High-strength impact-resistant melamine resin tableware and preparation method thereof

A melamine resin and impact-resistant technology, which is applied in the field of high-strength impact-resistant melamine resin tableware and its preparation, can solve the problems of inability to meet the use requirements of high-end tableware, high migration of free formaldehyde, poor comprehensive mechanical properties, etc., and achieve saving Labor and equipment costs, low migration, and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

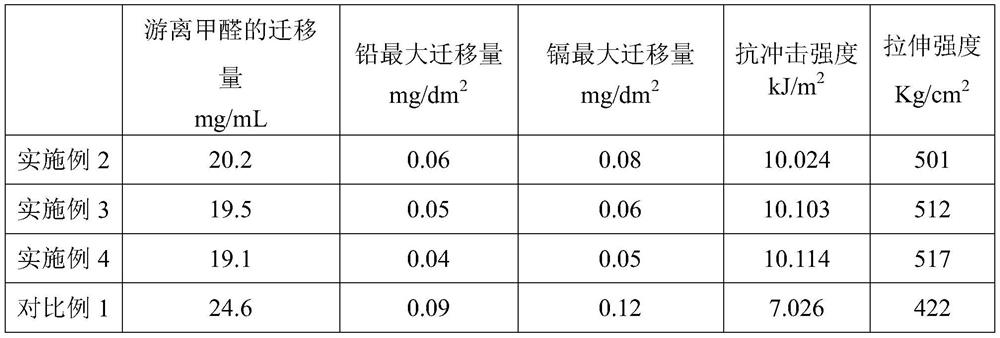

Examples

Embodiment 1

[0053] A high-strength impact-resistant melamine resin tableware is made of the following raw materials in parts by weight:

[0054] 60-75 parts of melamine-formaldehyde resin,

[0055] 16-22 parts of ethylene-methyl methacrylate copolymer powder,

[0056] 25-33 parts of elastomer,

[0057] 5-8 parts of cellulose,

[0058] 1.5-2.5 parts of zinc peroxide,

[0059] 3-5 parts of aluminum borate whiskers,

[0060] 3-5 parts of nano silicon dioxide,

[0061] 2.5-3.5 parts of zinc stearate,

[0062] 1-2 parts of triethanolamine,

[0063] 1.5-2 parts of methylmalonic acid.

[0064] In this embodiment, the high-strength impact-resistant melamine resin tableware is preferably, but not limited to, made of raw materials including the following parts by weight:

[0065] 68 parts of melamine-formaldehyde resin,

[0066] 19 parts of ethylene-methyl methacrylate copolymer powder,

[0067] 29 parts of elastomer,

[0068] 6.5 parts of cellulose,

[00...

Embodiment 2

[0086] A high-strength impact-resistant melamine resin tableware is made of the following raw materials in parts by weight:

[0087] 60 parts of melamine-formaldehyde resin,

[0088] 16 parts of ethylene-methyl methacrylate copolymer powder,

[0089] 25 parts of elastomer,

[0090] 5 parts of cellulose,

[0091] 1.5 parts of zinc peroxide,

[0092] Aluminum borate whiskers 3 parts,

[0093] Nano silicon dioxide 3 parts,

[0094] Zinc stearate 2.5 parts,

[0095] 1 part of triethanolamine,

[0096] 1.5 parts of methylmalonic acid.

[0097] In this embodiment, the melamine-formaldehyde resin is melamine-formaldehyde resin powder with a particle size of 3000 mesh.

[0098] In this embodiment, the particle size of the ethylene-methyl methacrylate copolymer powder is 3000 mesh.

[0099] In this embodiment, the elastomer is a mixture of ethylene acrylate elastomer and ethylene-octene copolymer.

[0100] In this embodiment, the mass ratio of the ethylene acrylate elastomer ...

Embodiment 3

[0108] A high-strength impact-resistant melamine resin tableware is made of the following raw materials in parts by weight:

[0109] 75 parts of melamine-formaldehyde resin,

[0110] 22 parts of ethylene-methyl methacrylate copolymer powder,

[0111] 33 parts of elastomer,

[0112] 8 parts of cellulose,

[0113] Zinc peroxide 2.5 parts,

[0114] Aluminum borate whiskers 5 parts,

[0115] Nano silicon dioxide 5 parts,

[0116] Zinc stearate 3.5 parts,

[0117] 2 parts of triethanolamine,

[0118] 2 parts methylmalonic acid.

[0119] In this embodiment, the melamine-formaldehyde resin is melamine-formaldehyde resin powder with a particle size of 4000 mesh.

[0120] In this embodiment, the particle size of the ethylene-methyl methacrylate copolymer powder is 4000 mesh.

[0121] In this embodiment, the elastomer is a mixture of ethylene acrylate elastomer and ethylene-octene copolymer.

[0122] In this embodiment, the mass ratio of the ethylene acrylate elastomer to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com