Multi-layer nuclear shell structural fluorin-containing polymer particle and thermoplastic polyolefin product having the same

A multi-layer core-shell structure, thermoplastic polyolefin technology, used in layered products, synthetic resin layered products, chemical instruments and methods, etc. , the problem of insufficient critical shear rate, etc., to reduce surface defects, improve transparency, and reduce the number of crystal points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

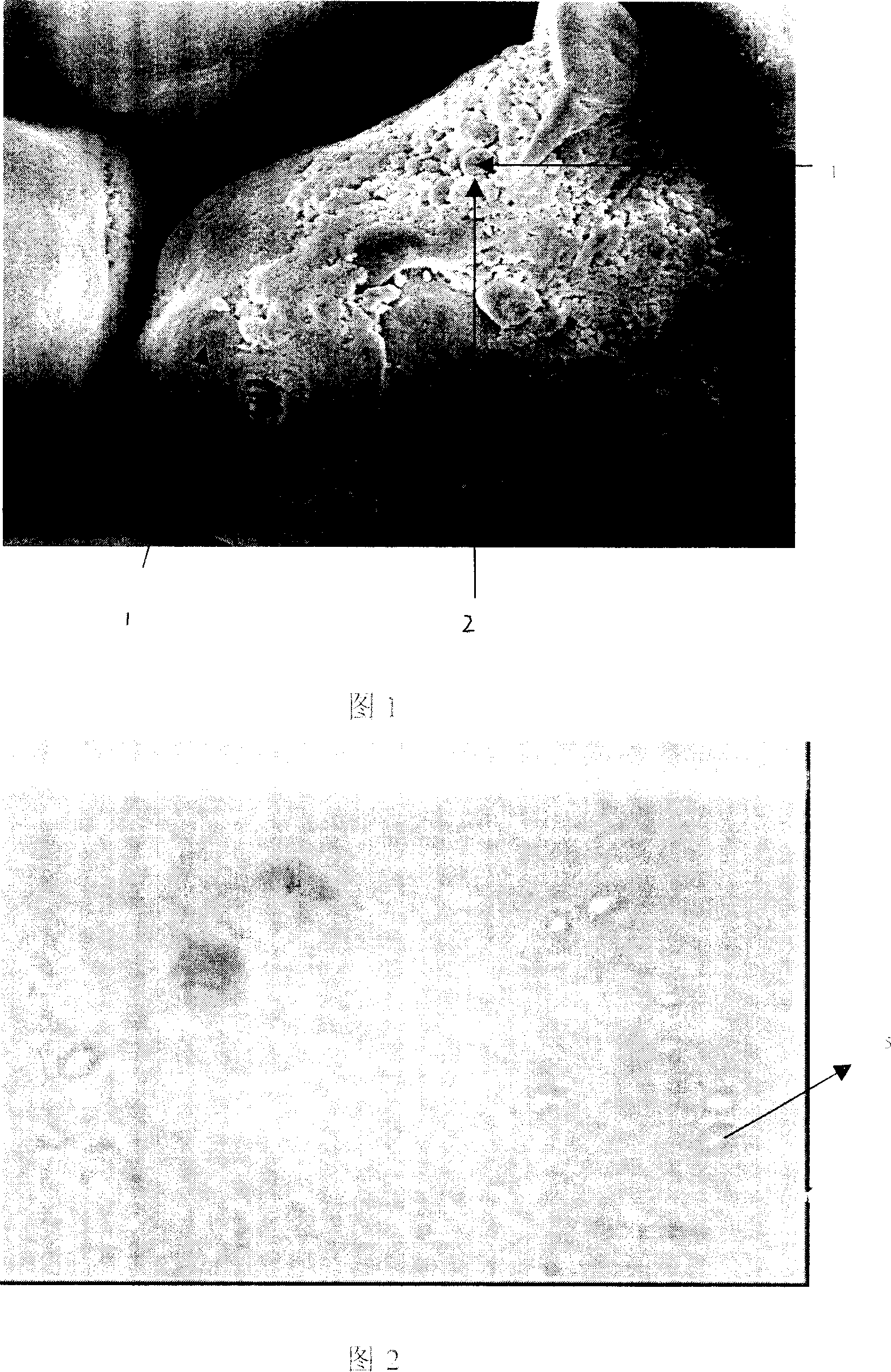

Image

Examples

Embodiment

[0040] The fluoropolymer of the present invention is obtained by in-situ transfer suspension polymerization.

[0041] Fluoropolymer A

[0042]Add 25 grams of deionized water, 2 grams of NaCl, 0.02 grams of nonylphenol polyoxyethylene ether into a 250 ml three-neck flask equipped with a thermometer, reflux device and stirring device, adjust the pH value to 5 with dilute hydrochloric acid, start stirring and add 3 The mixed monomer of methacrylate methyl ester and maleic anhydride (mass ratio 95 / 5, industrial product refining de-inhibition polymerization agent) with 0.65g AIBN dissolved in the gram is controlled at a temperature lower than 50°C, and 120 milliliters of the mixture is added dropwise within 1 hour. Ethylene fluoride-hexafluoropropylene copolymer concentrated dispersion (FKM emulsion L636 emulsion 30% solid content Solvay Solexis S.P.A), after the dropwise addition, add 1.5 grams of active calcium phosphate, slowly feed nitrogen to drive away oxygen, at 4 ° C / min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com