Patents

Literature

289 results about "Methacrylate copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methacrylic acid - methyl methacrylate copolymer (1:1), also known as Methacrylic Acid Copolymer, Type A – NF, is an excipient used in pharmaceutical manufacturing. It is a solid white powder with dissolution above pH of 6.0, and is used in enteric coatings for fast dissolution in the upper bowel, for granulation...

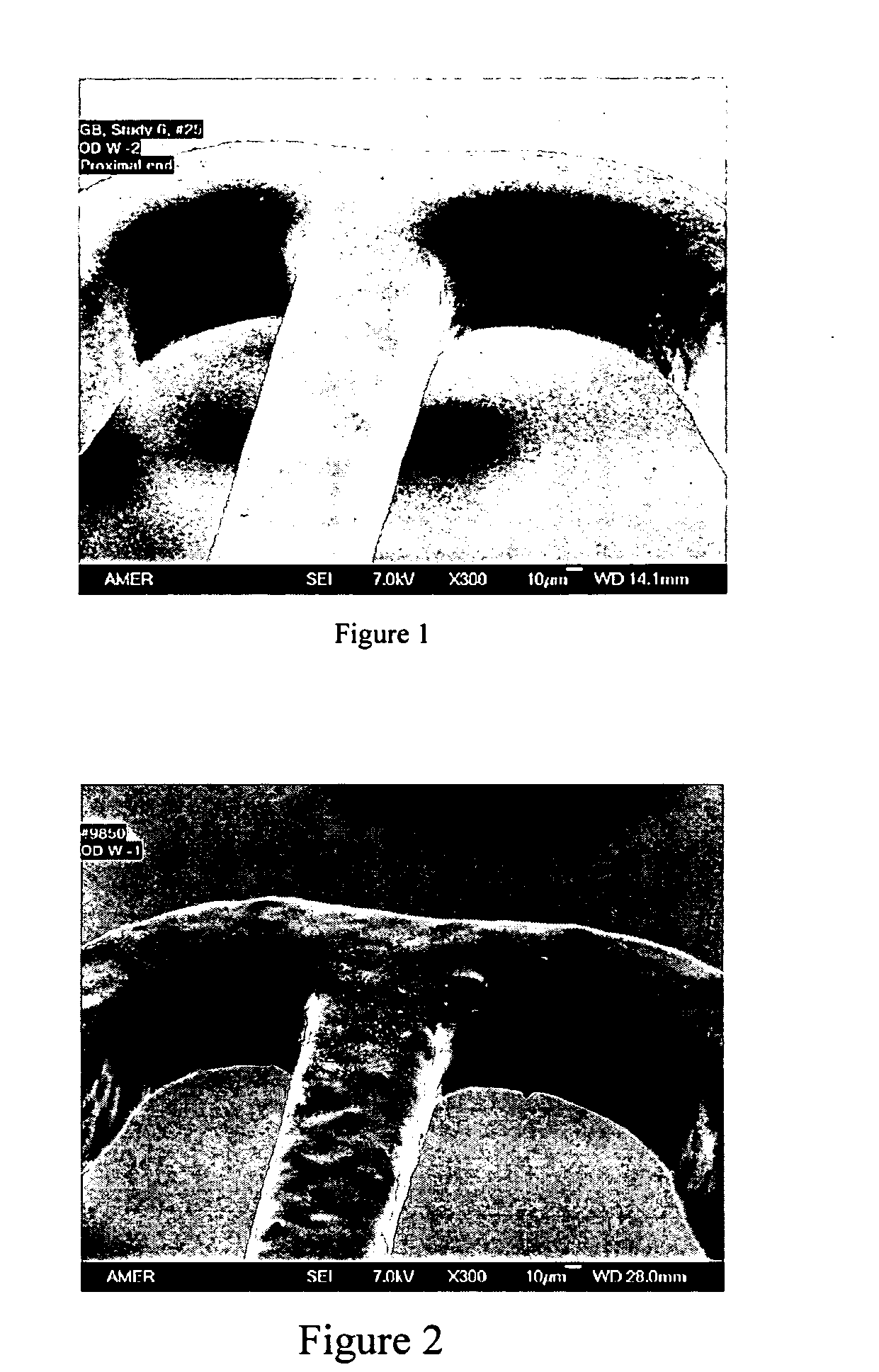

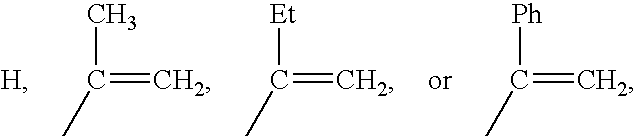

Methacrylate copolymers for medical devices

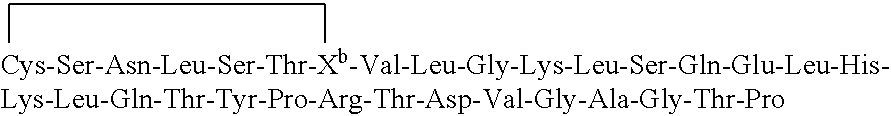

A polymer of hydrophobic monomers and hydrophilic monomers is provided. It is also provided a polymer blend that contains the polymer and another biocompatible polymer. The polymer or polymer blend and optionally a biobeneficial material and / or a bioactive agent can form a coating on an implantable device such as a drug delivery stent. The implantable device can be used for treating or preventing a disorder such as atherosclerosis, thrombosis, restenosis, hemorrhage, vascular dissection or perforation, vascular aneurysm, vulnerable plaque, chronic total occlusion, patent foramen ovale, claudication, anastomotic proliferation for vein and artificial grafts, bile duct obstruction, ureter obstruction, tumor obstruction, or combinations thereof.

Owner:ABBOTT CARDIOVASCULAR

Matrix for transdermal drug delivery

InactiveUS7097853B1Remove cleanHeavy loadMedical devicesAdhesive dressingsMacromonomerPressure sensitive

A transdermal drug delivery device involving a macromonomer-containing acrylate or methacrylate copolymer, a softener, and a drug. Also a pressure sensitive skin adhesive involving a macromonomer containing acrylate or methacrylate copolymer and a softener.

Owner:3M INNOVATIVE PROPERTIES CO

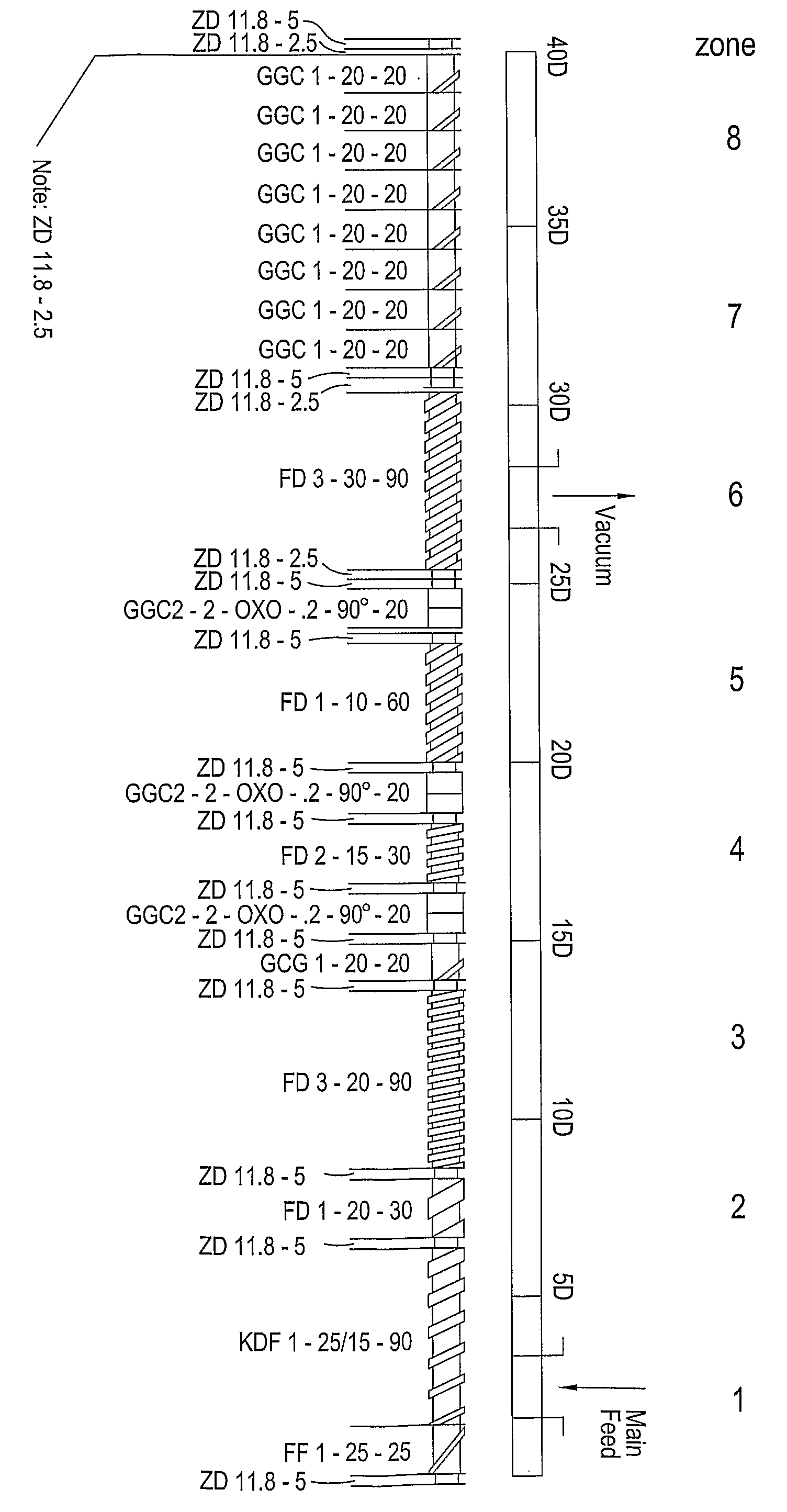

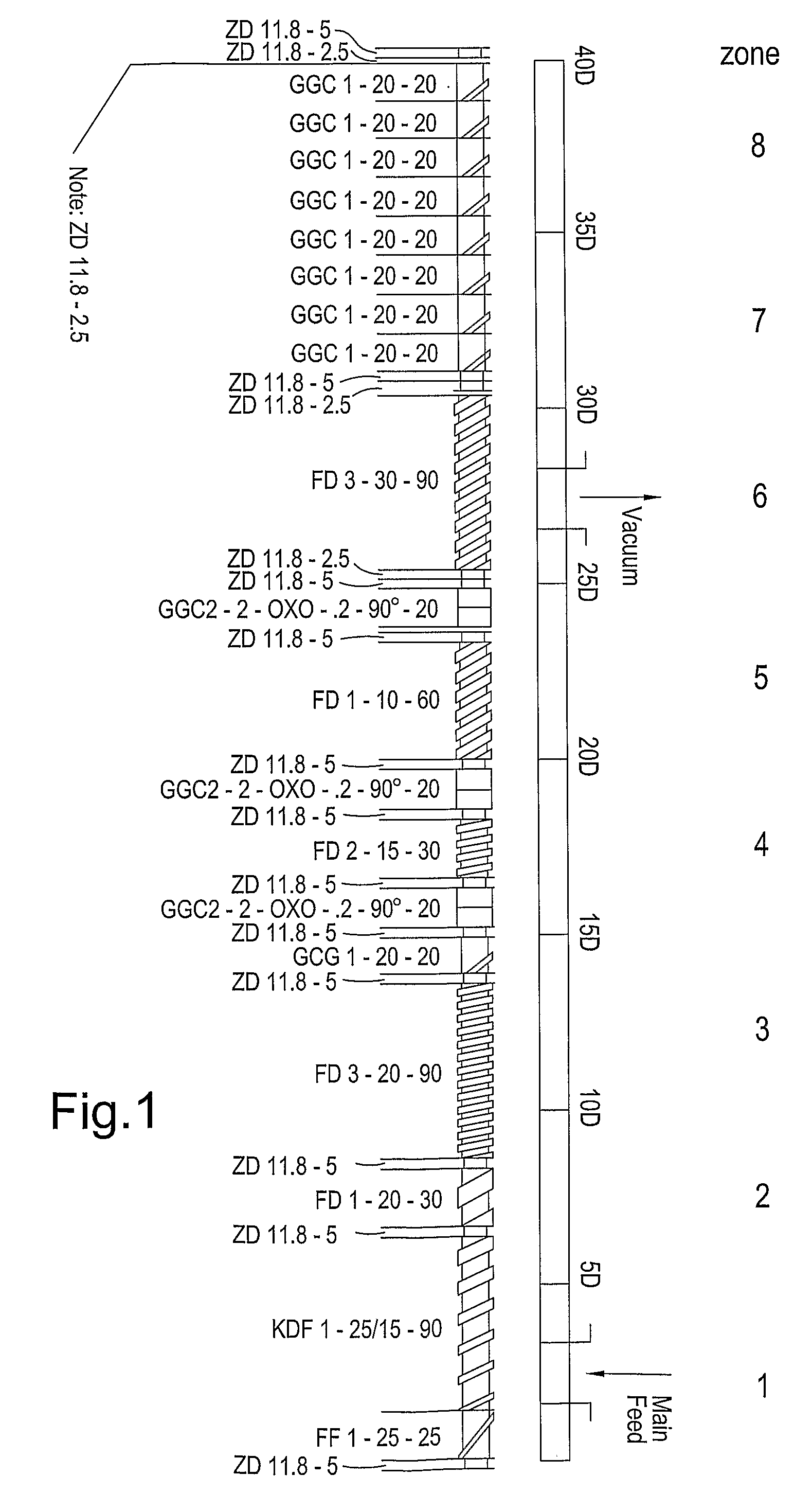

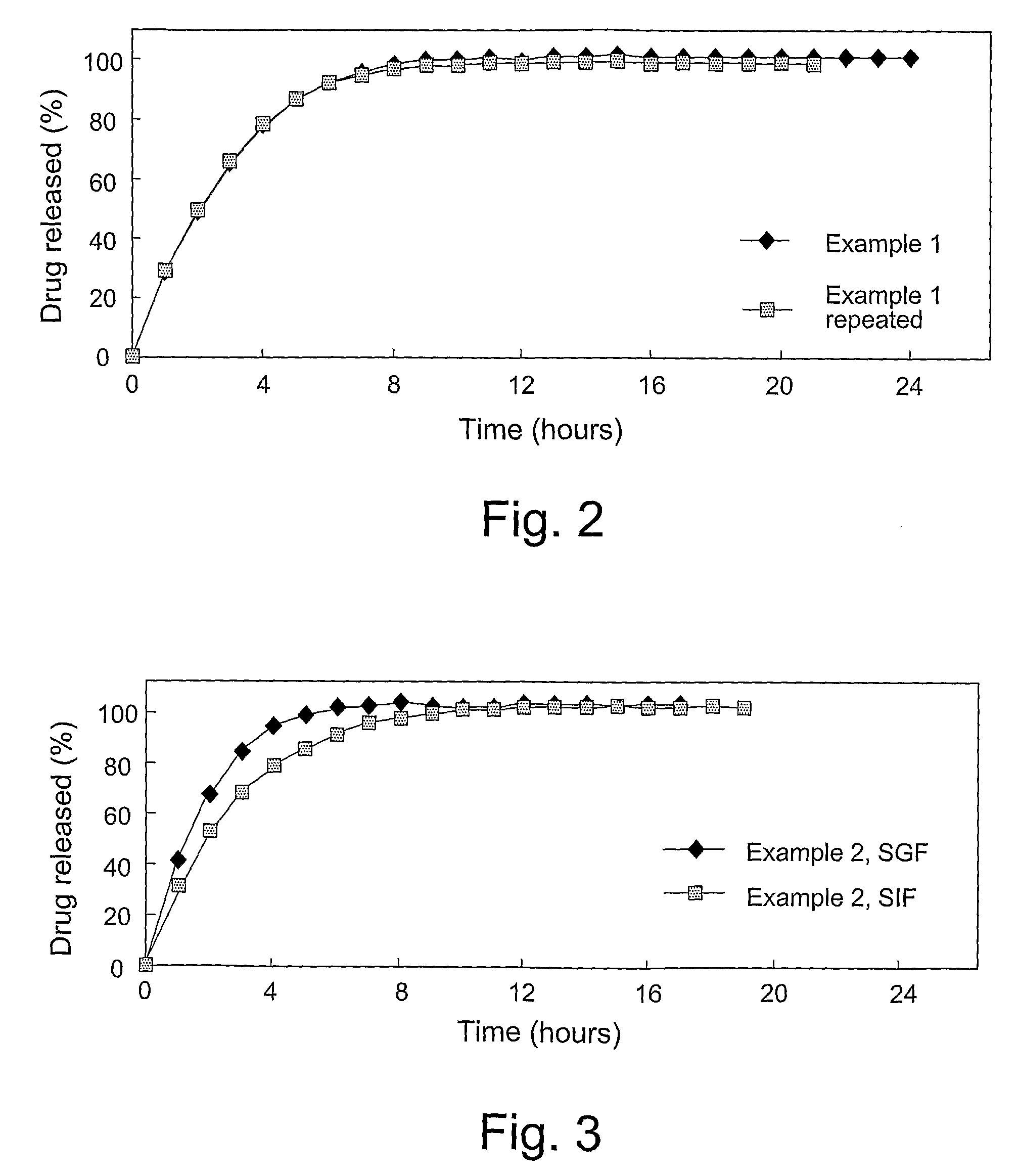

Multiparticulates

InactiveUS20080260815A1Reduce adhesionReduce the required powerOrganic active ingredientsPowder deliveryActive agentExcipient

Extrusion of a mix containing a pharmaceutically active agent can be achieved using a plasticising excipient in an amount sufficient to act as plasticiser and also act as lubricant, thereby avoiding the need for inclusion of a lubricant. The invention provides multiparticulates with controlled release properties, substantially free of lubricant. The present invention is preferably directed to extruded multiparticulates containing an opioid such as oxycodone, an ammonium methacrylate copolymer such as Eudragit® RSPO, a plasticising excipient such as preferably stearyl alcohol and a water permeability modifier such as preferably Eudragit® RLPO. The obtained multiparticulates show a release rate profile which is pH-independent.

Owner:EURO-CELTIQUE SA

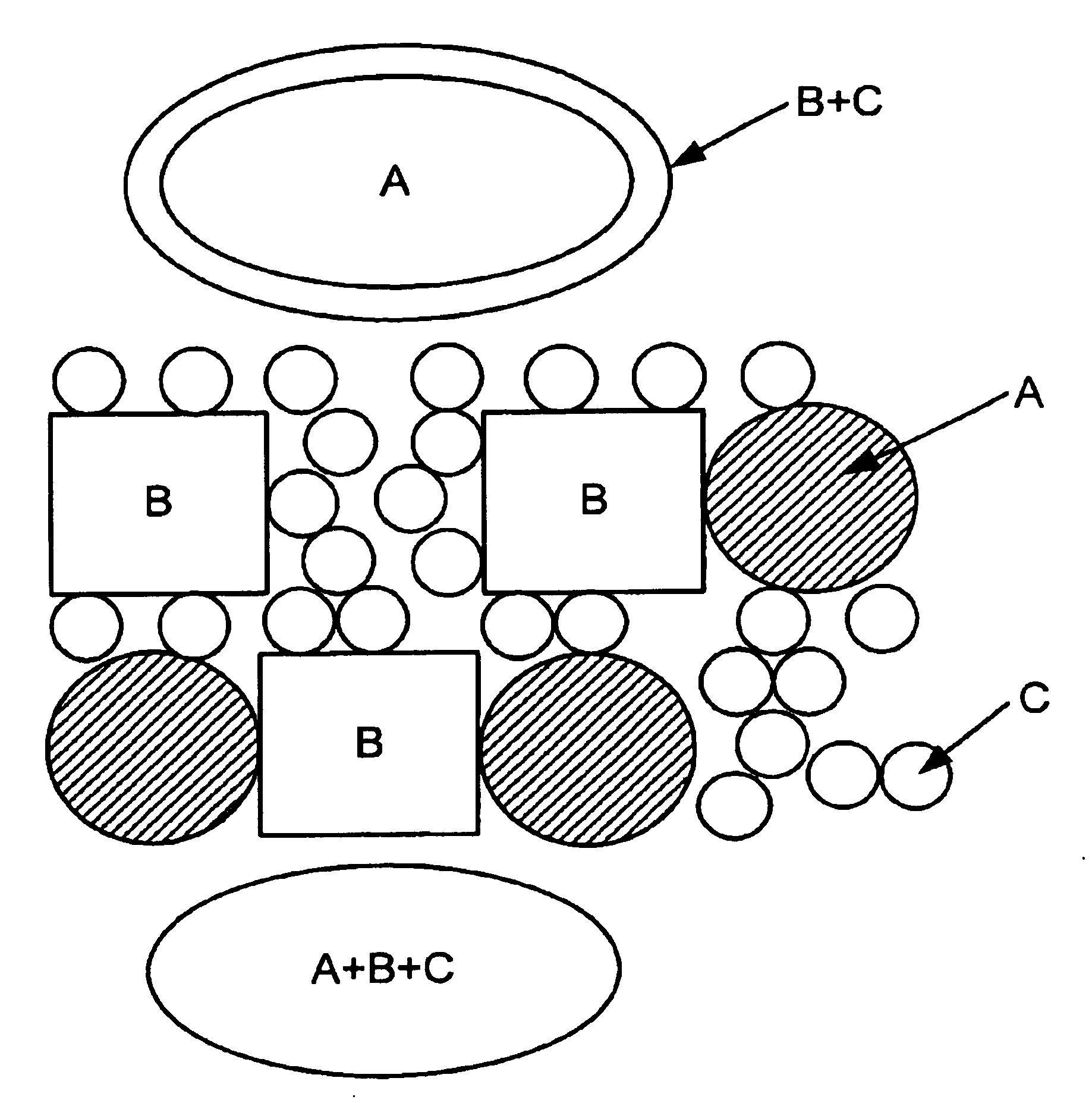

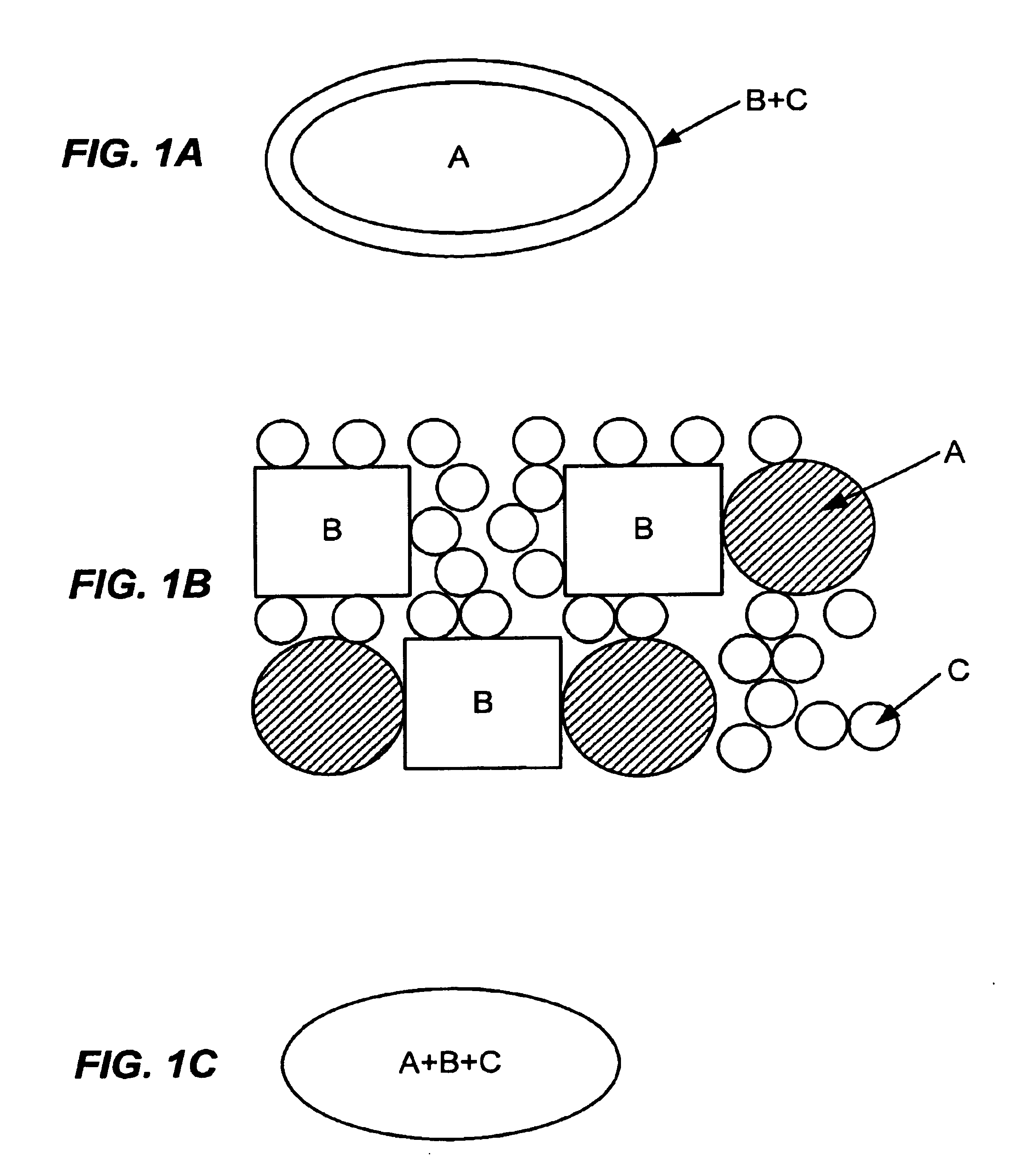

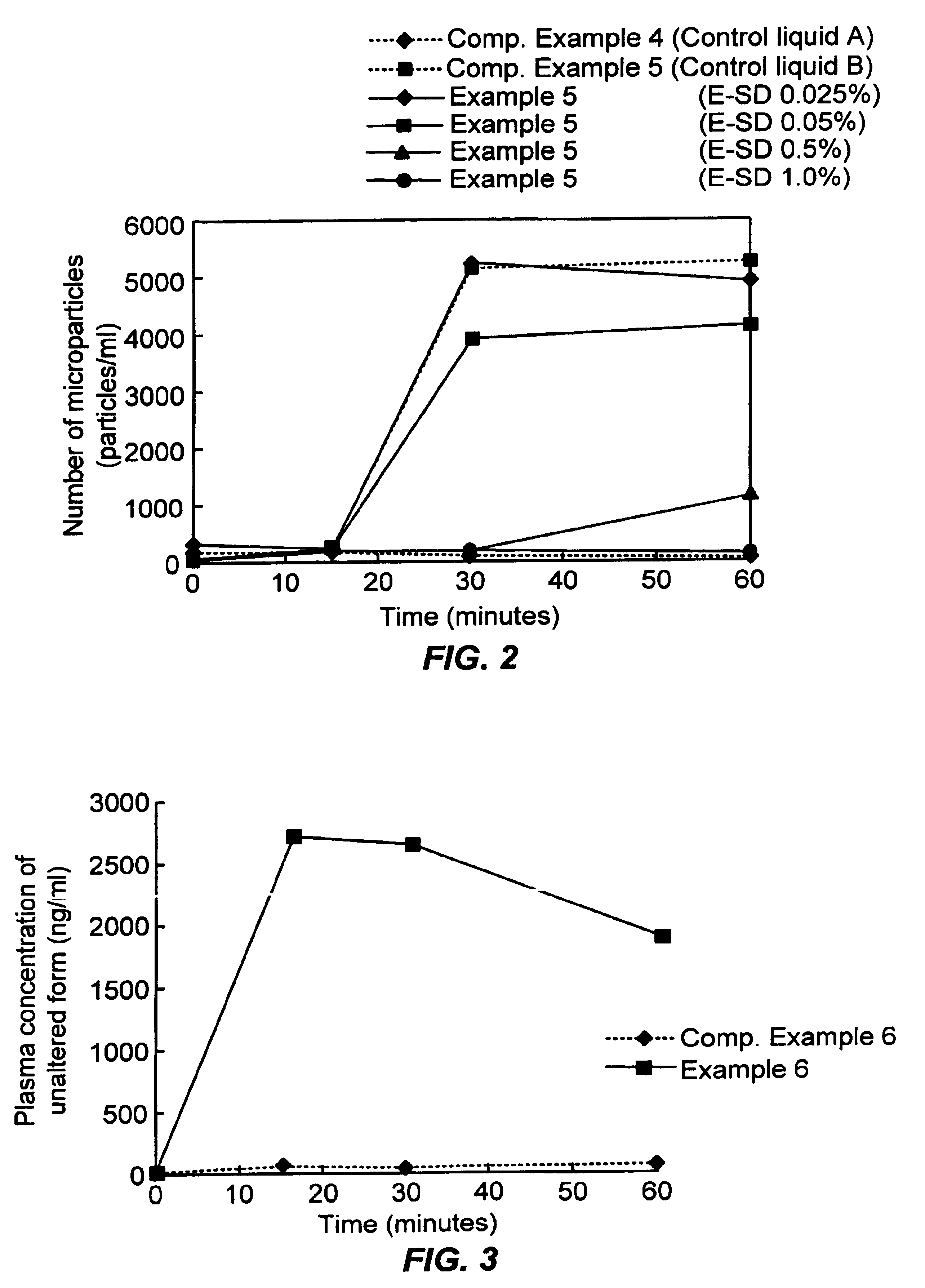

Pharmaceutical composition for oral use with improved absorption

InactiveUS7008640B2Promote absorptionDifficult to absorbBiocideNervous disorderBULK ACTIVE INGREDIENTAcid substances

The present invention presents a pharmaceutical composition for oral use with improved absorption, which comprises drug, aminoalkyl methacrylate copolymer E, and acidic substance and is obtained by bringing said 3 components together and uniformly mixing at least this polymer and this acidic substance, and a method of improving oral absorption by using this pharmaceutical composition. Moreover, the present invention presents an agent for improving oral absorption that increases drug permeability of the digestive tract mucous membrane and / or mucous layer present on the surface of this membrane, whose active ingredient is aminoalkyl methacrylate copolymer E. In addition, the present invention presents an oral agent for improving absorption by increasing drug permeability of the digestive tract mucous membrane and / or the mucous layer distributed over this mucous membrane, whose effective component is aminoalkyl methacrylate copolymer E.

Owner:ASTELLAS PHARMA INC

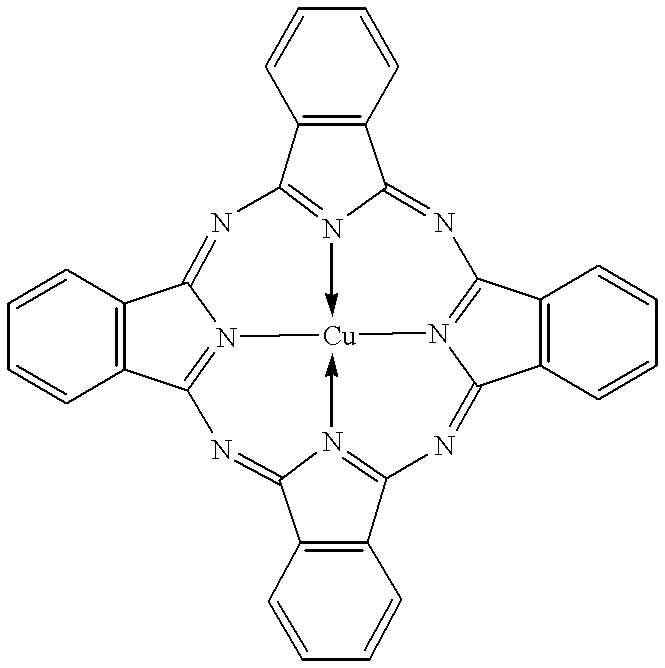

Fluorescent conversion filter and color display device using the same

InactiveUS6249372B1Facilitates its fine patteringImprove the display effectOptical filtersSolid-state devicesDisplay deviceWavelength

A fluorescent conversion filter includes a fluorescent conversion film which facilitates converting light from a wavelength region between near ultraviolet and green to light in the red region which can be finely patterned. A color display device can be produced which includes the fluorescent conversion filter. The fluorescent conversion filter includes a fluorescent conversion film and a light absorption film on the display side surface of the flourescent conversion film. The flourescent conversion film has an absorbance of 1 or less in the wavelength region between 450 nm and 520 nm. The light absorption film has an absorbance of greater than I in the wavelength region between 450 nm and 520 nm. The fluorescent conversion film contains a photo-curing resin or a photo- and thermo-setting resin, that contains an acrylate polymer, a methacrylate polymer or an acrylate-methacrylate copolymer as its main component.

Owner:SHARP KK

Composition and device structure for iontophoresis

Device structure 100 for iontophoresis provides electrode 101 and electrically conductive layer 102. Electrically conductive layer 102 contains active ingredient D and basic water swelling methacrylate copolymer P1 and / or acidic water swelling methacrylate copolymer P2. Electrode 101 and electrically conductive layer 102 are placed into a hollow of backing 103 and electrode terminal 104 is connected to electrode 101 through backing 103. Adhesive layer 105 is set around backing 103, and liner 106 to be removed when using the device, is placed so as to cover the hollow of backing 103.

Owner:HISAMITSU PHARM CO INC

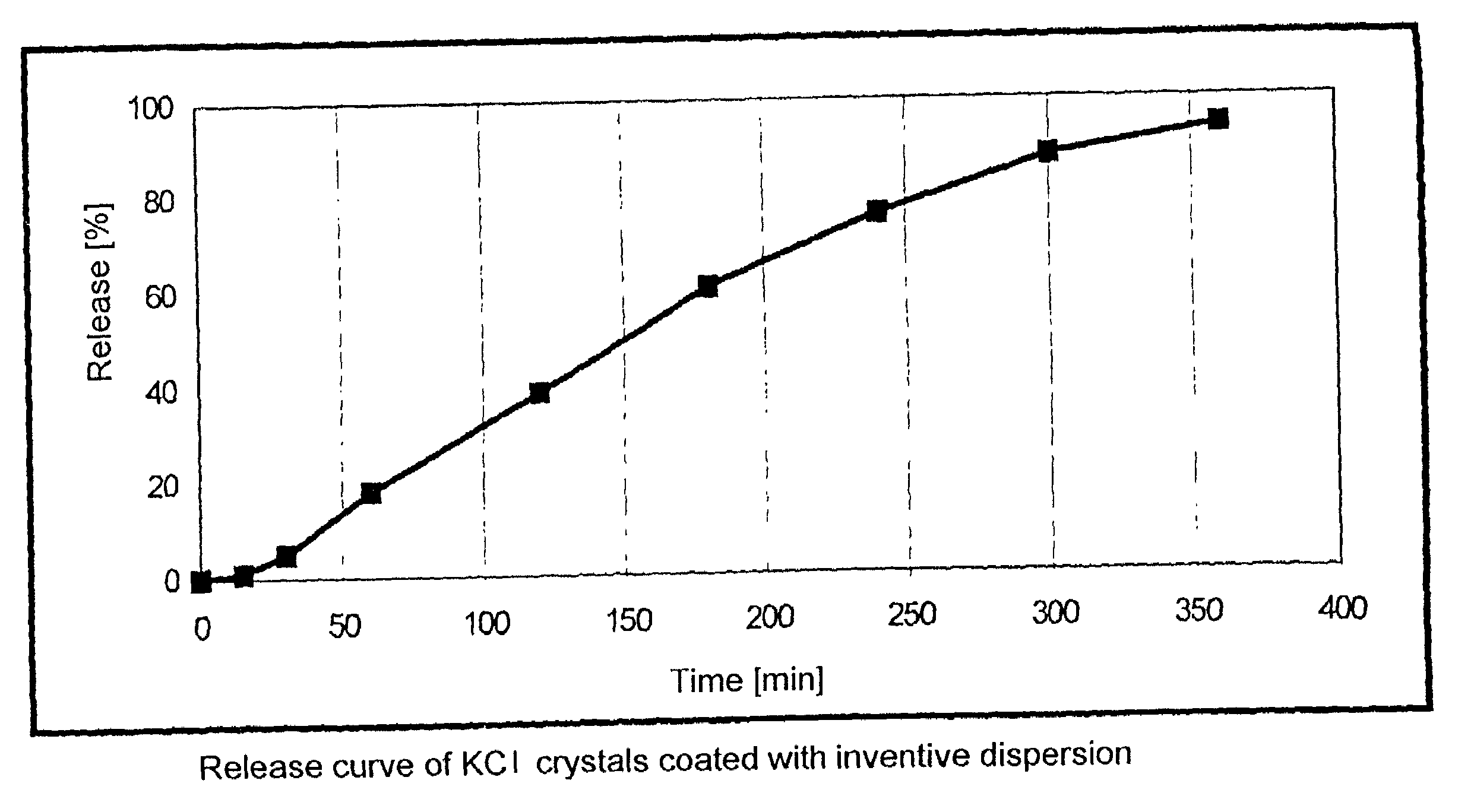

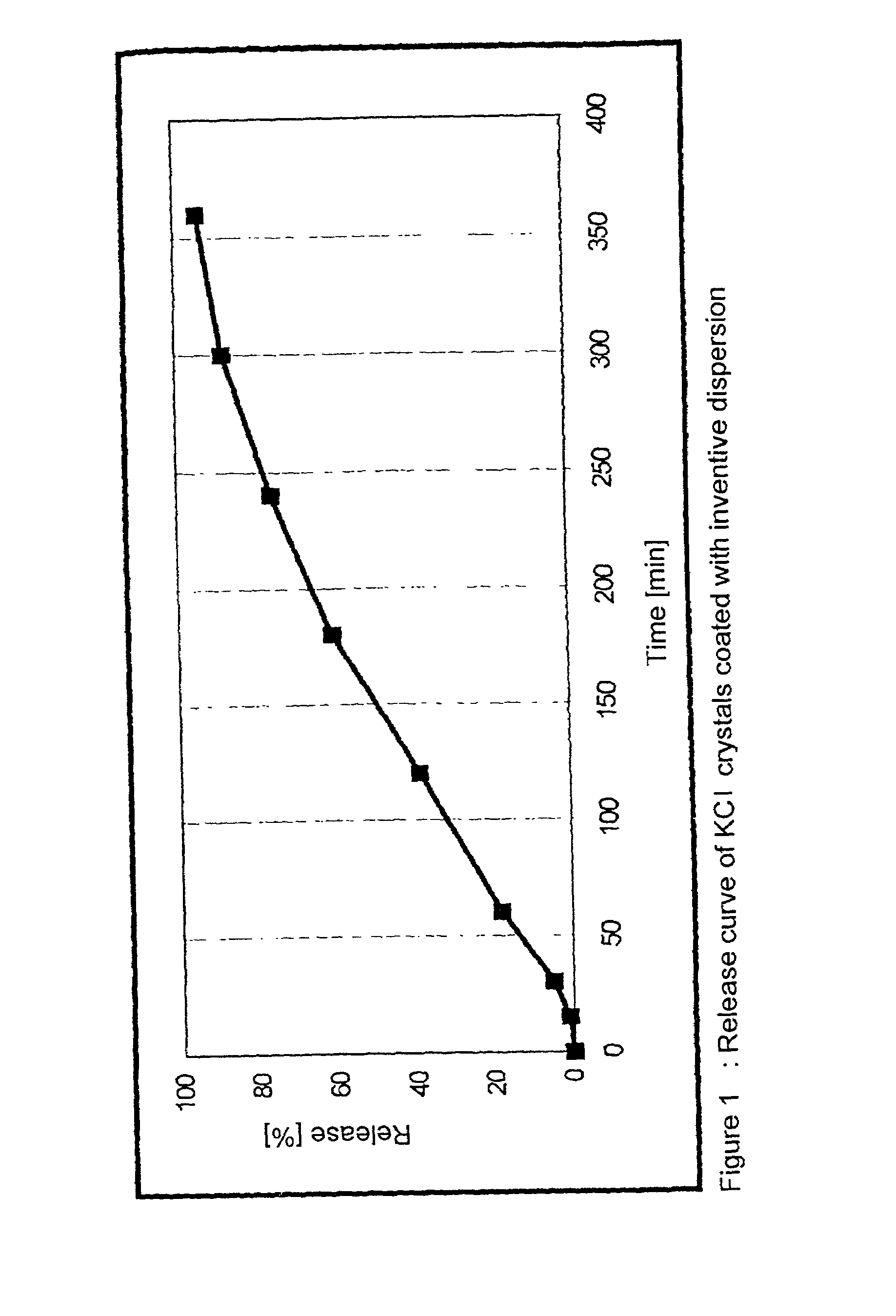

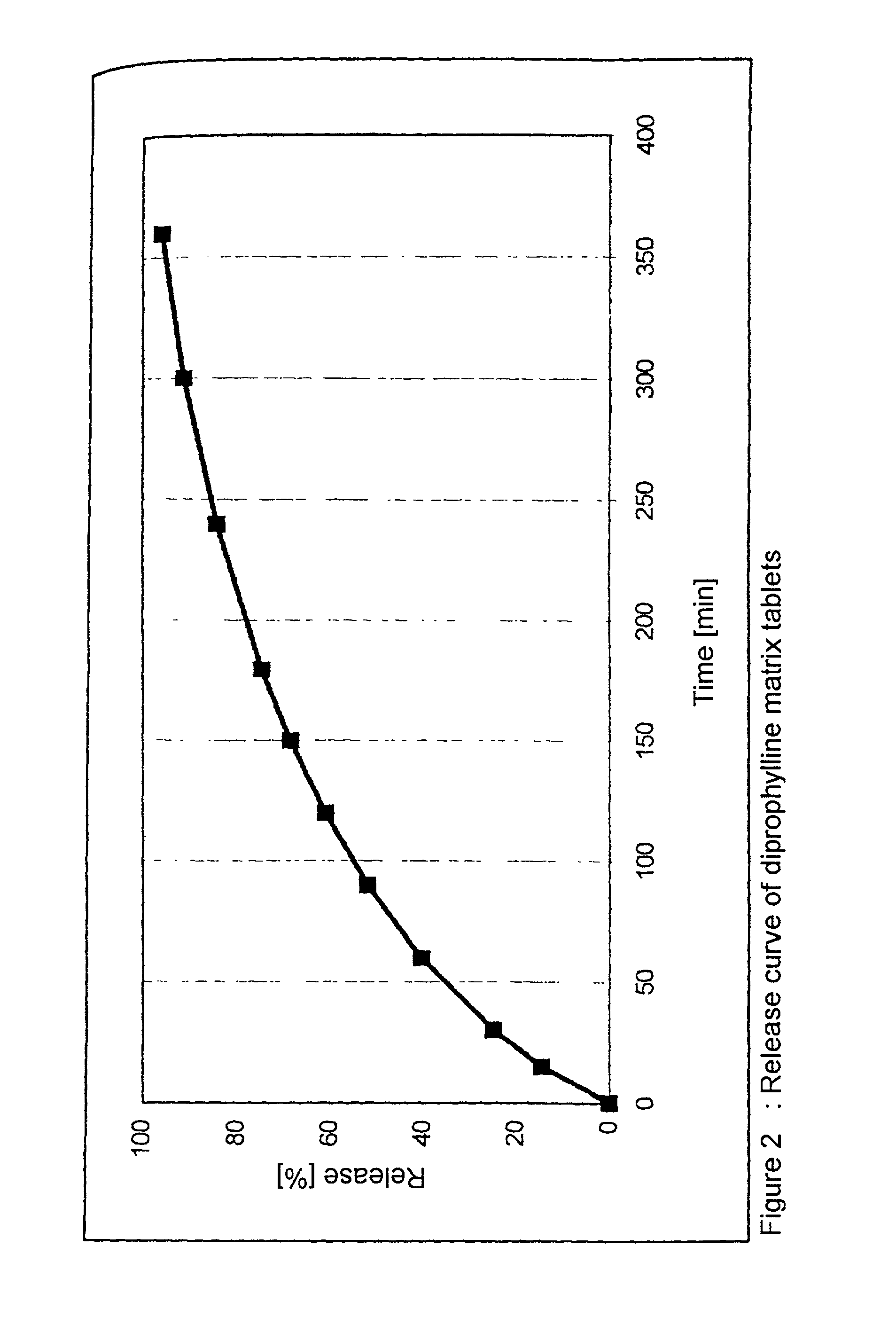

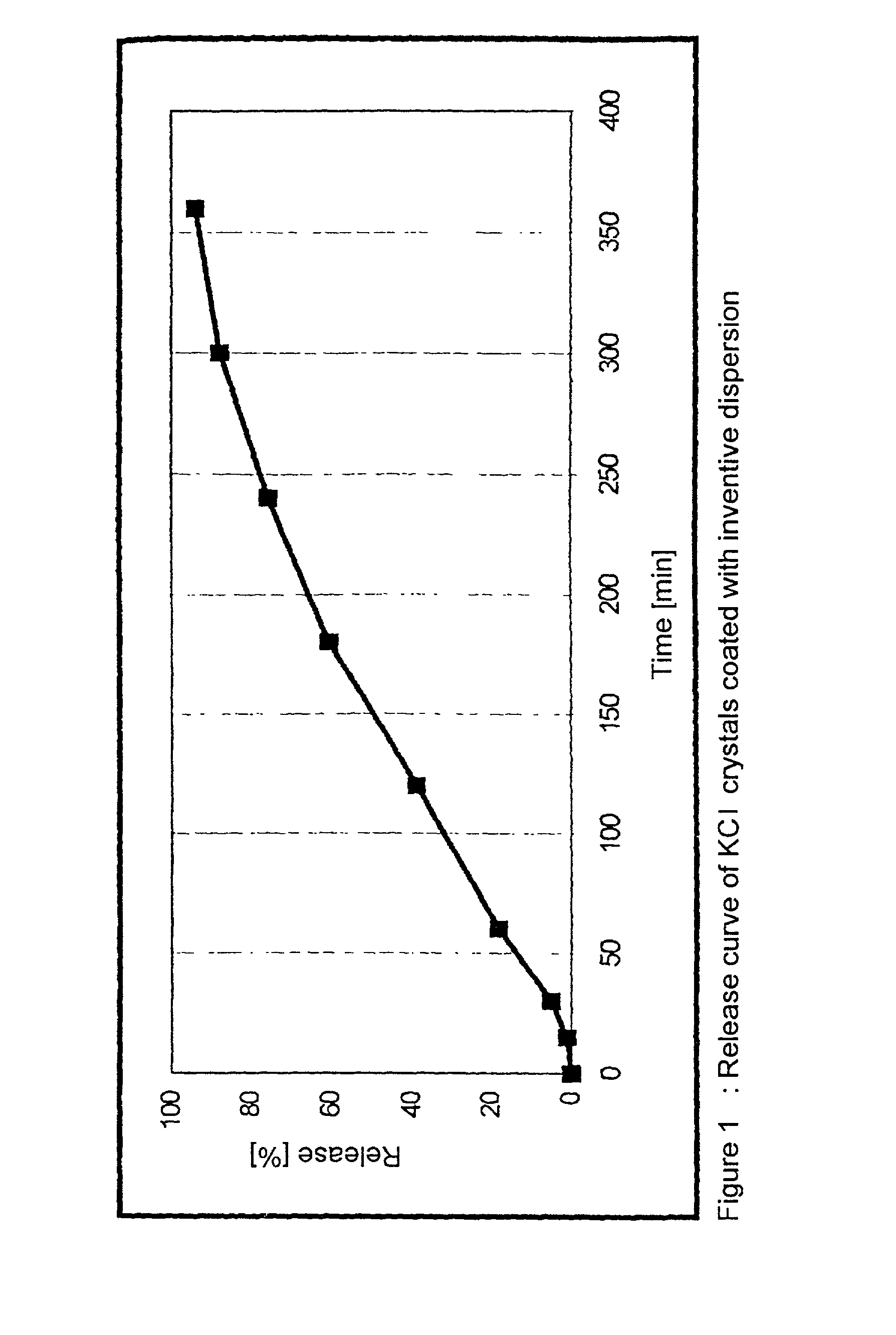

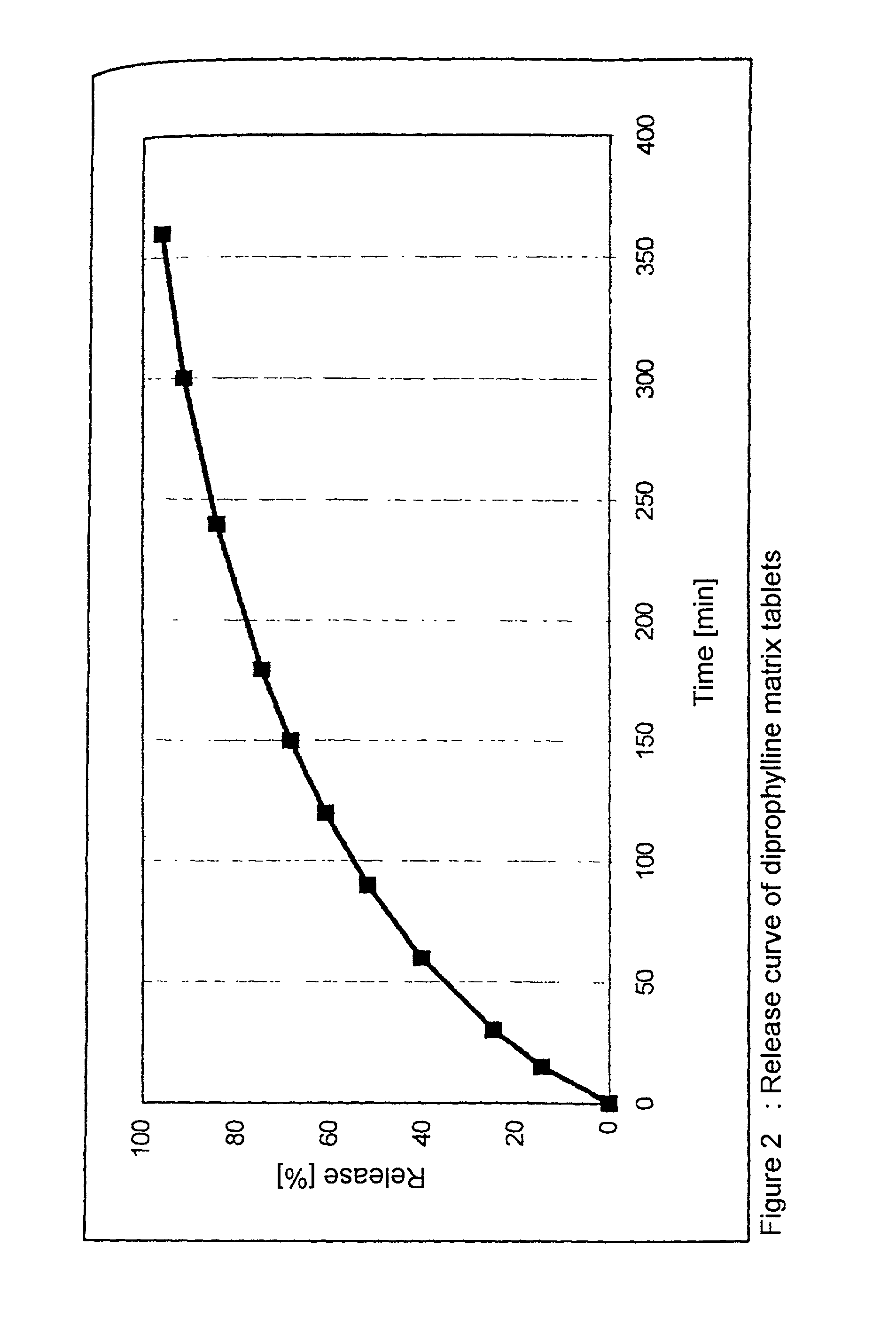

Dispersion comprising a non-ionic emulsifier

InactiveUS6998140B2Quality improvementPrevent crystallizationPowder deliveryTransportation and packagingVitrificationNon ionic

The invention relates to a dispersion suitable for use as coating agent and binder for pharmaceutical forms, having a solids content of 10–70% by weight consisting ofa) from 90 to 99% by weight of a methacrylate copolymer consisting of at least 90% by weight of (meth)acrylate monomers containing neutral radicals and having a glass transition temperature Tg of from −20° C. to +20° C. as determined by the DSC method, andb) 1–10% by weight of a nonionic emulsifier having an HLB of from 15.2 to 17.3.

Owner:EVONIK OPERATIONS GMBH

Multilayer dosage forms, which contain active substances and which comprise a neutral core, and an inner and outer coating consisting of methacrylate copolymers and methacrylate monomers

The invention relates to a multilayer dosage form comprised of: a) a neutral core; b) an inner coating consisting of a methacrylate copolymer; c) an outer coating consisting of a copolymer of which 40 to 95% by weight is composed of radically polymerized C1 to C4 alkyl esters of acrylic acid or of methacrylic acid and of which 5 to 60% by weight is composed of (meth)acrylate monomers having an anionic group in the alkyl radical. The invention is characterized in that the inner coating is essentially comprised of a methacrylate copolymer, of which at least up to 90% by weight consists of (meth)acrylate monomers with neutral radicals, which, in accordance with DIN 53 787, has a minimum film formation temperature of no higher than 30° C., and which contains the pharmaceutical active substance in bound form.

Owner:EVONIK ROEHM GMBH

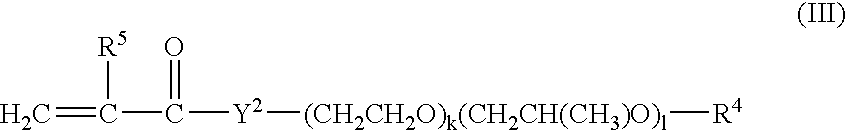

Compound oil-soluble viscosity reducer for reducing viscosity of thickened oil and preparation method of compound oil-soluble viscosity reducer

The invention relates to a compound oil-soluble viscosity reducer for reducing viscosity of thickened oil and a preparation method of the compound oil-soluble viscosity reducer. The compound oil-soluble viscosity reducer is compounded of a ternary oil-soluble copolymer and an oil-soluble fatty alcohol polyoxyethylene ether nonionic surfactant. The compound oil-soluble viscosity reducer is characterized by comprising the following contents: 1) preparing octadecyl methacrylate; 2) preparing SMA which is a maleic anhydride-styrene-octadecyl methacrylate copolymer; 3) preparing SMZA which is an ester copolymer of maleic anhydride-styrene-acrylamide and higher alcohols; and 4) compounding the SMA or SMZA copolymer with a surfactant, wherein the mass ratio of the surfactant to the terpolymer is (0.5-1) to (1-3), and adding a solvent and stirring for an hour at 60 DEG C. The compound oil-soluble viscosity reducer is wide in raw material source, low in price, free of pollution, and simple in synthetic process, and has a wide market prospect.

Owner:NABAI KECHUANG BEIJING TECH DEV

Pesticide water suspending nano capsule prepn and its preparing method

The present invention discloses water suspended nano pesticide capsule preparation prepared via emulsion polymerization process. It has capsule shell of styrene, isocyanate, acrylate and methacrylate copolymer, and core comprising ididacloprid, high effect cypermethrin or diflubenzuron as effective component; contains pesticide 0.2-5 wt%, capsule shell 5-30 wt%, additive 10-35 wt% and water in proper proportion. The nano capsule is disersive spherical particle of size smaller than 100 nm. Compared with traditional pesticide preparation forms, the present invention has the features of water based solvent, nano level dispersive effective component, high stability, etc. and may be used in killing various pests of fruit tree, vegetable, flower, cotton, tobacco, etc.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

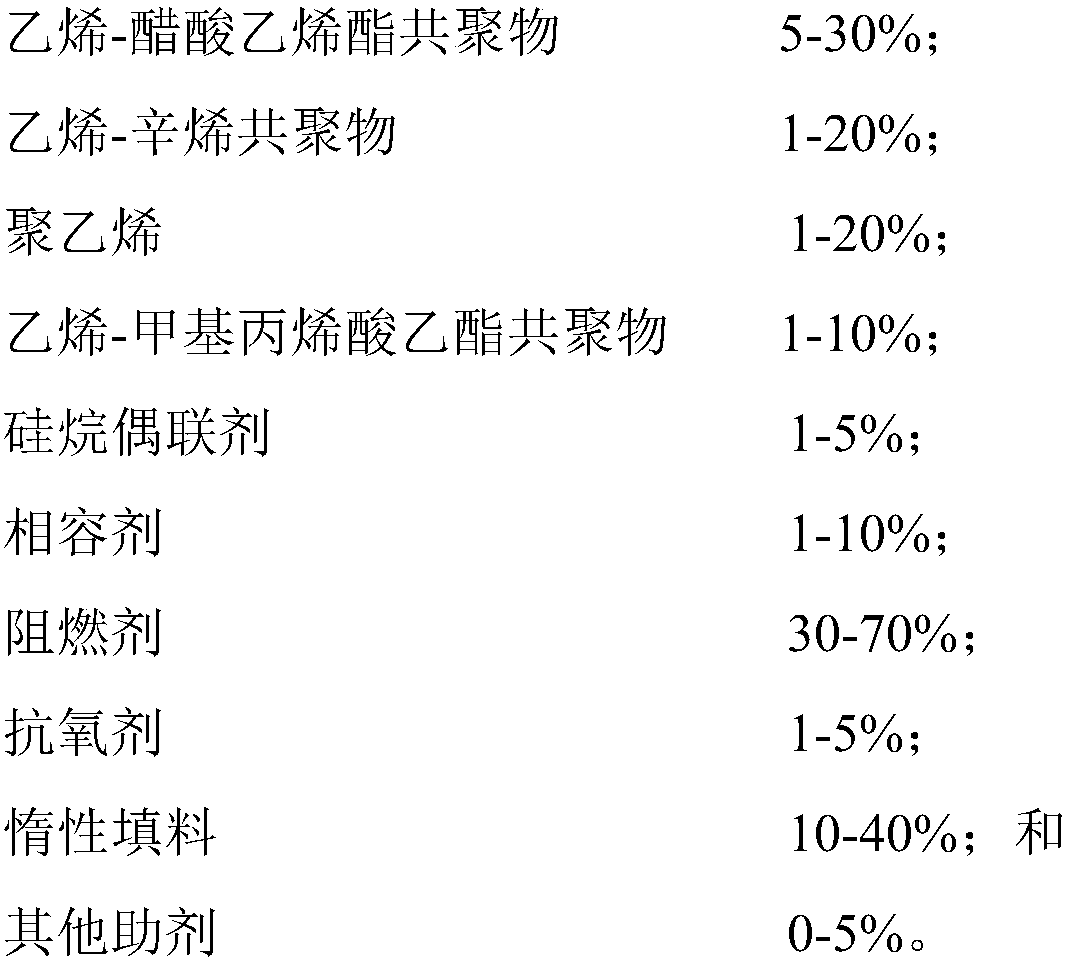

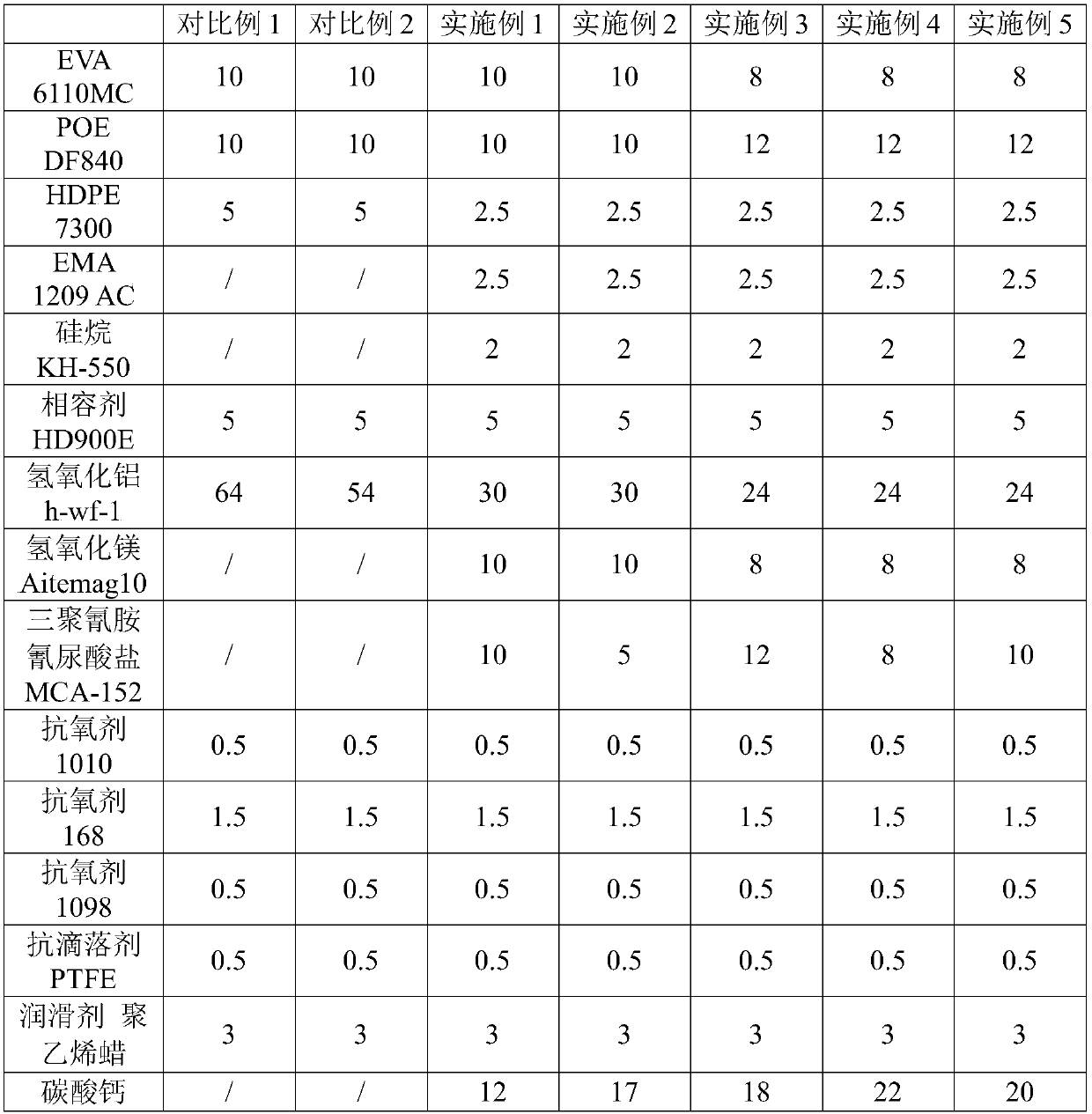

B1-grade flame-retardant irradiation crosslinking low-smoke halogen-free insulated cable material and preparation method thereof

InactiveCN109627567AStable processing technologyIncrease productionPlastic/resin/waxes insulatorsPolymer scienceAntioxidant

The invention discloses a B1-grade flame-retardant irradiation crosslinking low-smoke halogen-free insulated cable material and a preparation method thereof. The B1-grade flame-retardant irradiation crosslinking low-smoke halogen-free insulated cable material is prepared from, by mass, 5-30% of ethylene-vinyl acetate copolymer (EVA), 1-20% of ethylene-octylene copolymer (POE), 1-20% of polyethylene (PE), 1-10% of ethylene-ethyl methacrylate copolymer (EMA), 1-5% of silane, 1-10% of a compatilizer, 40-70% of a flame retardant, 1-5% of an antioxidant, 0-5% of other auxiliaries and 10-40% of inert filler. The cable material can meet B1-grade flame-retardant requirements and has good mechanical performance and processing performance.

Owner:上海至正新材料有限公司

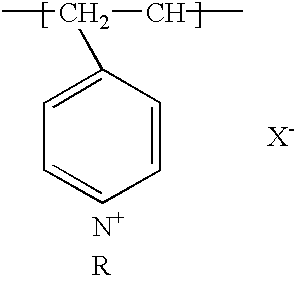

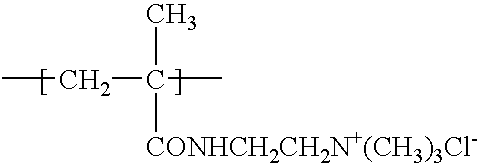

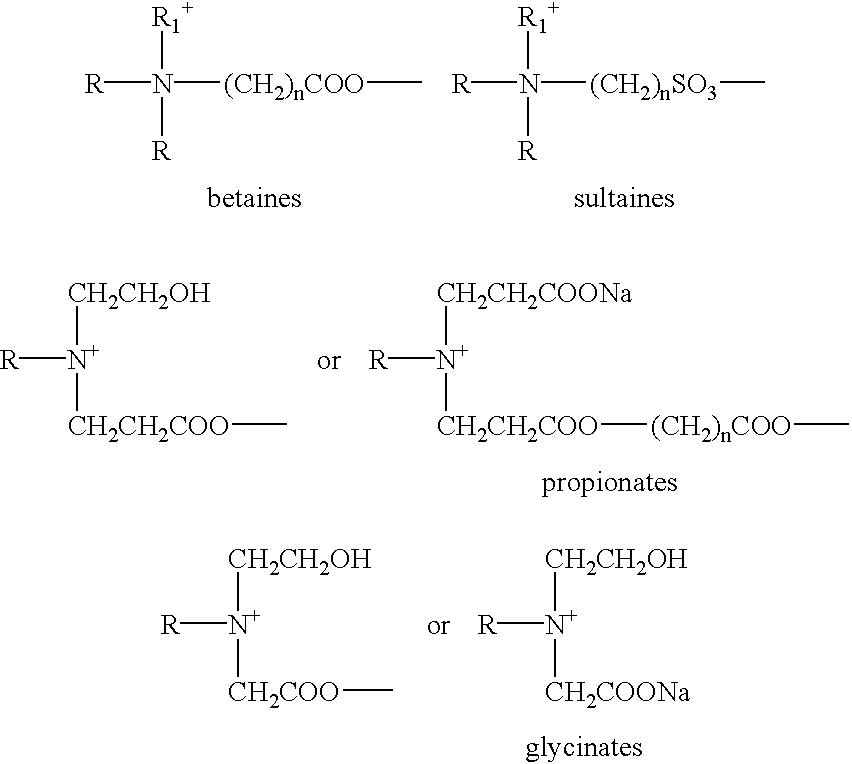

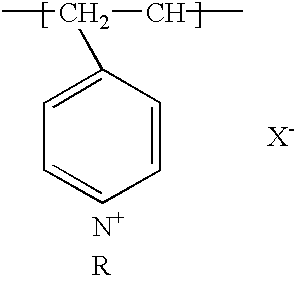

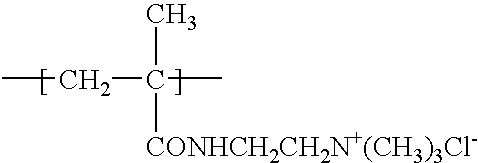

Amphoteric Ethyl Methacrylate Copolymers and Use Thereof

ActiveUS20080089853A1Improve storabilitySimpler transportation optionCosmetic preparationsBiocideDouble bondMethyl acrylate

The present invention relates to amphoteric copolymers which comprise ethyl methacrylate, if appropriate a N-vinyllactam compound, at least one monoethylenically unsaturated carboxylic acid and at least one compound with α,β-ethylenically unsaturated double bond and at least one cationogenic and / or cationic group in copolymerized form, to cosmetic and pharmaceutical compositions which comprise such copolymers, to preparation methods, and to the use of these copolymers.

Owner:BASF AG

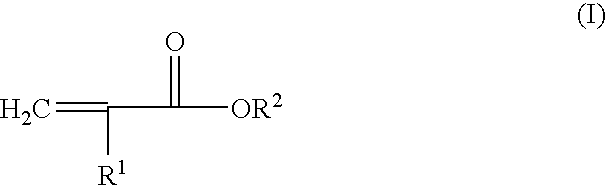

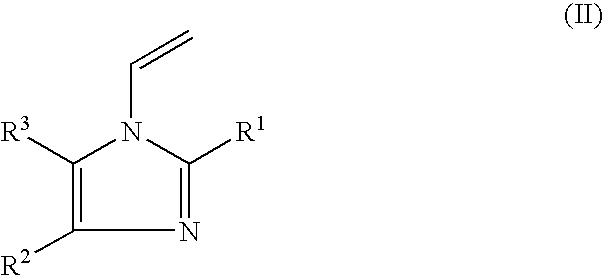

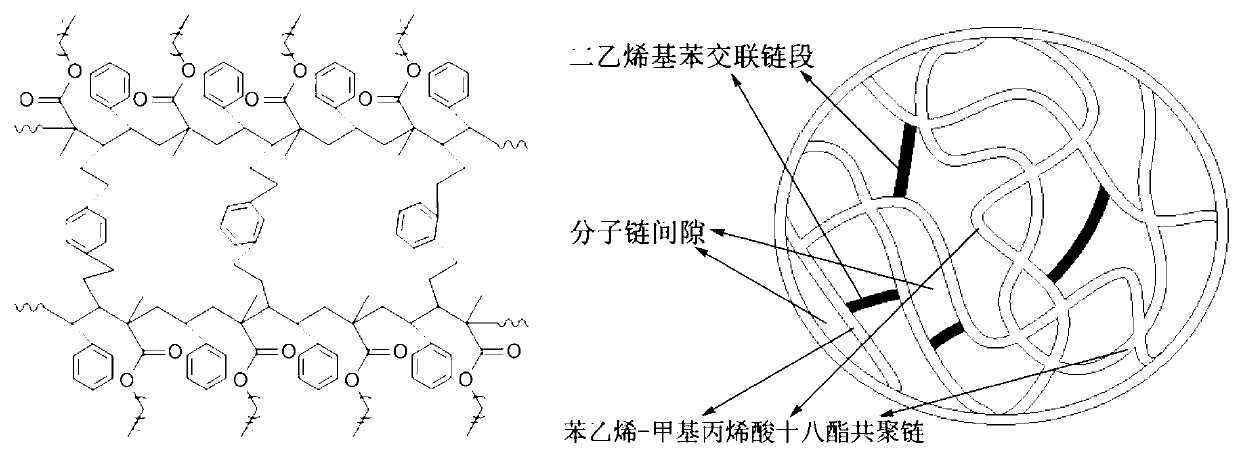

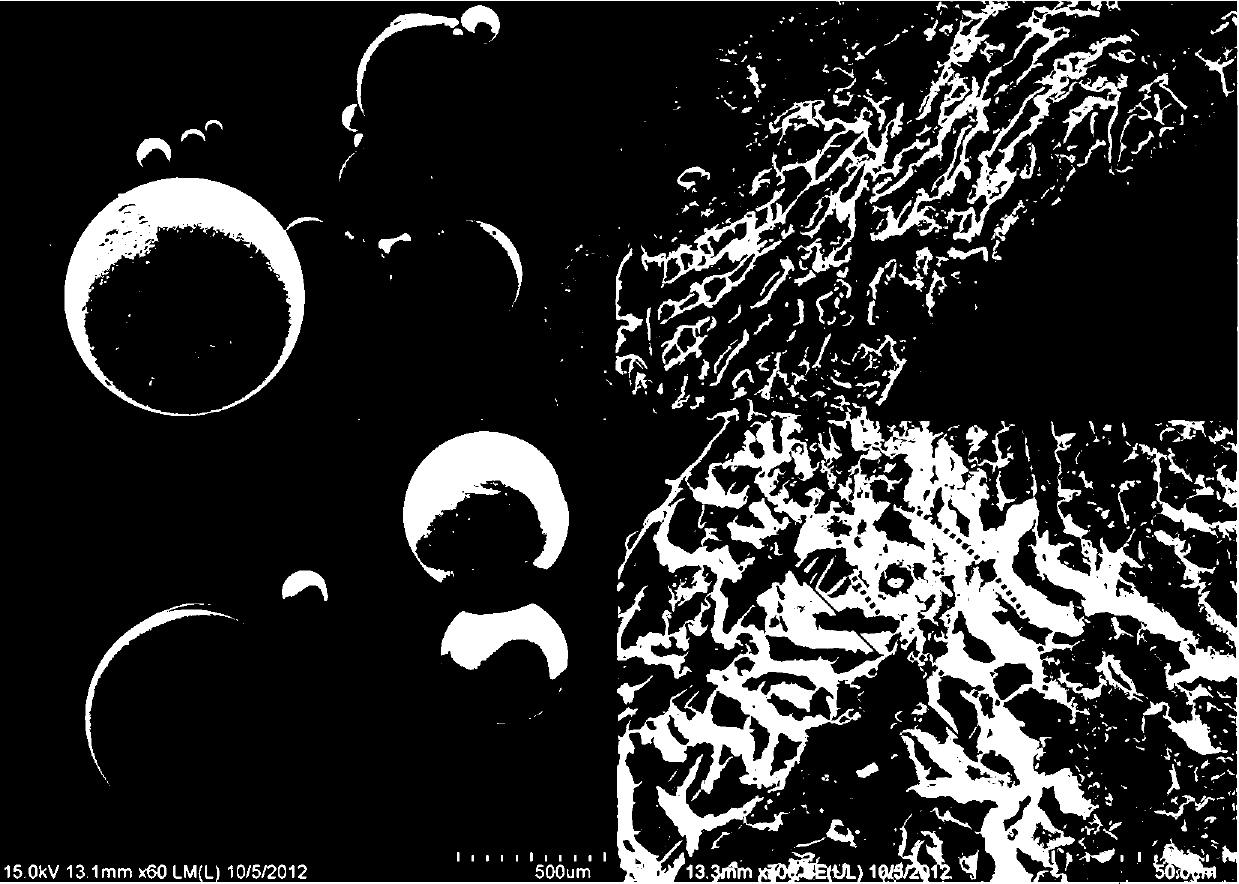

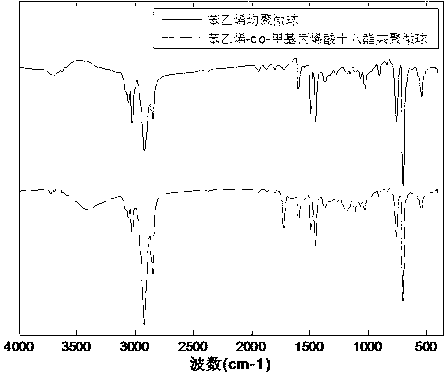

High compressive polystyrene-co-octadecyl methacrylate copolymer resin microsphere and preparation method thereof

The invention discloses a high compressive polystyrene-co-octadecyl methacrylate copolymer resin microsphere which is a crosslinking copolymer prepared by taking divinylbenzene as a cross-linking agent, taking styrene as a first monomer, taking octadecyl methacrylate as a second monomer and adding a pore-foaming agent. According to the high compressive polystyrene-co-octadecyl methacrylate copolymer resin microsphere, a long-chain flexible monomer of the octadecyl methacrylate is introduced to be copolymerized with the styrene, and therefore, the compressive strength of the resin microsphere as parents of ion exchange resin or adsorbent resin is obviously improved, the strength increase efficiency reaches more than a dozen times, and the resin microsphere cannot be crushed on account of structural defects per se in the use process.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Dispersion comprising a non-ionic emulsifier

InactiveUS20030060381A1Quality improvementPrevent crystallizationCosmetic preparationsPowder deliveryVitrificationMeth-

The invention relates to a dispersion suitable for use as coating agent and binder for pharmaceutical forms, having a solids content of 10-70% by weight consisting of a) from 90 to 99% by weight of a methacrylate copolymer consisting of at least 90% by weight of (meth)acrylate monomers containing neutral radicals and having a glass transition temperature Tg of from -20° C. to +20° C. as determined by the DSC method, and b) 1-10% by weight of a nonionic emulsifier having an HLB of from 15.2 to 17.3.

Owner:EVONIK OPERATIONS GMBH

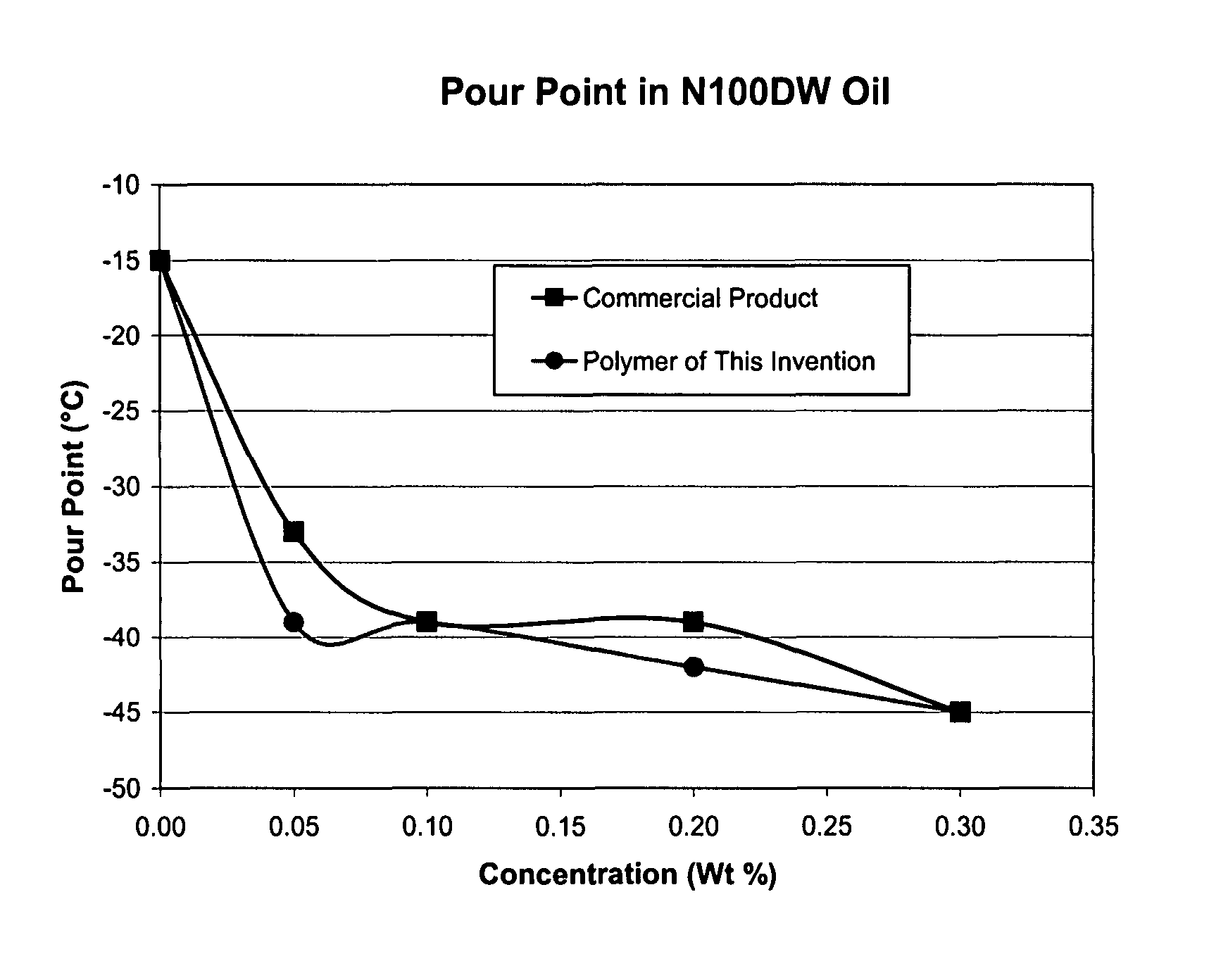

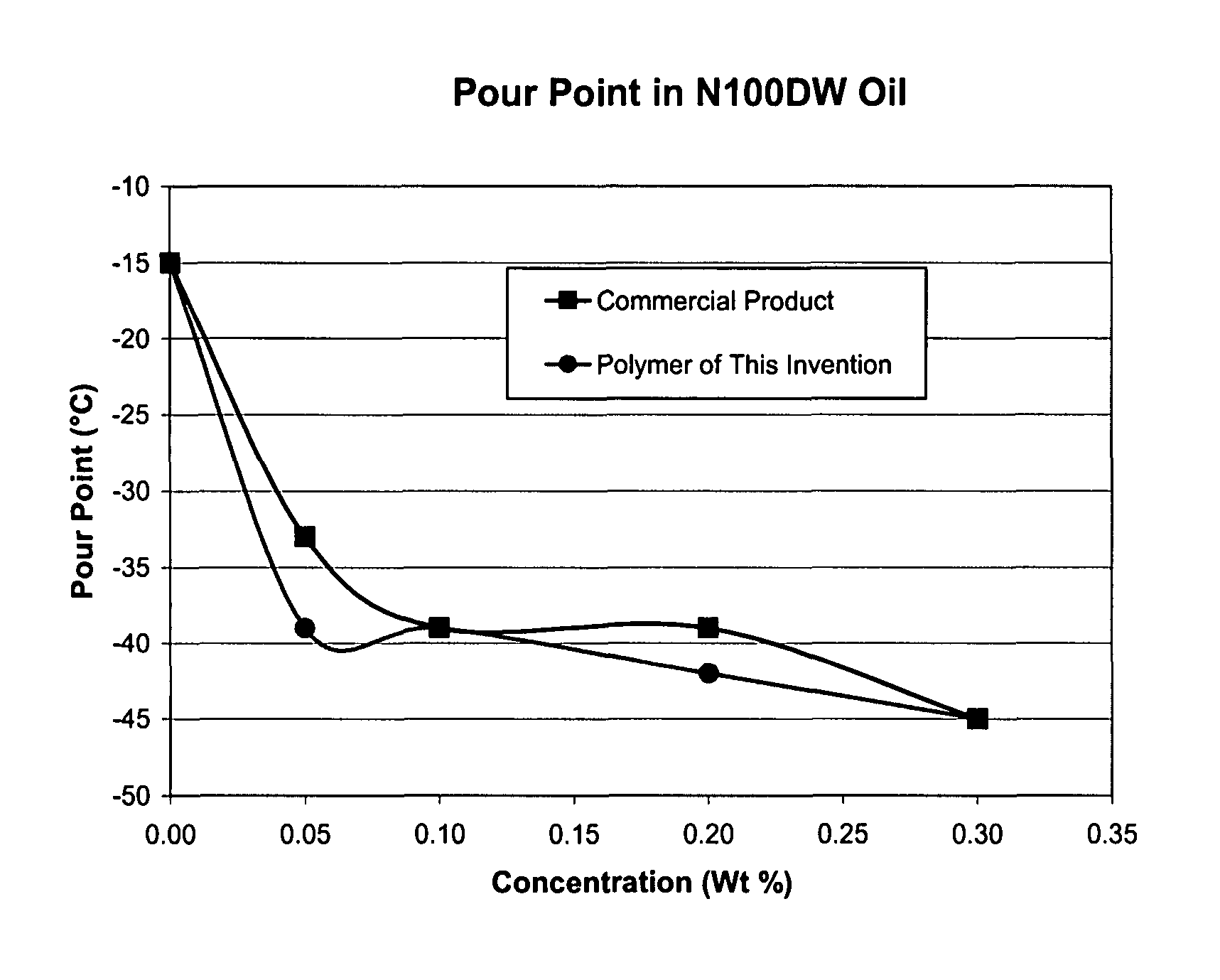

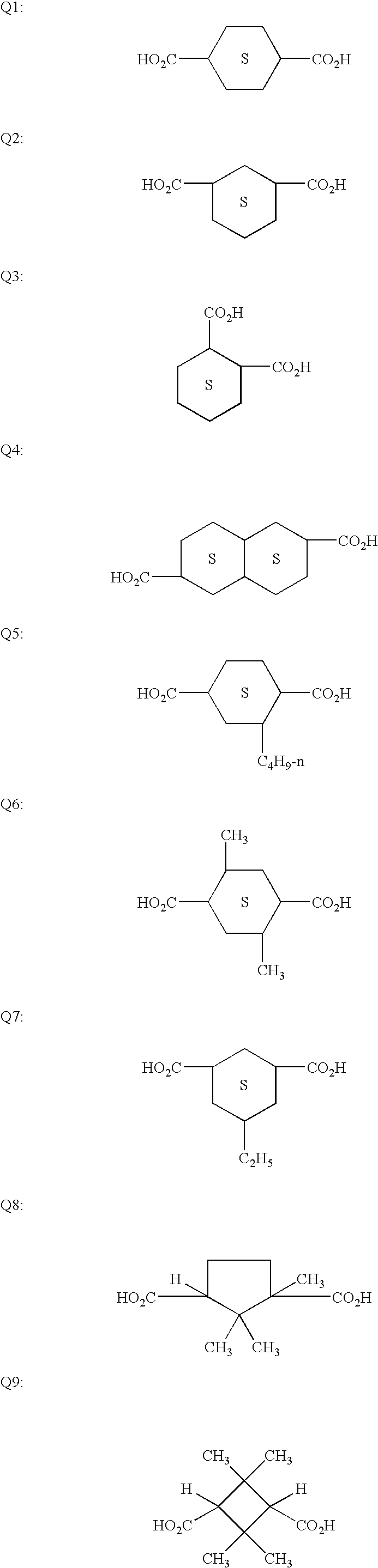

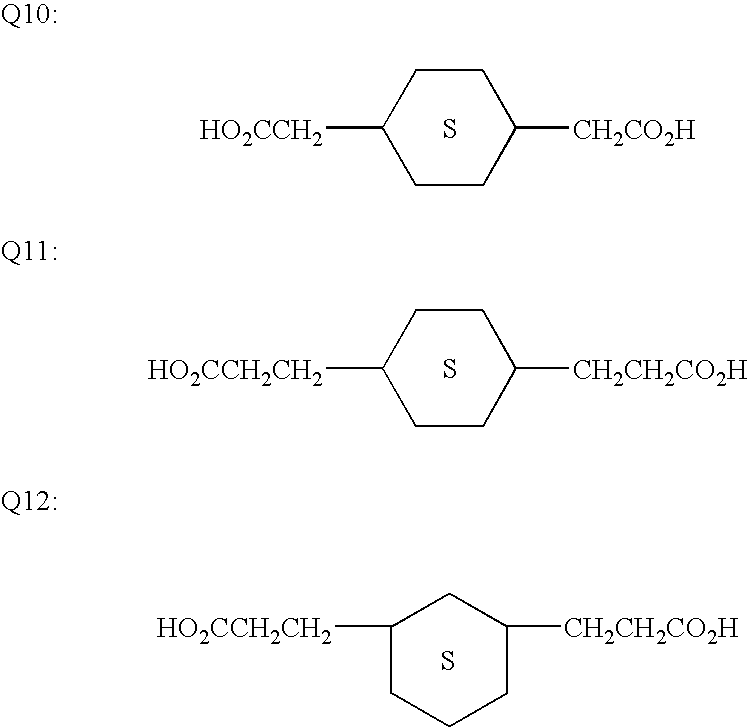

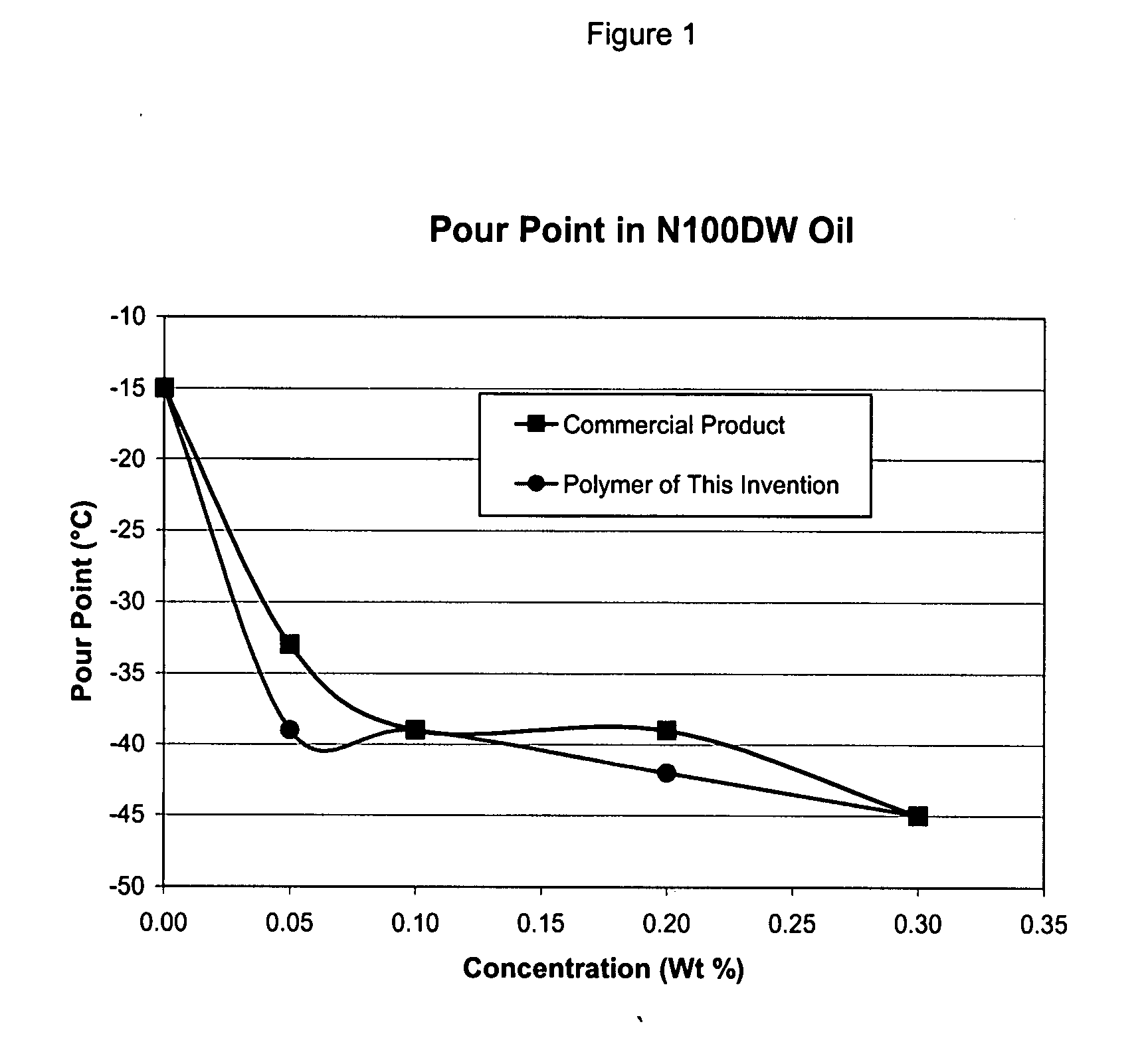

Methacrylate copolymer pour point depressants

ActiveUS8143202B2Improve low temperature performanceLubricant compositionDepressantOrganic chemistry

Poly methacrylate copolymers are disclosed which comprising from about 60 to about 96 weight percent of a C12-C16 alkyl methacrylate and from about 40 to about 4 weight percent of a C18-C30 alkyl methacrylate and provide excellent low temperature properties to lubricating oils.

Owner:CIBA CORP

Coextruded toner receiver layer for electrophotography

InactiveUS20060115664A1Resist damageDecorative surface effectsDuplicating/marking methodsPolyesterLow-density polyethylene

The invention relates to a toner receiver member comprising a base, at least one tie layer adjacent to said base, and at least one toner receiver layer adjacent said at least one tie layer on the side opposite to the base, wherein said at least one toner receiver layer comprises a layer of branched polyester or a mixture of styrene acrylate copolymer with an ethylene methacrylate copolymer or with a low density polyethylene.

Owner:EASTMAN KODAK CO

Silicone-modified methacrylic resin as well as preparation method and application thereof

InactiveCN103087329AImprove heat resistanceHigh glass transition temperatureCoatingsVitrificationOrganic solvent

The invention relates to modified methacrylic resin, and discloses silicone-modified methacrylic resin as well as a preparation method and application thereof. The silicone-modified methacrylic resin is prepared from 100 parts of functional methacrylate copolymer, 20-70 parts of active MQ silicone, 100-500 parts of organic solvent, and 0.2-10 parts of catalyst in a manner of evenly mixing. The silicone-modified methacrylic resin is firstly kept still for 10-20 minutes at 70-100 DEG C, and then cured for 1-2 hours at 140-180 DEGC to obtain a heat-resistant hydrophobic coating of the silicone-modified methacrylic resin. The heat resistance of the silicone-modified methacrylic resin disclosed by the invention is obviously improved; the glass-transition temperature can be up to over 250 DEG C; the hydrophobicity and the stain resistance are obviously improved; the water contact angle of a copolymer film can be up to over 120 DEG C; the water absorption of three days is smaller than 0.1%; and the stain resistance is level zero.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

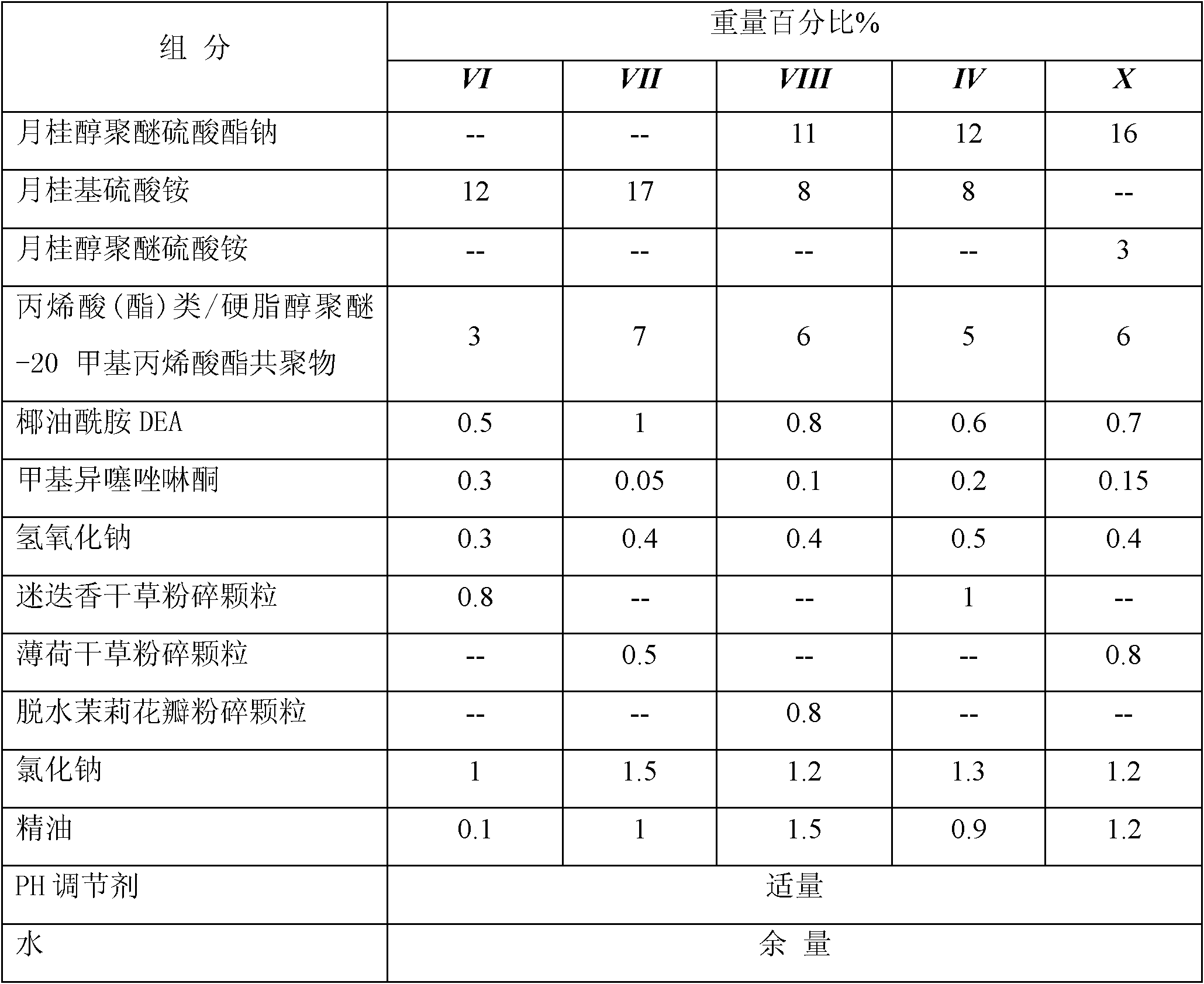

Amino acid cleansing cream and preparation method thereof

ActiveCN102327198AImprove stabilityNo phototoxicityCosmetic preparationsToilet preparationsBetaineCocoyl glutamate

The invention discloses an amino acid cleansing cream and a preparation method thereof. The amino acid cleansing cream comprises the following components in percent by weight: 3-8 percent of glycerol, 0.05-0.2 percent of hydroxyethylcellulose, 5-13 percent of propylene glycol, 25-30 percent of sodium lauroyl glutamate, 5-8 percent of sodium cocoyl glutamate, 0.5-1.5 percent of ethal-octadeca-composite fatty alcohol, 0-2 percent of ethylene glycol distearate, 0.2-0.6 percent of cetearyl alcohol ether (20), 0.5-1.5 percent of cocoaminopropyl dimethyl betaine, 0.5-1.5 percent of cetearyl alcoholether-60 myristyl glycol, 1-3 percent of acrylate / polyoxyethylene-20 stearin alcohol ether methacrylate copolymer, 0.4-0.8 percent of citric acid, 0.1-0.2 percent of diazolidiny urea, 0.10-0.15 percent of methyl phydroxybenzoate and the balance of deionized water. the amino acid cleansing cream has better stability and solid content of sodium lauroyl glutamate of more than or equal to 25 percent,and can create a comfortable and clear microenvironment for healthy growth and metabolism for skin cells on the face.

Owner:SHENZHEN GENE BIOLOGICAL TECH

Multi-layer nuclear shell structural fluorin-containing polymer particle and thermoplastic polyolefin product having the same

ActiveCN101117393AReduce the number of crystal pointsHigh transparencySynthetic resin layered productsPolymer sciencePolyolefin

The present invention relates to a fluorin-containing polymer granule with multilayer core shell structure and thermoplastic polyolefin products. The gross weight of the fluorin-containing polymer granule include: a) 20 to 80 percent by weight of fluorin-carbon polymer core materials; b) 5-30 percent by weight of intermediate-layer of acrylate copolymer, methacrylate copolymer, or their compounds; c) 15-50 percent by weight of polymer outer layer with melting point at 50-100 DEG C; The average granular diameter of fluorin-containing polymer granules is 0.1-10 mm. Fluorin-contain polymer granules of the present invention, being added with thermoplastic polyolefin melt, can be not only dispersed evenly but significantly improve critical shear rate and obviously speed up the time for the removal of melt rupture; thereby reducing surface defects of extruded products and improving transparency of thin film.

Owner:GUANGZHOU SHINE POLYMER TECH

Pharmaceutical formulation for oral delivery of bisphosphates

InactiveUS20050182028A1Minimizing potential esophageal irritationMinimize irritationBiocidePhosphorous compound active ingredientsDosing regimenPharmacy

The present invention discloses a method for treating or preventing a bone disorder in a mammal in need thereof comprising orally administering to said mammal a pharmaceutically effective amount of a pharmaceutical composition of at least one bisphosphonate, or a pharmaceutically acceptable salt or esters thereof, and at least one aminoalky methacrylate copolymer, according to a dosing schedule having a dosing interval selected from once-weekly dosing, twice-monthly dosing, once-monthly, once-quarterly and once-annually dosing. The present invention further discloses a method for treating or preventing a bone disorder in a mammal in need thereof comprising continuously orally administering a unit dosage per-day to said mammal in a short time for a long time therapy.

Owner:CHEN CHIH MING JAMES

Antimicrobial Compositions

Antimicrobial compositions which are active against bacteria, yeast and mold spores are described. The compositions may be blends of (I) an acrylate / methacrylate copolymer having a hydrophobic network structure and (II) a preservative component comprising comprising (A) an isothiazolinone or (B)phenoxyethanol and either (i) a 1,2-diol or (ii) benzoic acid and dehydroacetic acid.

Owner:ISP INVESTMENTS INC

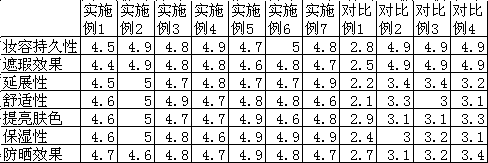

Air cushion BB cream for look beautifying and skin caring

InactiveCN108186405AImprove stabilityGood nutrition and moisturizing effectCosmetic preparationsBody powdersCross-linkSkin color

The invention discloses an air cushion BB cream for look beautifying and skin caring. The BB cream comprises diphenylsiloxyphenyl polytrimethylsiloxane, butanediol dioctanoic acid / dicaprate, polydimethylene siloxane, cyclopentasiloxane, cetyl PEG / PPG-10 / 1 polydimethylsiloxane, sorbitan stearin, acrylic acid / stearyl alcohol acrylic acid ester / polydimethylsiloxane methacrylate copolymer, polydimethylsiloxane crosspolymer, trimethylsiloxyphenyl dimethicone, HDI / trimethylol hexyl lactone cross-linked polymer, disteardimonium hectorite, titanium dioxide, tin oxide, synthetic fluorophlogopite, ironoxide, mica, polyhydric alcohols, magnesium sulfate, silica and water balance. According to the BB cream, emulsifier, emollient, stabilizer and film-forming agent are selected, the stability, efficacyand feeling of use of products are fully considered, the best formula component thereof is obtained, and the BB cream has the effects of correcting skin color, isolating ultraviolet rays and nourishing and moisturizing the skin.

Owner:FOSHAN WENSENTE INTPROP SERVICE CO LTD

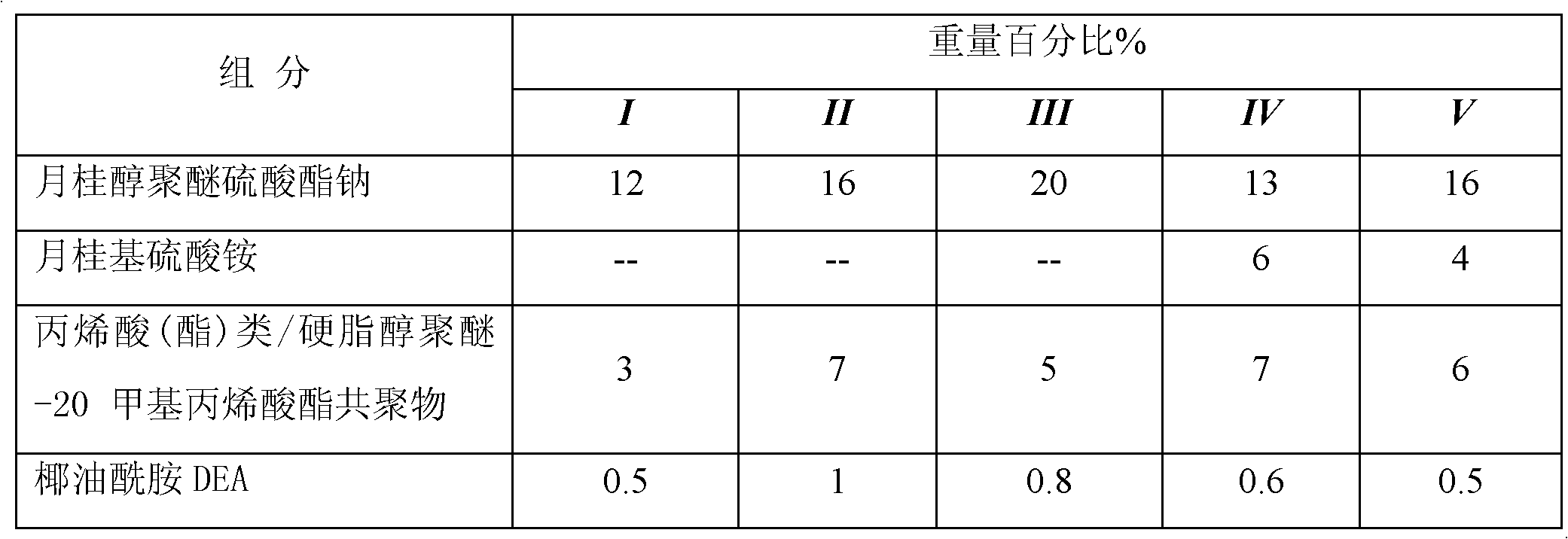

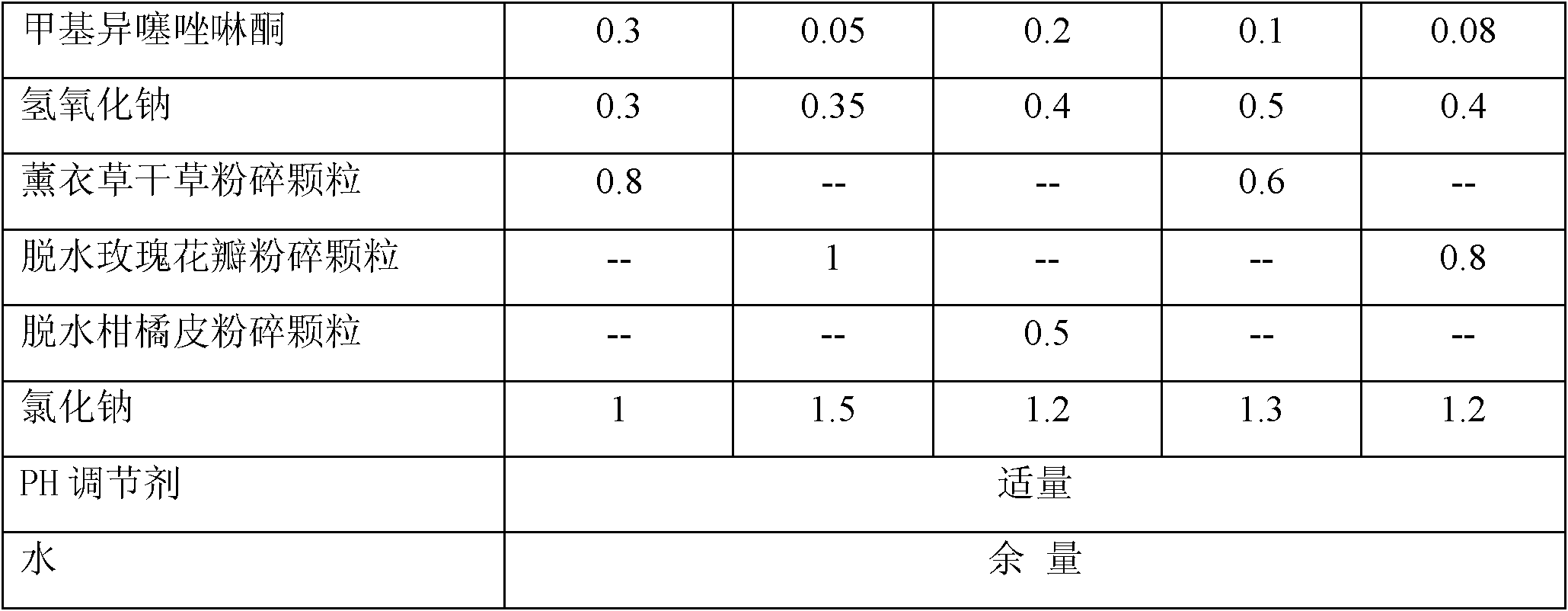

Bath cream and preparation method thereof

ActiveCN102048668AEasy to cleanImprove cleanlinessCosmetic preparationsToilet preparationsMethyl-isothiazolinoneMassage

The invention provides a bath cream and a preparation method thereof. The bath cream mainly comprises the following components in weight percent: 12-20% of surface active agent, 3-7% of crylic acid (ester) / stearyl alcohol polyether-20 methacrylate copolymer, 0.5-1% of coconut oil amide DEA, 0.05-0.3% of methyl isothiazolinone, 0.3-0.5% of sodium hydroxide, 0.5-1% of dehydrated plant smashed particles and 1-1.5% of sodium chloride. The bath cream of the invention improves the utilization efficiency of plants, and plays a certain action of massage on skins by adding stable suspended dehydrated plant smashed particles, and improves the cleaning efficacy of the bath cream.

Owner:厦门诚享东方股份有限公司

Methacrylate copolymer pour point depressants

Poly methacrylate copolymers are disclosed which comprising from about 60 to about 96 weight percent of a C12-C16 alkyl methacrylate and from about 40 to about 4 weight percent of a C18-C30 alkyl methacrylate and provide excellent low temperature properties to lubricating oils.

Owner:CIBA CORP

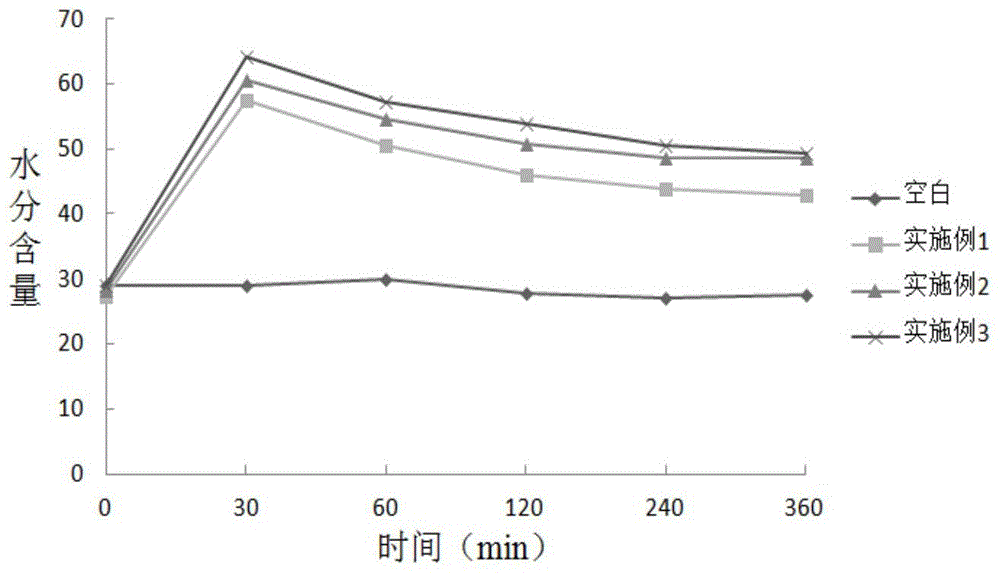

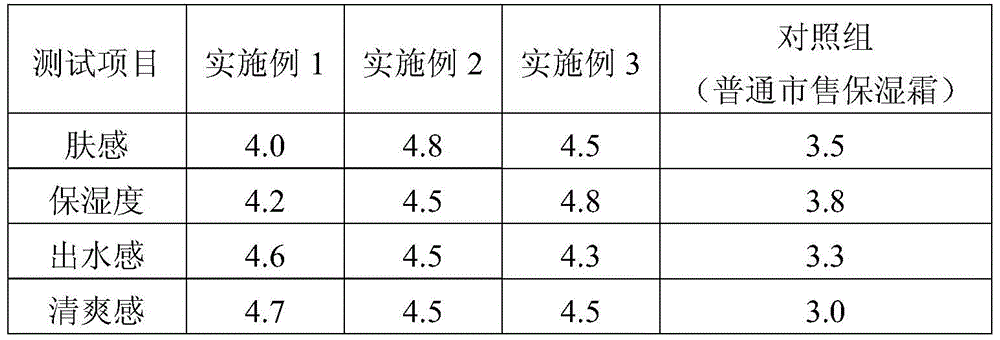

Water moisturizing cream and preparation method thereof

ActiveCN105769643AFast stabilityGuaranteed stabilityCosmetic preparationsToilet preparationsCross-linkBetaine

The invention provides water moisturizing cream. The water moisturizing cream is prepared from the following components: cyclopentasiloxane, polydimethylsiloxane, cetyl PEG / PPG-10 / 1 polydimethylsiloxane, cyclopentasiloxane / polydimethylsiloxane cross-linked polymer, essence, glycerol, butanediol, propylene glycol, panthenol, glycine betaine, sodium chloride, crylic acid (ester) / beheneth-25 methacrylate copolymer, sodium hydroxide, sodium hyaluronate, daisy flower extract, kappaphycus alvarezii extract, chlorella / white lupine protein fermented product, glycyrrhiza glabra root extract, extract of all-grass of Bacopa monnieri ( L .) Wettst., bio-saccharide gum, phenoxyethanol / ethylhexylglycerin and deionized water. The water moisturizing cream provided by the invention is good in stability, good in closing property, and durable in moisture retention, and has soft and smooth applying feel.

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

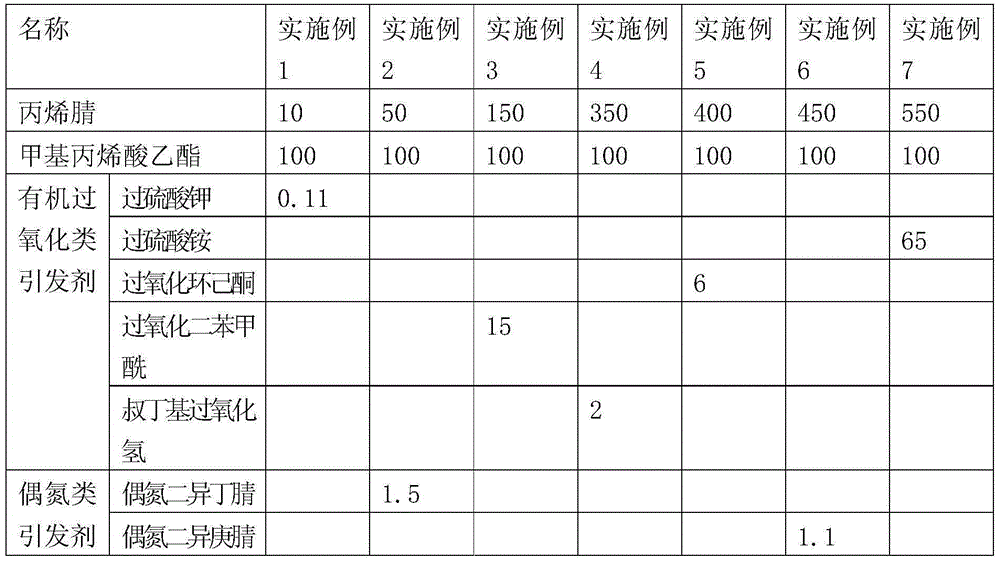

Preparation method of anti-coagulation hemodialysis membrane

ActiveCN106466562AImprove hydrophilicityExcellent anticoagulant propertiesSemi-permeable membranesSuction devicesFiberCerium

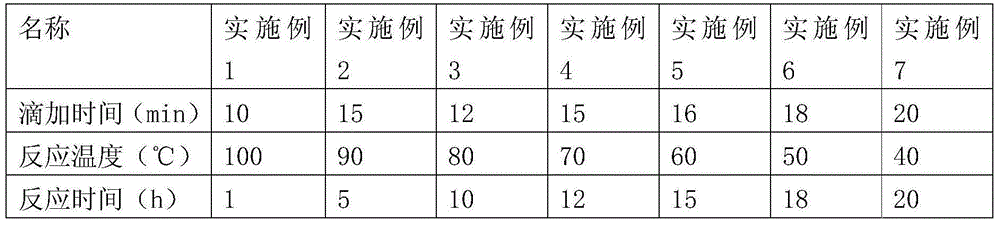

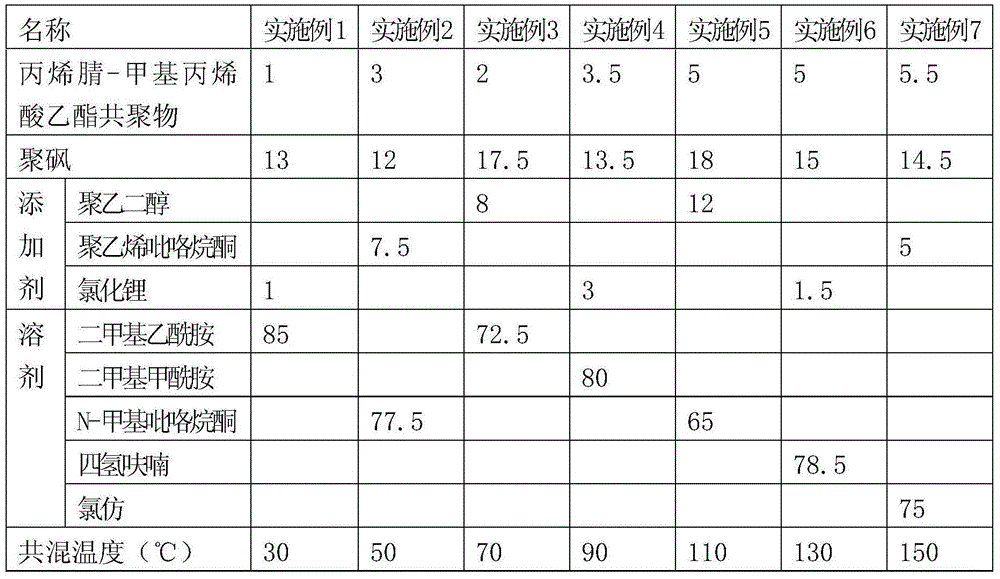

The invention relates to a preparation method of an anti-coagulation hemodialysis membrane. The preparation method includes the steps of: a) adding acrylonitrile and ethyl methacrylate into a reaction kettle according to mass ratio of 0.1-5.5:1, stirring the mixture and dropwise adding a polymerization initiator to initiate free radical polymerization to obtain an acrylonitrile-ethyl methacrylate copolymer; b) blending 1-5.5% of the acrylonitrile-ethyl methacrylate copolymer, 12-18% of polysulfone, 1-12% of an additive, and 65-85% of a solvent to prepare a membrane solution, and spinning the membrane solution to manufacture hollow-fiber hemodialysis membrane; and c) dissolving an active monomer containing an alkene double bond and a hydrophilic group in deionized water, and adding a cerium ammonium nitrate grafting initiator to prepare a soaking water solution, and soaking the hollow-fiber hemodialysis membrane in the soaking water solution to initiate a grafting reaction of the active monomer on the surface of the hollow-fiber hemodialysis membrane, and cleaning the hollow-fiber hemodialysis membrane. The surface hydrophilicity of the hemodialysis membrane is significantly improved. The hemodialysis membrane has high biocompatibility and anti-coagulation performance.

Owner:江苏朗生生命科技有限公司

Method for preparing inorganic aluminosilicate polymer and inorganic macromolecule composite gelled material

InactiveCN101544484AIncrease profitPromote resource utilizationCement productionSlagResource utilization

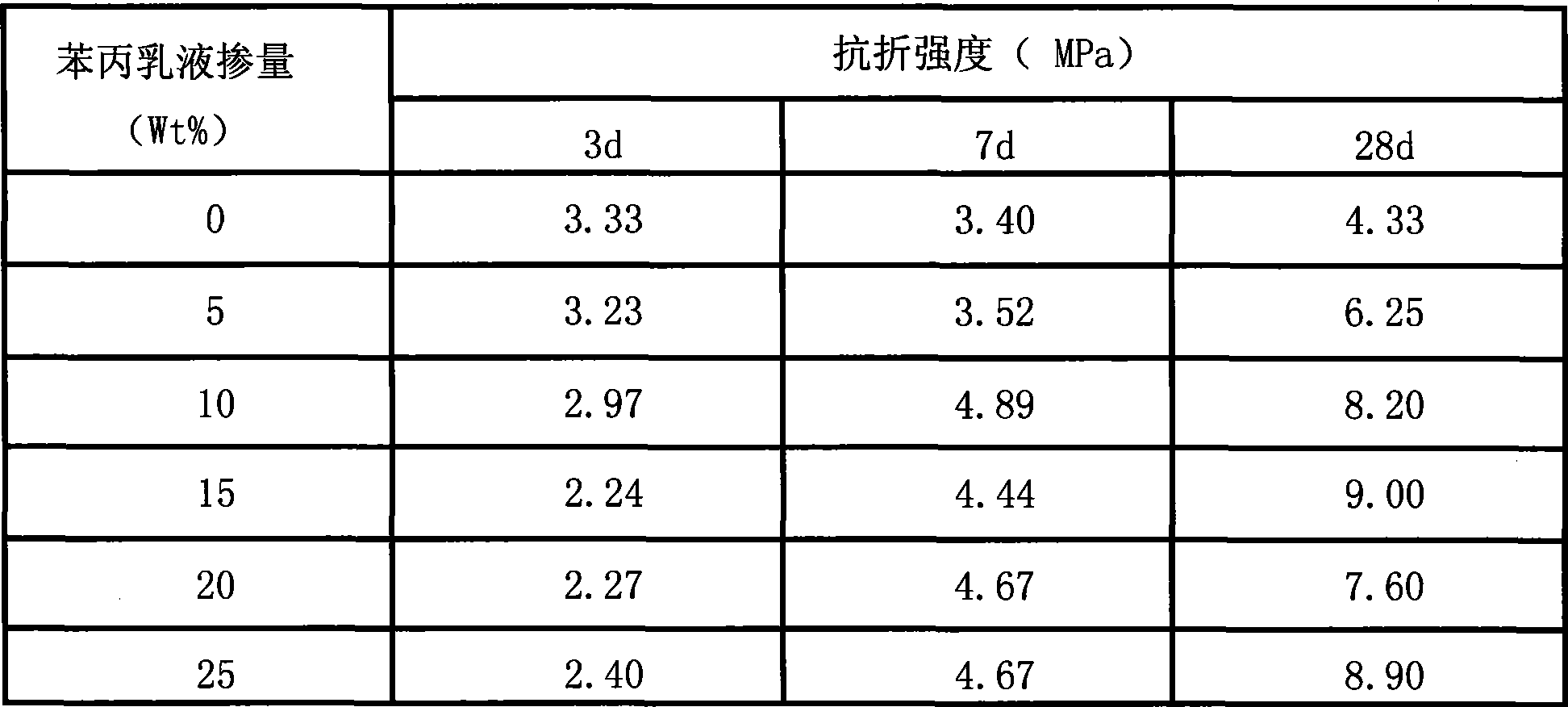

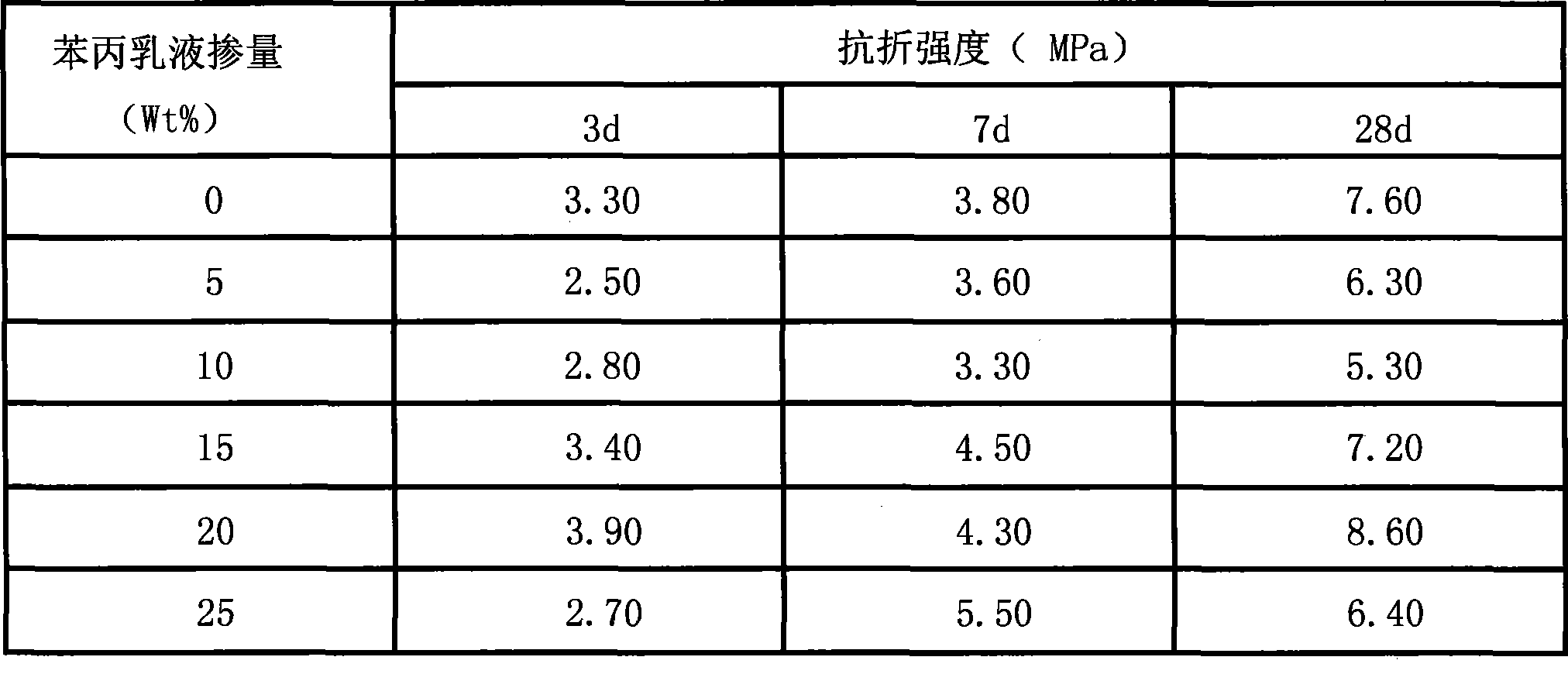

The invention discloses a method for preparing an inorganic aluminosilicate polymer and organic macromolecule composite gelled material. In the method, phosphatic slag or slag capable of providing inorganic aluminosilicate components and styrene / methacrylate copolymer emulsion are utilized to produce phosphatic slag or slag inorganic aluminosilicate polyer and organic macromolecule composite gelled material under the action of sodium silicate excitants; wherein the amount of the styrene / methacrylate copolymer emulsion is 5-25 percent of the weight of the phosphatic slag or slag, and the amount of the alkali excitant sodium silicate is 13 percent of the weight of the phosphatic slag or slag; and the flexural strength of the inorganic aluminosilicate polymer and organic macromolecule composite is superior to the inorganic aluminosilicate polymer in 28-day age, and the 28-day maximum flexural strength is 2.08 times of that of the inorganic aluminosilicate polymer. The preparation process has no discharge of waste water, waste gas and waste slag, does not need heating, is green, environment-friendly and energy-saving, reduces the consumption, and is one effective approach for large-scale resource utilization of industrial solid wastes.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Film-forming oil-control composition and cosmetic

PendingCN112675054AImprove the anti-sweat and anti-friction effectKeep dryCosmetic preparationsBody powdersPolymer scienceMeth-

The invention relates to the technical field of cosmetics and particularly relates to a film-forming oil-control composition and a cosmetic. The film-forming oil-control composition disclosed by the invention is prepared from the following ingredients: trimethylsiloxysilicate, hydroxyapatite and an acrylic(acrylate) / polytrimethylsiloxane methacrylate copolymer. High-polymer film formers, i.e., the trimethylsiloxysilicate and the acrylic(acrylate) / polytrimethylsiloxane methacrylate copolymer and special oil taking powder, i.e., the hydroxyapatite are compounded and have a synergistic effect, the anti-sweat friction-resistant effect of a base makeup can be effectively improved, skin can be kept dry and clear through continuously absorbing excessive sebum, the problem of makeup dissolving caused by sebum secretion is solved, and a base makeup choice with excellent makeup holding performance is provided for customers.

Owner:广州集妍化妆品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com