Variable light distribution device based on silicon-based nitride and preparation method thereof

A nitride and light distribution technology, applied in optical components, TV system components, semiconductor/solid-state device components, etc., can solve the problems of limiting device integration and miniaturization, high production costs, and cumbersome processes, and achieve The preparation method is simple and easy, the processing technology is stable, and the effect of good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

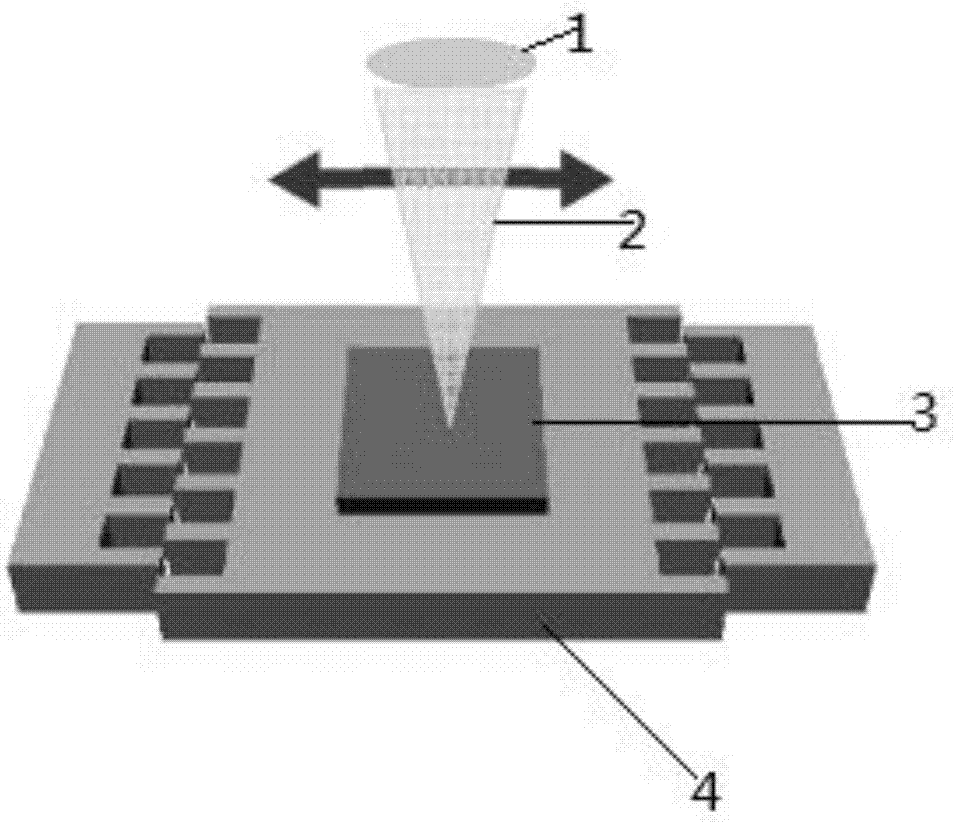

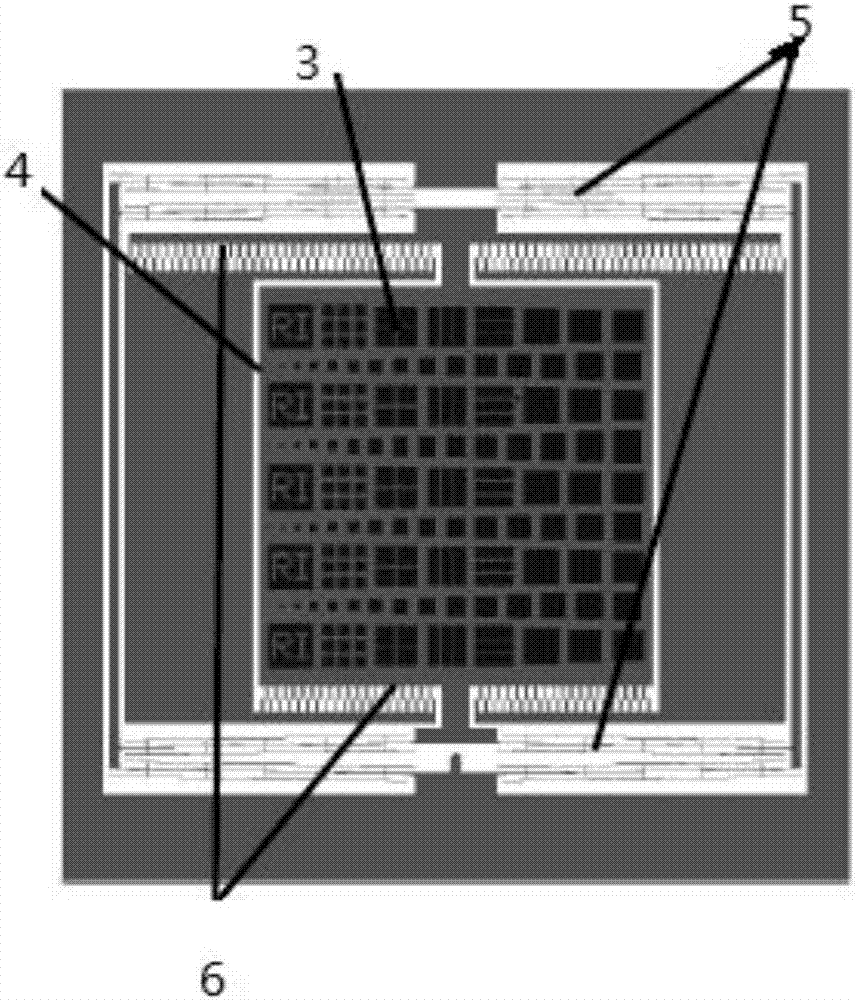

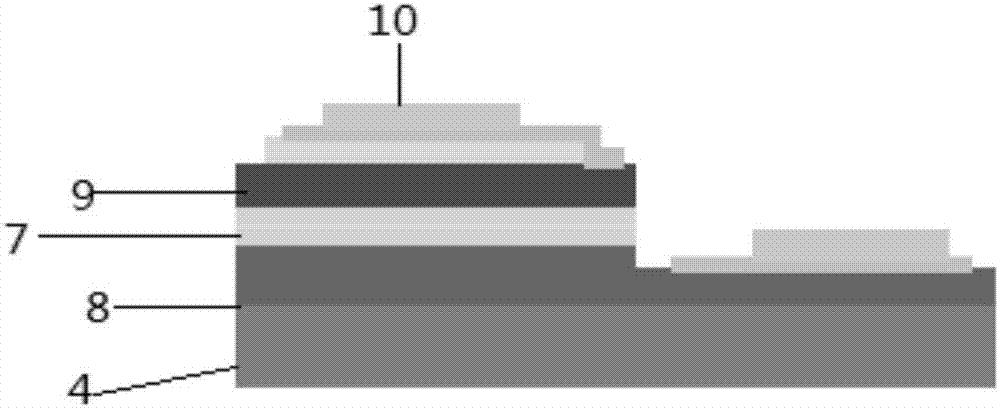

[0035] figure 1 It is a schematic diagram of the overall structure of an embodiment of the silicon-based nitride-based variable light distributor of the present invention. Such as figure 1 As shown, the variable light distributor of this embodiment includes: lens 1, GaN-based LED light source 3, Si substrate 4, electrostatic MEMS micro-actuator 60, comb driver 61, quantum well GaN 7, N-GaN 8, P-GaN 9, EL electrode 10; the GaN-based LED light source is grown on the Si substrate 4; the lens 1 is completely adhered to the GaN-based LED light source 3; the electrostatic MEMS micro-actuator 60 includes A comb driver 61 composed of a fixed-toothed comb and a movable-toothed comb; the fixed-toothed comb is connected to the Si substrate 4, and the movable-toothed comb is fixed under the GaN-based LED light source 3; by applying a voltage, the GaN-based The LED lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com