Method for processing gum dipping tyre fabric fibers or cord threads based on high-energy electrons

A technology of impregnated cord fabric and high-energy electronics, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc., can solve the problems of low solid content of impregnated glue, large energy consumption, scarcity of equipment, etc., and achieve control Costs and repairs, increased productivity, ease of cost and repair effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

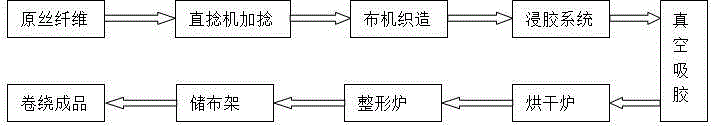

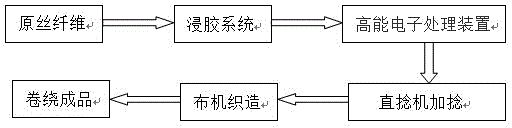

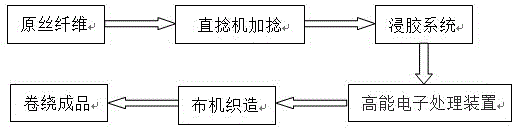

Image

Examples

Embodiment 1

[0028] This embodiment is carried out by using the method of the present invention for treating dipped cord fabric fibers or cords based on high-energy electrons. The selection range of the voltage is between 200~600KV, and the selection range of the radiation absorbed dose is between 0.5~60KGy. In this embodiment, the electron beam irradiation voltage is adjusted to 200KV, the radiation absorption dose is 20KGy, and the impregnating glue is cured.

[0029] In order to ensure the best curing effect, the cord fibers or cords can always be cured in an oxygen-limited environment made of protective gas. The main purpose is to prevent the occurrence of oxygen inhibition. The protective gas can be selected from nitrogen, carbon dioxide, One or more combinations of inert gases. In order to ensure continuous production and uniform irradiation, a transmission system, such as a conveyor belt or a conveyor roller, can be set up to transport the cord fabric fibers or cords.

[0030] The...

Embodiment 2

[0032] Regarding the above-mentioned embodiment 1, in this embodiment, the voltage of electron beam irradiation is adjusted to 600KV, the radiation absorption dose is 60KGy, and the impregnating glue is cured. The radiation-curable impregnating glue of this embodiment is composed of 200 parts of polyisocyanate, 240 parts of acrylate and 20 parts of vinyl ether monomer in parts by weight.

Embodiment 3

[0034] As for the above-mentioned embodiment 1, in this embodiment, the voltage of the electron beam irradiation is adjusted to 200KV, the radiation absorption dose is 0.5KGy, and the impregnating glue is cured. The radiation-curable impregnating glue of this embodiment is composed of 300 parts of polyisocyanate, 180 parts of acrylate and 40 parts of vinyl ether monomer in parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com