Patents

Literature

34results about How to "Raise the starting temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

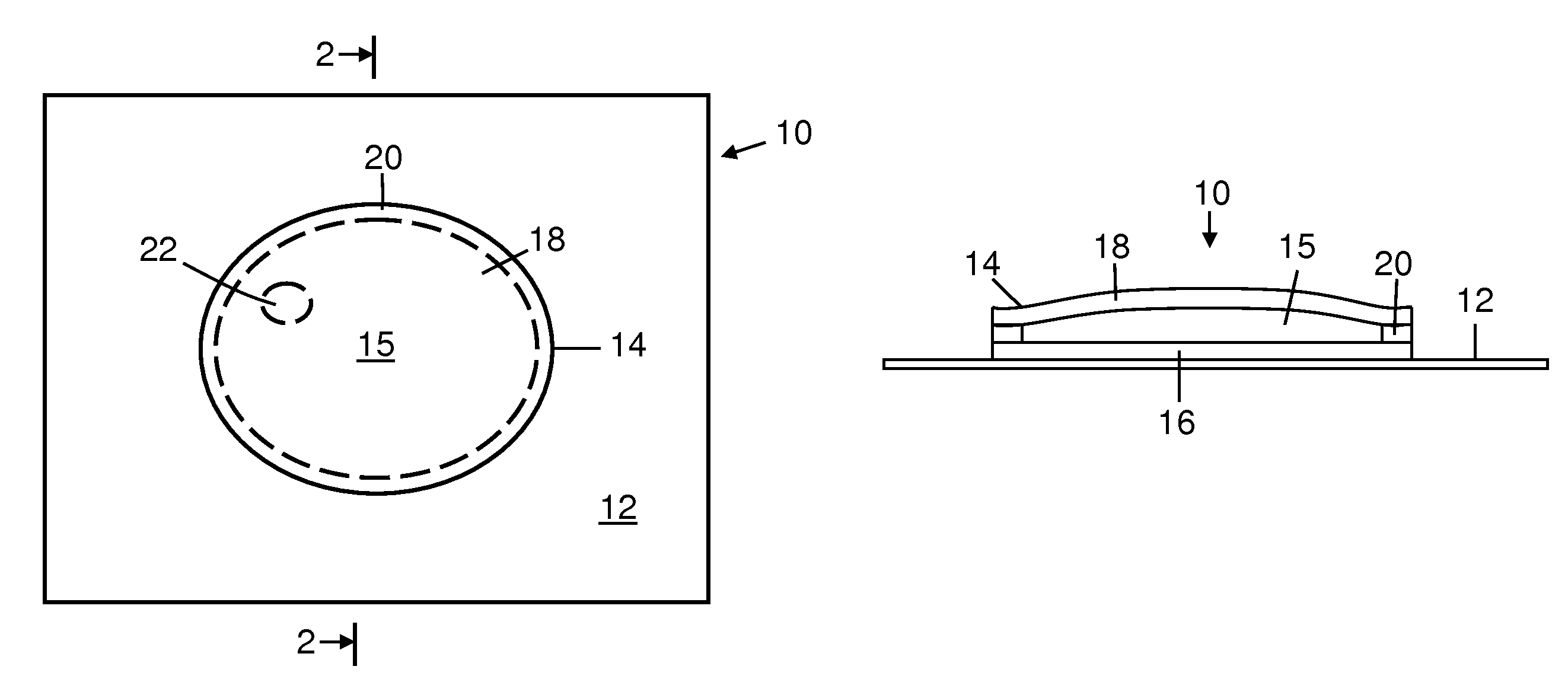

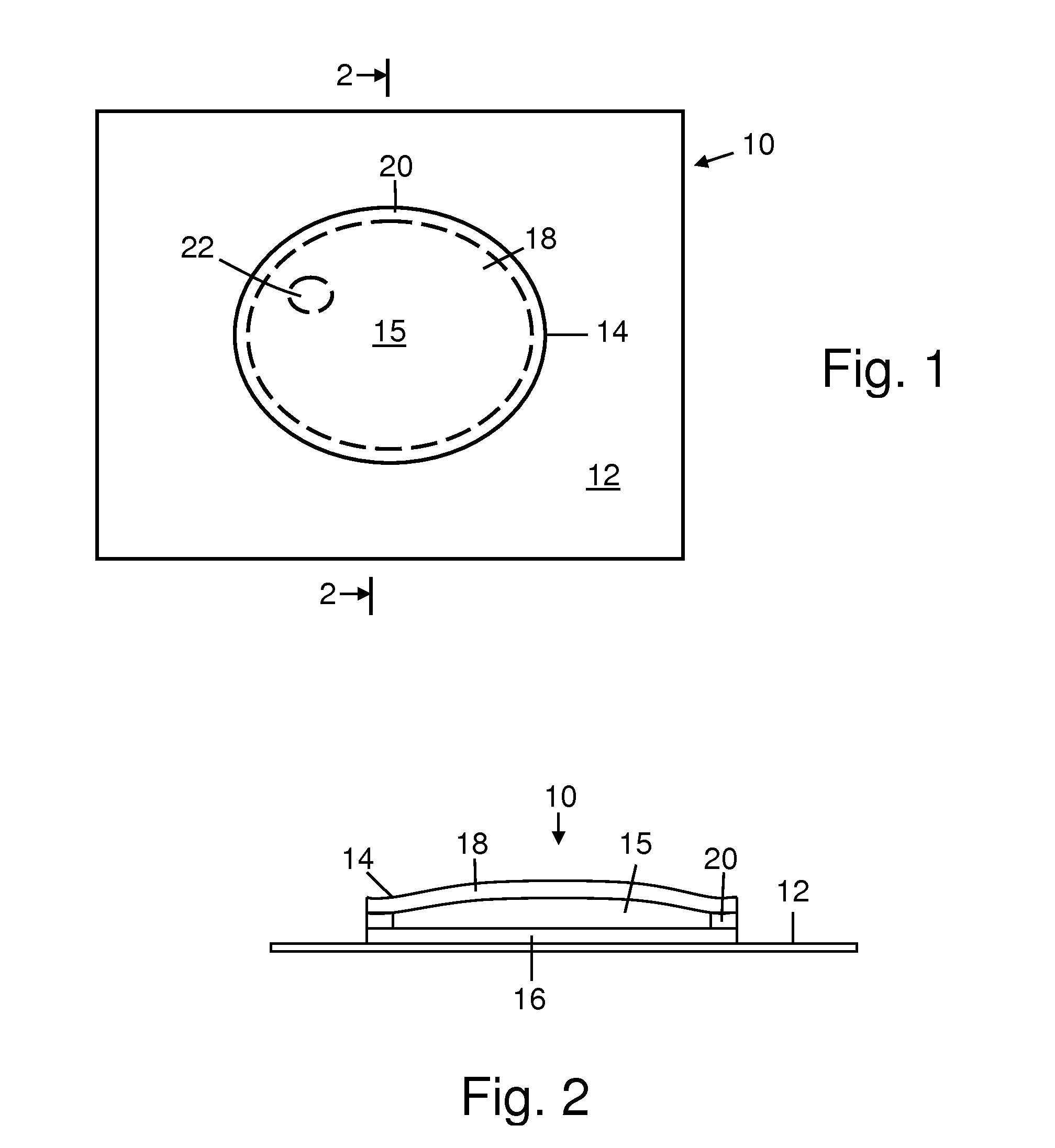

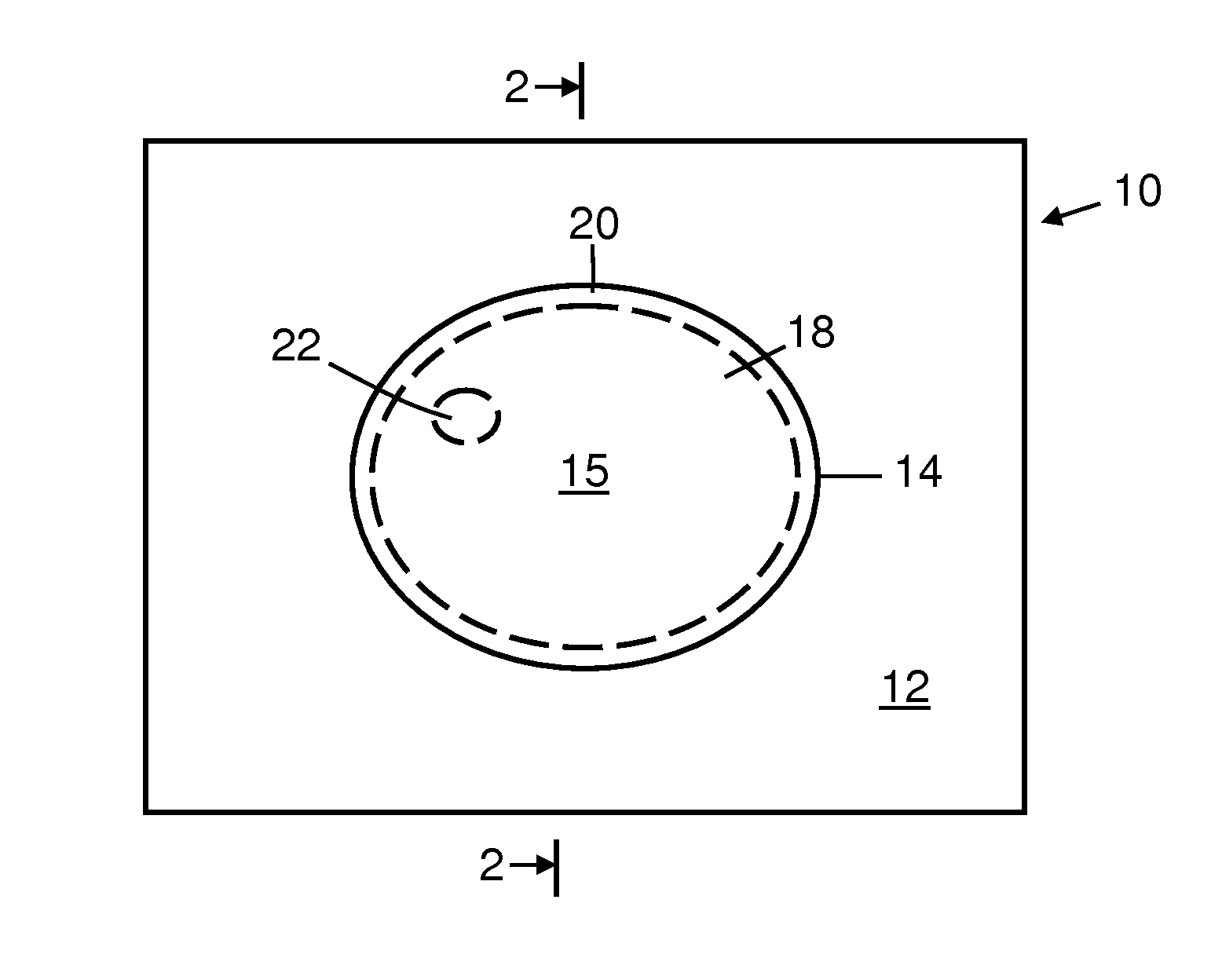

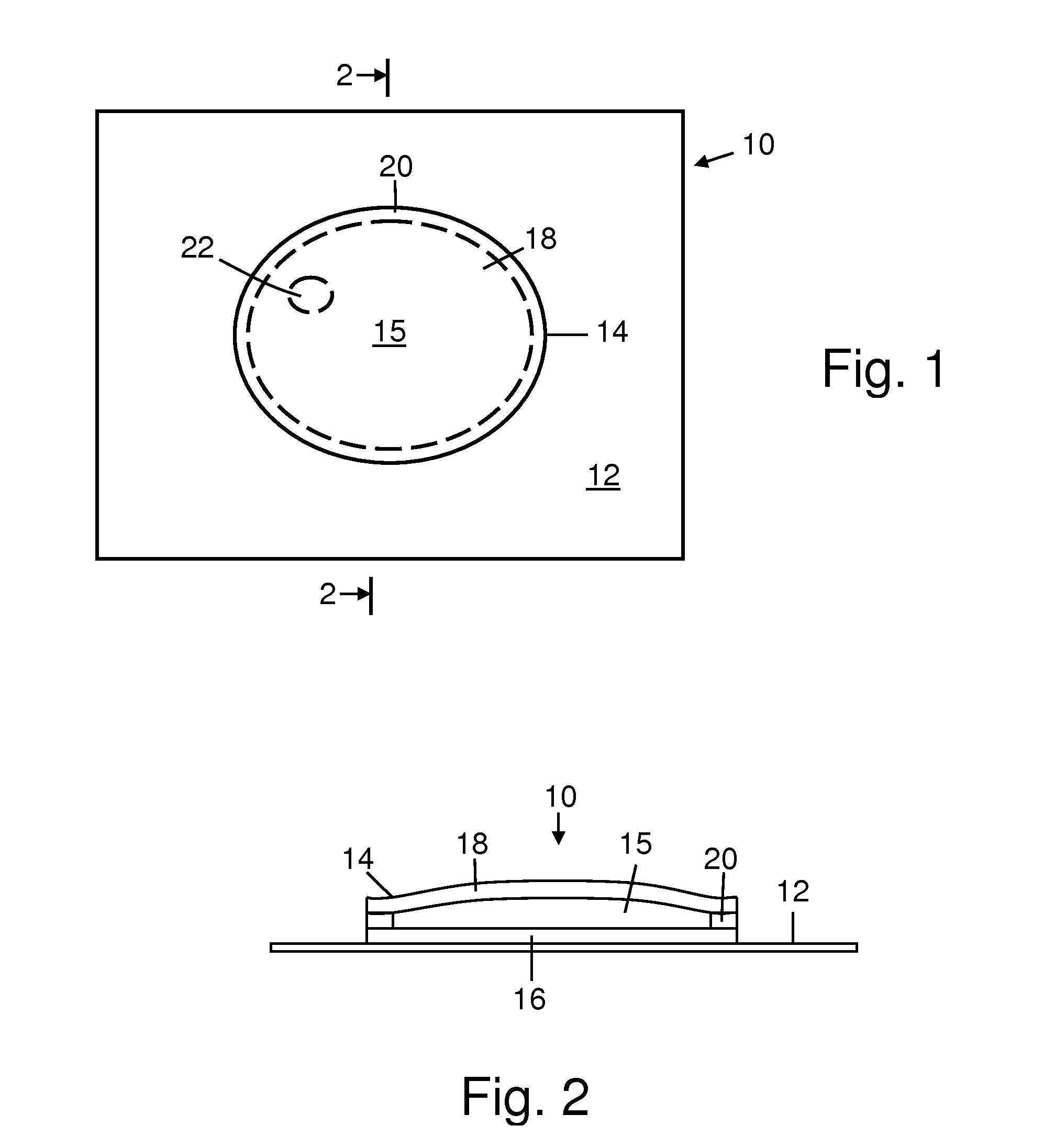

Freeze indicators with a controlled temperature response

ActiveUS8122844B2Raise the starting temperatureLow-cost ingredientThermometer detailsThermometers using physical/chemical changesTemperature responseLiquid medium

A freeze indicator can include an indicator dispersion having an aqueous liquid medium and organic material indicator particles dispersed in the aqueous liquid medium. The indicator dispersion can have an initial appearance before freezing and an irreversibly different appearance after freezing and can exhibit a freeze-onset temperature of about −1.9° C. or higher. Some factors helpful to providing a relatively high freeze onset temperature are employment of a proteinaceous ice-nucleating agent, control of pH, use of a protein stabilizer and control of the ratio of protein stabilizer to ice-nucleating agent.

Owner:TEMPTIME CORP

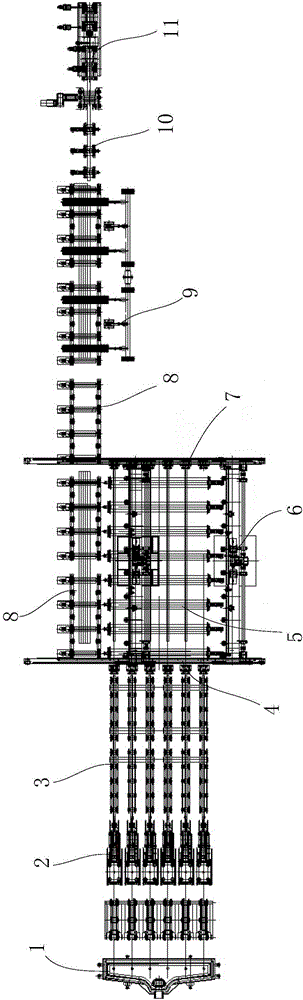

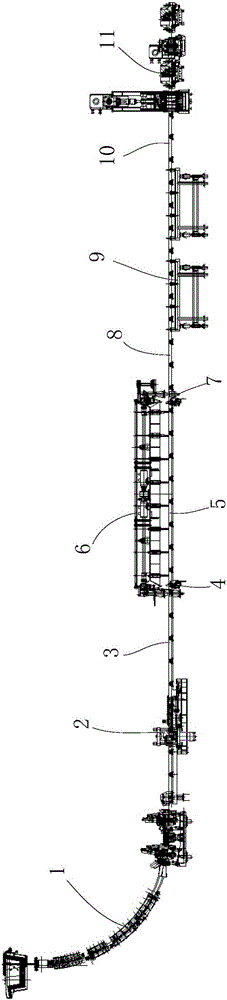

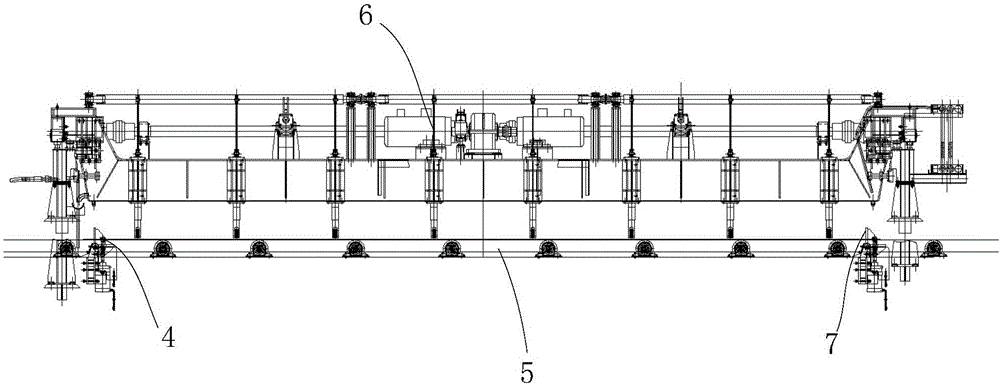

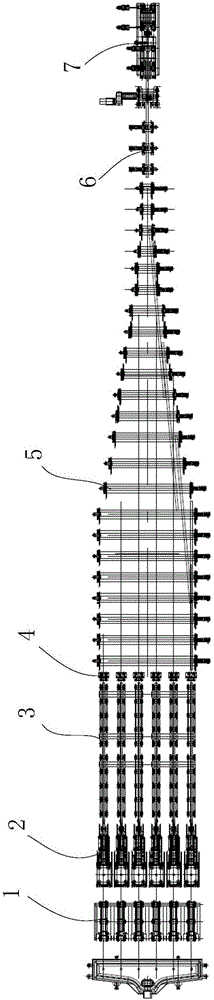

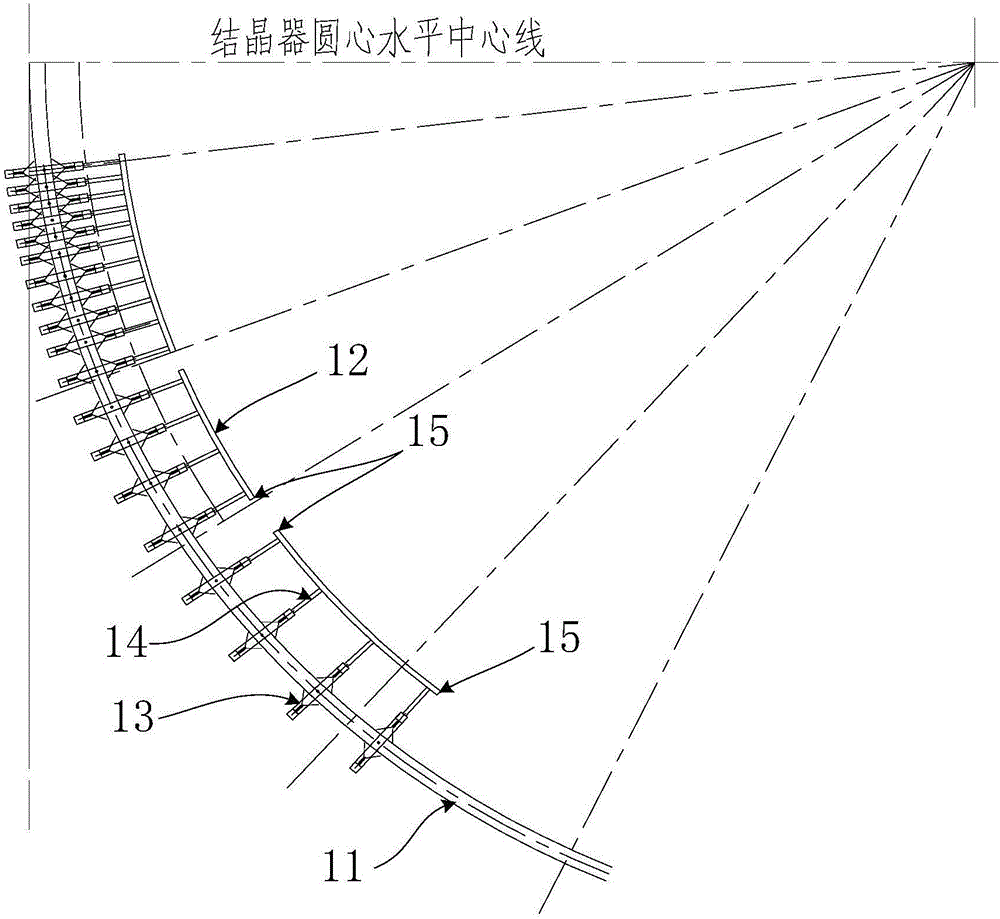

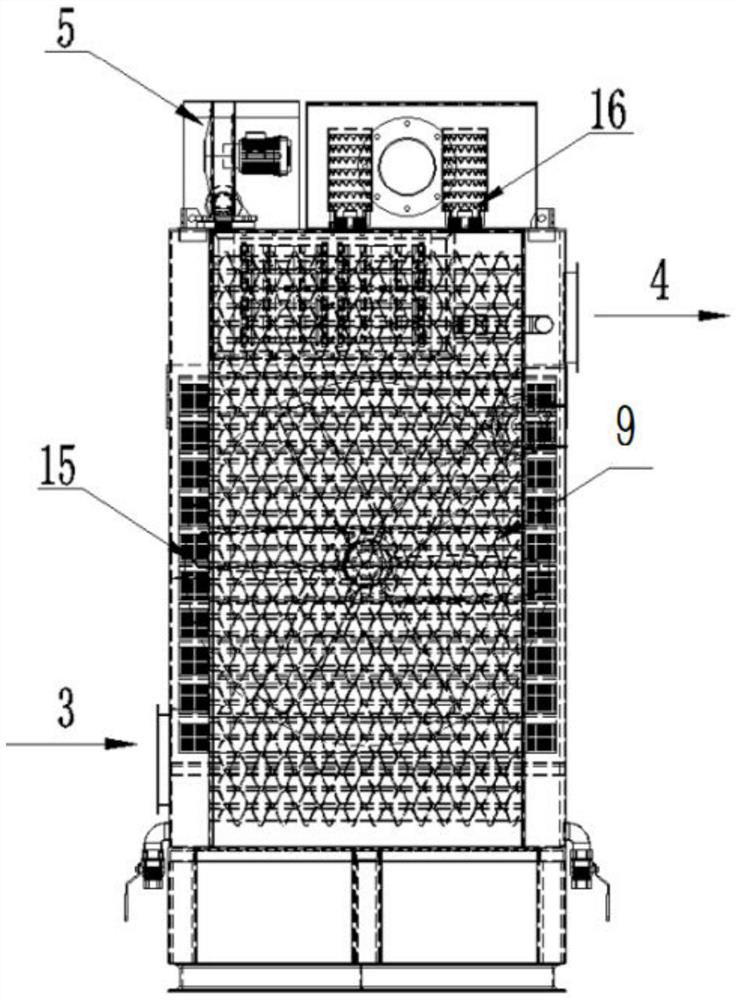

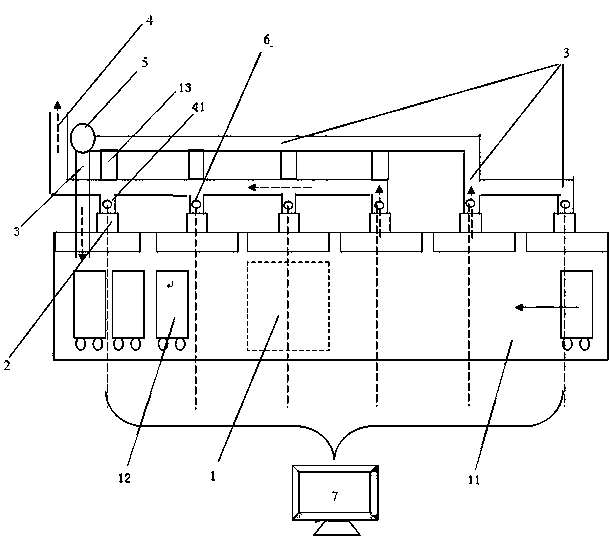

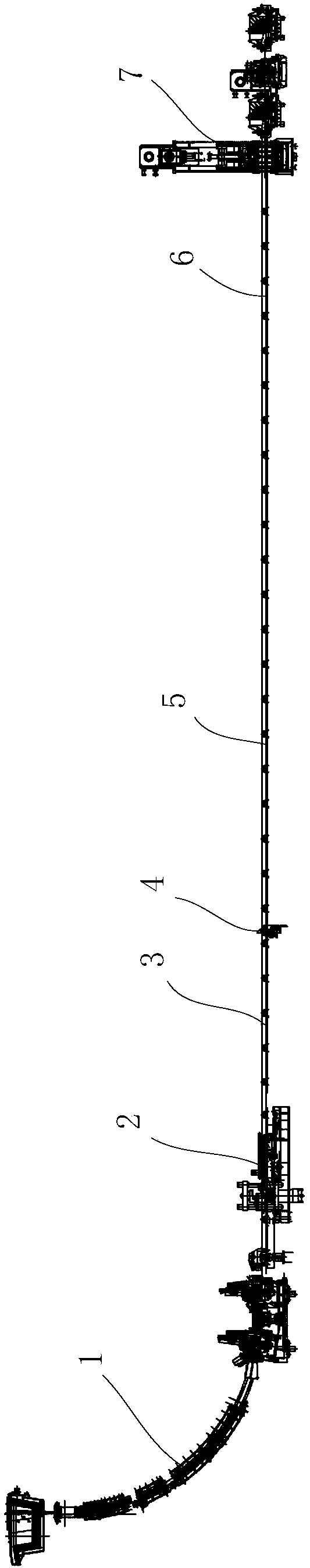

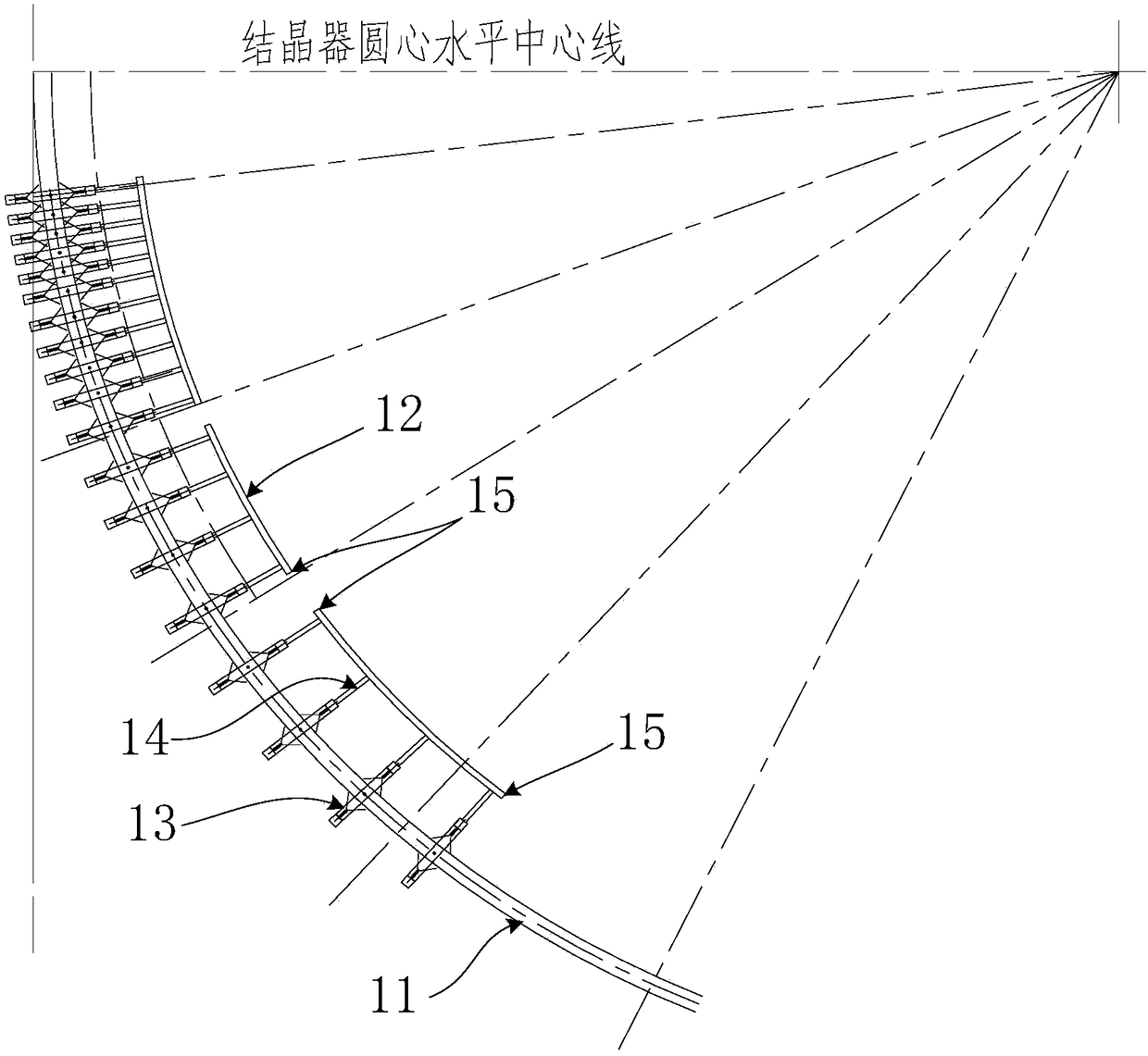

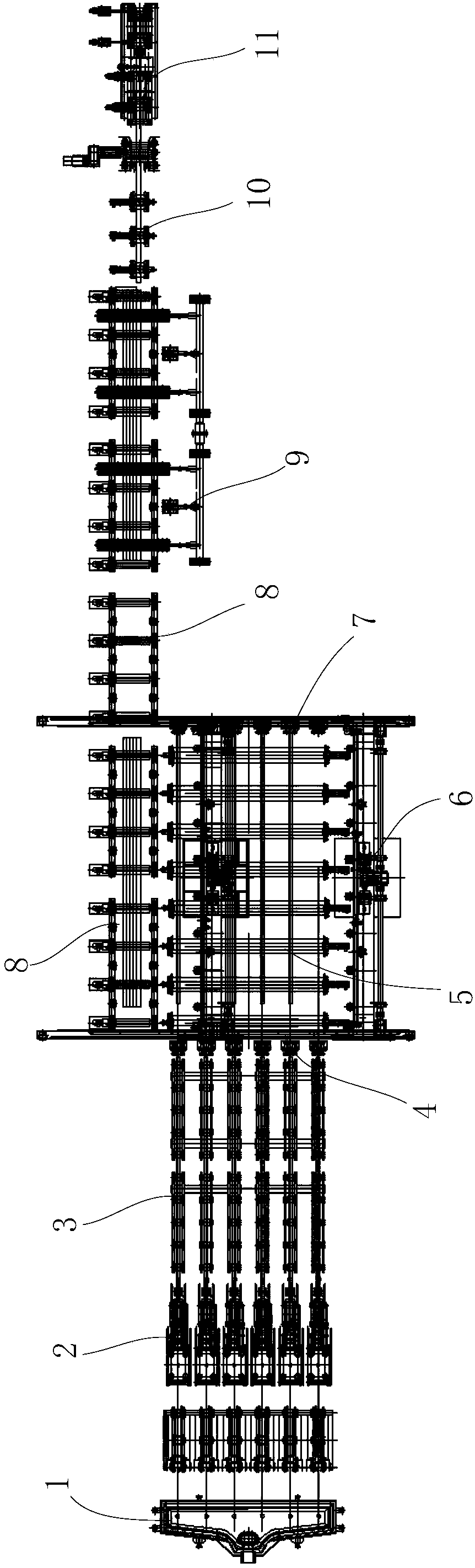

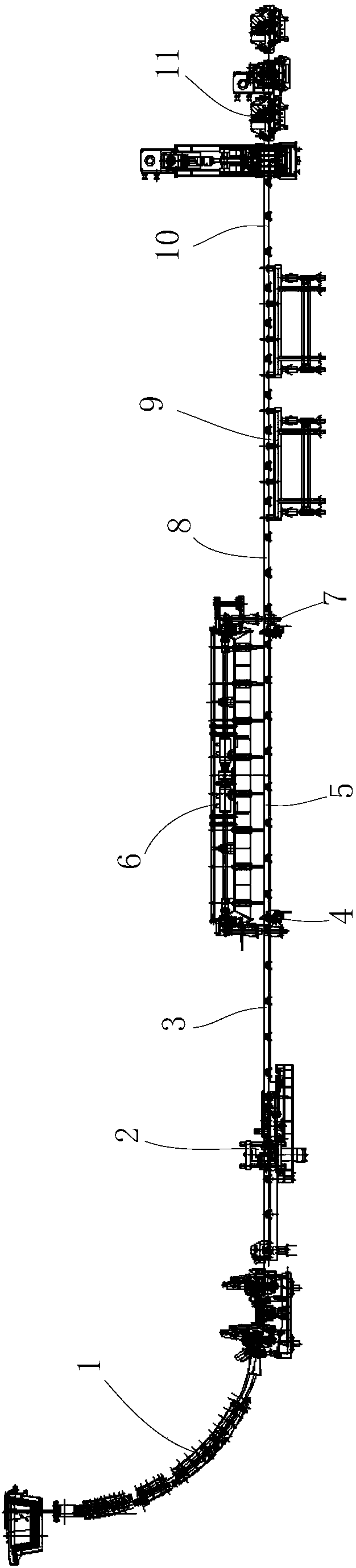

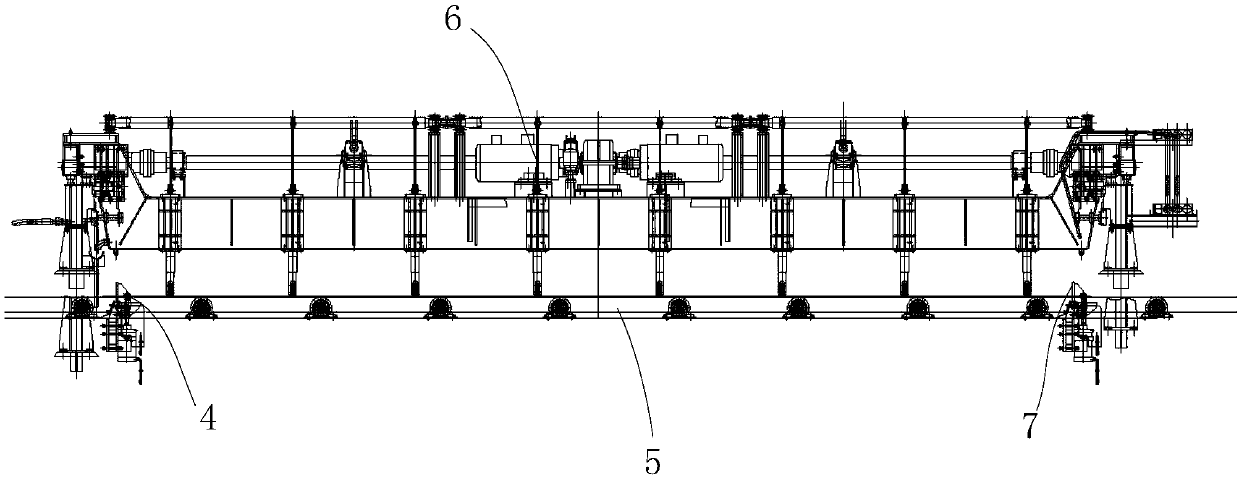

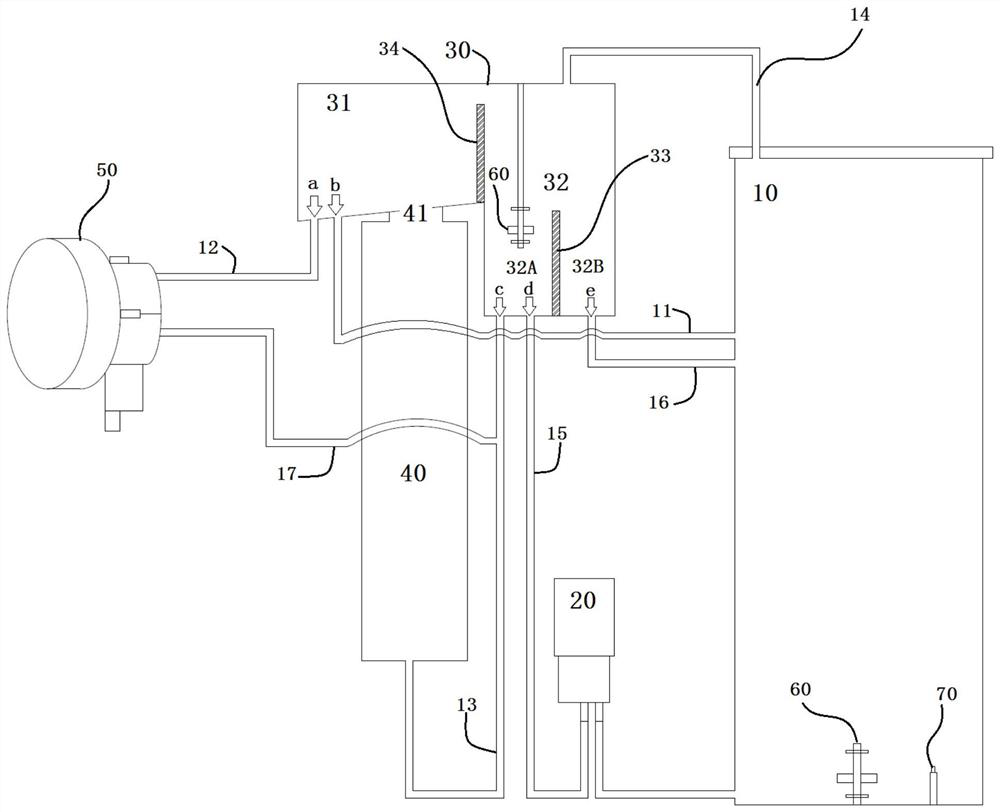

High-speed direct-delivery direct-rolling system and method for wire bar continuously-cast slabs

ActiveCN106180192AReduce temperature lossAvoid damageWork cooling devicesMetal rolling arrangementsEngineeringContinuous casting

The invention provides a high-speed direct-delivery direct-rolling system and method for wire bar continuously-cast slabs. The system comprises a small-radius high-drawing-speed continuous casting machine, a fast hydraulic shear, a cut slab roller table, a slab discharging roller table, a grouped cast slab hot-delivery roller table, a single-cast-slab delivery roller table and a wire bar rolling mill which are sequentially and compactly arranged. A transverse steel transfer machine is arranged between the slab discharging roller table and the grouped cast slab hot-delivery roller table. A steel bar splitting machine is arranged between the grouped cast slab hot-delivery roller table and the single-cast-slab delivery roller table. Cast slabs are gathered into groups on the slab discharging roller table and transferred into the grouped cast slab hot-delivery roller table from the transverse steel transfer machine. The grouped cast slabs are split into single cast slabs through the steel bar splitting machine and delivered to the wire bar rolling mill through the single-cast-slab delivery roller table for rolling. The small-radius high-drawing-speed continuous casting machine is efficient in continuous casting, the drawing-out temperature of the cast slabs is high, the shape of the cast slabs is regular, and the temperature loss is small; and the cutoff speed of the cast slabs is high, and the initial temperature of the cast slabs is high. All streams of the cast slabs are grouped at a high speed through the transverse steel transfer machine and delivered in a grouped manner through the hot-delivery roller table for steel rolling, and by means of the manner, the temperature drop is extremely small in the delivery process of the cast slabs.

Owner:CISDI ENG CO LTD

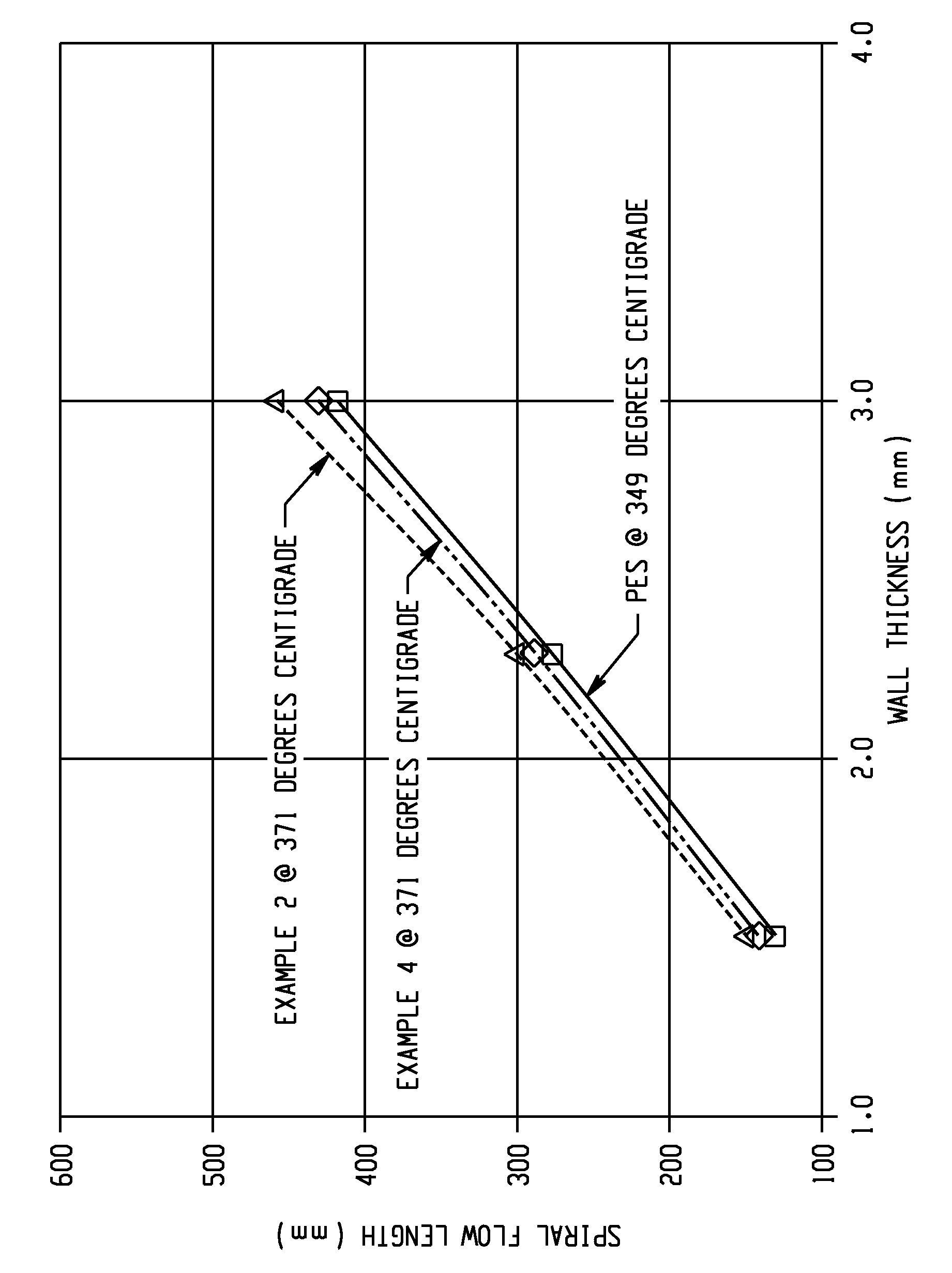

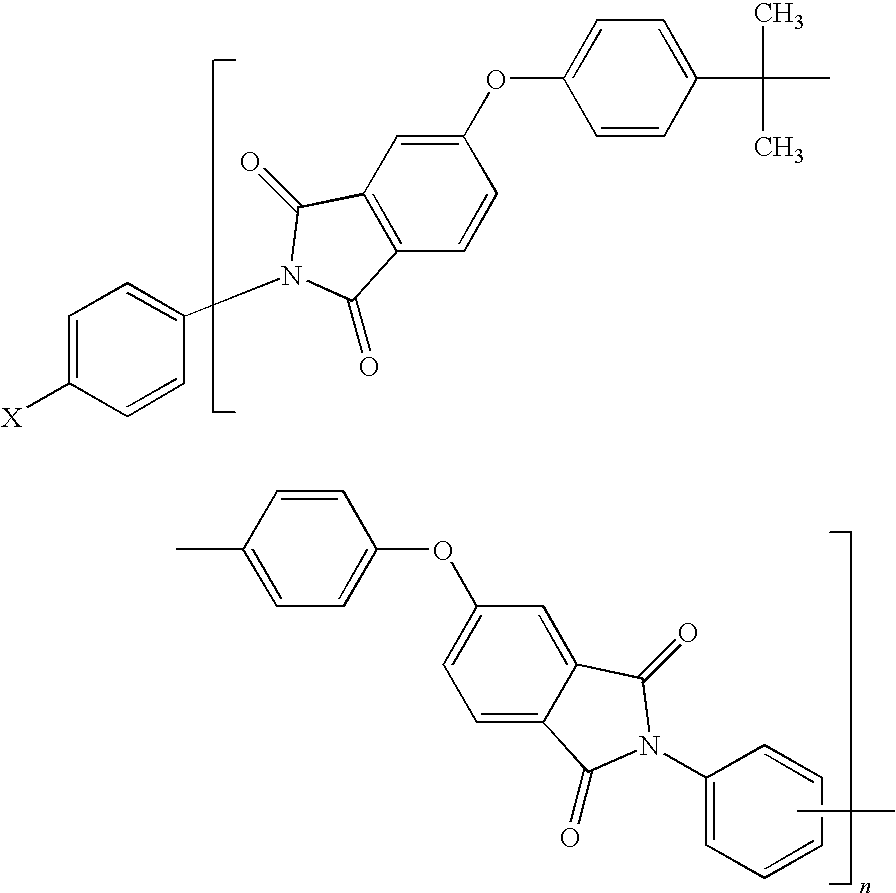

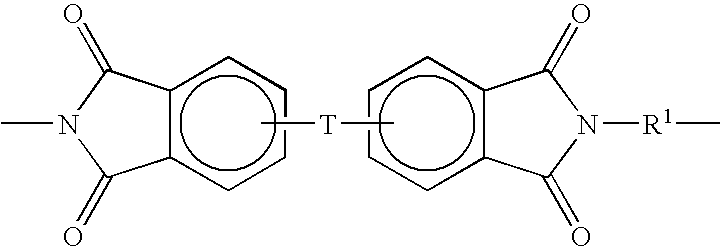

Polyetherimide and polyetherimide sulfone blends having automotive lighting applications

ActiveUS8545988B2Raise the starting temperatureIncrease stiffnessSynthetic resin layered productsGlass/slag layered productsArylPolyetherimide

Compositions and articles of manufacture made therefrom for use in high temperature application, such as automotive reflectors, have a minimum haze onset temperature of about 205° C. and are made from a transparent, miscible blend of from about 30 to about 70 weight percent of a polyetherimide sulfone comprising greater than or equal to 50 mole percent of the polymer linkages have an aryl sulfone group and from about 70 to about 30 weight percent of a polyetherimide or polyimide.

Owner:SHPP GLOBAL TECH BV

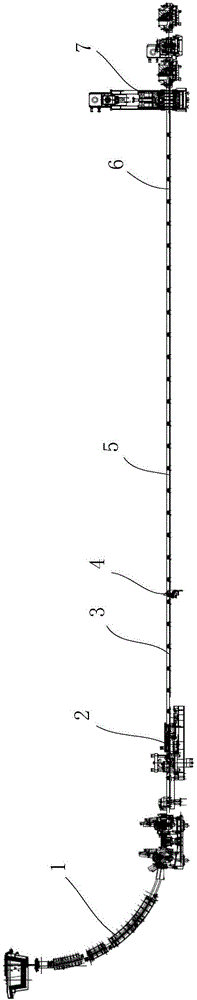

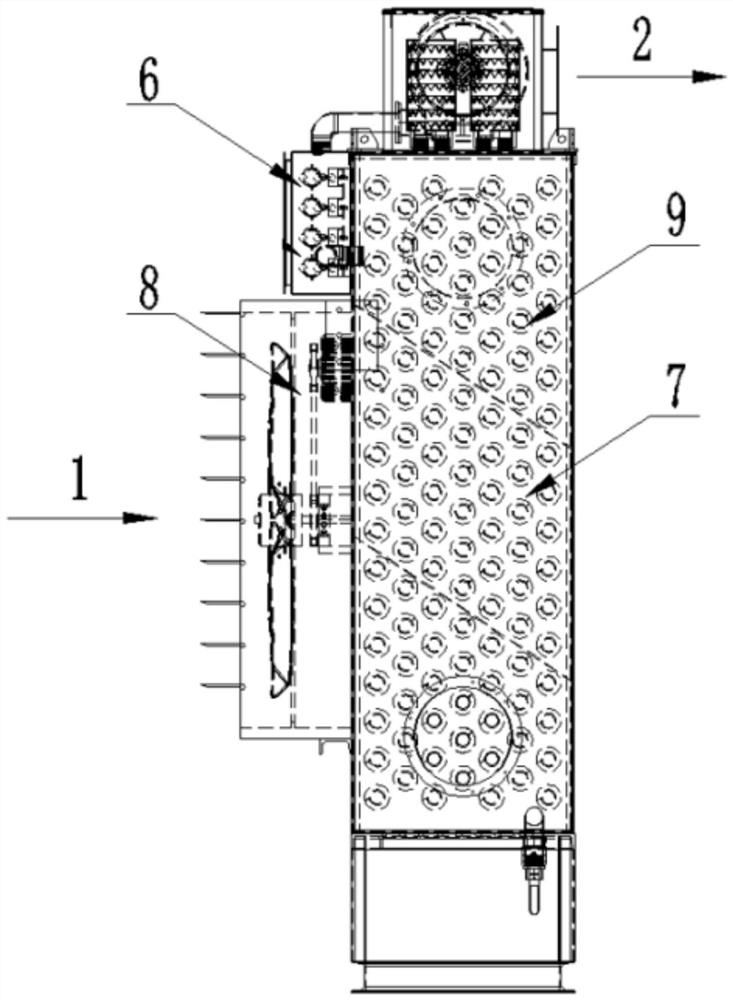

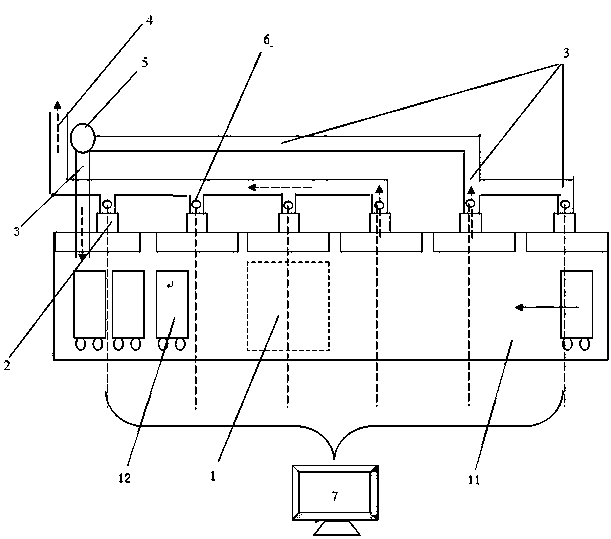

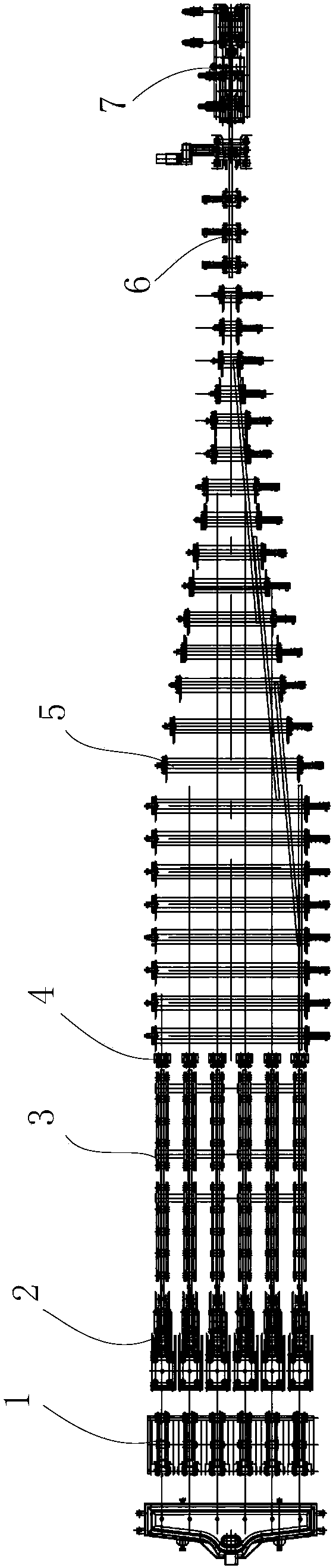

Wire rod continuous casting billet heating-free direct rolling system and method

ActiveCN106180191AReduce temperature lossReduce temperature dropMetal rolling arrangementsWire rodRolling mill

The invention provides a wire rod continuous casting billet heating-free direct rolling system and method. The wire rod continuous casting billet heating-free direct rolling system comprises a continuous casting machine, a rapid hydraulic shear, a cut roller bed, a casting billet stream gathering roller bed, a transportation hot delivery roller bed and a wire rod rolling mill which are closely arranged in sequence. The casting billet stream gathering roller bed gathers casting billets on each stream onto the transportation hot delivery roller bed. A gate mechanism used for blocking the casting billets from entering and releasing the casting billets is arranged between the cut roller bed and the casting billet stream gathering roller bed. According to the wire rod continuous casting billet heating-free direct rolling system and method, efficient continuous casting of the continuous casting machine is conducted, and the casting billets are high in pull-out temperature, regular in shape, low in temperature loss, rapid in shearing and high in initial temperature; by means of the gate mechanism, the sheared casting billets sequentially enter the high-speed casting billet stream gathering roller bed in order, operation is easy and convenient, and production is easy to organize; and when the casting billets reach an inlet of the rolling mill, the temperature of the casting billets is high, and the casting billets can be directly rolled in a heating-free mode, so that the damage to the rolling mill is small.

Owner:CISDI ENG CO LTD

Freeze indicators with a controlled temperature response

ActiveUS20110209658A1Raise the starting temperatureLow-cost ingredientThermometer detailsThermometers using physical/chemical changesTemperature responseLiquid medium

A freeze indicator can include an indicator dispersion having an aqueous liquid medium and organic material indicator particles dispersed in the aqueous liquid medium. The indicator dispersion can have an initial appearance before freezing and an irreversibly different appearance after freezing and can exhibit a freeze-onset temperature of about −1.9° C. or higher. Some factors helpful to providing a relatively high freeze onset temperature are employment of a proteinaceous ice-nucleating agent, control of pH, use of a protein stabilizer and control of the ratio of protein stabilizer to ice-nucleating agent.

Owner:TEMPTIME CORP

Preparation method of lightweight polypropylene material

ActiveCN110054801ANarrow down the decomposition temperature rangeImprove the effectPolypropyleneDecomposition

The invention relates to a preparation method of a lightweight polypropylene material. The preparation method includes the steps: (1) uniformly mixing sodium bicarbonate and citric acid to obtain a micro-porous foaming agent for polypropylene; (2) wrapping the micro-porous foaming agent for the polypropylene by silicone oil to obtain a micro-porous foaming agent for organic silicon wrapped polypropylene; (3) uniformly mixing the micro-porous foaming agent for the organic silicon wrapped polypropylene, the polypropylene, fillers, antioxidants, heat stabilizers and microcapsule erythritol to obtain a finished product. According to the method, the citric acid and the microcapsule erythritol are added, the initial thermal decomposition temperature of the sodium bicarbonate is improved, a decomposition temperature interval is reduced, foaming effects are improved, an erythritol material is an excellent middle temperature phase-change material, and phase-change temperature is 119-124 DEG C.When the temperature rises to exceed the phase-change temperature, phase-change of the erythritol is implemented, heat is slowly absorbed / temperature rise is prevented, so that thermal decomposition of the sodium bicarbonate serving as a foaming agent is delayed, and foaming effects are improved.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

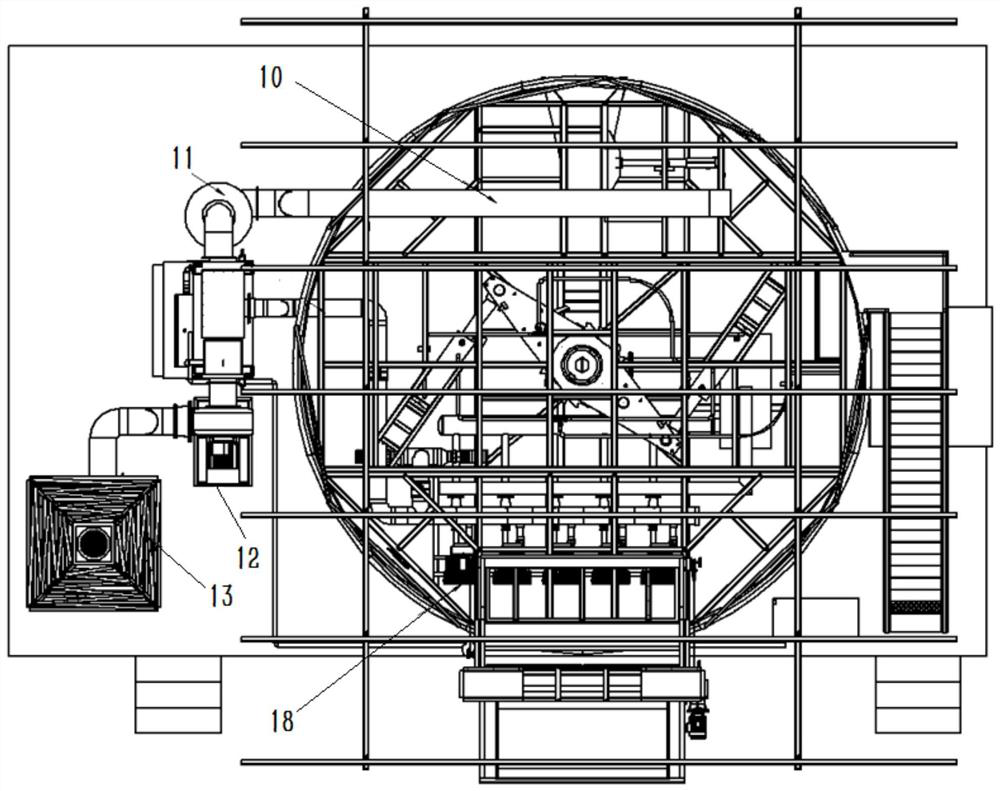

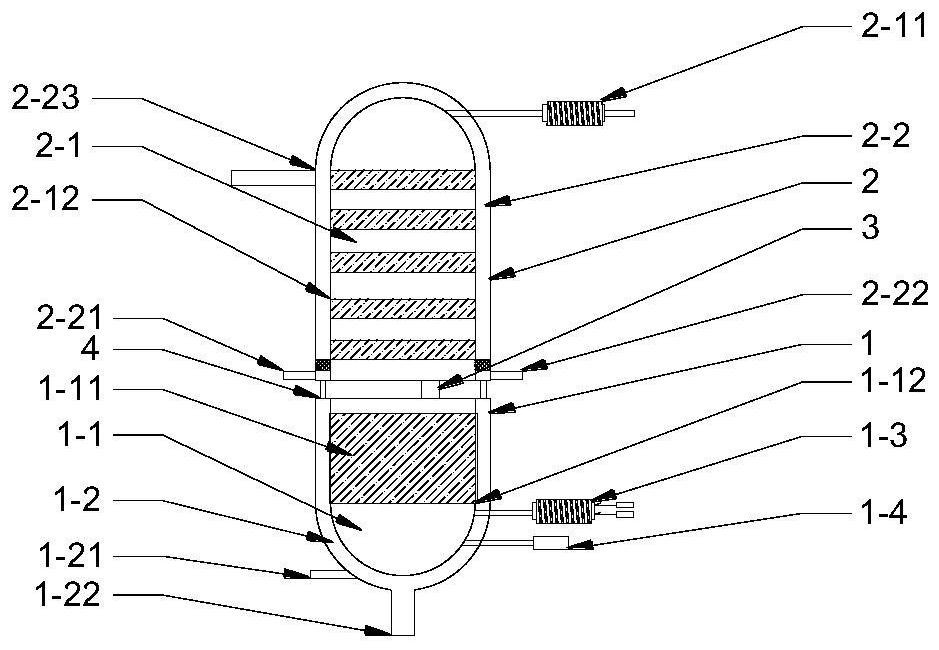

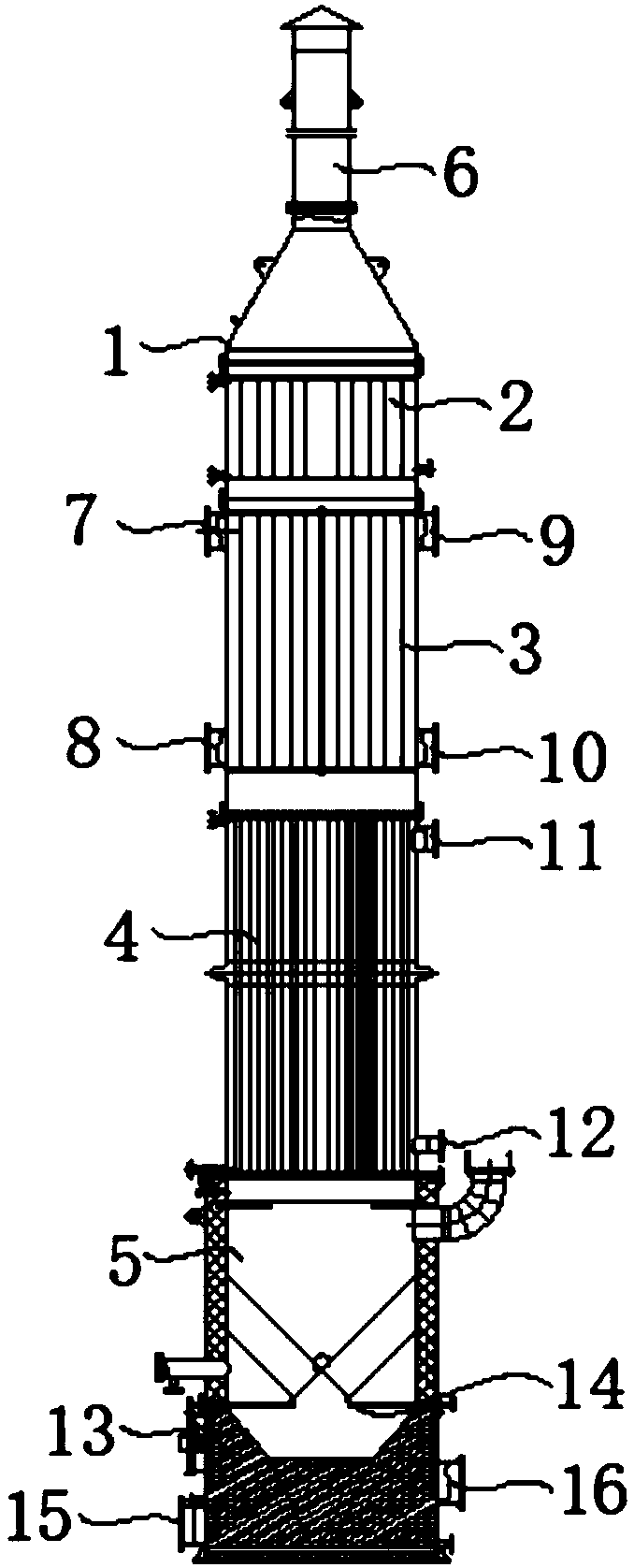

Livestock and poultry waste harmless sterilization waste heat recovery device

PendingCN111825490AAvoid secondary pollutionRaise the starting temperatureCombination devicesBio-organic fraction processingEnvironmental engineeringFermentation

The invention discloses a livestock and poultry waste harmless sterilization waste heat recovery device. The waste heat recovery body is provided with an air inlet, a first air outlet, an atmosphere inlet and a second air outlet. Two ends of an air outlet pipeline are respectively communicated with a fermentation tank and the air inlet; an ozone generator is arranged in the waste heat recovery main body; one end of an induced draft fan is communicated with the first air outlet, and the other end of the induced draft fan is communicated with a chimney pipeline; a finned tube is arranged in thewaste heat recovery main body; the finned tube is communicated with the atmosphere inlet; and the second air outlet is communicated with the fermentation tank. Through the arrangement of the structure, heat energy generated by fermentation of the livestock and poultry waste harmless treatment equipment can be recycled, secondary pollution of the air is avoided through ozone deodorization treatment, and energy is saved.

Owner:NANJING MAOZE NEW ENERGY EQUIP CO LTD

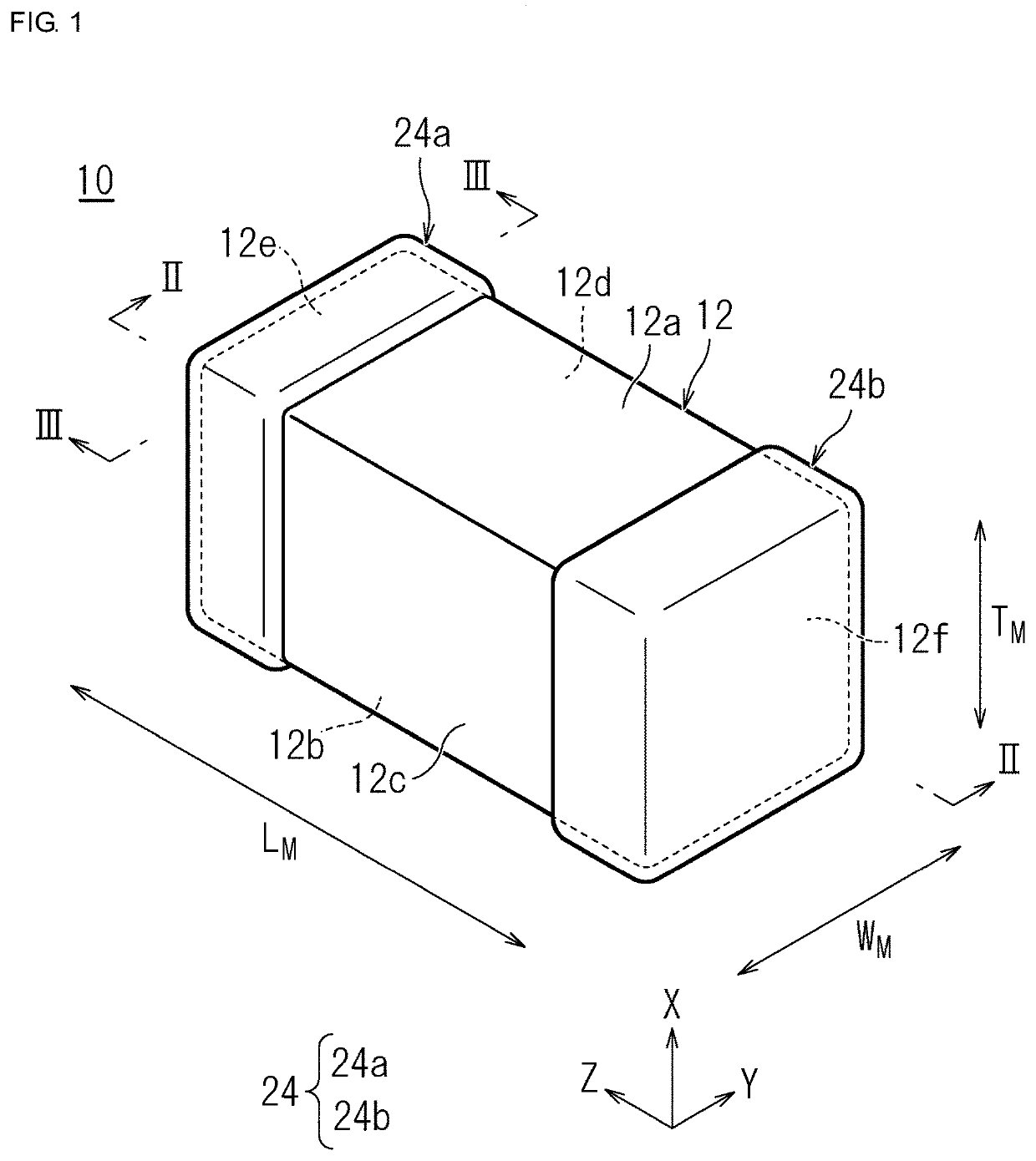

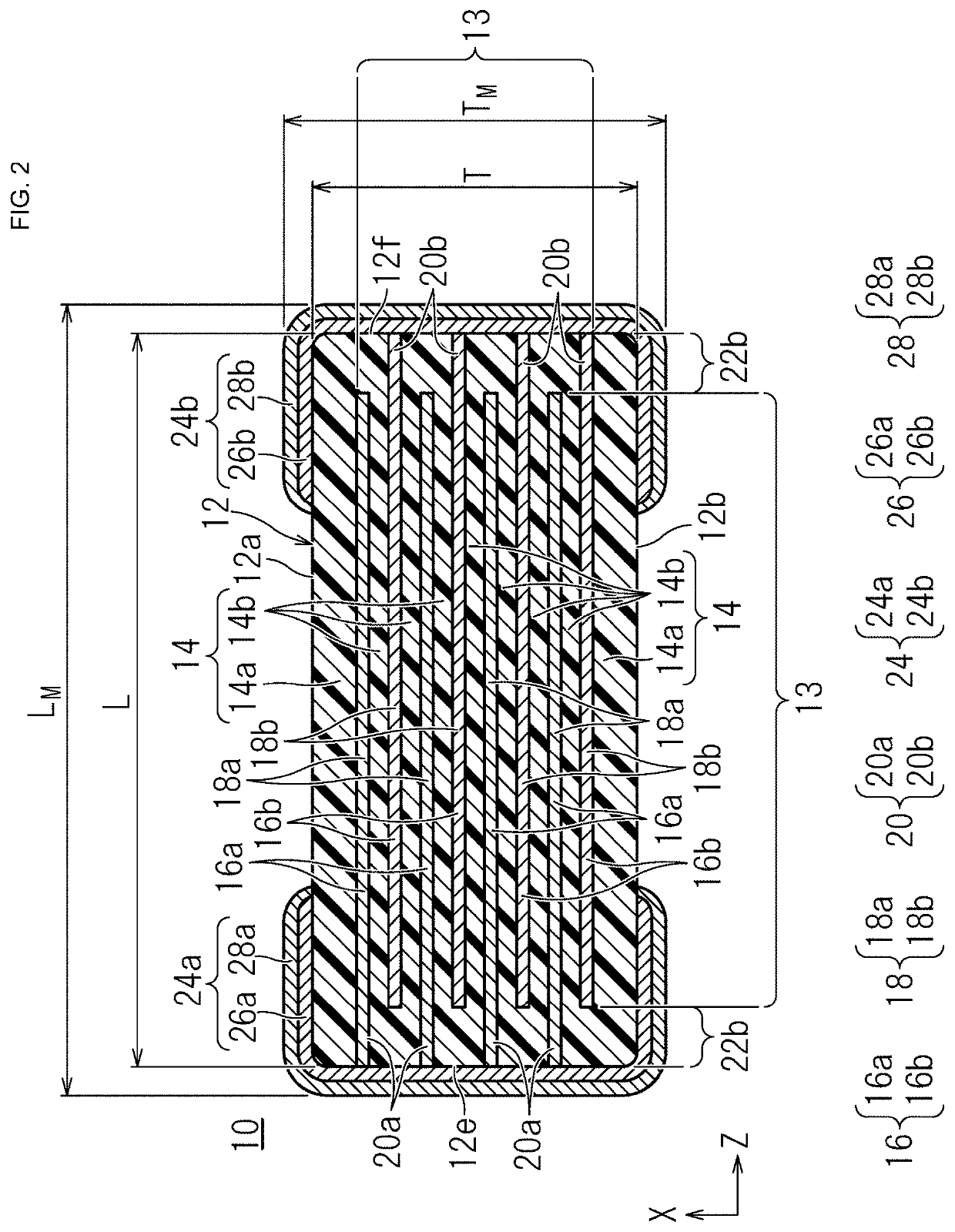

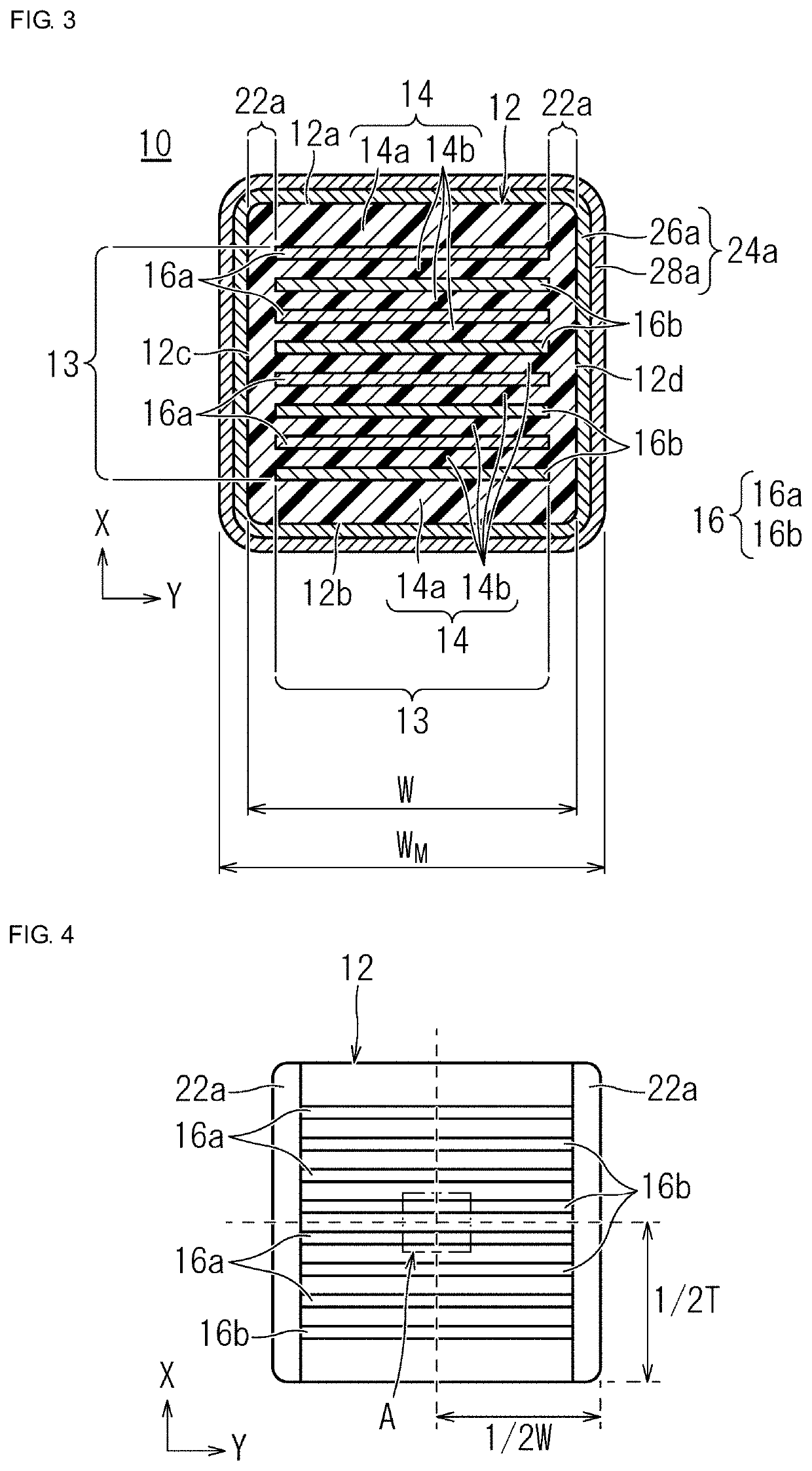

Multilayer ceramic capacitor

ActiveUS20200185152A1Suppress deterioration in smoothnessReduce the probability of short circuitFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorDielectric layer

A multilayer ceramic capacitor that includes outer electrodes and a multilayer body having stacked inner electrode layers and dielectric layers. The dielectric layers in an effective section contain, relative to 100 parts by mole of Ti, 0.7 to 1.2 parts by mole of Si, 0.9 to 1.1 parts by mole of Dy, 0.24 to 0.34 parts by mole of Mg, 0.17 to 0.23 parts by mole of Al, 0.09 to 0.11 parts by mole of Mn, and 0.04 to 0.06 parts by mole of V. The dielectric layers have a Ba / Ti molar ratio of 1.0073 to 1.0083.

Owner:MURATA MFG CO LTD

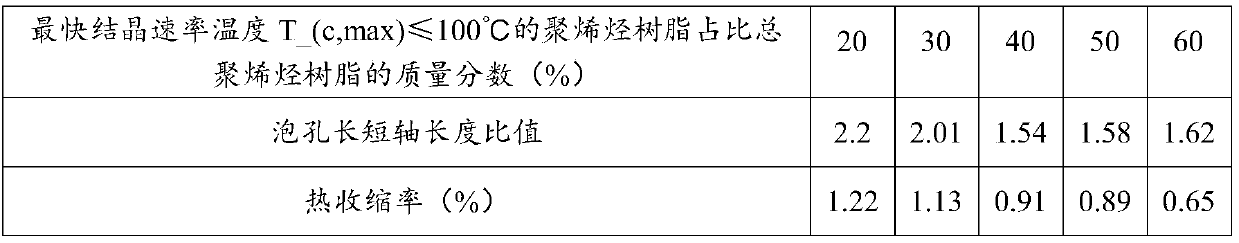

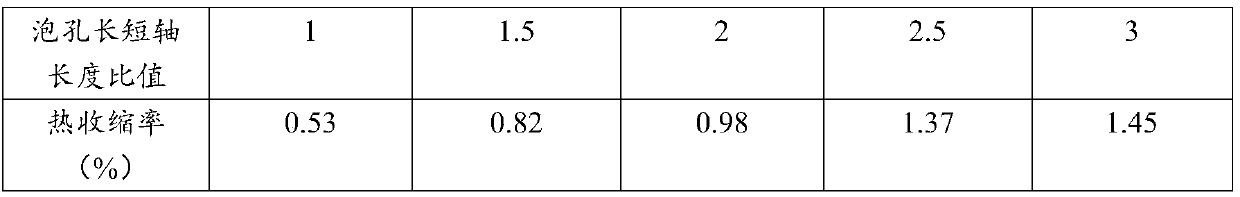

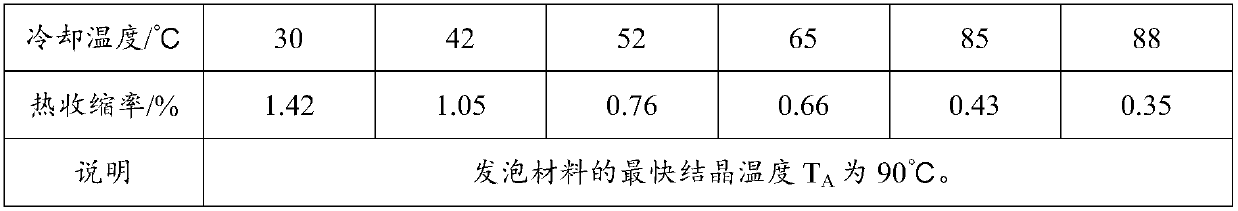

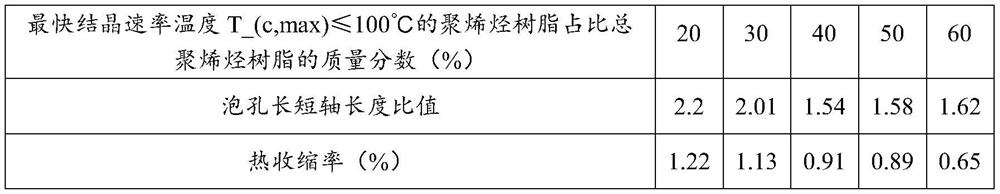

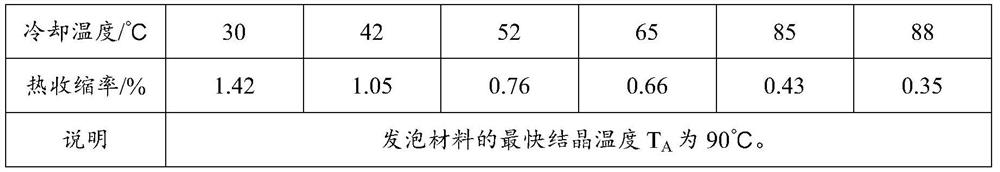

High temperature resistant cross-linked polyolefin foamed material and preparation method thereof

ActiveCN109251388ARaise the starting temperatureLow heat shrinkageHigh energy electron irradiationCross-link

The invention discloses a high temperature resistant cross-linked polyolefin foamed material and a preparation method thereof. The raw materials include, by weight, 60-90 parts of polyolefin resin, 2-20 parts of a foaming agent and 0.1-10 parts of processing aids. Specifically, the polyolefin resin includes polyolefin resin with a maximum crystallization rate temperature T_(c, max) of lower than or equal to 100DEG C, and the polyolefin resin with the maximum crystallization rate temperature T_(c, max) of lower than or equal to 100DEG C accounts for more than or equal to 40% of the mass fraction of the polyolefin resin. The preparation method includes: mixing polyolefin, the foaming agent and the processing aids; performing melt extrusion into sheets; then subjecting the sheets to high-energy electron irradiation crosslinking treatment; and then heating the irradiated sheets, conducting foaming by a foaming furnace, then carrying out cooling shaping, and performing rolling-up. The cross-linked polyolefin foamed material provided by the invention increases the difference of temperature in a tensile zone and the crystallization temperature in the foaming process, and can increases thestarting temperature of heat shrinkage produce by the material and reduce the heat shrinkage rate.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

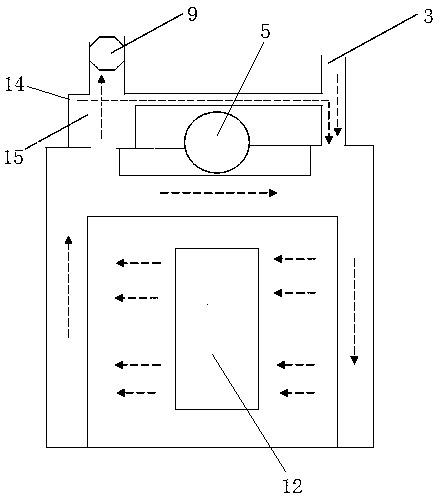

Waste heat recovery energy-saving drying oven and waste heat recovery method thereof

ActiveCN108955105AEffectively guide and control the use of openingGuidance and control using the openingDrying gas arrangementsDrying solid materialsWaste heat recovery unitRecovery method

The invention relates to a waste heat recovery energy-saving drying oven and a waste heat recovery method thereof. The waste heat recovery energy-saving drying oven comprises a furnace body, a hot airsupply pipeline, a dehumidifying fan, recycling pipelines, dehumidifying air pipelines, temperature and humidity detectors, an automatic regulating valve, drying oven waste heat recovery and utilization systems and a server. The waste heat recovery energy-saving drying oven is characterized in that the furnace body is provided with an air supplementing inlet and the temperature and humidity detectors, the hot air supply pipeline communicates with the furnace body, the furnace body is internally provided with a plurality of drying cavities communicating mutually, and the upper portion of eachdrying cavity is provided with the corresponding dehumidifying air pipeline or the corresponding recycling pipeline; the dehumidifying fan is provided with a recycling opening and an exhaust outlet, and the recycling pipelines and the dehumidifying air pipelines communicate with the recycling opening and the exhaust outlet of the dehumidifying fan correspondingly; the drying oven waste heat recovery and utilization systems are mounted in the dehumidifying air pipelines and the recycling pipelines; and the adjusting regulating valve is mounted at the exhaust outlet of the dehumidifying fan, theair supplementing inlet communicates with the recycling pipelines, and the server is connected with the temperature and humidity detectors, the automatic regulating valve and a hot air supply system.Compared with the prior art, the waste heat recovery energy-saving drying oven and the waste heat recovery method thereof have the characteristics of concise and reasonable structure, convenient use,high energy utilization rate, low cost and the like.

Owner:JUSHI GRP CO

A heating-free direct rolling system and method for continuous casting slabs of wire and rod

ActiveCN106180191BReduce temperature lossReduce temperature dropMetal rolling arrangementsWire rodContinuous casting

The invention provides a wire rod continuous casting billet heating-free direct rolling system and method. The wire rod continuous casting billet heating-free direct rolling system comprises a continuous casting machine, a rapid hydraulic shear, a cut roller bed, a casting billet stream gathering roller bed, a transportation hot delivery roller bed and a wire rod rolling mill which are closely arranged in sequence. The casting billet stream gathering roller bed gathers casting billets on each stream onto the transportation hot delivery roller bed. A gate mechanism used for blocking the casting billets from entering and releasing the casting billets is arranged between the cut roller bed and the casting billet stream gathering roller bed. According to the wire rod continuous casting billet heating-free direct rolling system and method, efficient continuous casting of the continuous casting machine is conducted, and the casting billets are high in pull-out temperature, regular in shape, low in temperature loss, rapid in shearing and high in initial temperature; by means of the gate mechanism, the sheared casting billets sequentially enter the high-speed casting billet stream gathering roller bed in order, operation is easy and convenient, and production is easy to organize; and when the casting billets reach an inlet of the rolling mill, the temperature of the casting billets is high, and the casting billets can be directly rolled in a heating-free mode, so that the damage to the rolling mill is small.

Owner:CISDI ENG CO LTD

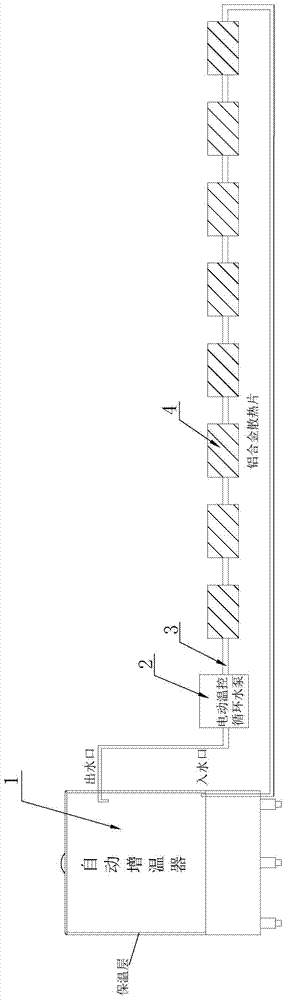

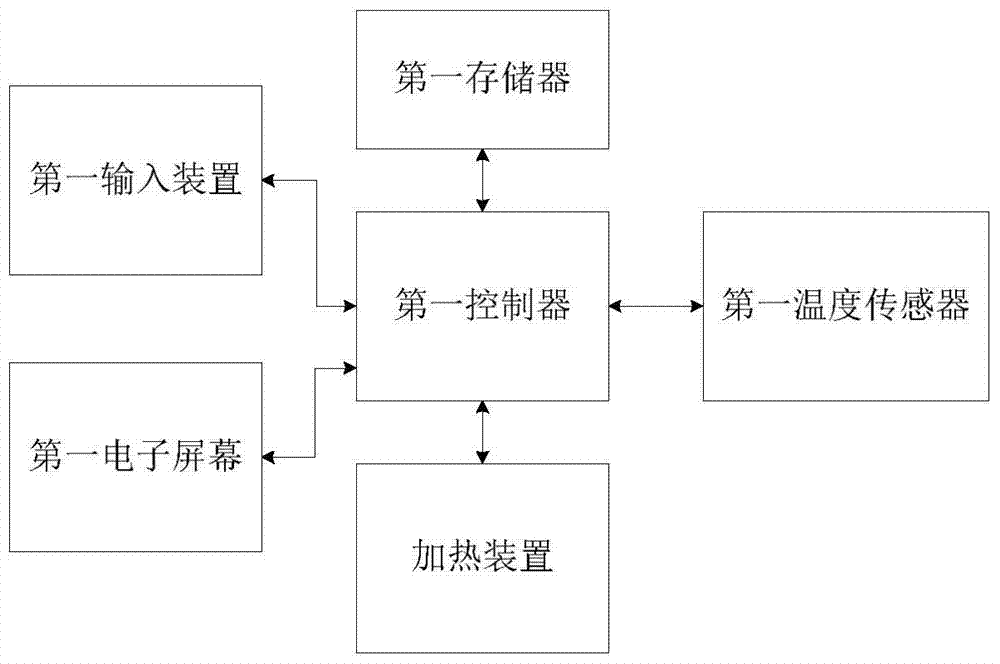

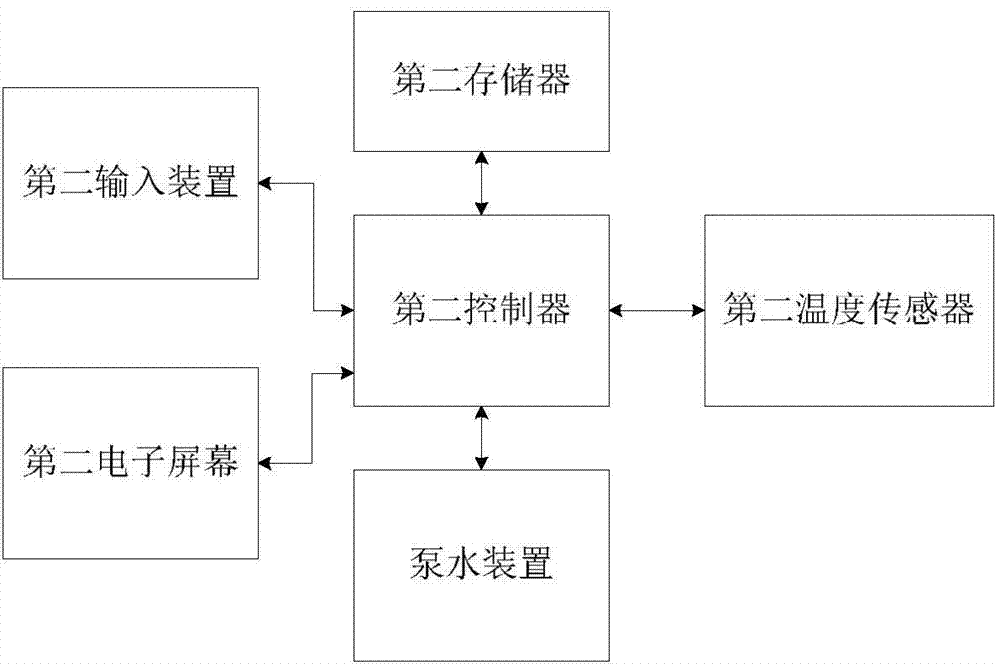

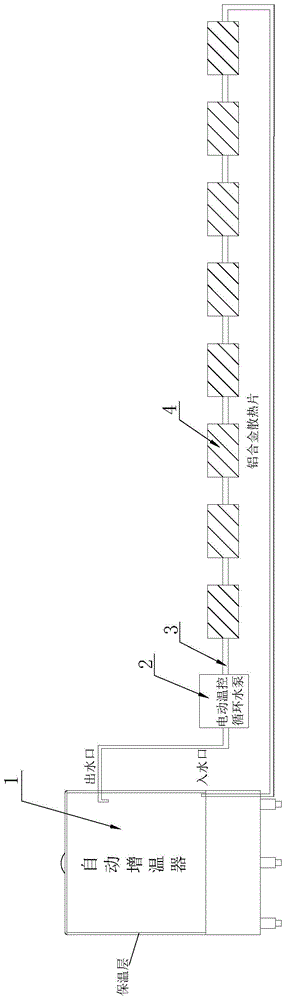

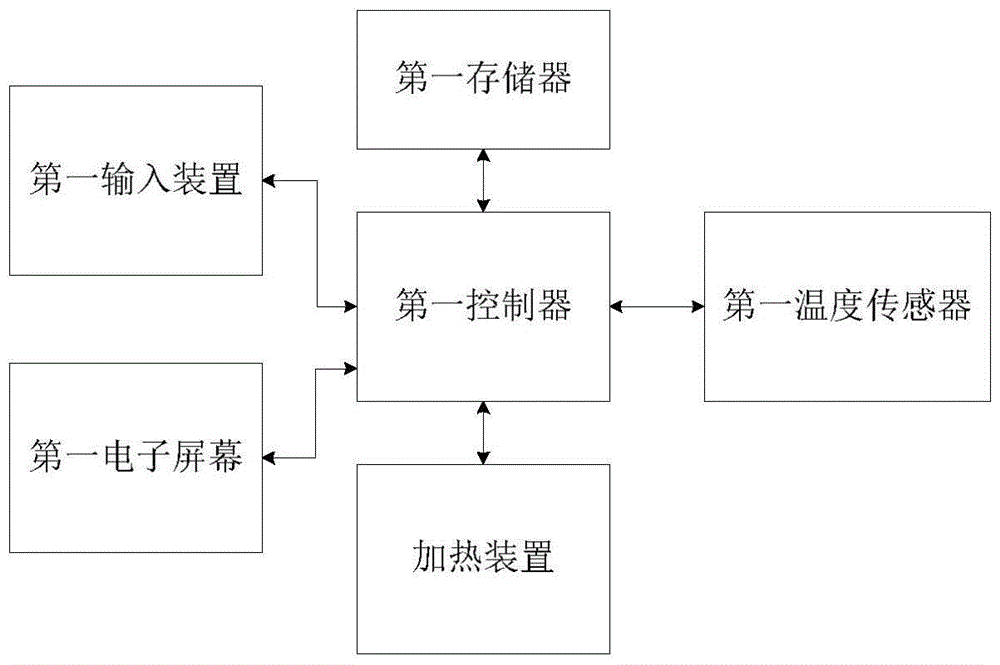

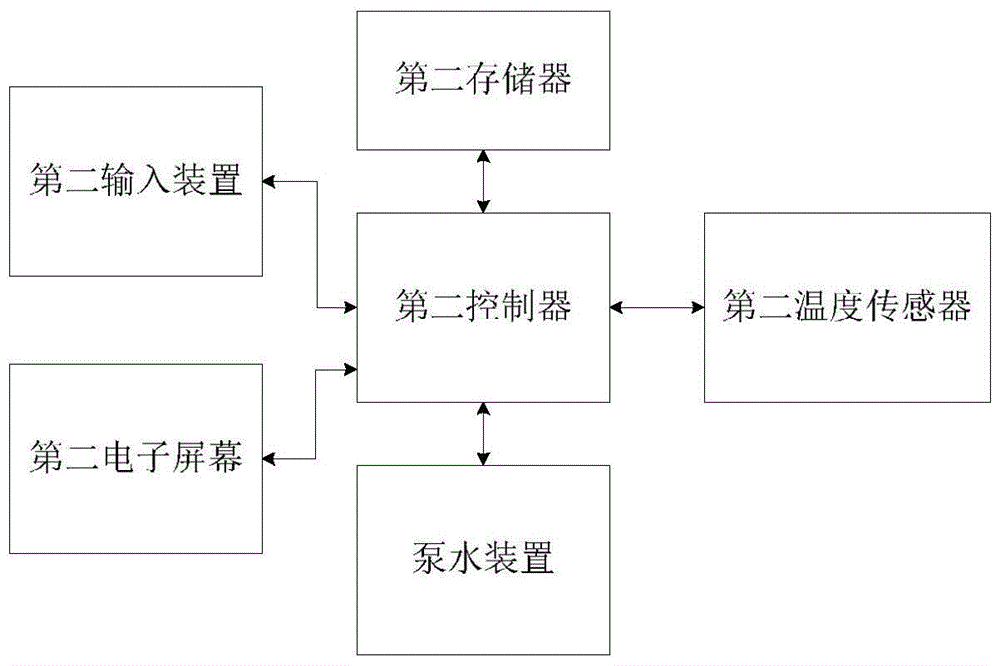

Full-automatic low-energy-consumption warming system of greenhouse

ActiveCN104488610ANo need to addNo pollution in the processClimate change adaptationSaving energy measuresWater useTemperature control

The invention discloses a full-automatic low-energy-consumption warming system of a greenhouse. The full-automatic low-energy-consumption warming system comprises an electric temperature control circulating water pump, a water conveying pipe, heat radiation sheets and an automatic warming device with a heat preservation function, wherein the automatic warming device is provided with a liquid capacity cavity, a water outlet and a water inlet; the water outlet of the automatic warming device, the electric temperature control circulating water pump, the plurality of heat radiation sheets and the water inlet are connected in sequence by the water conveying pipe to form a heat-transfer cycle loop; heat absorption coatings coat the outer parts of the heat radiation sheets. The starting temperature of repeatedly heating a heat transfer medium is very high through the heat preservation function of the automatic warming device and the heat absorption function of the heat radiation sheets coated with heat absorption materials, so that the energy consumption is extremely saved, the energy efficiency is high and the warming cost is saved. Overall, the full-automatic low-energy-consumption warming system has the advantages of energy conservation, environment friendliness and no pollution, uniformity in warming, low cost and high energy efficiency, full-automatic warming, water conservation, and flexibility and convenience for setting, and can be widely popularized and applied.

Owner:李众彻

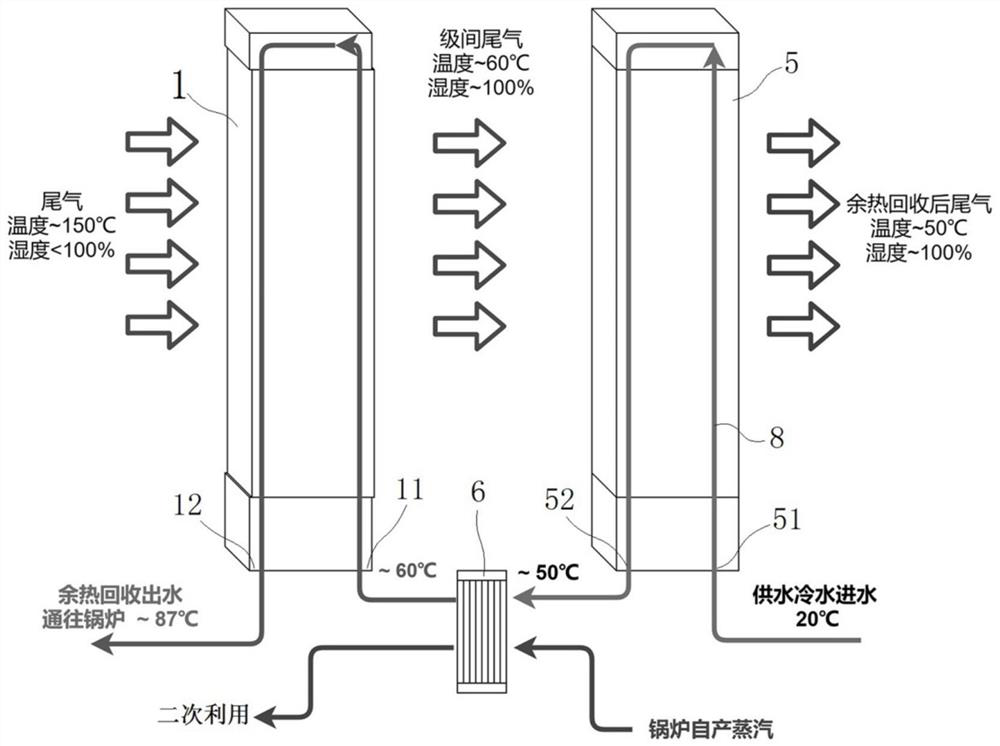

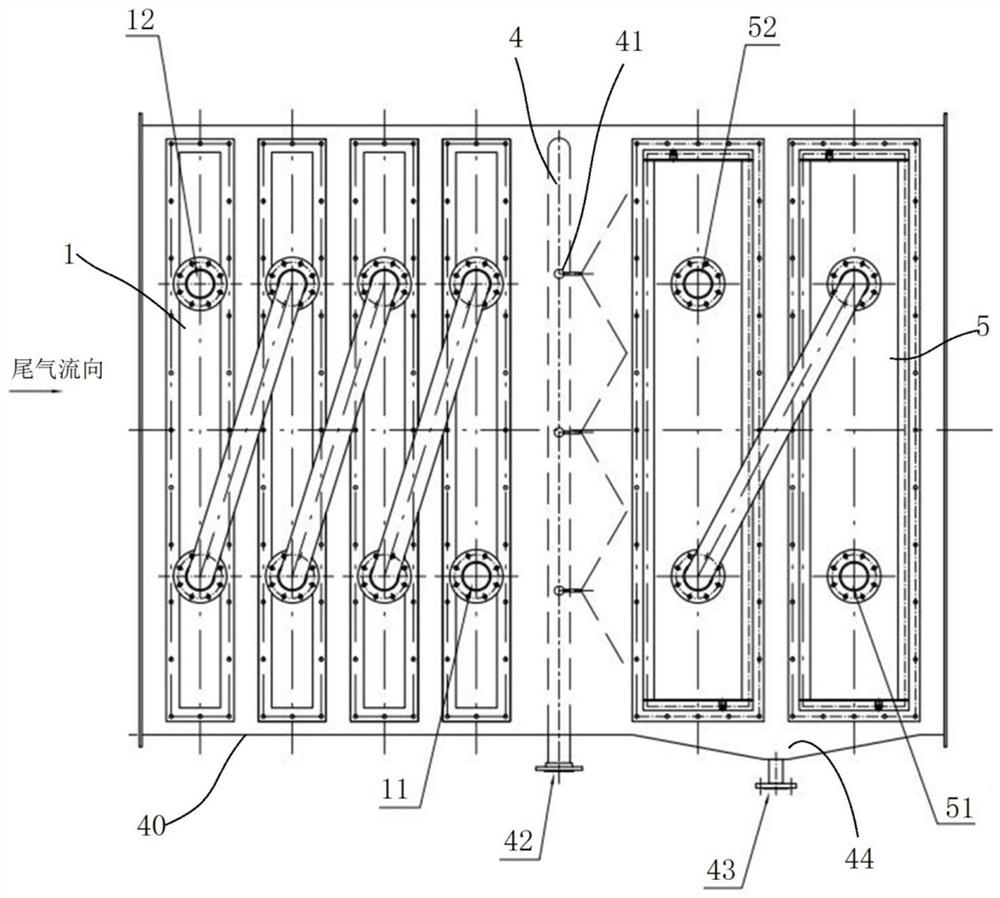

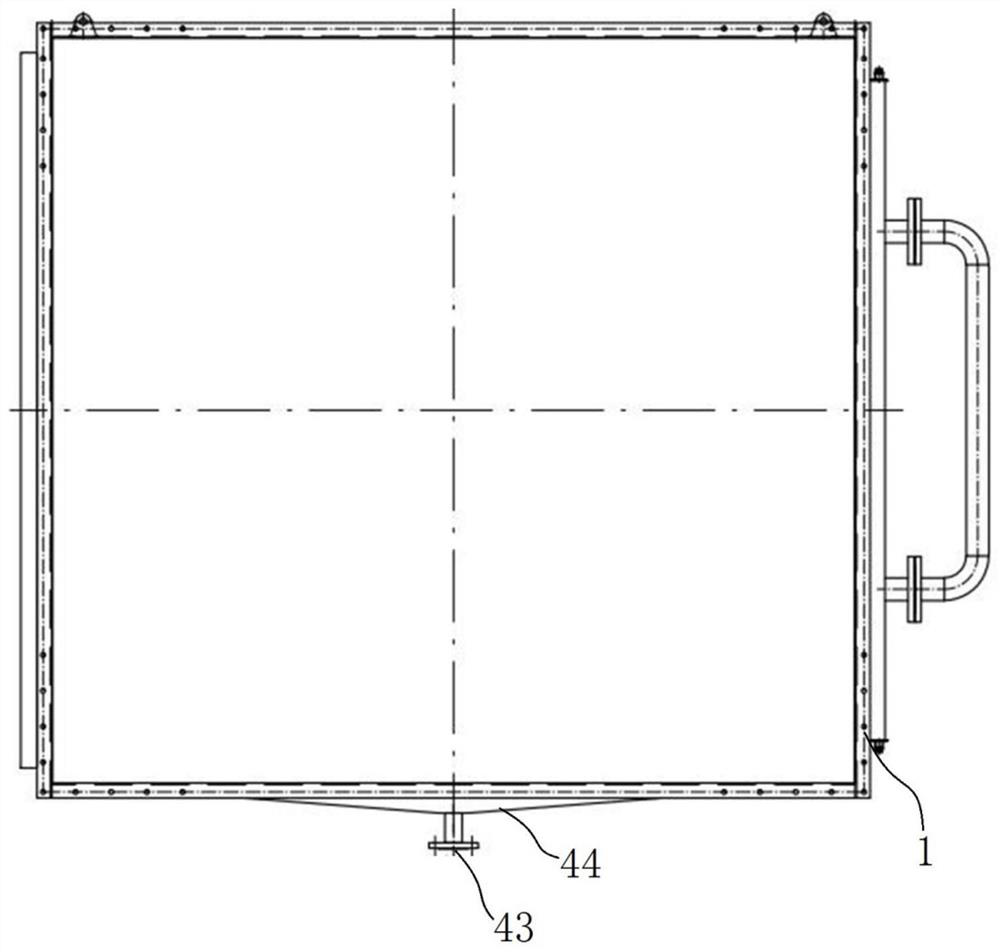

Waste heat recovery system, boiler system and waste heat recovery method

PendingCN112879895AIncrease profitRaise the starting temperatureWaste gas energyCombustion technology mitigationFlueCorrosion resistant

The invention relates to a waste heat recovery system, a boiler system and a waste heat recovery method. The waste heat recovery system comprises a first heat exchanger and a second heat exchanger which are sequentially arranged in a flue, wherein the first heat exchanger is an air-water heat exchanger made of a common material; the second heat exchanger is an air-water heat exchanger made of a corrosion-resistant material; a plate-type third heat exchanger is arranged between the two heat exchangers; a first heat exchange medium sequentially flows through the second heat exchanger, the third heat exchanger and the first heat exchanger, exchanges heat with the flue gas in the second heat exchanger and the first heat exchanger and exchanges heat with steam introduced into the boiler system in the third heat exchanger; a temperature control module is arranged to control the temperature of a first heat exchange medium in the first heat exchanger to be within a set temperature range slightly higher than the dew point temperature, so that water vapor in the flue gas cannot be condensed on the surface of the first heat exchanger and can be concentrated on the surface of the second heat exchanger; and good corrosion resistance is achieved on the premise of efficient heat exchange, and the overall cost is low.

Owner:SHANGHAI DONGRUN HEAT EXCHANGE EQUIP MFG

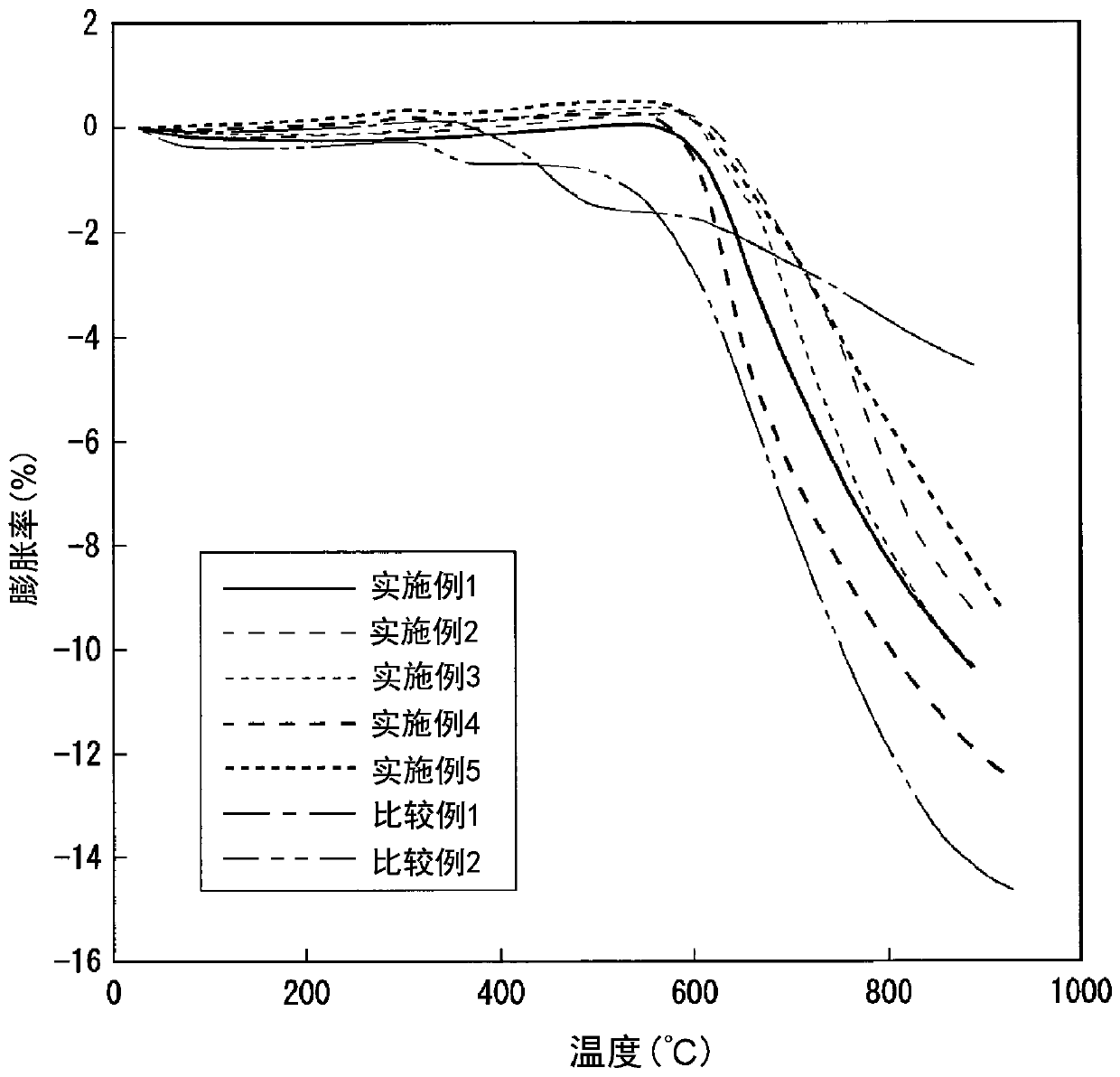

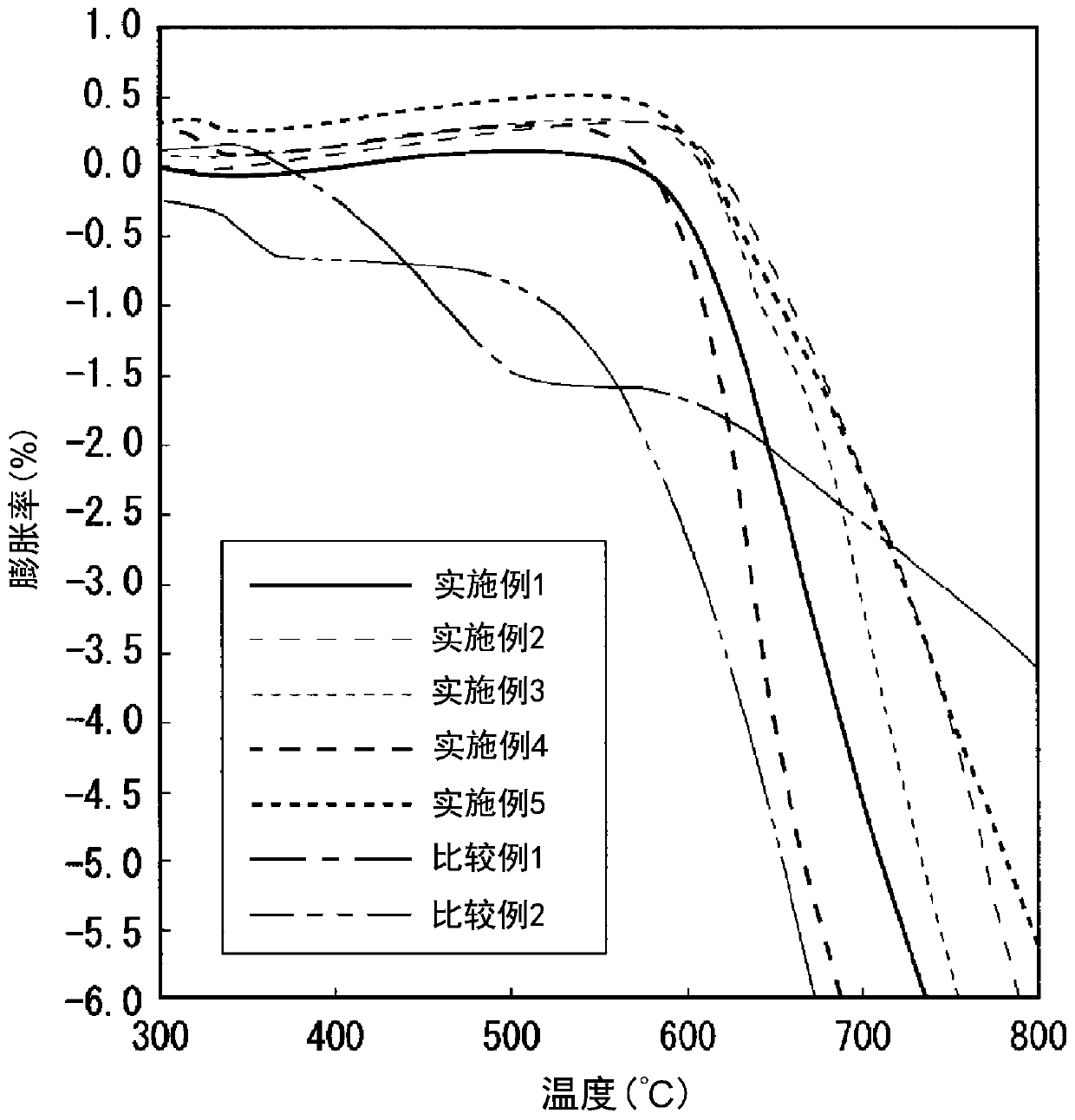

Copper powder and method for manufacturing same

PendingCN110114174ASmall particle sizeReduce oxygen contentConductive layers on insulating-supportsTransportation and packagingHydrogen atmosphereCopper

Provided are an inexpensive copper powder and a method for manufacturing the same, the copper powder having a low oxygen content despite having a small particle diameter, and the copper powder havinga high shrinkage initiation temperature when heated. In the present invention, high-pressure water is blown in a non-oxidizing atmosphere into molten copper heated to a temperature 250-700 DEG C (preferably 350-650 DEG C, and more preferably 450-600 DEG C) higher than the melting point of copper while the molten copper is dropped, and the molten copper is rapidly solidified, whereby a copper powder having an average particle diameter of 1-10 [mu]m, a crystalline diameter Dx(200) in the (200) face of 40 nm or greater, and an oxygen content of 0.7% by mass or less is manufactured.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Pig manure fermentation site construction and fermentation method

InactiveCN110698231AEfficient dischargeInhibit mildewBio-organic fraction processingClimate change adaptationBiotechnologyPig farms

The invention discloses a pig manure fermentation site construction and fermentation method, and belongs to the technical field of pig manure fermentation. The pig manure fermentation site construction and fermentation method comprises the following steps: pouring the ground of a pig manure stacking field to form an inclination of 5 degrees, building a small ditch with the width of 25cm and the depth of 20cm at the edge of the lower side of the ground, so that pretreated material exudate flows into a urine storage tank through the small ditch, urine leached from pig manure is effectively discharged, and the situation of mildewing during fermentation is prevented; determining the construction size of a fermentation workshop of a ten thousand pig farms to be 20-30m long, 7.5-8m wide and 3.5mhigh, selecting a sunshine plate as a cover top, so that the room temperature in the fermentation workshop is increased after penetrating of solar heat energy through the sunshine plate, increasing of the initial temperature of fermentation materials is accelerated, wherein ventilation holes are reserved in the top so that gas such as water vapor generated during material fermentation can be dissipated and exhausted.

Owner:湖南明镜生物科技有限公司

Composite curing agent for MUF resin adhesive, and application of composite curing agent in production of medium-high density fiberboards

ActiveCN110499129ASolving pre-curing problemsImprove effectivenessNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesHexamethylenetetramineFirming agent

The invention belongs to the field of wood adhesives, relates to a curing agent, especially relates to a composite curing agent for an MUF resin adhesive. The composite curing agent comprises 15-35 wt% of ammonium persulfate, 20-28 wt% of hexamethylenetetramine, 18-27 wt% of p-toluenesulfonic acid and 18-27 wt% of ethanolamine. The invention also relates to an application of the composite curing agent for the MUF resin adhesive in the production of medium-high density fiberboards. The composite curing agent disclosed by the invention has an excellent latency and a high hydrogen ion release starting temperature, can promote rapid curing of the resin at a high temperature, and also has the advantages of excellent curing performance and long working life. The curing agent is blended with theadhesive to effectively prevent the pre-curing problem of the adhesive in pipeline airflow drying, and can rapidly release hydrogen ions in the high-temperature hot pressing process to rapidly cure the adhesive, so the comprehensive performances of the boards is improved, and the production efficiency is greatly improved.

Owner:大亚木业(肇庆)有限公司 +1

Composite curing agent for muf resin adhesive and its application in the production of medium and high density fiberboard

ActiveCN110499129BSolving pre-curing problemsImprove effectivenessNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolymer scienceMethyl benzene

Owner:大亚木业(肇庆)有限公司 +1

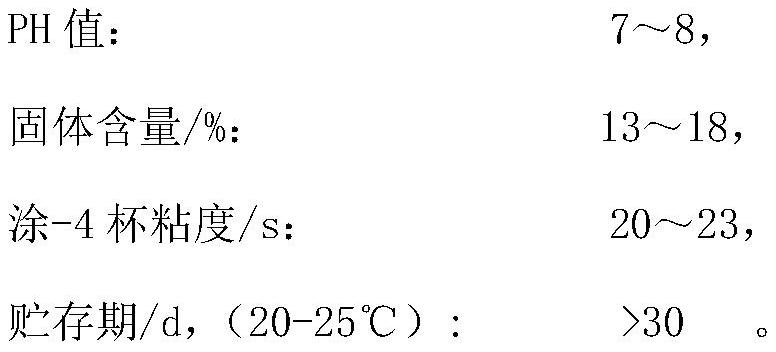

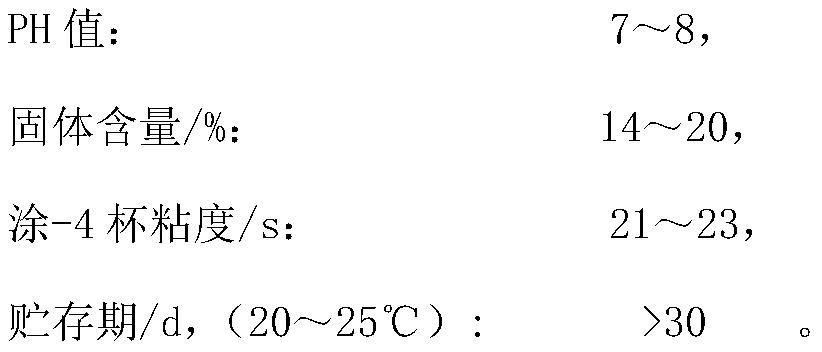

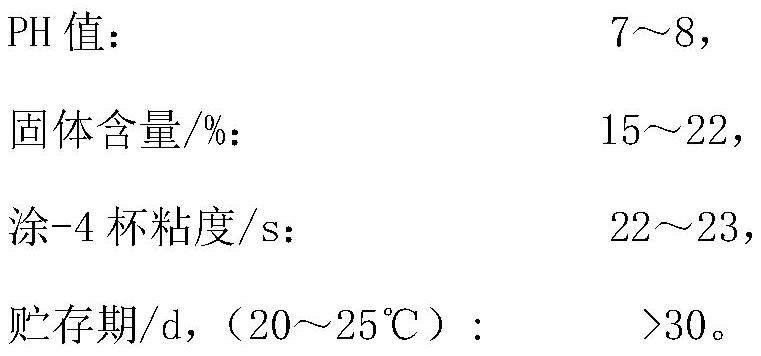

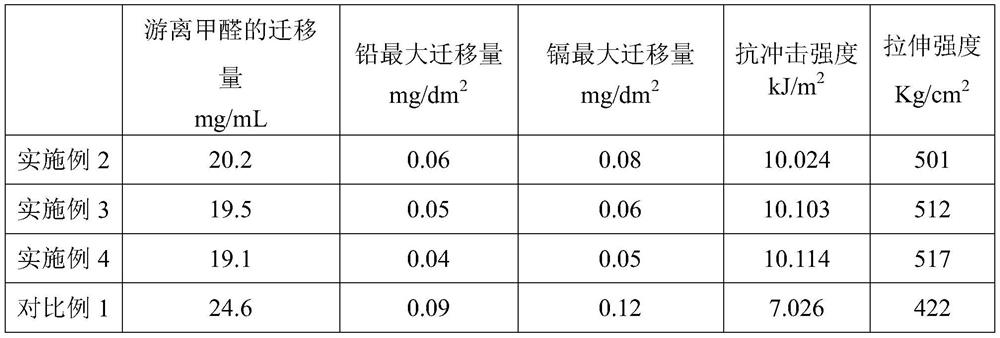

High-strength impact-resistant melamine resin tableware and preparation method thereof

The invention discloses high-strength impact-resistant melamine resin tableware and a preparation method thereof. The high-strength impact-resistant melamine resin tableware is prepared from the following raw materials in parts by weight: 60 to 75 parts of melamine-formaldehyde resin, 16 to 22 parts of ethylene-methyl methacrylate copolymer powder, 25 to 33 parts of an elastomer, 5 to 8 parts of cellulose, 1.5 to 2.5 parts of zinc peroxide, 3 to 5 parts of aluminum borate whiskers, 3 to 5 parts of nano silicon dioxide, 2.5 to 3.5 parts of zinc stearate, 1 to 2 parts of triethanolamine and 1.5 to 2 parts of methylmalonic acid. The high-strength impact-resistant melamine resin tableware is high in impact strength, high in tensile strength, excellent in mechanical property, resistant to impact (impact), not prone to damage and cracking and the like; the migration volume of free formaldehyde is low, and the maximum migration volume of lead and cadmium is also low and is lower than the migration volume of free formaldehyde and the maximum migration volume of lead and cadmium in a comparison file 1, so that the tableware is healthy, environment-friendly and non-toxic; and in addition, the thermal decomposition initial temperature reaches 145 DEG C or above, the thermal decomposition initial temperature is high, and the heat resistance is good.

Owner:晋江市旭佰日用品有限责任公司

A kind of preparation method of lightweight polypropylene material

ActiveCN110054801BThe onset temperature of thermal decomposition increasesRaise the starting temperatureSodium bicarbonatePolymer science

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

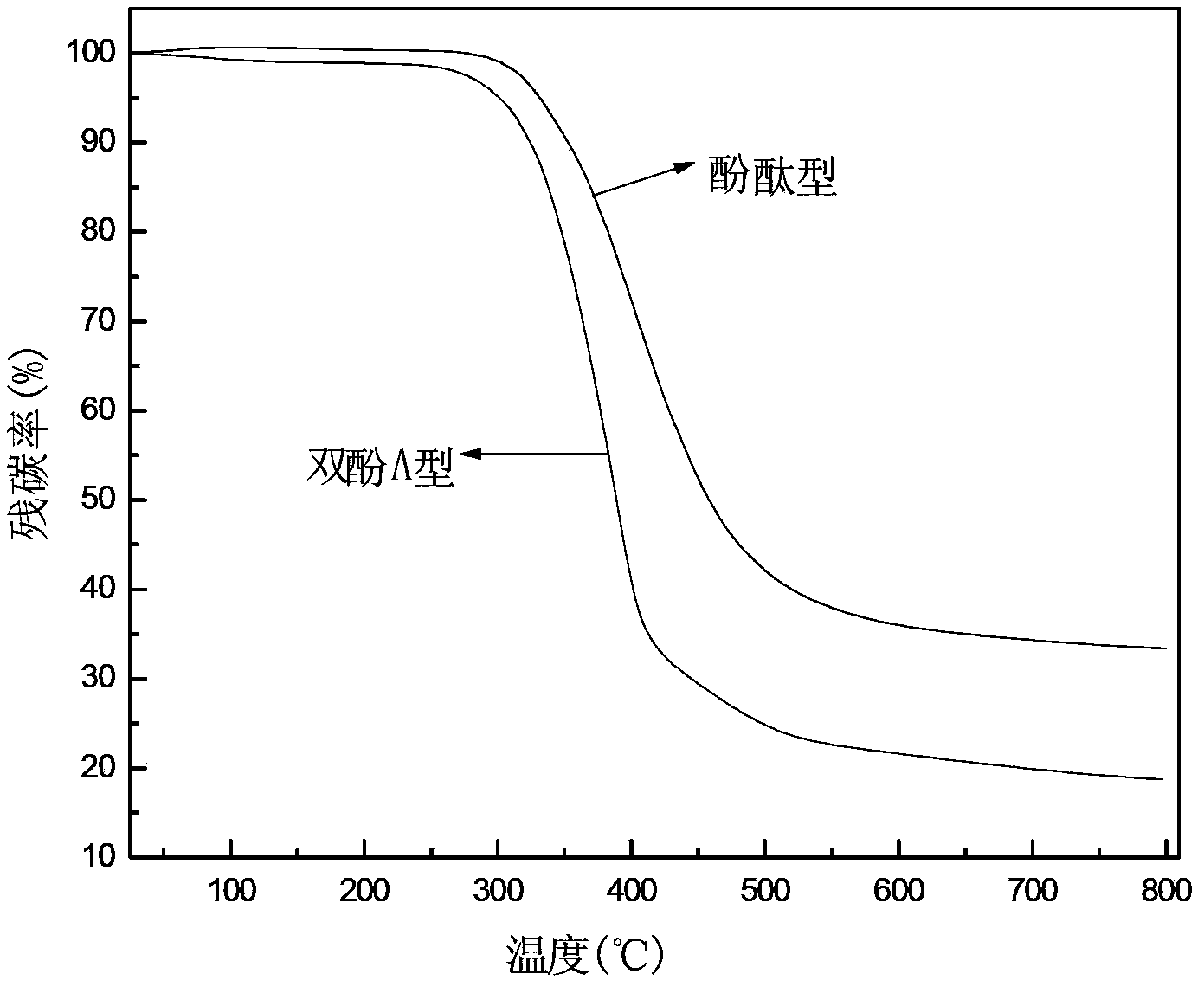

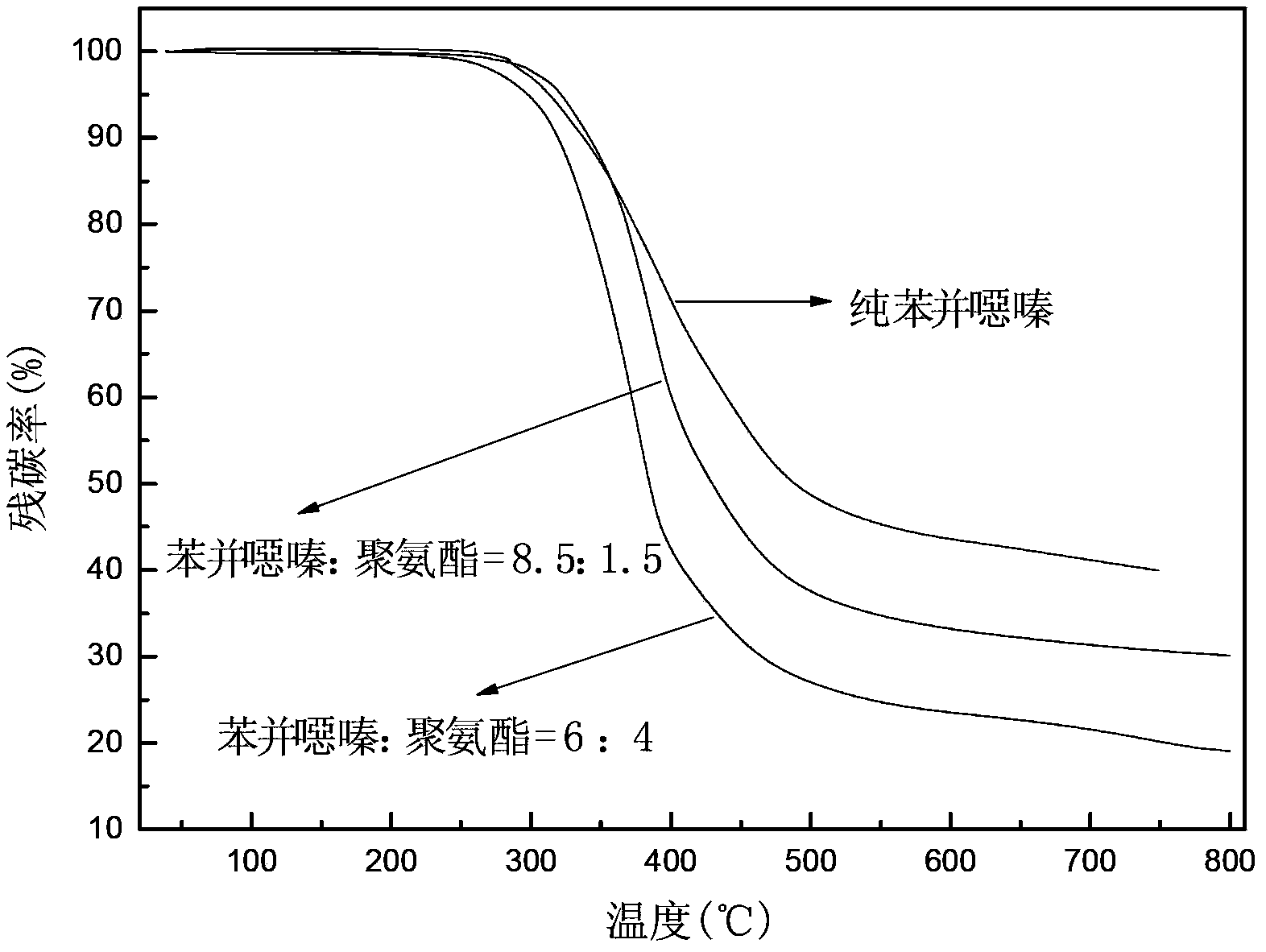

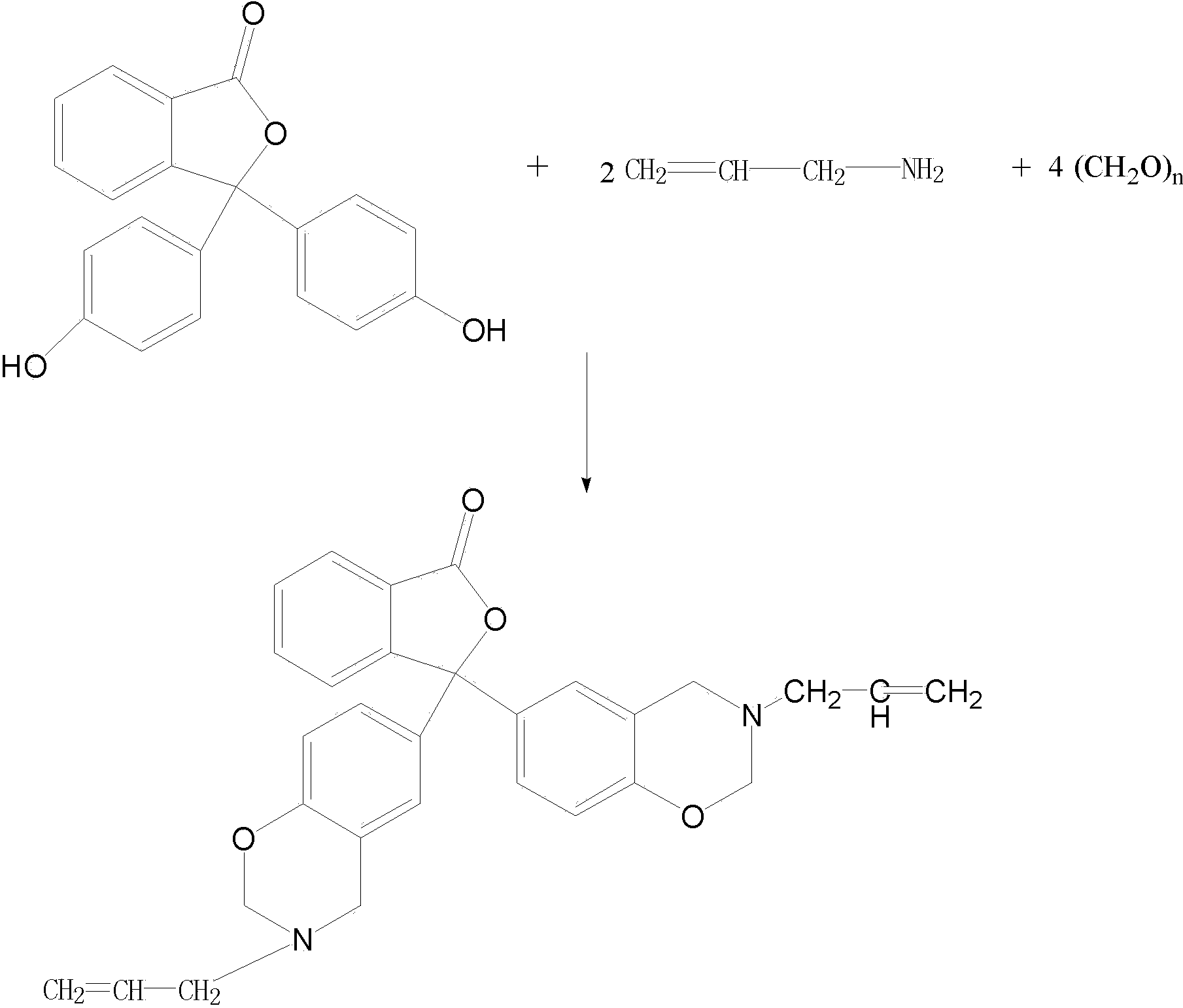

Preparation method of phenolphthalein allyl amine-type benzoxazine/polyurethane blend resin

The invention discloses a preparation method of phenolphthalein allyl amine-type benzoxazine / polyurethane blend resin. The preparation method comprises the following steps of: synthesising phenolphthalein allyl amine-type benzoxazine by virtue of a solvent method at first, and then synthesising the polyurethane prepolymer of phenol-blocked-NCO; dissolving the phenolphthalein allyl amine-type benzoxazine and the polyurethane prepolymer of phenol-blocked-NCO in acetone; adequately stirring to uniformly disperse the phenolphthalein allyl amine-type benzoxazine and the polyurethane prepolymer of phenol-blocked-NCO; performing vacuum drying treatment; and then performing program curing to obtain the blend resin. According to the preparation method, the brittleness of benzoxazine is improved by virtue of the good low temperature flexibility and processability of the polyurethane prepolymer, thus improving the processability of benzoxazine; and moreover, polyurethane can form a cross-linked network shape with benzoxazine during curing, thus increasing the cross-linking degree of benzoxazine, and then improving the thermodynamic property of benzoxazine to a certain extent.

Owner:HEFEI UNIV OF TECH

Acetic acid cracking equipment for preparing ketene

PendingCN114797681ARaise the starting temperatureReduce usagePyrolysis reactionsKetenes preparationHigh energyEvaporator

The acetic acid cracking device comprises a preheating section and a cracking section, the preheating section is composed of a preheating cavity and a first heat supply jacket, the bottom of the first heat supply jacket is connected with a natural gas inlet pipe and an air inlet pipe, and the lower section of the preheating cavity is connected with a metering pump and an acetic acid evaporator; the cracking section comprises a cracking cavity and a second heat supply jacket, the upper end of the cracking cavity is connected with a condensation pipe, and the bottom of the cracking cavity is communicated with the preheating cavity through a connecting pipe; a natural gas supplementing pipe and an air supplementing pipe are arranged at the lower end of the second heat supply jacket, a waste gas discharging pipe is arranged at the upper end of the second heat supply jacket, and the second heat supply jacket communicates with the first heat supply jacket through two symmetrically-arranged second connecting pipes. According to the invention, the problem of high energy consumption of the ketene process is solved, the mode of combining the first heat supply jacket and the second heat supply jacket is utilized, heat in the first heat supply jacket is fully utilized, the initial temperature of the second heat supply jacket is increased, and the use amount of natural gas is reduced.

Owner:湖州周吴鼎盛化工有限公司

Formaldehyde byproduct steam tail gas processor

InactiveCN108413418AImprove the problem of uniform mixingWell mixedIncinerator apparatusCombustionEngineering

The invention discloses a formaldehyde byproduct steam tail gas processor. The formaldehyde byproduct steam tail gas processor comprises a processor body; the processor body is provided with a hot water section, an upper tail gas air preheating section, a middle heat exchange section and a bottom combustion section in sequence from top to bottom; the upper tail gas air preheating section is provided with a preheating front air inlet at the upper part of one side and a preheating back air outlet at the lower part; the upper tail gas air preheating section is provided with a preheating front tail gas inlet at the upper part of the other side and a preheating back tail gas outlet at the lower part; a steam exhaust port is formed in the upper part of one side of a middle heat exchange section,and a hot water inlet is formed in the lower part; an air inlet is formed in one side of a bottom combustion section; and a tail gas inlet is formed in the other side of the bottom combustion section. Compared with the prior art, the formaldehyde byproduct steam tail gas processor adopts automatic operation without needing special operators, and is convenient to operate.

Owner:无锡市惠浩塑胶机械有限公司

The preparation method of reinforced modified PBT copolyester

ActiveCN104119519BHigh intrinsic viscosityImprove mechanical propertiesPolymer scienceEngineering plastic

The invention relates to a preparation method of enhanced modified PBT copolyester, which is a copolyester that can be used in the field of film and engineering plastics. Formic acid, inorganic crystallization nucleating agent, terephthalic acid or dimethyl terephthalate, and 1,4-butanediol are liquid-phase polymerized to obtain reinforced modified PBT polyester in one step. This method improves the mechanical properties and heat resistance of PBT, and can avoid the disadvantages of glass fiber blended modified PBT polyester, such as poor toughness, strong hygroscopicity, poor fluidity, high injection temperature and pressure, and serious equipment wear and tear.

Owner:SINOPEC YIZHENG CHEM FIBER +1

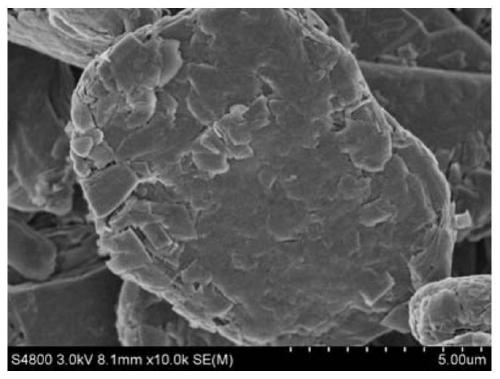

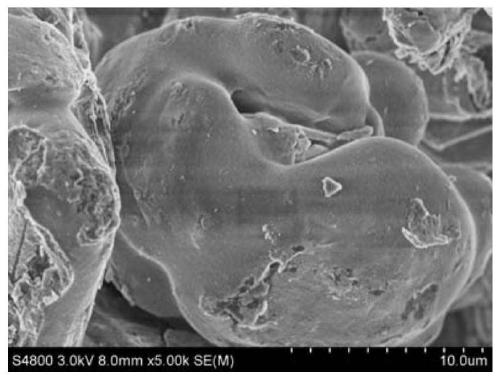

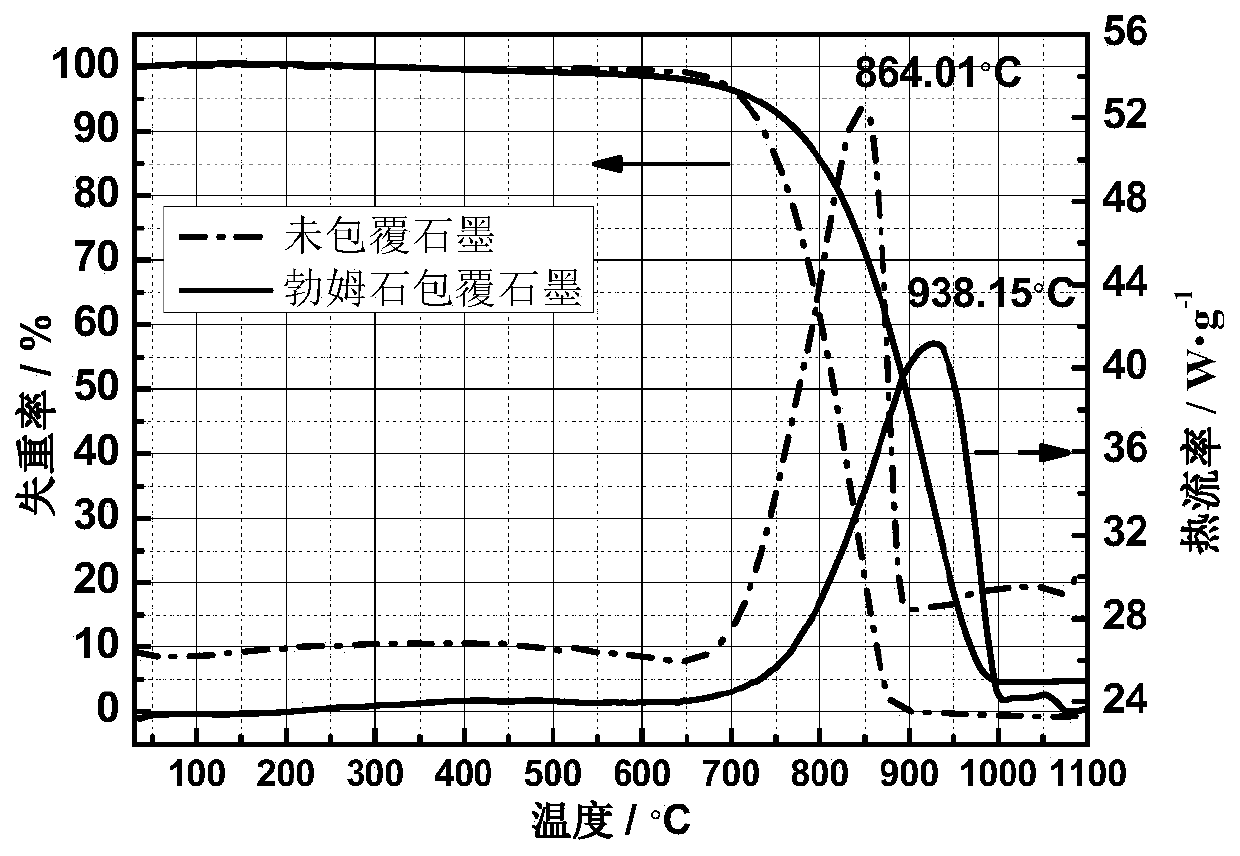

A kind of boehmite-coated graphite composite negative electrode material, its preparation method and application

ActiveCN108091856BUniform dense and complete coating effectLow priceSecondary cellsNegative electrodesElectrolytic agentElectrical battery

The invention relates to a boehmite covered graphite composite negative electrode material as well as a preparation method and application thereof to a lithium-ion battery. The composite negative electrode material comprises a graphite substrate which is used as an inner core, and a cladding layer which is formed by uniformly and continuously cladding boehmite type aluminum oxide on the surface ofthe inner core. The method comprises the following steps: 1) mixing the graphite substrate, a boehmite solution and water; 2) carrying out spray drying on an obtained mixture to obtain the boehmite covered graphite composite negative electrode material. The method provided by the invention has the advantages of low price of raw materials, simple and environment-friendly process and easiness for industrialization; the prepared covered graphite negative electrode material has stable performance; compared with an uncovered graphite substrate, the obtained composite material has the advantages ofhigh jolt ramming, high compaction, high wetting property, high pole piece peeling strength and low pole piece rebound performance. A boehmite covering layer is introduced, so that thermal reaction between electrolyte and graphite can be effectively inhibited and a thermal runaway risk caused by extreme conditions including battery short circuit and the like is prevented.

Owner:贝特瑞(四川)新材料科技有限公司

A high-speed direct-feeding and direct-rolling system and method for continuous casting of wire rods

ActiveCN106180192BReduce temperature lossAvoid damageWork cooling devicesMetal rolling arrangementsEngineeringSteel bar

The invention provides a high-speed direct-delivery direct-rolling system and method for wire bar continuously-cast slabs. The system comprises a small-radius high-drawing-speed continuous casting machine, a fast hydraulic shear, a cut slab roller table, a slab discharging roller table, a grouped cast slab hot-delivery roller table, a single-cast-slab delivery roller table and a wire bar rolling mill which are sequentially and compactly arranged. A transverse steel transfer machine is arranged between the slab discharging roller table and the grouped cast slab hot-delivery roller table. A steel bar splitting machine is arranged between the grouped cast slab hot-delivery roller table and the single-cast-slab delivery roller table. Cast slabs are gathered into groups on the slab discharging roller table and transferred into the grouped cast slab hot-delivery roller table from the transverse steel transfer machine. The grouped cast slabs are split into single cast slabs through the steel bar splitting machine and delivered to the wire bar rolling mill through the single-cast-slab delivery roller table for rolling. The small-radius high-drawing-speed continuous casting machine is efficient in continuous casting, the drawing-out temperature of the cast slabs is high, the shape of the cast slabs is regular, and the temperature loss is small; and the cutoff speed of the cast slabs is high, and the initial temperature of the cast slabs is high. All streams of the cast slabs are grouped at a high speed through the transverse steel transfer machine and delivered in a grouped manner through the hot-delivery roller table for steel rolling, and by means of the manner, the temperature drop is extremely small in the delivery process of the cast slabs.

Owner:CISDI ENG CO LTD

A fully automatic low-energy-consumption heating method for greenhouses

ActiveCN104488611BNo need to addNo pollution in the processClimate change adaptationRenewable energy machinesHigh energyEngineering

The invention discloses a full-automatic low-energy-consumption warming method of a greenhouse. The full-automatic low-energy-consumption warming method comprises the following steps: mounting a warming system, setting, keeping heat, heating by solar energy, electrically heating, and carrying out heat-transfer cycle. The warming system comprises a warming device with heating and heat preservation functions, an electric temperature control circulating water pump and a plurality of heat radiation sheets coated with heat absorption coatings, wherein the warming device, the electric temperature control circulating water pump and the heat radiation sheets are connected in sequence to form a heat-transfer cycle loop. The starting temperature of repeatedly heating a heat transfer medium is very high through the heat preservation function of the warming device and the heat absorption function of the heat radiation sheets coated with heat absorption materials, so that the energy consumption is extremely saved, the energy efficiency is high and the warming cost is saved. Overall, the full-automatic low-energy-consumption warming method has the advantages of energy conservation, environment friendliness and no pollution, uniformity in warming, low cost and high energy efficiency, full-automatic warming, water conservation, and flexibility and convenience for setting, and can be widely popularized and applied.

Owner:杨春杰

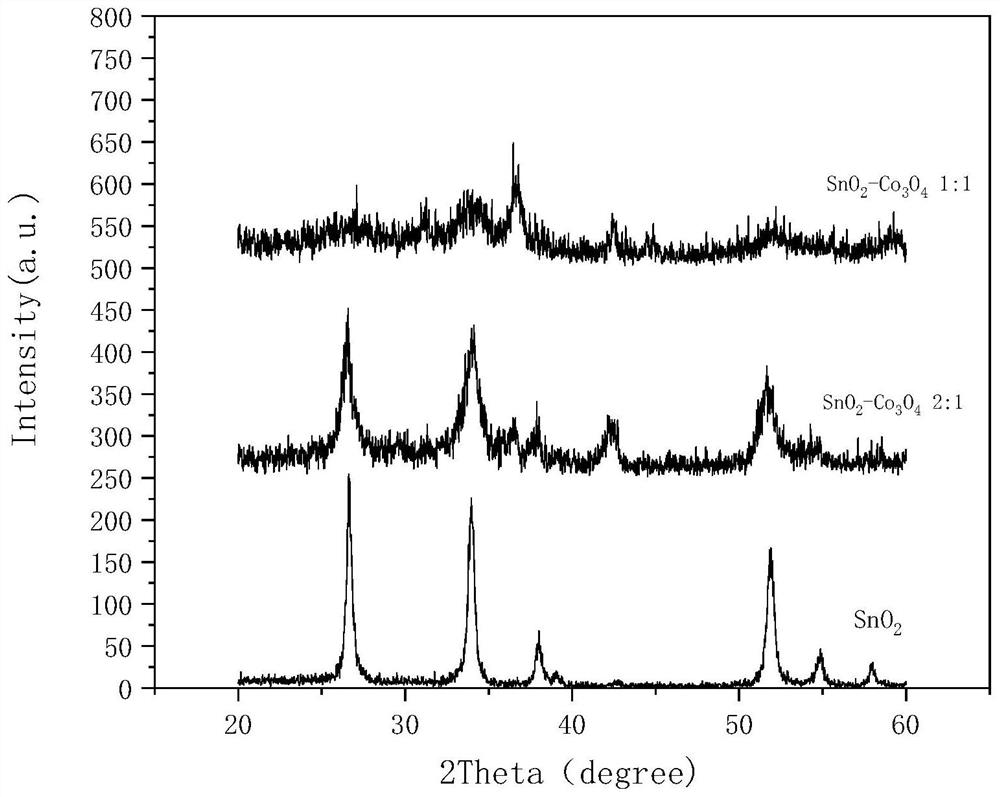

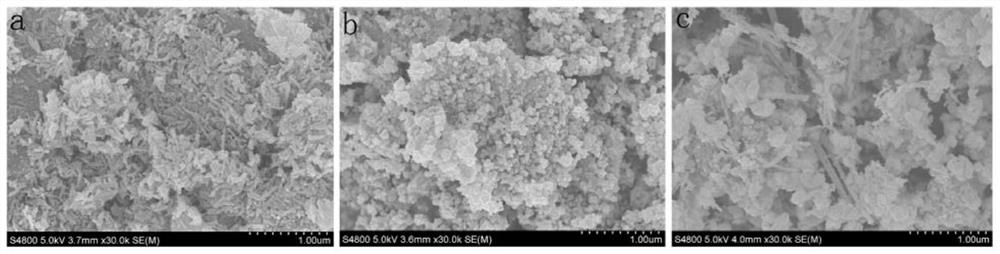

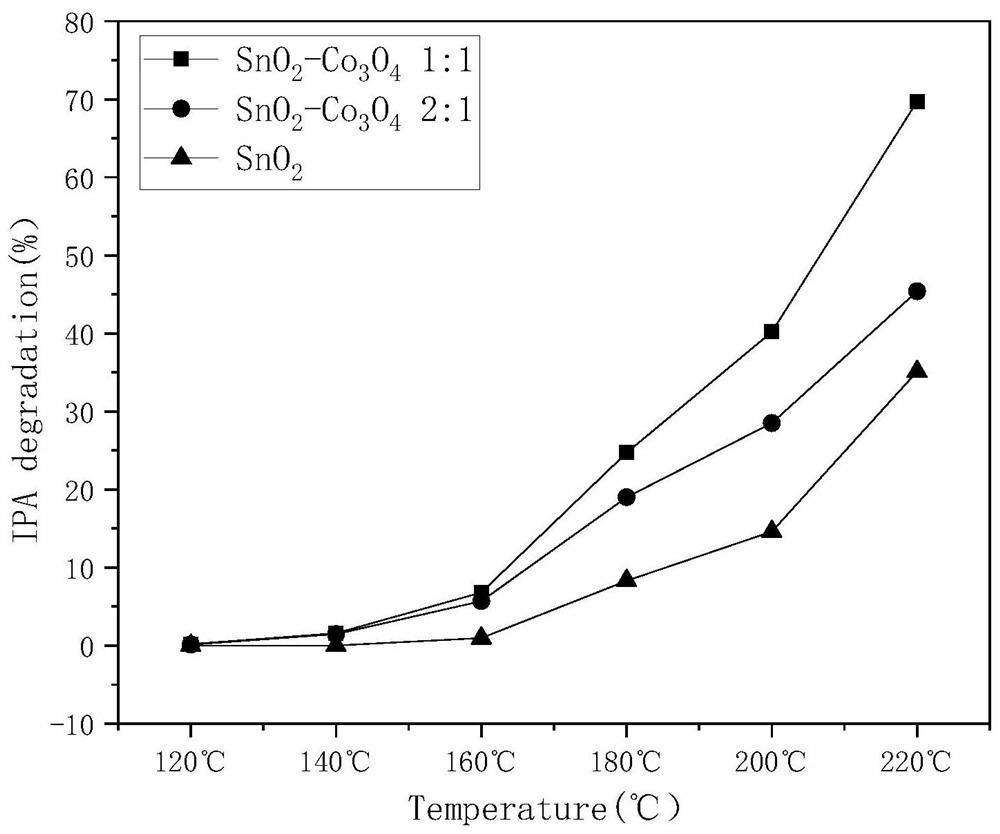

Preparation method of tin oxide composite tricobalt tetroxide photothermal catalyst and its application in thermal catalysis

ActiveCN111111677BImprove photocatalytic activityRaw materials are cheap and easy to getDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystOxygen vacancy

The invention discloses a preparation method of a tin oxide composite tricobalt tetroxide photothermal catalyst and its application in thermal catalysis. Dissolve tricobalt tetroxide in the mixed solution of organic solvent and water, stir to dissolve, add tin salt and surfactant, continue to stir until completely dissolved; place the obtained mixture in a hydrothermal reaction kettle, and cool to room temperature after hydrothermal reaction , centrifuged, washed, and dried to obtain a precursor; the obtained precursor was calcined at 300-600° C. for 3-5 hours at a high temperature to obtain a tin oxide composite tricobalt tetroxide photothermal catalyst. The tin oxide composite tricobalt tetroxide oxygen-containing defect material prepared by the method of the present invention improves the SnO 2 Defects with low thermocatalytic activity lead to the generation of oxygen vacancies. Oxygen vacancies can trap electrons or holes generated by thermal excitation, effectively inhibit carrier recombination, and thus improve thermal catalytic activity. This method is low in cost and high in yield. It can degrade organic pollutants under dark and high temperature conditions.

Owner:LIAONING UNIVERSITY

Method for modifying epoxy resin through amino-terminated hyperbranched polymer-grafted graphene oxide

The invention discloses a method for modifying epoxy resin through amino-terminated hyperbranched polymer-grafted graphene oxide. The method comprises the following steps: preparing graphite oxide from flake graphite utilized as a raw material by adopting a Hummers oxidation method, adding the graphite oxide into a beaker, adding distilled water and forming a graphene oxide mixed solution by virtue of ultrasonic waves; stirring for dissolving triethylene tetramine in N,N-dimethylformamide, raising the temperature to 55-65 DEG C, dropwise adding a mixed solution of methyl methacrylate and methanol, continuously raising the temperature to 80-120 DEG C and reacting for 6-10 hours to get an amino-terminated hyperbranched polymer; further adding the graphene oxide mixed solution and NaOH, regulating the pH value to be 5-10, performing ultrasonic dispersion for 2-8 hours at the temperature of 80-120 DEG C, evaporating the methanol, cooling to room temperature, adding water to precipitate a product, drying to get the amino-terminated hyperbranched polymer-grafted graphene oxide capable of toughening and modifying the epoxy resin. The method disclosed by the invention is wide in raw material source, simple in preparation process, pollution-free, lower in cost and beneficial to industrial large-scale production.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Backflow preheating water supply system

PendingCN113899075ARaise the starting temperatureLow costFluid heatersWater/sewage treatmentWater flowEngineering

The invention provides a backflow preheating water supply system, which is characterized in that a water tank of the water supply system supplies water to a balanced reservoir through a water pump and supplies water to a water outlet switch and a heater from the balanced reservoir through the water pump, the water pump is directly communicated with the bottom of the balanced reservoir through a water feeding pipe, and the balanced reservoir is communicated with the bottom of the heater; the balanced reservoir comprises a backflow cavity and a water level balance cavity; the backflow cavity is arranged on an overflow port at the top of the heater and is communicated with the overflow port; wherein the horizontal height of the water level balance cavity is equal to that of the heater, a first water level baffle is arranged in the water level balance cavity, and the first water level baffle is divided into a first area and a second area; and the height of the first water level baffle is lower than that of the overflow port in the horizontal direction. According to the backflow preheating water supply system provided by the invention, multiple preheating backflow can be completed, heated water flows back to the reservoir, meanwhile, the initial temperature of the reservoir is increased in a repeated backflow mode, boiling and expanding water in the heater can only enter the backflow cavity through the overflow port of the heater, it is guaranteed that outlet water is really boiling water, and the temperature is higher.

Owner:SHENZHEN ANGEL DRINKING WATER IND GRP

Cross-linked polyolefin foam material with high temperature resistance and preparation method thereof

ActiveCN109251388BRaise the starting temperatureLow heat shrinkageHigh energy electron irradiationPolymer science

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com