B1-grade flame-retardant irradiation crosslinking low-smoke halogen-free insulated cable material and preparation method thereof

A technology for insulating cables and cable materials, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

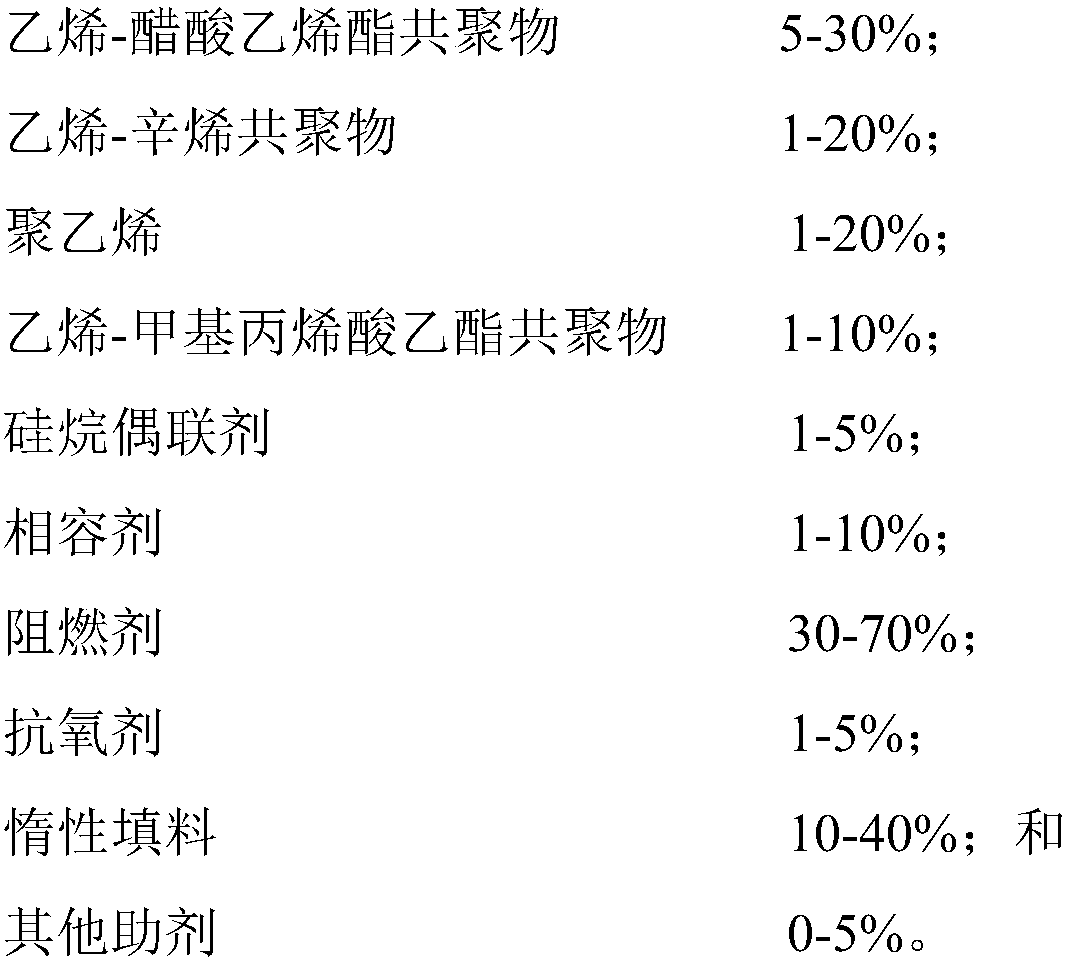

Method used

Image

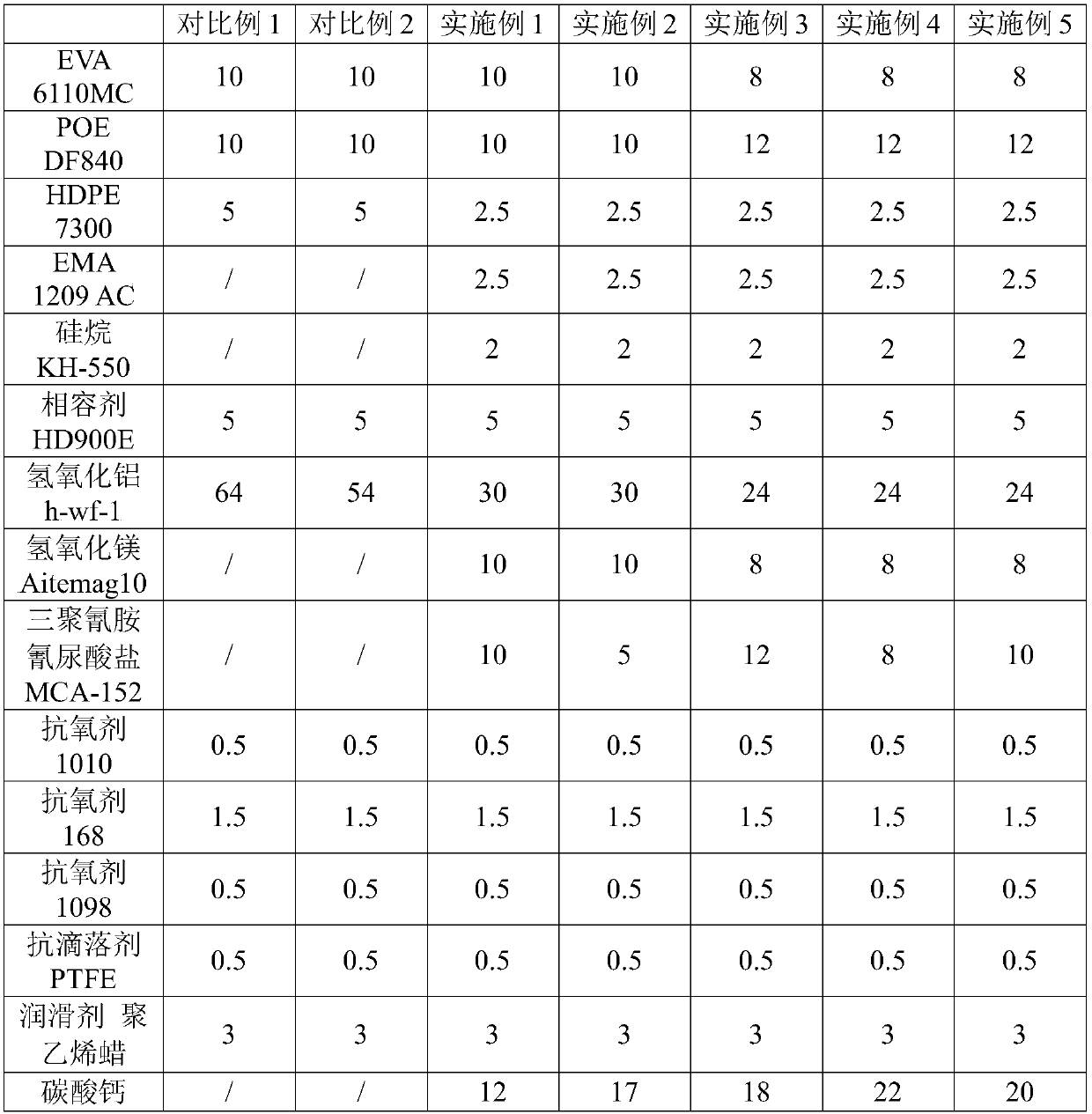

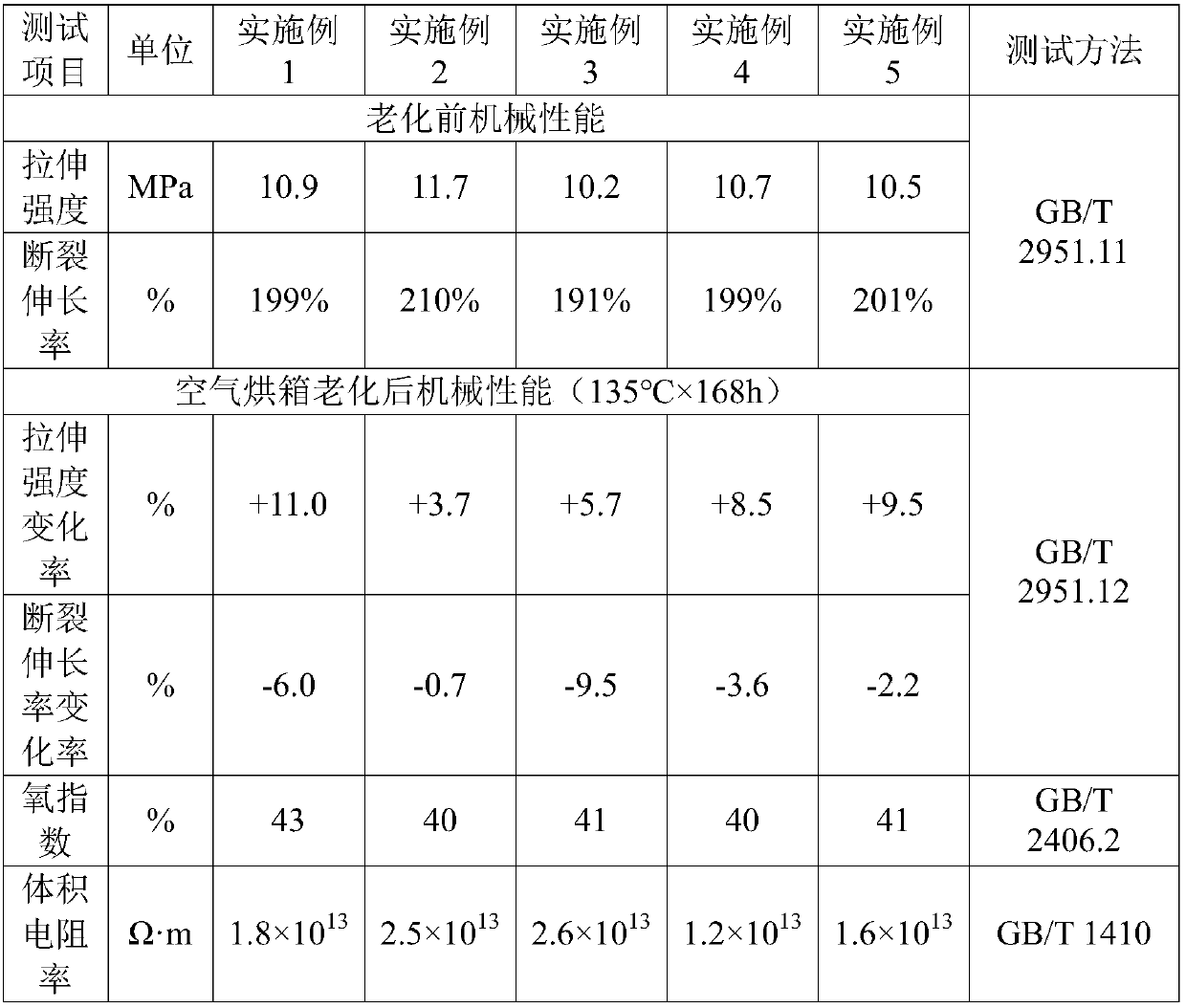

Examples

preparation example Construction

[0106] The present invention also provides a preparation method of cable material, the method comprising:

[0107] mixing the respective raw materials with corresponding mass fractions; and

[0108] Extrude the mixed raw materials and granulate;

[0109] In this way, the cable material is obtained.

[0110] The mixing, extruding and granulating in the preparation method of the cable material of the present invention can be carried out by adopting conventional mixing, extruding and granulating methods in the field. For example, the raw materials can be mixed using an internal mixer; the raw materials can be further mixed, sheared, kneaded, plasticized and / or extruded using a twin-screw extruder and / or a single-screw extruder; extrusion cooling Finally, the extruded material can be pelletized using a pelletizer.

[0111] Preferably, the preparation method of cable material of the present invention may comprise the following steps:

[0112] (1) Prepare the corresponding raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com