Patents

Literature

35 results about "High energy electron irradiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seven-layer coextrusion membrane for transfusion and its production method

InactiveCN1970288AGood optical performanceGood flexibilitySynthetic resin layered productsLow-density polyethyleneHigh energy electron irradiation

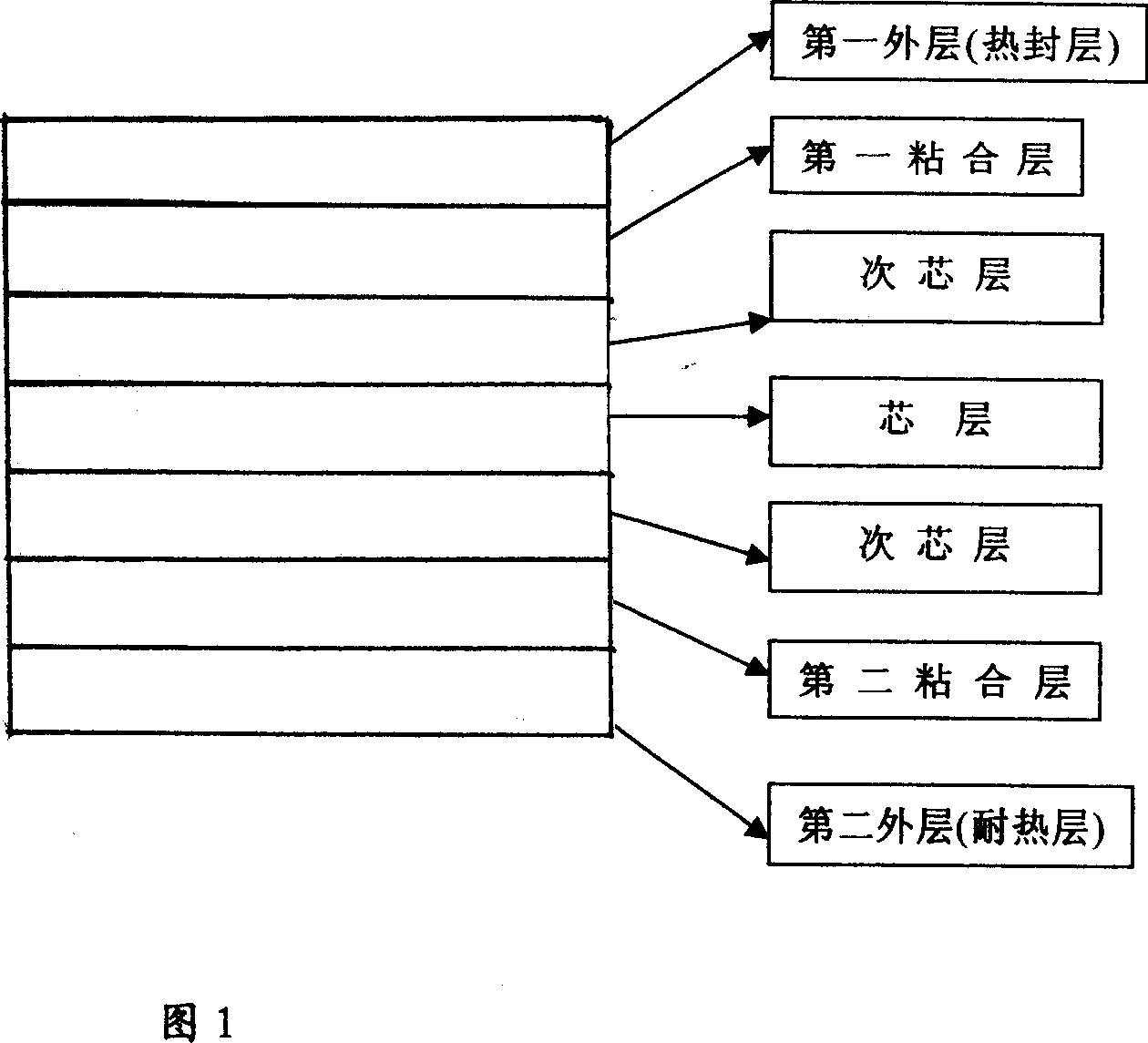

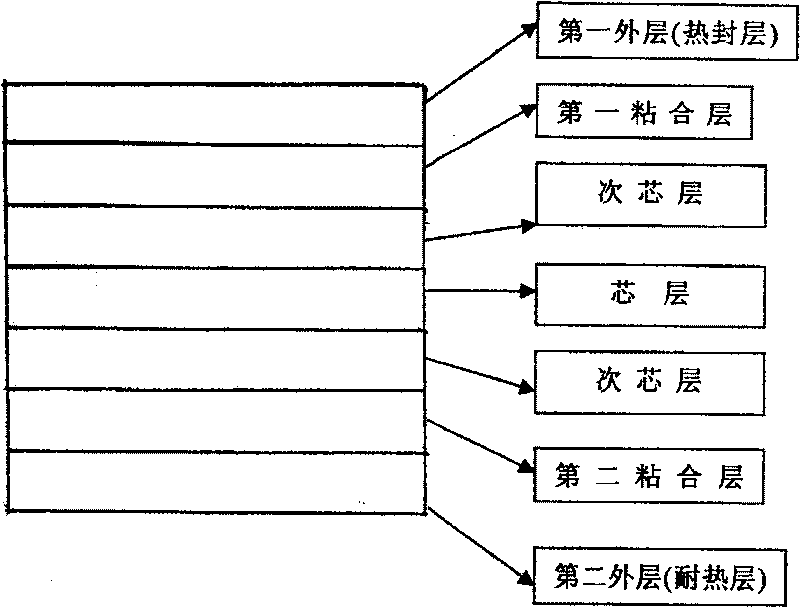

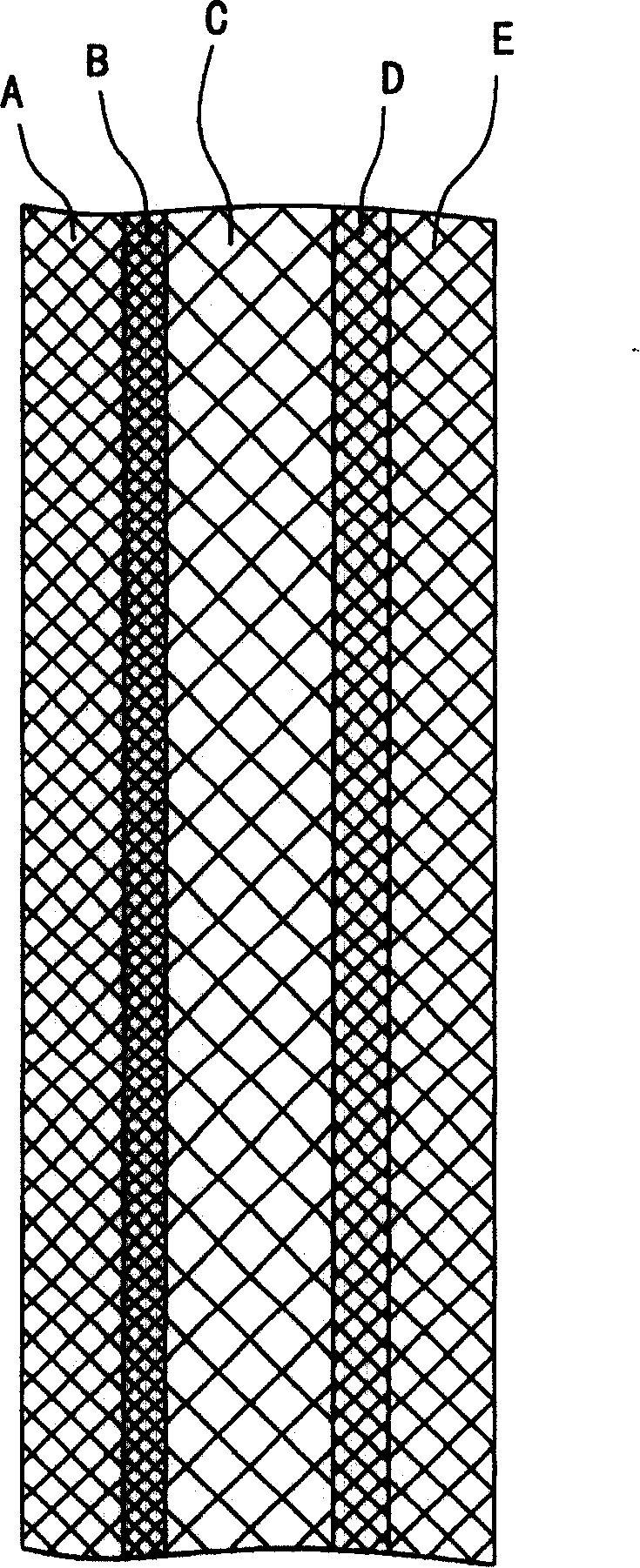

The seven layer common transfusion liquid membrane usually comprises a vinyl copolymer formed core layer, two metallocene yarns low density polyethylene formed sub core layers, polyacrylic acid or polypropylene or high intensity polyethylene selected No.1 outside layer, polyester, copolyester, polypropylene or nylon formed No.2 outside layer, No.1 adhesion layer between sub core layer and No.1 outside layer, and No.2 adhesion layer between No.2 outside layer and core layer. Using this seven extruder to melt and extrude materials of each layer through seven layers conical or flat overlaid mold head and 100 degree purified gas with computer controlling the inflation film diameter and thickness, it makes the double layer film roll, after Co60 lighting or hard electron radiating to get high resistance, transpancy, flexibility, in conformity to all kinds of medical, biological or chemical regulations.

Owner:安徽双津实业有限公司

Antistatic thermo-shrinkage material and manufacturing method thereof

ActiveCN101255246ALow resistivityAvoid it happening againOther chemical processesHigh energy electron irradiationThermal contraction

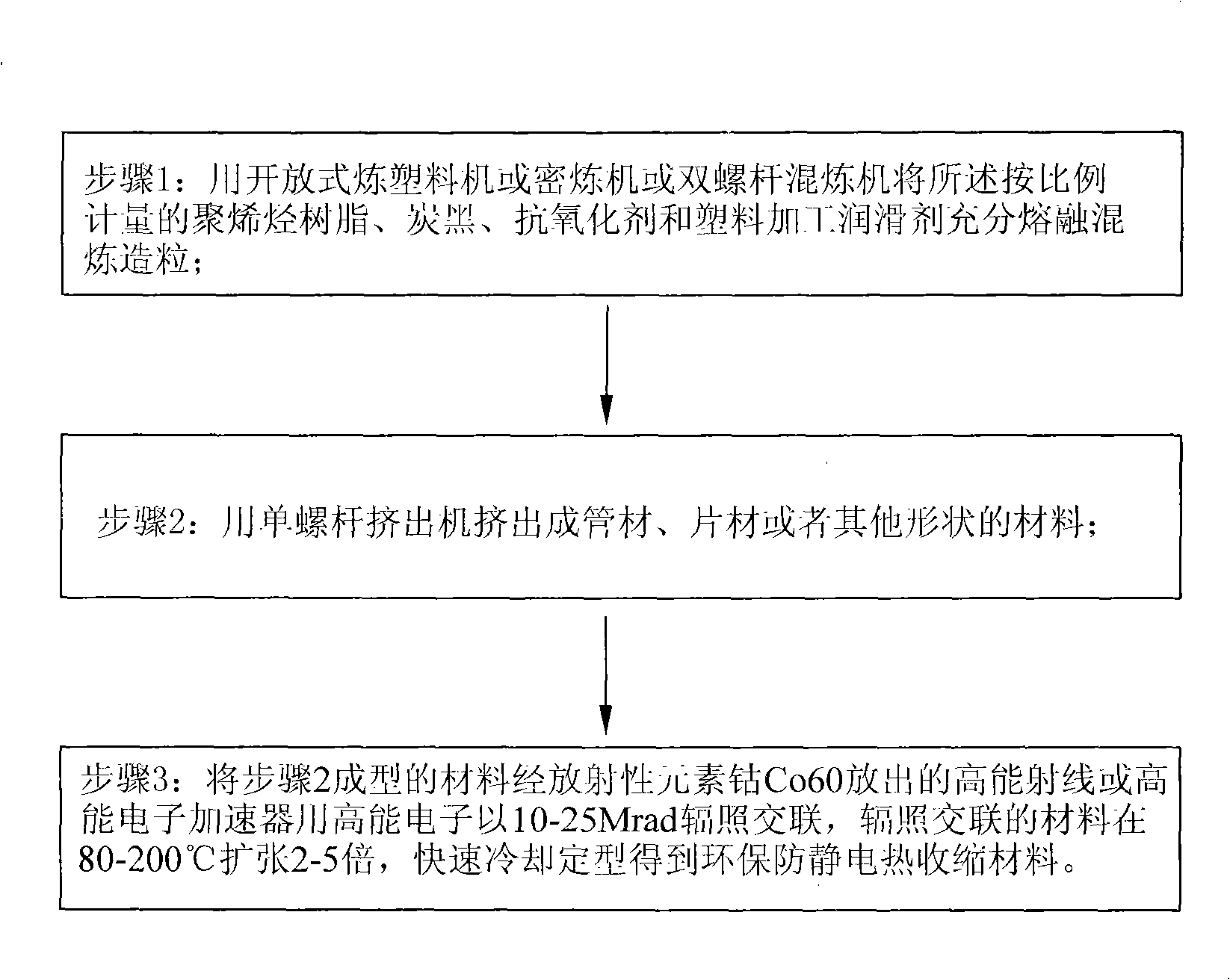

The invention provides an anti-static thermal contraction material, comprising( by weight): polyolefine resin 100 portion, carbon black 12-20 portion, antioxidant 0.3-1.0 portion, plastic processing lubricant 0.5-1.5 portion. The invention also provides a producing method for the anti-static thermal contraction material, comprising: step 1: adequately fusing the polyolefine resin, carbon black, antioxidant and plastic processing lubricant to mix and granulate; step 2: extruding and moulding; step 3: crosslinking the material moulded in step 2 by high energy electron irradiation and then expanding; quickly cooling and shaping to obtain green anti-static thermal contraction material. The thermal contraction material has less resistivity to prevent the static generating and accumulating, at the same time with contraction feature on heating.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

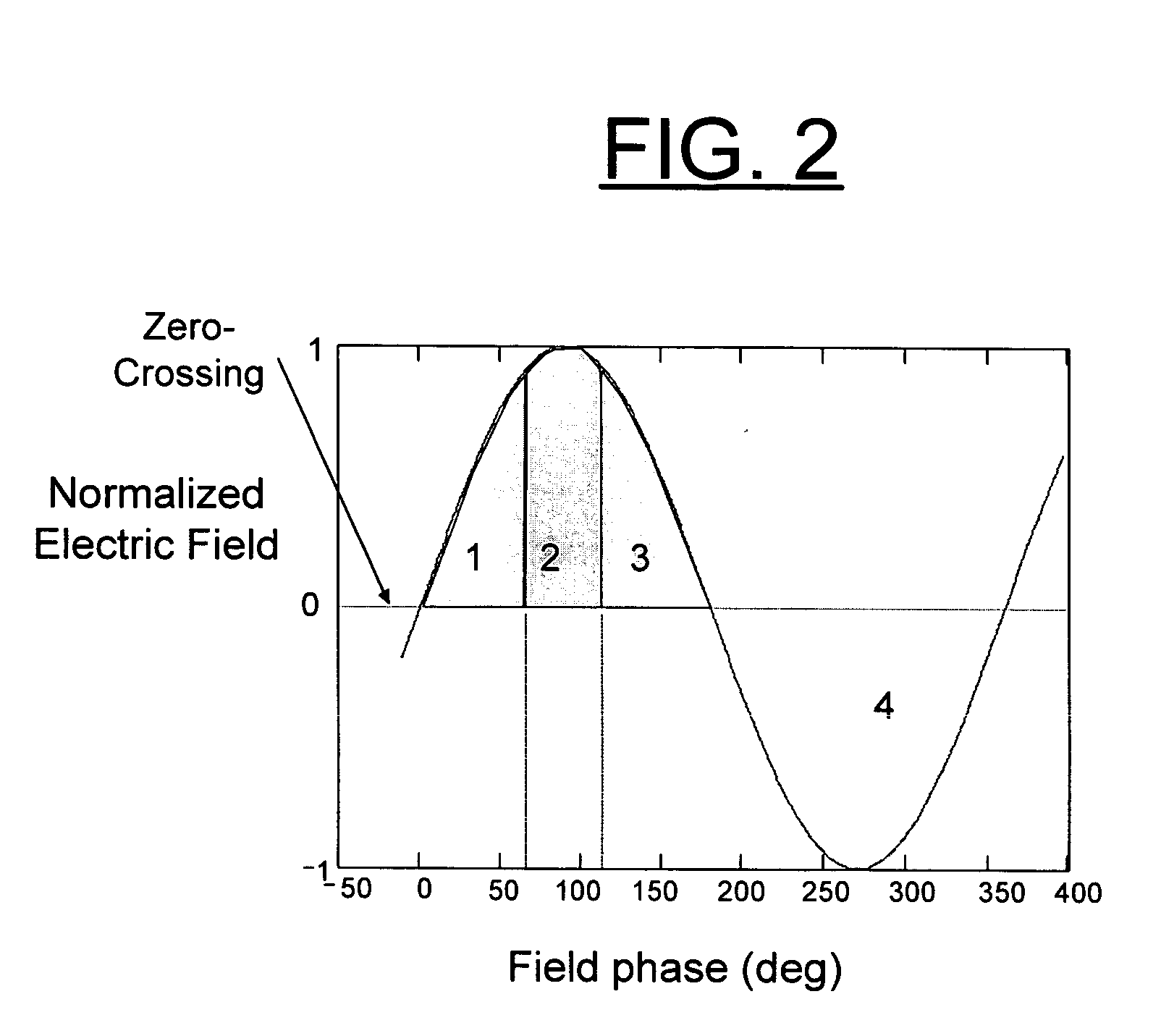

Laparoscopic tumor therapy using high energy electron irradiation

ActiveUS20060060793A1Optical radiation measurementElectrotherapyAbnormal tissue growthHigh energy electron irradiation

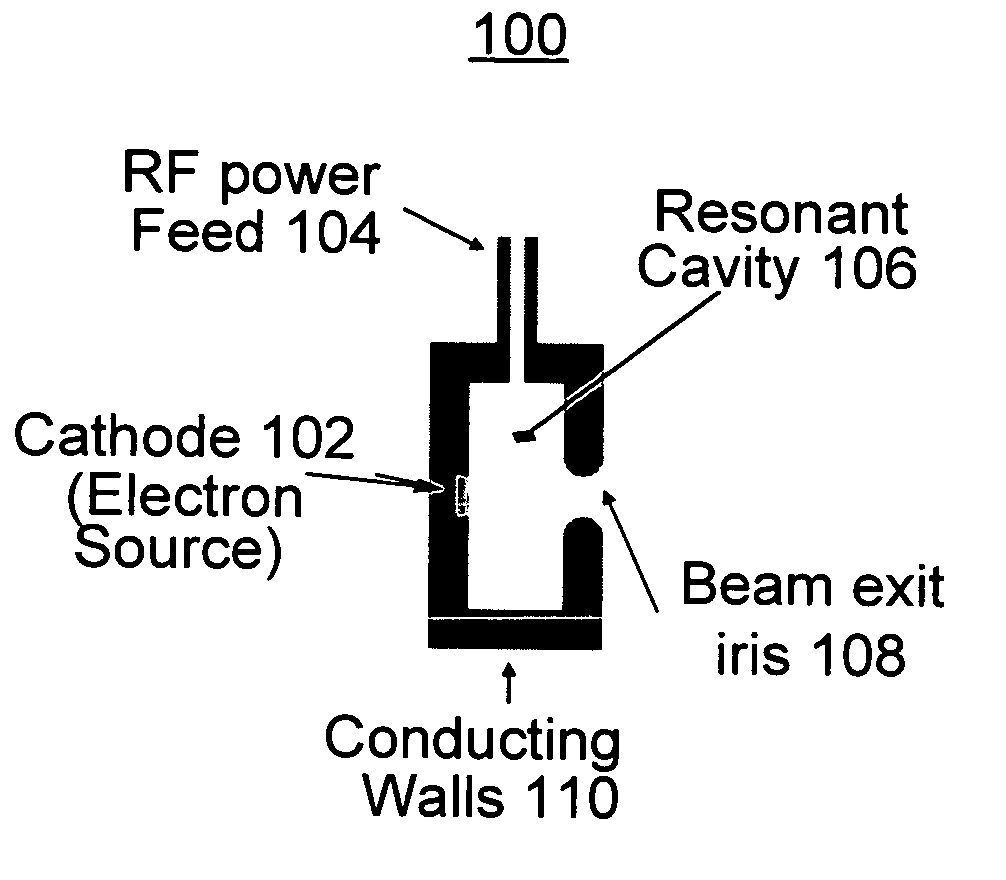

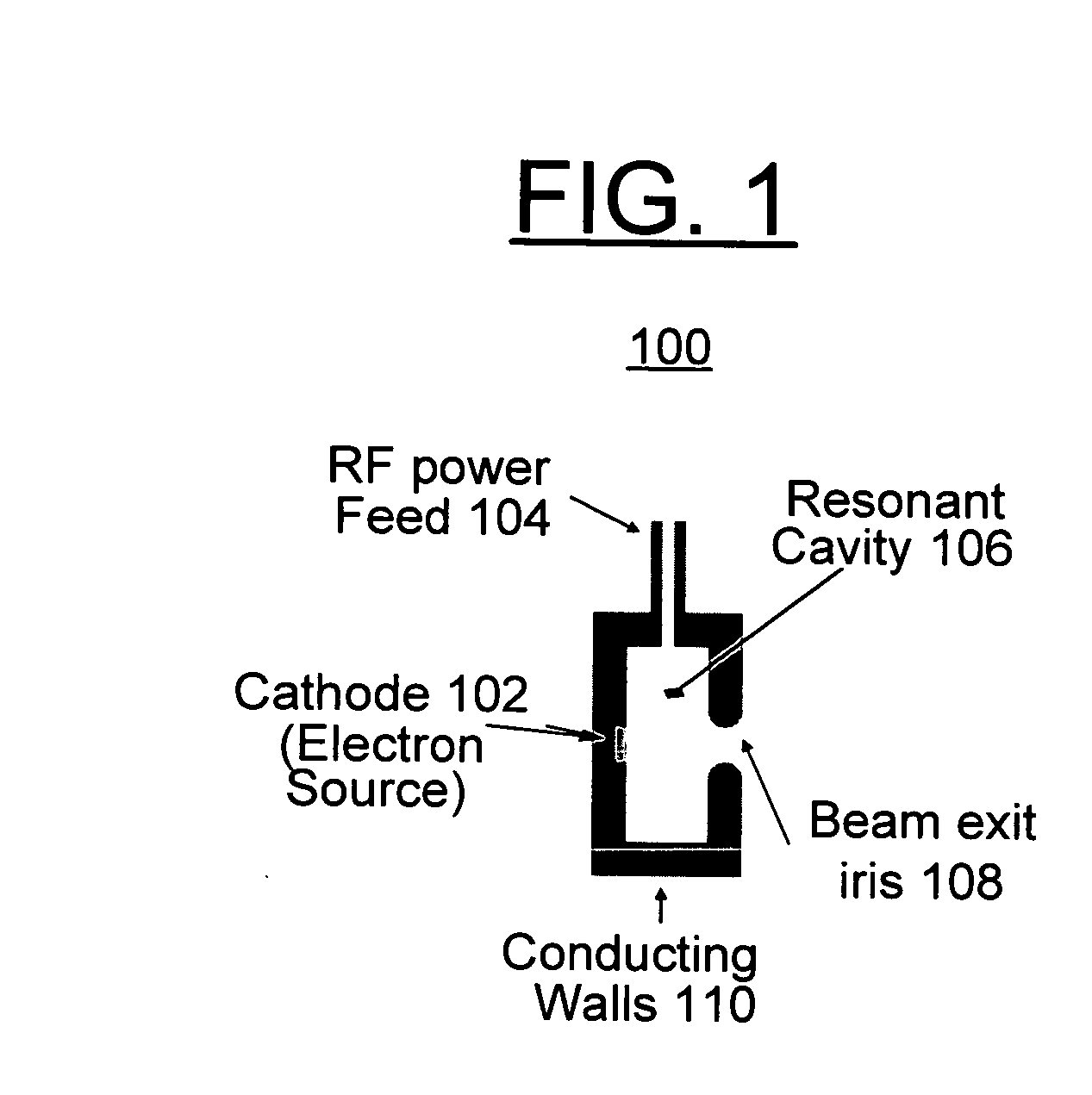

A laparoscopic tumor therapy method and an articulated electron beam transport system are provided for use with a high power, long focus electron source for tumor therapy. The high power, long focus electron source generates an e-beam. The e-beam is transported through a laparoscopic tube proximate a target tumor for electron irradiation therapy.

Owner:UCHICAGO ARGONNE LLC

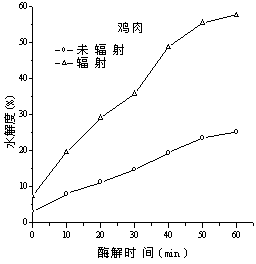

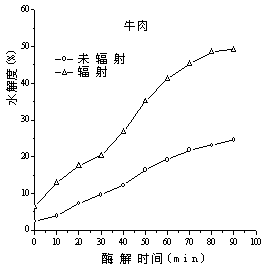

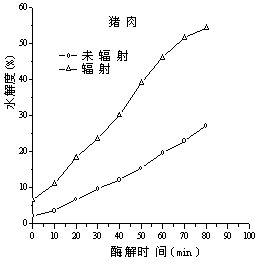

Processing method for improving enzymolysis efficiency of animal protein by utilizing high energy electron beam irradiation technology

ActiveCN103960682AStrong penetrating powerImprove hydrolysis efficiencyFood electrical treatmentFood preparationHigh energy electron irradiationHigh energy

The invention relates to a processing method for improving the enzymolysis efficiency of animal protein by utilizing a high energy electron beam irradiation technology, belonging to the technical fields of high energy electron radiation processing and livestock and poultry meat deep processing. The processing method comprises the following steps: thawing the animal protein (chicken and beef etc.), cleaning, grinding and adding water for enzyme hydrolysis after high energy electron beam irradiation, wherein the rate of hydrolysis can be increased by more than 2 times compared to the non irradiation treatment, which greatly shortens the time of hydrolysis. According to the invention, the high energy electron irradiation treatment is increased based on the conventional enzymatic hydrolysis method, which is characterized by loosening the dense organization structure of animal protein by utilizing the high energy electron beam irradiation, destroying a plurality of chemical bond of protein and the stability of the protein texture, helping the enzyme solution effectively penetrate, improving the enzymolysis efficiency and speed. Various microorganisms in the raw meat are effectively killed by the irradiation treatment and dispense with the complex enzymolysis process of hot sterilization and cooling for the raw meat, which ensure the health and safety in the production process, shorten the processing time and reduce the energy consumption during production.

Owner:SHANGHAI ACAD OF AGRI SCI +1

Preparation method of crosslinked polyethylene electric-conductive foam material

InactiveCN107602978AQuality improvementReduce mutual interferenceLow-density polyethyleneHigh energy electron irradiation

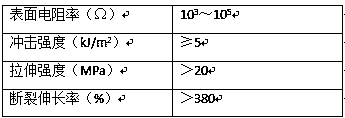

The invention discloses a preparation method of a crosslinked polyethylene electric-conductive foam material. The preparation method includes the steps of: 1) respectively diluting azodicarbonamide, conductive carbon black, a toughener, an antioxidant, a lubricant and a colorant with low-density polyethylene, and performing extruding granulation through a twin-screw extruder; 2) uniformly mixing low-density polyethylene with the diluted raw materials in a stirrer; 3) performing extrusion through a single screw extruder to obtain a sheet material and reeling the sheet material; 4) performing high-energy electron irradiation crosslinking treatment; and 5) foaming the material through a foaming process to obtain the foam sheet material. The preparation method can effectively improve dispersibility of the electric-conductive carbon black and reduces usage amount thereof. The foam material has fine and uniform pores, stable electrical resistivity, good electric-conductivity, high mechanicalstrength and good processability.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

Crosslinked polyolefin foaming material with antibacterial function and preparation method thereof

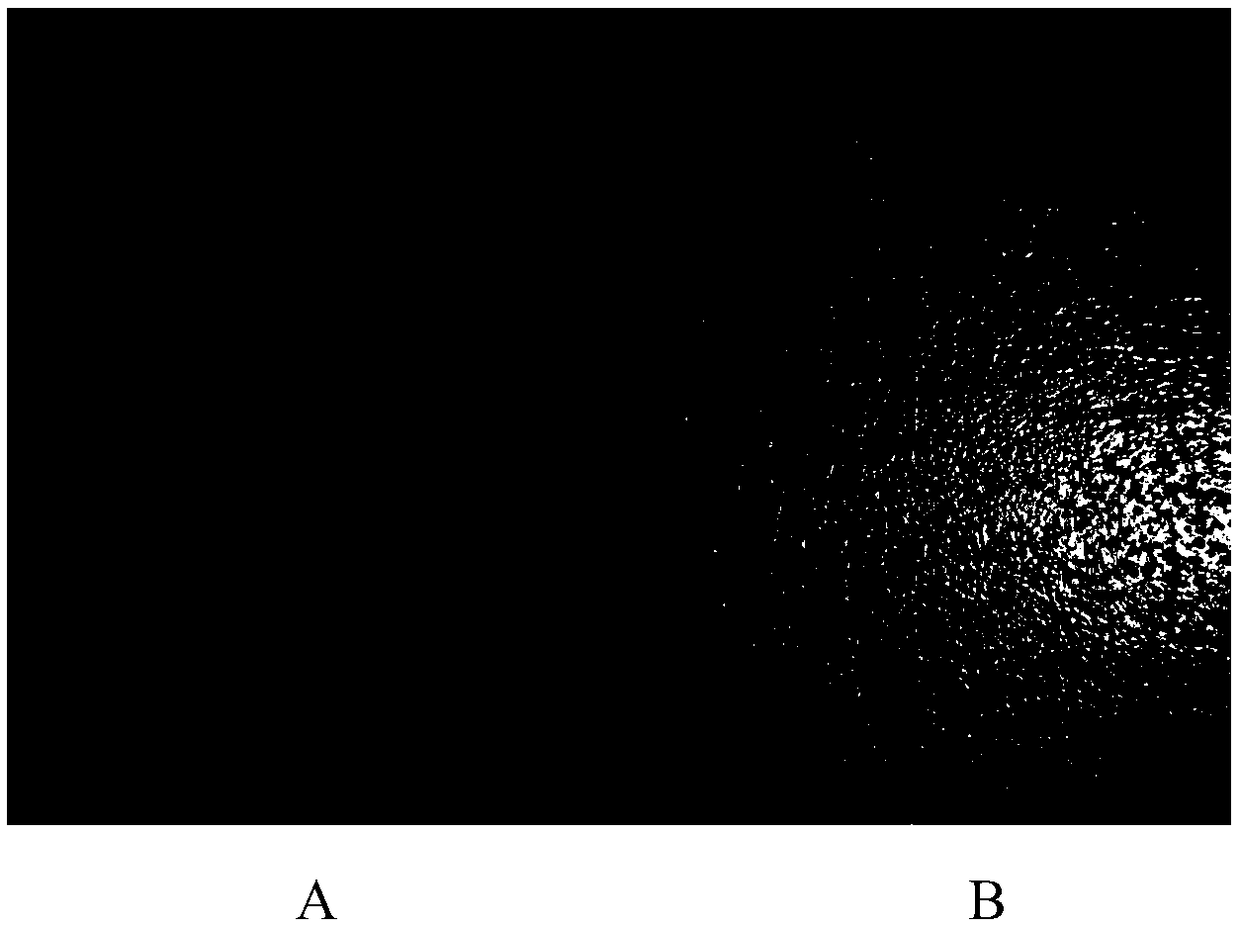

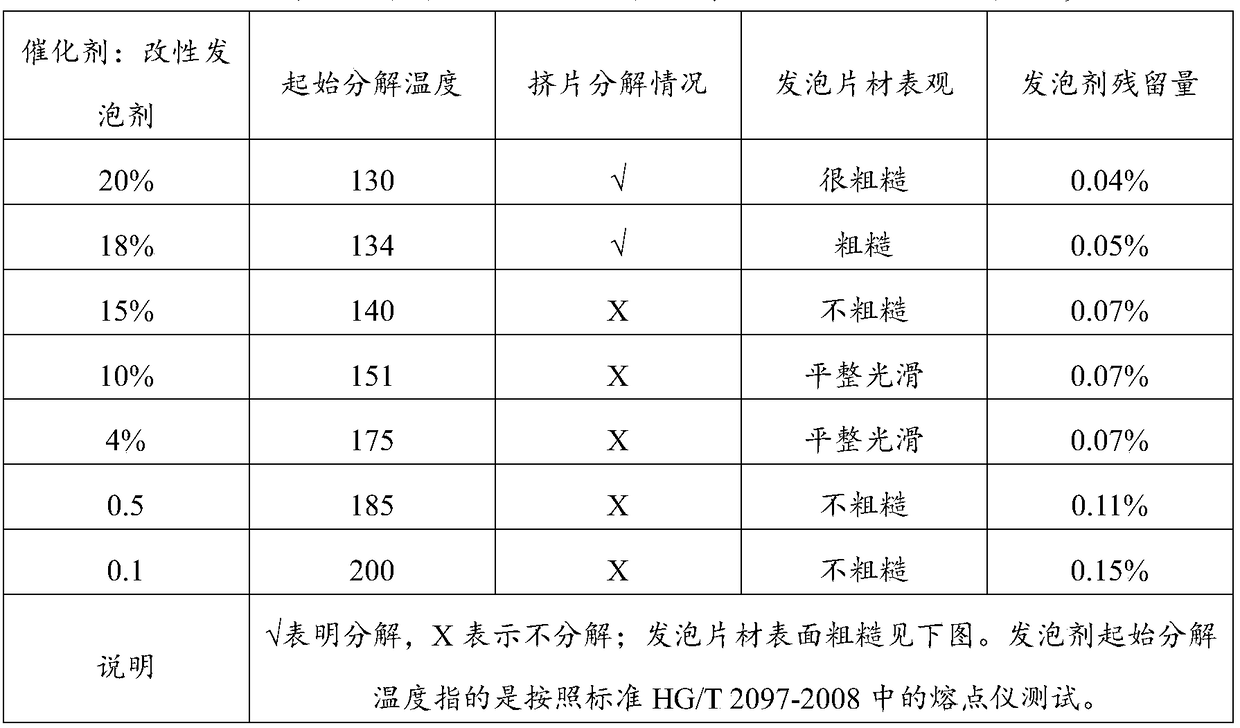

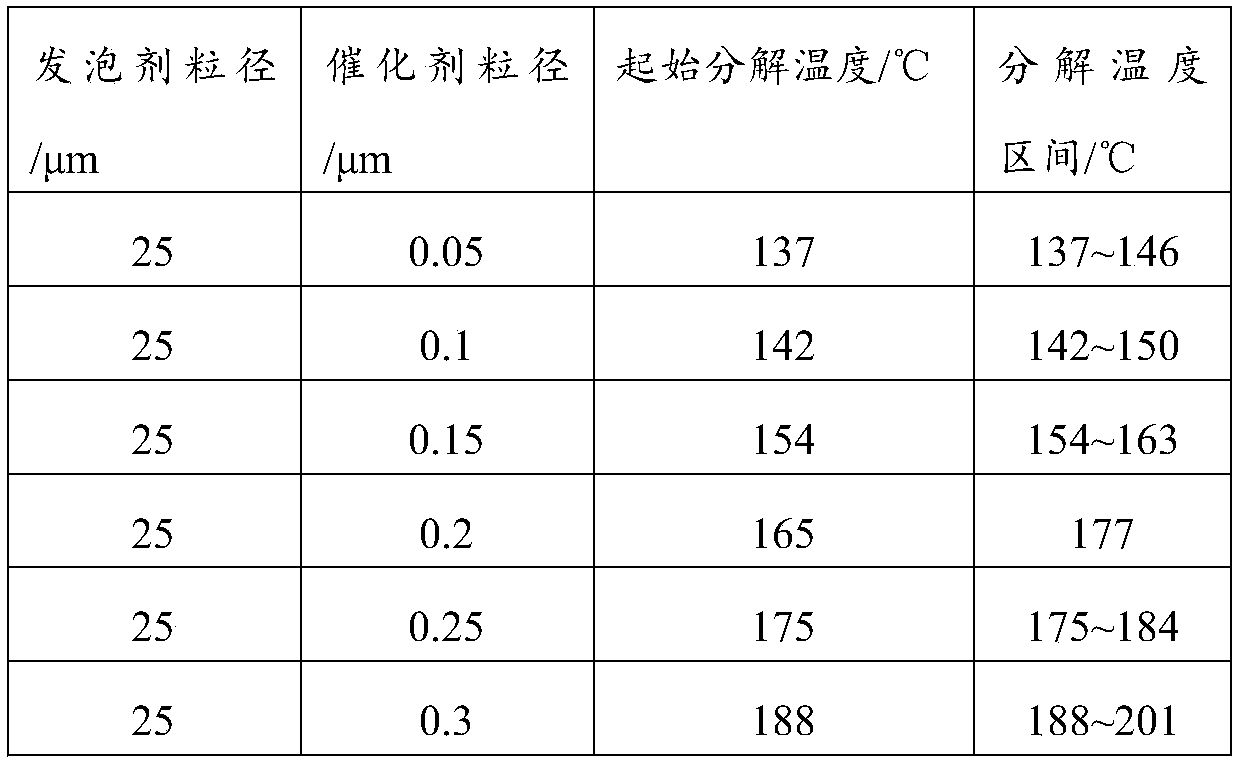

The invention discloses a crosslinked polyolefin foaming material with an antibacterial function and a preparation method thereof. The crosslinked polyolefin foaming material is prepared from the following raw materials in parts by weight: 45 to 91.5 parts of polyethylene resin, 5 to 30 parts of an ethylene copolymer, 2 to 20 parts of a modified foaming agent, 0.05 to 0.8 part of an antibacterialagent and 0.4 to 3 parts of a processing aid. The method comprises the following steps: firstly, mixing and granulating one part of the polyethylene resin, one part of the ethylene copolymer, the modified foaming agent and the processing aid to obtain spherulites A; secondly, mixing and granulating the rest part of the polyethylene resin, the rest part of the ethylene copolymer and the antibacterial agent to obtain spherulites B; mixing the spherulites A and the spherulites B, and extruding the mixture to obtain a sheet; and treating the sheet through high-energy electron irradiation crosslinking and a foaming process to obtain the crosslinked polyolefin foaming material. The foaming material disclosed by the invention is extremely good in antibacterial effect and high in antibacterial efficiency.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

Laparoscopic tumor therapy using high energy electron irradiation

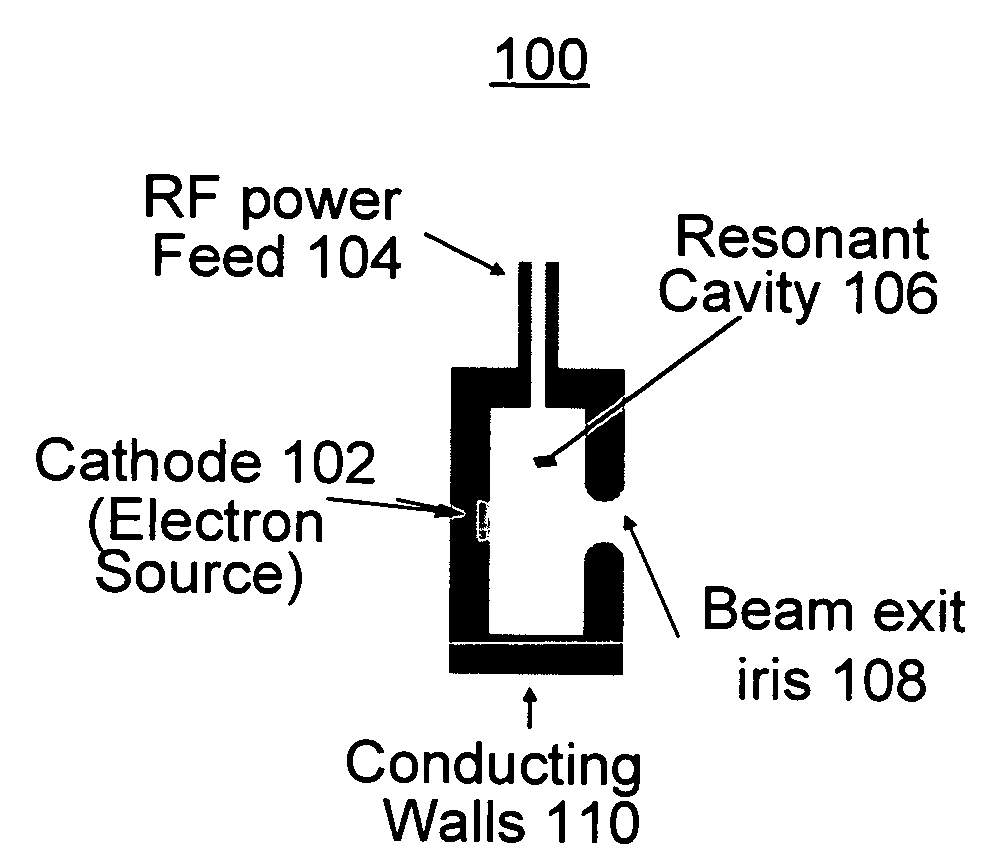

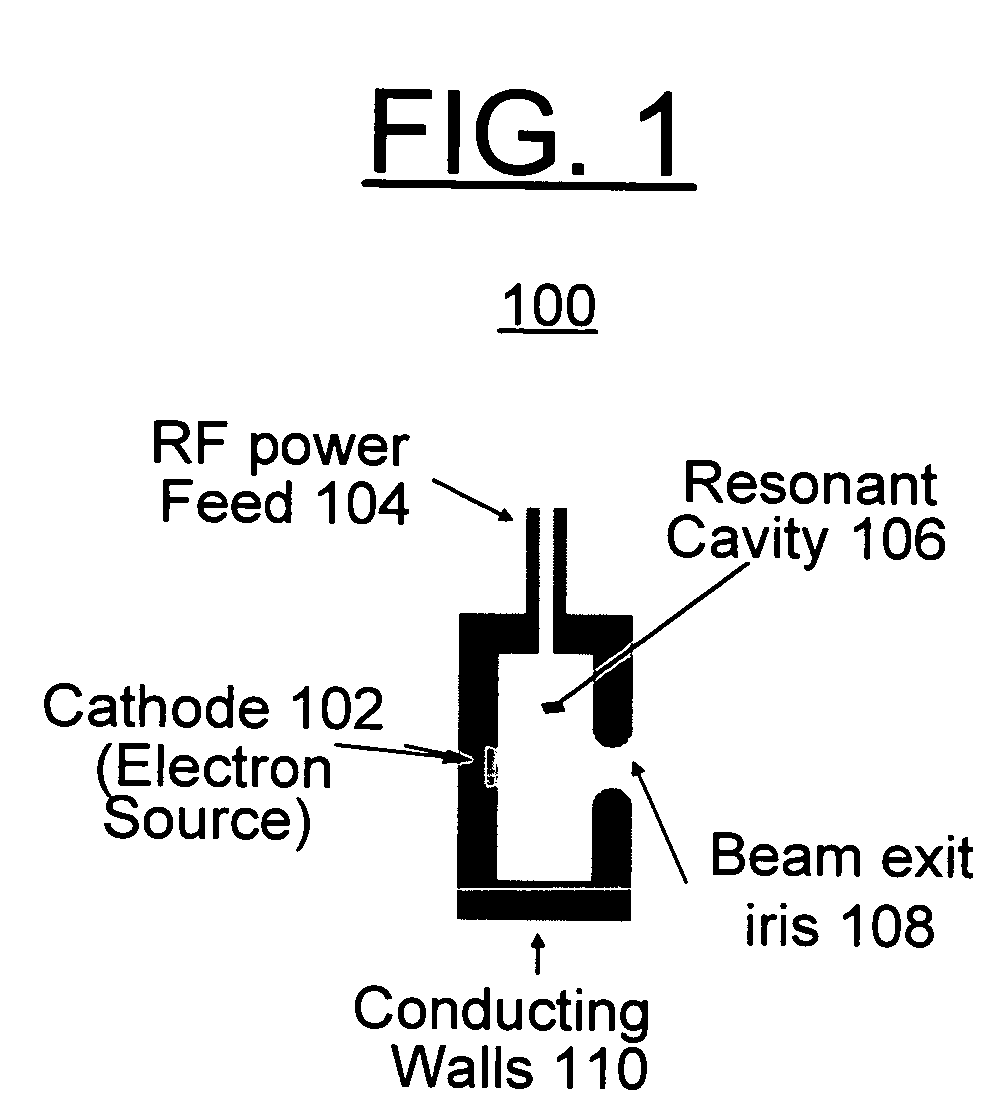

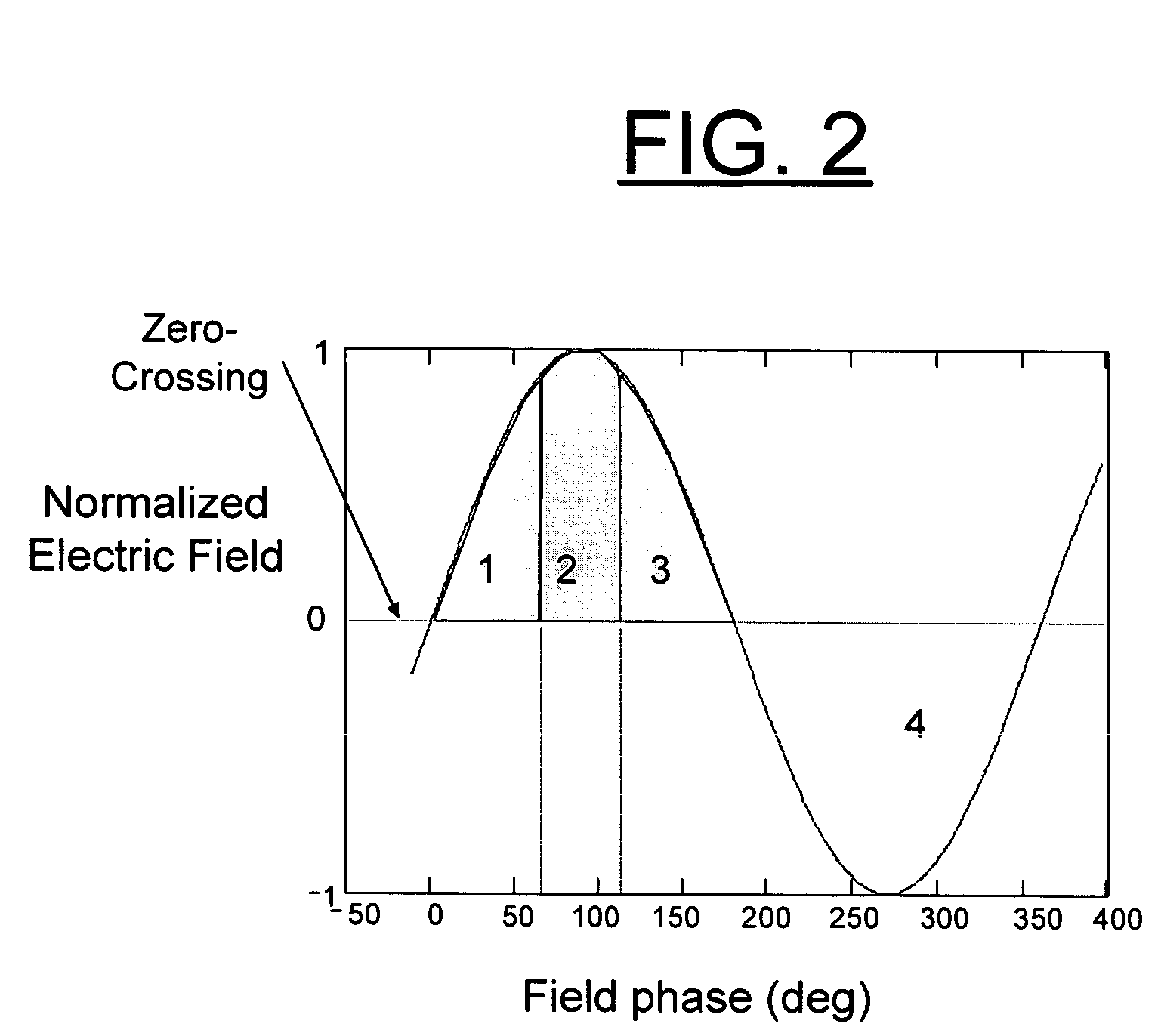

ActiveUS7312461B2Optical radiation measurementElectrotherapyHigh energy electron irradiationElectron source

Owner:UCHICAGO ARGONNE LLC

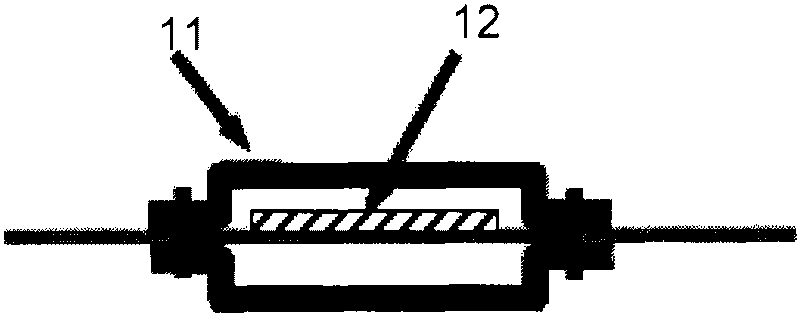

In-situ measurement device and method for space charges of dielectric material under electron irradiation

InactiveCN104237659AEliminate the effects ofRealize in-situ measurementElectrical measurementsHigh energy electron irradiationVacuum pumping

The invention discloses an in-situ measurement device and method for space charges of a dielectric material under electron irradiation. The in-situ measurement device and method for the space charges of the dielectric material under electron irradiation are characterized in that an electron accelerator is used for simulating irradiation of high-energy electrons of a space electrified environment on samples to be tested, and meanwhile in-situ measurement is carried out on distribution of the space charges of the dielectric material by using a pulsed electro-acoustic method. The in-situ measurement device mainly comprises the electron accelerator, a vacuum target chamber, a vacuum pumping system and a pulsed electro-acoustic method measurement system. The device can be used for measuring the distribution of the space charges of the dielectric material under high-energy electron irradiation and providing important material characteristic parameters for charging and discharging mechanisms and effect studies of the dielectric material.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

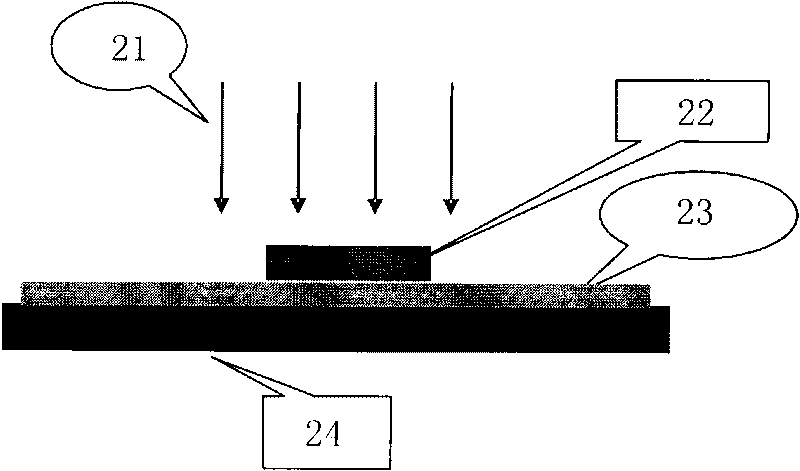

Electron-irradiation resisting shielding material and method for preparing same

InactiveCN101748319AImprove shielding effectLittle effect on thermal conductivityMagnetic/electric field screeningMetal layered productsHigh energy electron irradiationIrradiation

The invention relates to electron-irradiation resisting shielding material and a method for preparing the same. The electron-irradiation resisting shielding material comprises 15-35 percent by volume of Mo or W and 65-85 percent by volume of AlN, wherein the Mo or W is used as the high Z metallic phase, and the AlN is used as the Z dielectric phase. The insulating high-energy electron-irradiation resisting shielding material has higher shielding efficiency than the high atomic number metal such as tantalum, tungsten and lead, has high thermal conductivity, can reduce the dosage of the electron-irradiation deposition agent by over two orders of magnitude without destroying the original radiating condition of the components and can ensure that the temperature of the chip meet the normal work requirement when the components are working.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

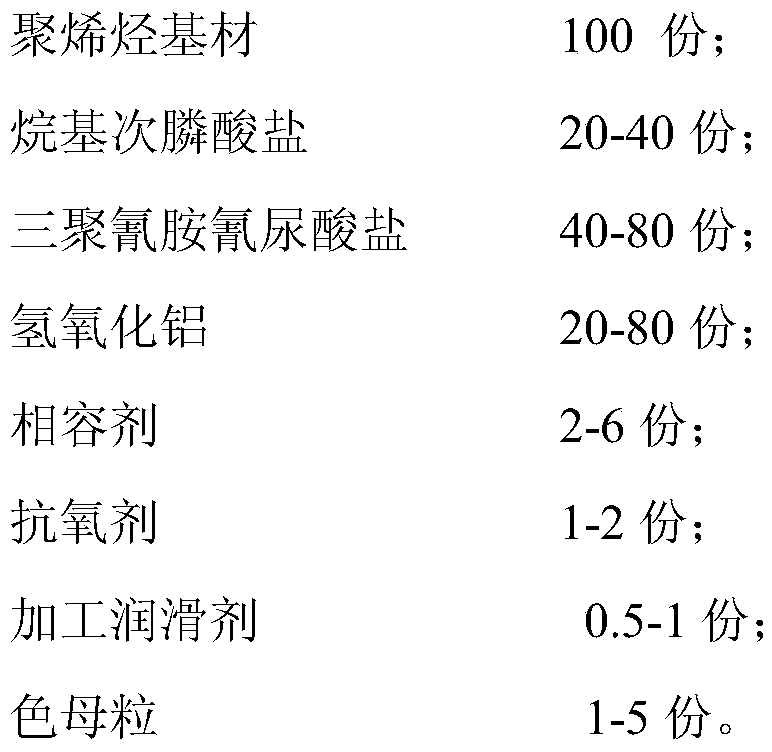

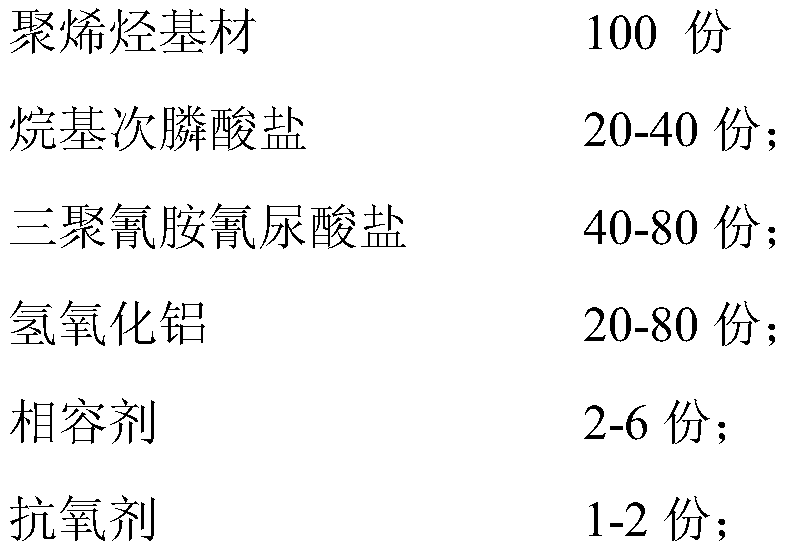

Radiation crosslinking halogen-free non-red phosphorus flame retardant heat shrinking material and preparation method thereof

InactiveCN109776930AExpand the range of speciesIncrease the scope of applicationHigh energy electron irradiationCross-link

The invention discloses a radiation crosslinking halogen-free non-red phosphorus flame retardant heat shrinking material. The radiation crosslinking halogen-free non-red phosphorus flame retardant heat shrinking material is prepared from the following components in parts by weight: 100 parts of a polyolefin substrate, 20 to 40 parts of alkyl phosphinate, 40 to 80 parts of melamine cyanurate, 20 to80 parts of aluminium hydroxide, 2 to 6 parts of a compatibilizer, 1 to 2 parts of an antioxidant, 0.5 to 1 part of a processing lubricant and 1 to 5 parts of a color masterbatch. The radiation crosslinking halogen-free non-red phosphorus flame retardant heat shrinking material disclosed by the invention does not contain toxic or harmful substances such as halogen, red phosphorus, lead, mercury,cadmium and hexavalent chromium; crosslinking can be realized by adopting gamma rays or high-energy electronic irradiation; the radiation crosslinking halogen-free non-red phosphorus flame retardant heat shrinking material is used for producing radiation cross-linking halogen-free non-red phosphorus flame retardant heat shrinking materials and products thereof.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

Compact solid-state laser for laser ranging in space high-orbit environment

ActiveCN110535010ACompact structureImprove radiation resistanceActive medium materialSolid state laser constructional detailsHigh energy electron irradiationHigh energy

The invention relates to a compact solid-state laser for laser ranging in a space high-orbit environment, which belongs to the technical field of solid-state lasers. Double-layer metal seal is designed to carry out vacuum degassing on components and raw materials in all aspects of installation and adjustment and isolate optical components and electronic components in the laser. The chance of pollution damage, which is caused by high vacuum and weightlessness, of the laser is reduced. Anti-irradiation strengthening is carried out on the laser casing, and electrostatic sensitive devices are effectively isolated. The probability that the laser casing and sensitive devices are damaged due to irradiation charging of plasma and high-energy electrons is reduced. Anti-irradiation laser crystals are used with a structural reinforcement technology to reduce the chance of laser component failure caused by total dose irradiation of high-energy particles. A virtual confocal unstable cavity and a multi-component integrated design technology are used to make the size of the laser highly compact.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Method for disinfecting operative instrument

InactiveCN103623445AEasy to operateLow implementation costChemicalsRadiationHigh energy electron irradiationHigh energy

The invention discloses a method for disinfecting an operative instrument. The method comprises the following steps of: placing the operative instrument to be disinfected into a closed spraying box; spraying and cleaning with a bio-enzyme cleaning agent for 15 to 20 minutes; then emptying the bio-enzyme cleaning agent; spraying and cleaning with medical iodophor for 5 to 10 minutes; emptying the medical iodophor; placing the operative instrument to be disinfected into ozonation water to soak for 5 to 10 minutes; taking out and drying; radiating the operative instrument to be disinfected by a high energy electronic irradiation accelerator. The method for disinfecting the operative instrument is simple in operation steps and low in implementation cost, has an ideal disinfecting effect, and can completely avoid cross infection caused by incomplete disinfecting of the operative instrument.

Owner:QINGDAO ANXIN MEDICAL DEVICES

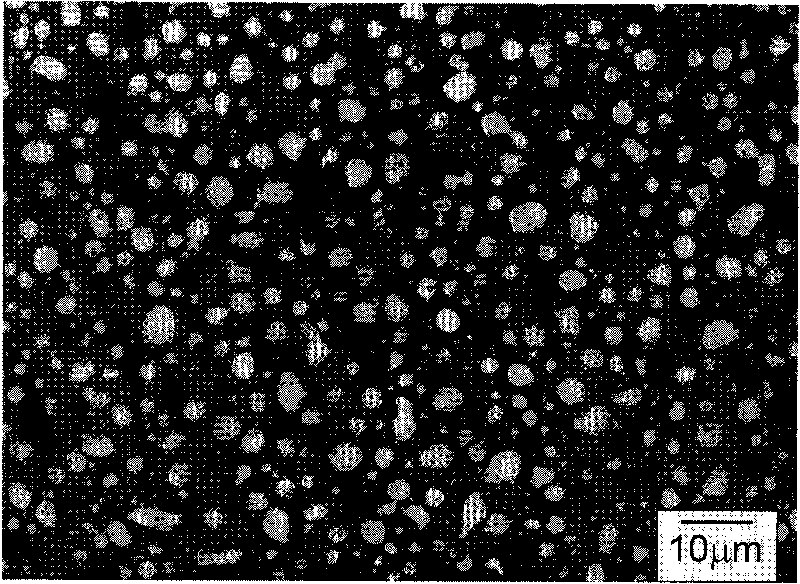

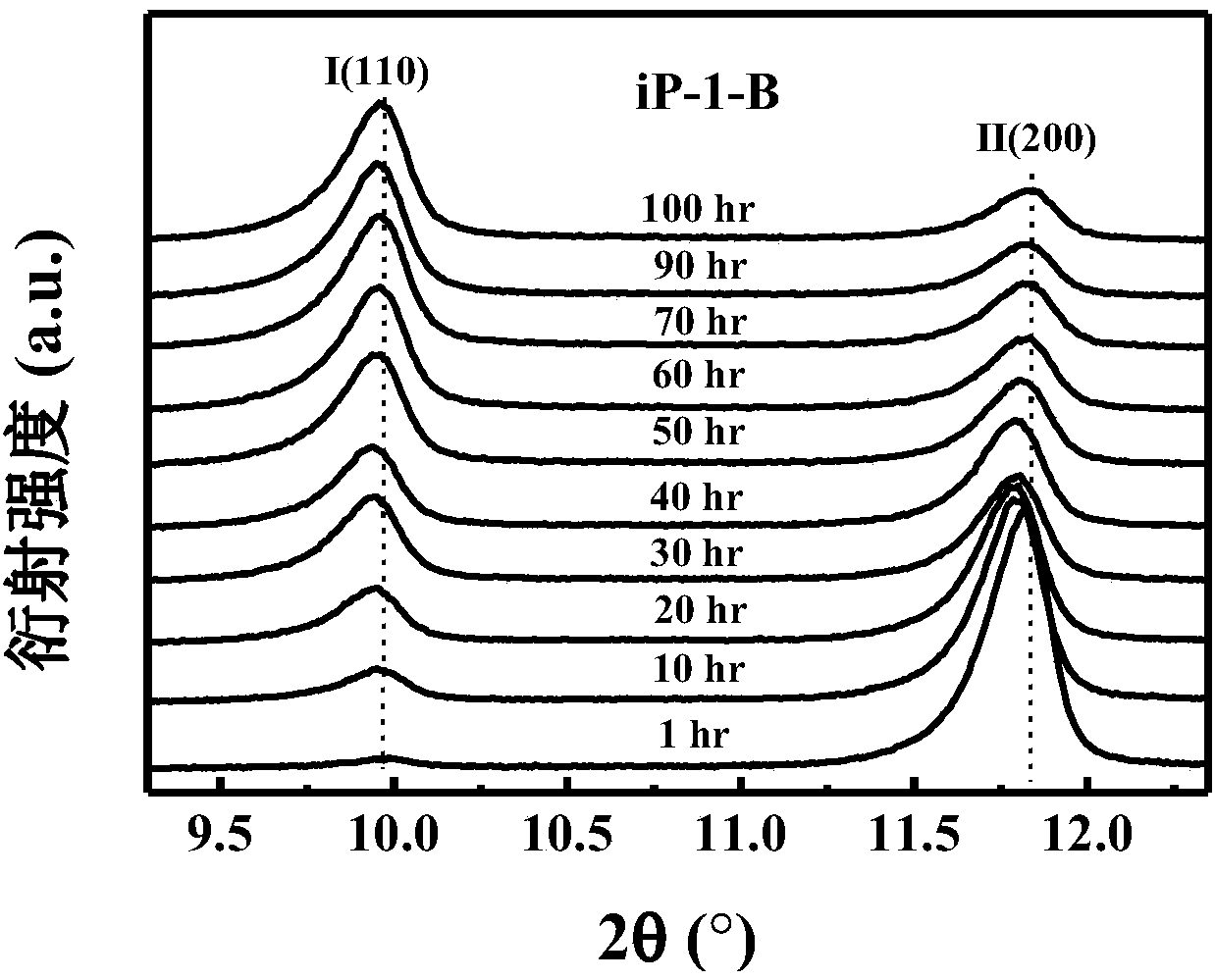

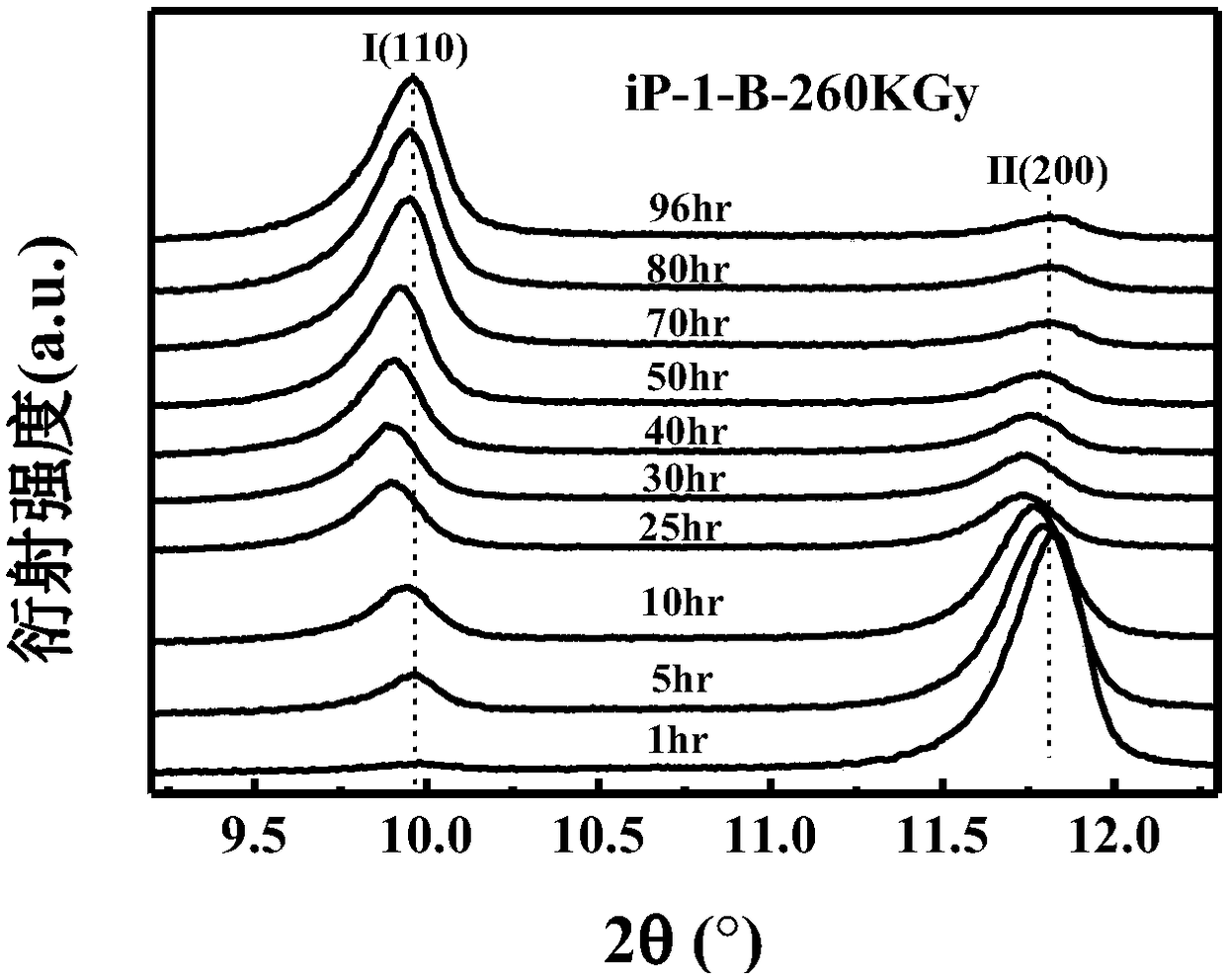

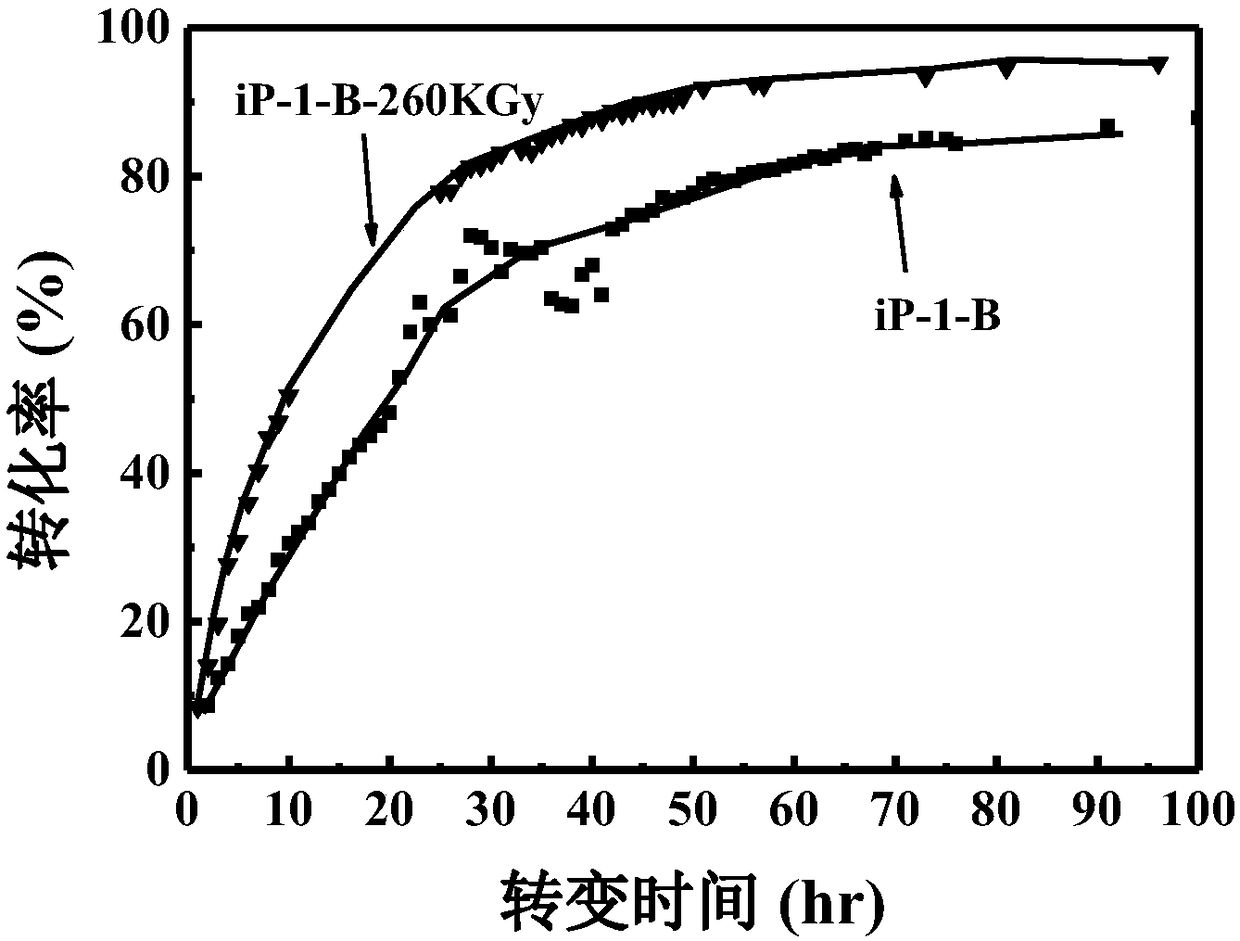

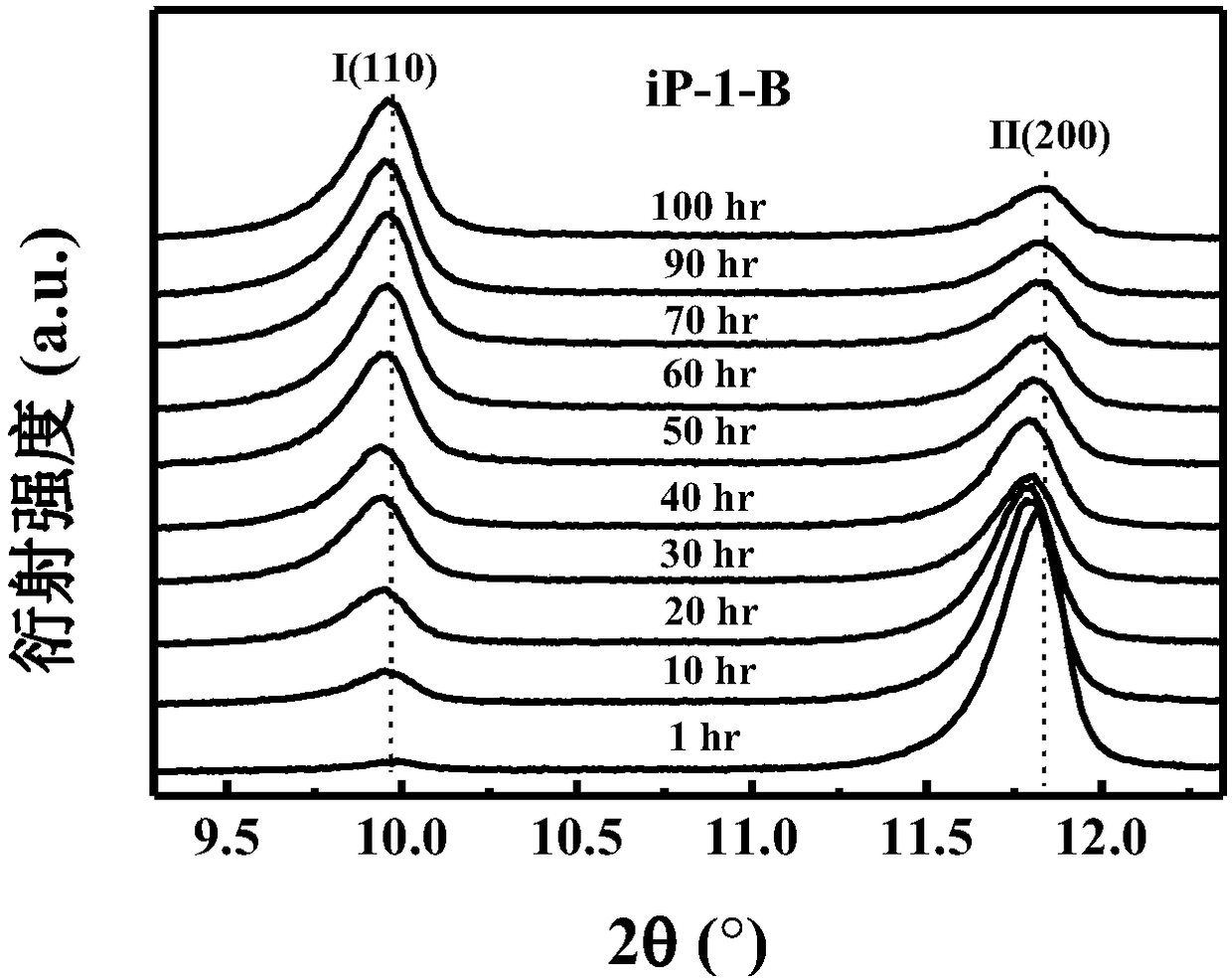

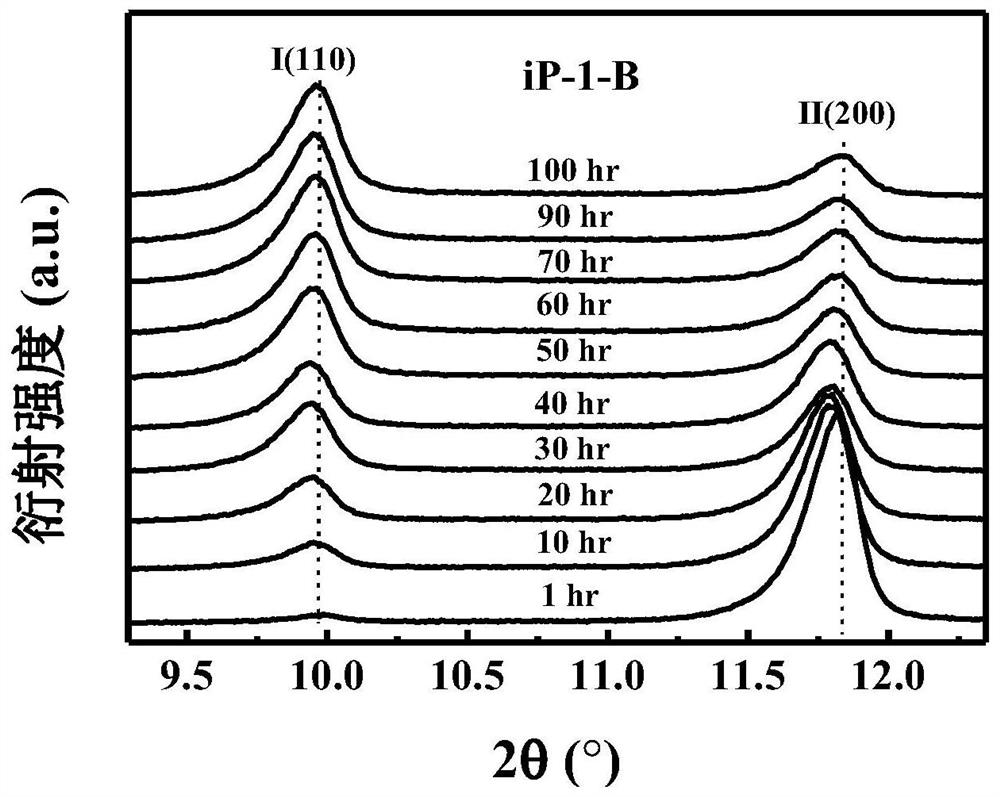

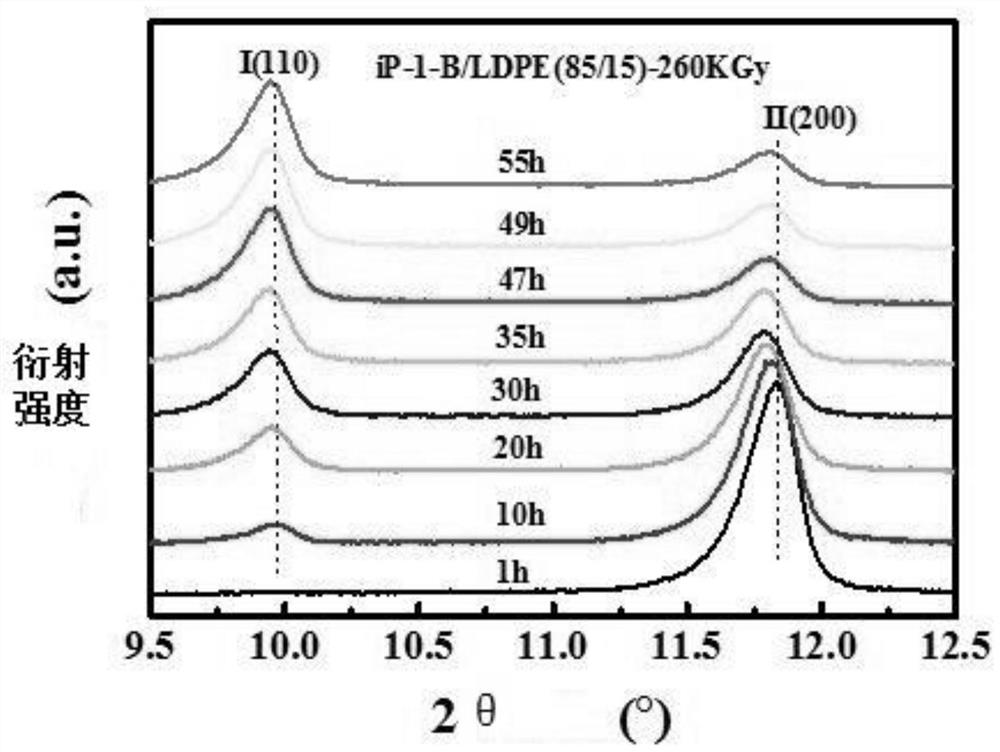

Method for promoting crystal form II-I transformation of isotactic poly-1-butylene through high energy electronic irradiation

InactiveCN108239294AEasy to changeImprove conversion rateHigh energy electron irradiationHigh energy

The invention discloses a method for promoting crystal form II-I transformation of isotactic poly-1-butylene through high energy electronic irradiation. The isotactic poly-1-butylene of a crystal formI is subjected to high energy electronic irradiation, and crystal form II-I transformation in homo-polymerized iP-1-B can be promoted by adopting the high energy electronic irradiation. The method disclosed by the invention is applicable to the homo-polymerized iP-1-B, a simple process is adopted, copolymerization or applied force field is not needed, the transformation time can be greatly shortened, a high conversion ratio is reached in a short time, and copolymerization is not needed.

Owner:TIANJIN UNIV

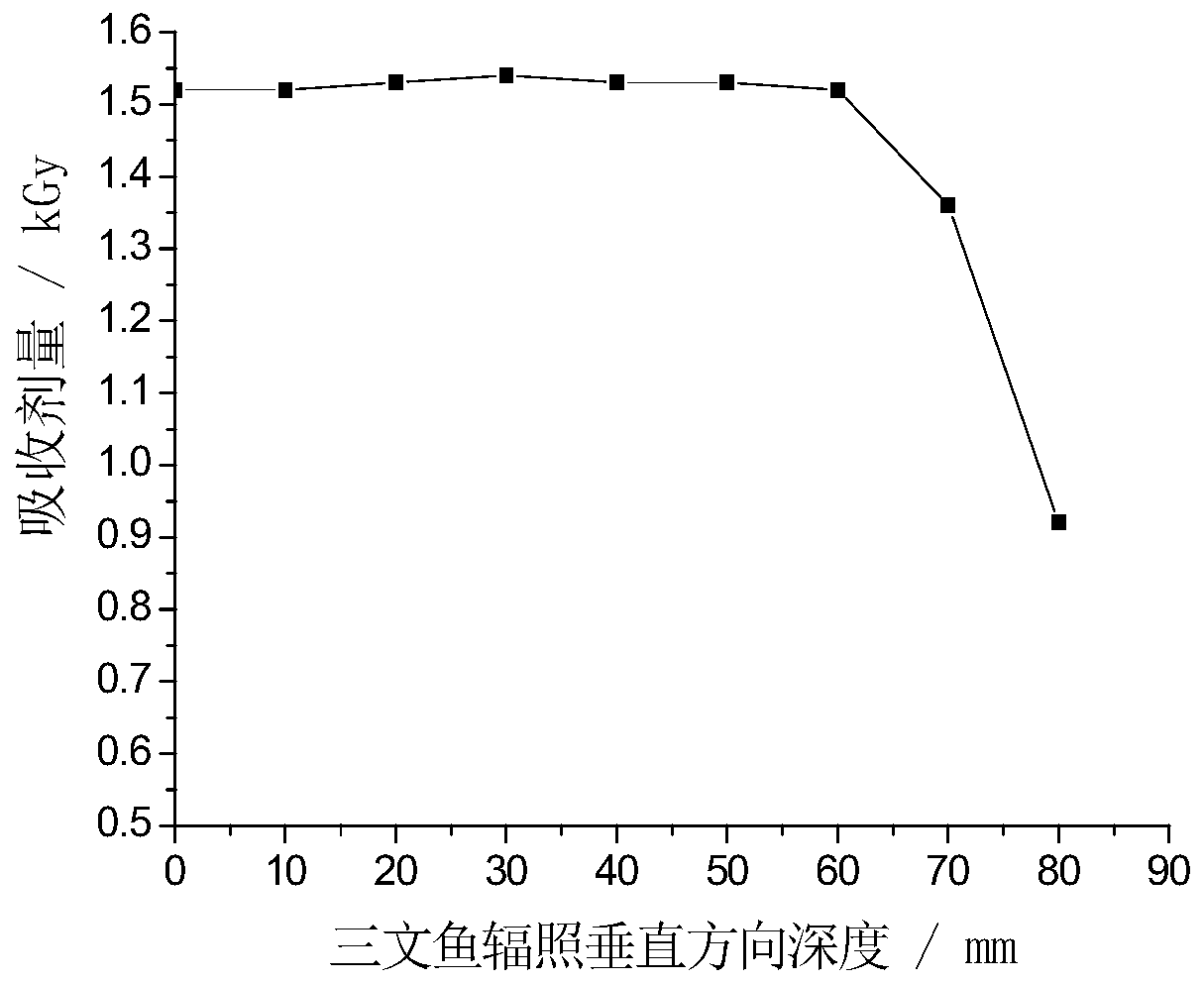

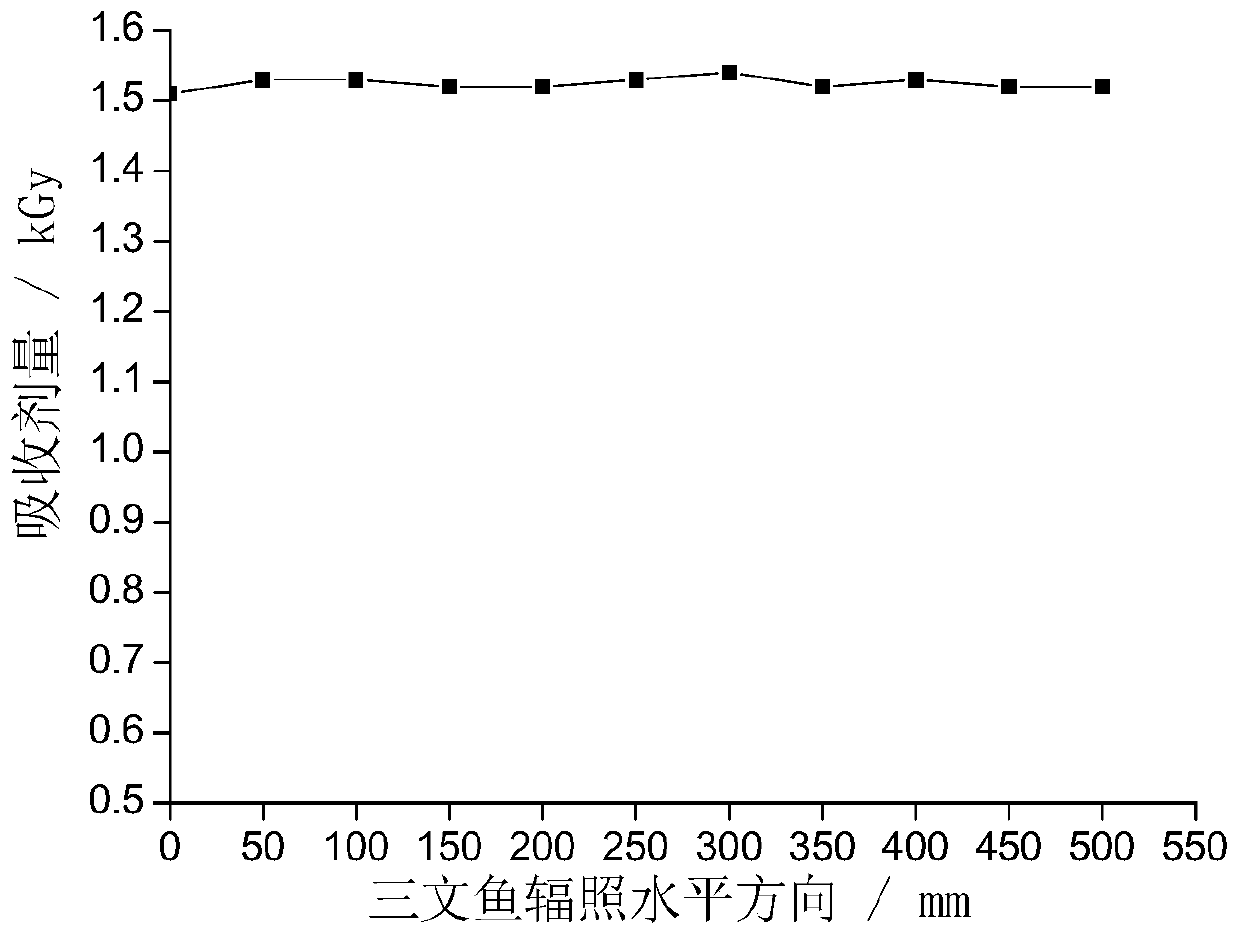

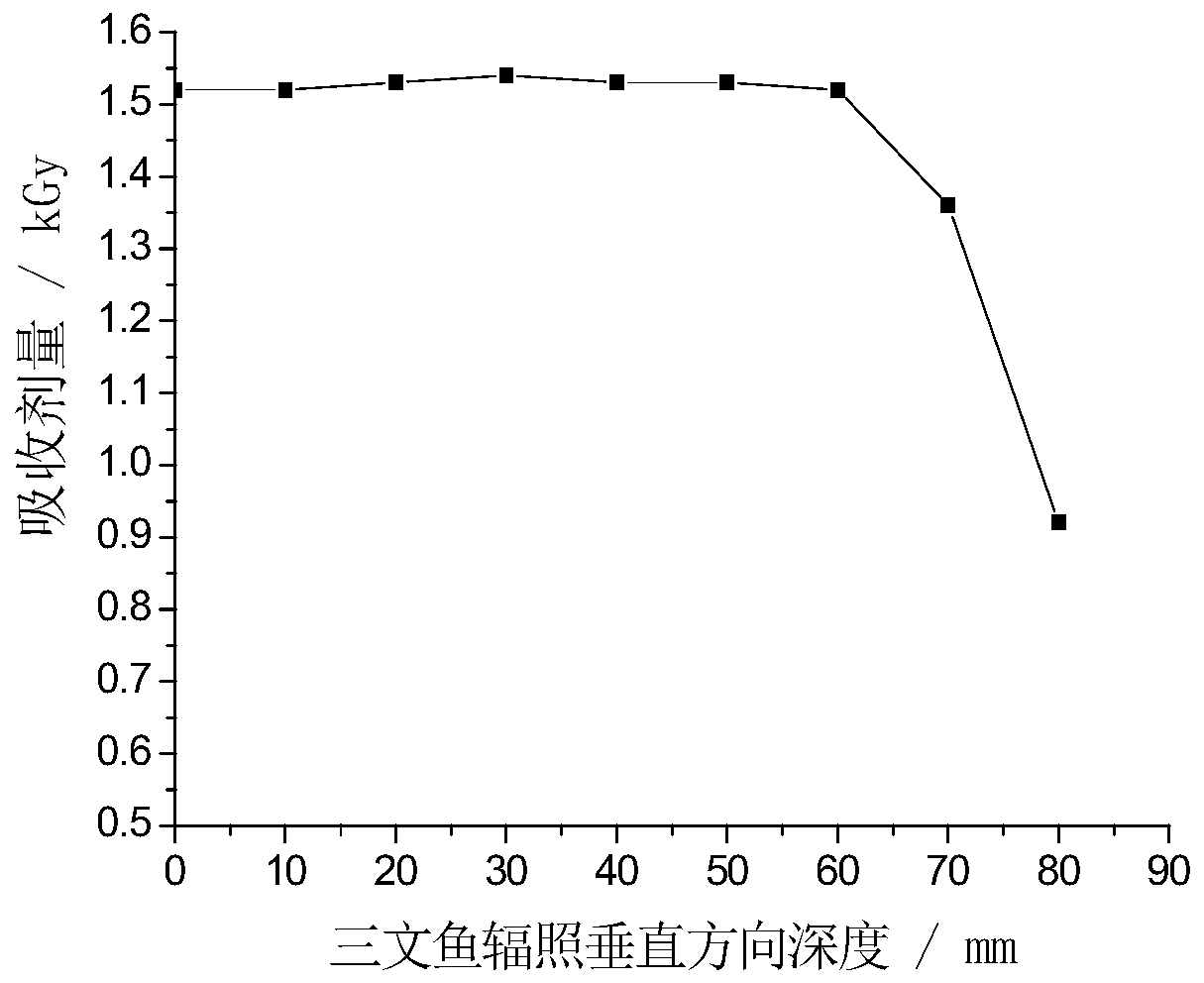

Method for treating fresh salmons by using electron beam irradiation combined with preservative

InactiveCN110012927AShort processing timeOvercome the smellMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsHigh energy electron irradiationElectron

The present invention discloses a method for treating fresh salmons by using an electron beam irradiation combined with a preservative. The method comprises the following main processes: heads, tailsand internal organs of fresh salmons are removed, the treated salmons are washed clean, the washed salmons are cut into slices, the salmon slices are soaked by preservation liquid, the soaked salmon slices are packaged, finally the packaged salmon slices are treated with a high-energy electron beam irradiation, and the treated salmon slices are stored at 1-4 DEG C and has a shelf life of up to 30days. The preservative is combined with the high-energy electron beam irradiation technology, the preservative can inhibit growth and reproduction of microorganisms during storage processes of the salmons, the high-energy electron beam irradiation can directly kill some microorganisms in the product or destroy normal physiological metabolic functions of the microorganisms in varying degrees, and at the same time also play a passivation effect on enzyme activity in the salmons, so that the preservative is used to combine the electron beam irradiation treatment to produce a synergistic effect and control the growth and reproduction of the microorganisms during the storage processes, effectively reduce physiological metabolic strength of the product during the storage processes and thus realize a purpose of extending the shelf life of the fresh salmons.

Owner:SHANGHAI ACAD OF AGRI SCI +1

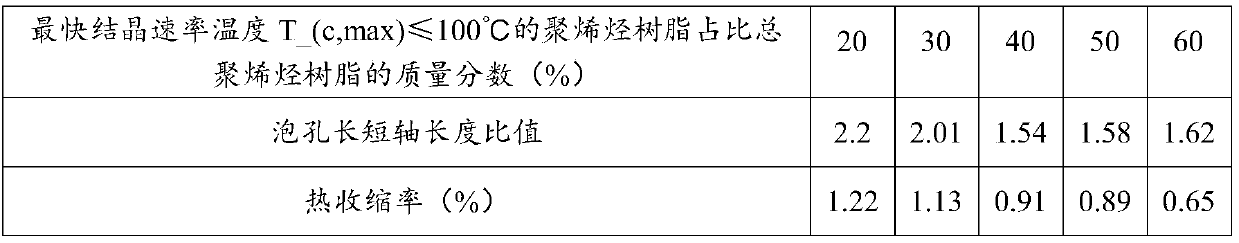

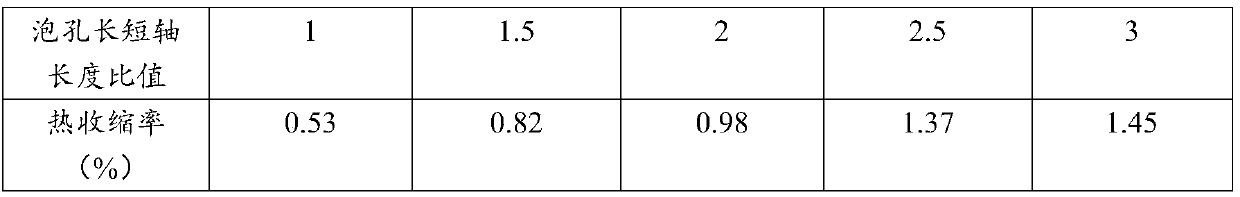

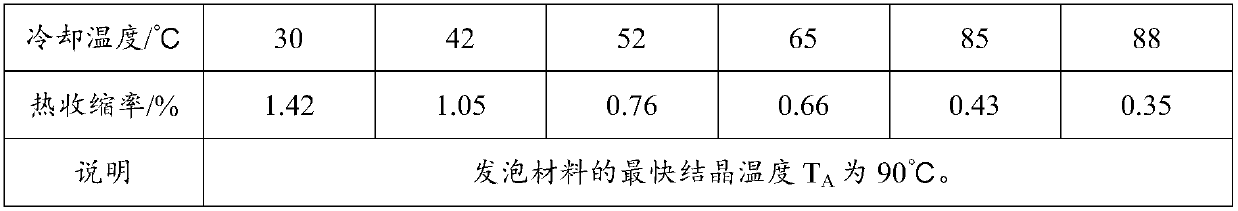

High temperature resistant cross-linked polyolefin foamed material and preparation method thereof

ActiveCN109251388ARaise the starting temperatureLow heat shrinkageHigh energy electron irradiationCross-link

The invention discloses a high temperature resistant cross-linked polyolefin foamed material and a preparation method thereof. The raw materials include, by weight, 60-90 parts of polyolefin resin, 2-20 parts of a foaming agent and 0.1-10 parts of processing aids. Specifically, the polyolefin resin includes polyolefin resin with a maximum crystallization rate temperature T_(c, max) of lower than or equal to 100DEG C, and the polyolefin resin with the maximum crystallization rate temperature T_(c, max) of lower than or equal to 100DEG C accounts for more than or equal to 40% of the mass fraction of the polyolefin resin. The preparation method includes: mixing polyolefin, the foaming agent and the processing aids; performing melt extrusion into sheets; then subjecting the sheets to high-energy electron irradiation crosslinking treatment; and then heating the irradiated sheets, conducting foaming by a foaming furnace, then carrying out cooling shaping, and performing rolling-up. The cross-linked polyolefin foamed material provided by the invention increases the difference of temperature in a tensile zone and the crystallization temperature in the foaming process, and can increases thestarting temperature of heat shrinkage produce by the material and reduce the heat shrinkage rate.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

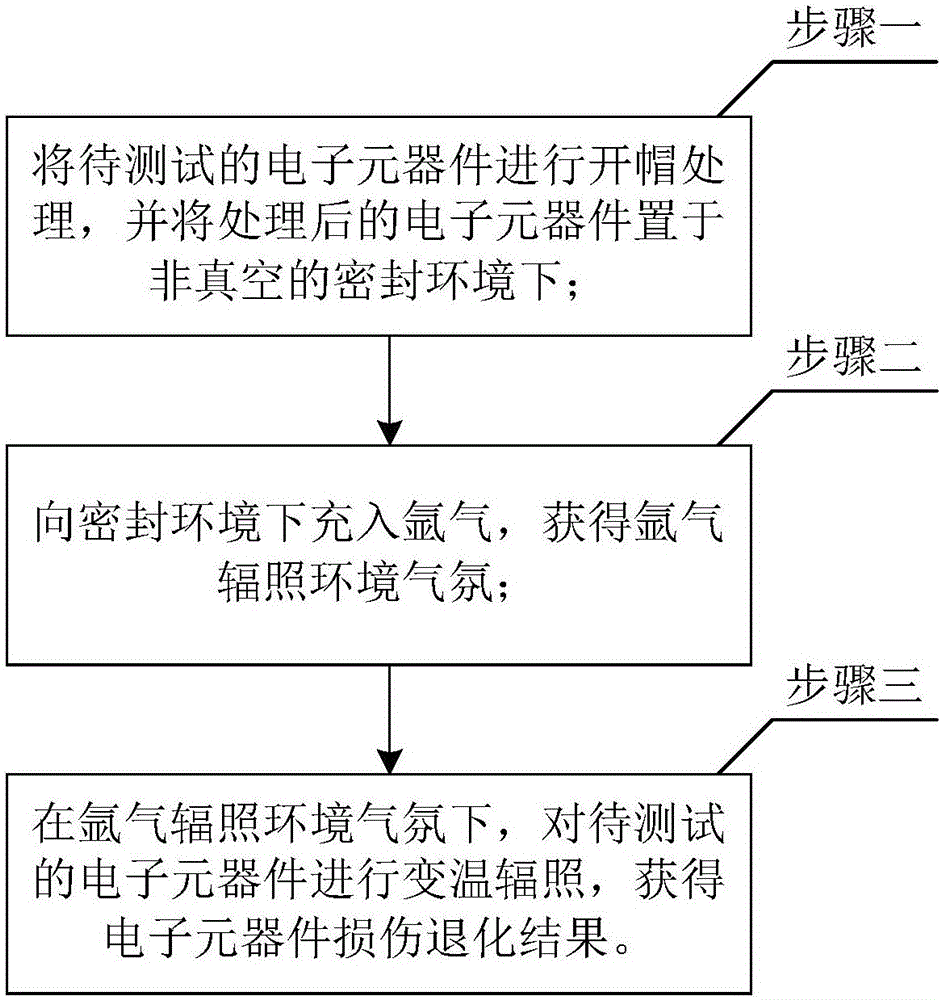

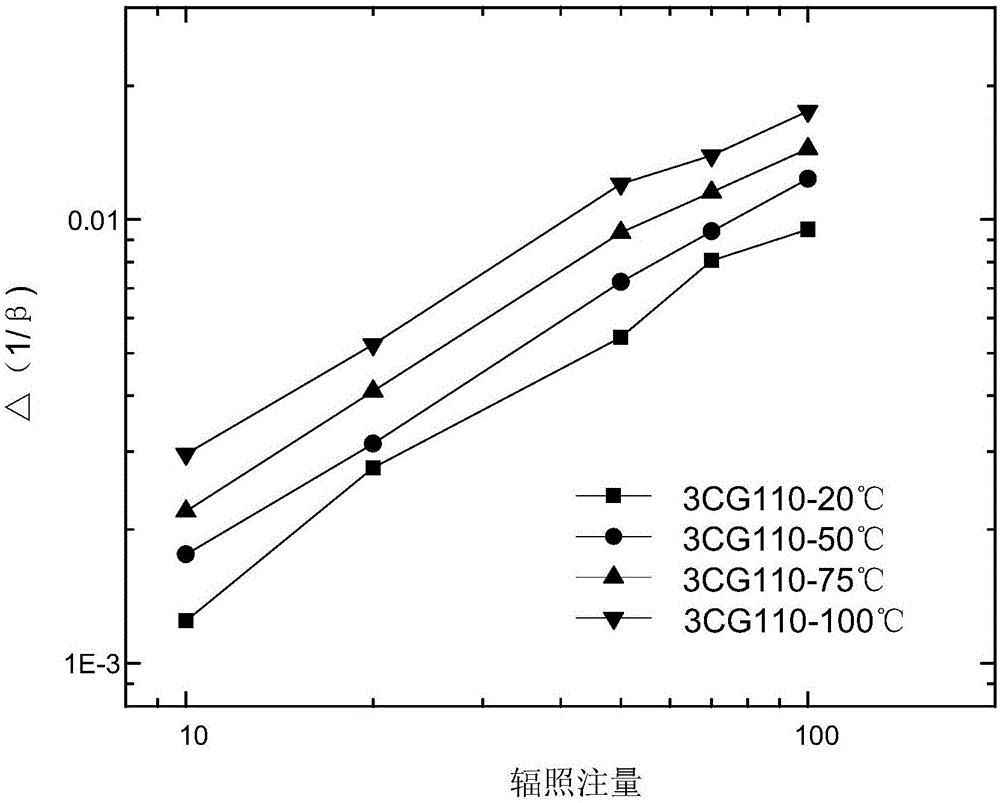

Method for in-situ test of high-energy electron irradiation effect of electronic component under temperature changing condition based on argon environment

ActiveCN106353622AImprove accuracyShorten the timeMeasuring interference from external sourcesHigh energy electron irradiationLow dose rate

The invention discloses a method for an in-situ test of a high-energy electron irradiation effect of an electronic component under a temperature changing condition based on an argon environment, and relates to the field of electronic technologies. The invention aims to solve the problem that during ground irradiation of an electronic component, due to influence of an environmental atmosphere and a temperature, an electrical property in-situ test is not accurate and the evaluating efficiency is low. The method disclosed by the invention adopts the argon environment, so that the influence of oxygen in the air and the influence of a negative pressure in vacuum irradiation in a process of irradiation test in the past can be effectively eliminated, and the accuracy of the in-situ test of the electronic component can be improved. Temperature-changing irradiation is performed during irradiation, and an environmental temperature condition for work of a bipolar transistor is selected in a temperature interval, so that according to the method, a low-dose rate enhancement effect acceleration test method that the in-situ test method has simple steps and is easy to operate. The method disclosed by the invention is suitable for space irradiation effect research and test of a bipolar electronic component.

Owner:HARBIN INST OF TECH

Preparation method of cross-linked polystyrene with high light transmittance

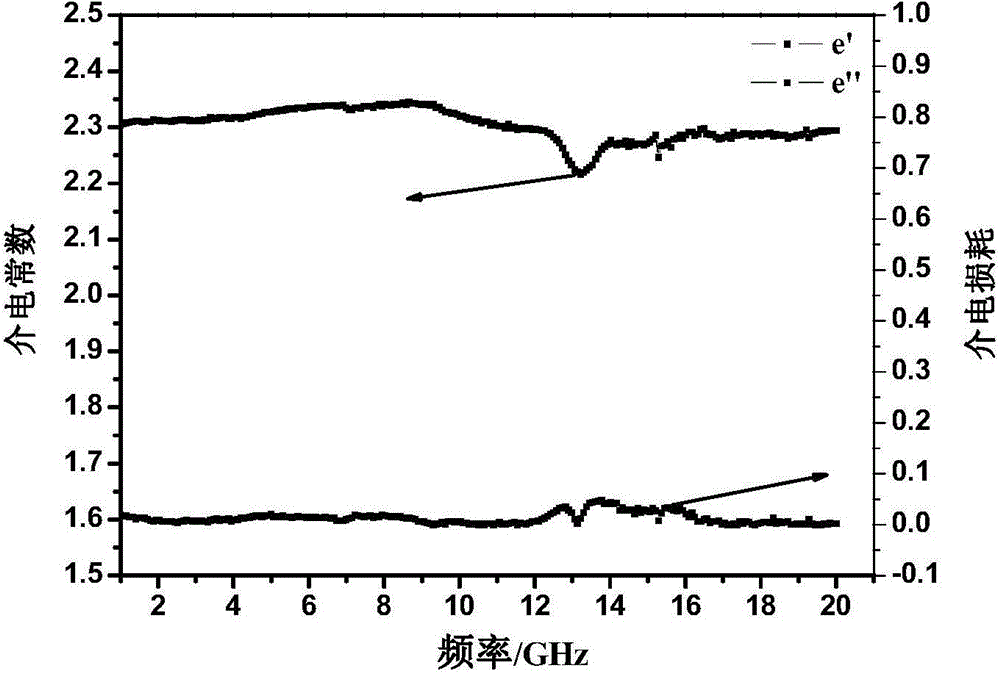

InactiveCN104672390AImprove qualityImprove densification performanceHigh energy electron irradiationCross-link

The invention discloses a preparation method of cross-linked polystyrene with high light transmittance, and belongs to the field of cross-linking polymerization of polymers. The method comprises steps as follows: 1), a polystyrene solution is prepared and uniformly mixed with divinyl benzene in a certain proportion; 2), the mixed solution is subjected to freezing layer by layer and high-energy electron irradiation layer by layer; 3), later forming of a cross-linked polystyrene material is completed through a temperature control process. The method has the main characteristics as follows: a product is pure and transparent and doesn't have defects of bubbles, impurities and the like; 2) the cross-linking polymerization process is performed at an ultralow temperature, and the product qualification ratio is high; 3), the product has excellent light transmittance, stable dielectric property, higher processing mechanical property and the like.

Owner:WUHAN UNIV OF TECH

Disinfection method of surgical instruments

InactiveCN106880857AEasy to operate, safe and reliableLow running costChemicalsRadiationHigh energy electron irradiationEngineering

The invention relates to a disinfection method of surgical instruments. The surgical instruments are counted and classified, and different types of instruments are separately disinfected. The disinfection method comprises the following steps: placing one surgical instrument to be disinfected into a closed spraying box, cleaning by spraying for 15 to 25 min by using a biological enzyme cleaning agent, and thoroughly discharging the biological enzyme cleaning agent; cleaning by spraying for 5 to 10 min by using medical iodophor, and thoroughly discharging the iodophor; placing the surgical instrument to be disinfected into ozone oxidized water, soaking for 5 to 10 min, and then taking out the surgical instrument; drying the surgical instrument, and oiling the surgical instrument; performing irradiation treatment on the surgical instrument to be disinfected for 2 to 5 min by using a high-energy electron irradiation accelerator; and finally orderly placing the instrument into a surgical instrument box or a dedicated packaging bag and sealing according to the type of the instrument. The disinfection method of the surgical instruments has the advantages of simple, safe and reliable operation, low operation and implementation cost, great convenience in use, short working time, capability of cleaning and disinfecting various medical instruments, suitability for being popularized in the medical field, and capability of preventing the cross infection caused by the un-thorough disinfection of the surgical instruments.

Owner:湖南大平安安全科技有限公司

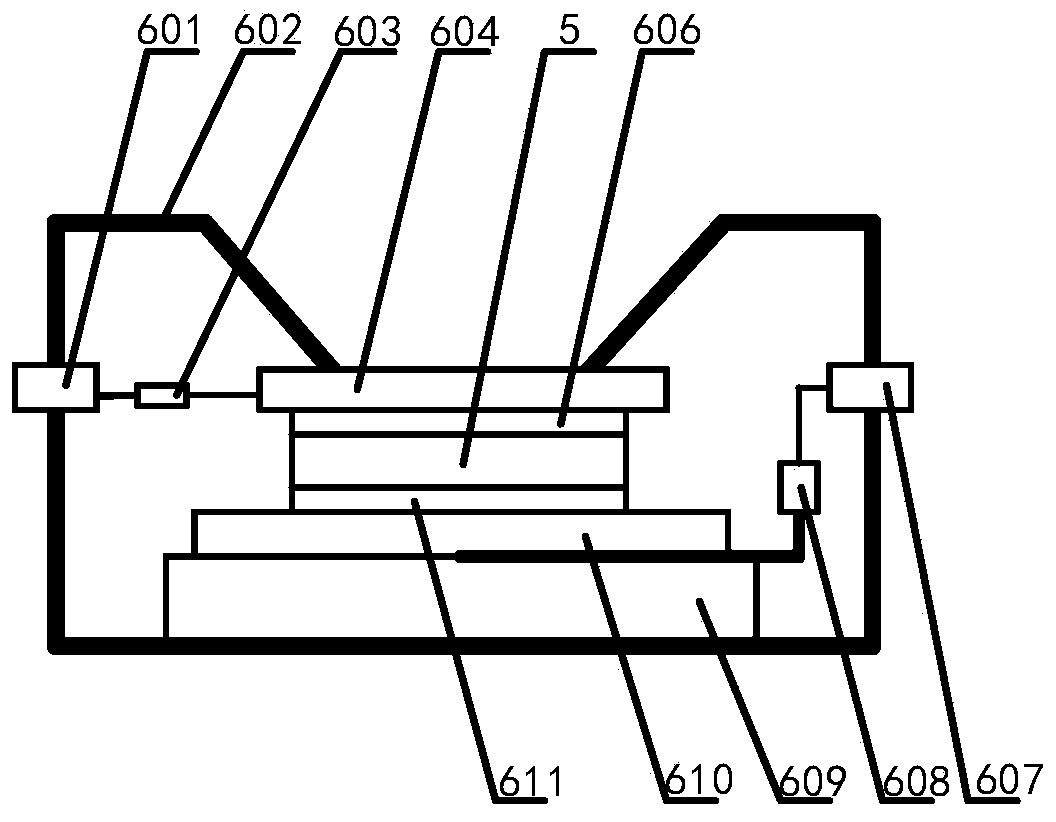

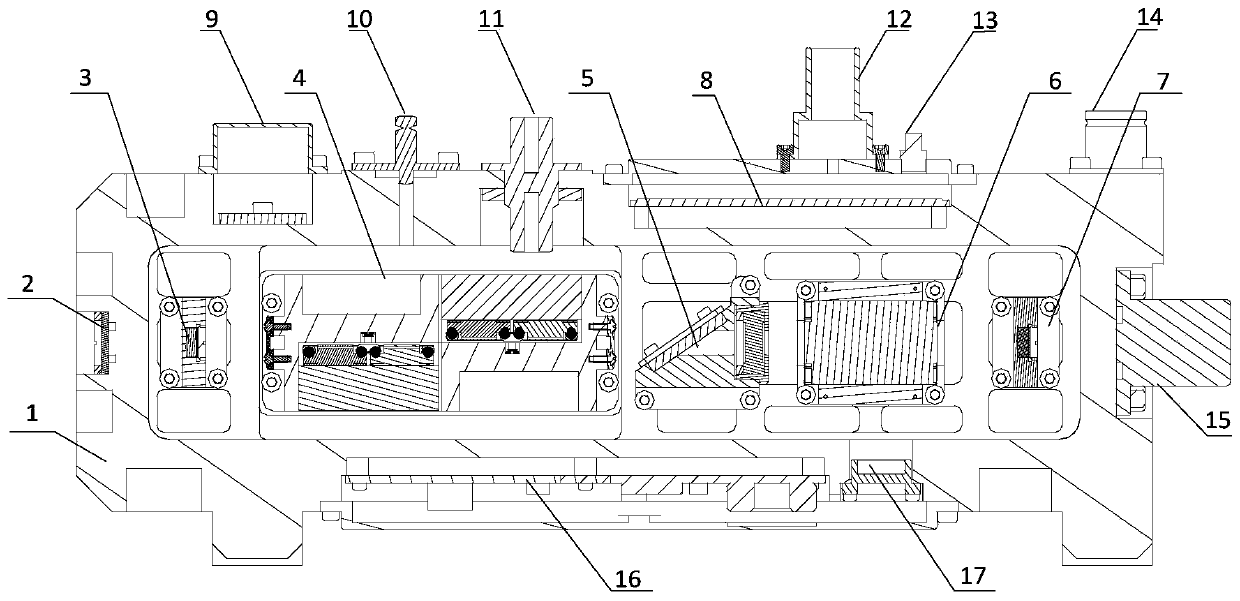

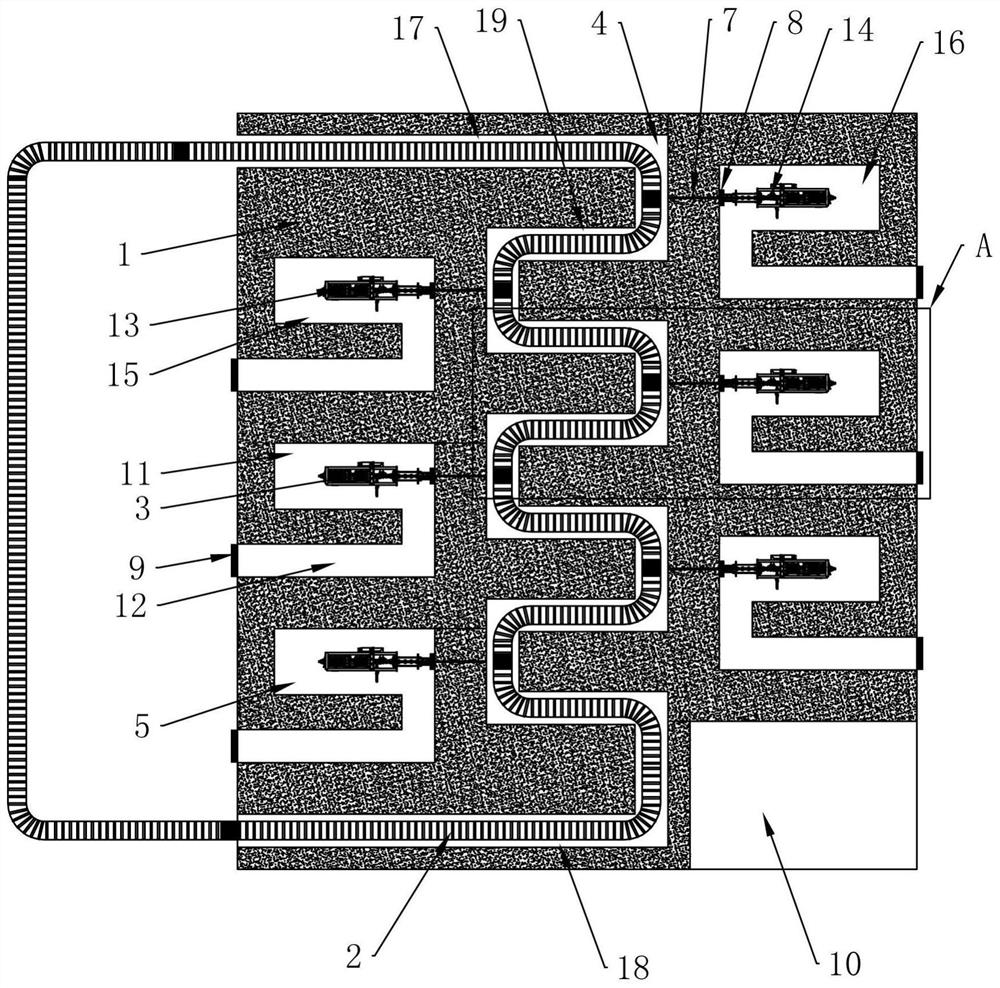

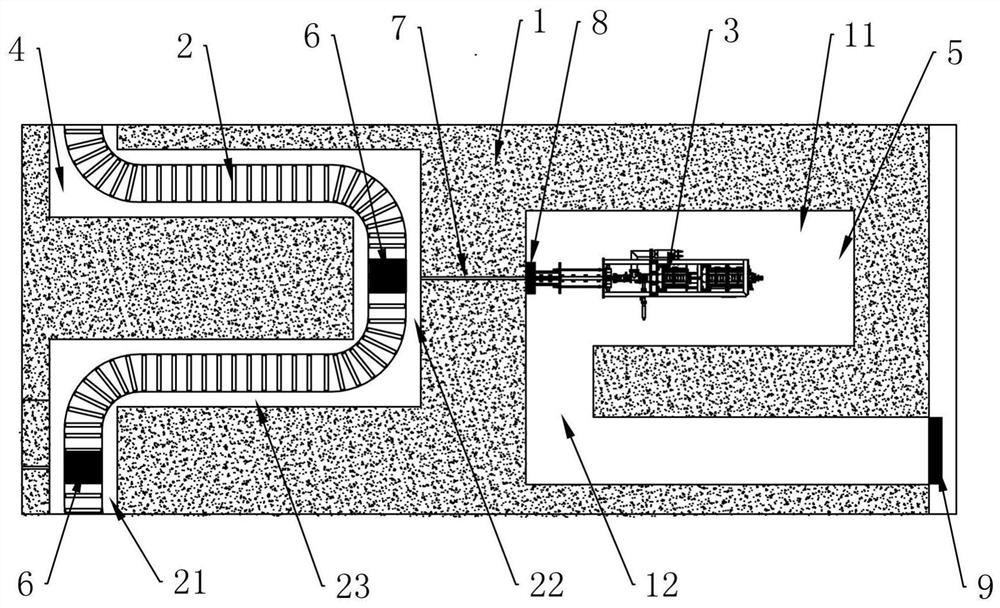

High-power high-energy electron irradiation station based on irradiation linear accelerator

PendingCN111968773ARealize double sided comparisonImprove irradiation efficiencyLinear acceleratorsIrradiation devicesHigh energy electron irradiationNuclear engineering

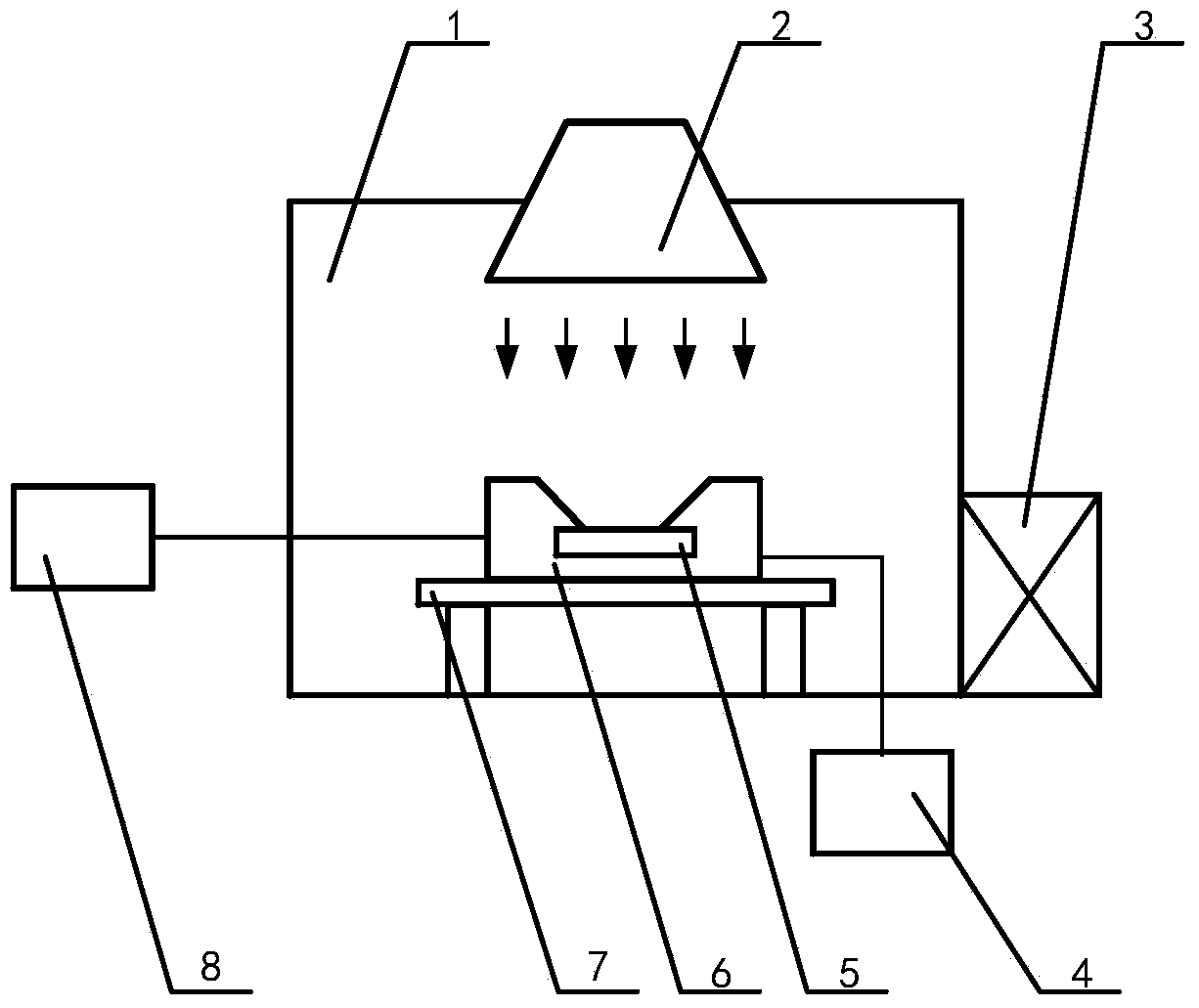

The invention discloses a high-power high-energy electron irradiation station based on an irradiation linear accelerator. The station comprises a ray protection building which is internally provided with a transportation channel and a plurality of accelerator chambers communicated with the transportation channel, wherein the plurality of accelerator chambers are located at two sides of the transportation channel; a under-beam conveying line which penetrates through the conveying channel, and is used for conveying a plurality of to-be-irradiated cargoes; and a plurality of linear accelerators which are arranged in the plurality of accelerator chambers respectively, wherein the plurality of linear accelerators respectively face the under-beam conveying line, and the plurality of linear accelerators are respectively used for carrying out double-sided irradiation on the two sides of the plurality of to-be-irradiated cargoes on the under-beam conveying line. The two sides of the goods on the under-beam conveying line are subjected to double-face irradiation through the linear accelerators, a turnover mechanism is not needed, the cost is reduced, and the irradiation efficiency is improved.

Owner:SHANGHAI SINOTEX HIGH ENERGY TECH

Preparation of novel sound insulation and noise reduction film for automotive trim

InactiveCN110450337AGuaranteed flexibilitySatisfy the use environmentFlat articlesLow-density polyethyleneHigh energy electron irradiation

The invention belongs to the technical field of high polymer materials, and particularly relates to preparation of a novel sound insulation and noise reduction film for automotive trim. According to the preparation, through specific preparation of raw materials including low-density polyethylene, a foaming agent, an antioxidant and an auxiliary agent, partition type extrusion, high-energy electronirradiation cross-linking and partition type foaming processes are combined, so that the effect of effectively preparing the sound insulation and noise reduction film for the automotive trim is achieved. The coiled material preparation method of the sound insulation and noise reduction film for the automotive trim is simple and effective, the preparation process is reasonable and efficient in operation, economical and practical, and a prepared coiled material has the advantages of being small in density, good in impact resistance, high in flexibility and elasticity, obvious in sound insulation and noise reduction effects and long in overall service life.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

Seven-layer coextrusion membrane for transfusion and its production method

InactiveCN1970288BGood optical performanceGood flexibilitySynthetic resin layered productsLow-density polyethyleneHigh energy electron irradiation

The seven layer common transfusion liquid membrane usually comprises a vinyl copolymer formed core layer, two metallocene yarns low density polyethylene formed sub core layers, polyacrylic acid or polypropylene or high intensity polyethylene selected No.1 outside layer, polyester, copolyester, polypropylene or nylon formed No.2 outside layer, No.1 adhesion layer between sub core layer and No.1 outside layer, and No.2 adhesion layer between No.2 outside layer and core layer. Using this seven extruder to melt and extrude materials of each layer through seven layers conical or flat overlaid moldhead and 100 degree purified gas with computer controlling the inflation film diameter and thickness, it makes the double layer film roll, after Co60 lighting or hard electron radiating to get high resistance, transpancy, flexibility, in conformity to all kinds of medical, biological or chemical regulations.

Owner:安徽双津实业有限公司

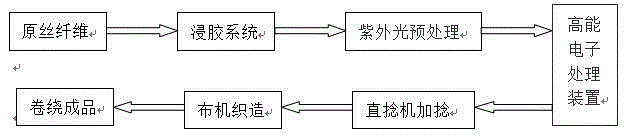

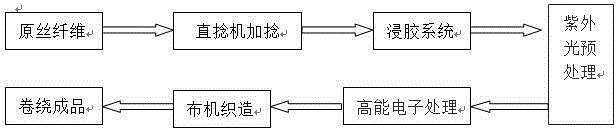

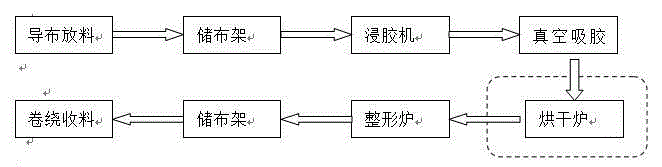

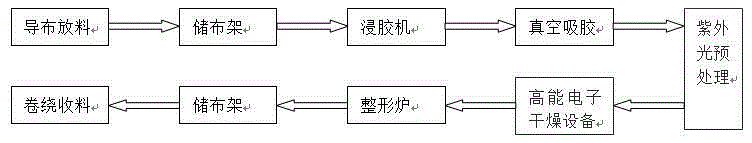

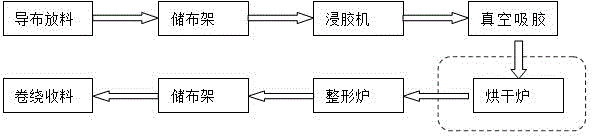

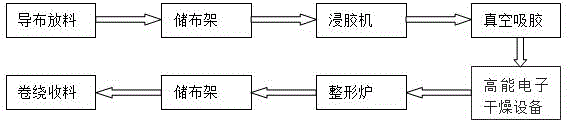

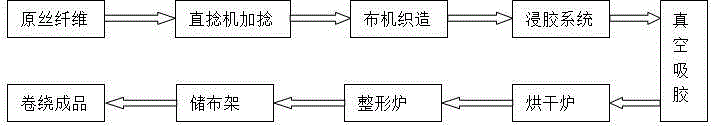

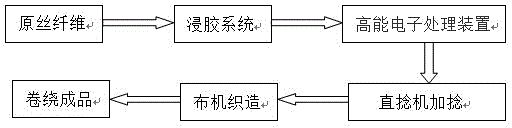

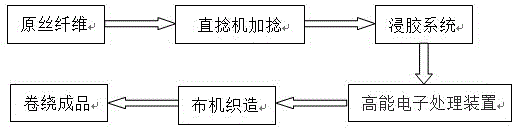

Method for processing impregnated cord fabric fiber or cord thread based on ultraviolet light and high-energy electrons

The invention provides a method for processing an impregnated cord fabric fiber or cord thread based on ultraviolet light and high-energy electrons, and belongs to the technical field of tire manufacturing. The method comprises the following steps: firstly, carrying out ultraviolet irradiation on the cord fabric fiber or cord thread impregnated with an irradiation-curing impregnating adhesive; and carrying out high-energy electron irradiation curing, wherein the irradiation absorption dose is 10-100KGy. Compared with the prior art, the method has the beneficial effects that a lot of energy sources do not need to be consumed; the targets of saving energy and reducing emission are achieved; meanwhile, the elapsed time of the irradiation curing process is short; the production efficiency is greatly improved; the anaerobic polymerization process is not required; compared with thermal drying equipment, production equipment provided by the invention is small in volume, simple in structure, and relatively easy to repair; and the cost is relatively easy to control.

Owner:HUBEI ERAY NUCLEAR TECH

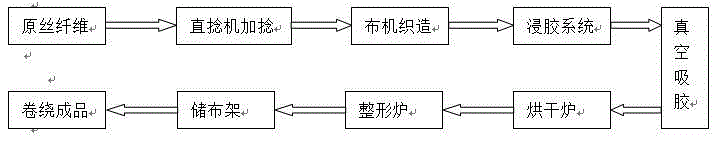

Method for drying dipped cord fabric based on ultraviolet light and high-energy electrons

The invention provides a method for drying a dipped cord fabric based on ultraviolet light and high-energy electrons, belonging to the technical field of the tire manufacturing. The method comprises the steps of carrying out UV irradiation on the front side and the reverse side of the cord fabric dipped with impregnating adhesive which can be solidified through irradiation, and then performing irradiation solidification by high-energy electrons, wherein the irradiation absorption dose is 10-100KGy. Compared with the prior art, the method has the beneficial effects that a great amount of energy is not required to be consumed, and the purposes of saving energy and reducing emission can be achieved; the irradiation solidification time is very short and the production efficiency is greatly improved; the oxygen polymerization inhibition resisting process is not required to be adopted; and the related production equipment has smaller volume compared with the heat drying equipment, has a simple structure, has easily-controllable cost and can be maintained easily.

Owner:江苏久瑞高能电子有限公司

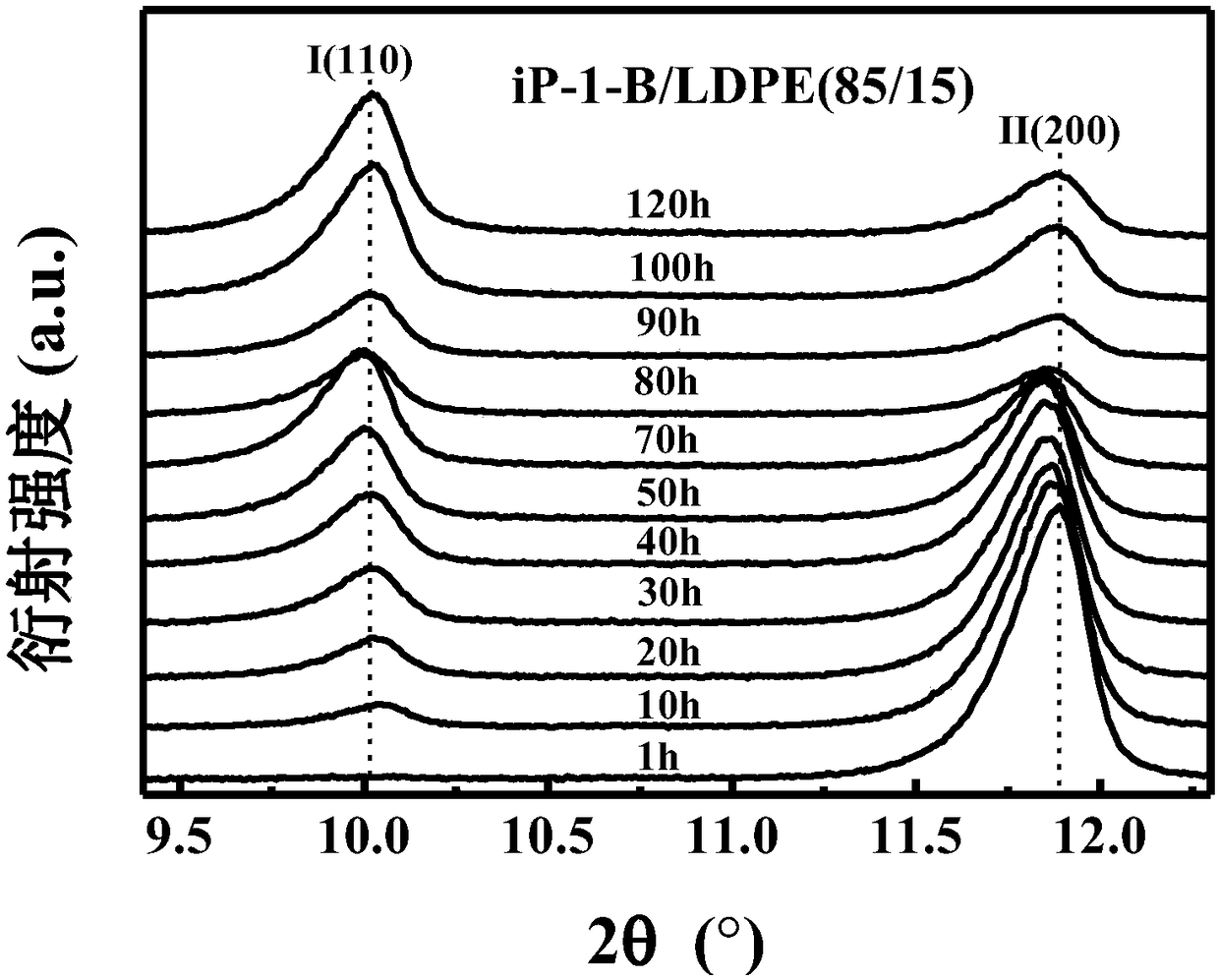

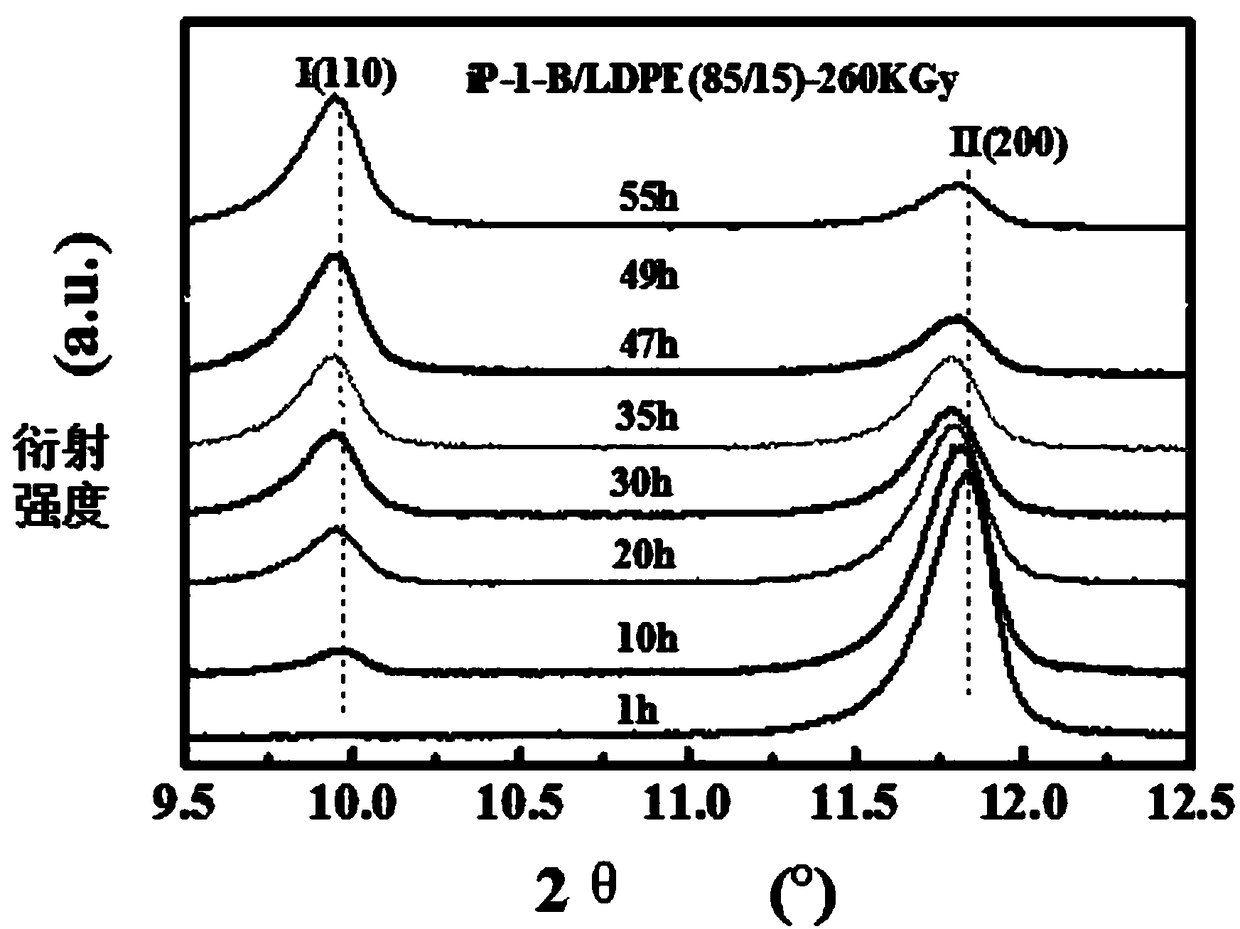

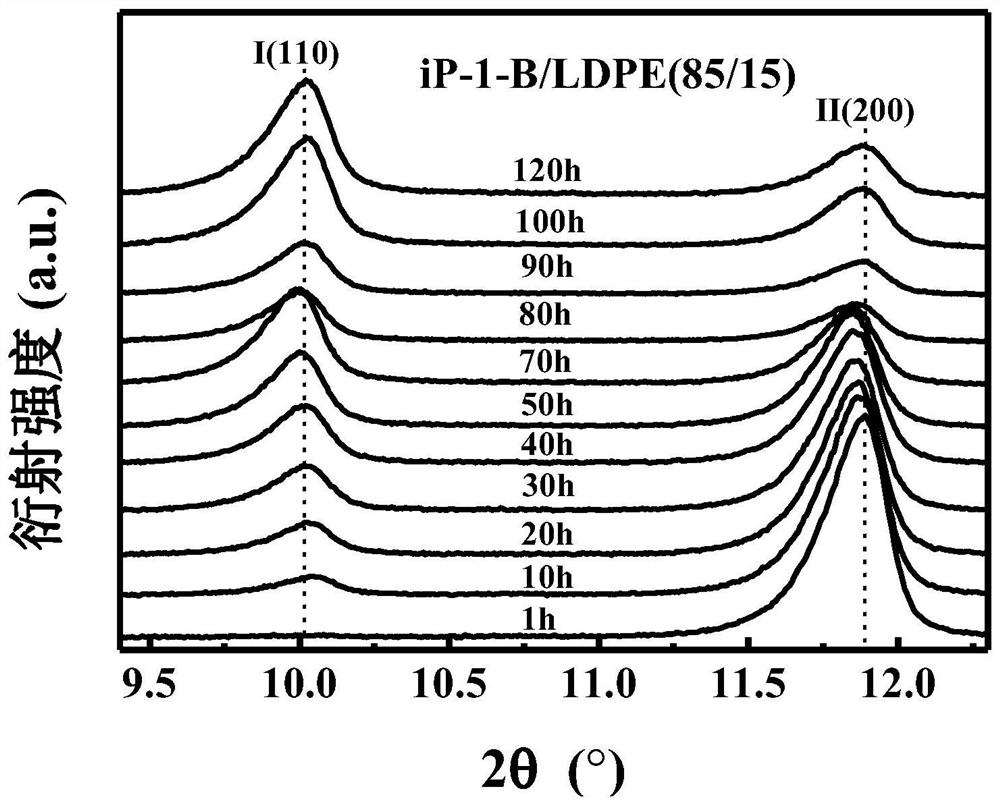

Method for promoting conversion of crystal form II in isotactic poly-1-butene composite into crystal form I by using high-energy electron irradiation

ActiveCN108250594AImprove conversion rateSave resourcesLow-density polyethyleneHigh energy electron irradiation

The invention discloses a method for promoting conversion of a crystal form II in an isotactic poly-1-butene composite into a crystal form I by using high-energy electron irradiation. According to theinvention, high-energy electron irradiation is carried out on a blended composite of isotactic poly-1-butene and low-density polyethylene to promote the conversion of the crystal form II in the iP-1-B blended composite into the crystal form I. The method is applicable to blended materials based on homopolymerized iP-1-B; process flow is simple; copolymerization or application of a force field isnot needed; conversion time can be greatly shortened; and a high conversion rate can be achieved within a short period of time, and copolymerization is not needed.

Owner:TIANJIN UNIV

A Method for Promoting Form II-I Transformation in Isotactic Poly(1-Butene) Composite Materials Using High Energy Electron Irradiation

ActiveCN108250594BImprove conversion rateSave resourcesHigh energy electron irradiationLow-density polyethylene

The invention discloses a method for promoting conversion of a crystal form II in an isotactic poly-1-butene composite into a crystal form I by using high-energy electron irradiation. According to theinvention, high-energy electron irradiation is carried out on a blended composite of isotactic poly-1-butene and low-density polyethylene to promote the conversion of the crystal form II in the iP-1-B blended composite into the crystal form I. The method is applicable to blended materials based on homopolymerized iP-1-B; process flow is simple; copolymerization or application of a force field isnot needed; conversion time can be greatly shortened; and a high conversion rate can be achieved within a short period of time, and copolymerization is not needed.

Owner:TIANJIN UNIV

High-energy electron based method for drying dipped cord fabric

InactiveCN104404764AShort timeReduce volumeFibre treatmentHigh energyHigh energy electron irradiation

The invention provides a high-energy electron based method for drying dipped cord fabric, and belongs to the technical field of tire manufacture. According to the method, the cord fabric dipped with irradiation curing dipping rubber is subjected to high-energy electron irradiation curing, wherein the irradiation adsorption dose is 0.5-60 KGy. Compared with the prior art, the high-energy electron based method has the benefits as follows: a large amount of energy is not required to be consumed, and purposes of energy saving and emission reduction are achieved; meanwhile, an irradiation curing process consumes very short time, and the production efficiency is increased greatly; and involved production equipment is smaller in size and simple in structure compared with thermal drying equipment, and the cost and maintenance are easy to control.

Owner:HUBEI ERAY NUCLEAR TECH

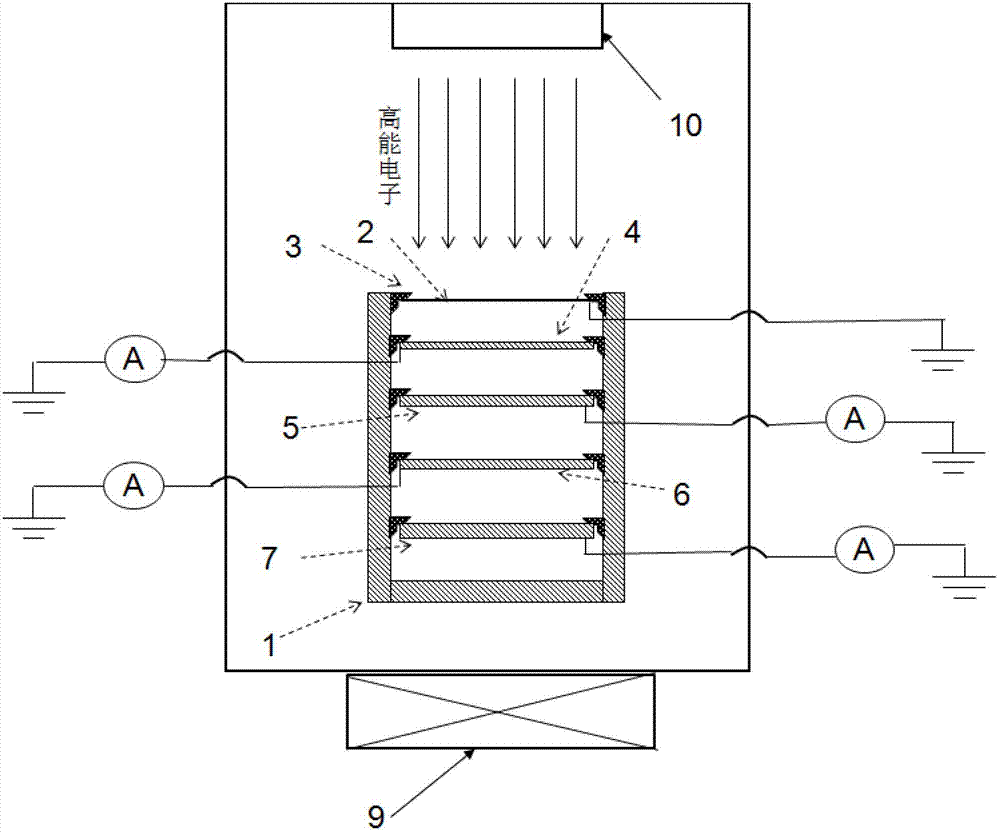

High-energy electron charging current testing system

ActiveCN102967750ASimple structureEasy to implementCurrent/voltage measurementInstrument screening arrangementsHigh energy electron irradiationPower flow

The invention belongs to the technical field of vacuum measurement, and particularly relates to a high-energy electron charging current testing system which comprises a vacuum system (9), an electron accelerator (10), an electronic shielding device and an electrometer, wherein the electron accelerator (10) and the electronic shielding device are arranged in the vacuum system (9); the electrometer is arranged outside the vacuum system (9); the electronic shielding device comprises four testing poles; the electron accelerator (10) is just facing to the upper end of the electronic shielding device; high-energy electron energy and beam current density can be selected within the energy range of 0.2-2MeV; and the electron accelerator (10) is started, and the electrometer is used for testing the current values of the testing poles. The high-energy electron charging current testing system can be used for testing the charging current values of all the testing poles under the condition of high-energy electron irradiation by utilizing a structure of multiple layers of testing poles with different thicknesses, and has the characteristics of being simple in structure, convenient to implement and the like; therefore, the test results of high-energy electron charging current with different energy can be obtained.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Innovative fresh Chinese wolfberry juice processing technology

PendingCN113598288ALow activity stateReduce lossesFood scienceHigh energy electron irradiationProcess engineering

The invention discloses an innovative fresh Chinese wolfberry juice processing technology. The innovative fresh Chinese wolfberry juice processing technology comprises the following steps of fresh fruit selection, cleaning, mechanical grinding, filling, cold sterilization and cold storage, wherein the fresh Chinese wolfberry juice adopts a cold sterilization technology, a high-energy electron irradiation sterilization technology is initiatively adopted in the Chinese wolfberry juice processing, and in the fresh fruit crushing process, crushing treatment is carried out by adopting a mechanical grinding principle. The innovative fresh Chinese wolfberry juice processing technology comprises the following steps of fresh fruit selection, cleaning, mechanical grinding, filling, cold sterilization and cold storage, wherein the cold sterilization technology is the electron irradiation sterilization technology, so that the fresh Chinese wolfberry juice can reach a sterile state, cells of the fresh Chinese wolfberry juice can be in a relatively low active state, and the refreshing time of the fresh Chinese wolfberry juice can be greatly prolonged. And low-temperature processing is adopted in the whole processing process, so that the loss of flavor substances is reduced to the greatest extent.

Owner:康本国 +1

Method for processing gum dipping tyre fabric fibers or cord threads based on high-energy electrons

InactiveCN104532433AShort timeReduce volumePretreated surfacesCoatingsHigh energy electron irradiationFiber

The invention provides a method for processing gum dipping tyre fabric fibers or cord threads based on high-energy electrons and belongs to the technical field of tyre manufacturing. The tyre fabric fibers or the cord threads dipped with irradiation solidification dipping gum are subjected to high-energy electron irradiation solidification, wherein irradiation absorbed dose is 0.5-60 KGy. Compared with the prior art, the method has the advantages that a large amount of energy does not need to be consumed, the purpose of energy saving and emission reducing is achieved, meanwhile, time consumed in the irradiation solidification process is short, production efficiency is greatly improved, compared with hot drying equipment, related production equipment is small in size and simple in structure, and cost and maintaining can be controlled easily.

Owner:HUBEI ERAY NUCLEAR TECH

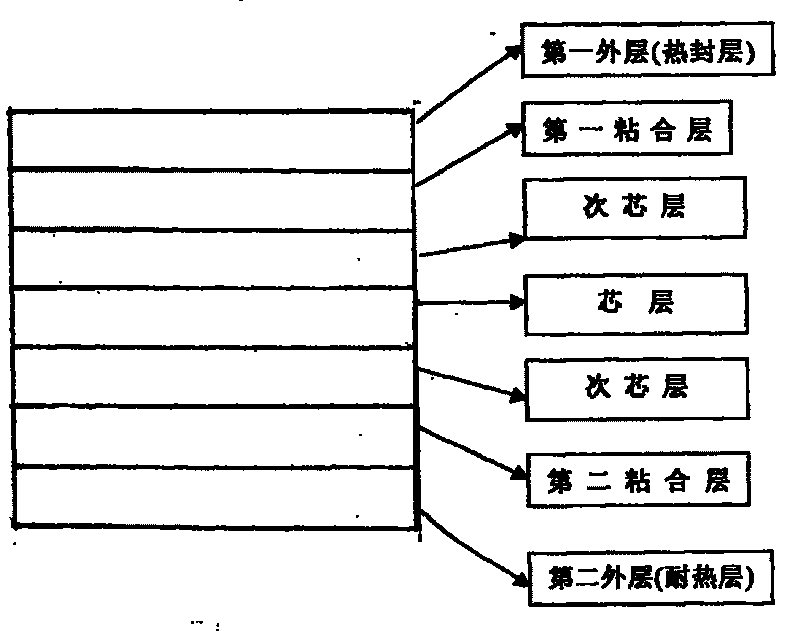

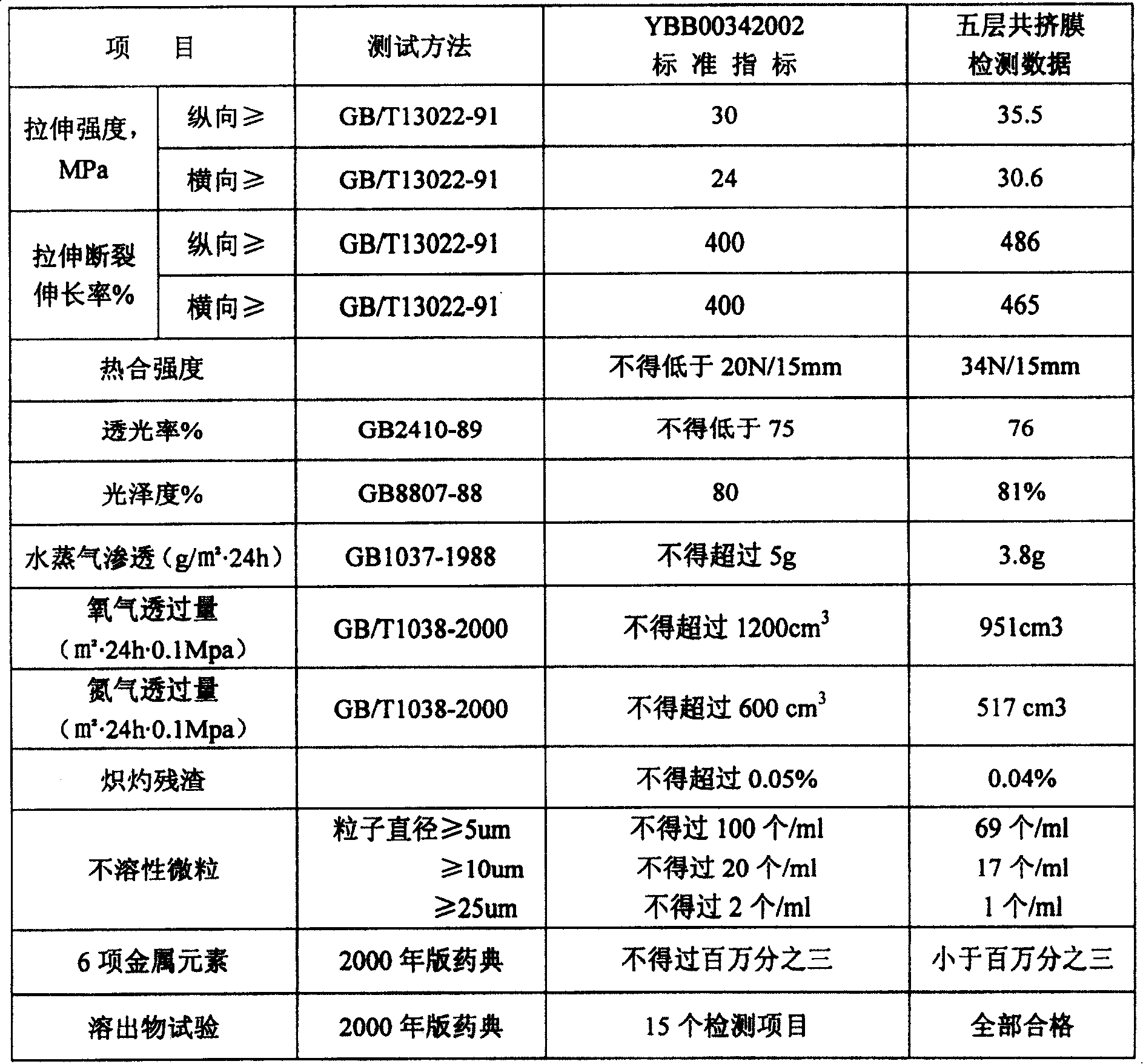

Multilayer co-extrusion transfusion film and manufacturing method thereof

The invention discloses a multi-layer common squeeze transfusion film and its manufacturing method. It has five layers structure, the first layer is the heat sealing inner layer A, which is the mixing resin composed of PP and SEBS hot plastic elastic polymers; the second layer is the adhering layer B, which is propene-ethylene polymers; the third layer is the core layer, which is the propene-ethylene / a-olefin elastomer; the fourth layer is the adhering layer D, which is the ethylene methyl acrylic resin polymers; the fifth layer is the wearable layer, which is the elastic resin PTMT. The manufacturing method is to implement high-energetic electronic radiation treatment to the multi-layer film so as to improve the heat-fast capability and the transparent degree of the products.

Owner:NINGBO HUAFENG PACKAGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com