Sieving type monosodium glutamate crystallization and separation process and equipment

A technology of crystallization separation and monosodium glutamate, which is applied in food preparation, application, food science, etc., can solve the problems of production efficiency and economic benefit impact, thickener structure is complicated, and occupies a large area, so as to achieve production efficiency and economic benefit. , Reduce invalid circulation and facilitate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

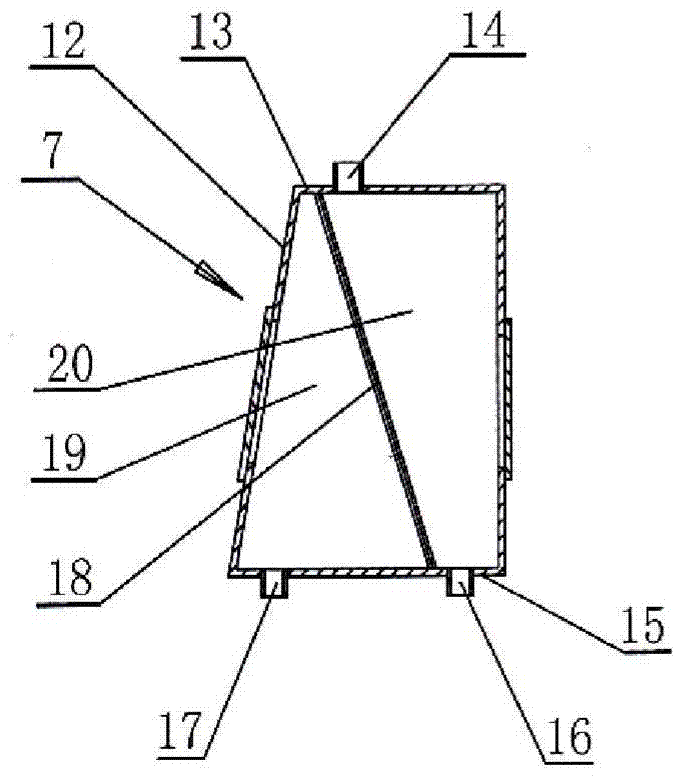

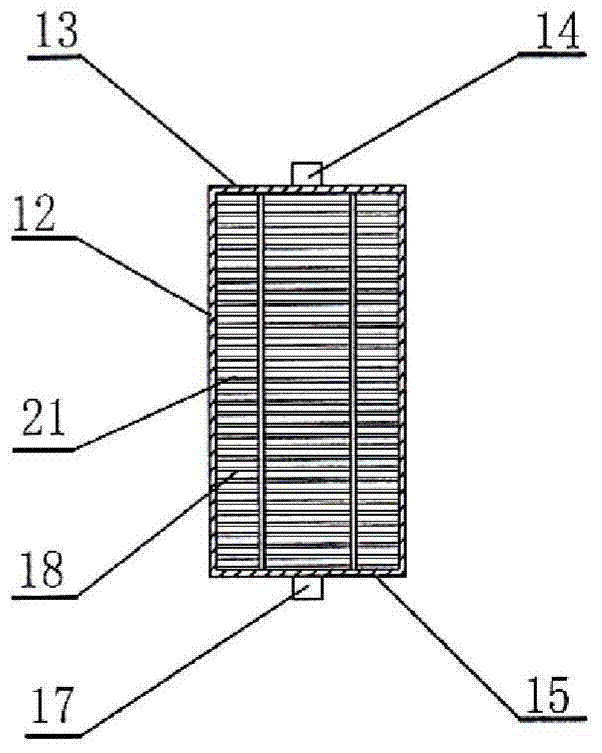

[0029] The general idea of the present invention is to improve the original thickener used to separate the large and small crystal particles, remove the step of backwashing, and directly separate the large and small crystal particles with the sieve. Introduce seven kinds of embodiments around this design below in conjunction with accompanying drawing:

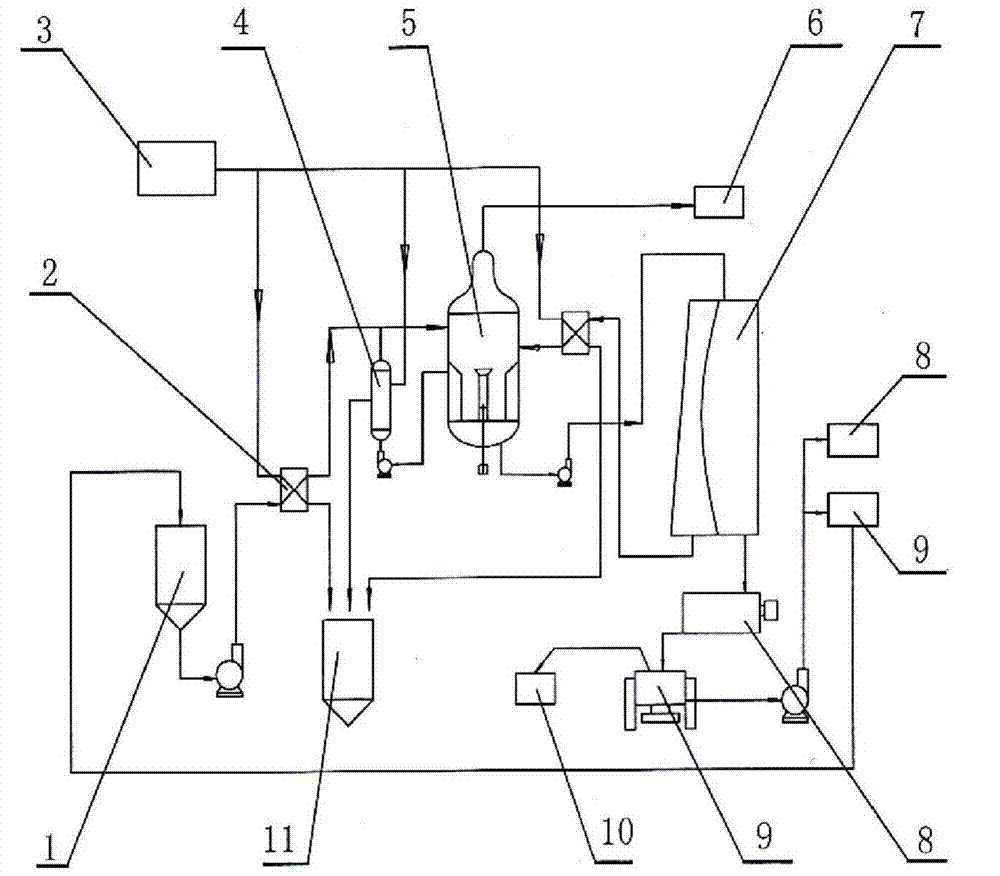

[0030] The first embodiment: figure 1 A continuous production monosodium glutamate crystallization and separation process and the main structure principle of the equipment are introduced. It can be seen in the figure that the decolorization liquid enters the decolorization liquid storage tank 1 from the decolorization equipment for standby, and is transported to the crystallization tank 5 by the delivery pump when necessary. During the transportation process, the decolorizing liquid is preheated to about 70°C by the plate heat exchanger 2, and after entering the crystallization tank 5, heat can be continuously supplemented b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com