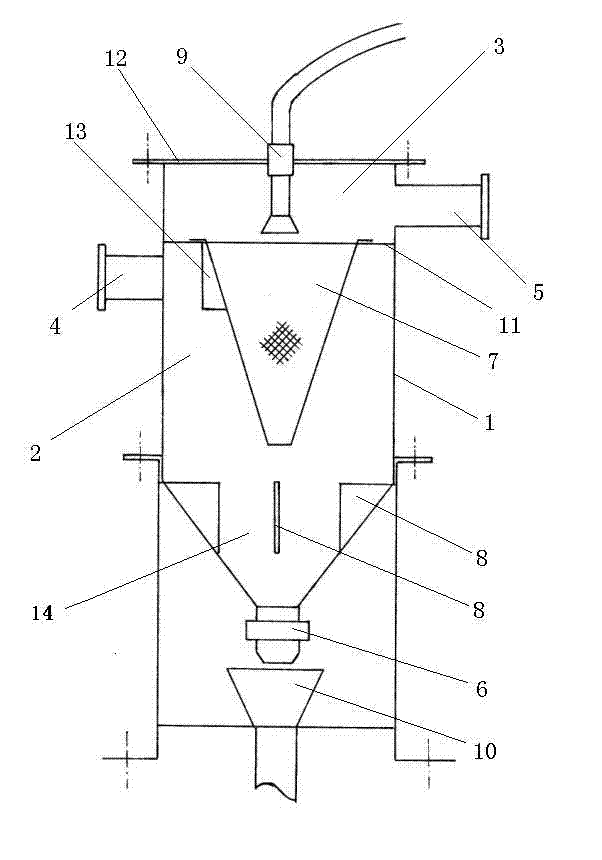

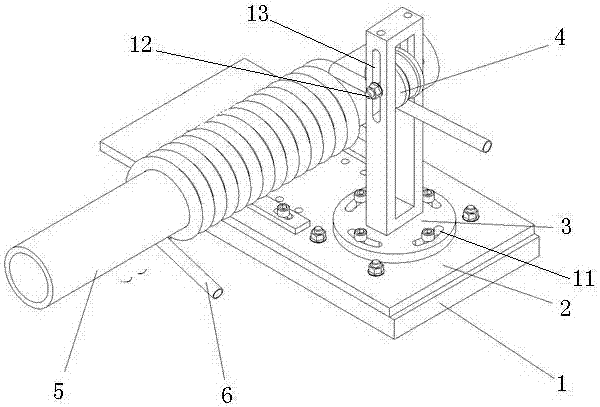

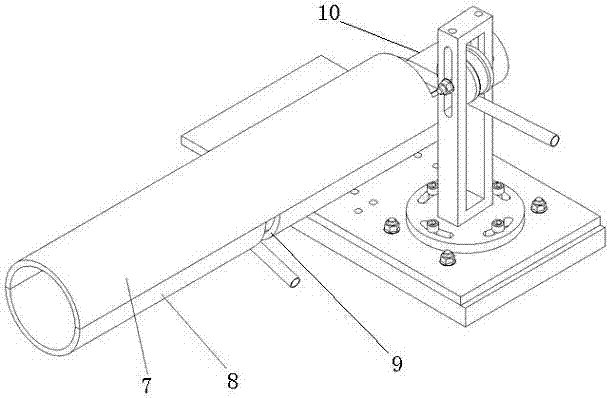

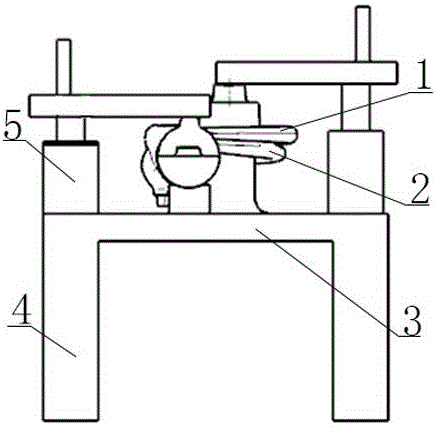

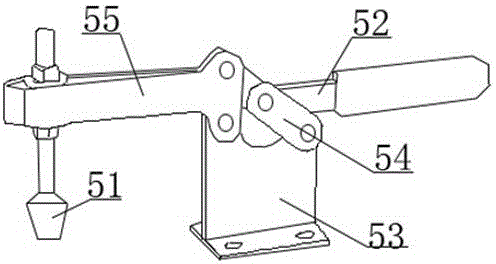

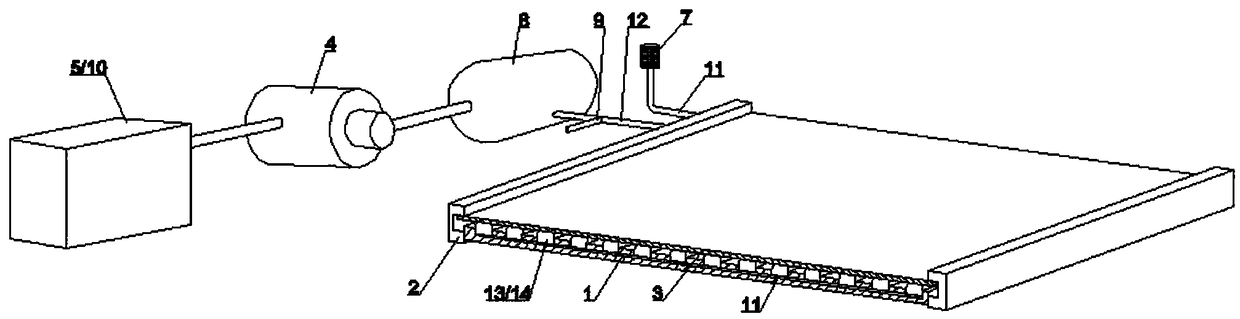

Device and method for forming seamless dual-layer spiral coil pipe

PendingCN107186022AAchieve moldingSimple structureShaping toolsHeat exchange apparatusClassical mechanicsStructural engineering

Provided are a device and method for forming a seamless dual-layer spiral coil pipe. The device is characterized by mainly comprising a lathe middle carriage, a base, a roller support, a roller, an inner pipe mold, the coil pipe, an outer pipe upper mold and an outer pipe lower mold. The base is fixed to the lathe middle carriage through T-shaped slotted bolts. The roller support is fixed to the base through screws. The roller is fastened with nuts after being adjusted to have the proper height. The end portion of the inner pipe mold is clamped in a three-claw chuck, and the tail of the inner pipe mold is jacked by a jacking base at the tail of a lathe. When the inner layer of the right-hand spiral coil pipe is formed, the middle carriage is moved rightwards, and when the outer layer of the right-hand spiral coil pipe is formed, the middle carriage is moved leftwards. With the device and method, the seamless dual-layer spiral coil pipe can be formed, the structure is simple, and the forming precision is controllable.

Owner:JIANGSU NEW HENGJI SPECIAL EQUIP

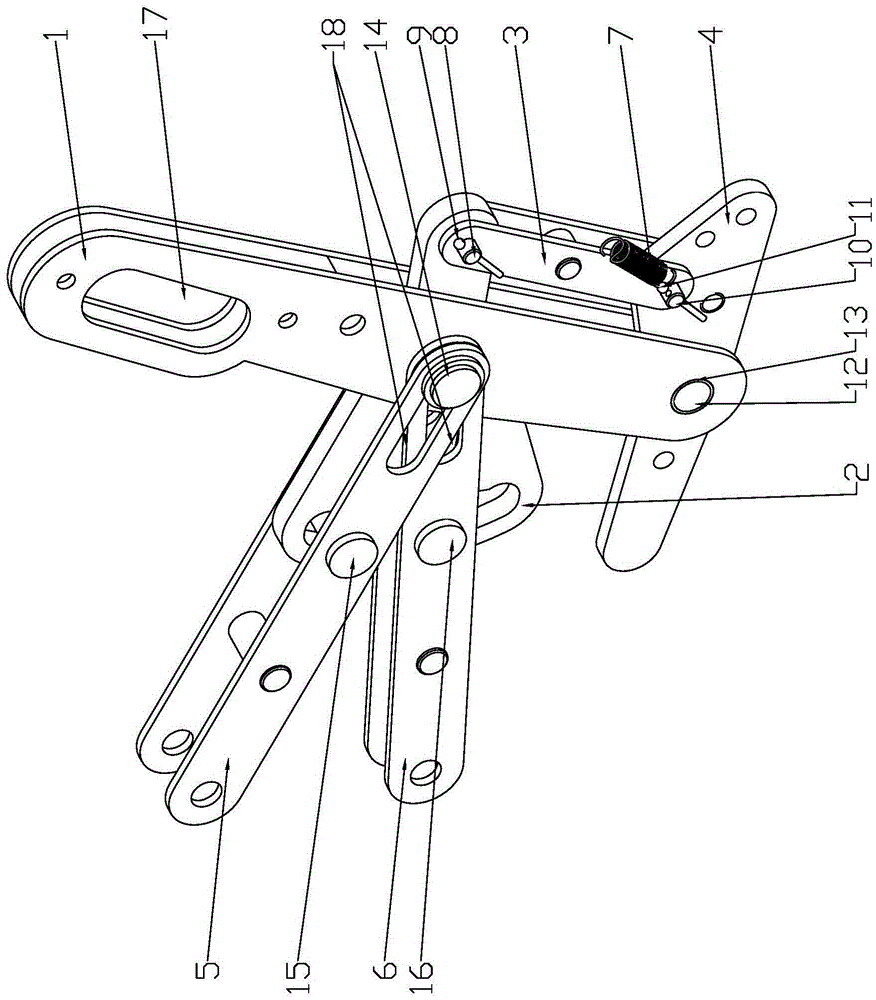

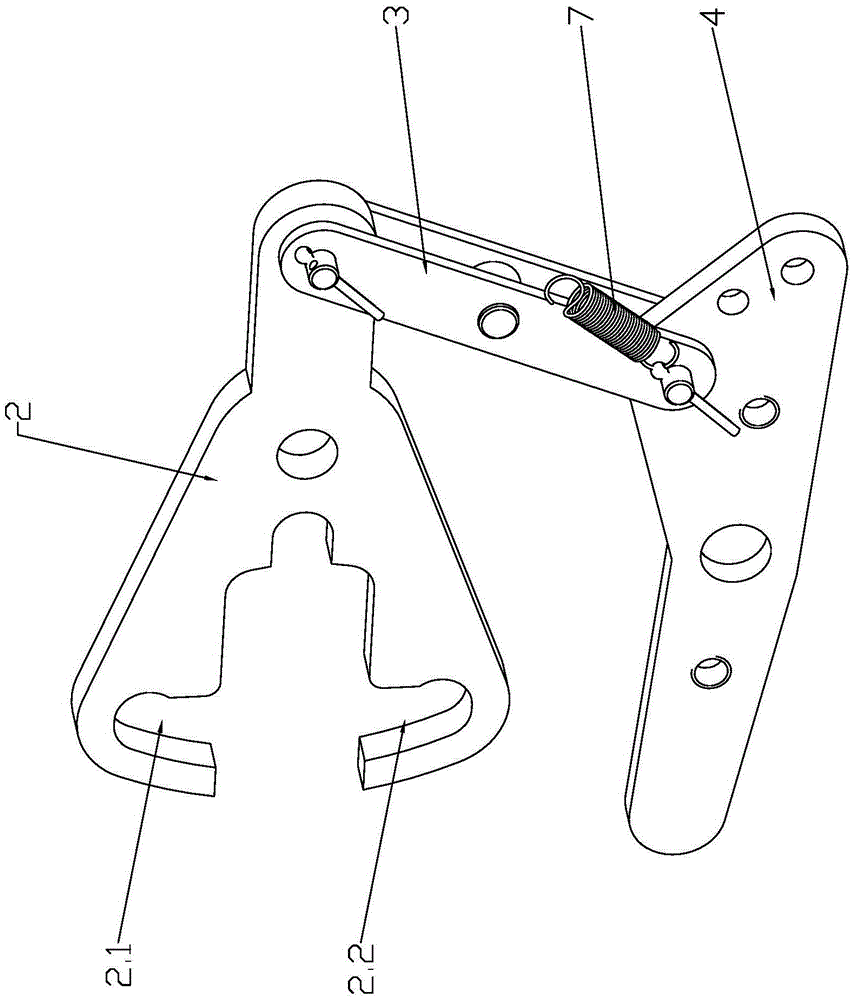

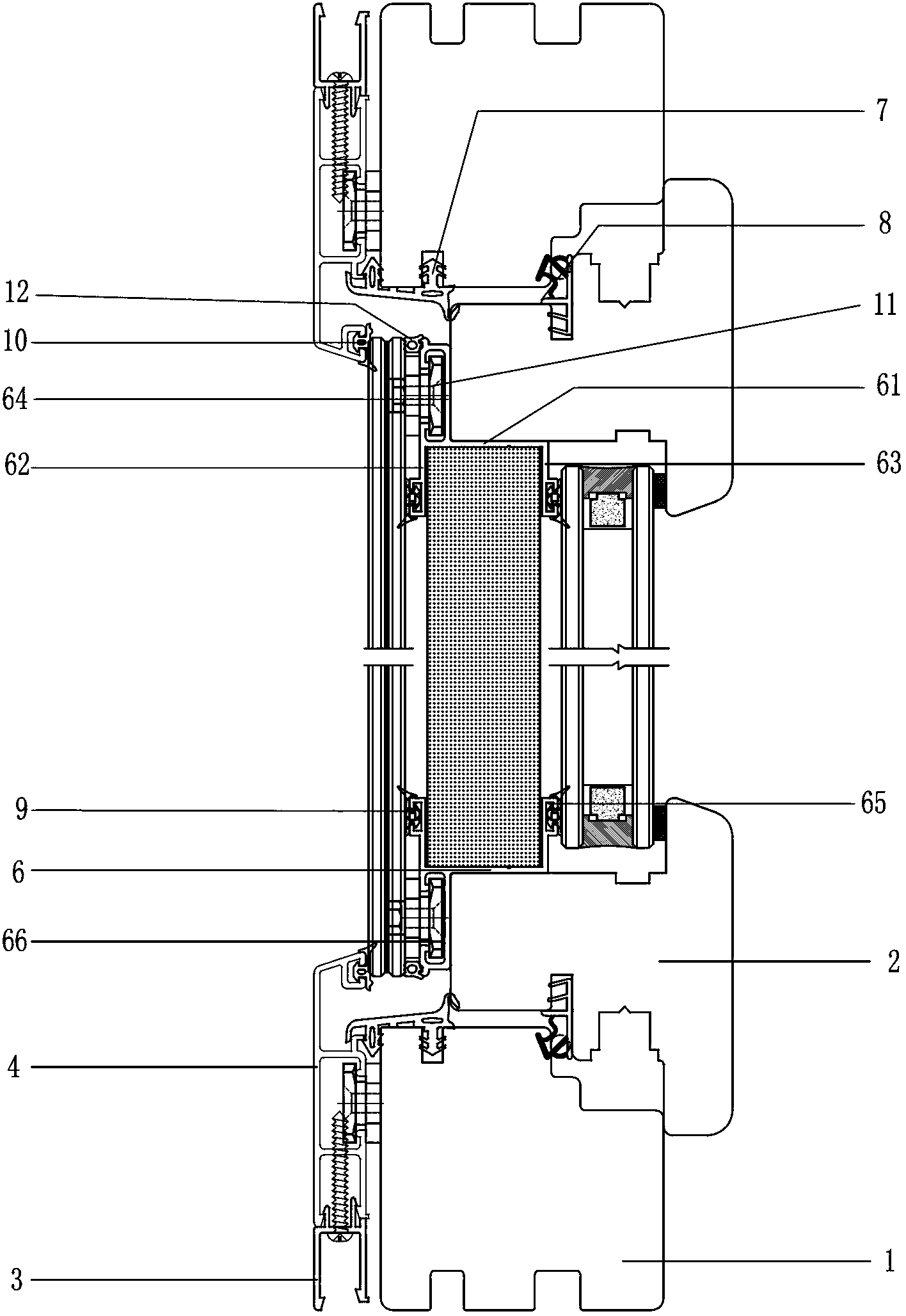

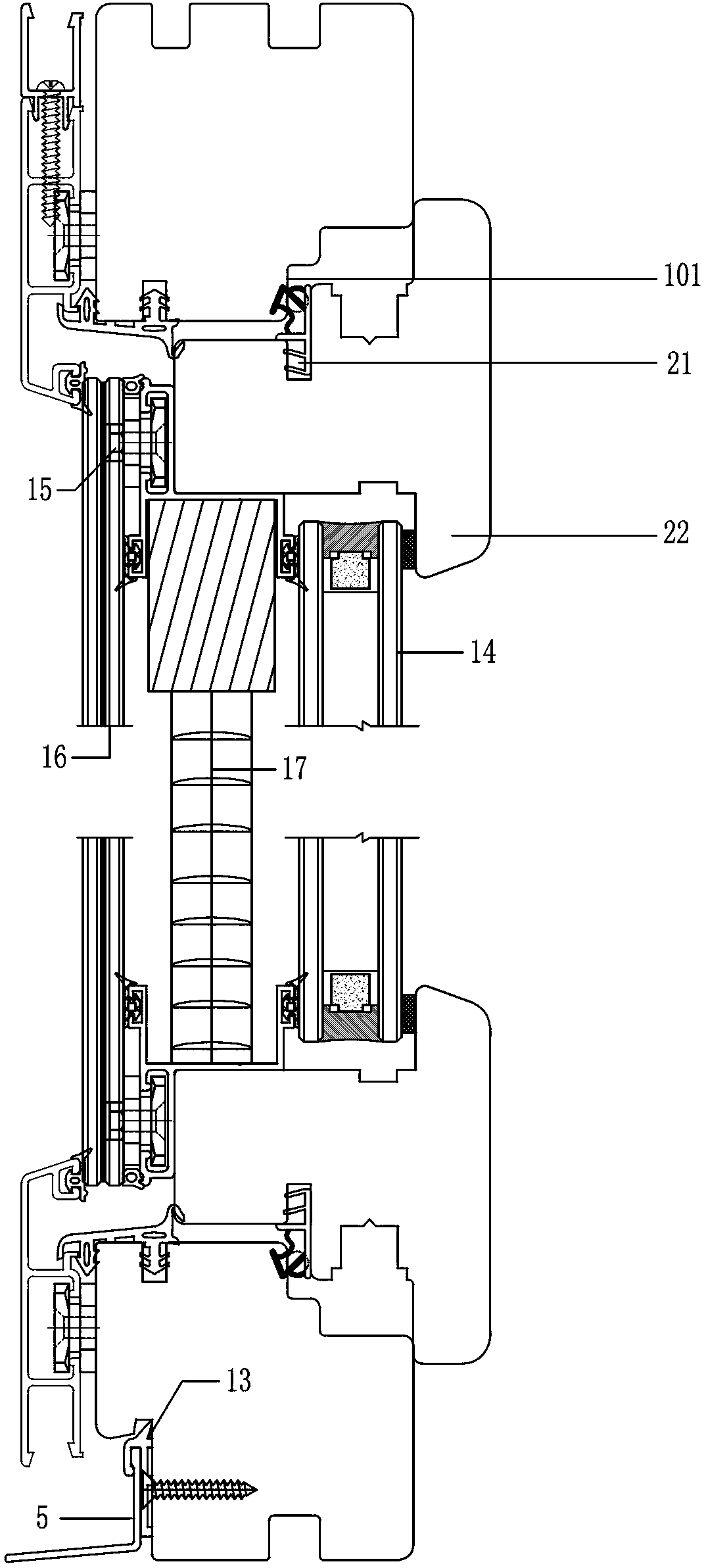

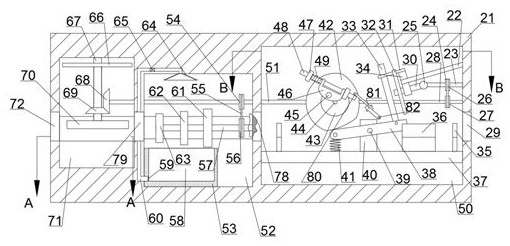

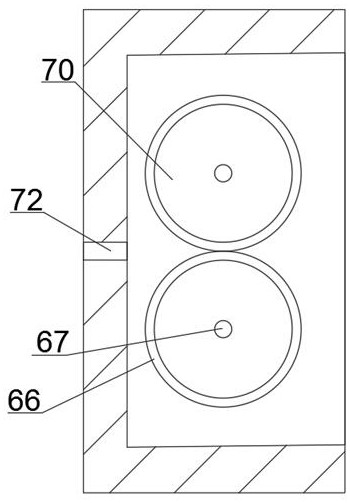

Selection device for normally-used and emergency power supplies of automatic transfer switching device

ActiveCN105551854AReduce frictionSimple structureContact driving mechanismsStandby powerTransfer switch

The invention relates to an automatic transfer switching device, in particular to a selection device for normally-used and emergency power supplies of the automatic transfer switching device, belonging to the technical field of a power supply device. The selection device comprises a control connection rod, a selection connection rod, a driven connection rod, a basic connection rod, a normally-used power supply switch-on connection rod and an emergency power supply switch-on connection rod, wherein the middle part of the basic connection rod is connected with the lower end of the control connection rod by a first rotation shaft, the right part of the basic connection rod is connected with the lower end of the driven connection rod by a second pin shaft, the upper end of the driven connection rod is connected with the right end of the selection connection rod by a first pin, and the middle part of the selection connection rod is sequentially connected with the middle part of the control connection rod and the right ends of the normally-used power supply switch-on connection rod and the emergency power supply switch-on connection rod by a central shaft. Since only a main coil is used for carrying out switch-on and switch-off motions on an automatic transfer switch, an extra latch tripping device is not needed to be arranged, thus, the production cost of a product is greatly reduced, and meanwhile, the selection device becomes more safe and reliable.

Owner:WUXI HANKWANG ELECTRIC

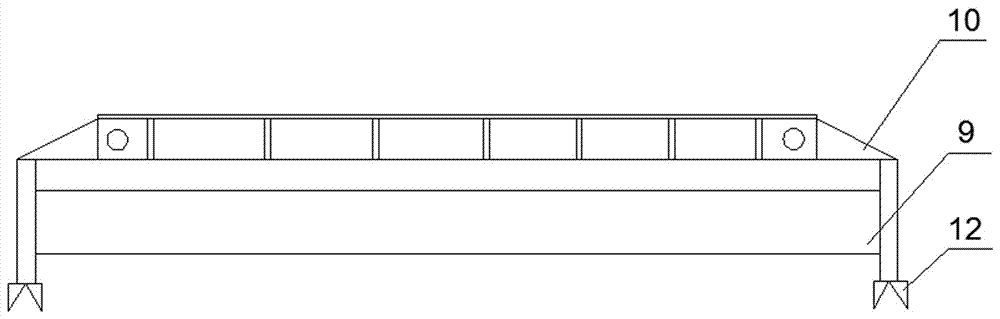

Low-temperature methanol-methanol winding tubular heat exchanger design and calculation method

InactiveCN102999707ANot easy to repairAvoid easy removalSpecial data processing applicationsMathematical modelProcess engineering

The invention provides a low-temperature methanol-methanol winding tubular heat exchanger design and calculation method and is mainly applicable to the fields of coal gas, coal methanol and other coal chemical industries comprising the fields of low-temperature gas purification and low-temperature liquefied separation for low-temperature methanol wash process at the temperature of -70 DEG C. The design and calculation process comprises basic structural design and a heat exchange process calculation process, wherein the process calculation comprises the steps of: determining qualitative temperature of a low-temperature methanol inlet / outlet, searching physical methanol parameters under the qualitative temperature and pressure, calculating logarithmic mean temperature difference, calculating a thermal load, determining the specification of a heat exchanger, determining a pipeline arrangement mode, and calculating a total heat transfer coefficient, total heat transfer area, effective heat exchange height of the heat exchanger and other main parts. According to the method, a complete mathematical model for low-temperature methanol-methanol winding tubular heat exchanger process calculation is provided, the mathematical model can be applied to the heat exchange process calculation process of winding pipe bundles, so that a whole set of methanol-methanol winding tubular heat exchanger is designed.

Owner:张周卫

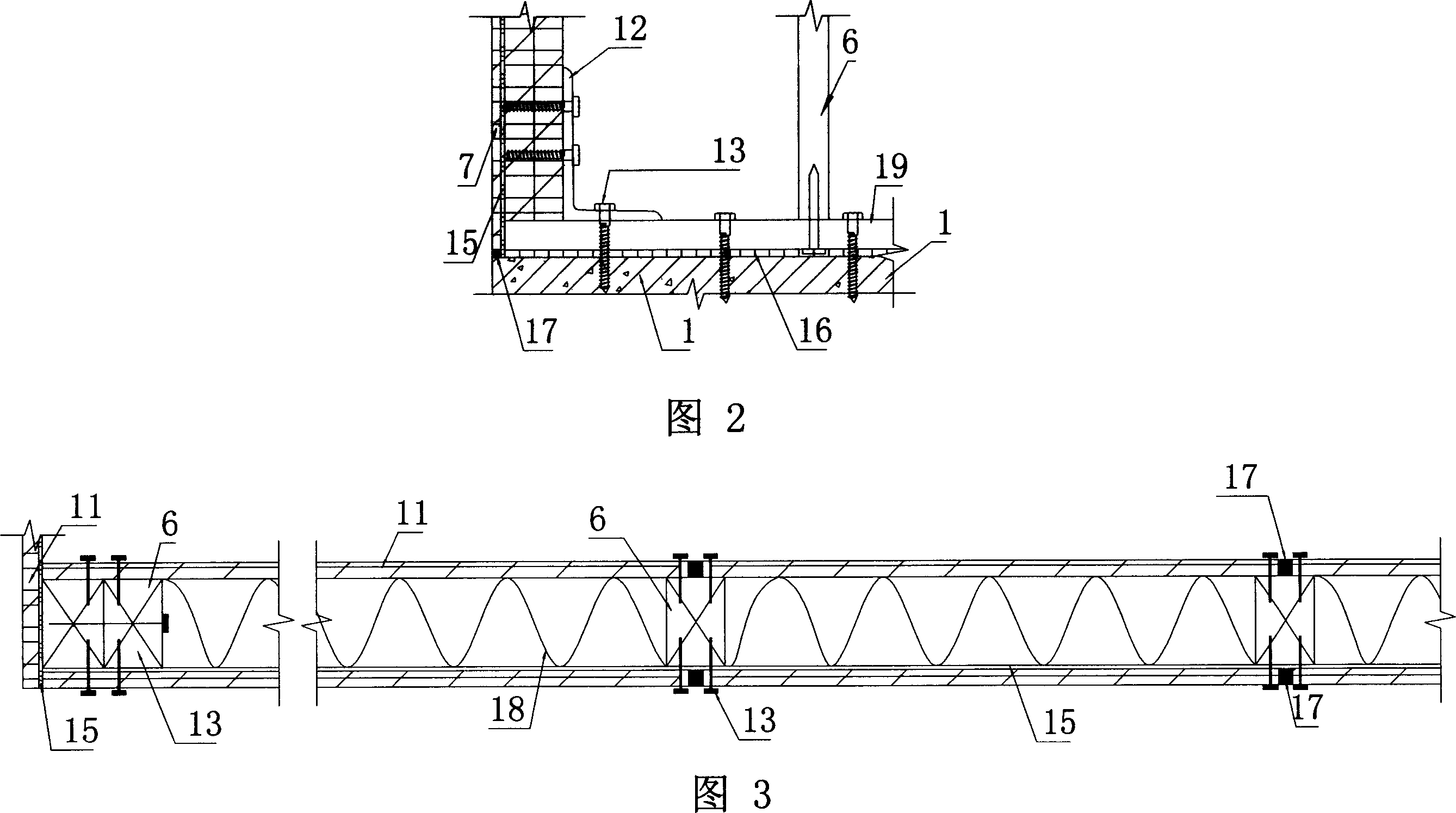

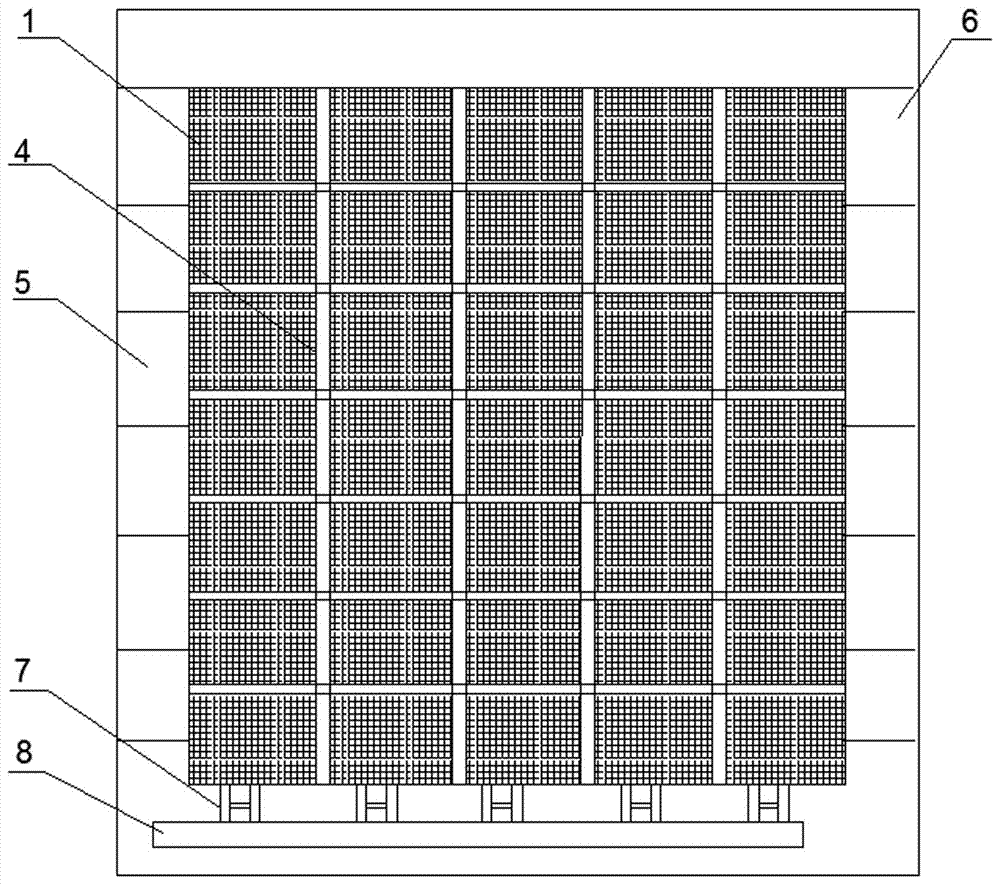

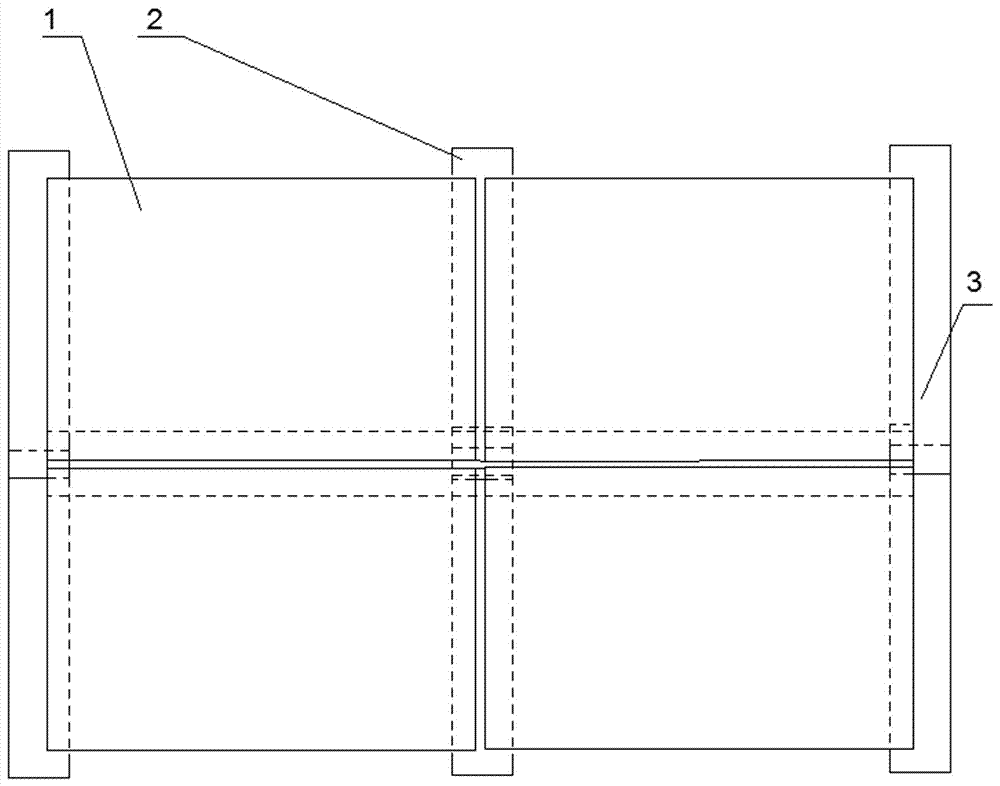

Photovoltaic roof structure easy to repair

PendingCN107060231AReduce usageGood waterproof and airtightPhotovoltaic supportsRoof covering using slabs/sheetsEngineeringElectrical and Electronics engineering

Owner:谢光华

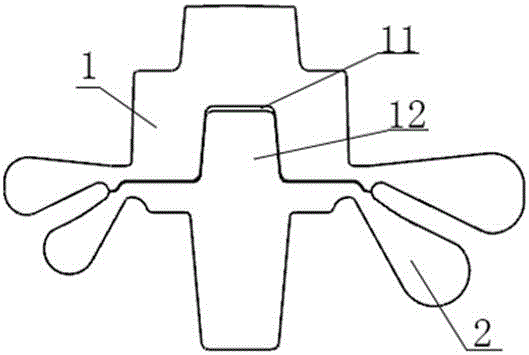

Seamless combination technology for sand cores of double-vortex volute

ActiveCN106180577AEasy to repairGood workmanshipFoundry mouldsFoundry coresDesign improvementAdhesive

The invention relates to a seamless combination technology for sand cores of a double-vortex volute. The seamless combination technology comprises the following steps: making cores; assembling the sand cores, to be specific, carrying out electrode corner cleaning on the sharp corners of the parts needing to be connected of the upper sand core and the lower sand core, coating the connecting parts with one layer of adhesive, covering the upper sand core on the lower sand core, placing the upper sand core and the lower sand core on an auxiliary tool together, clamping the upper sand core and the lower sand core for 1-2 minutes, solidifying the adhesive, and enabling a seam between the upper sand core and the lower sand core to be 0.1mm; soaking the sand cores, to be specific, placing the sand cores which are glued together in a paint mixing barrel and soaking the sand cores in a paint of which the baume degree reaches 30-60; and drying, to be specific, carrying out drying operation on the soaked sand cores by a drying oven, setting drying tine according to product structures, which is generally 16 minutes, and finishing the sand core technical process. The seamless combination technology has the advantages that the technology is perfect, the operation is convenient, the plate-isolated core drilling defects of a double-runner turbo-charging shell are solved, and by utilizing the auxiliary tool and die design improvement, casting plate-isolated core drilling defects caused by large sand core seams can be effectively solved.

Owner:江苏华培动力科技有限公司

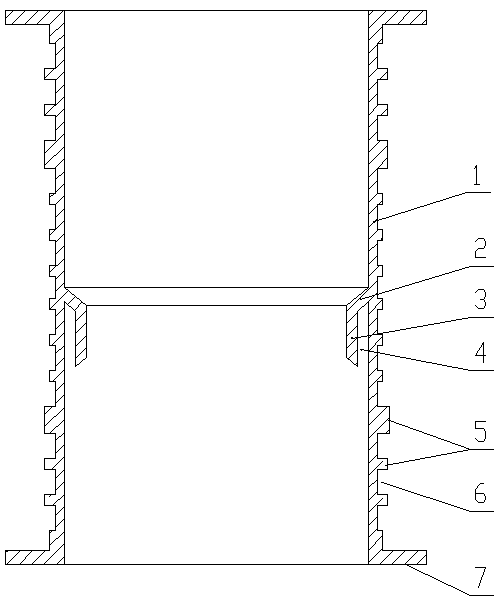

Side drainage type directly-embedded part and construction method thereof

The invention discloses a side drainage type directly-embedded part. The directly-embedded part comprises a straight pipe which is of a cylinder structure, a spigot and socket pipe is fixedly arrangedat the middle position in the straight pipe in the axial direction and comprises a horn mouth section and a straight pipe section, the outer ring of the thicker end of the horn mouth section is fixedly connected to the inner wall of the straight pipe, one end of the straight pipe section is fixedly connected to the thinner end of the horn mouth section, a spigot and socket ring groove is formed between the outer circle of the straight pipe section and the inner wall of the straight pipe, and pre-embedded positioning structures are arranged on the outer circumference and the two end parts of the straight pipe. The invention further discloses a construction method for the side drainage type directly-embedded part. According to the directly-embedded part and the construction method thereof,the usage amount of waterproof materials, backfilling materials and drainage branch pipe fittings can be decreased, the wall penetrating and chiseling and hole plugging operation can be reduced, the structural strength quality of a wall body can be improved, the construction difficulty and the construction cost can be lowered, the drainage safety can be greatly improved, and the pipeline blockageprobability can be lowered.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

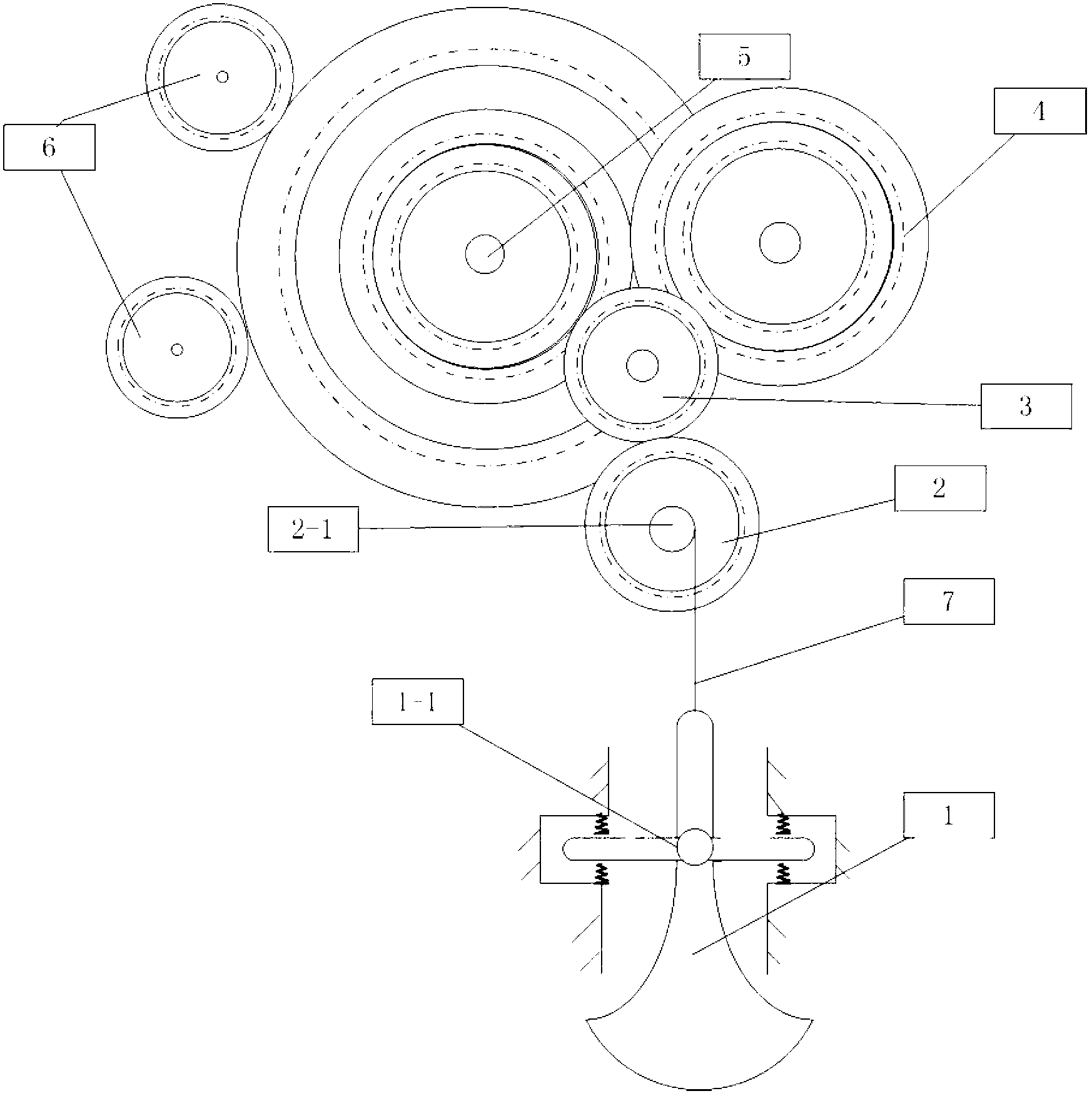

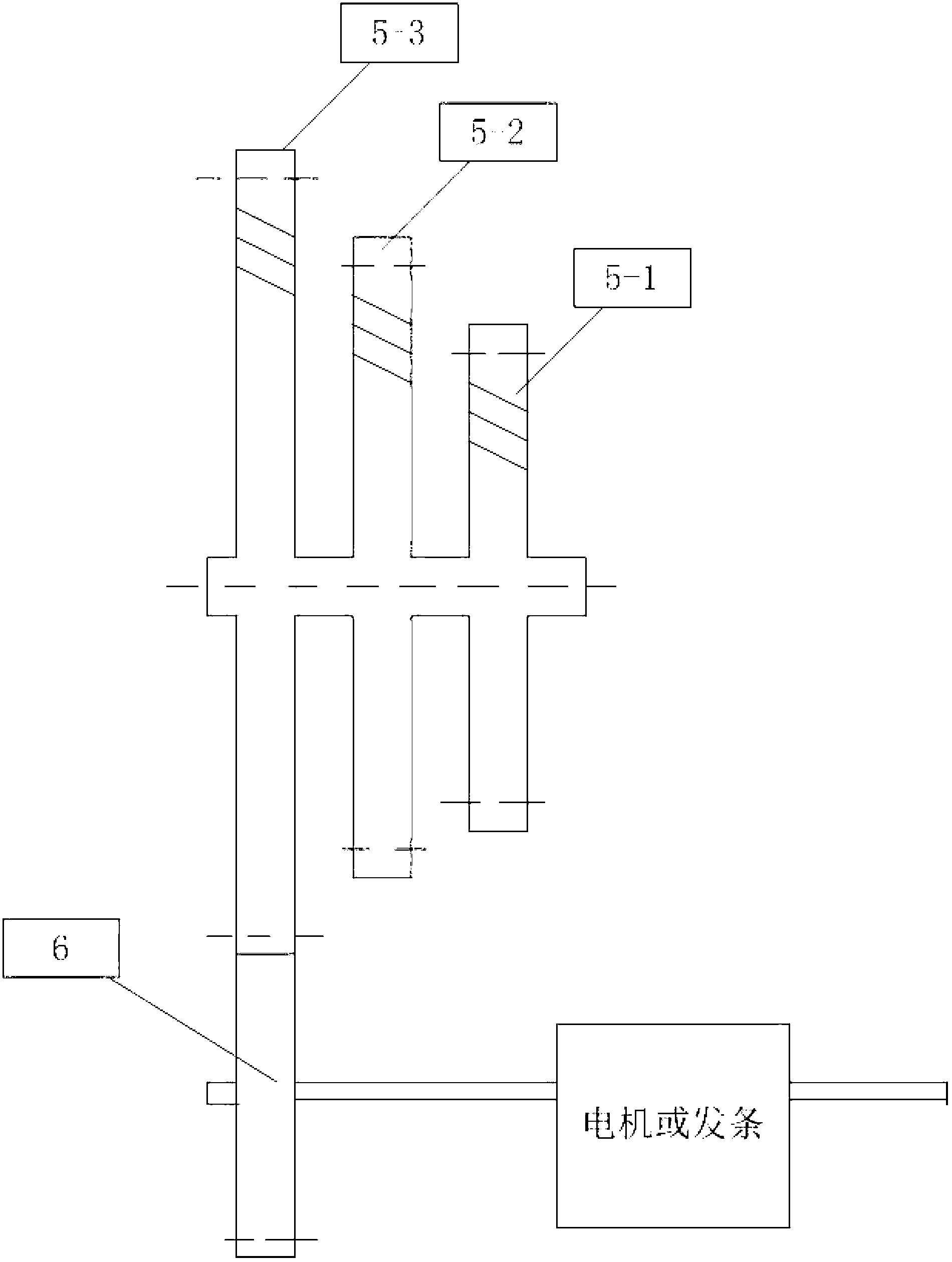

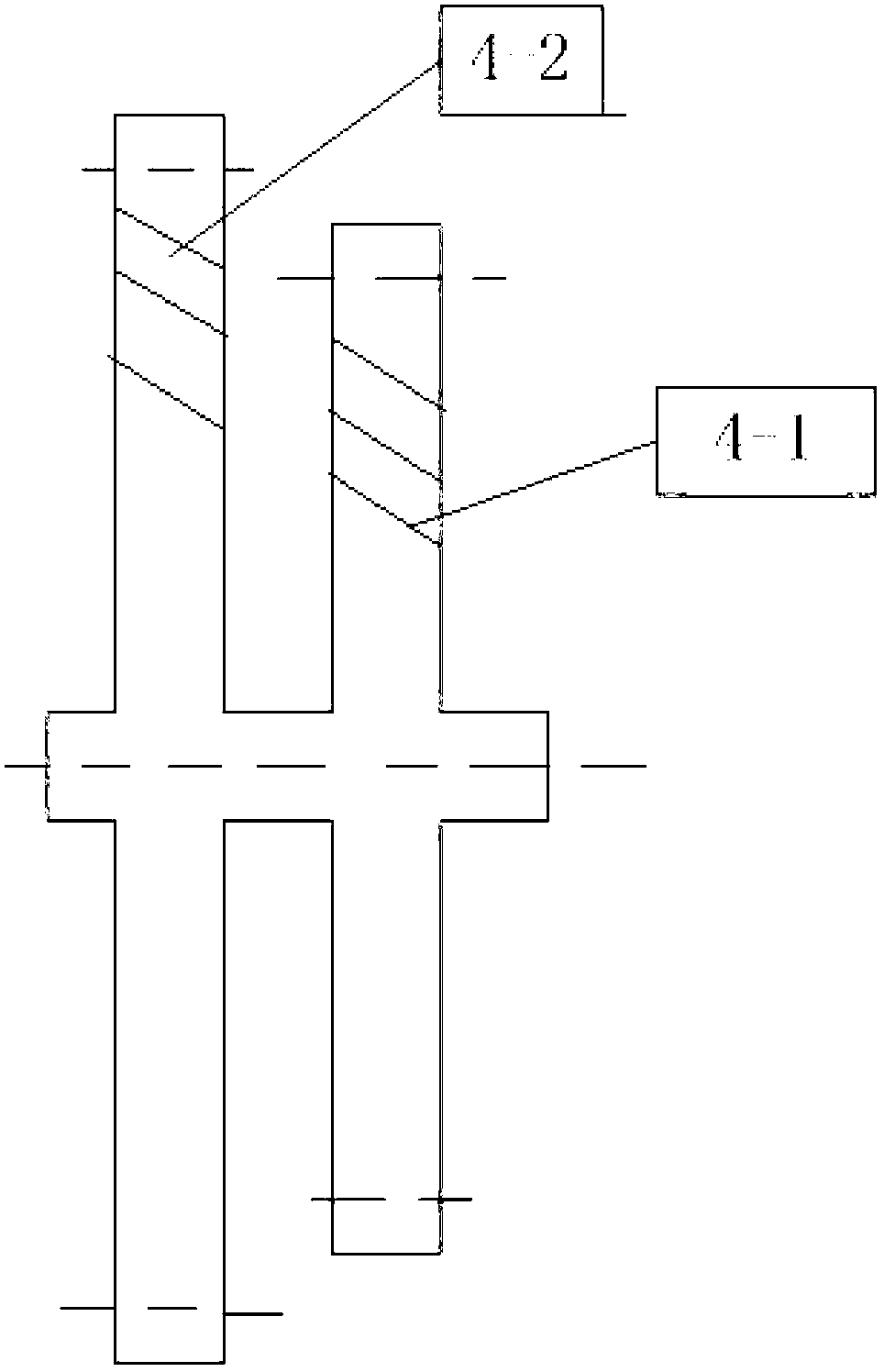

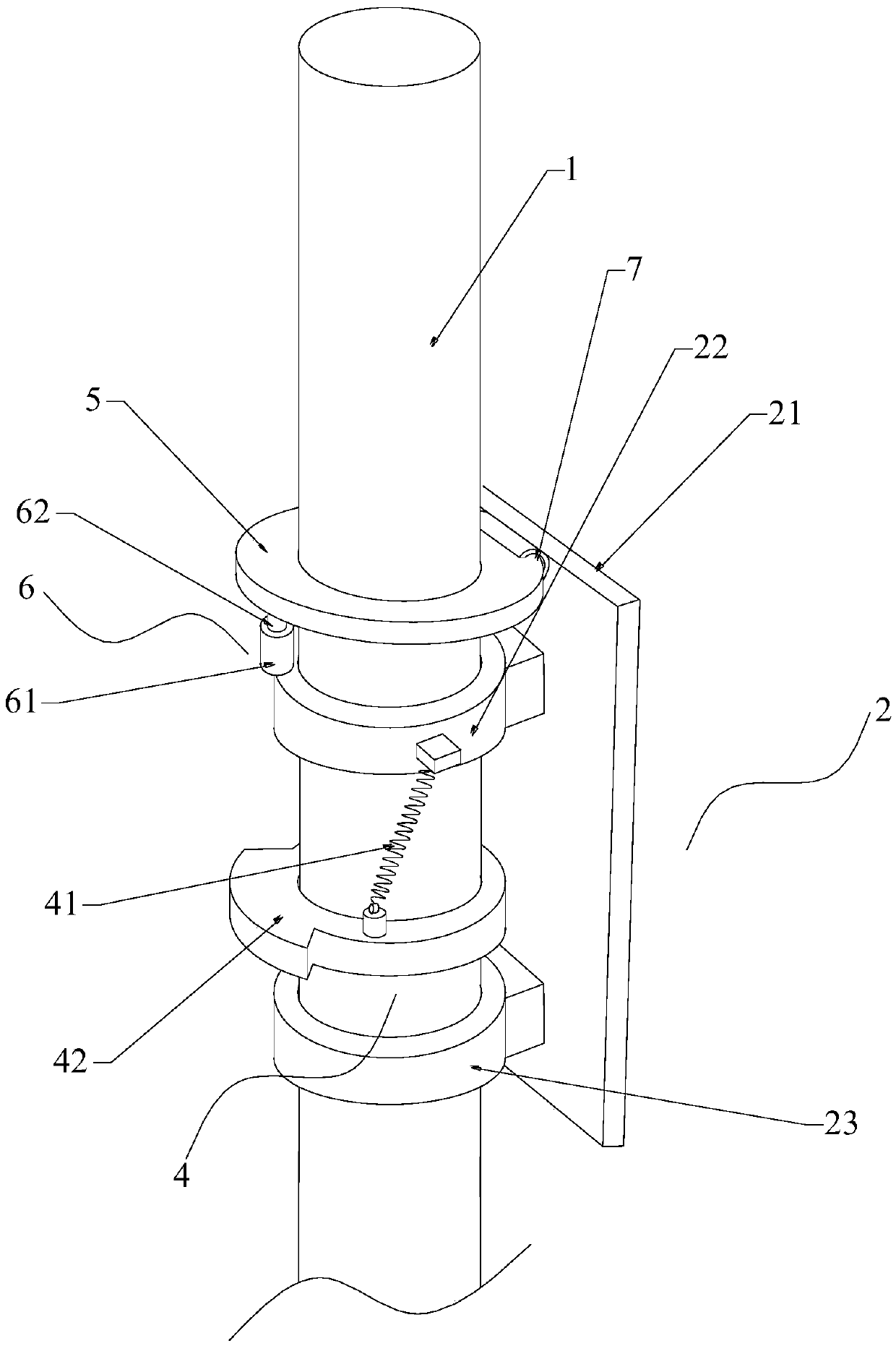

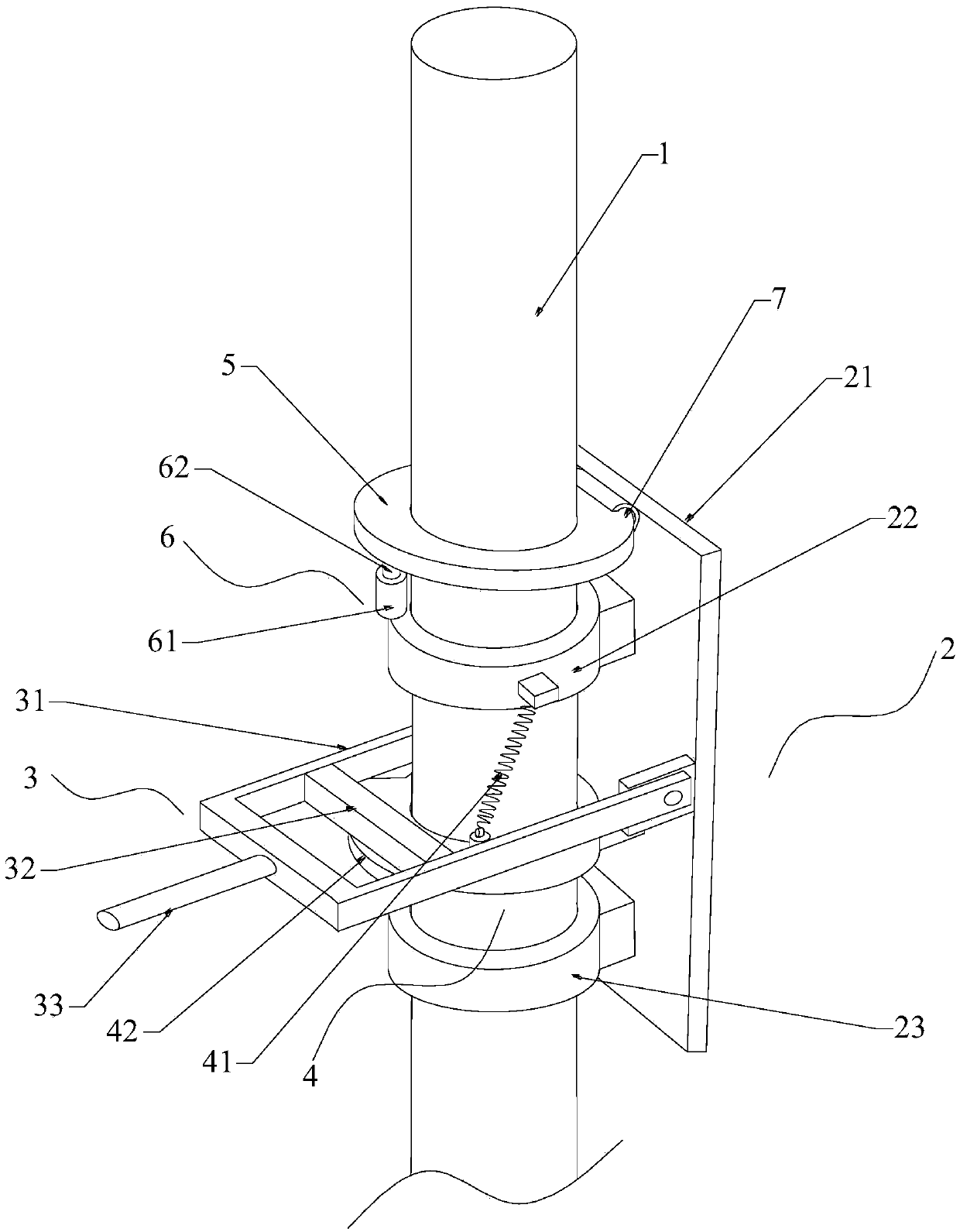

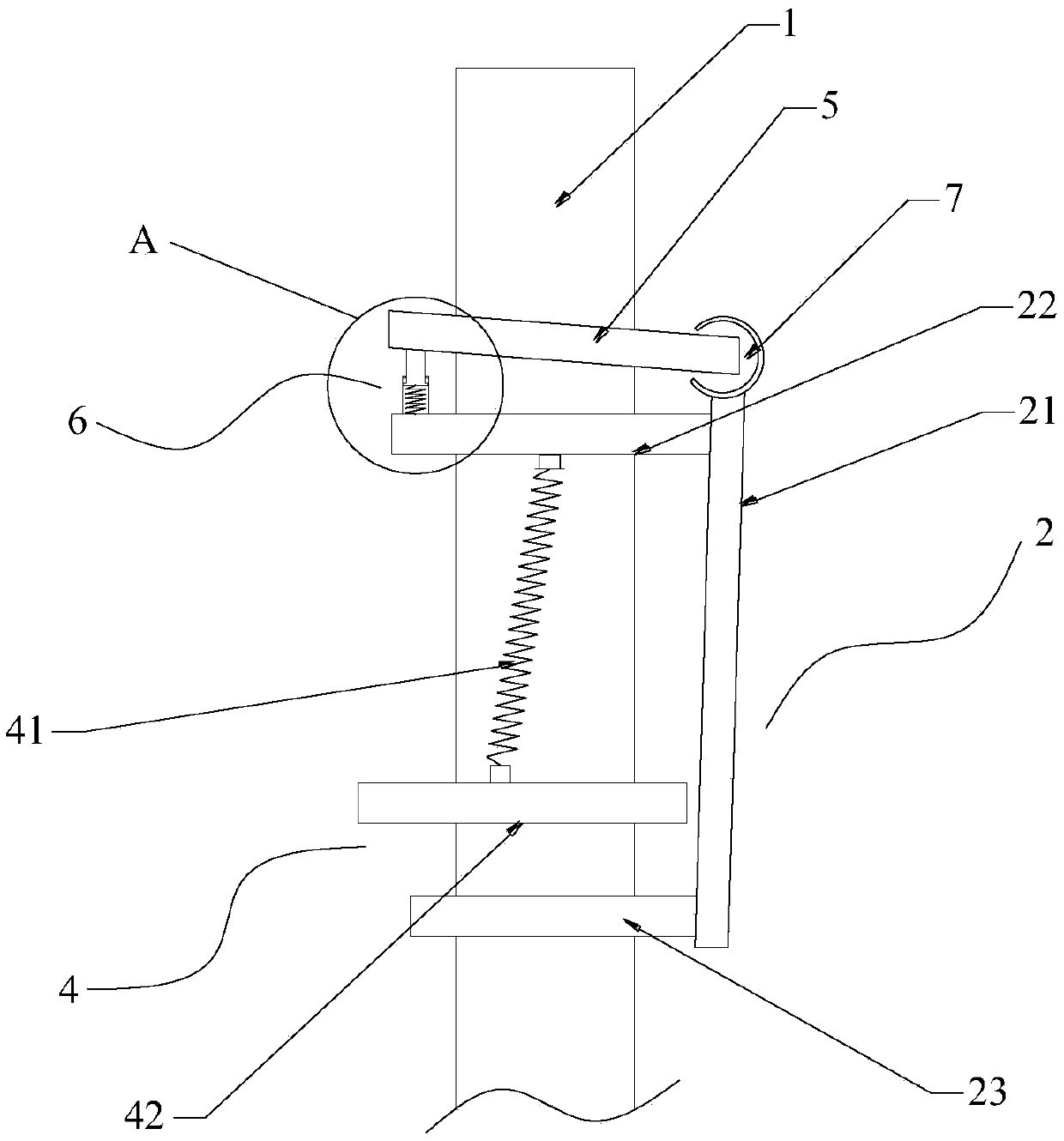

Wave energy drive device

InactiveCN103174578AImprove utilization efficiencyImprove transmission efficiencyMachines/enginesEngine componentsDrive wheelEnergy supply

The invention provides a wave energy drive device. A swing rod structure system (1) is provided with a cardan shaft (1-1), a torsion spring shaft is installed on a swing gear (2), the upper end of the swing rod structure system (1) is connected with the torsion spring shaft (2-1) of the swing gear through a drag rope (7), a transition gear (3) is meshed with the swing gear (2), an upper gear (4-1) of an auxiliary turning gear, and an upper gear ( 5-1) of a turning driving wheel, a lower gear (4-2) of the auxiliary turning gear is meshed with a middle layer gear (5-2) of the turning transmission gear, a one-way output shaft gear (6) is meshed with a lower gear (5-3) of the turning transmission gear, and a one-way output shaft is connected with an energy storage device. The wave energy drive device has strong operability and maneuverability, does not need to be placed at a fixed position, can move along with a mother body without affecting the action effect, is simple in structure and low in cost, and can be combined with other energy supply devices or a plurality of devices to reach driving demands.

Owner:三亚哈尔滨工程大学南海创新发展基地

Underwater cable solid filling material, preparation method and application

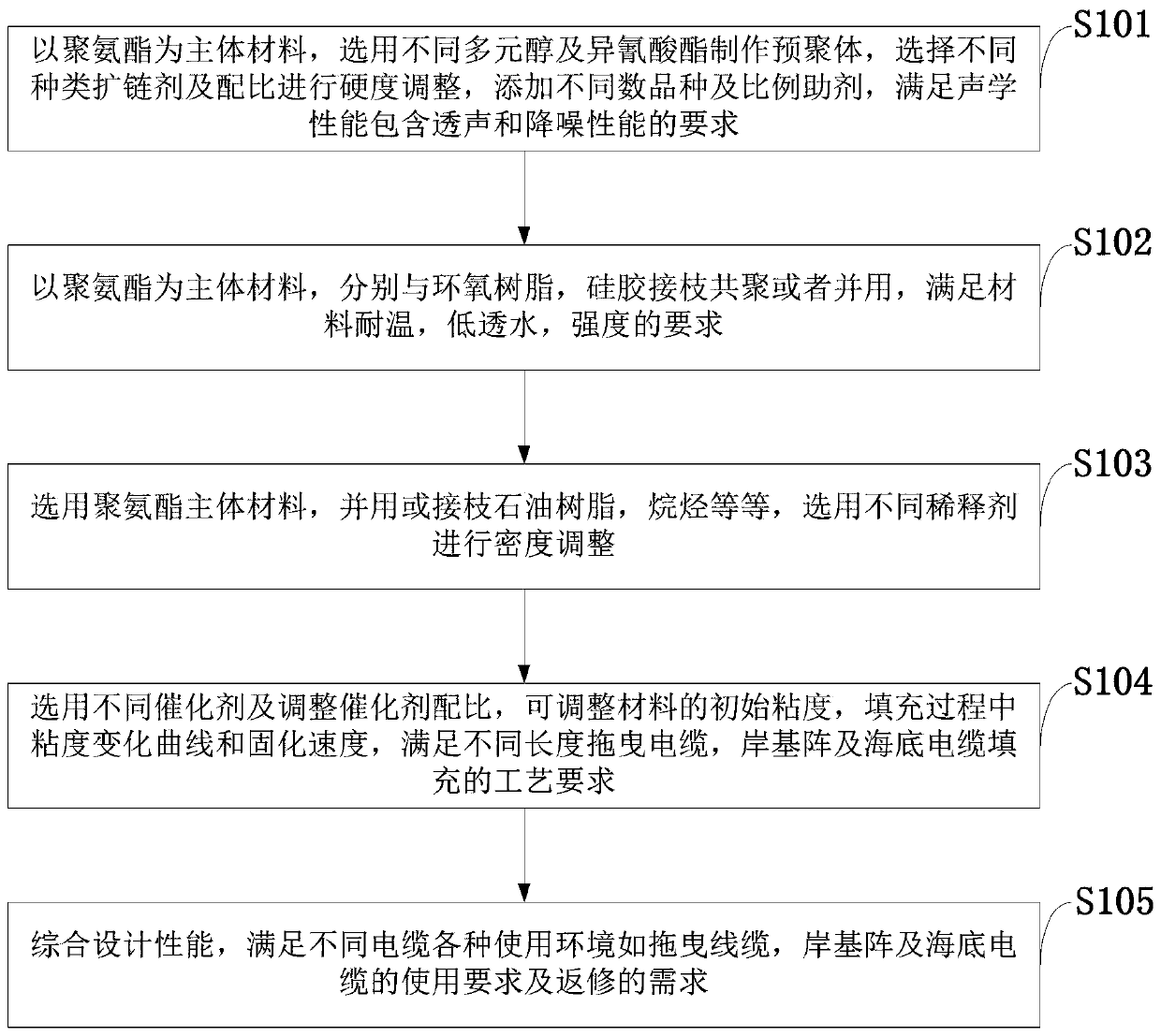

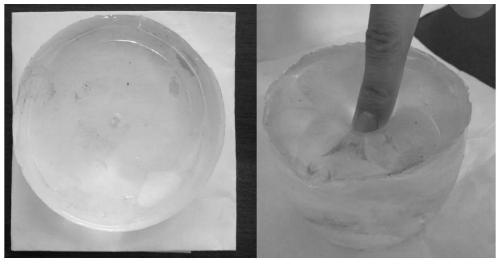

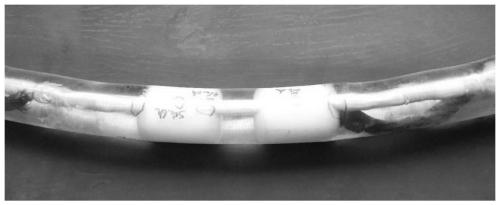

ActiveCN111518253AAdjustable initial viscosityMeet the process requirements of fillingSubmarine cablesInsulated conductorsEpoxyAlkane

The invention belongs to the technical field of filling materials, and discloses an underwater cable solid filling material, a preparation method and applications thereof. Polyurethane is adopted as amain material, different polyols and isocyanates are selected to prepare a prepolymer, different types of chain extenders and ratios are selected to carry out hardness adjustment, and different typesand ratios of assistants are added; polyurethane is used as the main material and is subjected to graft copolymerization or combined use with epoxy resin and silica gel respectively, and the requirements of temperature resistance, low water permeability, strength and adhesion of the material are met by adjusting the molecular structure of the material; the polyurethane main material is selected for grafting or petroleum resin and alkane are used together, and different diluents are selected for density adjustment so that the suspension requirements of the towing cable at different water depths are met; different catalysts are selected and the catalyst ratio is adjusted, the initial viscosity and the curing speed of the material can be adjusted, and different process requirements of customers are met; the storage life of the material can reach 5 years, and the material can be adjusted according to comprehensive performance requirements of products and is easy to repair.

Owner:李春梅

Trestle type column drilling rig lifting mechanism, trestle type column drilling rig and trestle type column drilling rig lifting method

The invention belongs to the technical field of trestle type column drilling rigs and provides a trestle type column drilling rig lifting mechanism which comprises a moving frame for movement on a trestle type column. The moving frame is hinged with a pressing rod mechanism for driving the moving frame to move up, and a supporting member for providing a supporting point required for driving the moving frame to move up under down pressing by the pressing rod mechanism is arranged under the pressing rod mechanism, and a locking plate for locking the moving frame to the trestle type column is further arranged on the moving frame. The problem is solved that a lifting mechanism in the prior art is prone to damage and is unstable when used.

Owner:SHIJIAZHUANG DEPU DRILLING EQUIP CO LTD

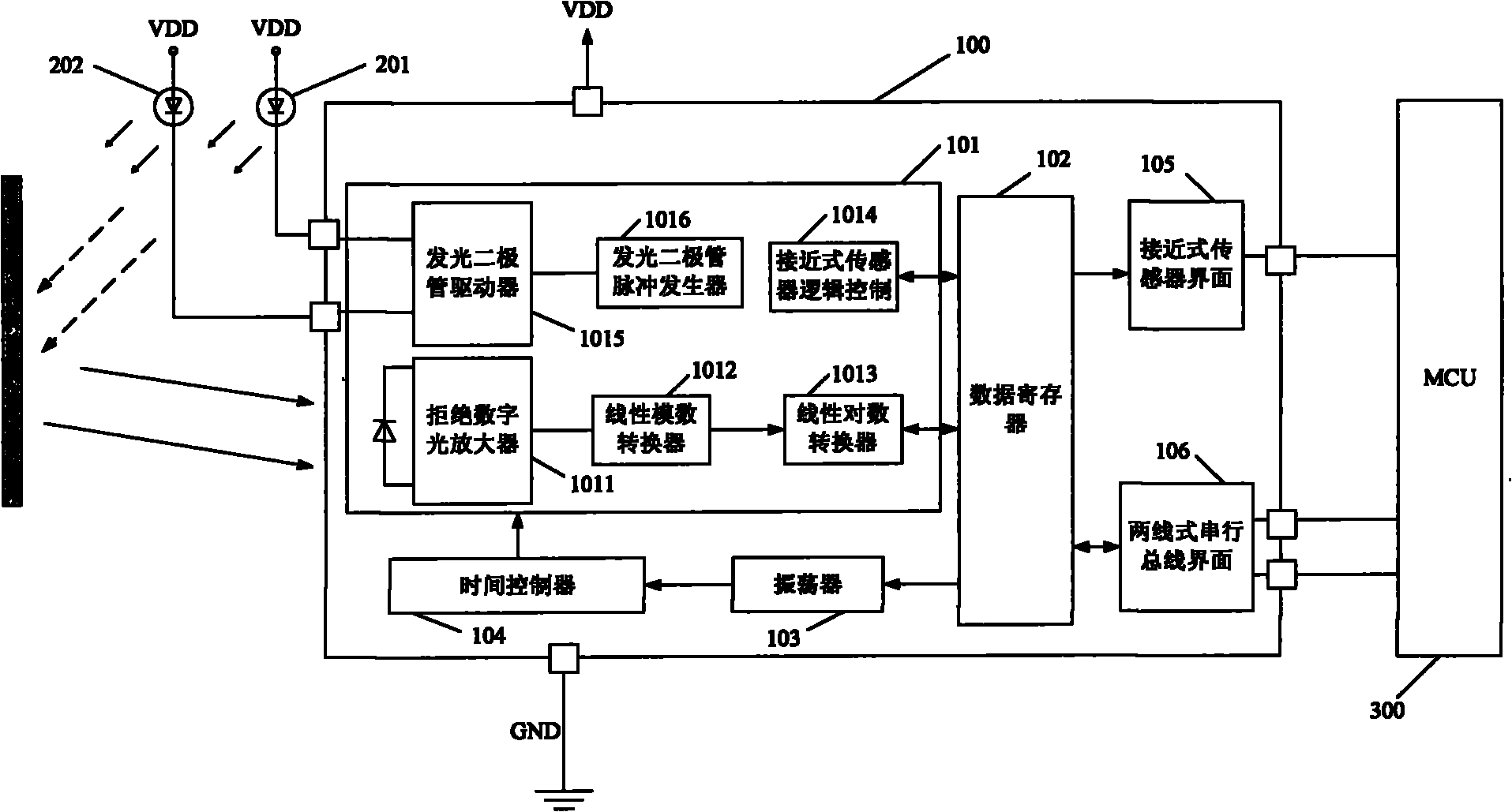

Mobile terminal and contactless type keystroke method thereof

InactiveCN102377848ANot easy to repairNovelty experienceTelephone set constructionsPhysicsMultipoint control unit

The invention discloses a mobile terminal and a contactless type keystroke method thereof. The mobile terminal comprises an optical type proximity sensor, a first light source, a second light source and an MCU (Multipoint Control Unit), wherein the first light source and the second light source are electrically connected with the optical type proximity sensor respectively, the optical type proximity sensor is further electrically connected with the MCU, and the first light source, the second light source and the optical type proximity sensor are arranged on the same outside surface of the mobile terminal. The traditional keystrokes which adopt a pressing mode using physical contact have service life, are easy to damage, and are difficult to repair, in addition, contactless type side keys are lacked in the prior art, thus, the invention innovatively provides the mobile terminal and the keystroke method, the real contact with the fingers is not needed, the condition that keystrokes are damaged due to the times of keystroke does not exist, and further, usage experience with richer novelty is brought for users of the mobile terminal.

Owner:SHANGHAI CHENXING ELECTRONICS SCI & TECH CO LTD

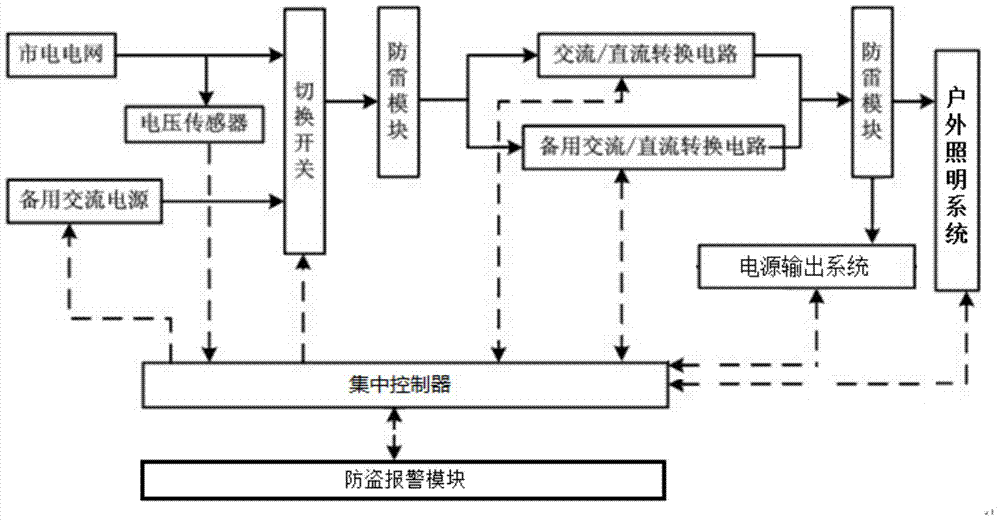

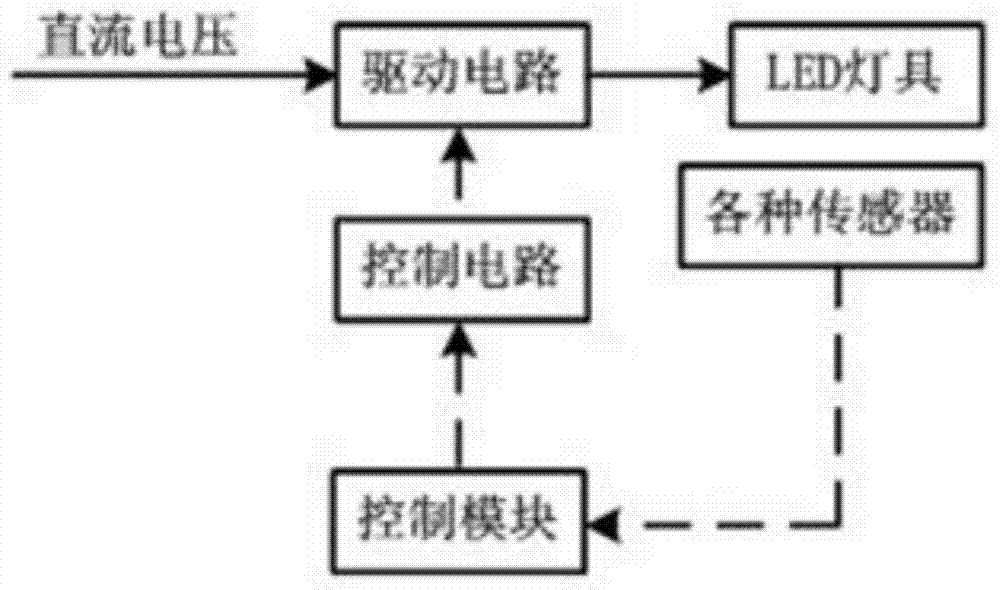

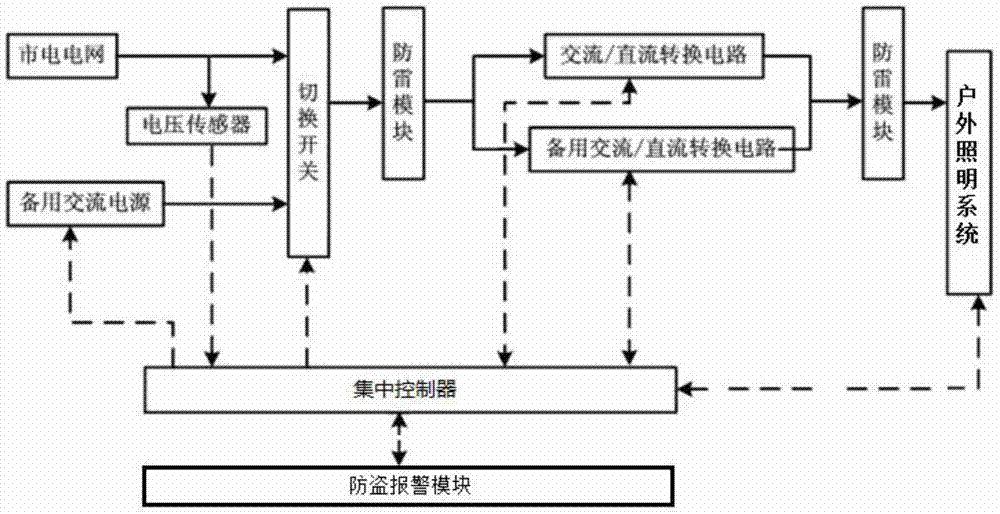

Outdoor centralized power supply system with charging function

InactiveCN103762713AEasy maintenanceImprove energy savingBatteries circuit arrangementsPower network operation systems integrationComputer moduleEngineering

The invention provides an outdoor centralized power supply system with the charging function. The outdoor centralized power supply system with the charging function comprises an alternating current / direct current conversion circuit, a standby alternating current / direct current conversion circuit, an outdoor illuminating system, a power output system and a centralized controller; the centralized controller is respectively connected with the alternating current / direct current conversion circuit, the standby alternating current / direct current conversion circuit, the outdoor illuminating system and the power output system and used for controlling all components in a centralized mode. A control module of the outdoor centralized power supply system is connected with a control circuit of each lamp, the control module can be used for presetting turning-on time and turning-off time of each lamp on one day and can also be used for presetting the brightness of each lamp in different time on one day, and therefore the function of controlling one single lamp is achieved; meanwhile, the outdoor centralized power supply system can also be used for charging external electric equipment.

Owner:AD TOYO LIGHTING GUANGZHOU

Road power generation system

InactiveCN109026575AAvoid dischargeImprove securityMachines/enginesMechanical power devicesFixed frameRoad surface

A road power generation system comprises a fixed frame, a protective layer, a wind power generation unit and electric equipment. The fixed frame is laid on a road pavement and fixedly connected to thepavement and / or road edge stone. An air inlet pipeline and an air outlet pipeline are arranged in the fixed frame, and a first groove is formed in the fixed frame. One end of the air inlet pipeline and one end of the air outlet pipeline both communicate with the first groove. The other end of the air inlet pipeline stretches out of one side of a road or the road edge stone and is connected with afirst one-way valve to prevent air from being discharged into the atmosphere from the air inlet pipeline. An airbag is arranged in the first groove and communicates with the air inlet pipeline and the air outlet pipeline, and the airbag is inflated and then protrudes out of a groove opening of the first groove. The protective layer is laid on the fixed frame. After the airbag is inflated, the protective layer is supported by the airbag. After the airbag is completely deflated, the protective layer is supported by the fixed frame. The wind power generation unit comprises a wind power generatorand a storage battery. The wind power generator comprises a hood, a generator body and a fan. The electric equipment is connected to the storage battery or the generator body.

Owner:叶尔兰·拜散

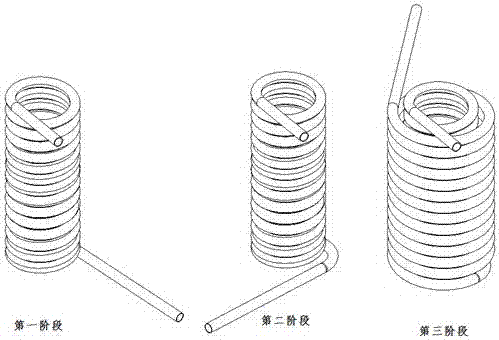

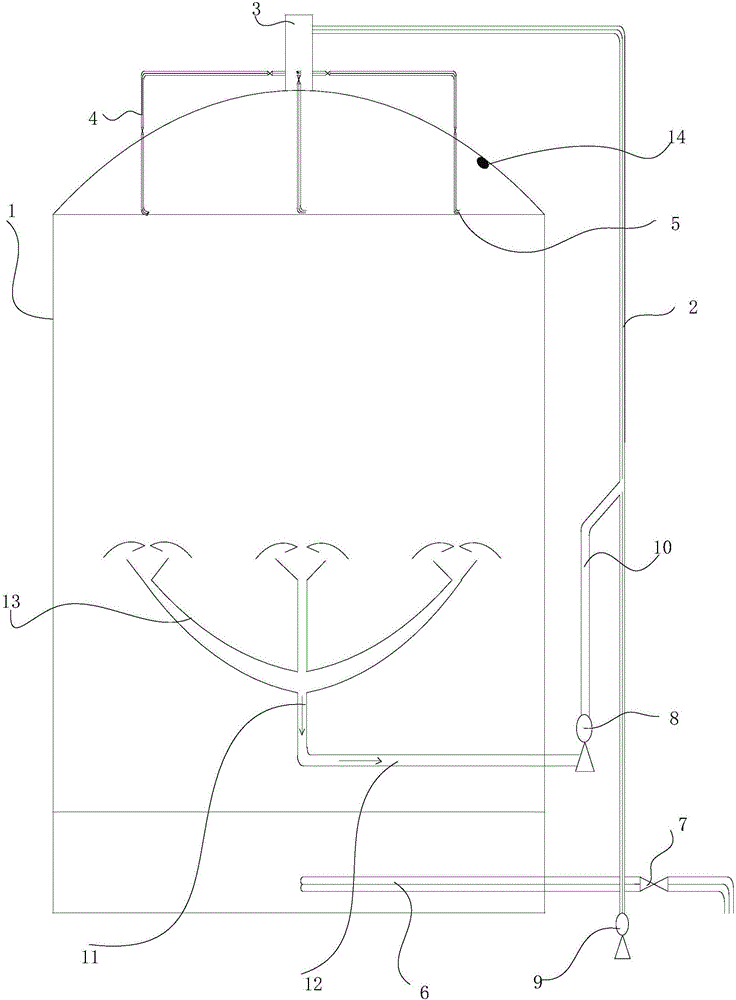

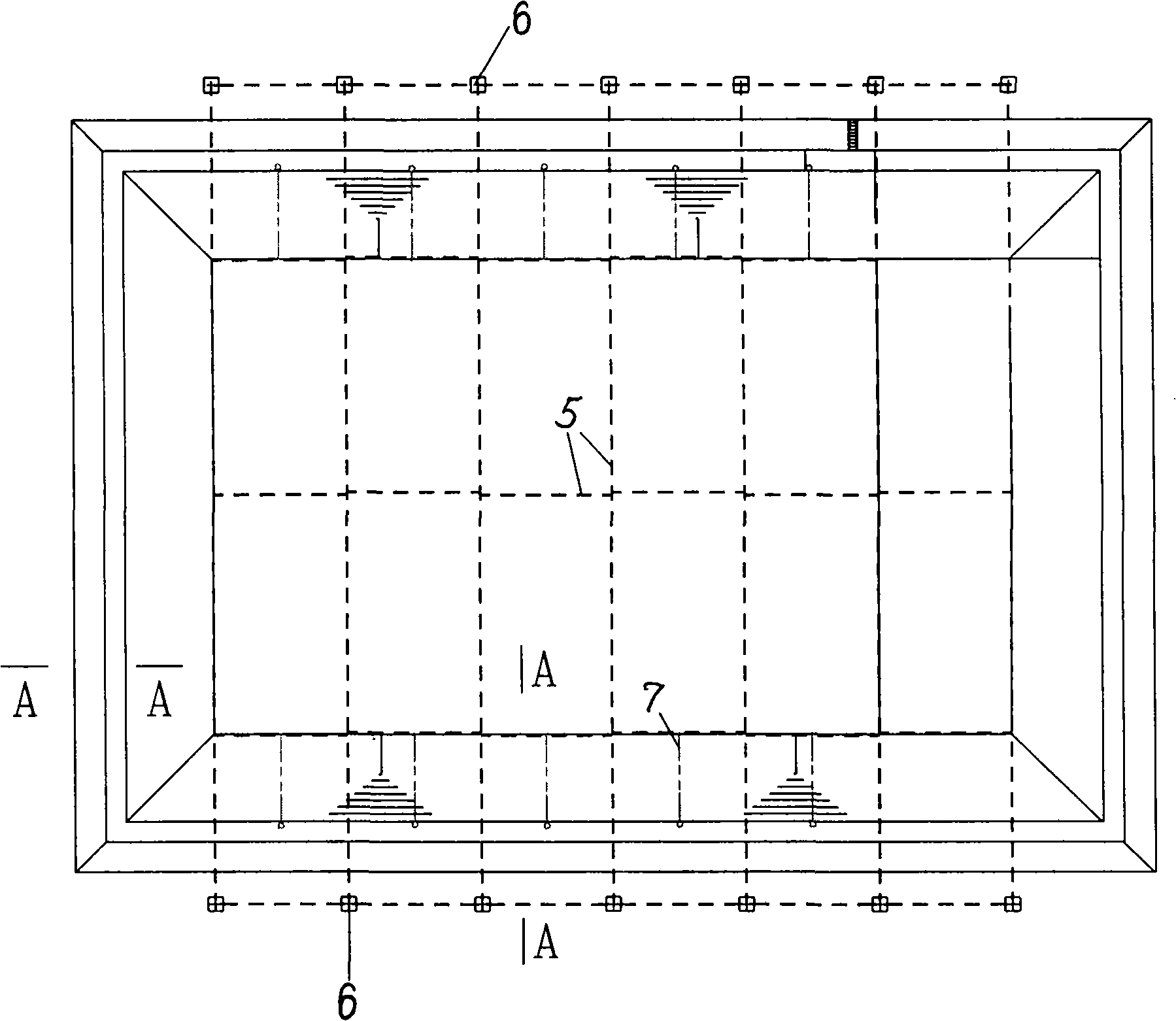

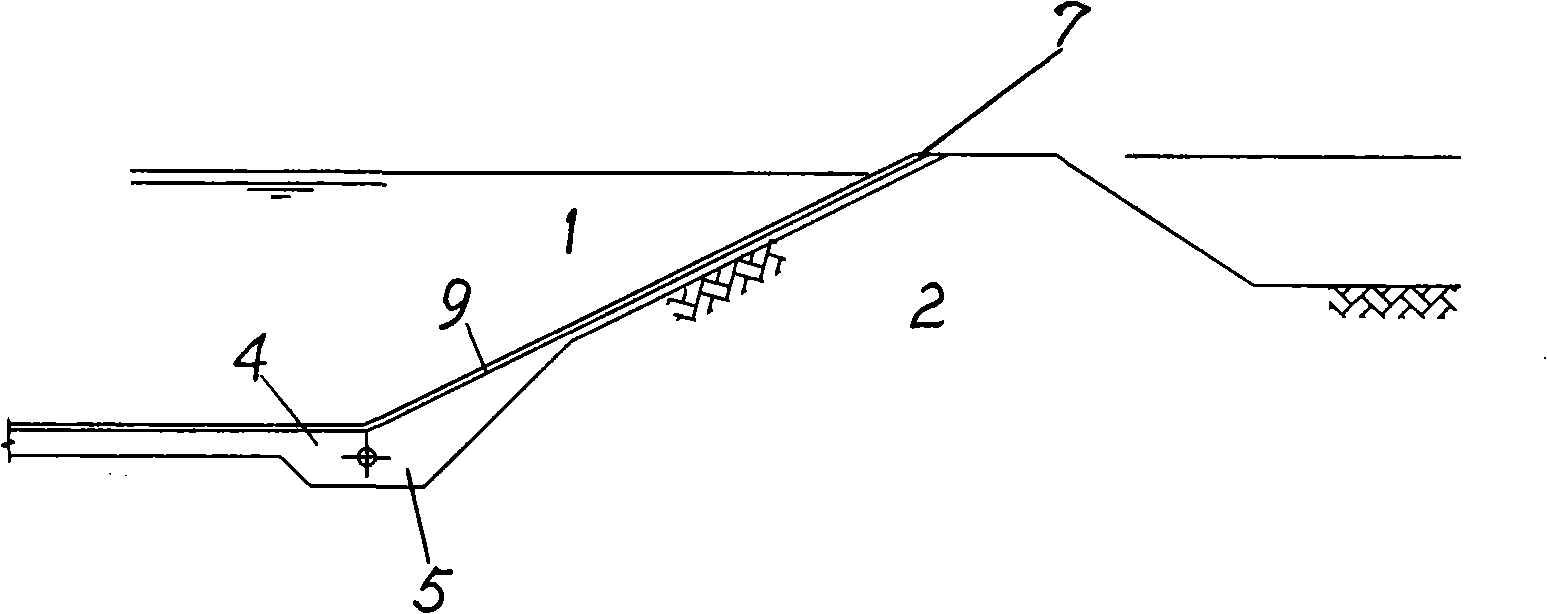

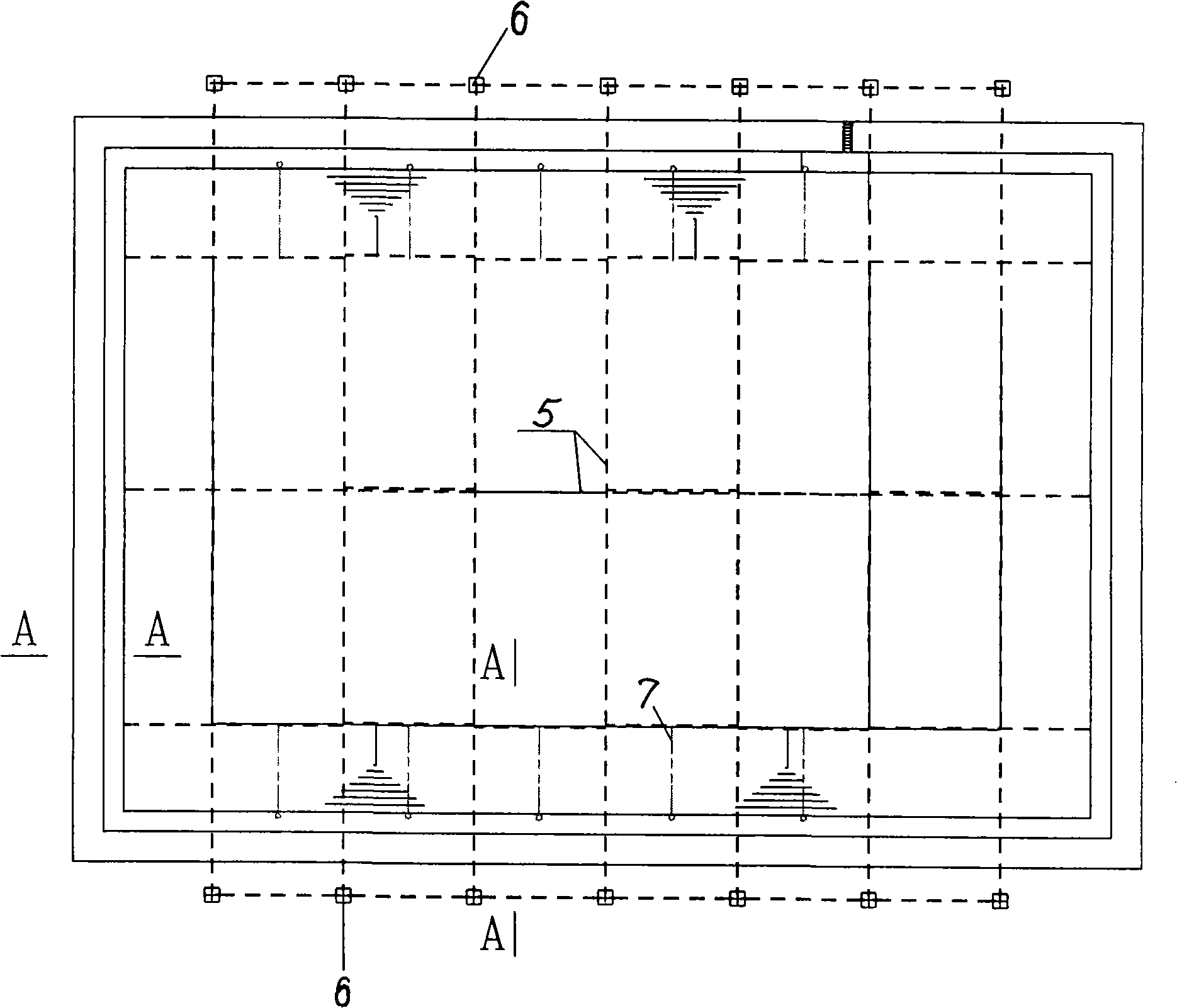

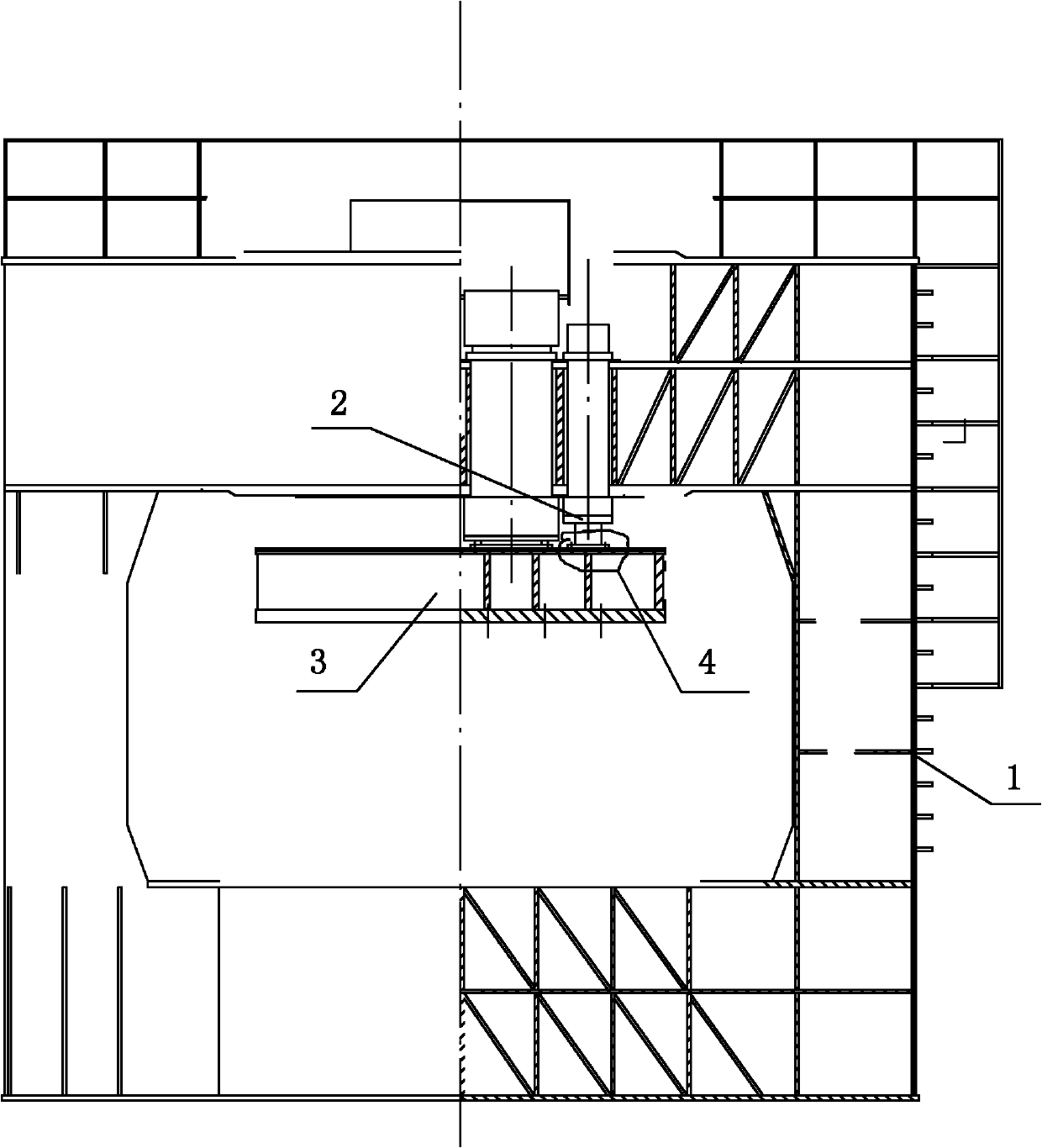

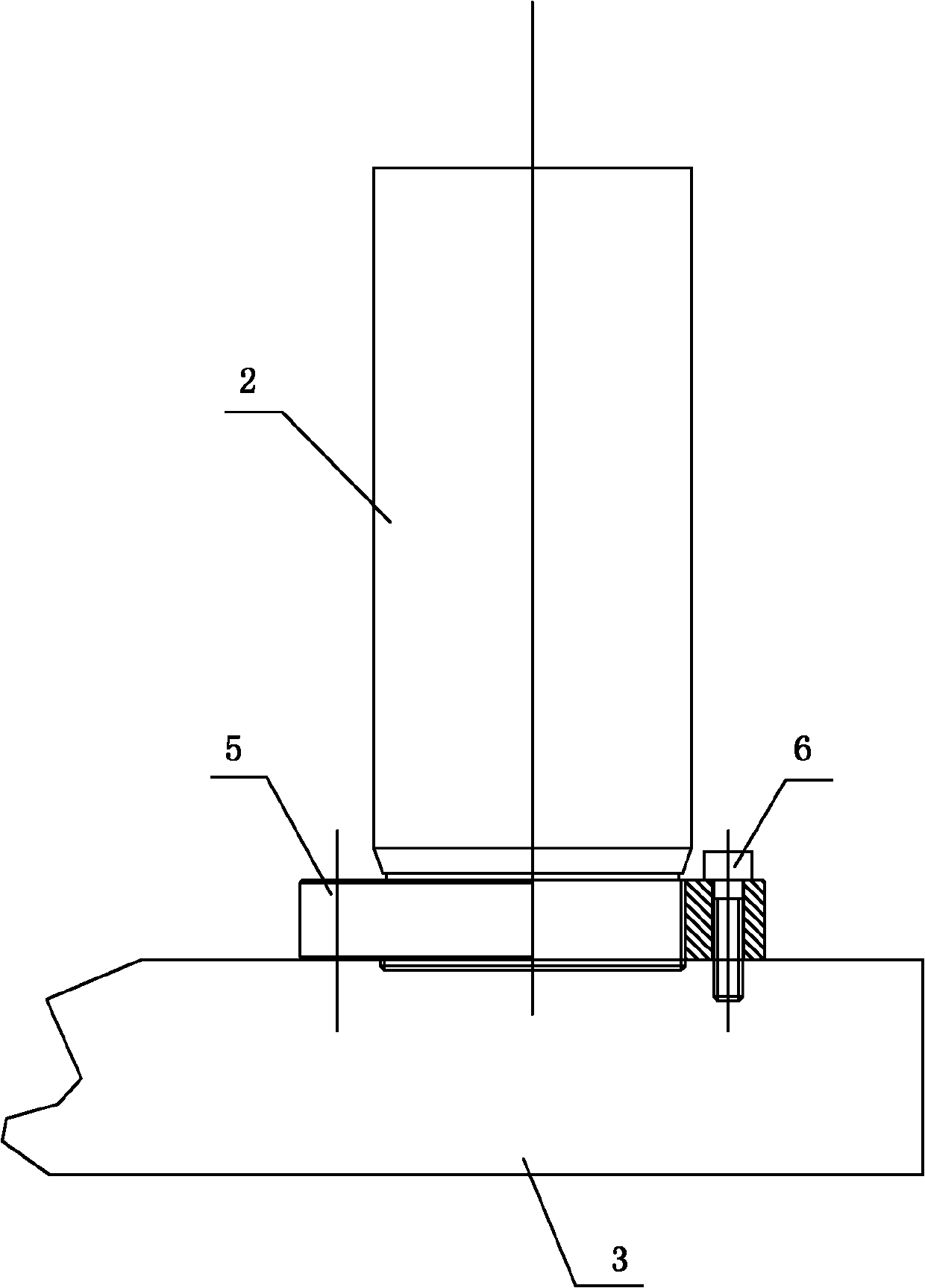

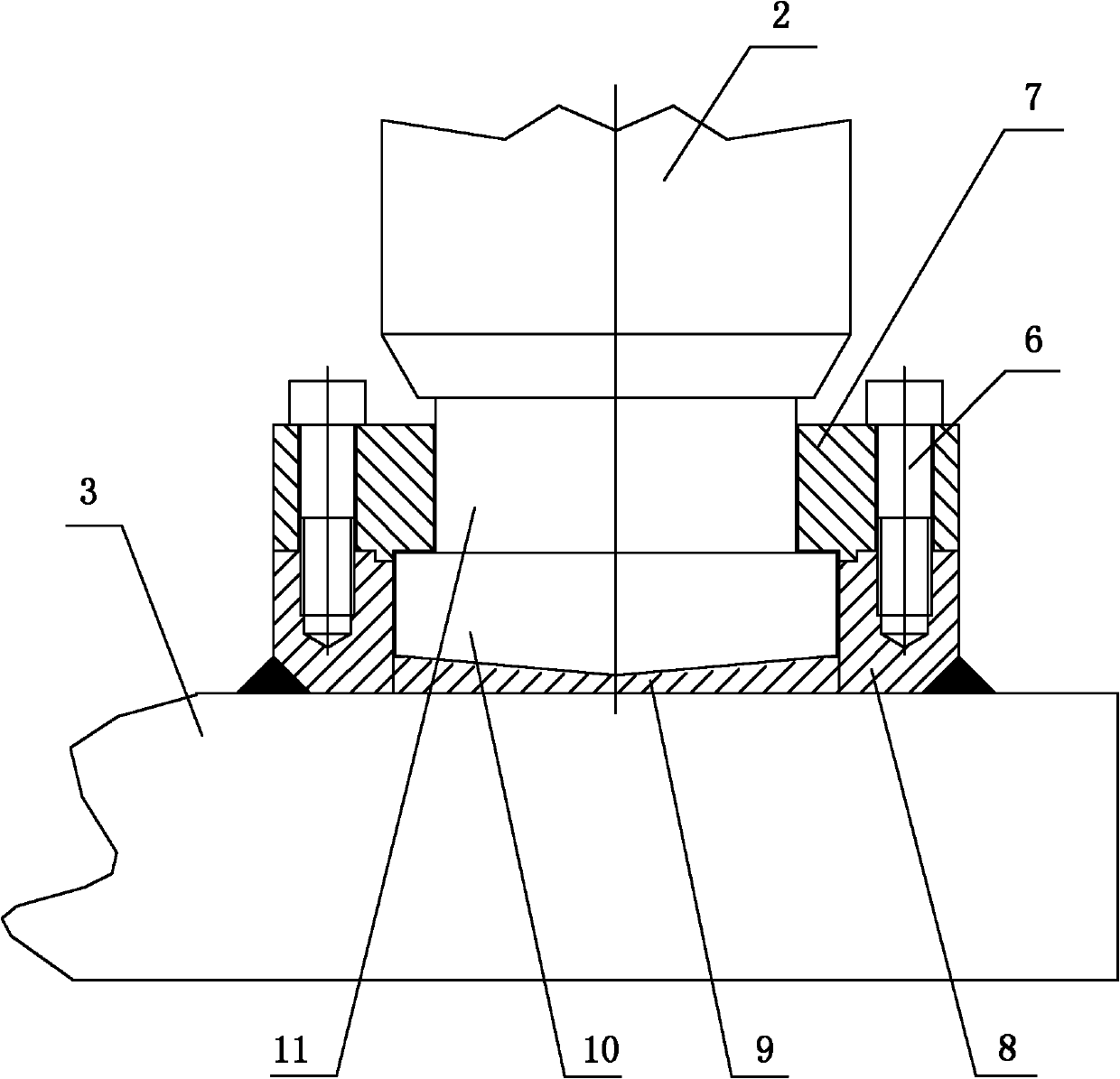

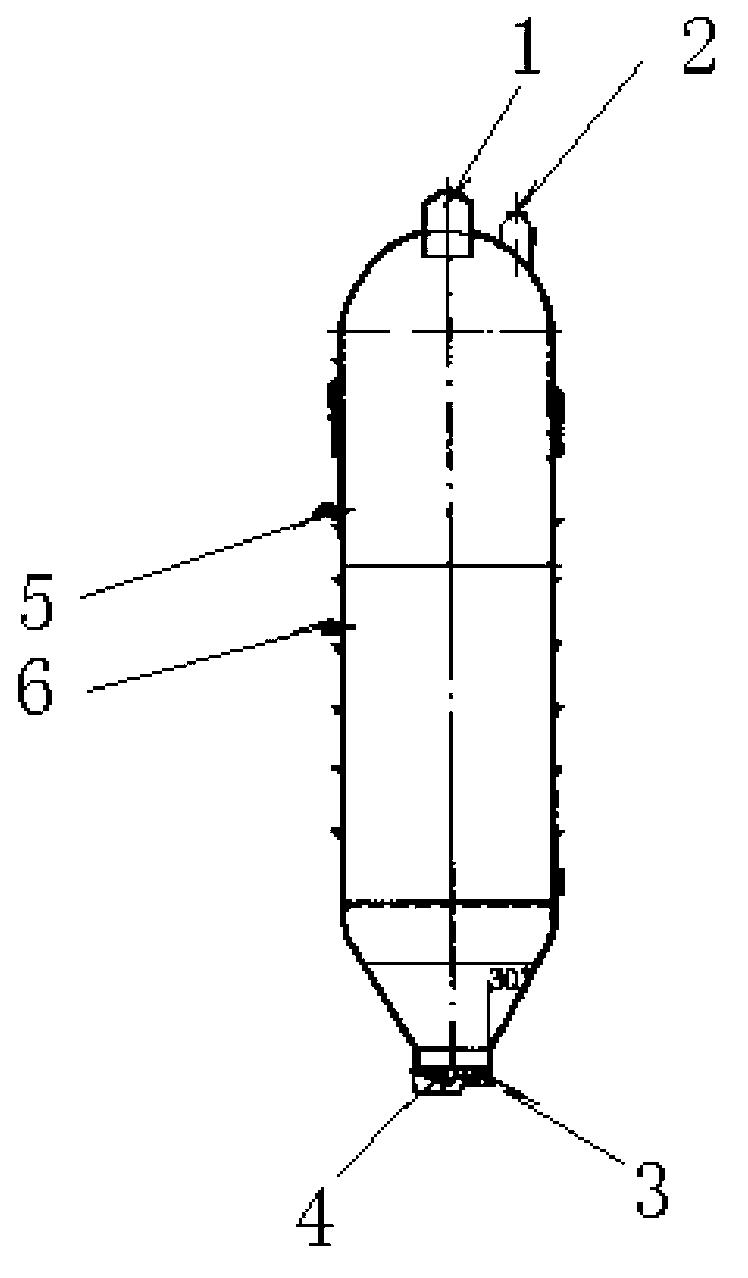

Non-mechanical-stirring sludge treatment anaerobic reactor and method for material circulation in reactor

PendingCN107434343ARealize no mechanical circulation stirringFully fermentedWater treatment parameter controlWater treatment flow arrangementsThermodynamicsProcess engineering

The invention brings forward a non-mechanical-stirring sludge treatment anaerobic reactor, which comprises a fermentation tank body and a feeding and discharging system. The feeding and discharging system comprises a main feed pipe and a discharge pipe which is communicated with the bottom of the tank body. The top of the tank body is provided with a feed inlet. A discharge end of the main feed pipe is communicated with the feed inlet. The feeding and discharging system also comprises a first feeding pump, which is used for pumping external materials into the tank body through the main feed pipe. A material circulation system comprises a material absorption header-pipe arranged at the lower middle part inside the tank body, and an auxiliary feed pipe which is arranged outside the tank body and is communicated with the main feed pipe. A discharge end of the material absorption header-pipe is communicated with the auxiliary feed pipe through a second feeding pump. The domestic sludge treatment technology is based on the non-mechanical-stirring anaerobic reactor. According to the technology, the anaerobic reactor adopts the mode of feeding at upper part and circulating at middle part to form an internal circulating fluid system of the material. Thus, problems such as nonuniform distribution, crusting at top of the tank, etc. are solved. The invention also brings forward a method for material circulation in the anaerobic reactor. According to the invention, anaerobic fermentation treatment of domestic sludge is mainly solved.

Owner:青岛中环能生物科技有限公司

Rubber reservoir

The invention relates to a rubber reservoir. The tank comprises a dam, a plurality of rubber liners and a bottom drainage system. The dam surrounds the reservoir. The rubber liners are respectively laid on inner surface of the reservoir. The bottom drainage system is arranged at the bottom of the reservoir, and comprises a plurality of sump pits, a filter layer and an exhaust system; the sump pits are arranged circlewise around the reservoir respectively. The filter layer is arranged at the bottom of the rubber liners and provided with a great amount of porous filter pipes which are classified into trunk pipes and branch pipes, two ends of the trunk pipes respectively extend to the sump pits. The exhaust system is arranged between the dam and the rubber liners around the reservoir, and conducts the filter layer and the atmosphere. The rubber reservoir has the following advantages and positive effects: 1. the rubber reservoir structure can effectively reduce construction cost; 2. a rubber reservoir structural system is easy for maintenance and management and convenient for quick emergency repair; and 3. the rubber reservoir is characterized by attractive appearance, simple construction and short construction period.

Owner:BAOSTEEL ENG & TECH GRP

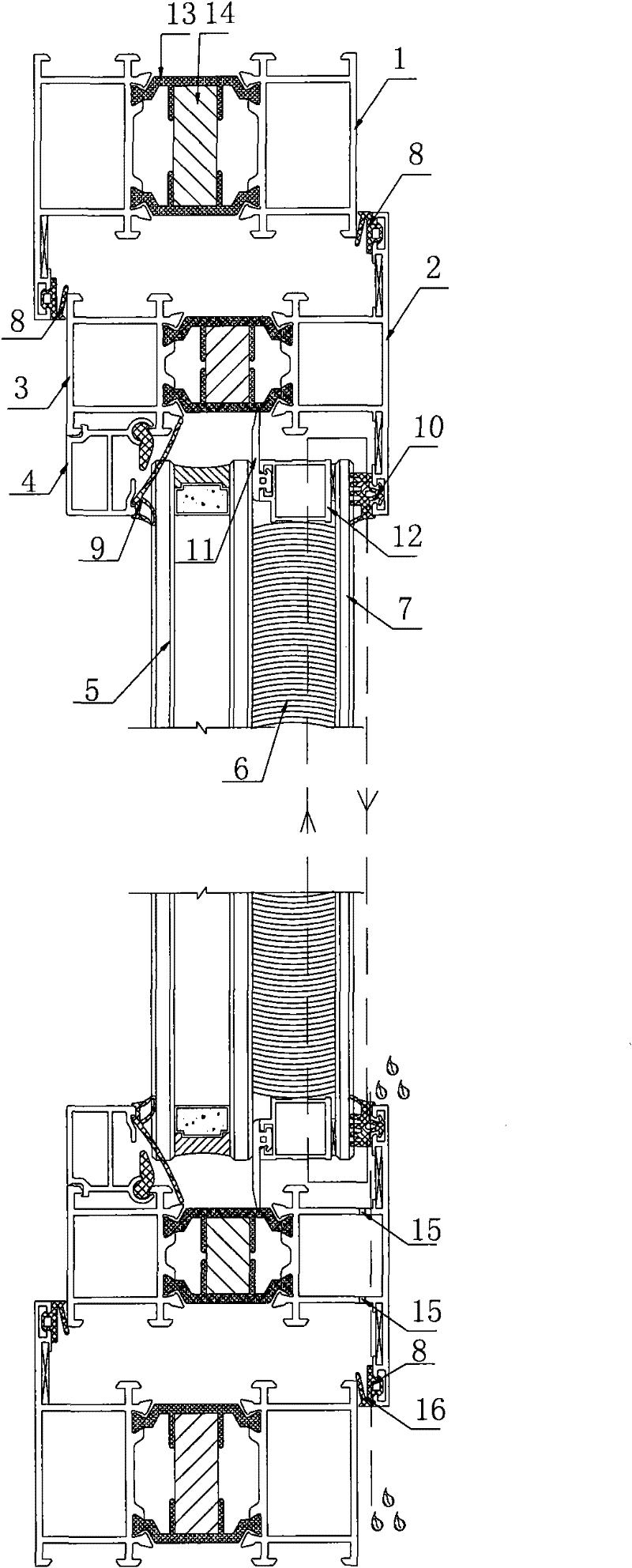

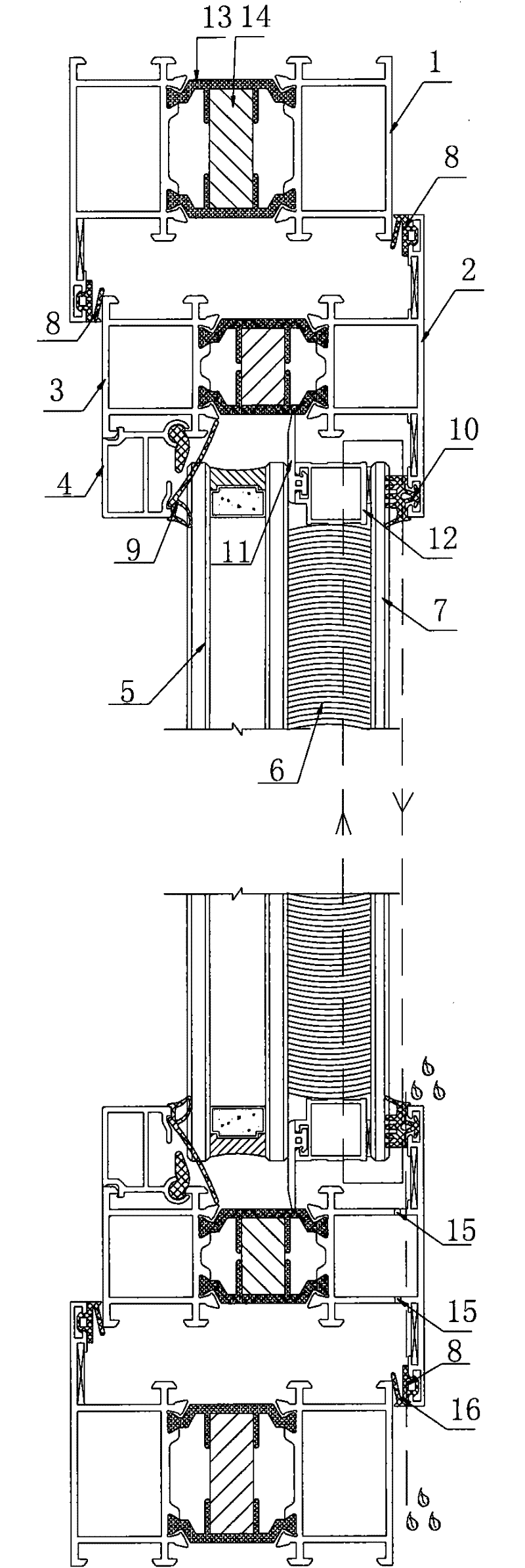

Sun shading and energy-saving aluminum alloy door and window

InactiveCN101705778BImprove the lighting environmentReduce energy consumptionDoor/window protective devicesCondensed water drain-offSash windowEngineering

Owner:浙江安贝格系统门窗科技有限公司

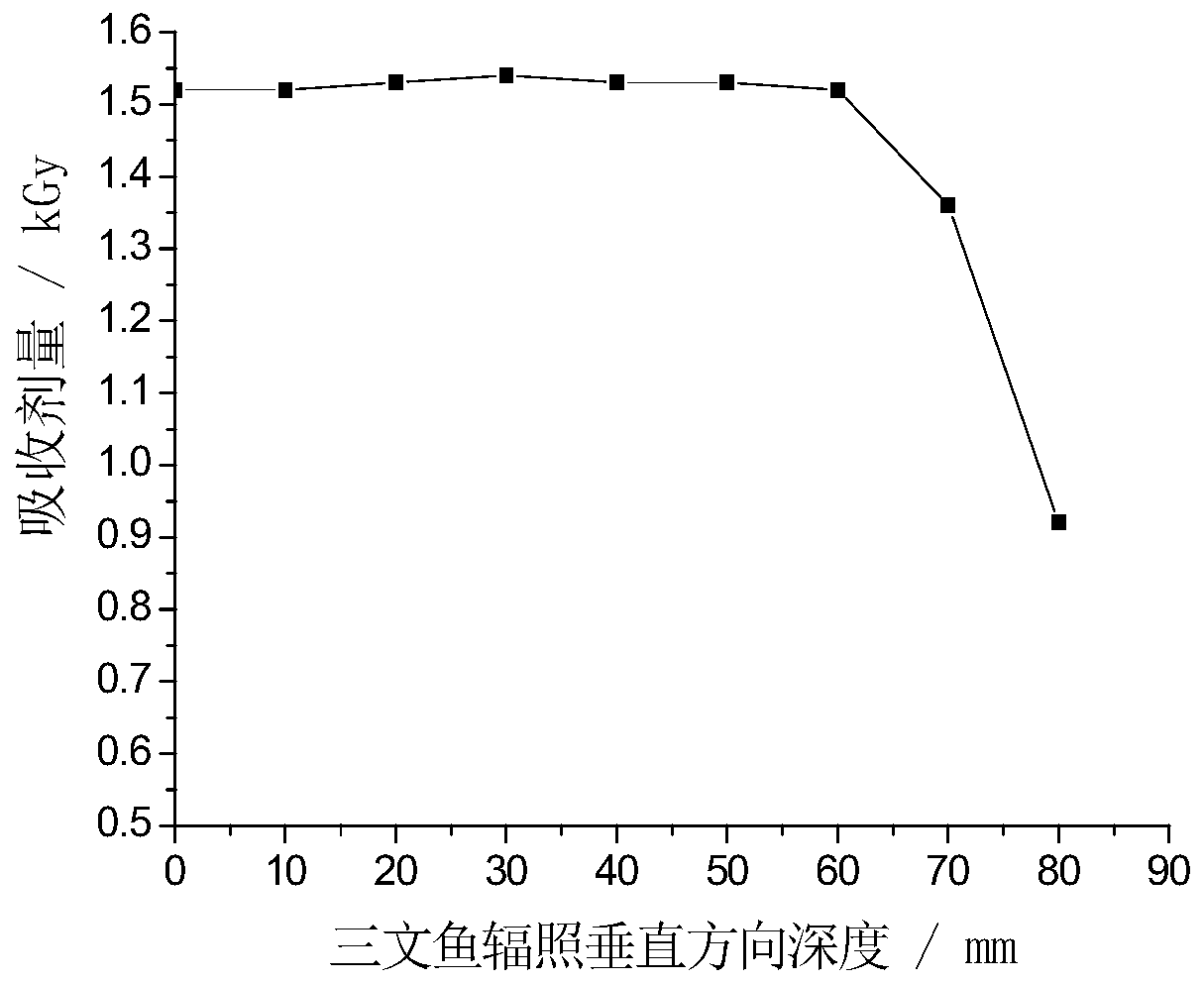

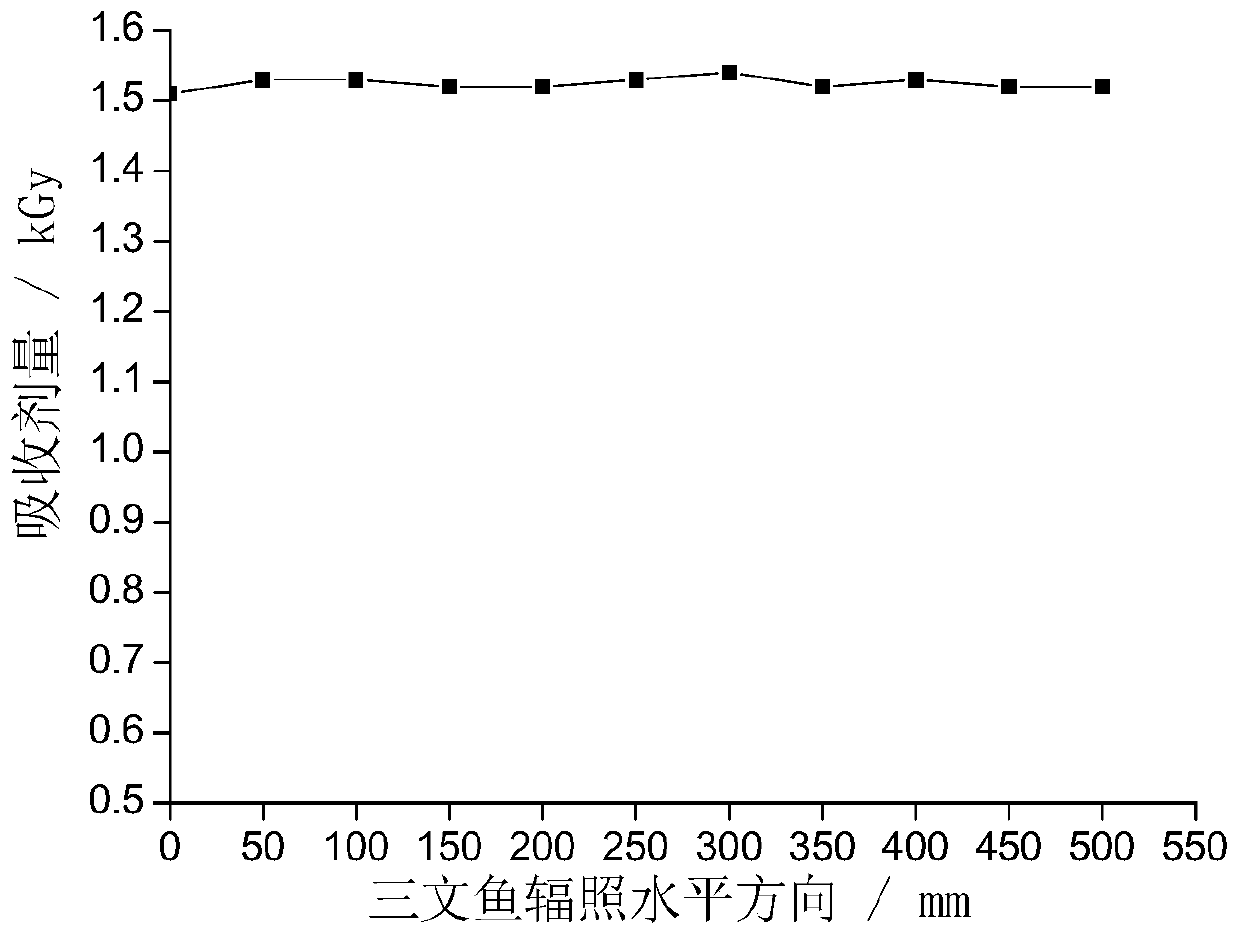

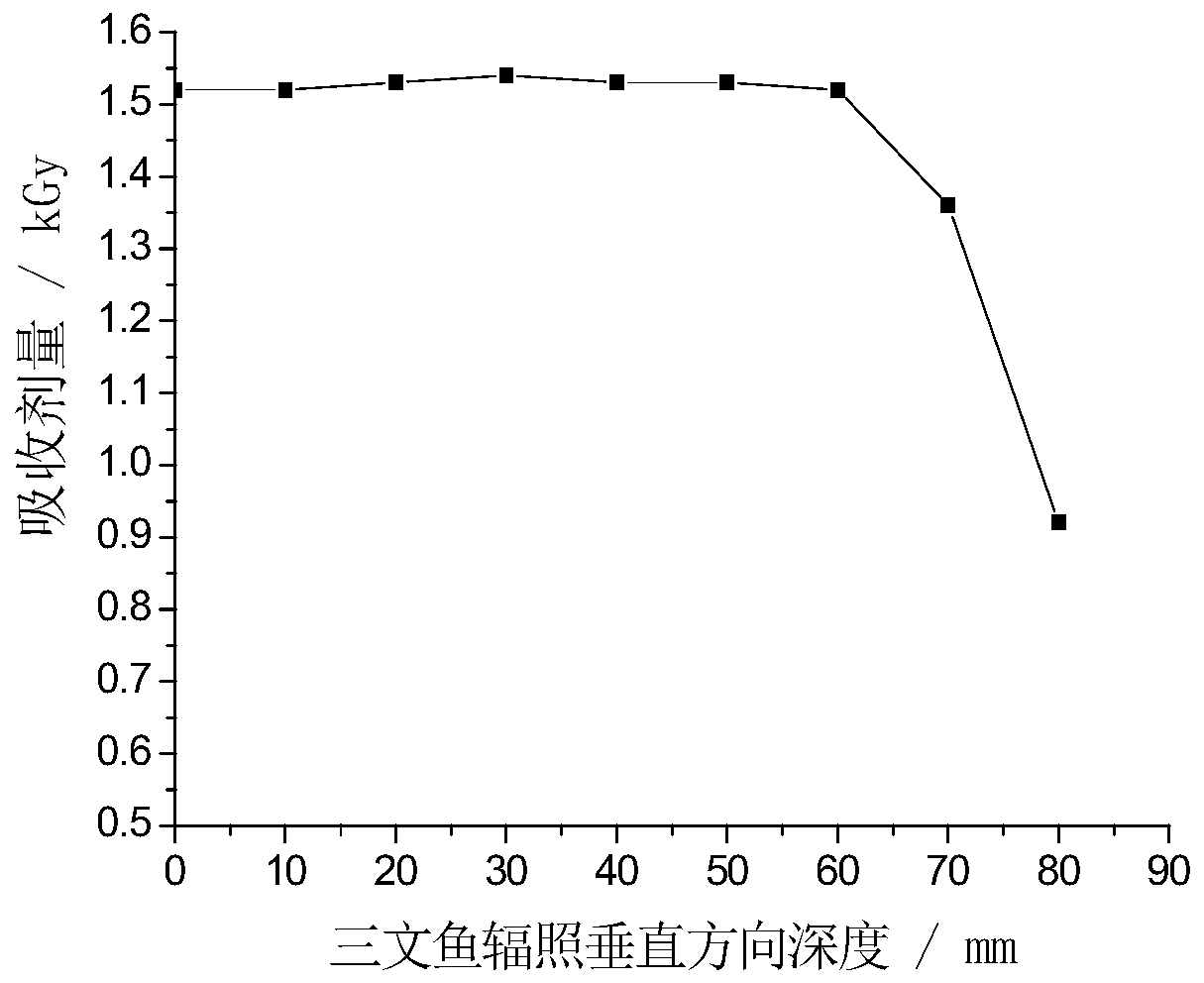

Method for treating fresh salmons by using electron beam irradiation combined with preservative

InactiveCN110012927AShort processing timeOvercome the smellMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsHigh energy electron irradiationElectron

The present invention discloses a method for treating fresh salmons by using an electron beam irradiation combined with a preservative. The method comprises the following main processes: heads, tailsand internal organs of fresh salmons are removed, the treated salmons are washed clean, the washed salmons are cut into slices, the salmon slices are soaked by preservation liquid, the soaked salmon slices are packaged, finally the packaged salmon slices are treated with a high-energy electron beam irradiation, and the treated salmon slices are stored at 1-4 DEG C and has a shelf life of up to 30days. The preservative is combined with the high-energy electron beam irradiation technology, the preservative can inhibit growth and reproduction of microorganisms during storage processes of the salmons, the high-energy electron beam irradiation can directly kill some microorganisms in the product or destroy normal physiological metabolic functions of the microorganisms in varying degrees, and at the same time also play a passivation effect on enzyme activity in the salmons, so that the preservative is used to combine the electron beam irradiation treatment to produce a synergistic effect and control the growth and reproduction of the microorganisms during the storage processes, effectively reduce physiological metabolic strength of the product during the storage processes and thus realize a purpose of extending the shelf life of the fresh salmons.

Owner:SHANGHAI ACAD OF AGRI SCI +1

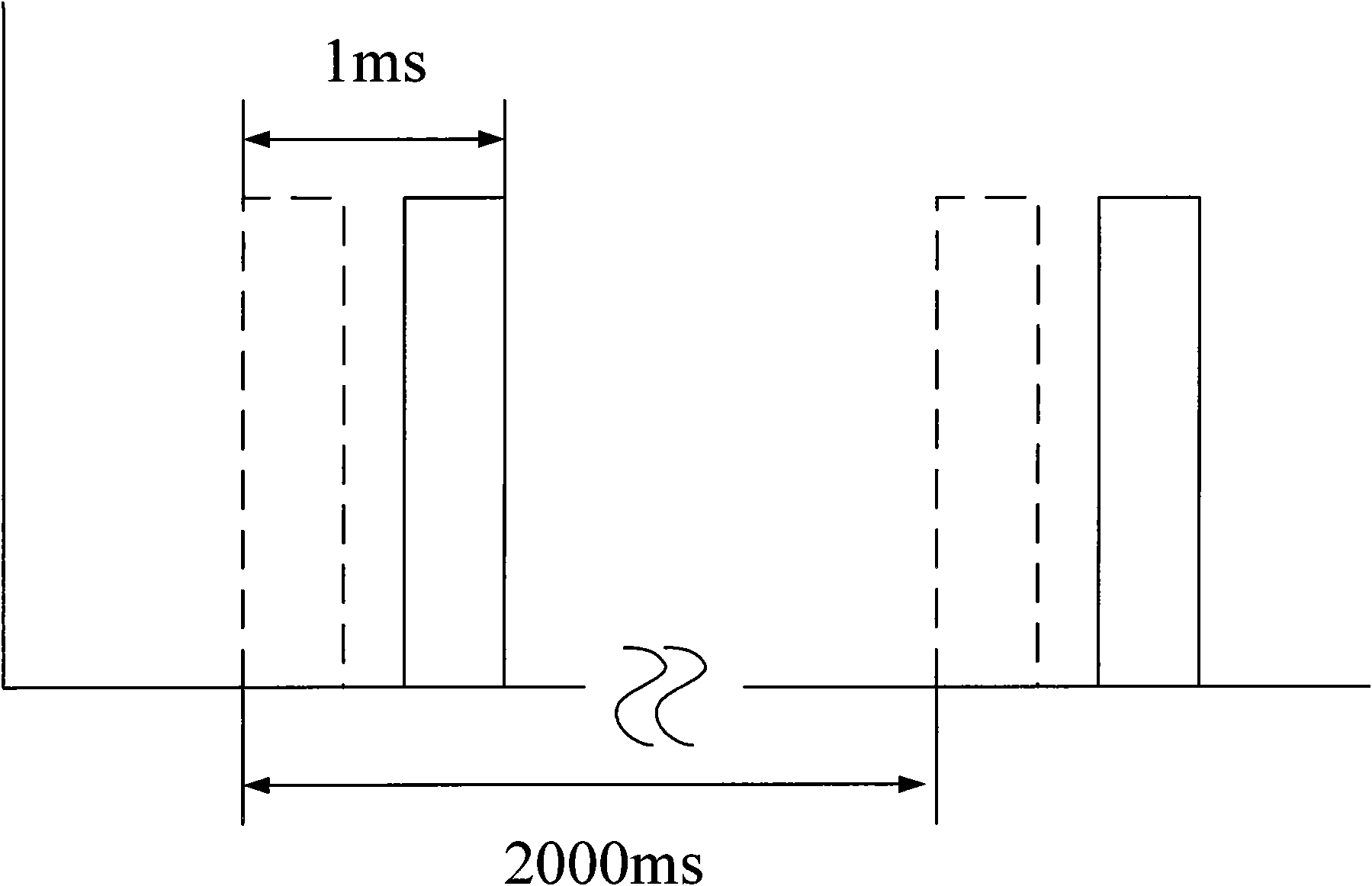

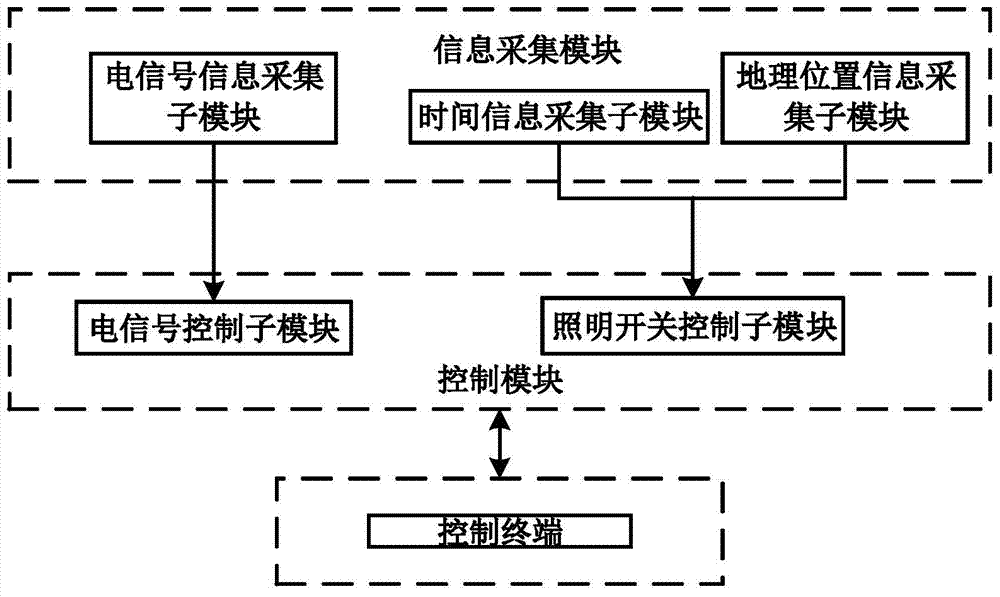

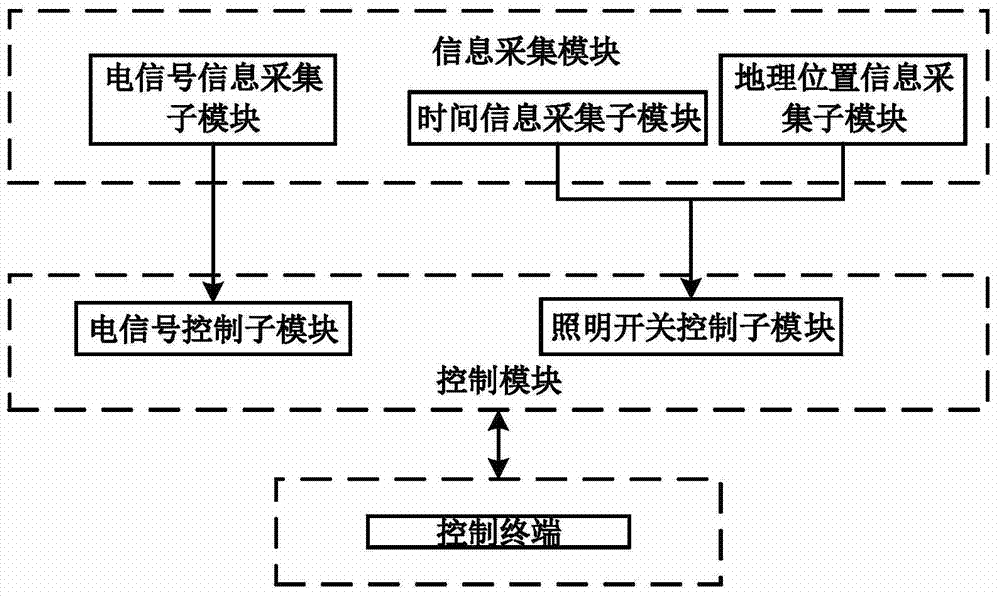

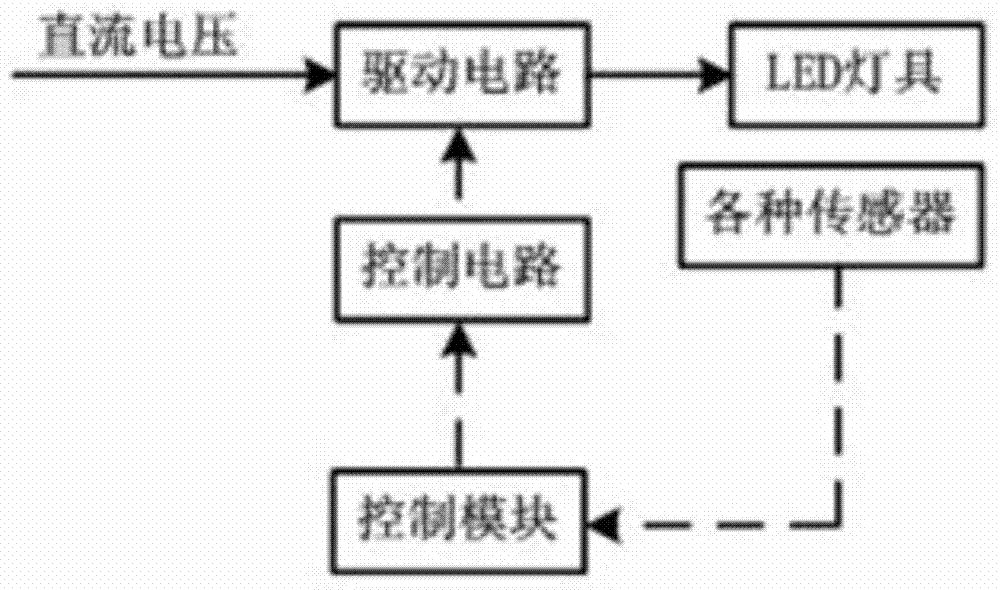

Centralized power supply system for outdoor lighting system

InactiveCN103763816AEasy maintenanceImprove energy savingPower network operation systems integrationElectric light circuit arrangementComputer moduleLighting system

The invention provides a centralized power supply system for an outdoor lighting system. The centralized power supply system comprises a voltage sensor, a standby AC power supply, a diverter switch, an AC / DC conversion circuit, a standby AC / DC conversion circuit, the outdoor lighting system, a centralized controller and an anti-theft alarm module. The centralized controller comprises an information collection module, a control module and a control terminal. The control module is connected with a control circuit of each lamp, the time for turning on each lamp and turning off each lamp in one day can be set in advance through the control module, the brightness of each lamp at different time intervals in one day can also be set in advance, and therefore a single-lamp control function can be achieved.

Owner:AD TOYO LIGHTING GUANGZHOU

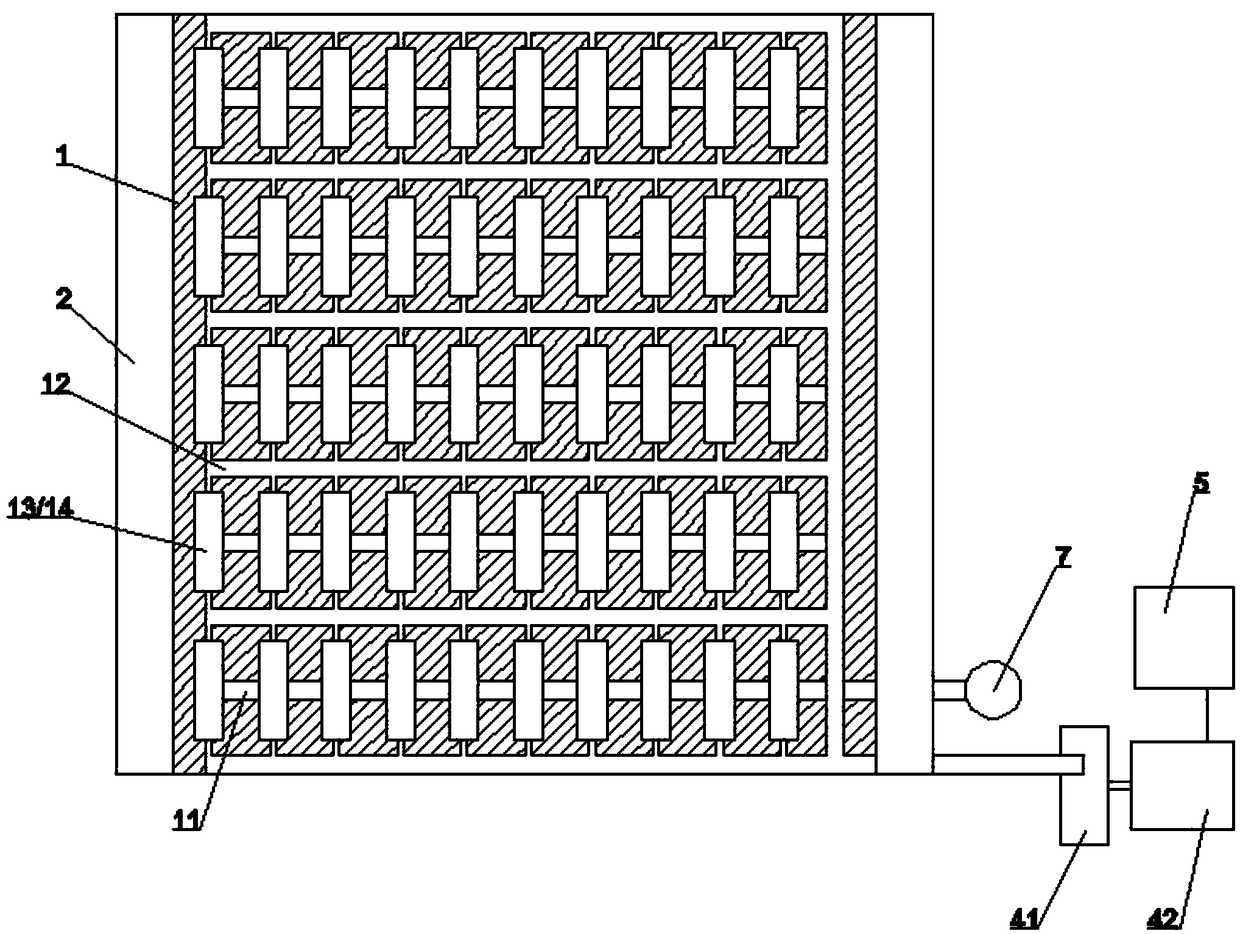

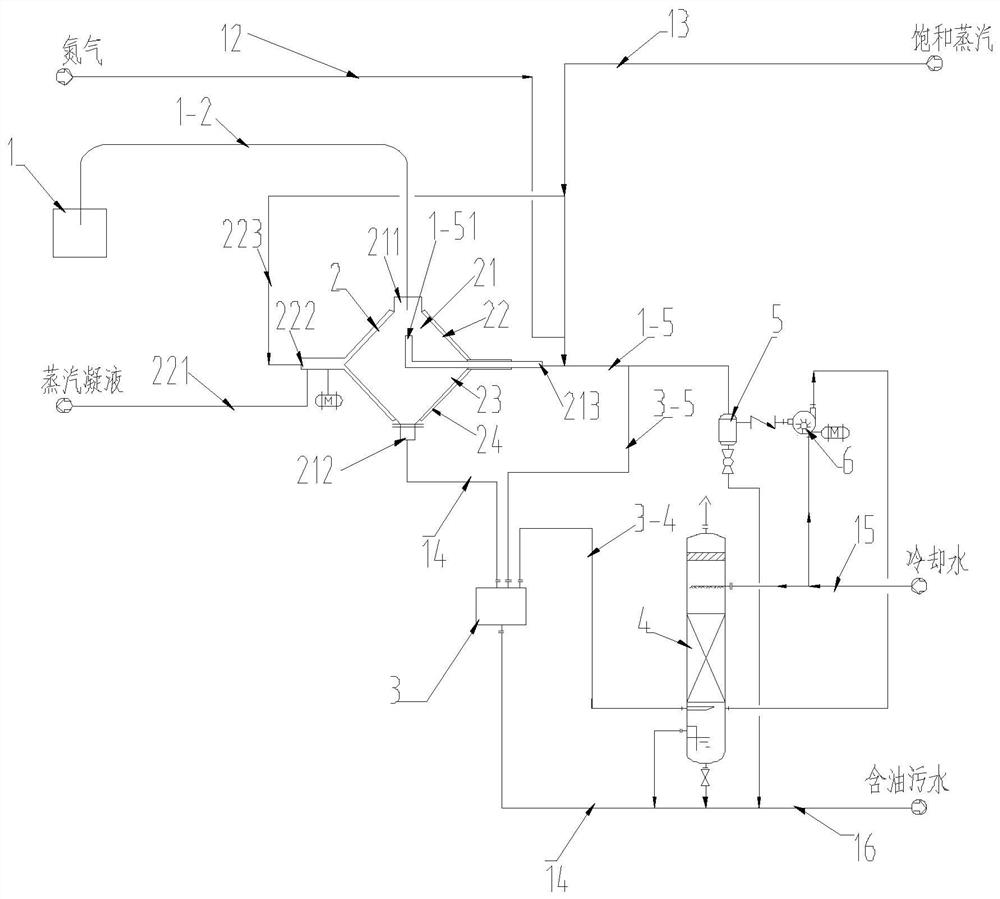

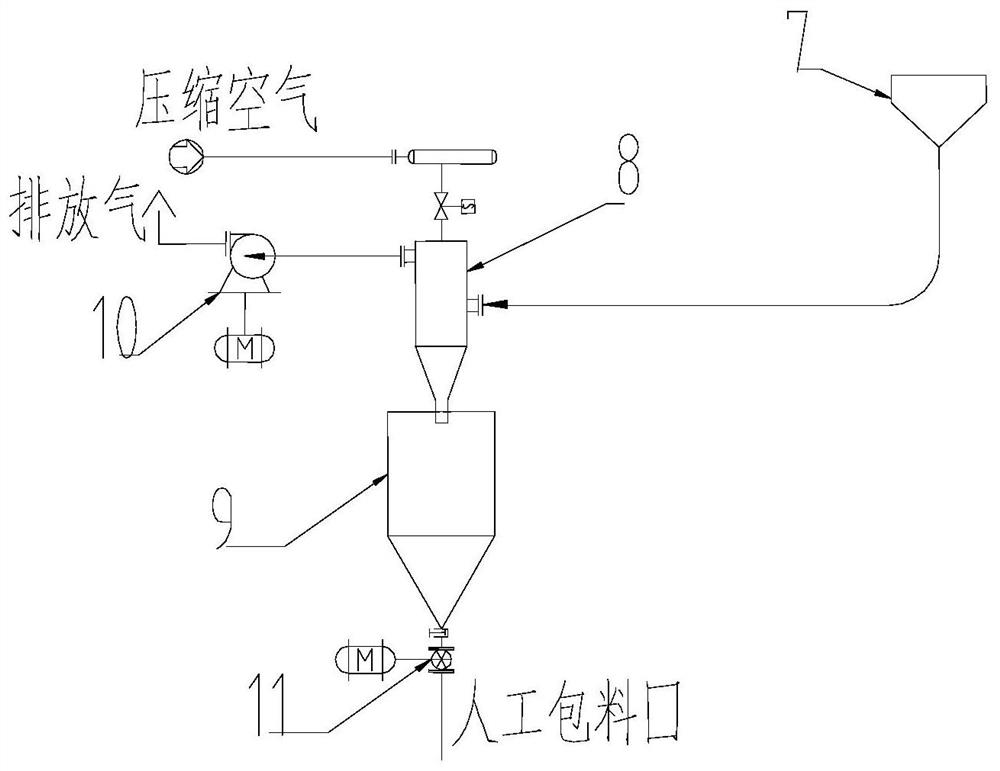

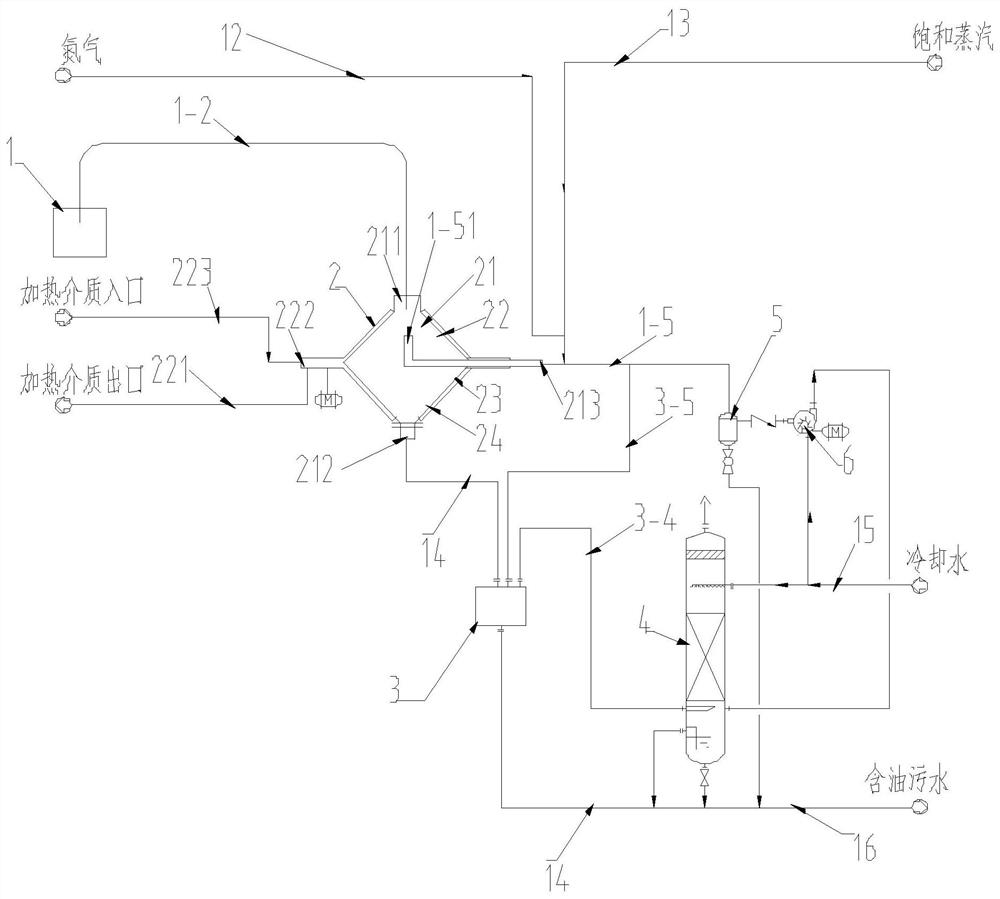

System and method for deeply removing VOC from polypropylene material and drying polypropylene material

PendingCN111790317AAvoid oxidation reactionsSmall footprintChemical/physical processesAir quality improvementPolymer sciencePolypropylene

The invention relates to a system for deeply removing VOC from a polypropylene material and drying the polypropylene material. The system comprises a raw material tank for placing a polypropylene material to be treated; a steam reactor, which comprises an inner shell and an outer shell, wherein a space between the inner shell and the outer shell is an interlayer, a space in the inner shell is an inner container, the inner shell is provided with a material inlet / outlet, a condensate outlet and a vacuum interface, the outer shell is provided with a heating medium inlet / outlet, the material inlet / outlet is communicated with the raw material tank through a feeding pipeline, and the heating medium inlet / outlet is communicated with a steam pipeline; a condensate tank, which is communicated withthe condensate outlet of the steaming reactor through a condensate pipeline; a vacuum pump, which is communicated with the vacuum interface of the steam reactor through a vacuum pipeline, wherein thevacuum interface is also communicated with the steam pipeline; and a product bin, which is used for placing the treated polypropylene material. The invention also relates to a method for deeply removing VOC from a polypropylene material and drying the polypropylene material.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

High-performance energy-saving aluminum-wood composite window system with built-in sunshade

ActiveCN103321558AImprove insulation effectStable structureFireproof doorsLight protection screensSash windowEngineering

The invention relates to a high-performance energy-saving aluminum-wood composite window system with a built-in sunshade. The high-performance energy-saving aluminum-wood composite window system comprises an aluminum frame material, a wood frame material, a wood sash material, hollow glass, shutters and single-layer glass. An adhesive tape bayonet is arranged at one end of the aluminum frame material facing the glass, a protruding block is further arranged on one side of the wood sash material facing the glass, a sash connecting piece is fixedly arranged on the outside of a window of the wood sash material, a C-shaped groove of the sash connecting piece is formed in the outside of the window of the wood sash material, a U-shaped groove is formed in the inner lateral side of the wood sash material, the hollow glass is fixed between one side of the U-shaped groove and the protruding block of the wood sash material, the shutters are arranged in the U-shaped groove of the sash connecting piece, a connecting piece is arranged in the C-shaped groove of the sash connecting piece, the other side of the connecting piece is fixed on the single-layer glass, and the outdoor side of the single-layer glass butts against the adhesive tape bayonet position of the aluminum frame material. A scheme of combining concealed sashes and the shutters is provided, a traditional method for achieving gluing of the glass and a section material in a glue injection mode is abandoned, a novel connecting method between the glass and the section material is provided, the structure is stable, operation is convenient, and practicality is good.

Owner:浙江瑞明节能门窗技术有限公司

Anti-eccentricity pressing piston rod connecting device of no-guiding slider type hydraulic press

InactiveCN102000748AEasy to cause scrapEasy to fixShaping safety devicesHollow articlesHydraulic cylinderBiochemical engineering

The invention belongs to the mechanical manufacturing field. The anti-eccentricity pressing piston rod connecting device of a no-guiding slider type hydraulic press relates to a piston rod and a working slider of a hydraulic cylinder and is characterized in that: the connecting device comprises a bolt, a pressing flange, a fixed support and a hinged support; a piston rod radial through hole is arranged in the middle part of the pressing flange, the aperture of the piston rod radial through hole is 3-5mm more than that of the radial part of the piston rod, a hinged support mounting hole is arranged in the middle part of the fixed support, and the aperture of the hinged support mounting hole is 3-5mm more than the maximum diameter of a piston rod ball head, the fixed support is welded on the working slider, and the hinged support is arranged in the hinged support mounting hole of the fixed support, the radial part of the piston rod penetrates through the piston rod radial through hole on the pressing flange, the radial part of the piston rod is arranged in a space surrounded by the pressing flange, the fixed support and the hinged support, and the pressing flange and the fixed support are fixed by a bolt; and the connecting device can effectively avoid damage to mechanical equipment, caused by eccentric pressing.

Owner:WUHAN YIYE STEEL STRUCTURE

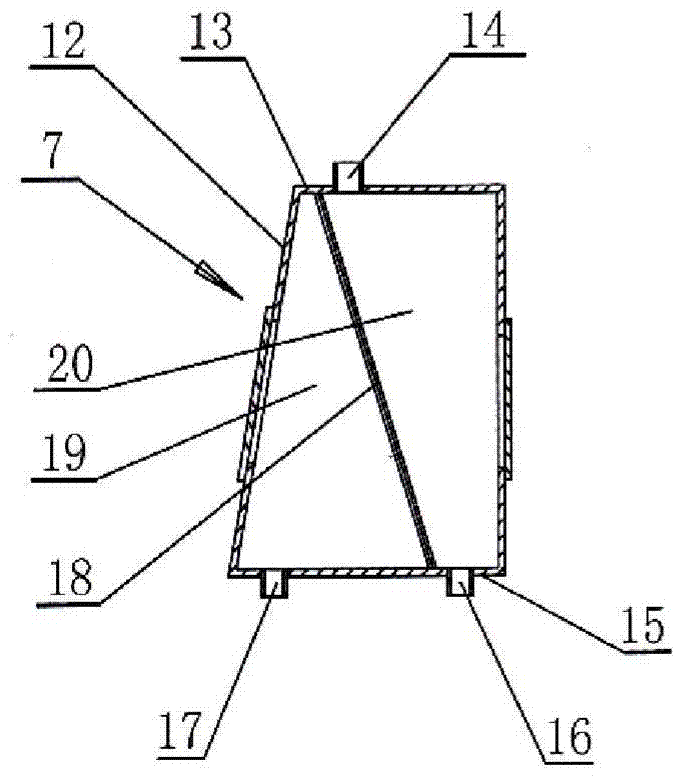

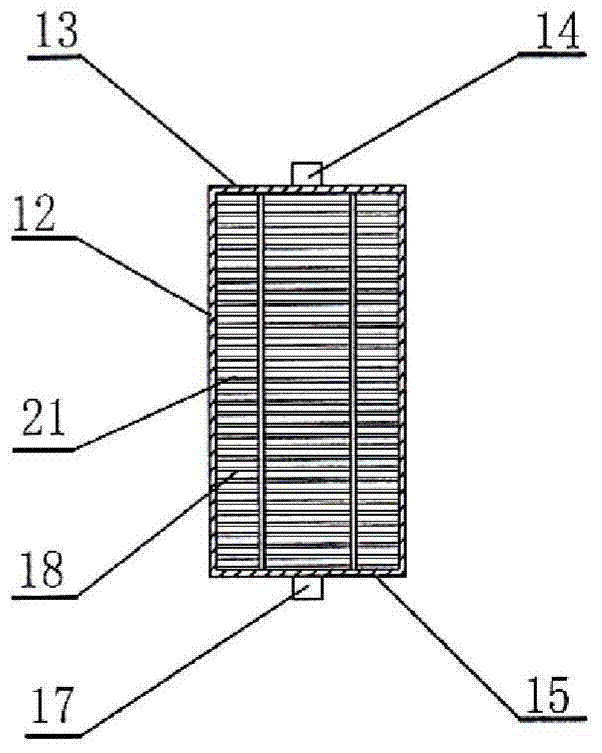

Sieving type monosodium glutamate crystallization and separation process and equipment

ActiveCN103610020AReduce volumeRapid and accurate separationFood preparationMonosodium glutamateCrystalline particle

The invention relates to a sieving type monosodium glutamate crystallization and separation process and equipment. According to the sieving type monosodium glutamate crystallization and separation process, a de-coloring solution is crystallized in a crystallization tank (5) and then is conveyed into a thickener (7) to separate large and small crystalline particles; the large particles are subsequently processed to prepare a finished product; the small particles are conveyed back to the crystallization tank (5) to be continually crystallized, and the thickener (7) is internally provided with a sieving sheet (18) for separating the large and small crystalline particles. The thickener (7) is provided with a tank body defined by an upper cover (13), a lower bottom (15) and peripheral wall plates; the upper cover (13) is provided with a feeding opening (14); the lower bottom (15) is provided with a material returning opening (17) communicated with the crystallization tank (5) and a discharging opening (16) communicated with a crystallization assisting groove (8); the sieving sheet (18) which is arranged obliquely arranged in the tank body; the feeding opening (14) and the discharging opening (16) are formed in one side of the sieving sheet (18); the material returning opening (17) is formed in the other side of the sieving sheet (18). The sieving type monosodium glutamate crystallization and separation process and equipment have the beneficial effects that after the monosodium glutamate is crystallized to enter the thickener, the small particles are sieved and conveyed back to the crystallization tank to be continually crystallized, and the large particles are prepared into the finished product; the large and small crystalline particles are separated rapidly and accurately; the circulation is reduced and the energy consumption is saved; crystalline grains of a product are ordered and the quality is improved.

Owner:TONGLIAO MEIHUA BIOLOGICAL SCI TECH CO LTD

Automatic repairing device for saw teeth of saw blade

InactiveCN111604547AFully patchedEfficient repairSawing tools dressing arrangementsMechanical engineeringIndustrial engineering

The invention discloses an automatic repairing device for saw teeth of a saw blade. The automatic repairing device comprises a body. A repairing space is arranged in the body. The right side wall of the repairing space is connected with a discharge space with an opening to the left. The left side wall of the repairing space is connected with an inlet. The left side wall of the inlet is connected with a polishing space. The left side wall of the polishing space is connected with a polishing inlet. The left side wall of the polishing inlet is connected with a straightening space. The left side wall of the straightening space is connected with a feeding space with an opening to the left. The automatic repairing device can fully repair some severely damaged saw blades. In a traditional industry, the saw teeth of the saw blade are not easy to be repaired, and the saw blade can be discarded when damaged. Compared with the traditional method, the automatic repairing device greatly reduces theloss of the saw blade. In addition, some of the saw blades are not easy to make, so that the unnecessary waste in the production is greatly reduced.

Owner:南京溧水高新产业股权投资有限公司

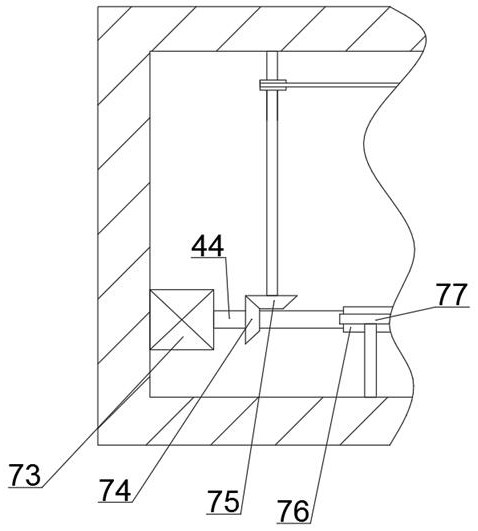

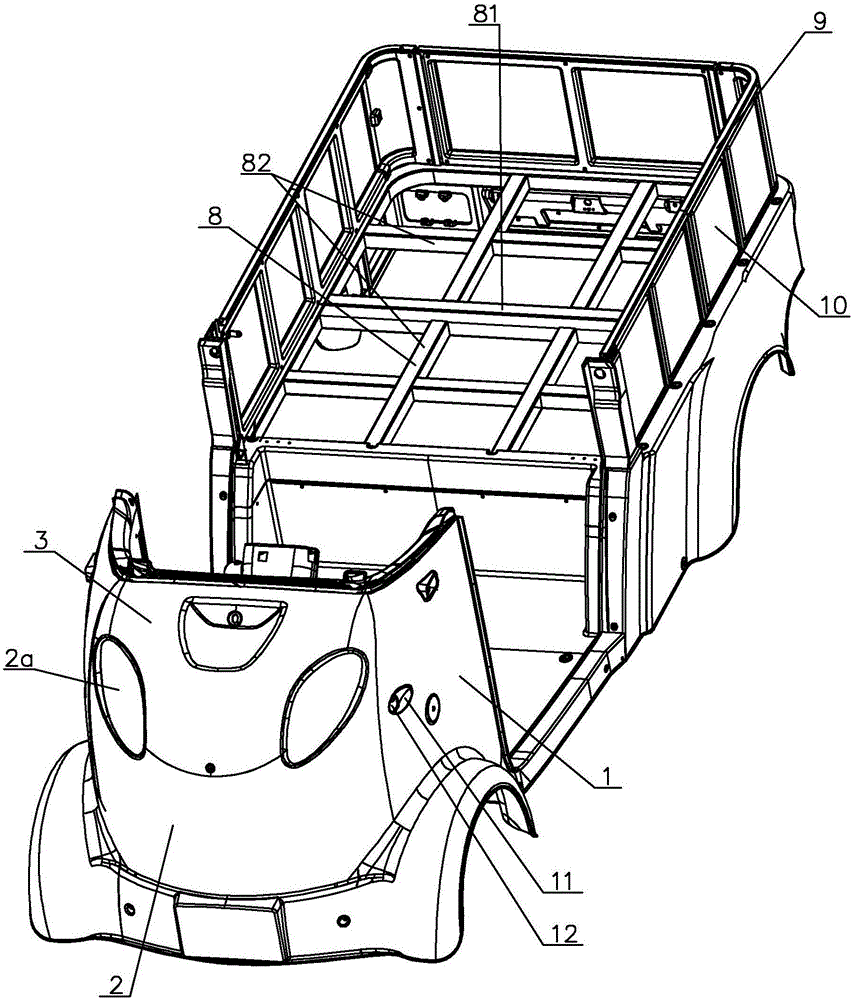

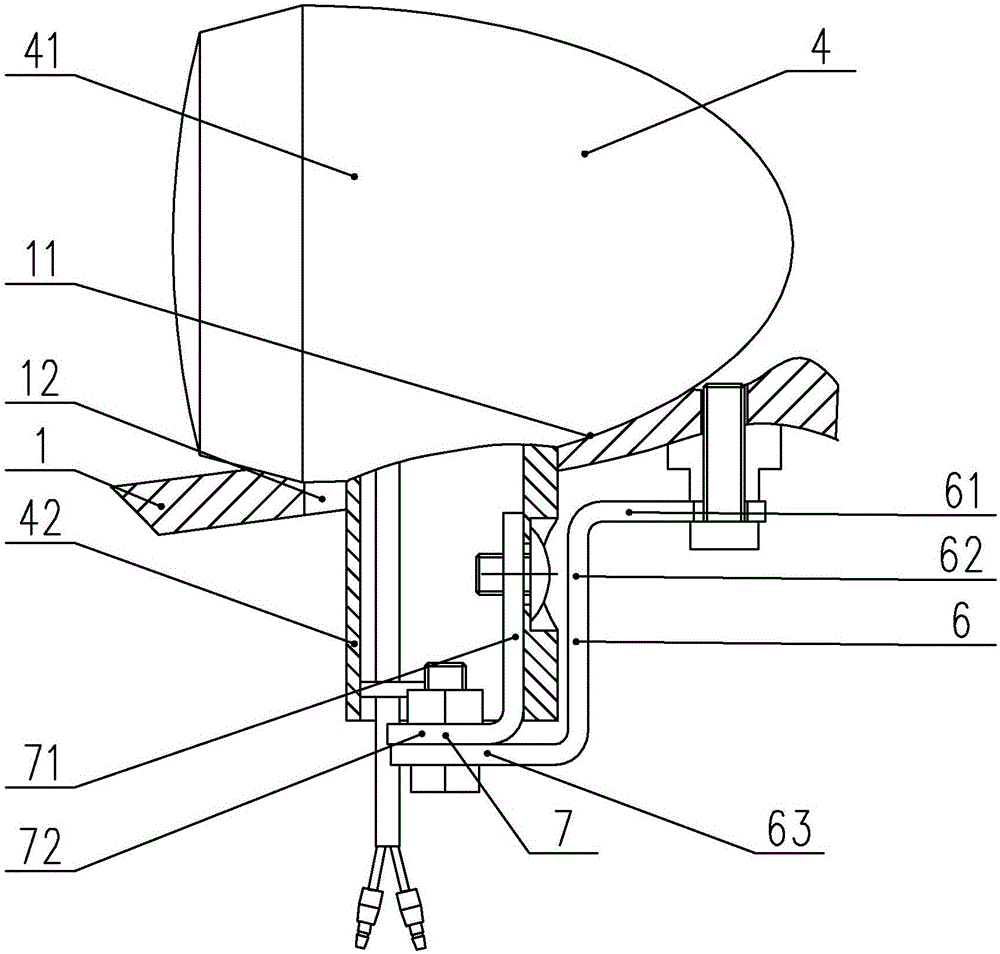

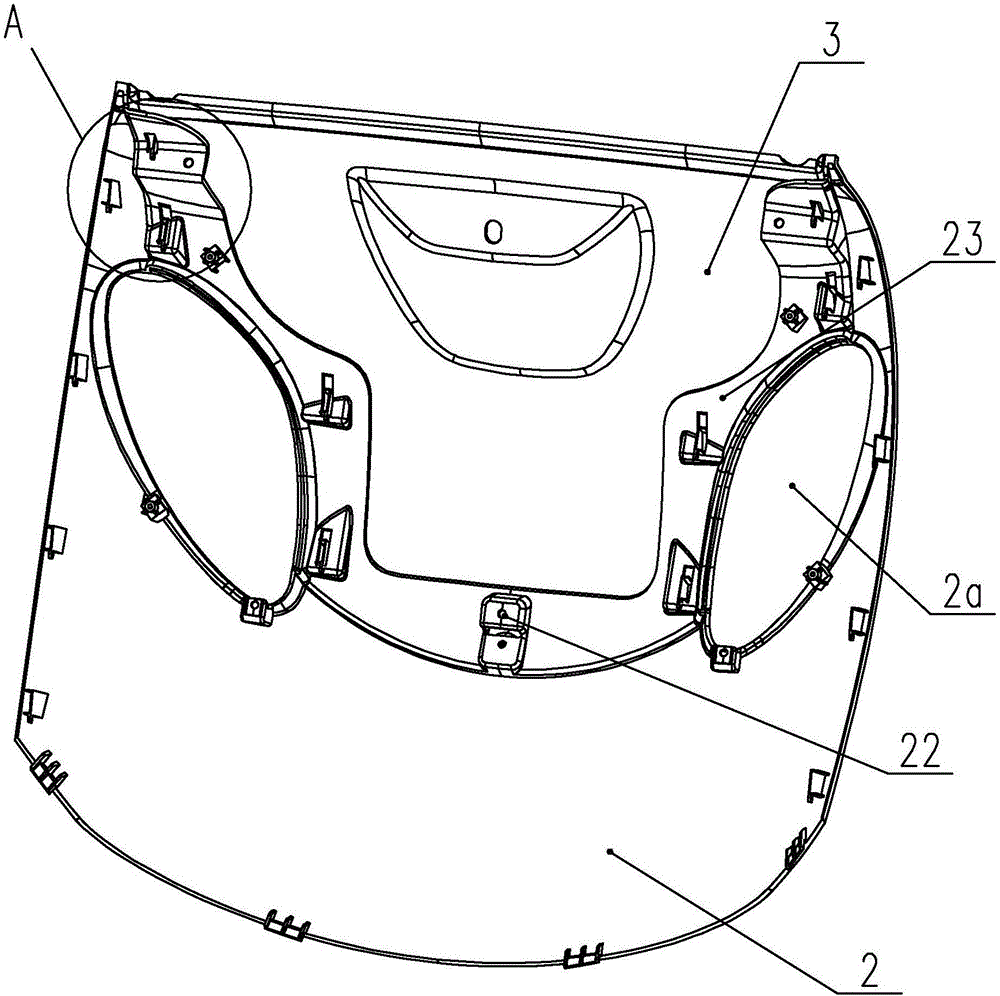

Body structure of vehicle

InactiveCN106379416APrevent protrudingAvoid damageOptical signallingMonocoque constructionsVehicle frame

Owner:LIFENG GRP

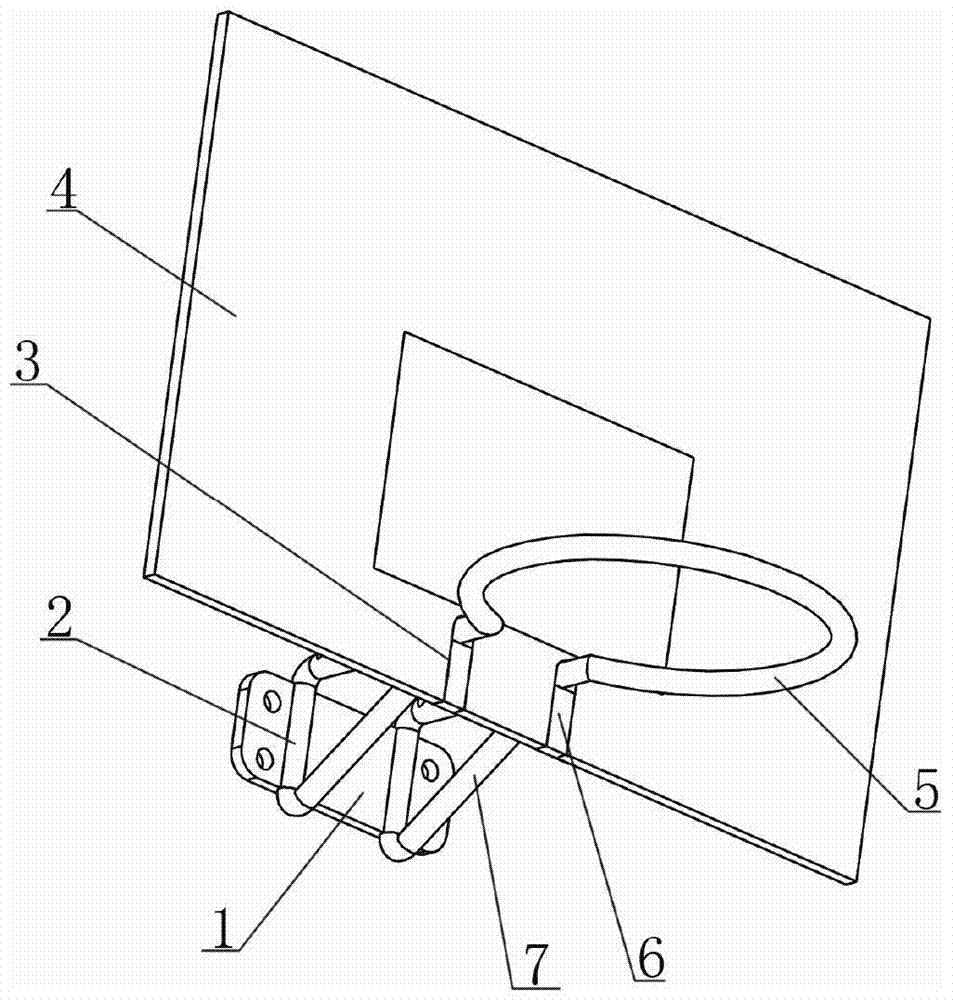

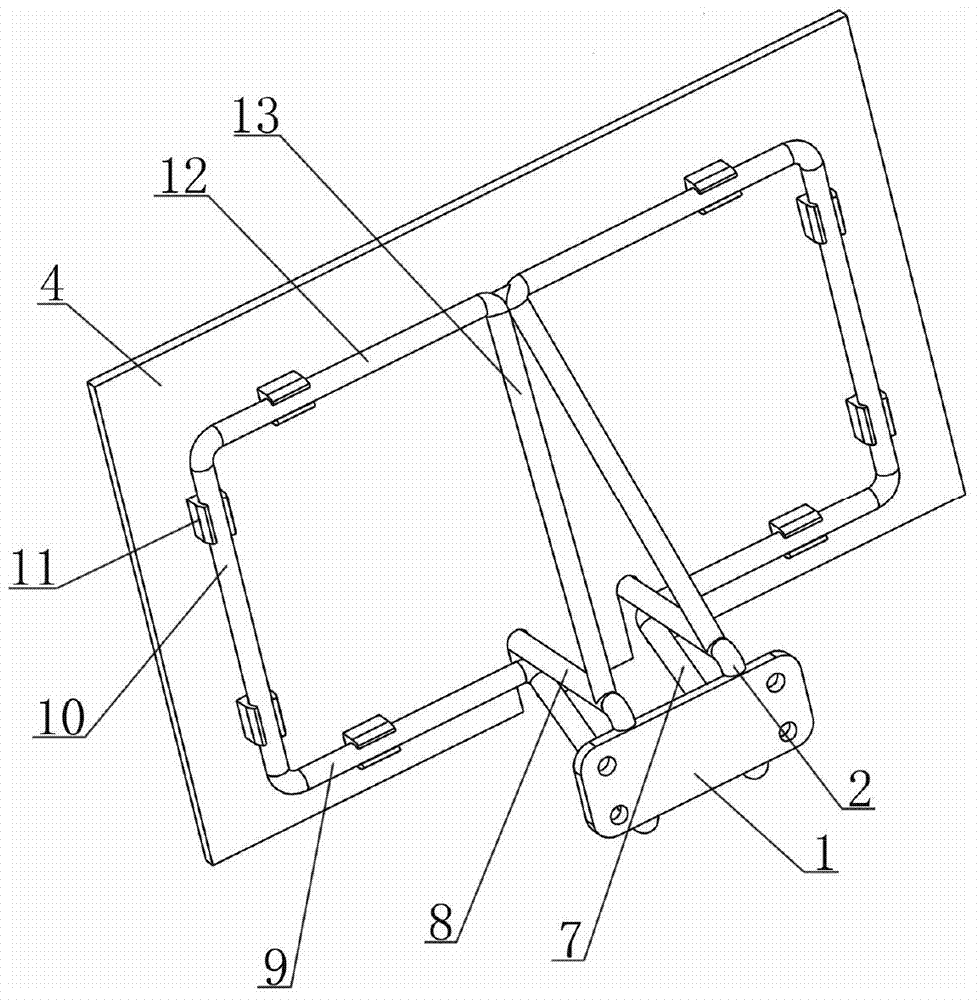

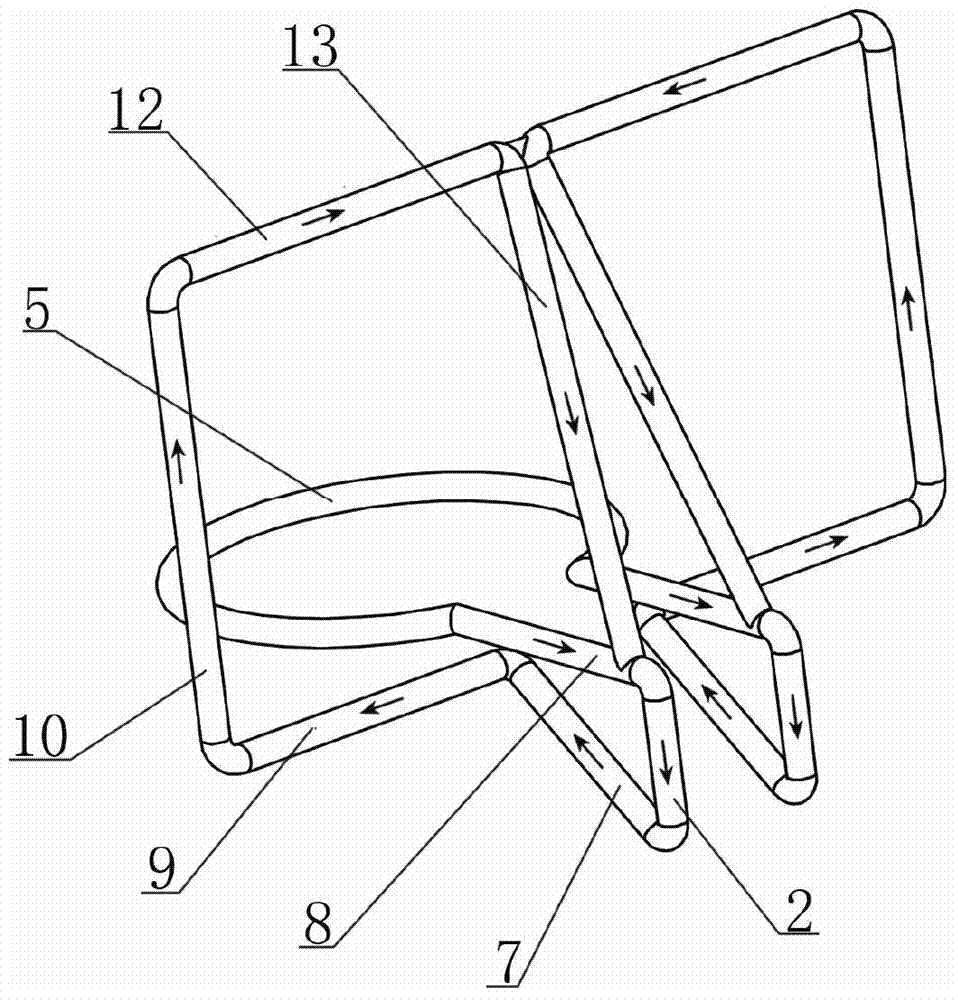

Basketball stand and manufacturing method thereof

InactiveCN104288974AGuaranteed StrengthHigh strengthBall sportsUltimate tensile strengthMechanical property

The invention discloses a basketball stand which comprises a basketball board support and a basketball board. The basketball board support is provided with a basketball ring, two transverse supporting parts are arranged on the rear side of the basketball ring, and two triangular supporting structures are arranged on the lower rear sides of the two transverse supporting parts. A rectangular frame structure is arranged above the front ends of the two triangular supporting structures, and a diagonal supporting pillar is arranged between the middle of the upper end of the rectangular frame structure and the rear end of each triangular supporting structure. The basketball ring, the two triangular supporting structures, the rectangular frame structure and the two diagonal supporting pillars are each formed by bending a steel pillar. Buckles are arranged on the rear side of the basketball board, and the basketball board is connected with the rectangular frame structure in a combined mode through the buckles. A flange plate is welded on the rear sides of the two triangular supporting structures. The basketball board support is formed by bending a steel pillar, the number of connecting points is small, strength is guaranteed, the defect that corrosion can happen easily due to multiple joints is overcome, and the structural design is scientific. The basketball board is supported and fixed by the basketball board support, the basketball ring and the basketball board support are of an integrated structure, so that the strength is high, and the basketball ring and the basketball board can both achieve good mechanical properties. The adopted method is simple and easy to implement, the method can be realized by a bending machine and welding equipment, cost is low, and machining efficiency is high.

Owner:李梦宁

Horizontal reaction kettle delayed coking equipment and process thereof

ActiveCN103059887AIncrease heightNot easy to repairThermal non-catalytic crackingCoking carbonaceous materialsTotal investmentWorking environment

The invention discloses a piece of horizontal reaction kettle delayed coking equipment and a process thereof, which has small investment, convenience for operation, high security coefficient of work environment and wide application scope of raw material source. The horizontal reaction kettle saves complex corollary equipment and support equipment, and does not need foundation. The investment volume of the horizontal reaction kettle related in the invention is 3-4 hundred thousand yuan, and the total investment volume is greatly reduced relative to vertical reaction kettles, so that the financial burden of enterprises is reduced; the raw material is conveyed and fed via a raw material distribution valve, so that multiple horizontal reaction kettles can be connected; the reaction time and the time for shoving cokes can be arranged by a manner of feeding or discharging the raw material, so that the overall coking processing quantity is proportional to the number of single horizontal reaction kettle which is connected with the raw material; and because of the annular cavity of the raw material distribution valve, the raw material is under the clockwise or anticlockwise flow state, is not easy to coke, and is easy to operate.

Owner:TIANJIN DONGSHENG IND & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com