High temperature resistant cross-linked polyolefin foamed material and preparation method thereof

A technology for cross-linking polyolefin and foaming material, which is applied in the field of cross-linking polyolefin foaming material and its preparation, and can solve problems such as the influence of sealing and buffering effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The raw material of cross-linked polyolefin foam material 1 with high temperature resistance includes 60 parts of polyolefin resin, 18 parts of blowing agent, 4 parts of toughening agent, 3 parts of coupling agent and 3 parts by weight. parts of antioxidants;

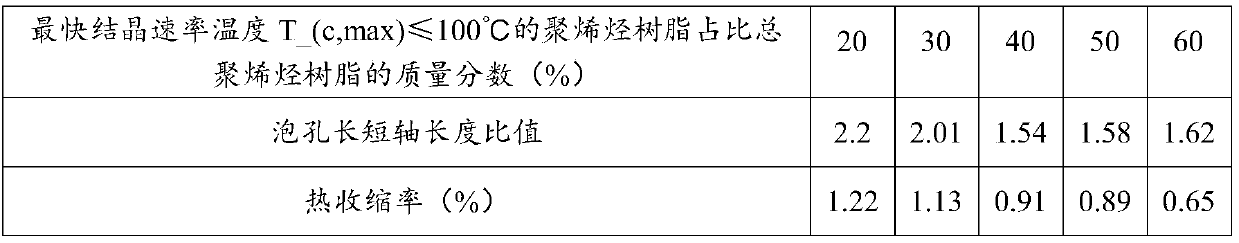

[0050] The polyolefin resin is composed of ultra-low-density polyethylene, medium-density polyethylene, and ethylene-methyl acrylate copolymer in a ratio of 1:3:1, and the fastest crystallization rate temperature T_(c,max) ≤ 100°C The mass fraction of olefin resin accounting for polyolefin resin is 40%;

[0051] The method for preparing the above-mentioned cross-linked polyolefin foam material 1 with high temperature resistance comprises the following steps:

[0052] ① Weighing polyolefin, foaming agent, toughening agent, coupling agent and antioxidant according to the weight percentage;

[0053] ②Mix polyolefin, foaming agent, toughening agent, coupling agent and antioxidant;

[0054] ③The raw materials mixed...

Embodiment 2

[0058] The raw material of the cross-linked polyolefin foam material 2 with high temperature resistance comprises 90 parts of polyolefin resin, 7 parts of foaming agent, 0.1 part of coupling agent and 0.4 part of antioxidant in parts by weight. ;

[0059] Wherein the polyolefin resin is low-density polyethylene, wherein the polyolefin resin with the fastest crystallization rate temperature T_(c,max)≤100°C accounts for 70% of the mass fraction of the polyolefin resin;

[0060] The method for preparing the above-mentioned cross-linked polyolefin foam material 2 with high temperature resistance comprises the following steps:

[0061] ① Weigh polyolefin, foaming agent, coupling agent and antioxidant according to the weight percentage

[0062] ②Mix polyolefin, foaming agent, coupling agent and antioxidant;

[0063] ③The raw materials mixed in step ② are melted and extruded into sheets;

[0064] ④ subject the sheet in step ③ to cross-linking treatment by high-energy electron irra...

Embodiment 3

[0067] The raw material of the cross-linked polyolefin foam material 3 with high temperature resistance includes 75 parts of polyolefin resin, 4 parts of blowing agent, 0.1 part of toughening agent, 0.2 part of coupling agent and 0.7 part by weight. parts of antioxidants;

[0068] Among them, the polyolefin resin is composed of low-density polyethylene, metallocene polyethylene, linear low-density polyethylene, ethylene-octene copolymer, ethylene-vinyl acetate copolymer, the ratio is 10:6:15:7:15, the most The mass fraction of polyolefin resin with fast crystallization rate temperature T_(c,max)≤100°C is 65%;

[0069] The method for preparing the above-mentioned cross-linked polyolefin foam material 3 with high temperature resistance comprises the following steps:

[0070] ① Weighing polyolefin, foaming agent, toughening agent, coupling agent and antioxidant according to the weight percentage; ② mixing polyolefin, foaming agent, toughening agent, coupling agent and antioxidan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com