High-energy electron based method for drying dipped cord fabric

A technology of impregnated cord fabric and high-energy electronics, which is applied in the field of tire manufacturing, can solve the problems of low solid content of impregnated glue, scarcity of equipment, and high energy consumption, and achieve the goals of cost control and maintenance, easy cost and maintenance, and improvement of production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

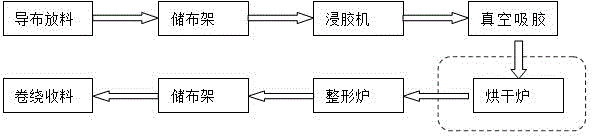

[0024] refer to figure 1 , this embodiment is a technical process for curing and drying dipped cord fabrics in a heat-drying manner, which belongs to the prior art, and includes sequentially guiding the cloth to discharge to the cloth storage rack, then entering the dipping machine for dipping, and then vacuum suction Recover the excess impregnated glue, then dry it through the drying oven, then enter the shaping oven for shaping, and finally wind up the material on the cloth storage rack.

Embodiment 2

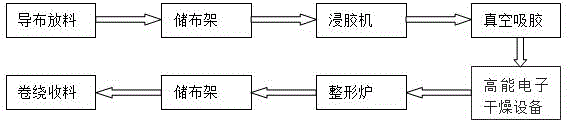

[0026] refer to figure 2 , this embodiment is the process flow of the method of drying dipped cord fabrics based on high-energy electrons according to the present invention. The difference from the prior art in Example 1 is that the cord fabrics are dried by high-energy electronic drying equipment after being vacuum-absorbed. The drying process is completed under the irradiation conditions of high-energy electrons.

Embodiment 3

[0028] With respect to the above-mentioned embodiment 2, this embodiment adopts the method of high-energy electron irradiation to cure the cord fabric impregnated with radiation-cured impregnating glue, wherein the selection range of the voltage is between 200 and 600KV, and the selection range of the radiation absorbed dose is Between 0.5~60KGy. In this embodiment, the electron beam irradiation voltage is adjusted to 200KV, the radiation absorption dose is 20KGy, and the impregnating glue is cured.

[0029] In order to ensure the best curing effect, the cord fabric can always be cured in an oxygen-limited environment made of protective gas. The main purpose is to prevent the occurrence of oxygen inhibition. The protective gas can be selected from nitrogen, carbon dioxide, and inert gas. A combination of one or more. In order to ensure continuous production and even and stable irradiation of the cord fabric, a transmission system, such as a conveyor belt or a conveyor roller,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com