Basketball stand and manufacturing method thereof

A technique for basketball stands and backboards, which is applied to ball games and sports accessories, etc. It can solve problems such as the difficulty of fixed connection between the ring and the backboard, increased processing difficulty and production cost, unreasonable design of the basketball stand structure, etc., and achieves guaranteed strength, Scientific structure design, good cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

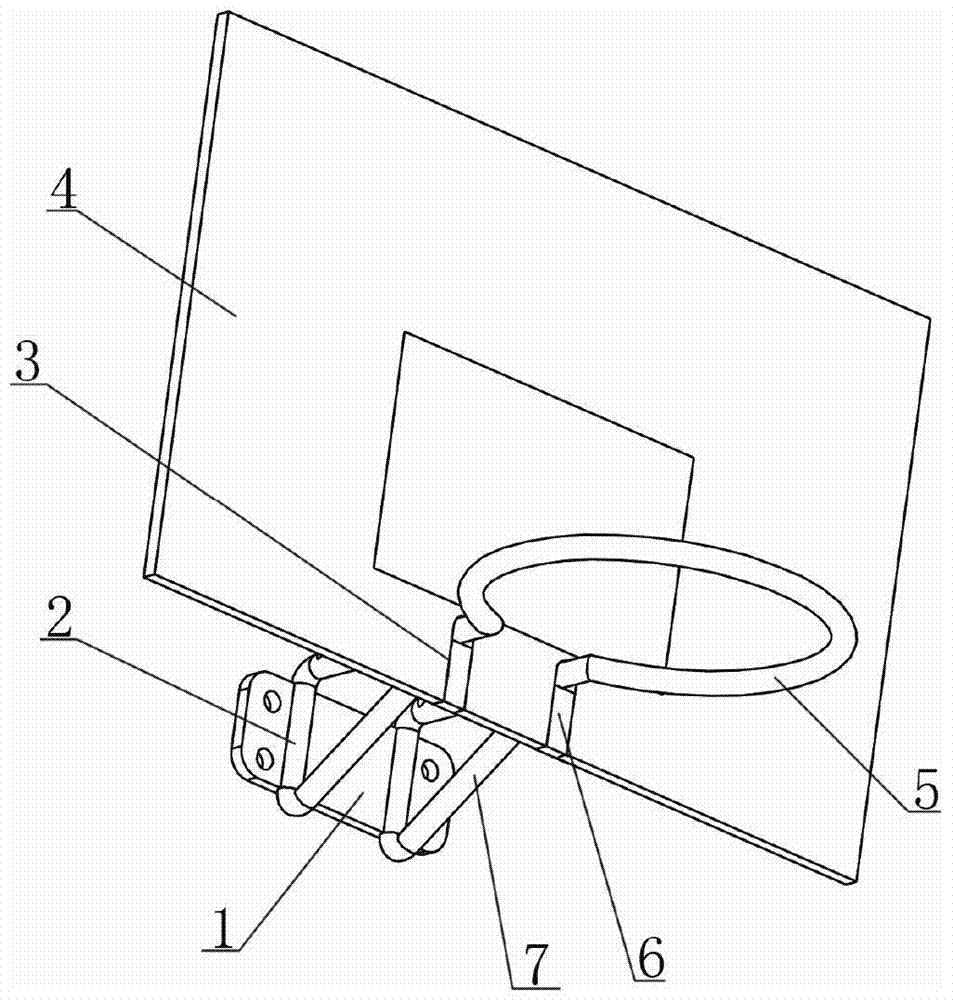

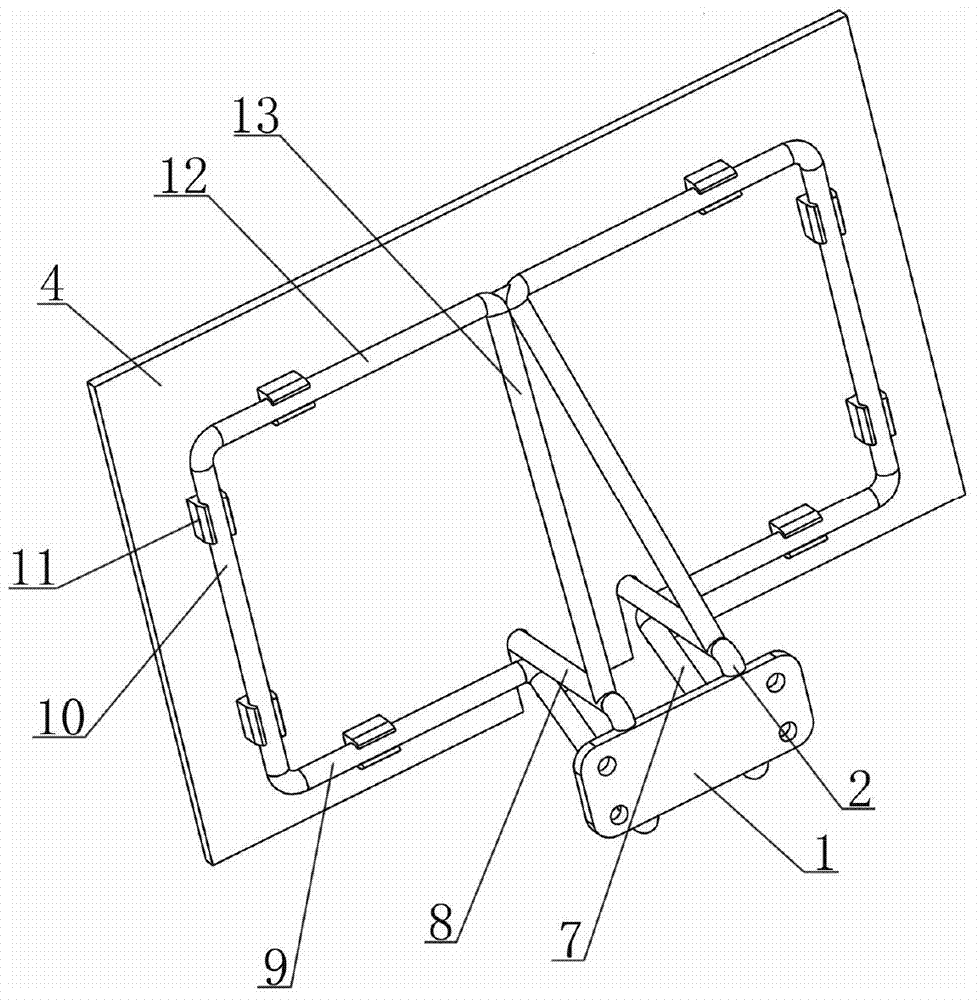

[0029] see Figure 1-2 As shown, the present invention includes a backboard bracket and a backboard 4. The backboard bracket is a left-right symmetrical structure, and a steel column is formed by bending.

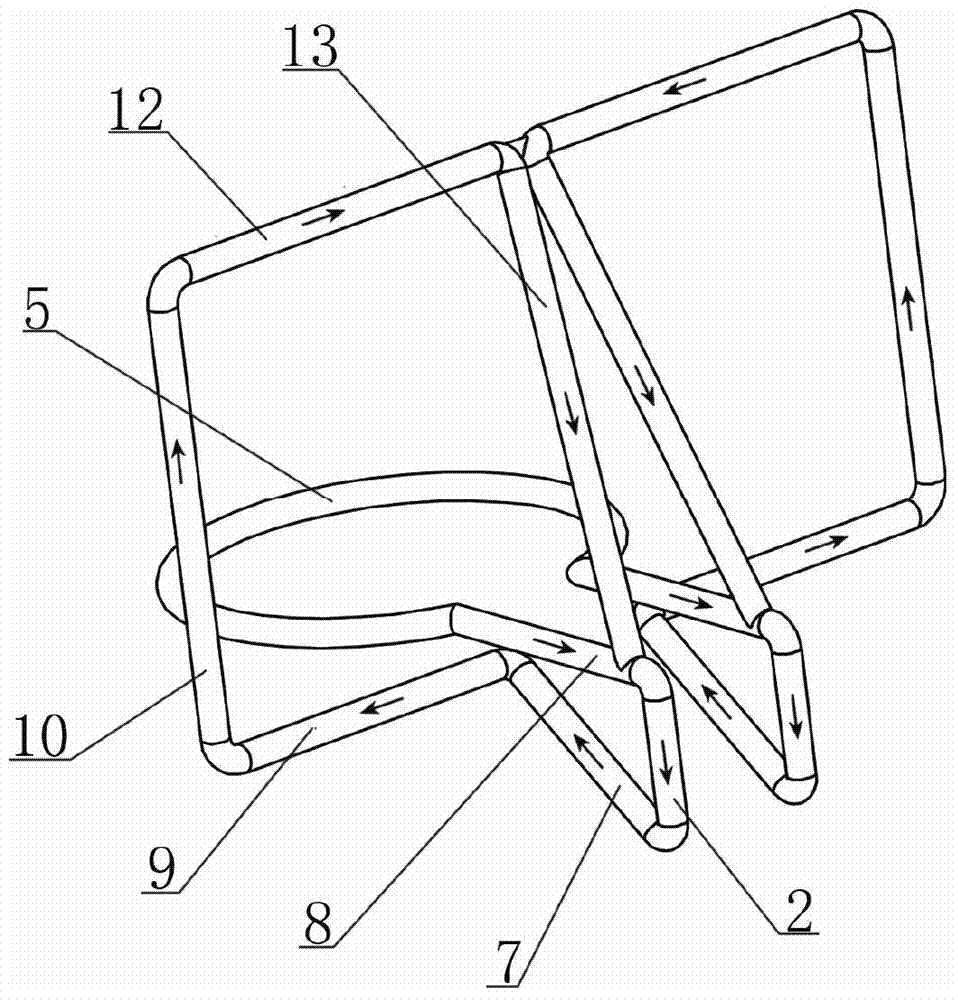

[0030] see image 3 , 4 As shown, the forming method of the backboard support is to bend a steel column from the middle to form an arc, and the angle of the arc is 135-145, thereby forming a left-right symmetrical basket 5 located in the horizontal direction; The two ends of the ring 5 are bent backward to form two parallel and horizontal cross braces 8; the rear ends of the two cross braces 8 are bent vertically downward to form two parallel and symmetrical uprights 2 ; The lower end of the column part 2 is bent forward and upward to form two parallel diagonal braces 7, the front ends of the diagonal braces 7 are located at the lower side of the front part of the cross brace 8; the front ends of the two diagonal braces 7 are all outward Bend 90 degrees to form two colli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com