Patents

Literature

72 results about "Silicon micromachining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

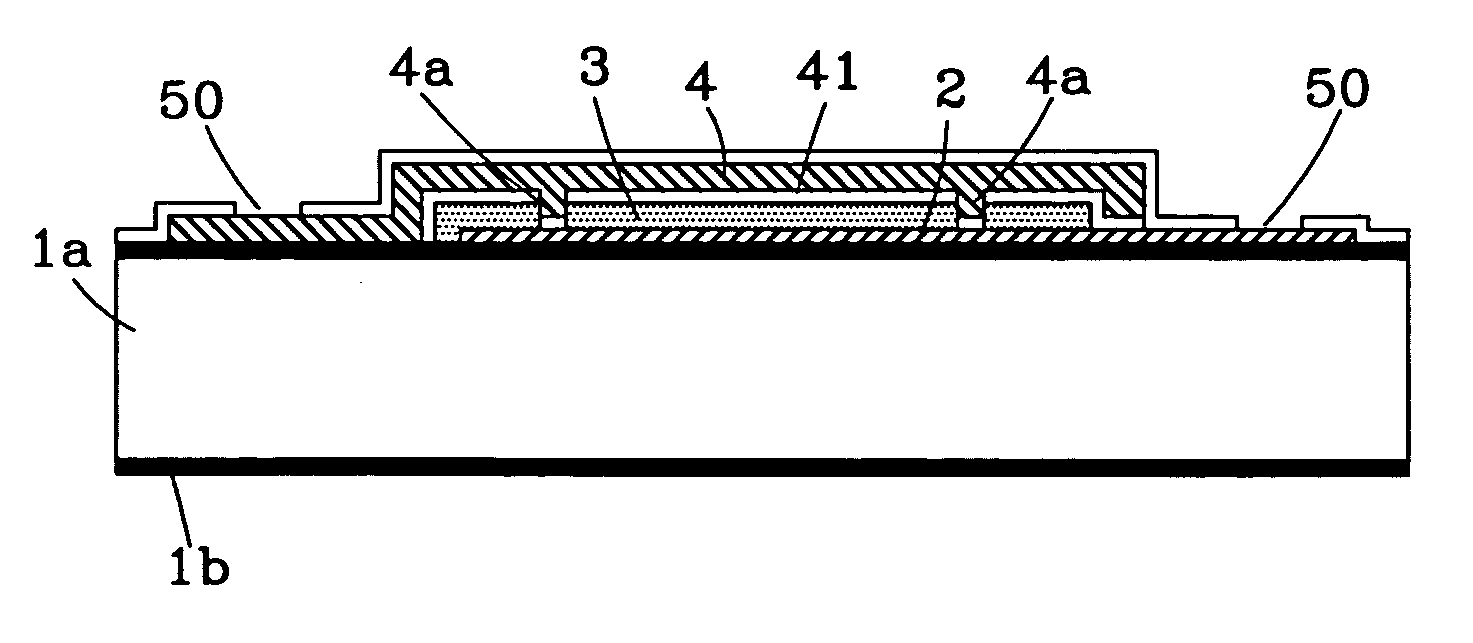

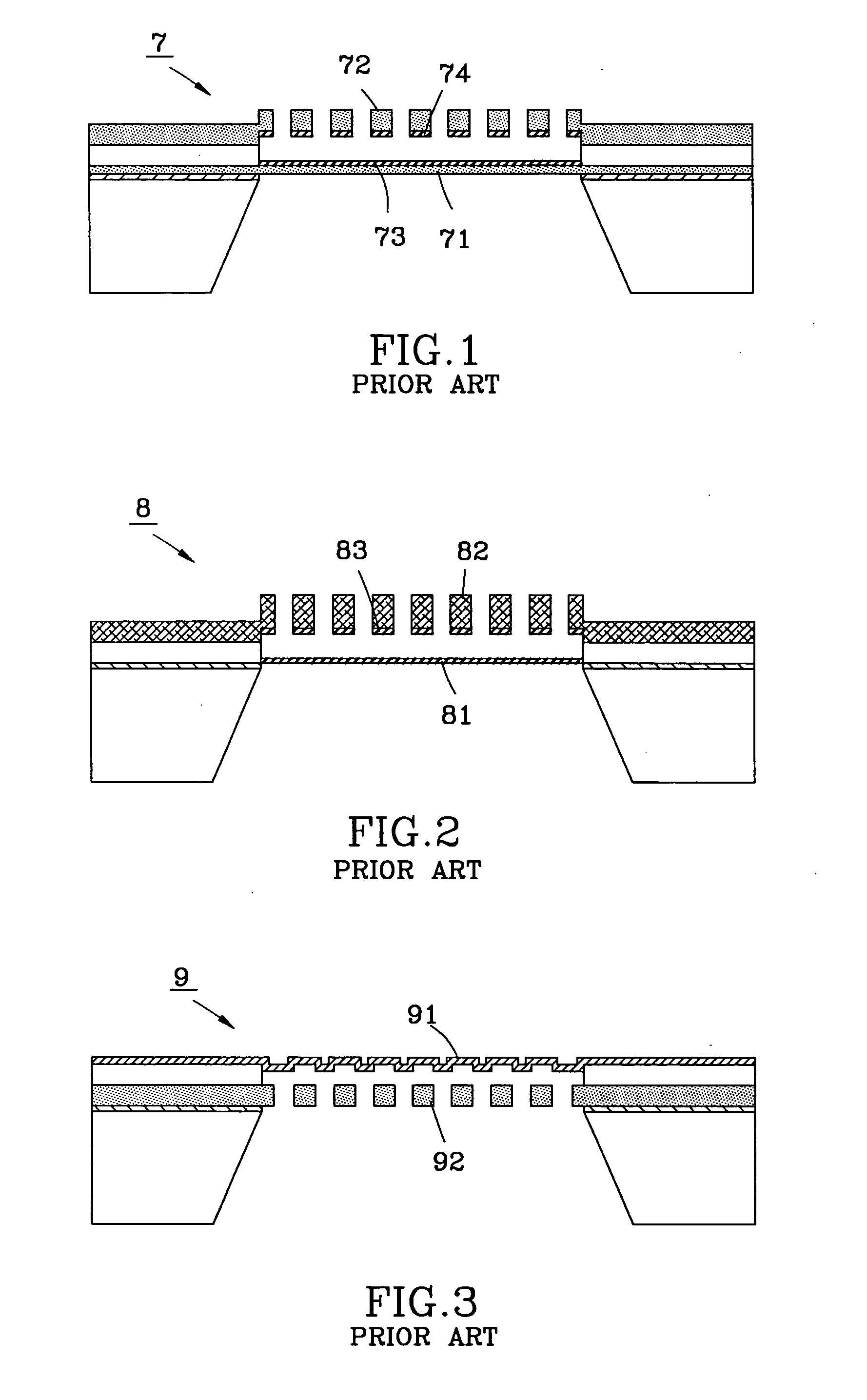

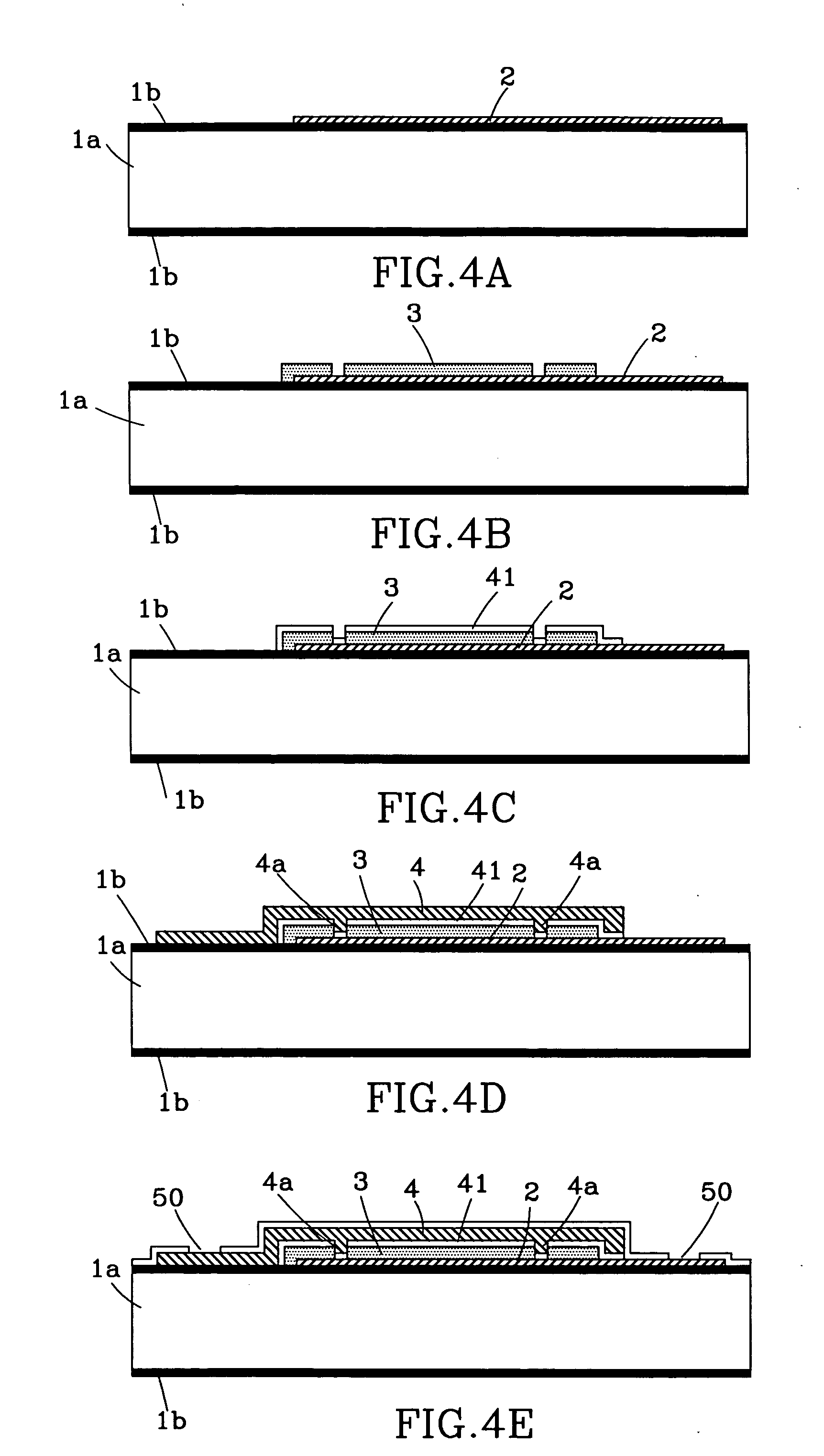

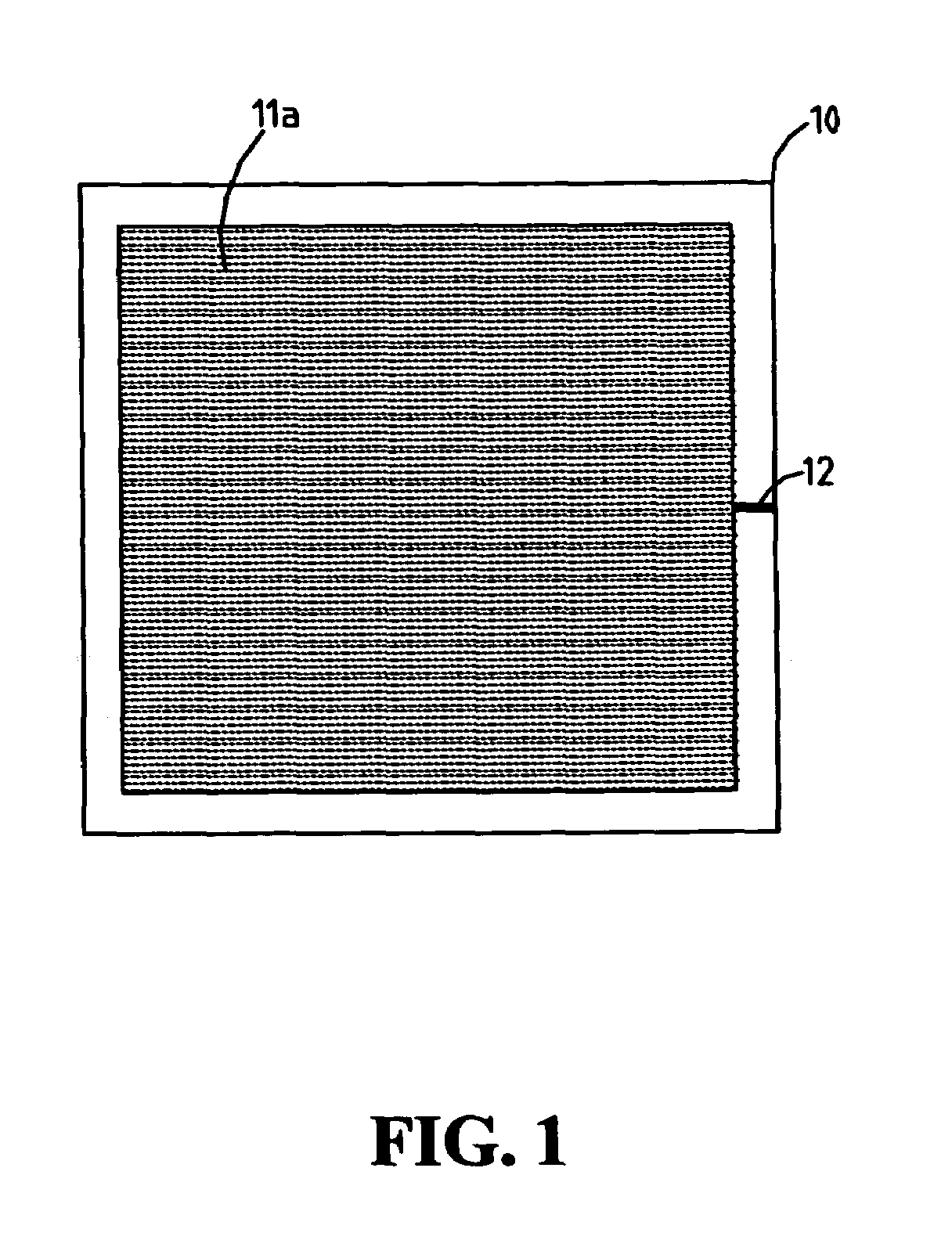

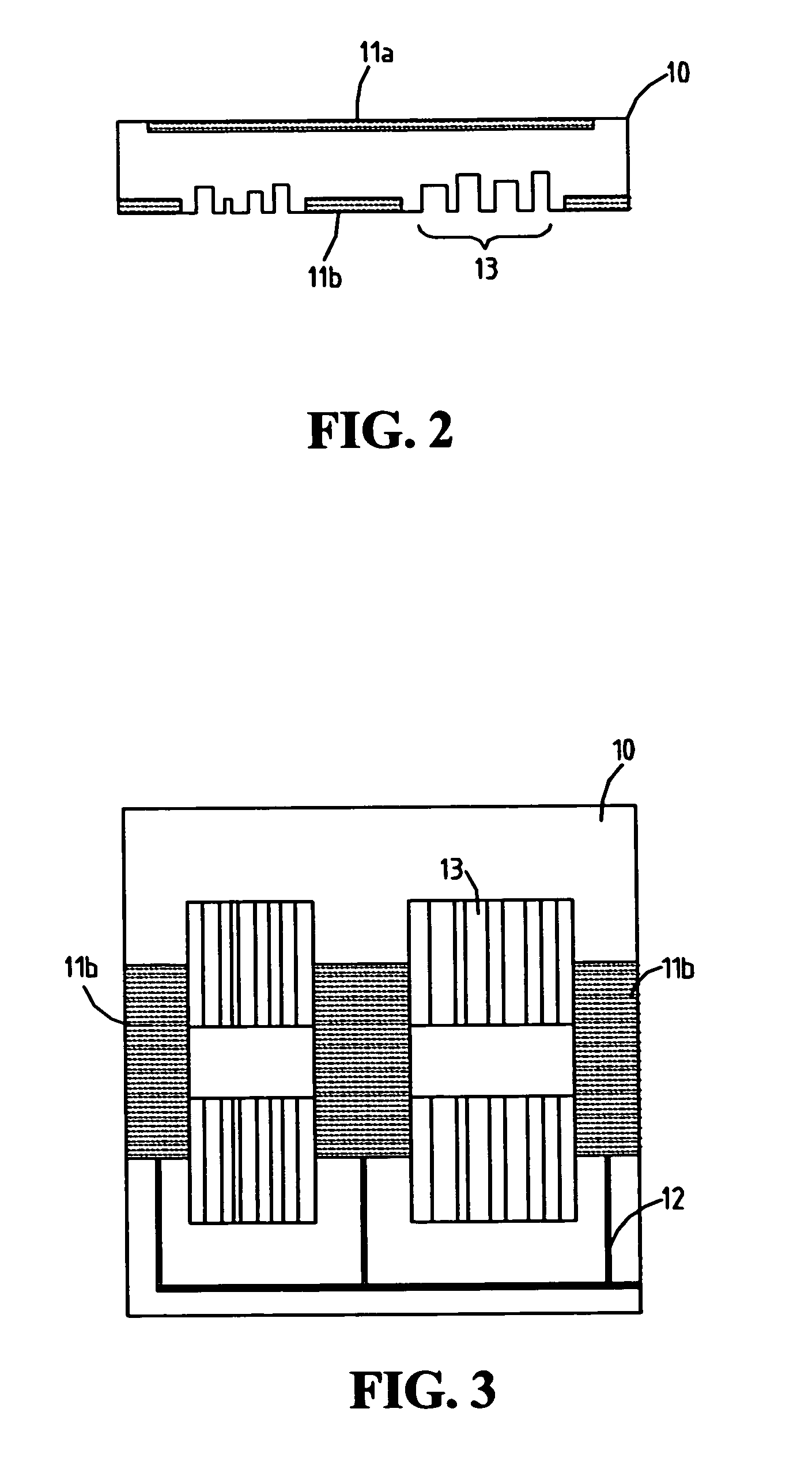

Method of making silicon-based miniaturized microphones

InactiveUS20060291674A1High sensitivityImprove reliabilityElectrostatic transducer microphonesDeaf-aid setsManufacturing cost reductionResonance

A method of making a silicon-based miniaturized microphone by means of the application of a combination of processes including a semiconductor manufacturing process and a silicon micro-machining technology. A silicon-based miniaturized microphone made by means of this method has a silicon substrate, which defines a resonance cavity, a diaphragm, a backplate having sound holes, and solder pads. This method is easy to perform, and suitable for a mass production to reduce the manufacturing cost.

Owner:MERRY ELECTRONICS CO LTD

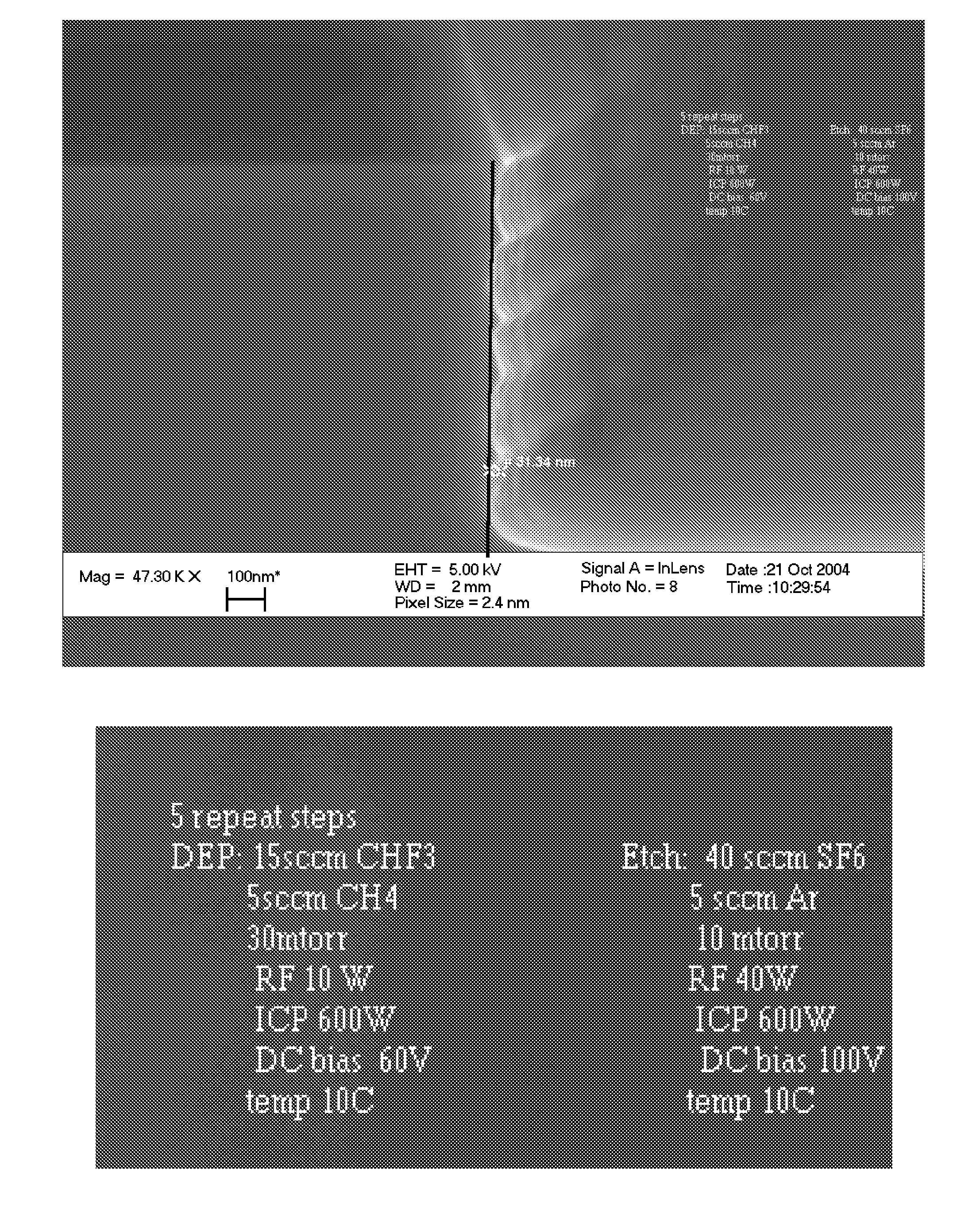

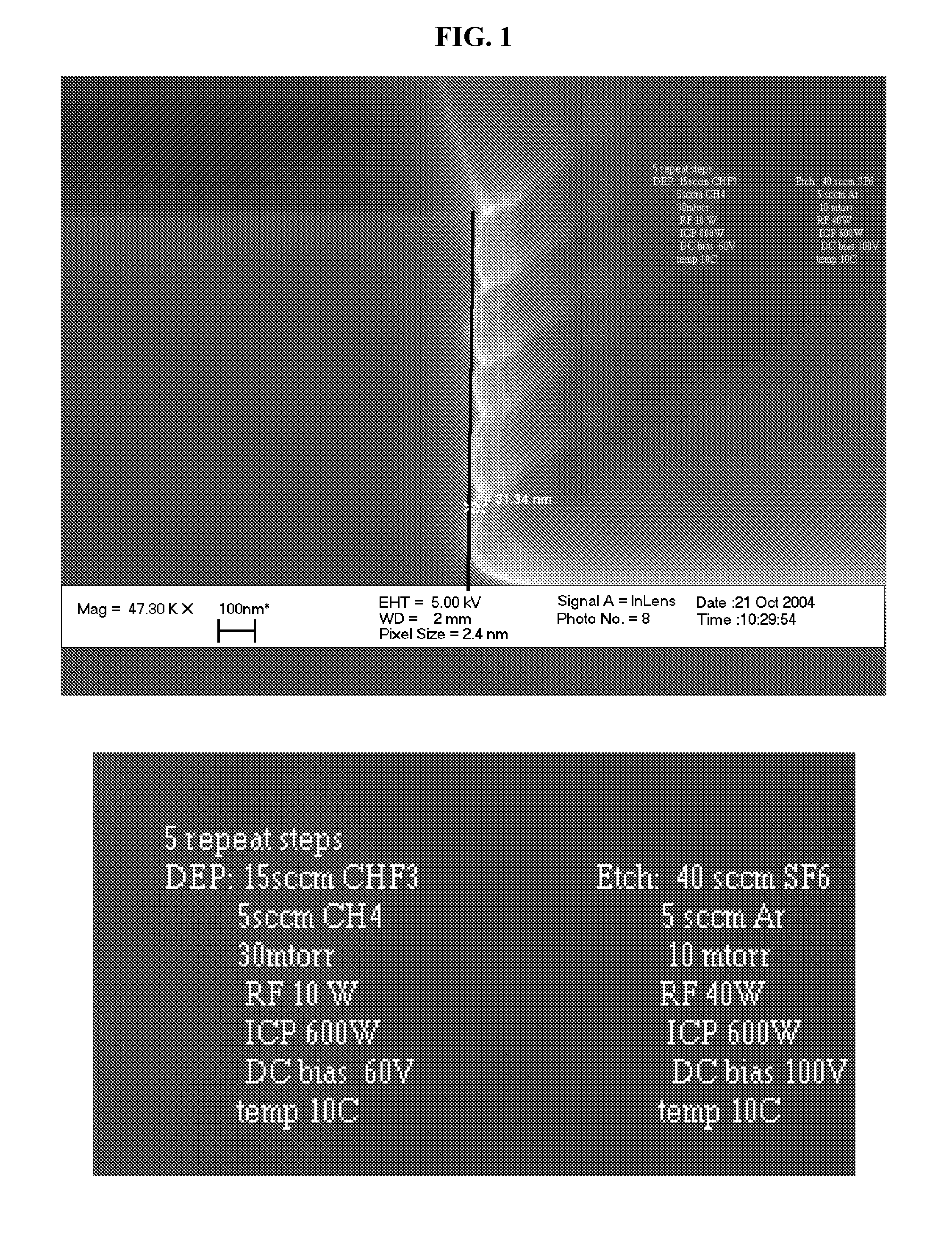

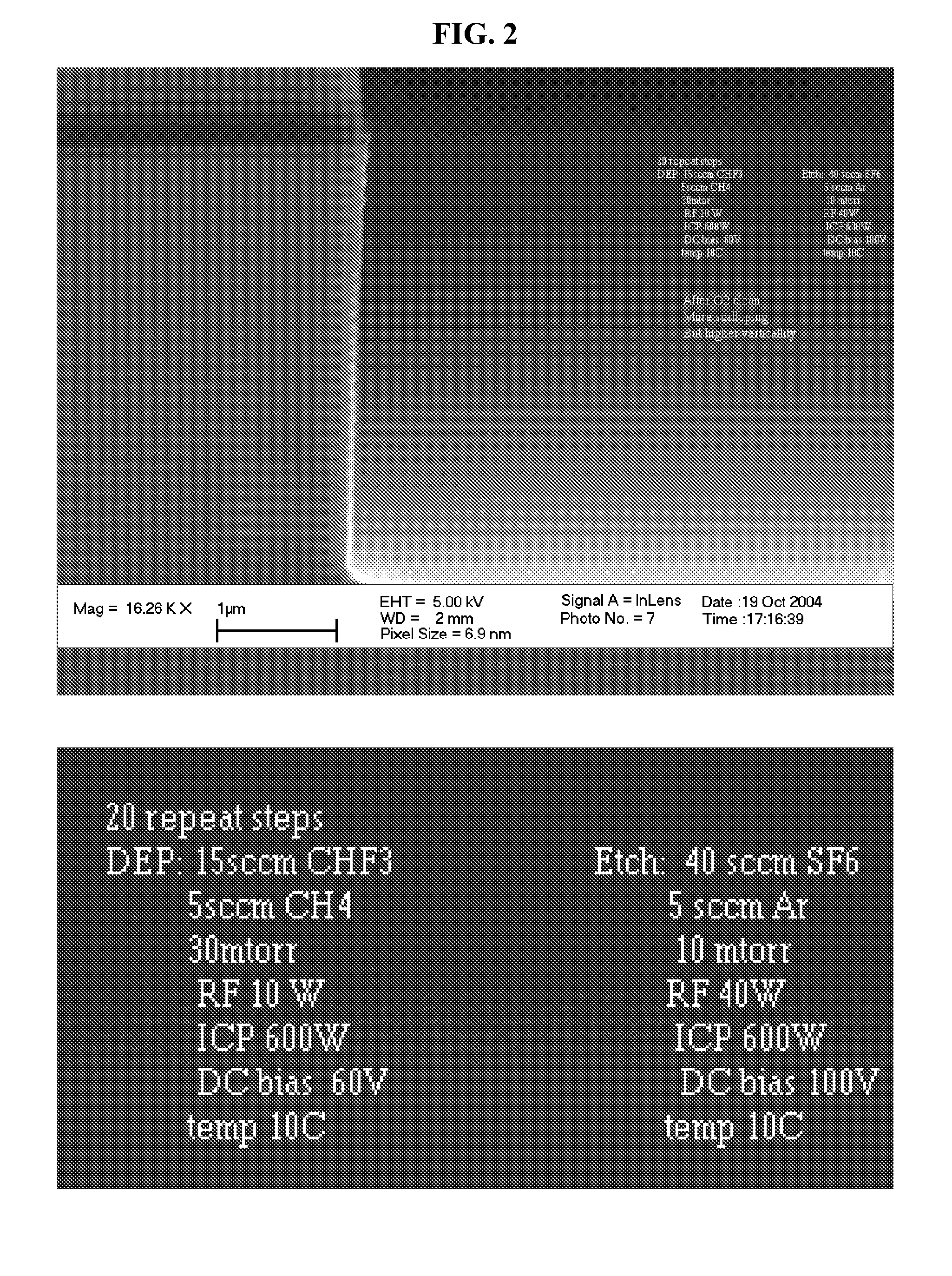

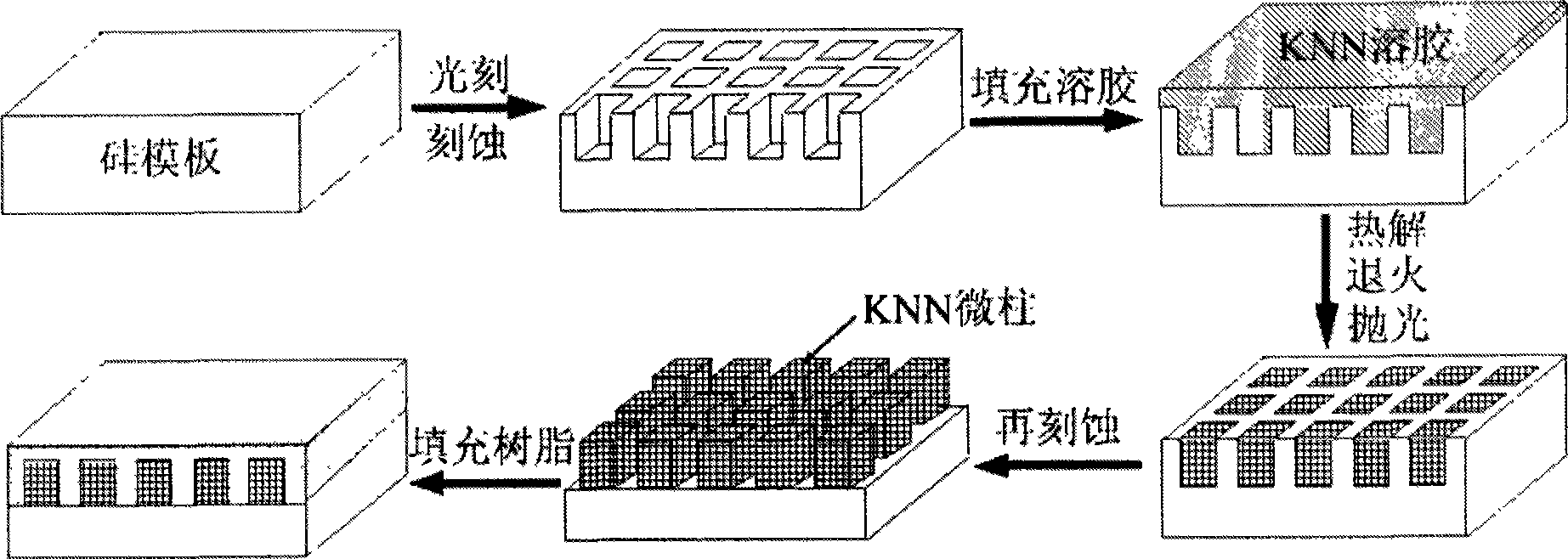

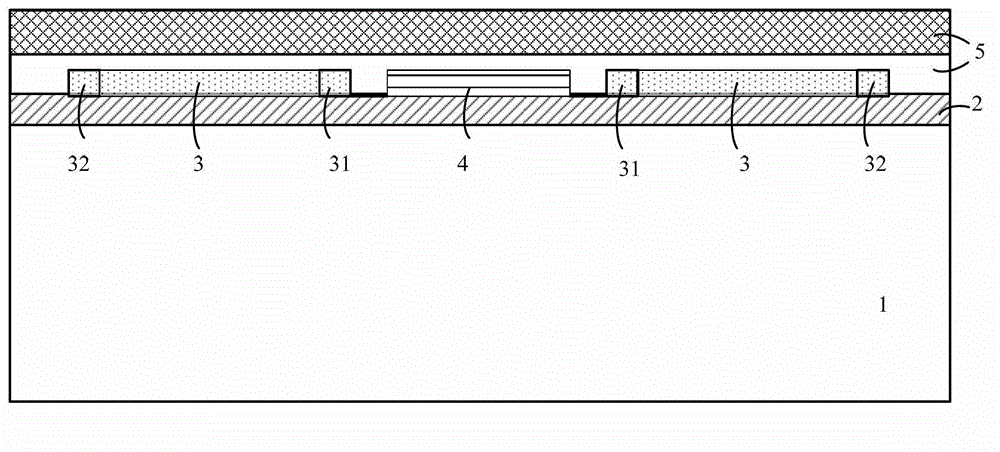

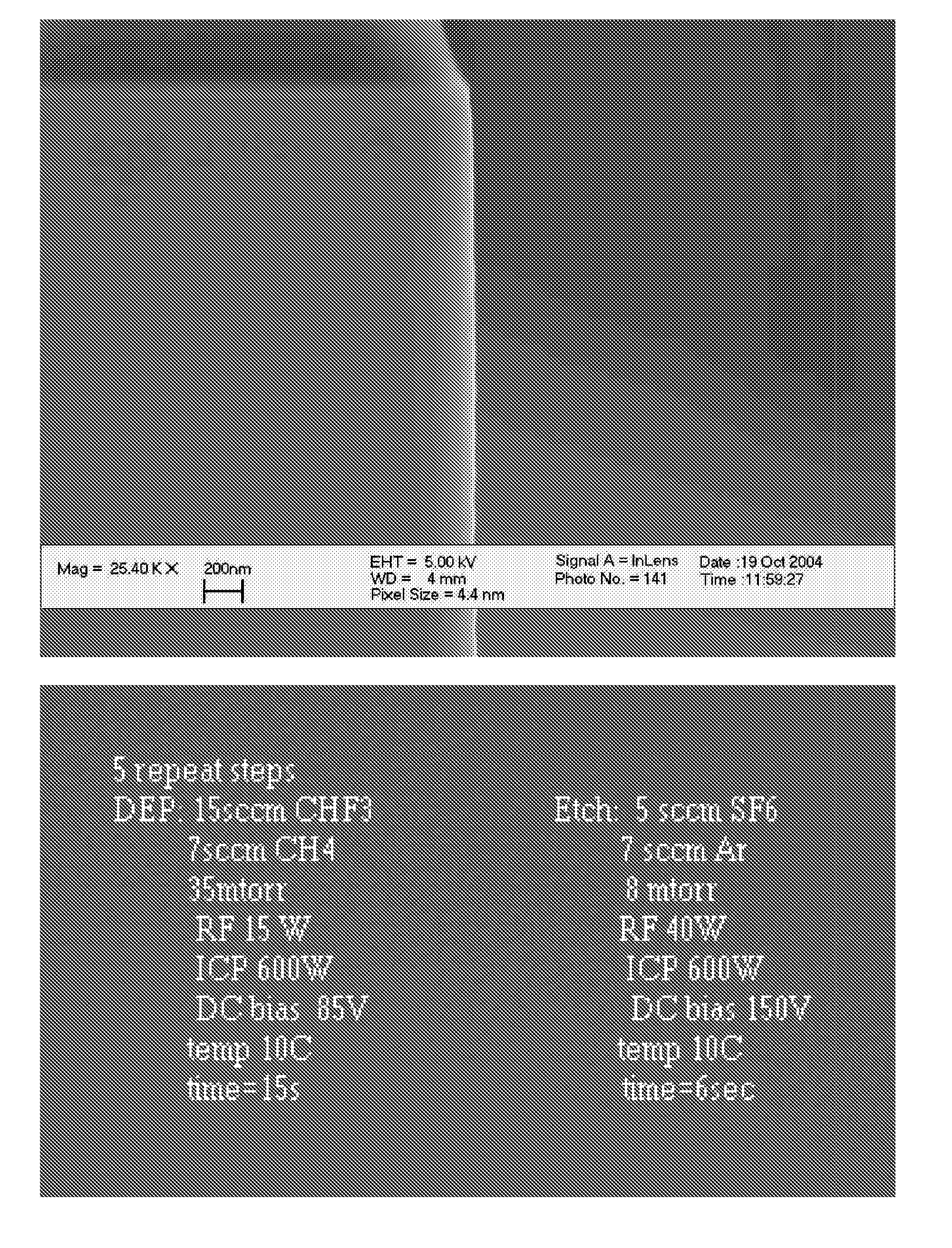

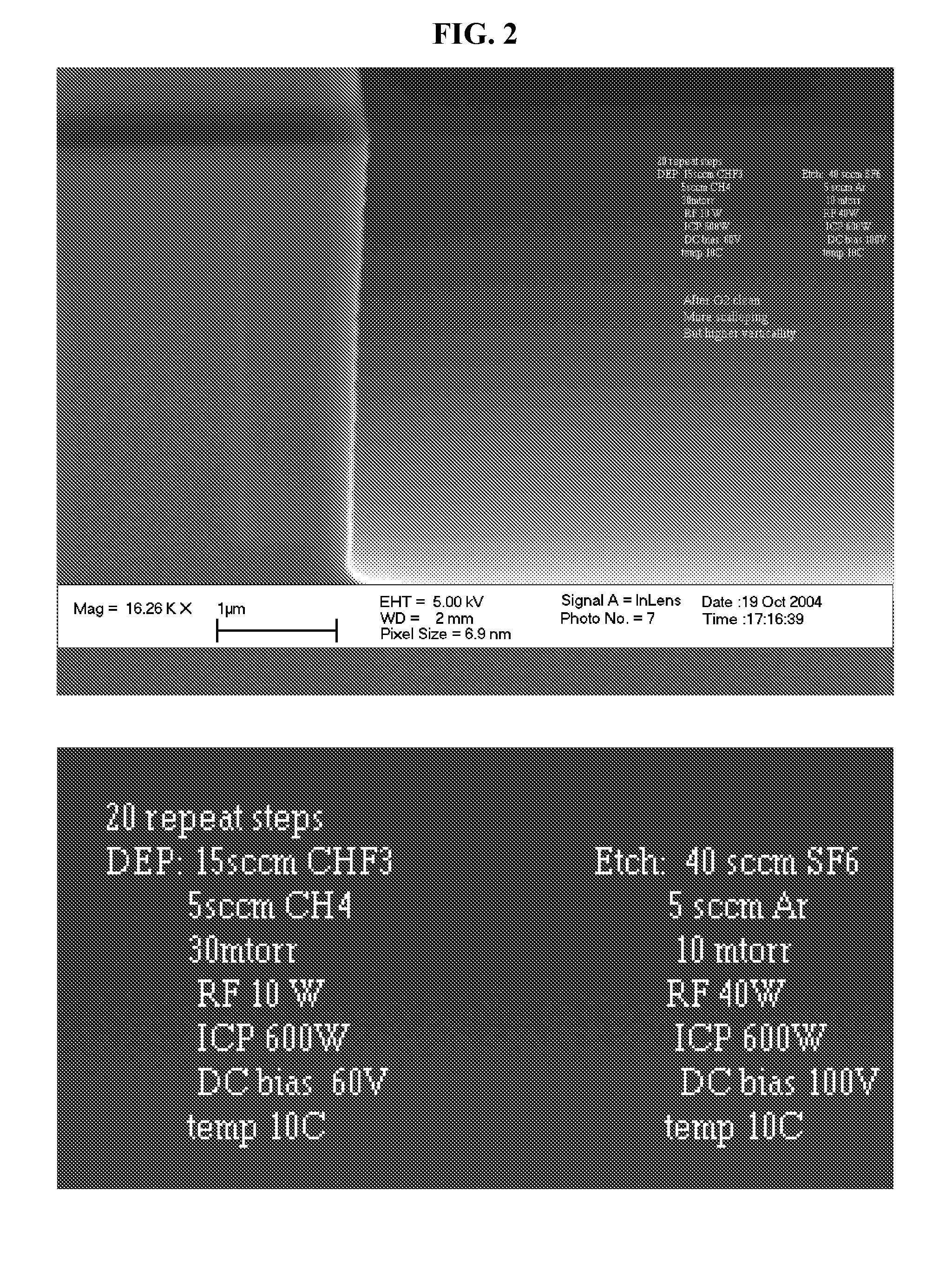

Etching radical controlled gas chopped deep reactive ion etching

ActiveUS20070015371A1Decorative surface effectsSemiconductor/solid-state device manufacturingInductively coupled plasmaChemical measurement

A method for silicon micromachining techniques based on high aspect ratio reactive ion etching with gas chopping has been developed capable of producing essentially scallop-free, smooth, sidewall surfaces. The method uses precisely controlled, alternated (or chopped) gas flow of the etching and deposition gas precursors to produce a controllable sidewall passivation capable of high anisotropy. The dynamic control of sidewall passivation is achieved by carefully controlling fluorine radical presence with moderator gasses, such as CH4 and controlling the passivation rate and stoichiometry using a CF2 source. In this manner, sidewall polymer deposition thicknesses are very well controlled, reducing sidewall ripples to very small levels. By combining inductively coupled plasmas with controlled fluorocarbon chemistry, good control of vertical structures with very low sidewall roughness may be produced. Results show silicon features with an aspect ratio of 20:1 for 10 nm features with applicability to nano-applications in the sub-50 nm regime. By comparison, previous traditional gas chopping techniques have produced rippled or scalloped sidewalls in a range of 50 to 100 nm roughness.

Owner:RGT UNIV OF CALIFORNIA

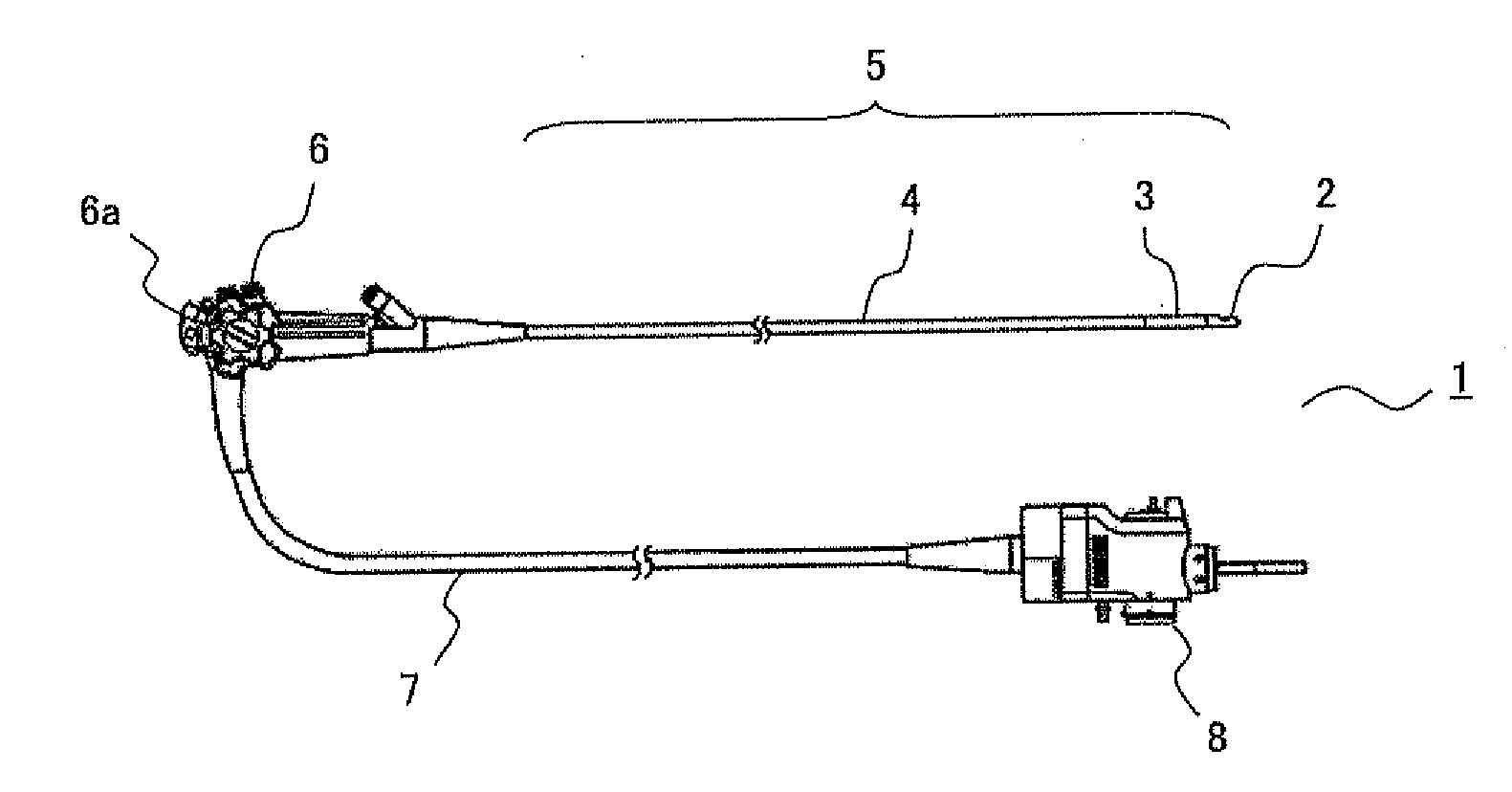

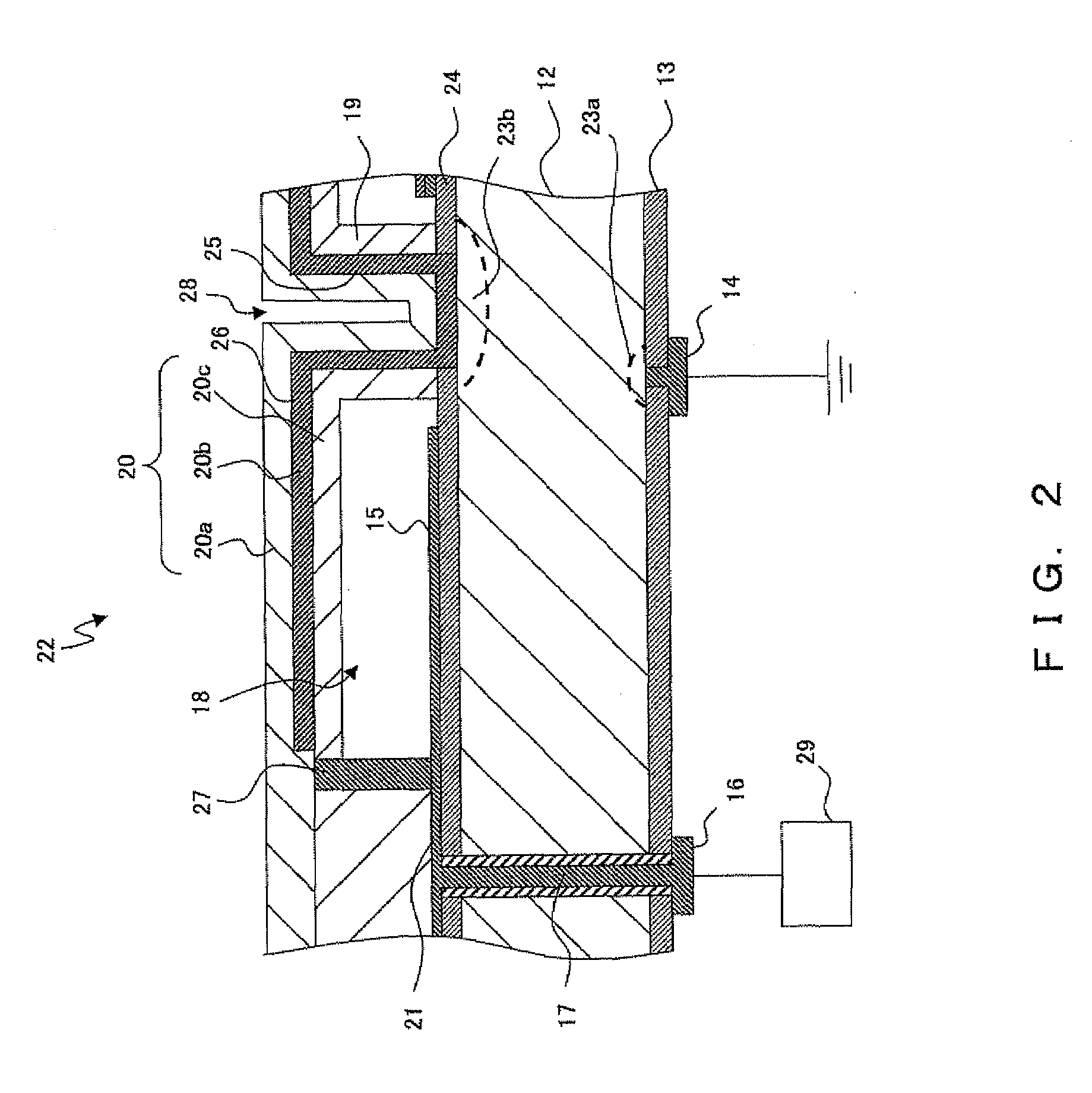

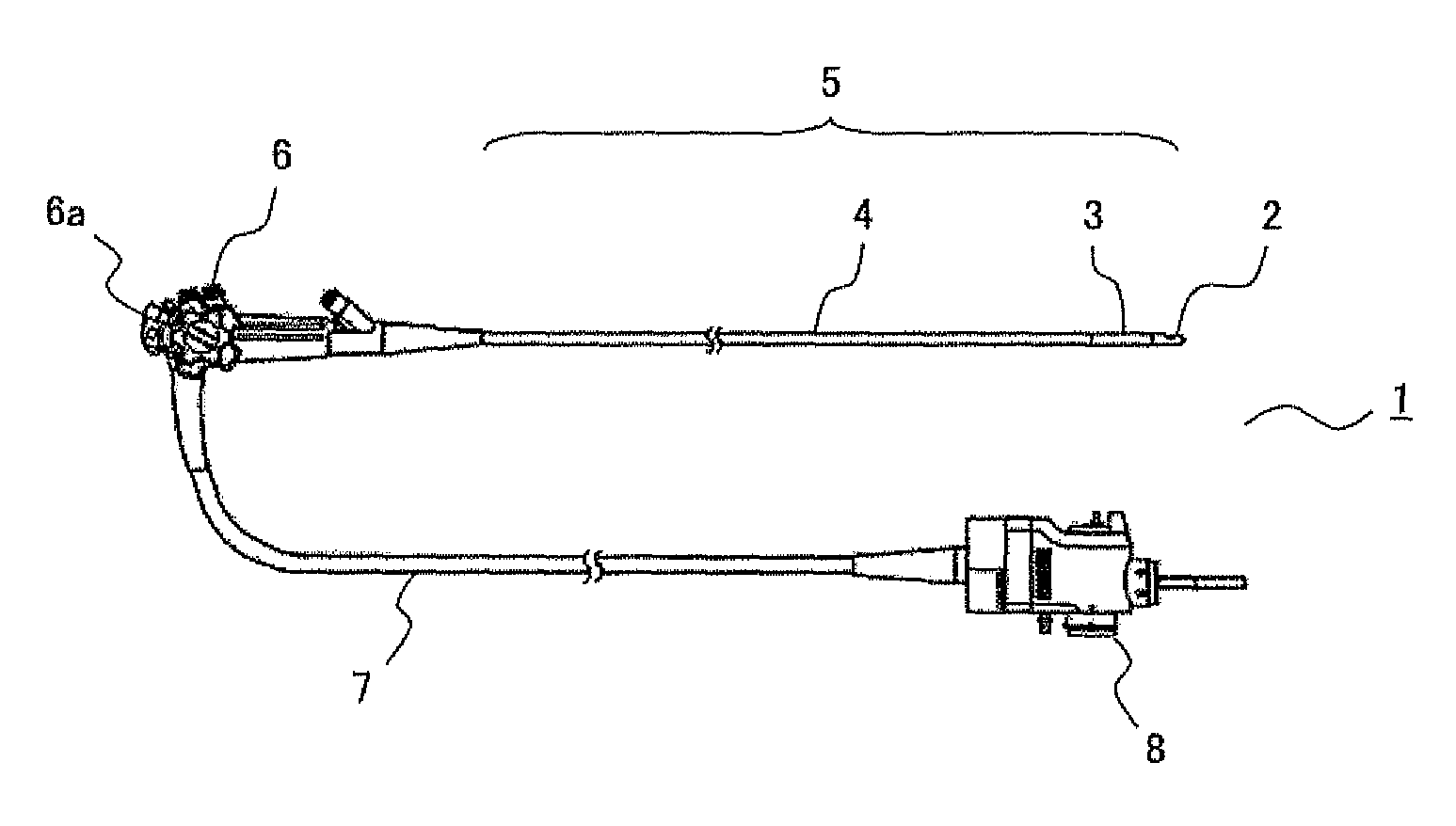

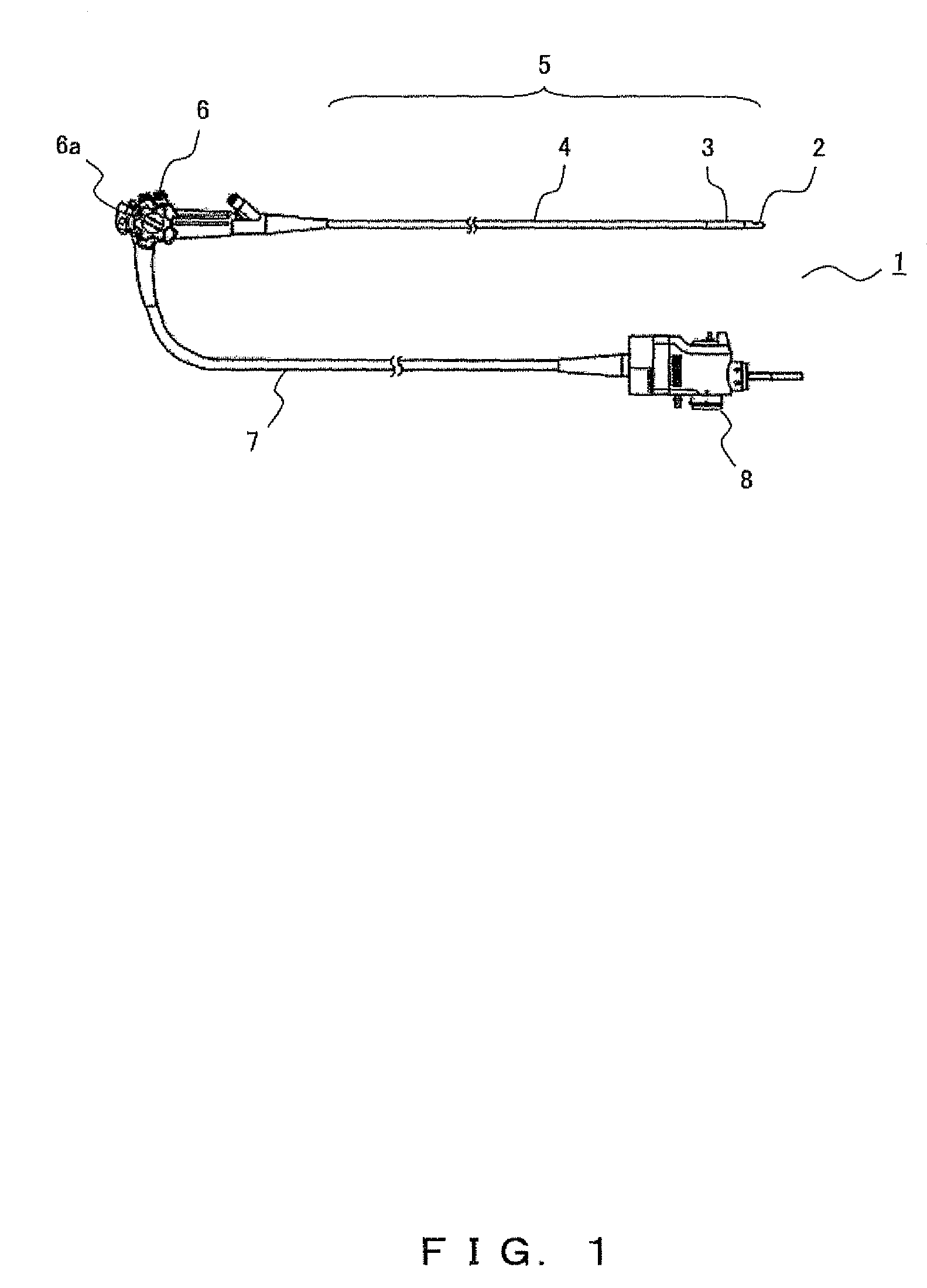

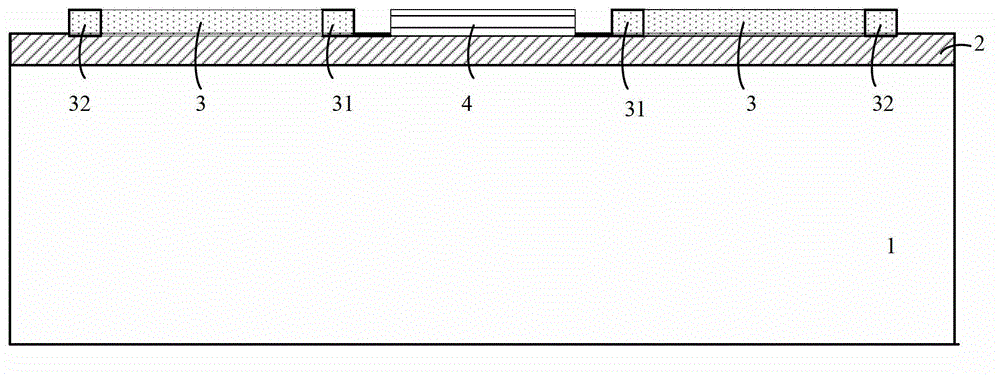

CAPACITIVE MICROMACHINED ULTRASONIC TRANSDUCER (cMUT) DEVICE AND IN-BODY-CAVITY DIAGNOSTIC ULTRASOUND SYSTEM

ActiveUS20080294055A1Ultrasonic/sonic/infrasonic diagnosticsCatheterCapacitanceCapacitive micromachined ultrasonic transducers

A capacitive micromachined ultrasonic transducer (cMUT) device, comprises: a cMUT obtained by processing a silicon substrate by using a silicon micromachining technique; and an oscillator circuit having the cMUT as a capacitor, and outputting a frequency modulation signal by modulating a frequency of an oscillation signal to be output on the basis of a change of capacitance of the cMUT.

Owner:OLYMPUS CORP

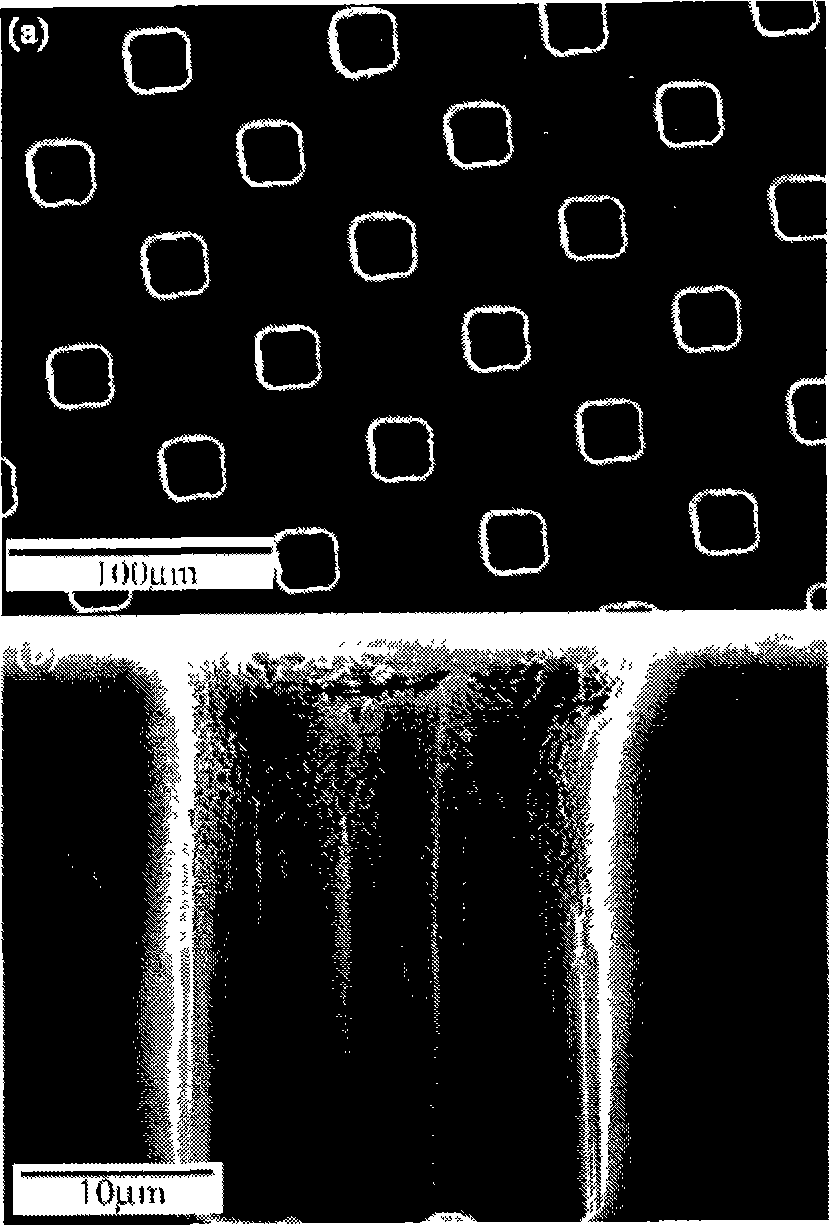

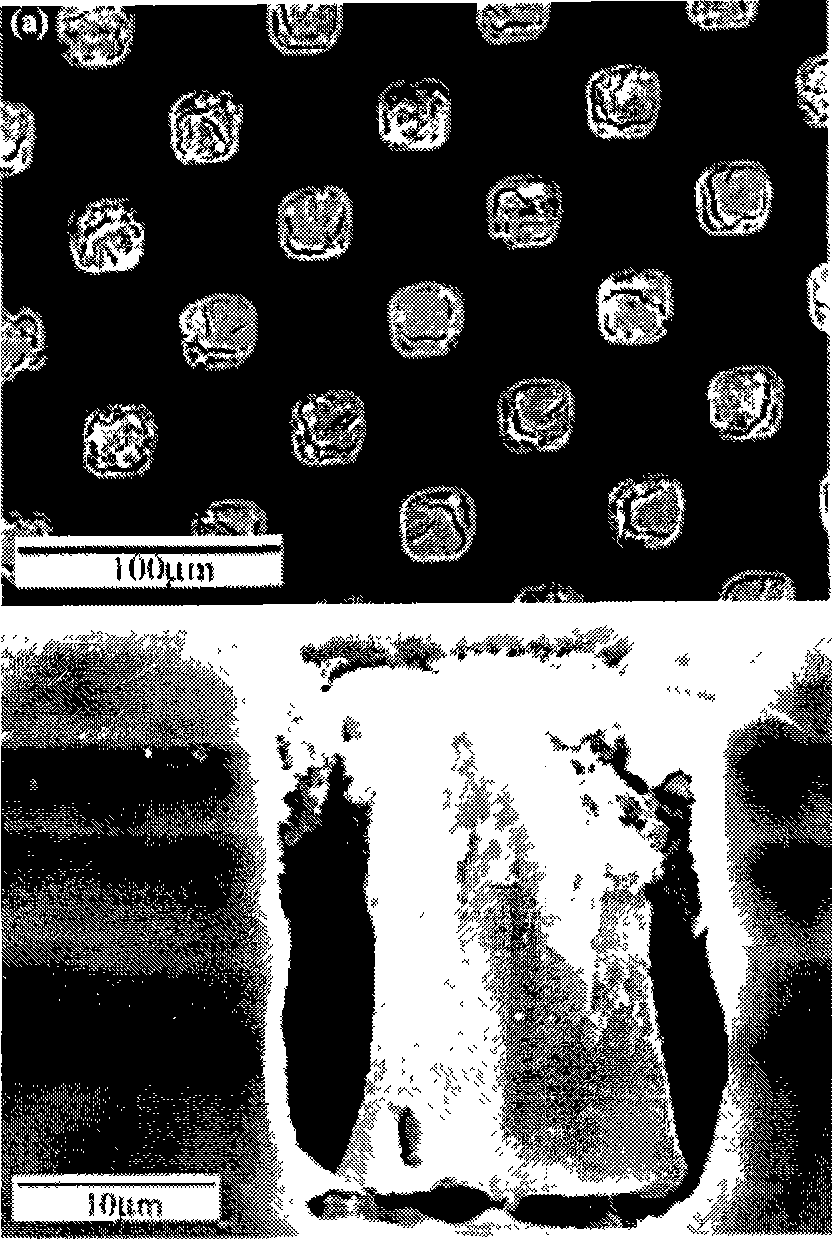

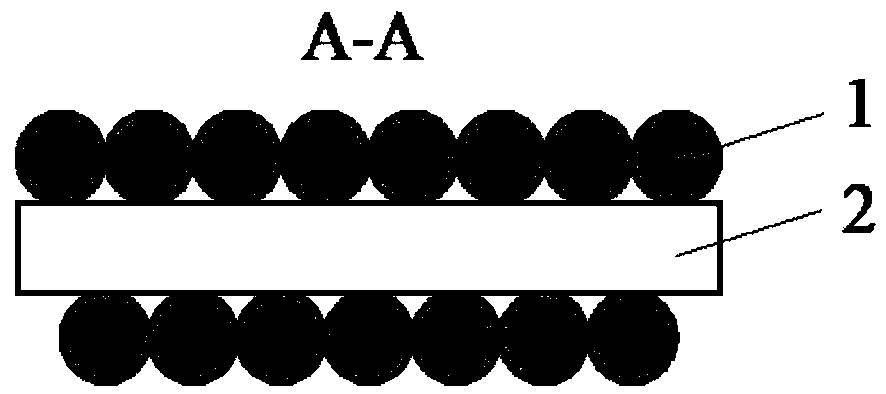

Microfine piezoelectric ceramics array structure composite material and preparation thereof

The invention discloses a hyperfine piezoelectric ceramic array structure composite material and a preparation method, belonging to the field of functional ceramics material and the preparation technology thereof. The preparation technique comprises: a metal alkoxide reflux method is adopted to prepare sol precursor, silicon micromachining technology is used for preparing a silicon template; then, piezoelectric ceramic microcolumn array which has the length and the width being 5-100 microns, the hole height being 1-500 microns and the spacing being 10-200 microns is prepared by sol padding template technique and the subsequent pyrogenation and annealing processing process; finally, the microcolumn array is compounded with polymer to obtain 1-3 type piezoelectric ceramic / polymer composite material. Compared with the traditional mechanical cutting technique, the invention can prepare the ceramic microcolumn with smaller size and better array period, and the minimum column width can reach 7mum, thereby being suitable for a micro electrical / mechanic system (MEMS); compared with the array preparation techniques such as heat pressing, laser cutting and the like, the invention has simple equipment condition and is easy to realize.

Owner:TSINGHUA UNIV

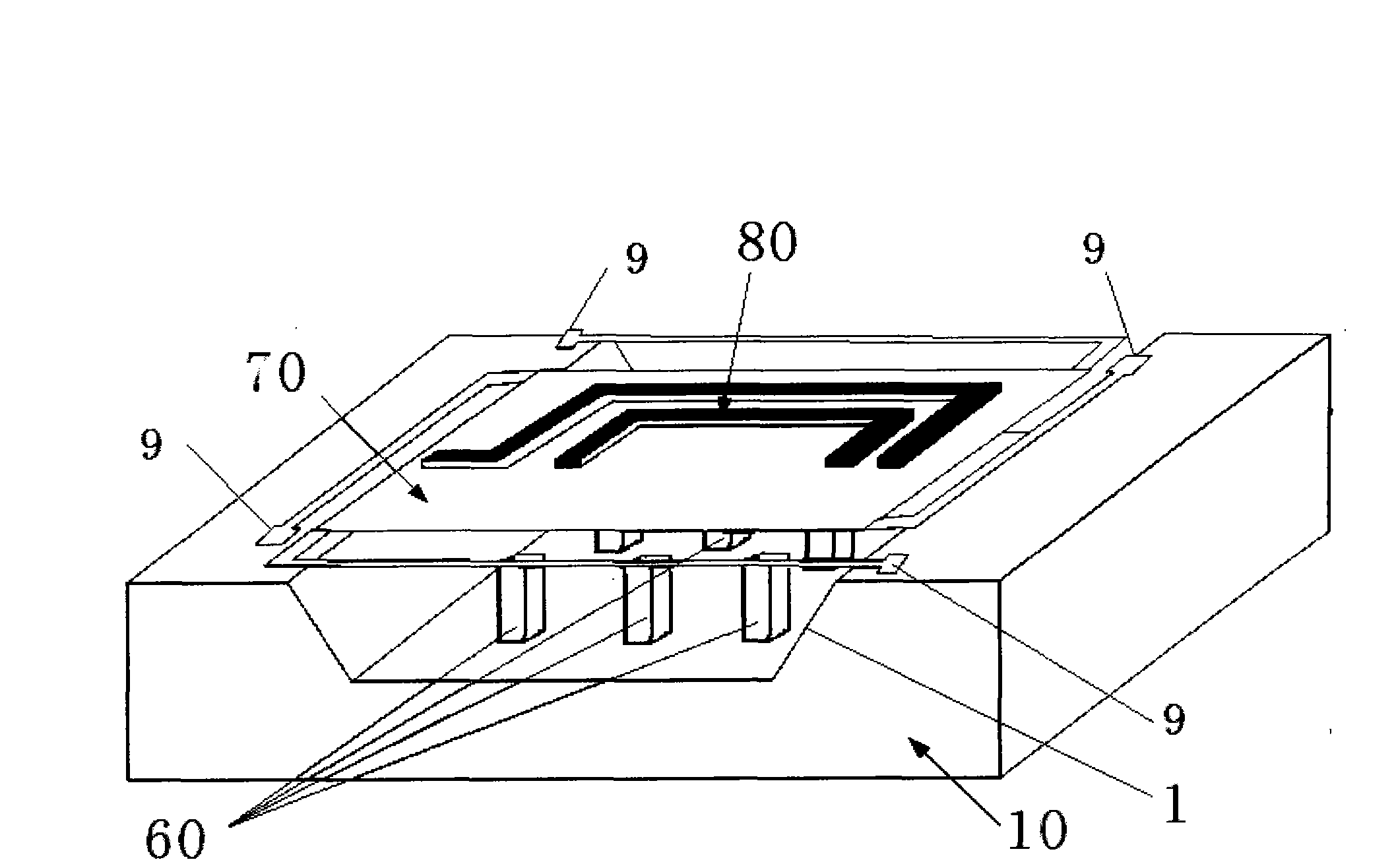

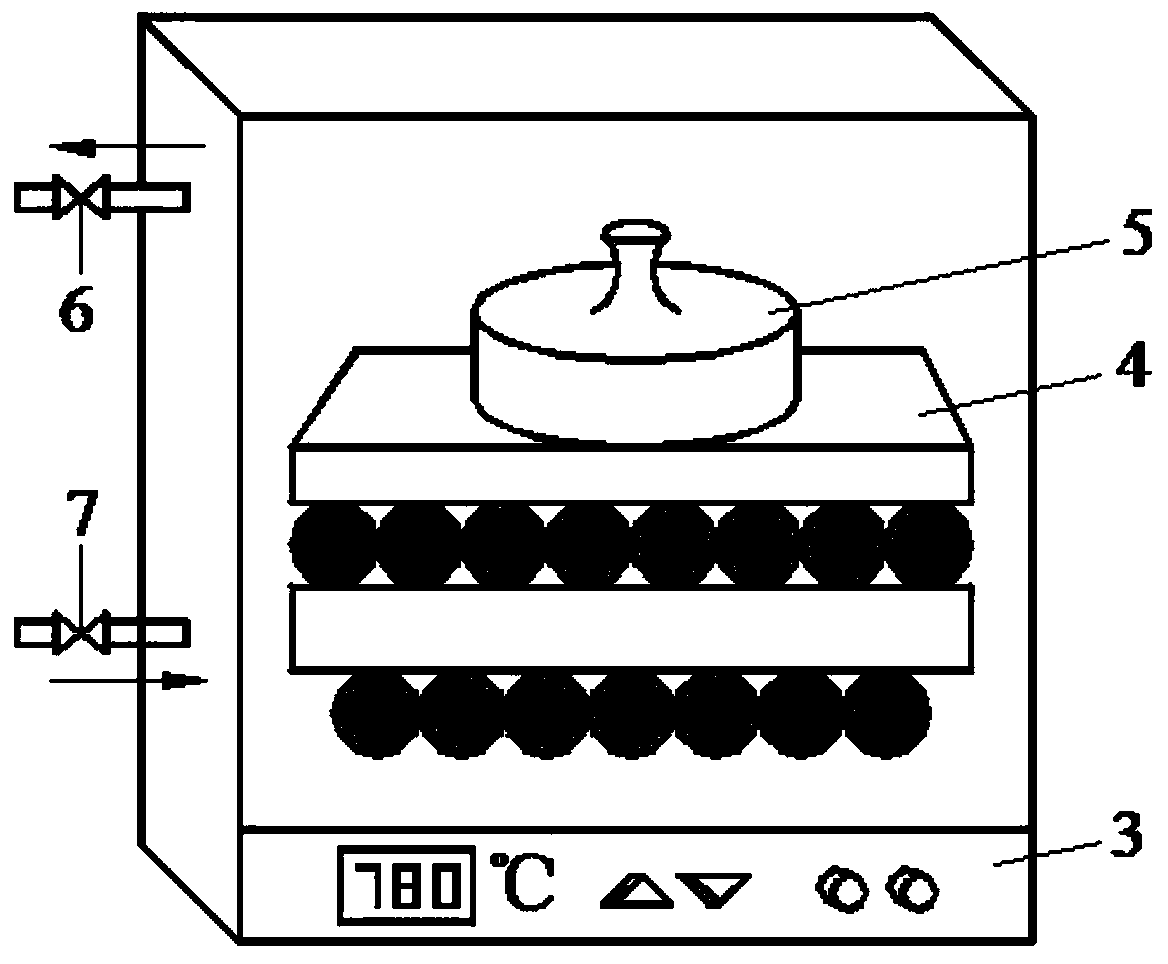

Micro electromagnetic energy harvester and a preparation method

InactiveCN101515746ASmall sizeReduce spacingPermanent magnetsInductances/transformers/magnets manufactureElectromagnetic energy harvesterCantilever

The invention relates to an electromagnetic energy harvester of a micro electro mechanical system (MEMS) and a preparation method. In the method, a three-dimensional micromachining method combining bulk silicon and surface micromachining technology is adopted, namely, a V-shaped silicon chip groove is etched by bulk silicon micromachining technology; a permanent magnet (array) of the energy harvester is electroplated in the V-shaped groove; diaphragms (a crab claw-shaped cantilever beam and a vibrating plate) and a flat spiral coil of the energy harvester are prepared by the surface micromachining technology. The electromagnetic energy harvester of the invention adopts the electroplating method to prepare the permanent magnet (array) instead of the micro-assembly or adhesion means of the permanent magnet of the traditional energy harvester, so that the energy harvester and preparation thereof can be compatible with the IC process.

Owner:北京大学科技开发有限公司

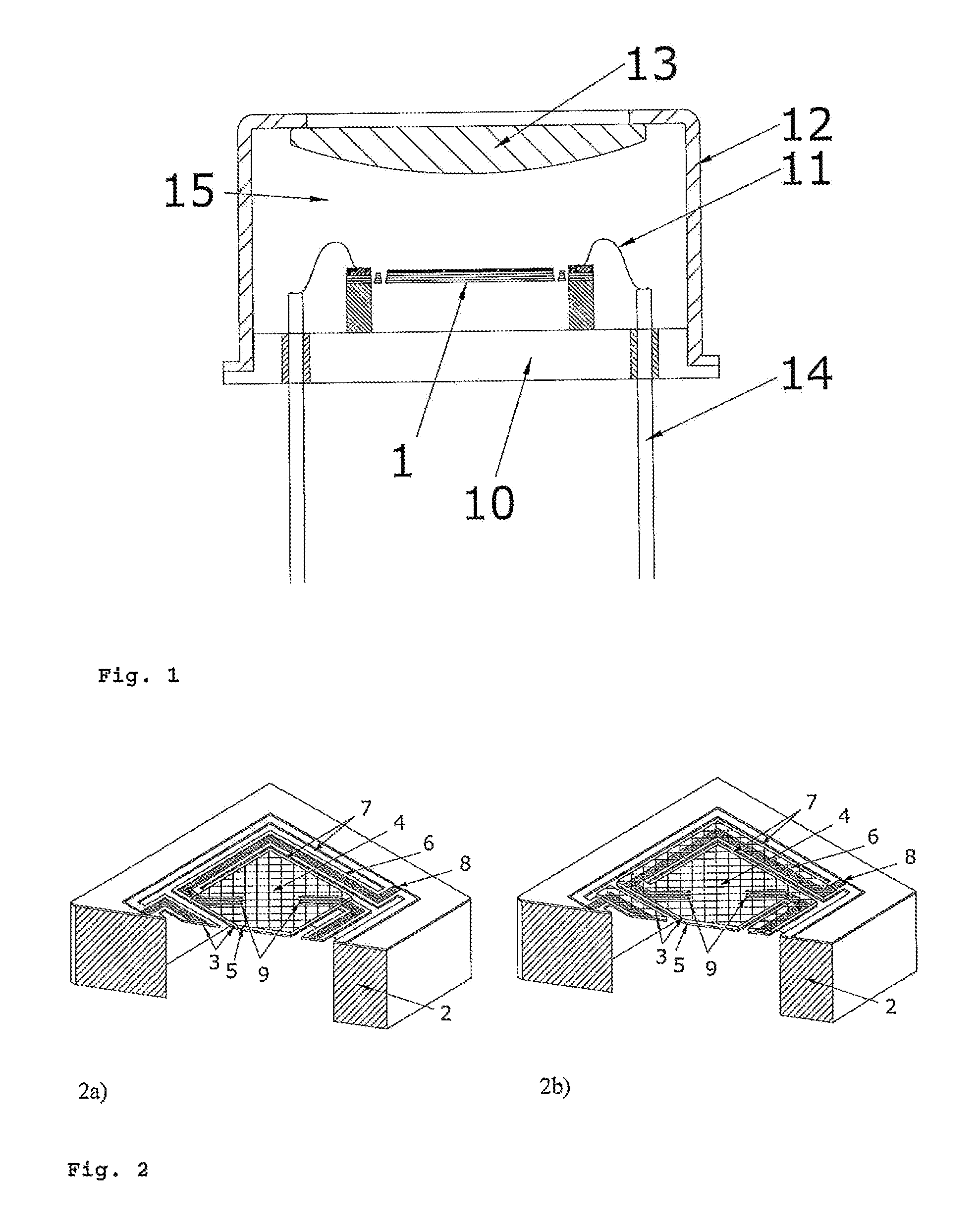

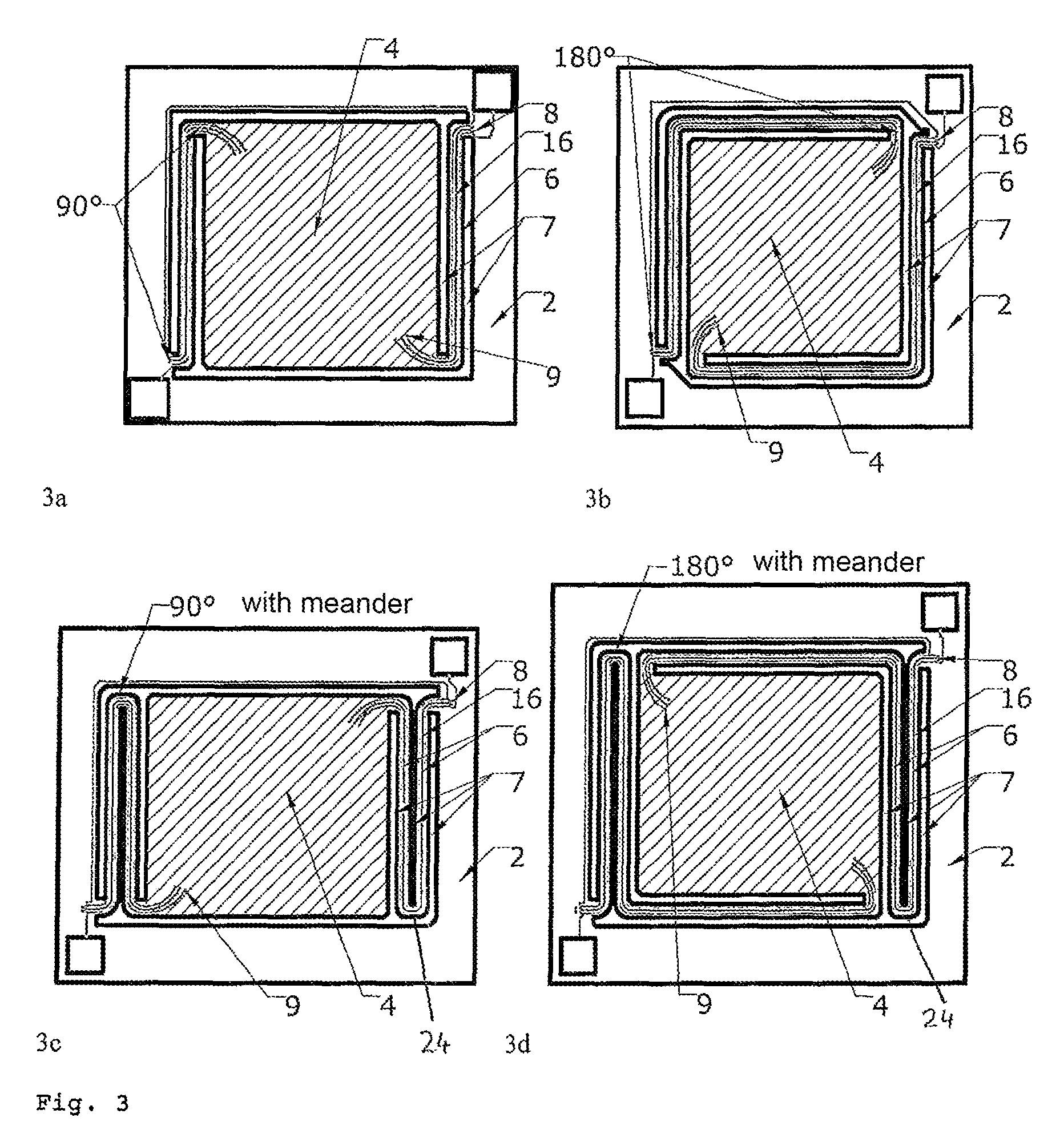

Thermopile infrared sensor by monolithic silicon micromachining

ActiveUS8592765B2High response rateSmall sizeSolid-state devicesMaterial analysis by optical meansThermopileEngineering

A thermal infrared sensor is provided in a housing with optics and a chip with thermoelements on a membrane. The membrane spans a frame-shaped support body that is a good heat conductor, and the support body has vertical or approximately vertical walls. The thermopile sensor structure consists of a few long thermoelements per sensor cell. The thermoelements being arranged on connecting webs that connect together hot contacts on an absorber layer to cold contacts of the thermoelements. The membrane is suspended by one or more connecting webs and has, on both sides of the long thermoelements, narrow slits that separate the connecting webs from both the central region and also the support body. At least the central region is covered by the absorber layer.

Owner:HEIMANN SENSOR GMBH

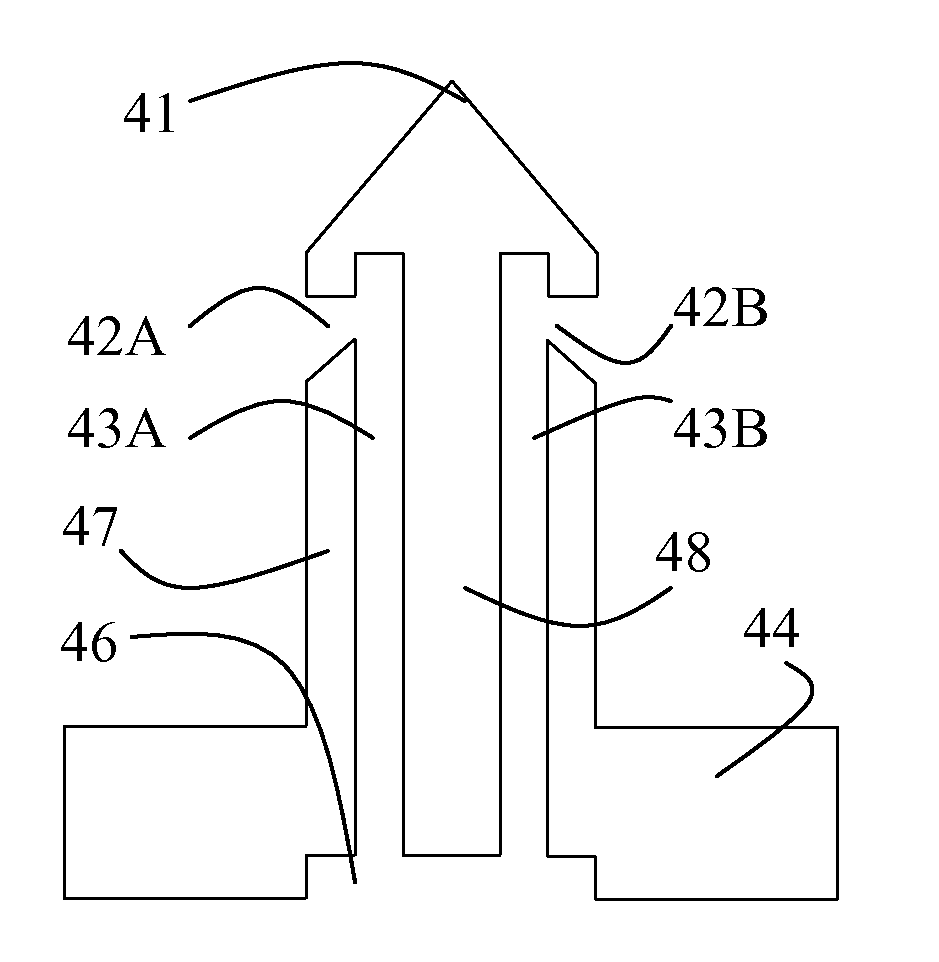

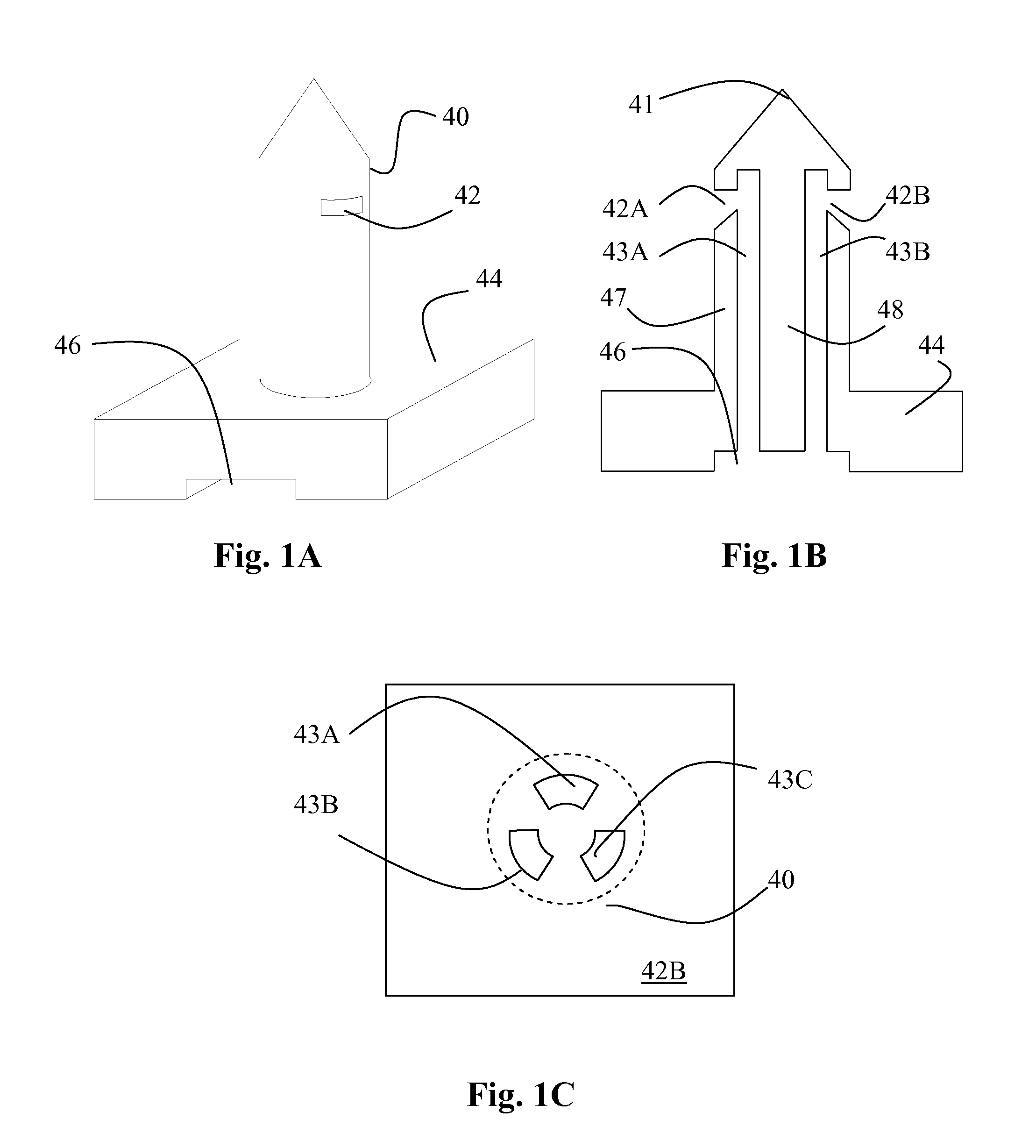

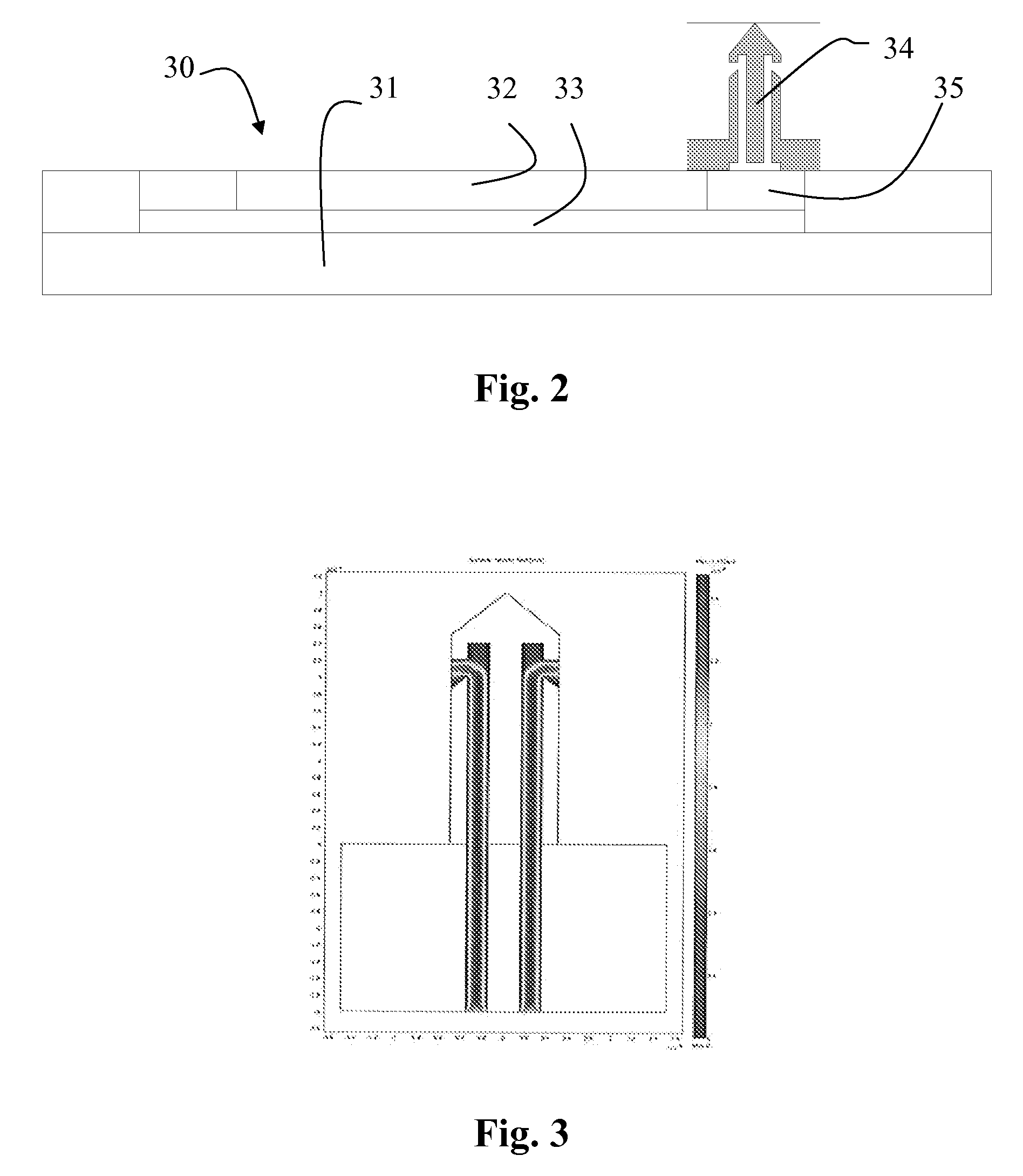

Microneedle

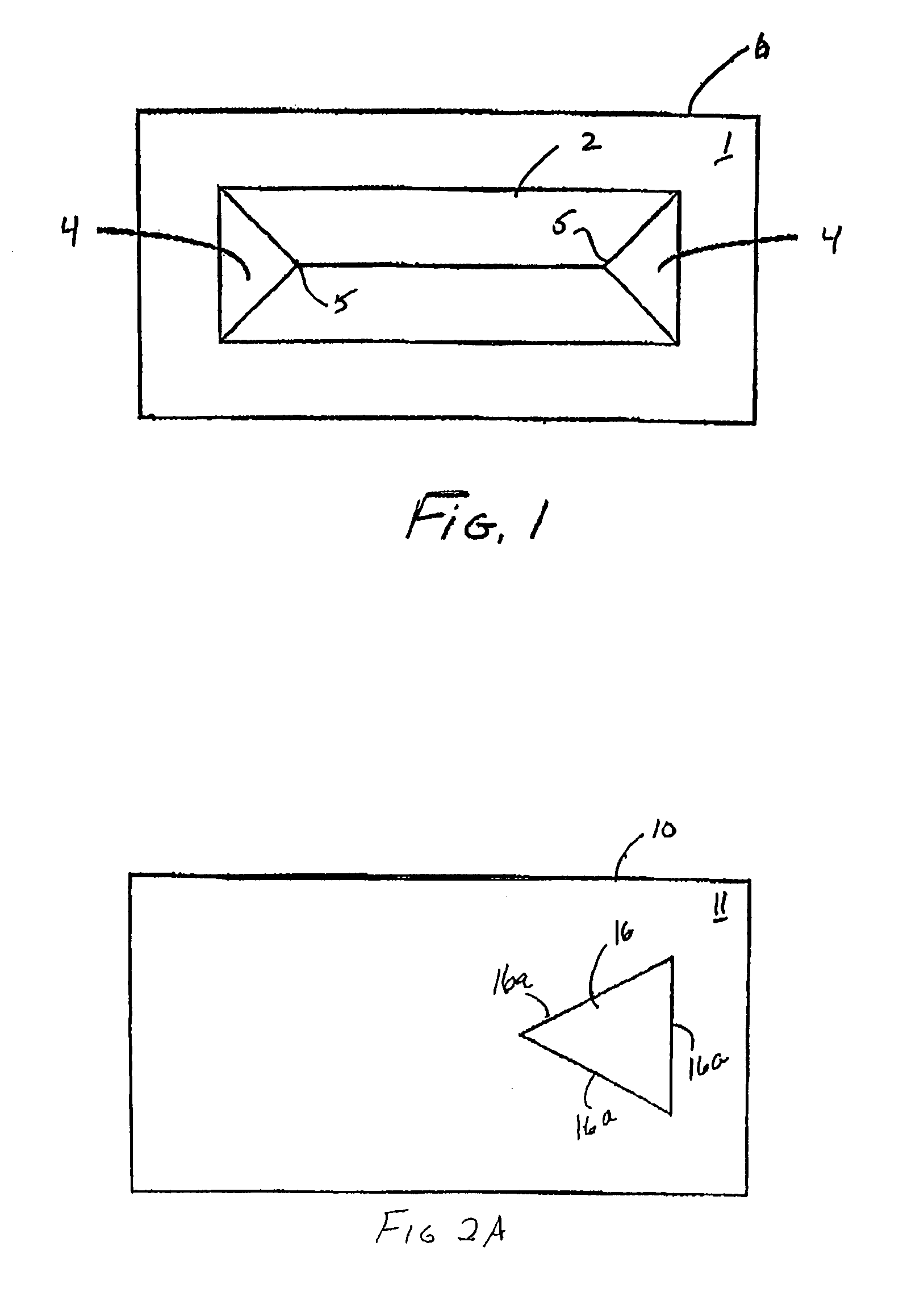

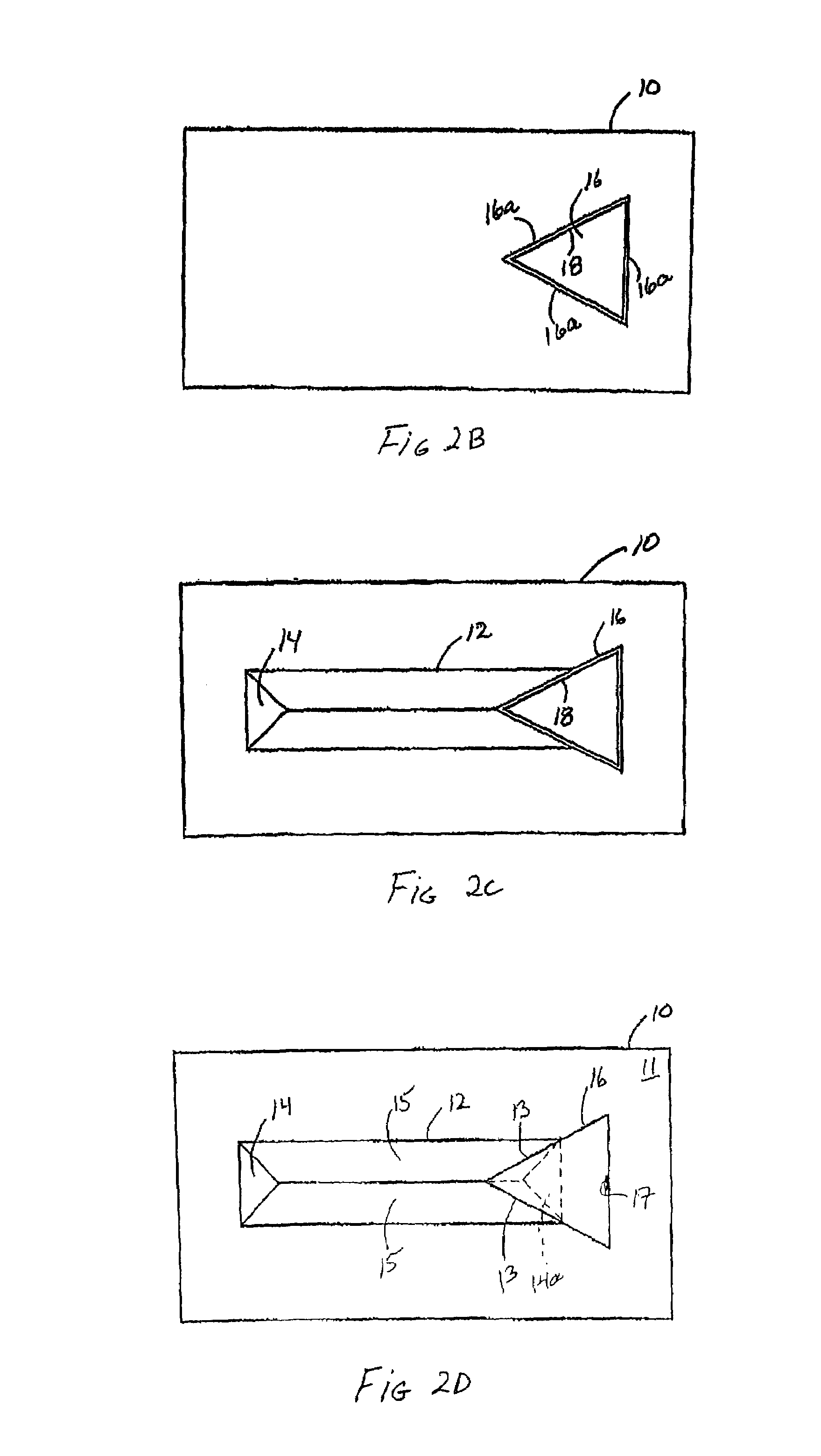

ActiveUS20120058506A1Large volume of fluidInhibit blood coagulationBioreactor/fermenter combinationsBiological substance pretreatmentsMicrofluidic channelMicro-needle

The application relates to microfluidic needles and their manufacturing methods. The microfluidic needle comprises an interface portion containing at least one fluid communication channel, an elongated needle portion (40) projecting away from the interface portion (44), the needle portion having a tip and sidewalls connecting the tip to the interface portion, and at least two microfluidic channels (43 A-B) within the needle portion in fluidic connection with the at least one communication channel, the microfluidic channels being at least partly oriented parallel to the elongated needle portion. According to the application, the microfluidic channels exit the needle portion at the sidewalls of the needle portion. The needle may be fabricated by ALD-assisted silicon micromachining. The needle can be used for injection and / or sampling fluids to / from tissue or individual cells.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT OY

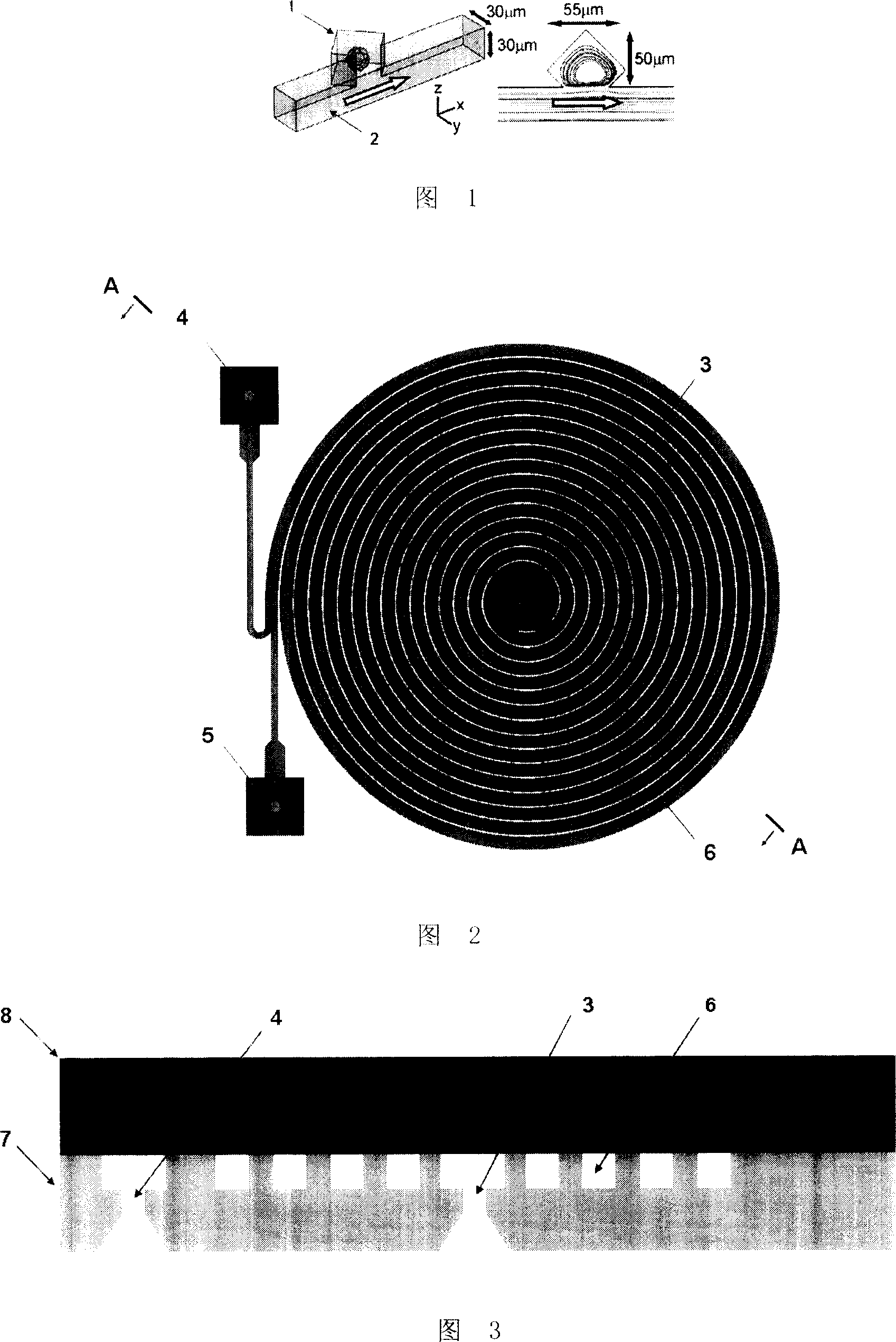

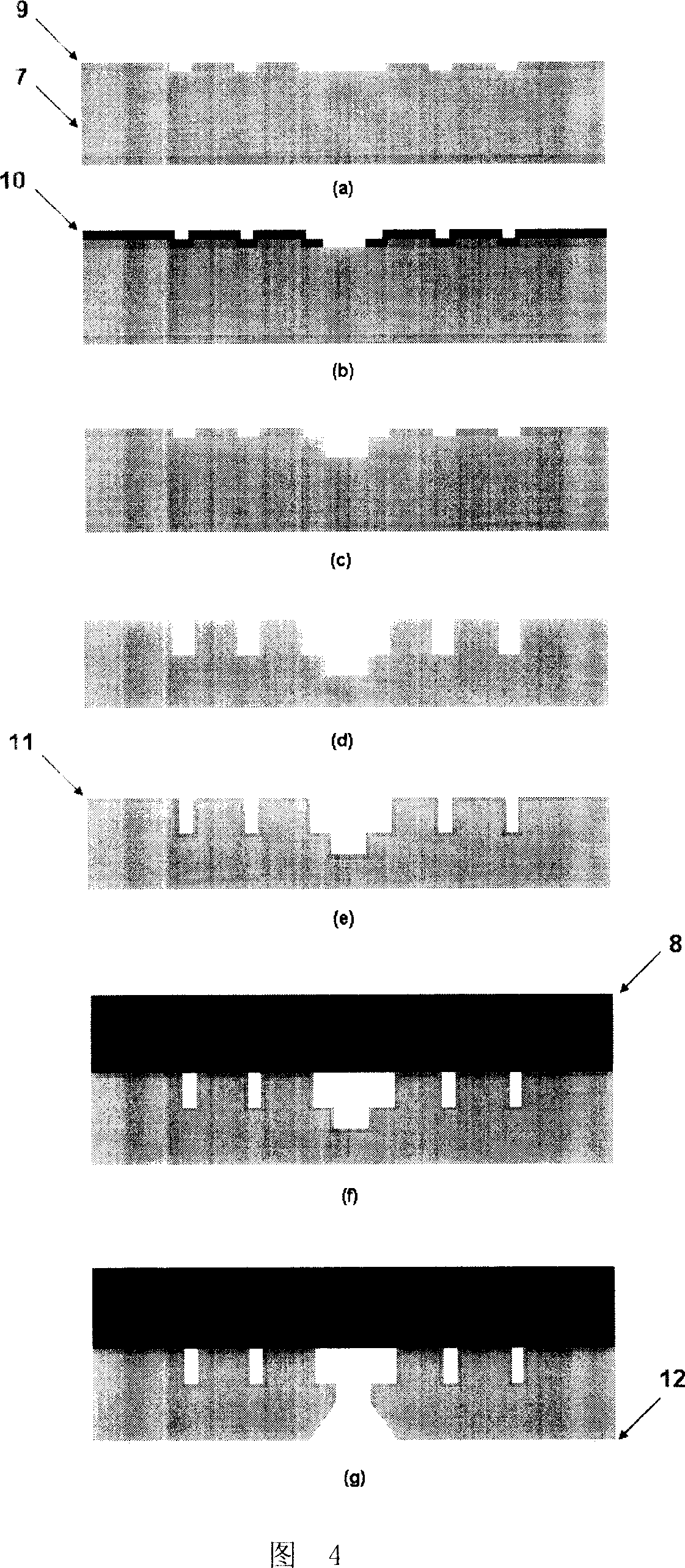

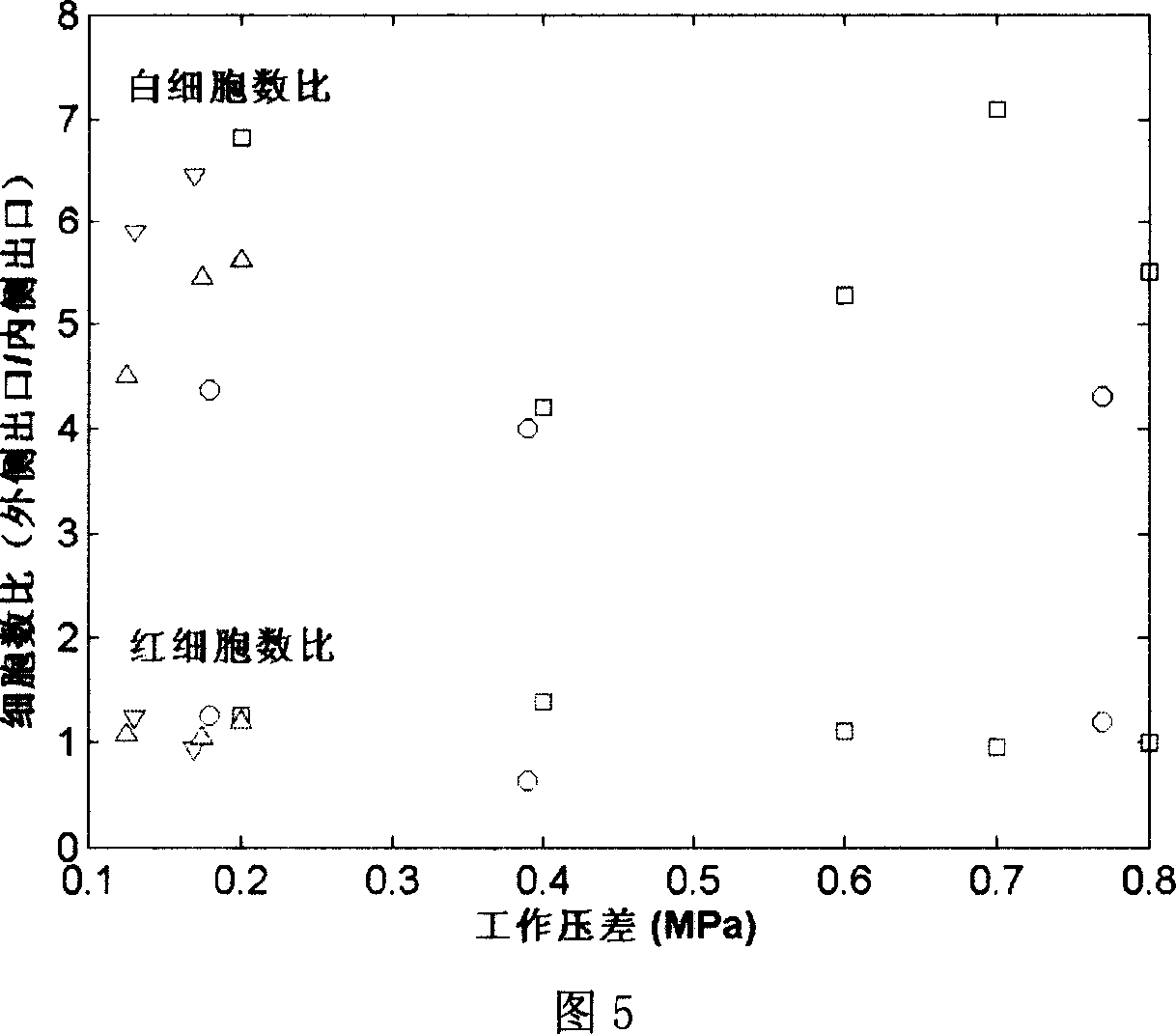

Microfluid centrifugal chip and its processing method

The invention relates to the making of a micro flow centrifugal chip. It comprises the chip base and cover plate, the base composed of a bended and continuous extending micro slot channel, with the curvature radius ranging 20-1000 micron, at least one inlet at the center of the micro slot channel, at least two outlets at the tail of the micro slot channel. It has a micro slot channel with micro curvature radius spinal, generating clutch acceleration speed to realize the centrifugal operation. It applies to micro processing, being able to realize excellent centrifugal effect, low in cost, and quick.

Owner:PEKING UNIV

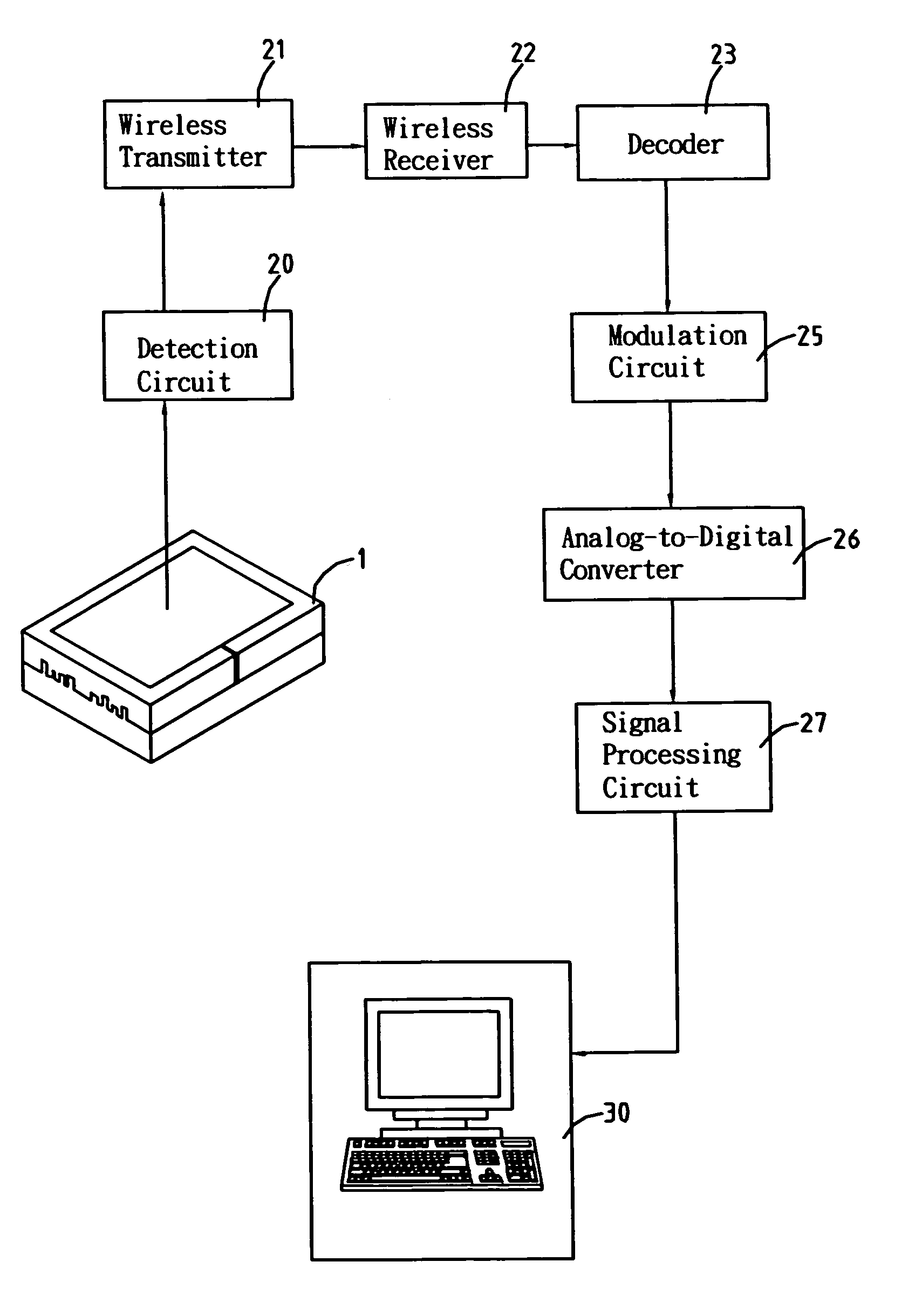

Micromachined mass flow sensor with condensation prevention and method of making the same

ActiveUS20140283595A1Save energy necessaryAccurate measurementVolume/mass flow by thermal effectsElectrical resistance and conductanceVaporization

Owner:WISENSTECH

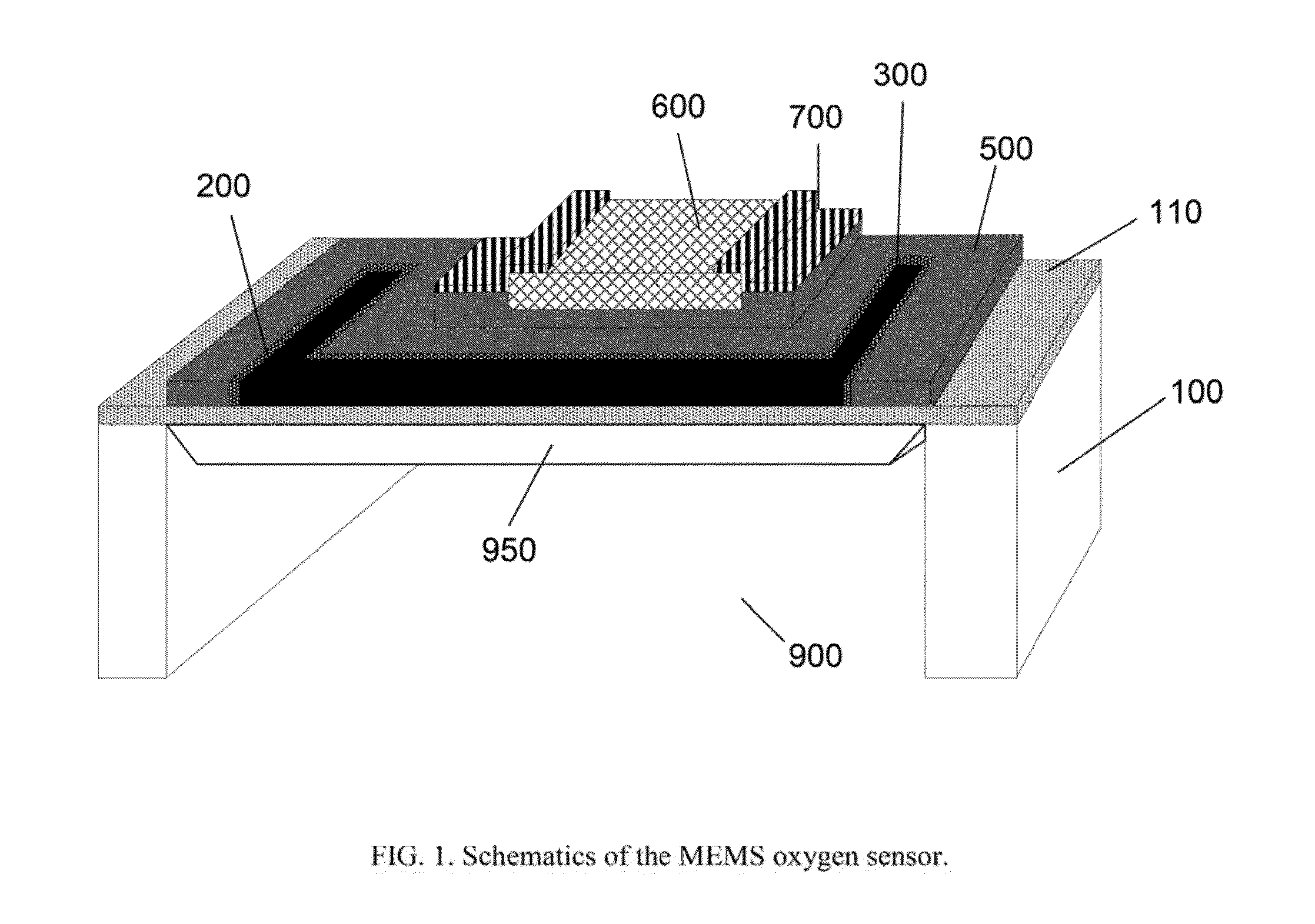

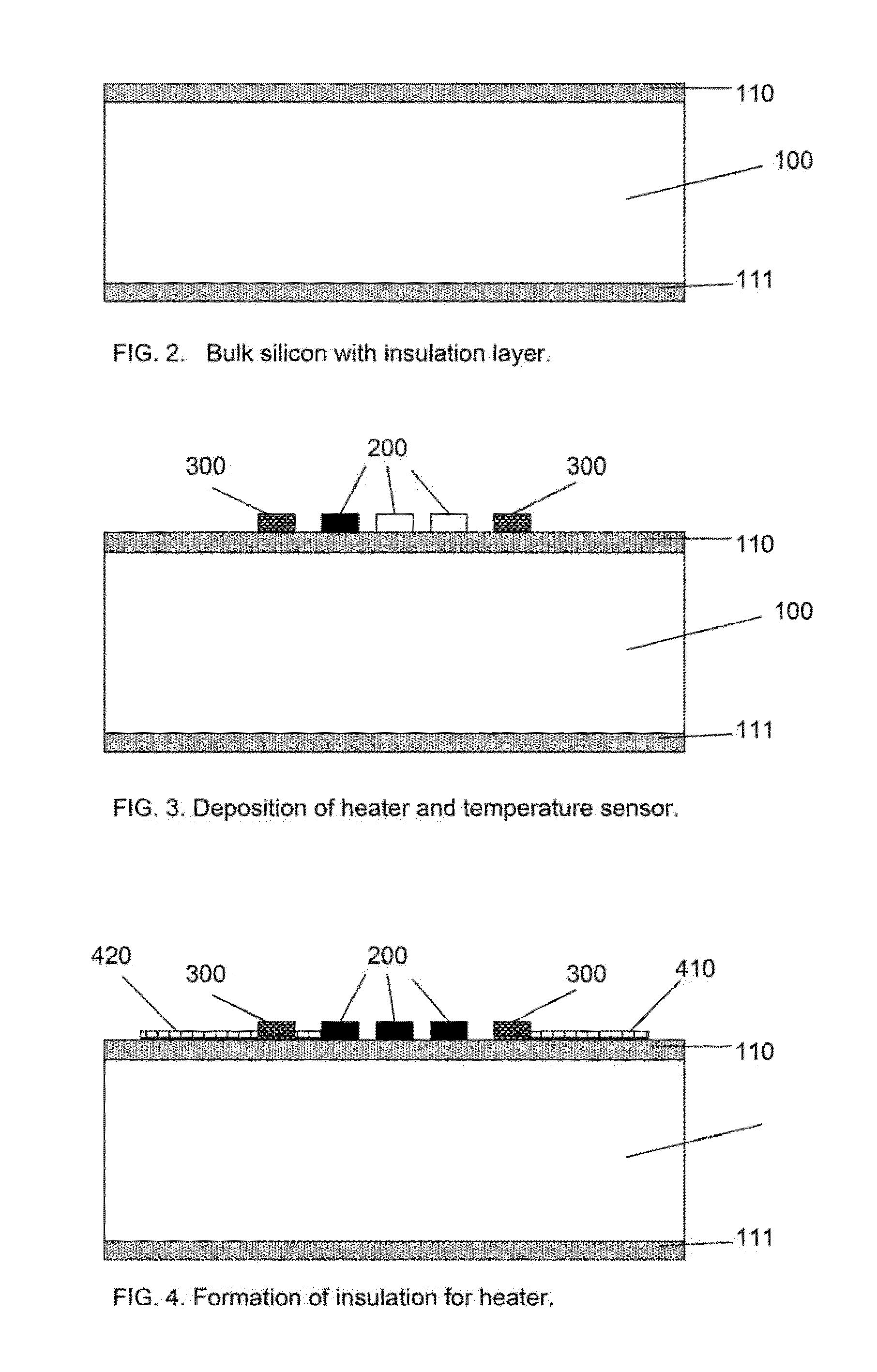

Micromachined oxygen sensor and method of making the same

ActiveUS20140318960A1Easy to manufactureFast response timeMaterial analysis by electric/magnetic meansSilicon oxygenElectrical battery

The design and manufacture method of an oxygen concentration sensor made with silicon micromachining (a.k.a. MEMS, Micro Electro Mechanical Systems) process for applications of oxygen measurement with fast response time and low power consumption is disclosed in the present invention. The said silicon oxygen concentration sensor operates with an yttrium stabilized zirconia oxide amperometric cell supported on a membrane made of silicon nitride with a heat isolation cavity underneath or a silicon nitride membrane with silicon plug for mechanical strength enforcement.

Owner:WISENSTECH

Nano-imprint system with mold deformation detector and method of monitoring the same

A system for nano-imprint with mold deformation detector is disclosed for real-time monitoring of the deformation of the mold. An electrostatic plate capacitor is embedded in the mold, serving as the deformation detector. The capacitor includes two opposite metal film electrodes formed by silicon micromachining technique on opposite surfaces of the mold and connected by a metal lead. During imprinting, the mold is acted upon by an external force and deformation occurs, which induces change of distance between the metal film electrodes and thus variation of the capacitance of the capacitor. The amount of deformation of the mold can then be assessed by comparing the capacitance with a reference. Thus, real-time detection and monitoring of the deformation of the nano-imprint mold is realized. Also disclosed is a method for carrying out the real-time monitoring of the deformation of the mold.

Owner:NATIONAL TSING HUA UNIVERSITY

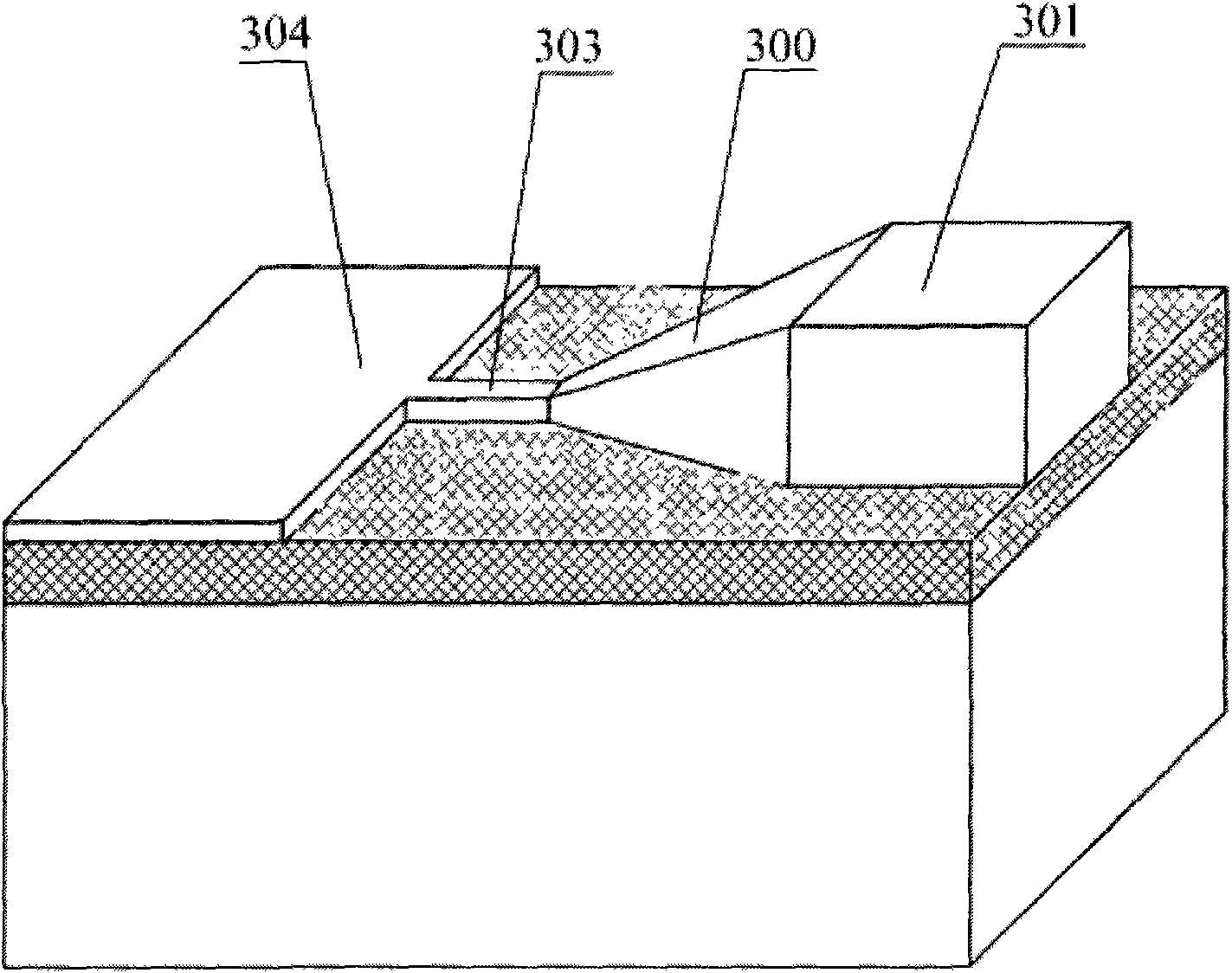

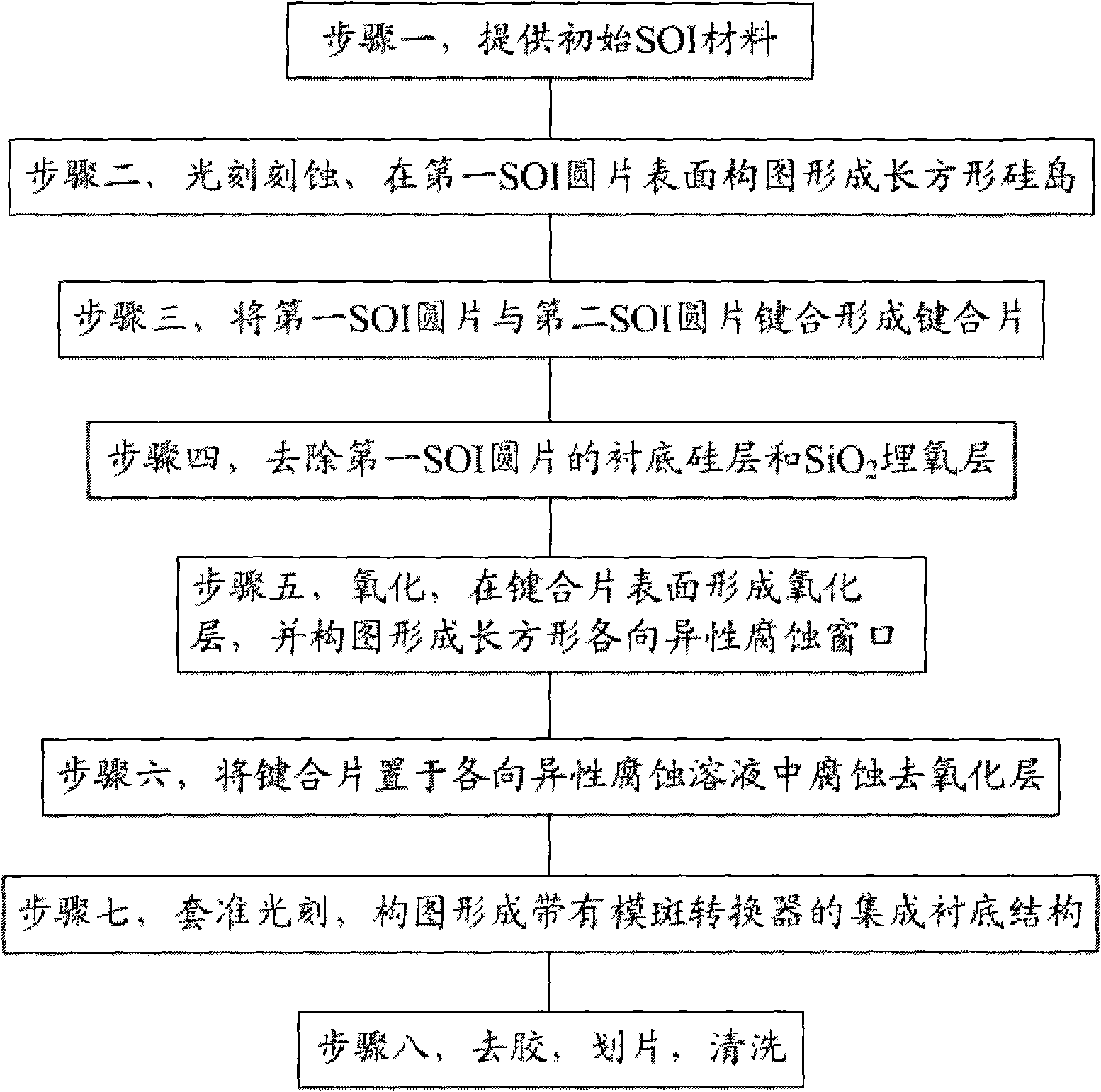

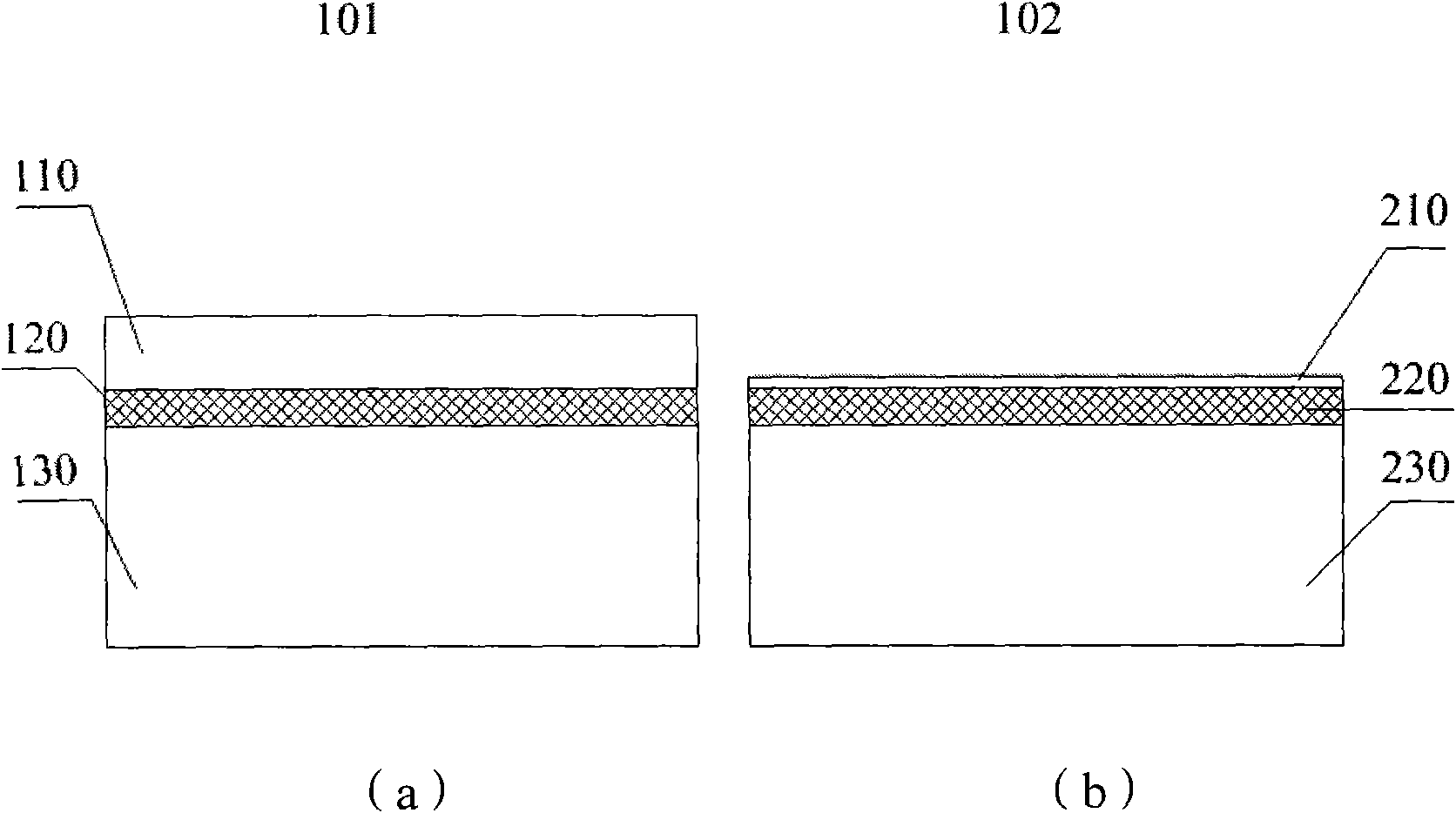

Manufacturing method of SOI base three-dimensional wedgy coupler integrated substrate structure

InactiveCN101655576AHigh surface quality of the structureImprove surface qualityOptical waveguide light guideMicro nanoPhotonics

The invention provides a manufacturing method of an SOI base three-dimensional wedgy coupler integrated substrate structure, which is characterized in that the method is realized by silicon micromachining technology. The related initial processing material is SOI material; the selective corrosion characteristic of different crystal surfaces of silicon material is utilized, and micro-electronic relative technology, such as anisotropic etch, bonding, photoetching, dry etching and the like is adopted to obtain SOI base three-dimensional wedgy coupler integrated substrate structure which respectively performs linear change in horizontal and vertical directions; a micro-nano size device zone connected with the output waveguide of the coupler has favorable surface quality, so that the inventioncan effectively improve the coupling efficiency of photonics device, such as general optical fiber, small-size plane waveguide and the like and provides favorable Wiener size photonics devices to prepare integrated substrate structure. The invention is the guarantee for preparing high-quality and high-sensitivity small-size photonics devices and has strong practicality.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI +1

Capacitive micromachined ultrasonic transducer (cMUT) device and in-body-cavity diagnostic ultrasound system

ActiveUS8157740B2Ultrasonic/sonic/infrasonic diagnosticsCatheterCapacitanceCapacitive micromachined ultrasonic transducers

A capacitive micromachined ultrasonic transducer (cMUT) device, includes: a cMUT obtained by processing a silicon substrate by using a silicon micromachining technique; and an oscillator circuit having the cMUT as a capacitor, and outputting a frequency modulation signal by modulating a frequency of an oscillation signal to be output on the basis of a change of capacitance of the cMUT.

Owner:OLYMPUS CORP

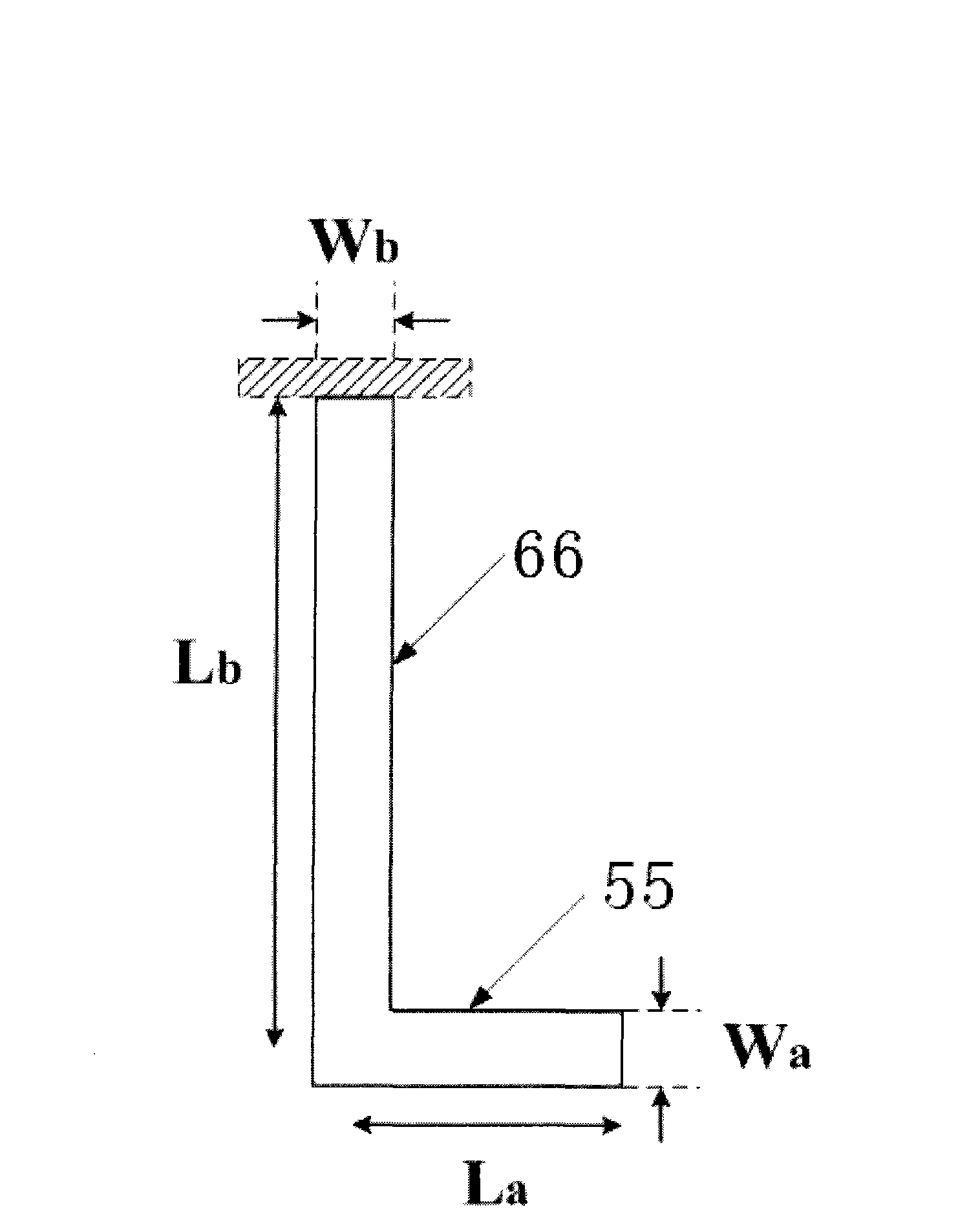

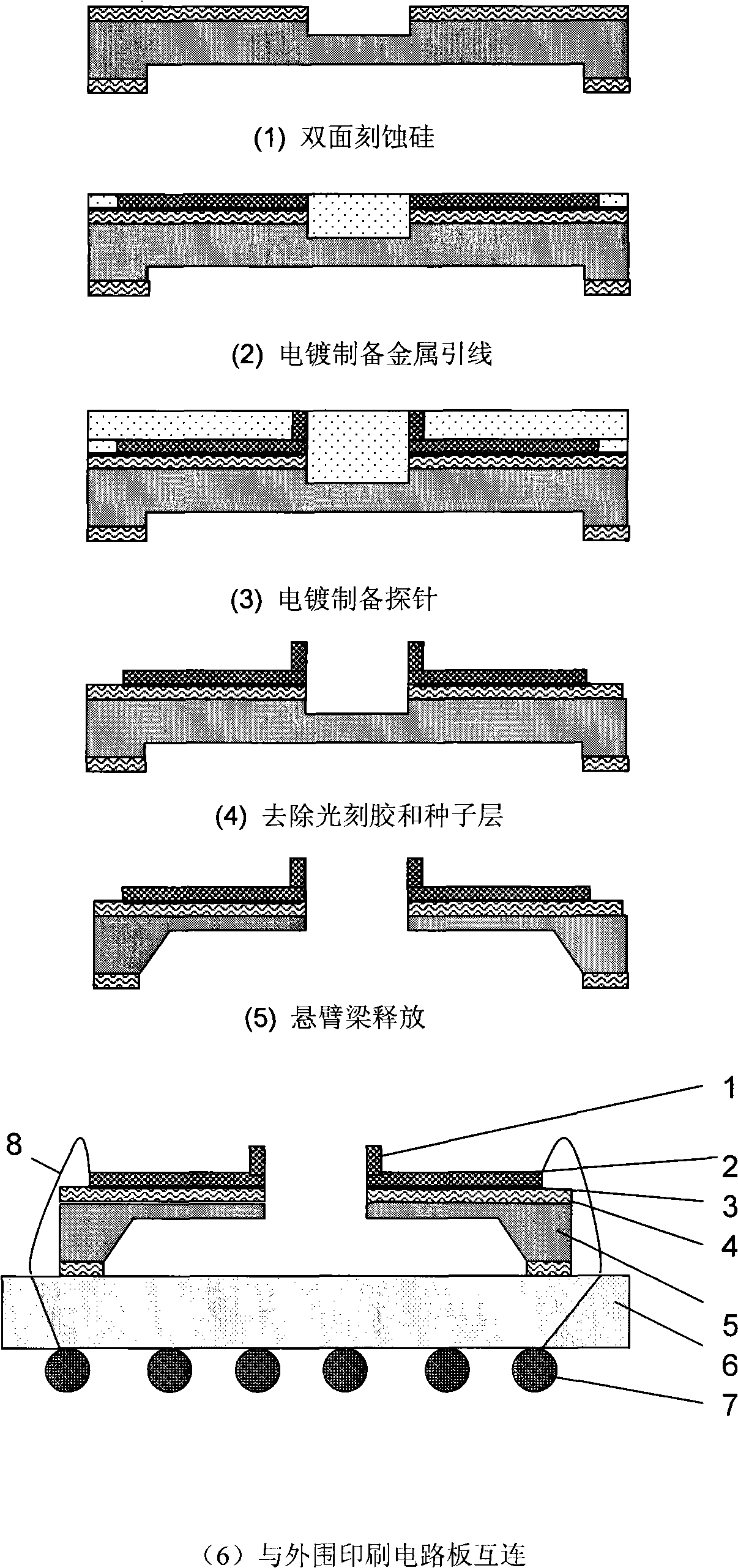

Metal-silicon compound cantilever beam type microelectronic mechanical system probe card and manufacture method thereof

InactiveCN101354404AImprove electrical performanceImprove mechanical propertiesTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamProbe card

The invention relates to a metal-silicon composite cantilever beam typed micron-electronic mechanical system probing card and a preparation method thereof; an ultraviolet thick film photolithography and bulk silicon micro-processing composite process is adopted to prepare a metal-silicon composite cantilever beam probing card structure, thus replacing an existing probing card structure consisting of single silicon or metal. The ultraviolet thick film photolithography process is used for preparing the metal probe with high depth / width ratio and metal circuit transmission wires below the probes, and the bulk silicon micro-processing composite process is used to prepare the silicon cantilever beam structure. The force during the testing process is commonly borne by the silicon cantilever beam and the metal circuit above the silicon cantilever beam; the electric and mechanical property of the probing card structure is controlled by adjusting the geometrical parameters of the metal circuit leads and the silicon cantilever beam; the probes above the probing card can be arranged by the positions of the pins of the chip to be tested; the probe tips are corresponding to the position of the pins of the chip one by one. The end of the metal circuit transmission wire leads the circuit to be connected on the back surface by a through hole electro-plating or wire punching type on a silicon substrate and leads the circuits to be connected onto printing circuit boards and test machine platforms further.

Owner:SHANGHAI JIAO TONG UNIV

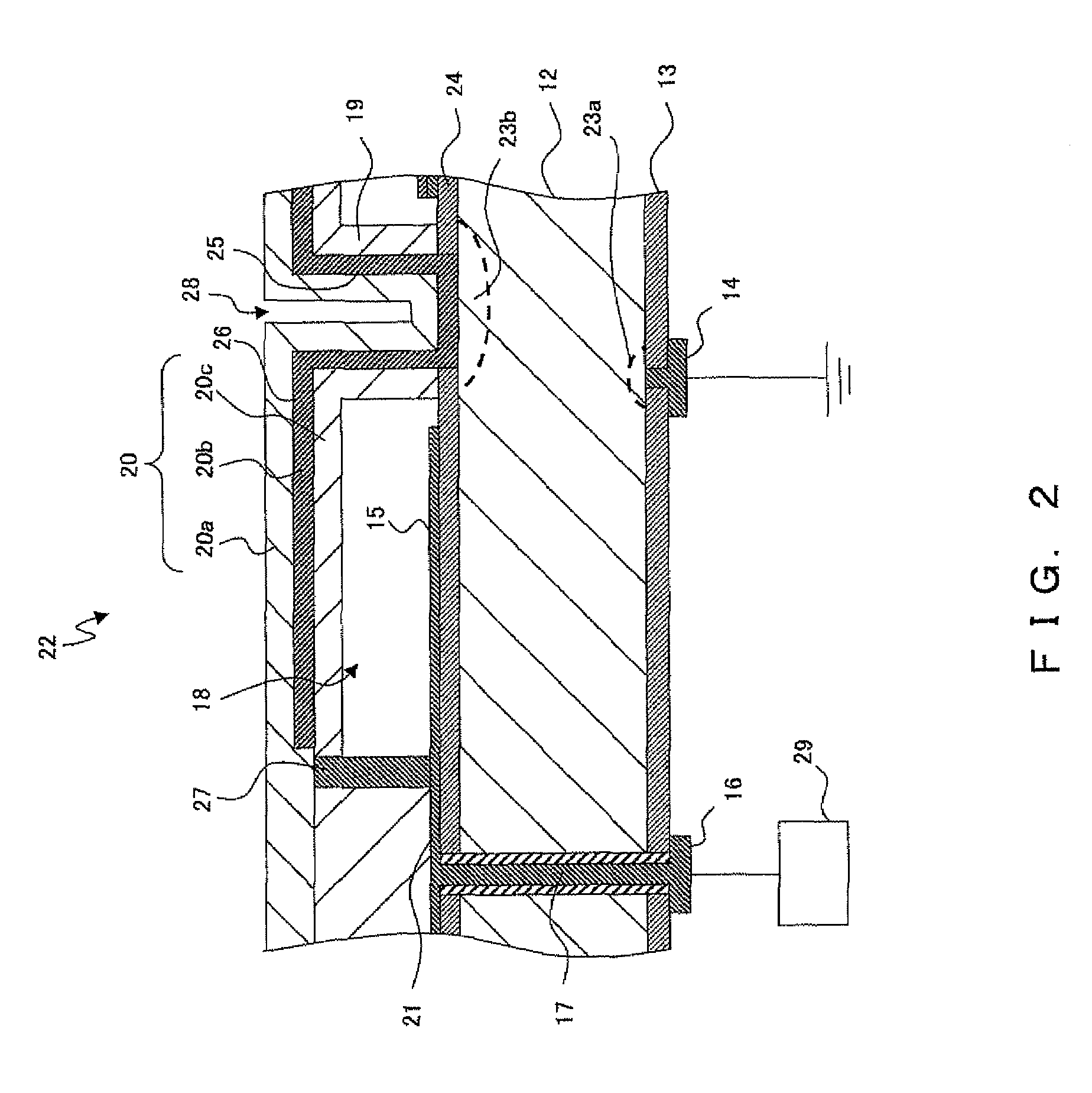

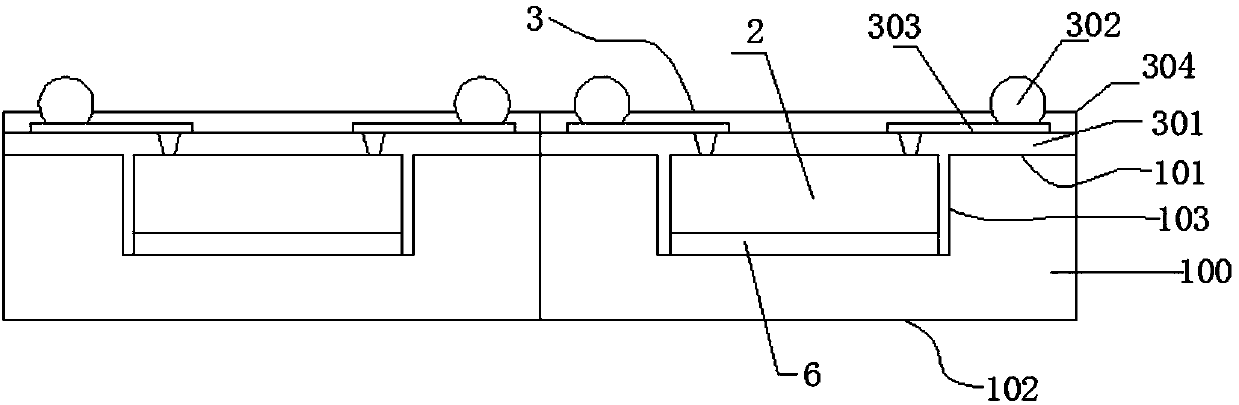

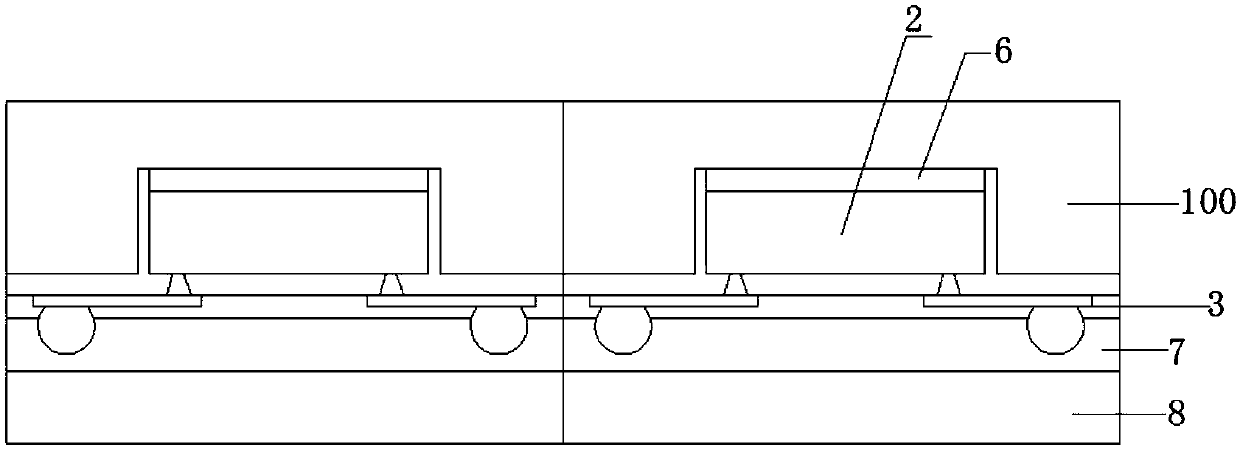

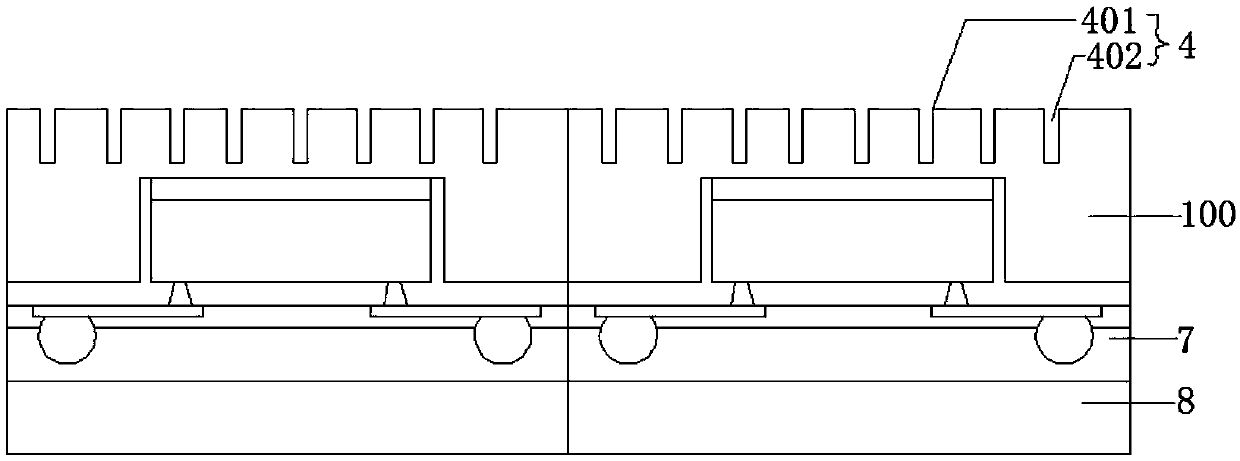

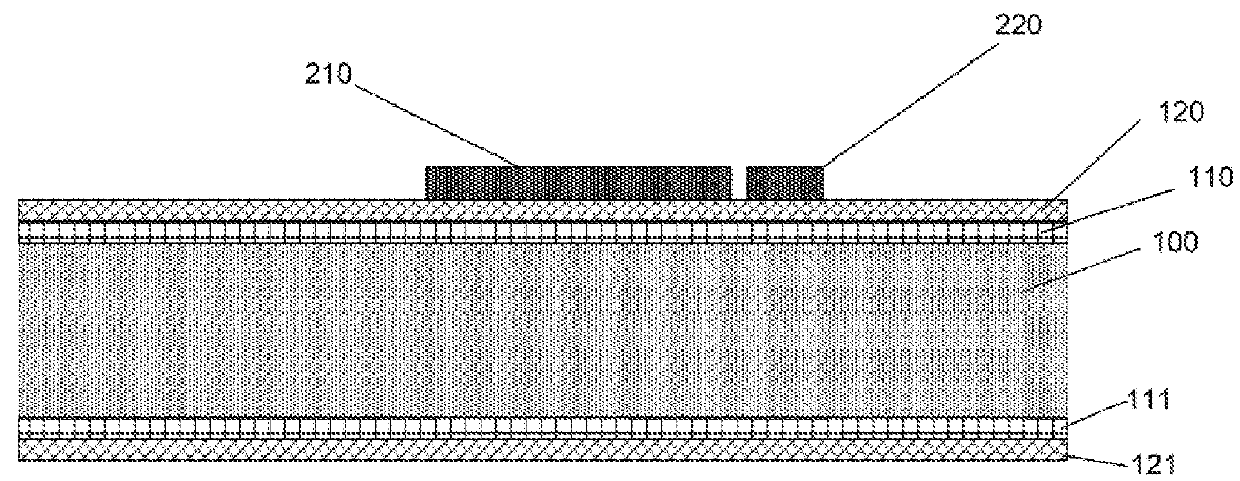

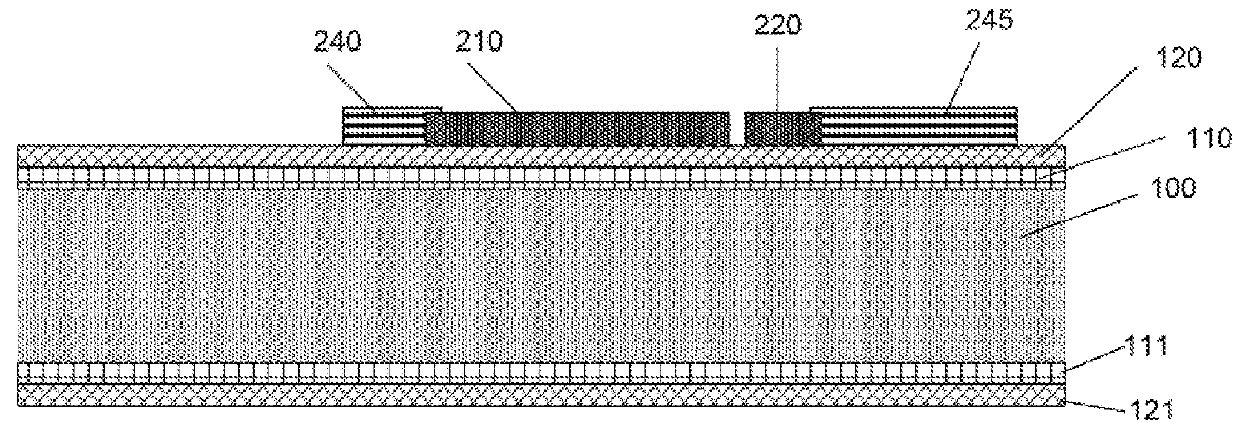

Silicon-based fan-out package of integrated heat-dissipation structure and wafer-level packaging method

PendingCN107946254AReduce interfaceImprove machining accuracySemiconductor/solid-state device detailsSolid-state devicesHeat sinkSilicon micromachining

The invention discloses a silicon-based fan-out package of an integrated heat-dissipation structure and a wafer-level packaging method. Based on a silicon-based fan-out package technology, a heat-dissipation structure is directly formed on a second surface of a silicon substrate after a chip is embedded. A wafer-level process is used for manufacturing, the machining is high-precision, the processis simple, and the price is low. Compared with conventional mechanically processed heat sinks, the silicon-based fan-out package can use a silicon micromachining process directly on a silicon substrate to produce a finer heat dissipation structure, create a larger heat dissipation area within the same unit volume, and achieve better heat radiation. This heat dissipation structure is directly integrated on the backside of a chip embedded in a silicon substrate, and has a high integration density, a small size, and a light weight. In addition, the interface between the external environment and the chip is reduced, and the heat dissipation effect is further improved. Preferably, a heat-dissipating cover plate with forced water cooling can be integrated on the heat dissipation structure of thesecond surface of the silicon substrate to obtain better heat dissipation efficiency.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

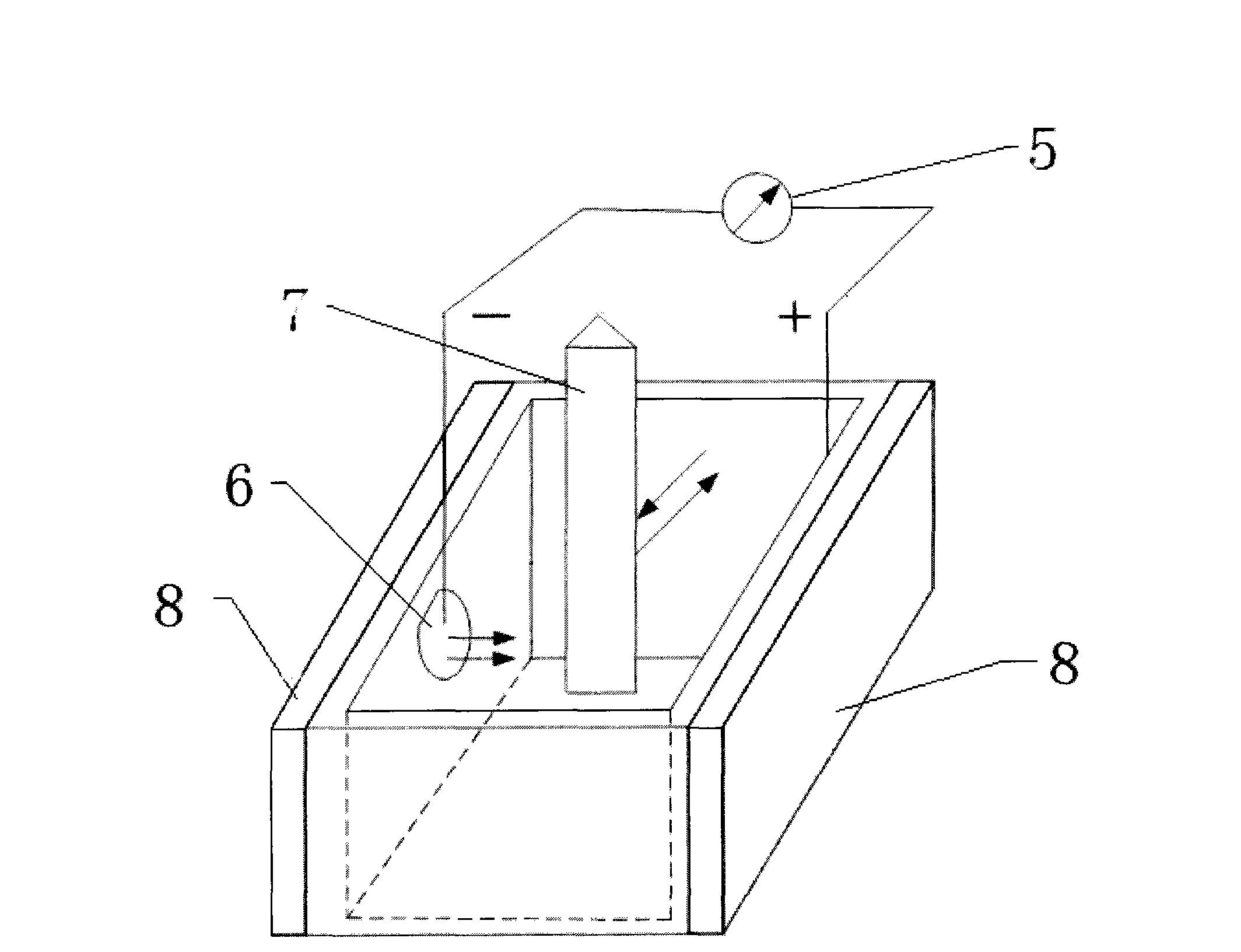

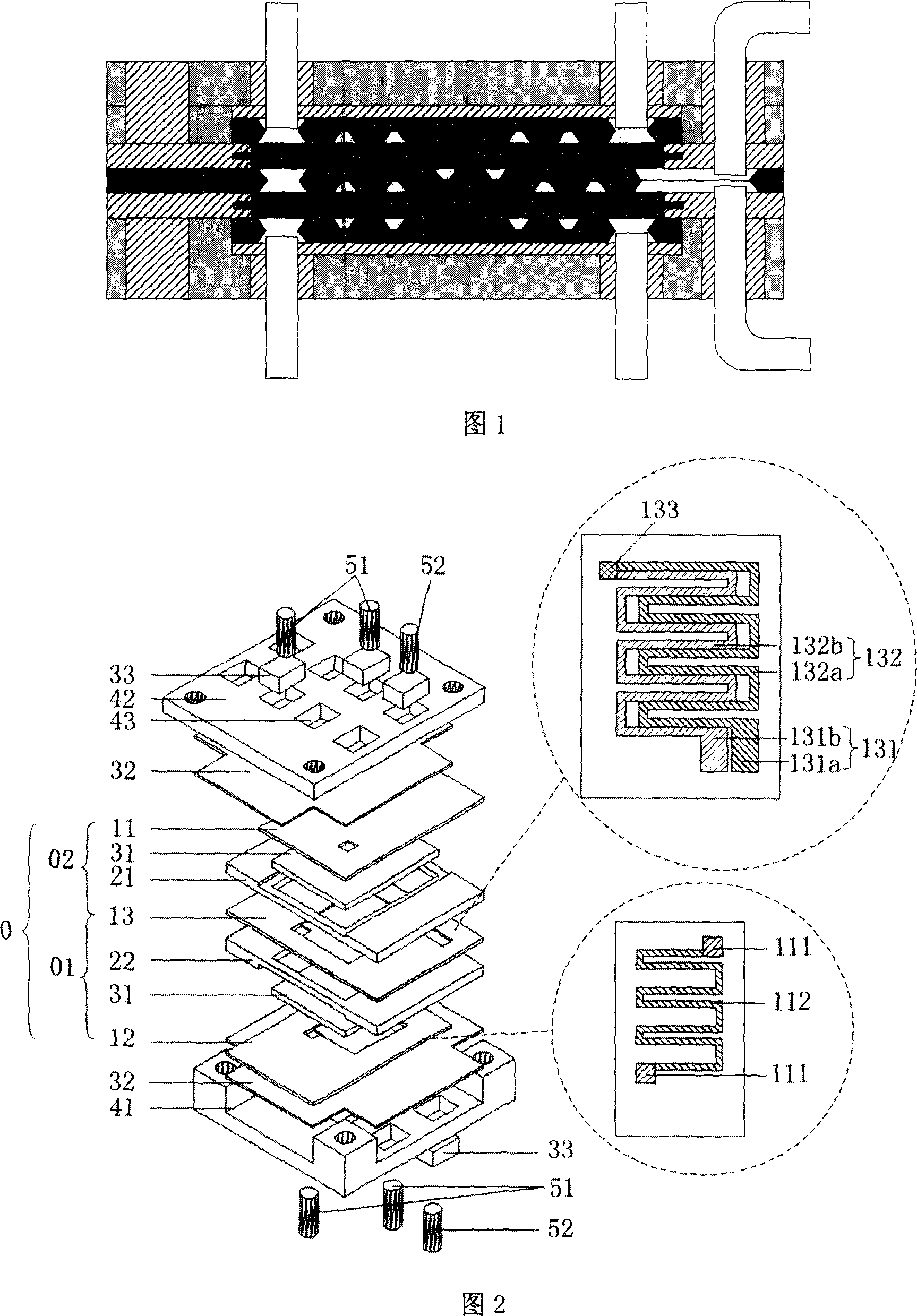

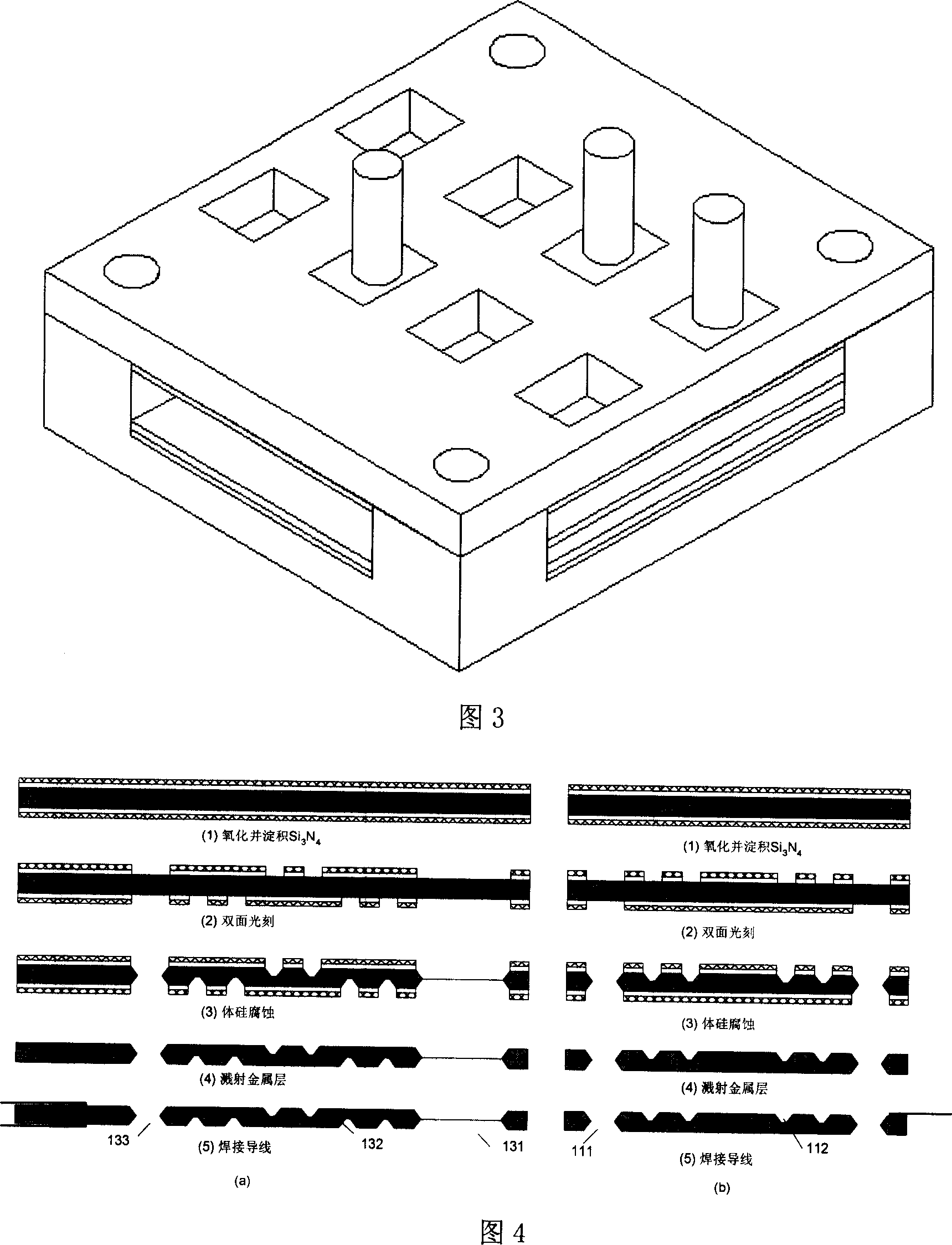

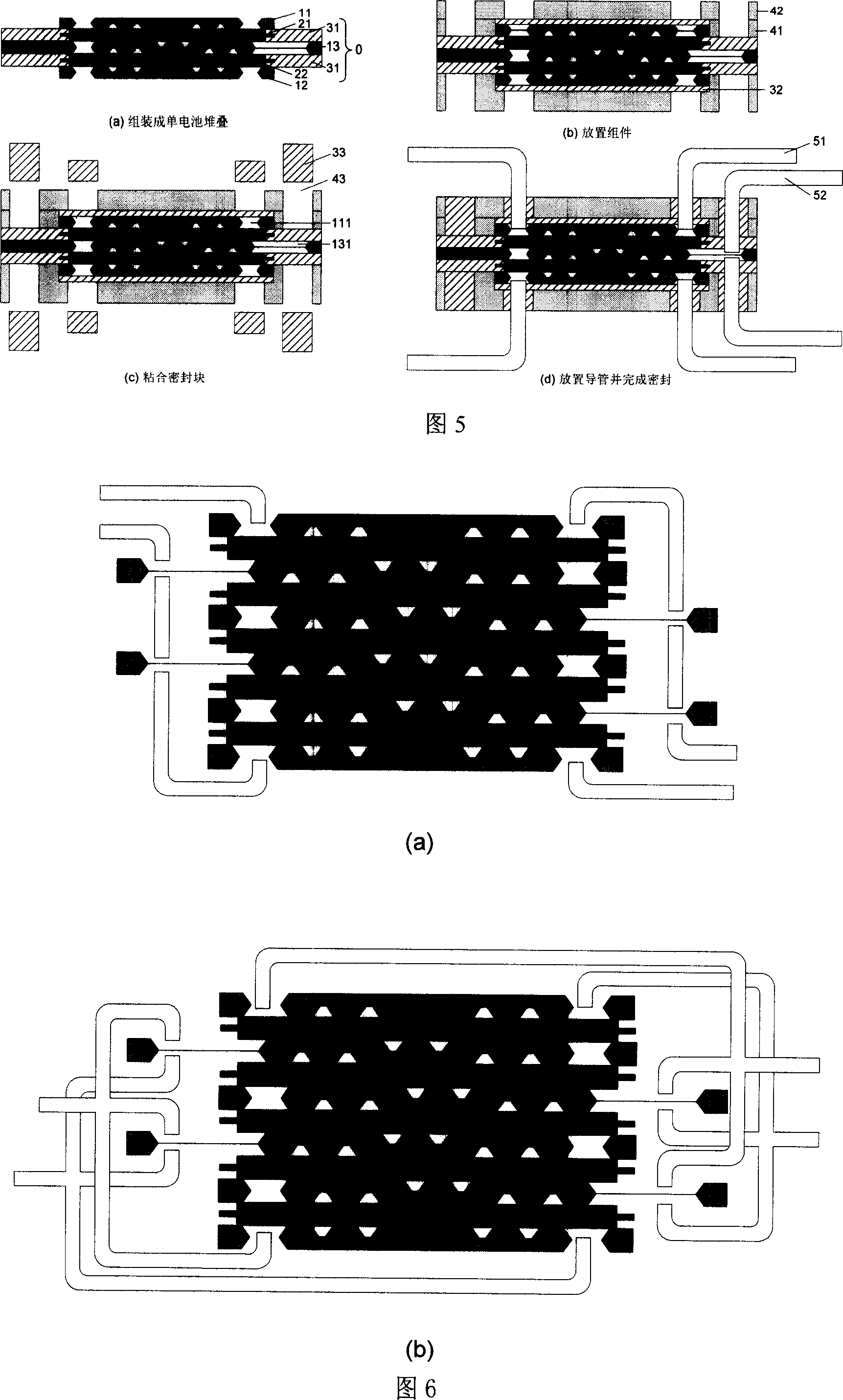

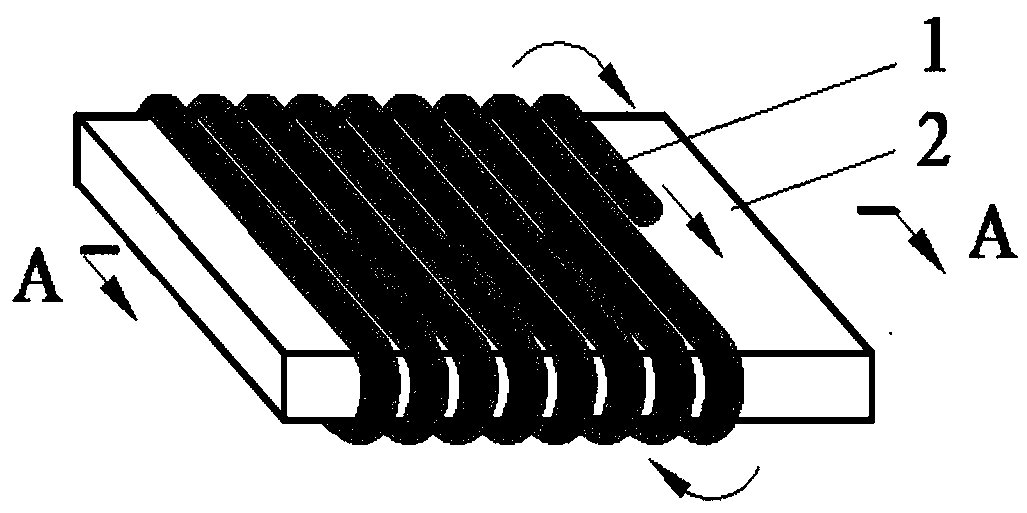

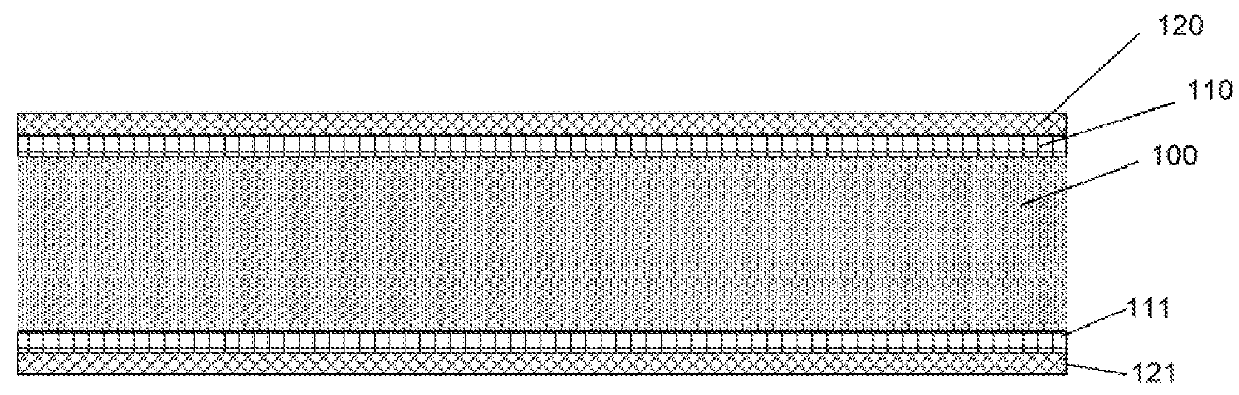

Stack silicon-base miniature fuel celles and manufacturing method

InactiveCN101000968AFlexible designLower battery internal resistanceSemi-permeable membranesFuel cells groupingElectrical batteryInternal resistance

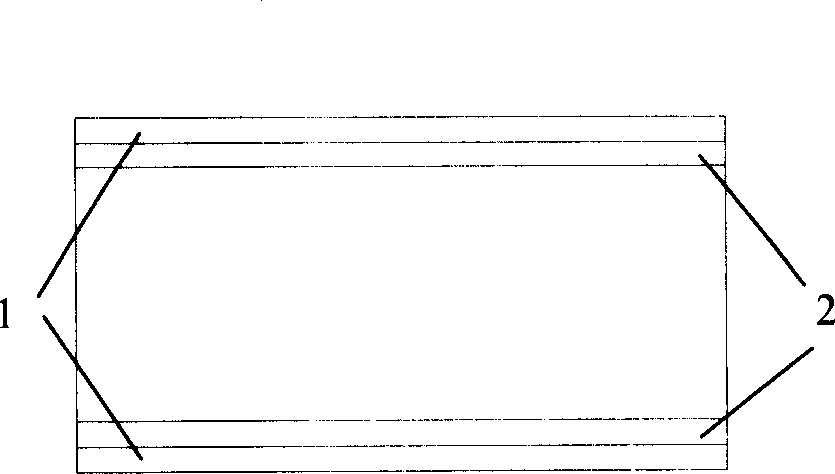

Stacked silicon-based micro fuel cell group and its production method belong to the field of micro-energy and micro-machining areas. It includes the single cell stacking, sealing component, claming component and fluid catheter. Two or more fuel cell single batteries form stack, which order is: the second outer plate (12), the second membrane electrode (22), the inner plate (13), the first membrane electrode (21) and the first outer plate (11), and use the clamping and sealing components to seal package. The production method includes processing silicon plate and seal packaging of different component parts, using silicon micro-machined to produce a drainage channel, packaging the single cell stack. The invention has small resistance of battery, small package size, flexible flow graphic design, various series and parallel forms, which can get a larger output current and voltage when a small increase in the volume of cases.

Owner:TSINGHUA UNIV

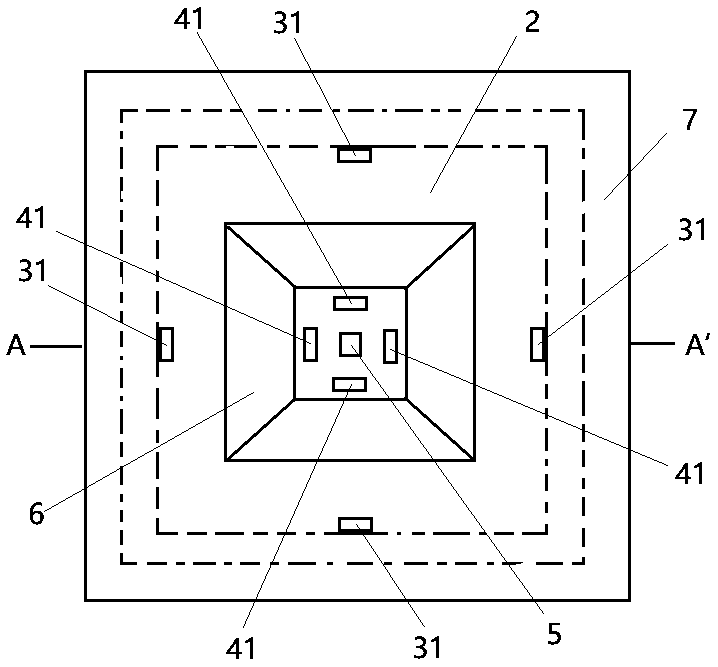

Wide-range air velocity transducer and manufacturing method thereof

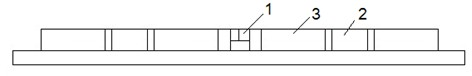

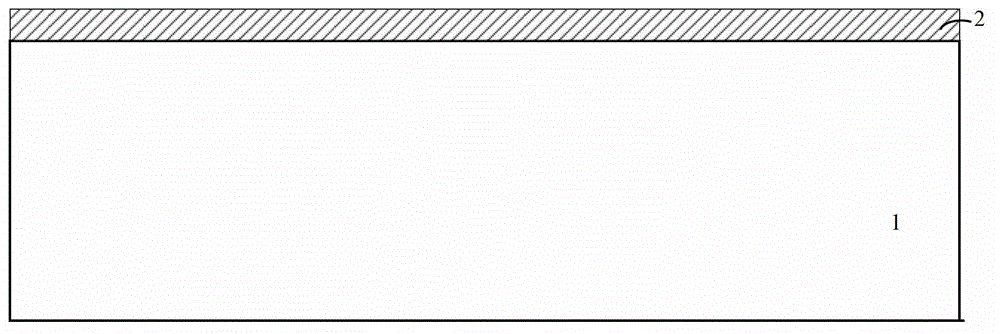

ActiveCN109001486AAccurate measurementLow costIndication/recording movementFluid speed measurement using thermal variablesAir velocityTransducer

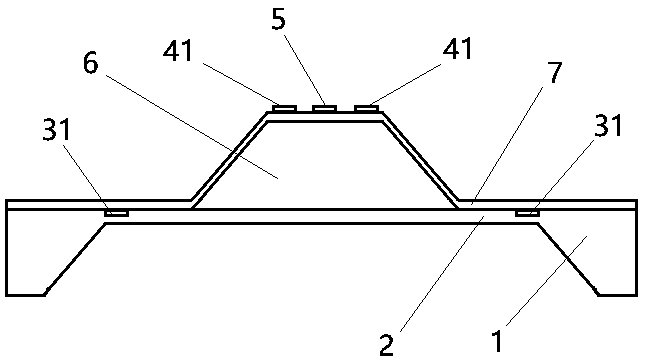

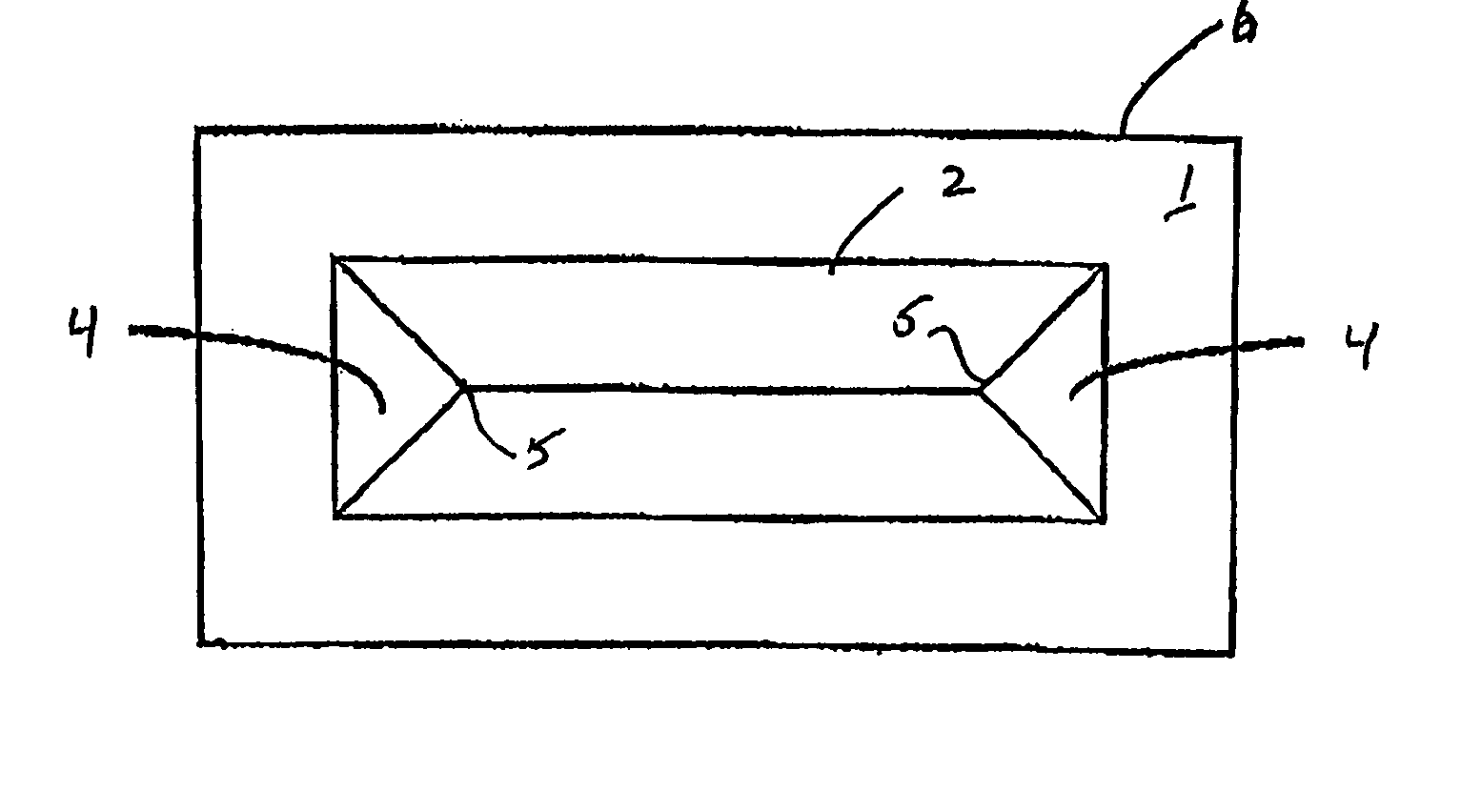

The invention relates to a wide-range air velocity transducer and a manufacturing method thereof. The wide-range air velocity transducer comprises a substrate (1), an elastic thin film (2), a heatingelement (5), a protruded table top (6), a thermal insulating layer (7), four pressure transducers (31) and four temperature transducers (41). On the basis of the design scheme, hardware is combined toconstitute the wide-range air velocity transducer, and correspondingly, the invention further relates to the manufacturing method of the wide-range air velocity transducer; thus according to the whole technical scheme, the thermal transducer principle is adopted, and air velocity and direction data can be accurately measured under the low air velocity; the piezoresistive effect is adopted, and air velocity and direction data can be accurately measured under the high air velocity; a bulk-silicon micromachining technology is adopted, the process is reliable, batch manufacturing is easy, and thecost is low; and not only that, a two-dimensional symmetrical structure is further adopted, and temperature drift is small.

Owner:SOUTHEAST UNIV

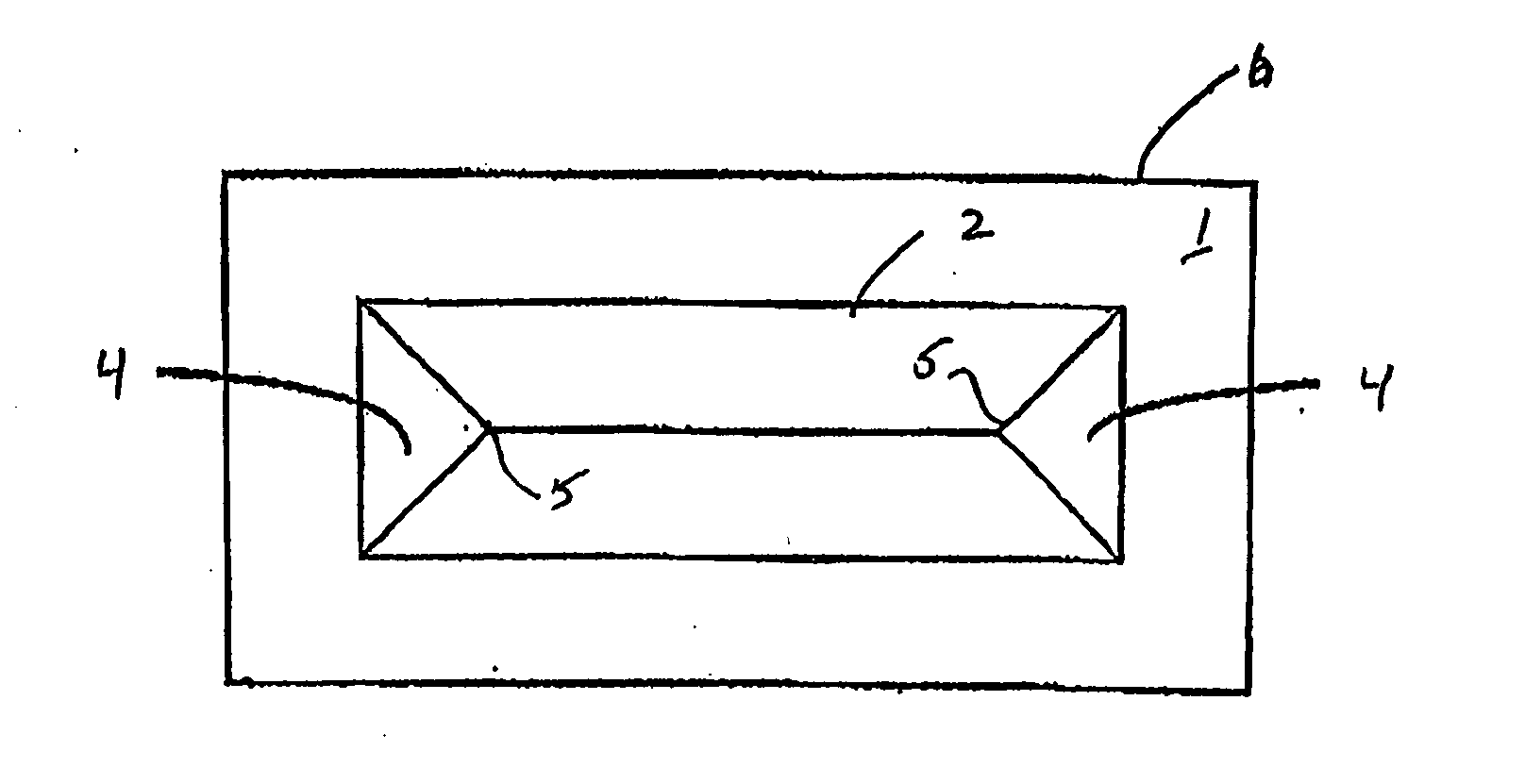

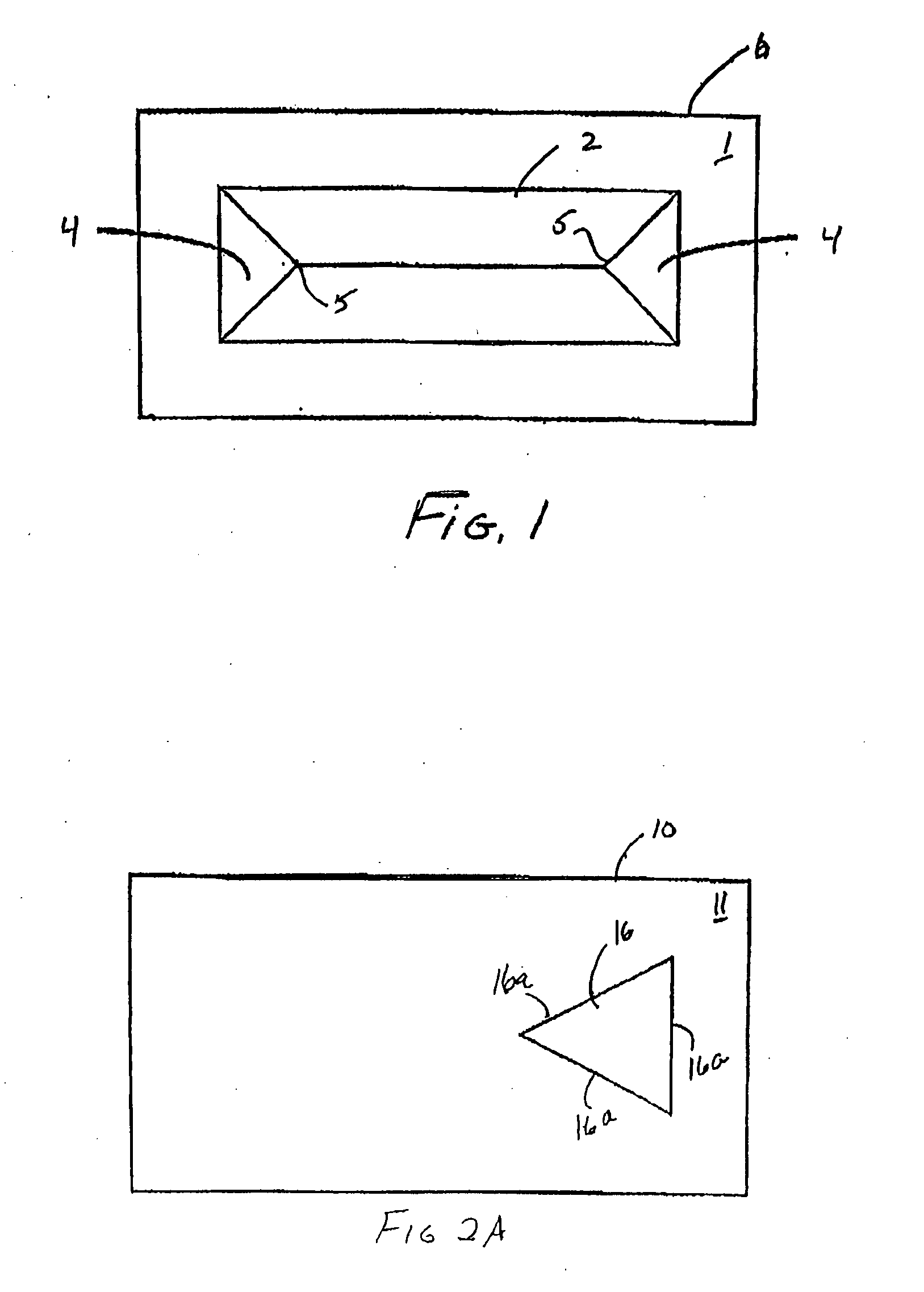

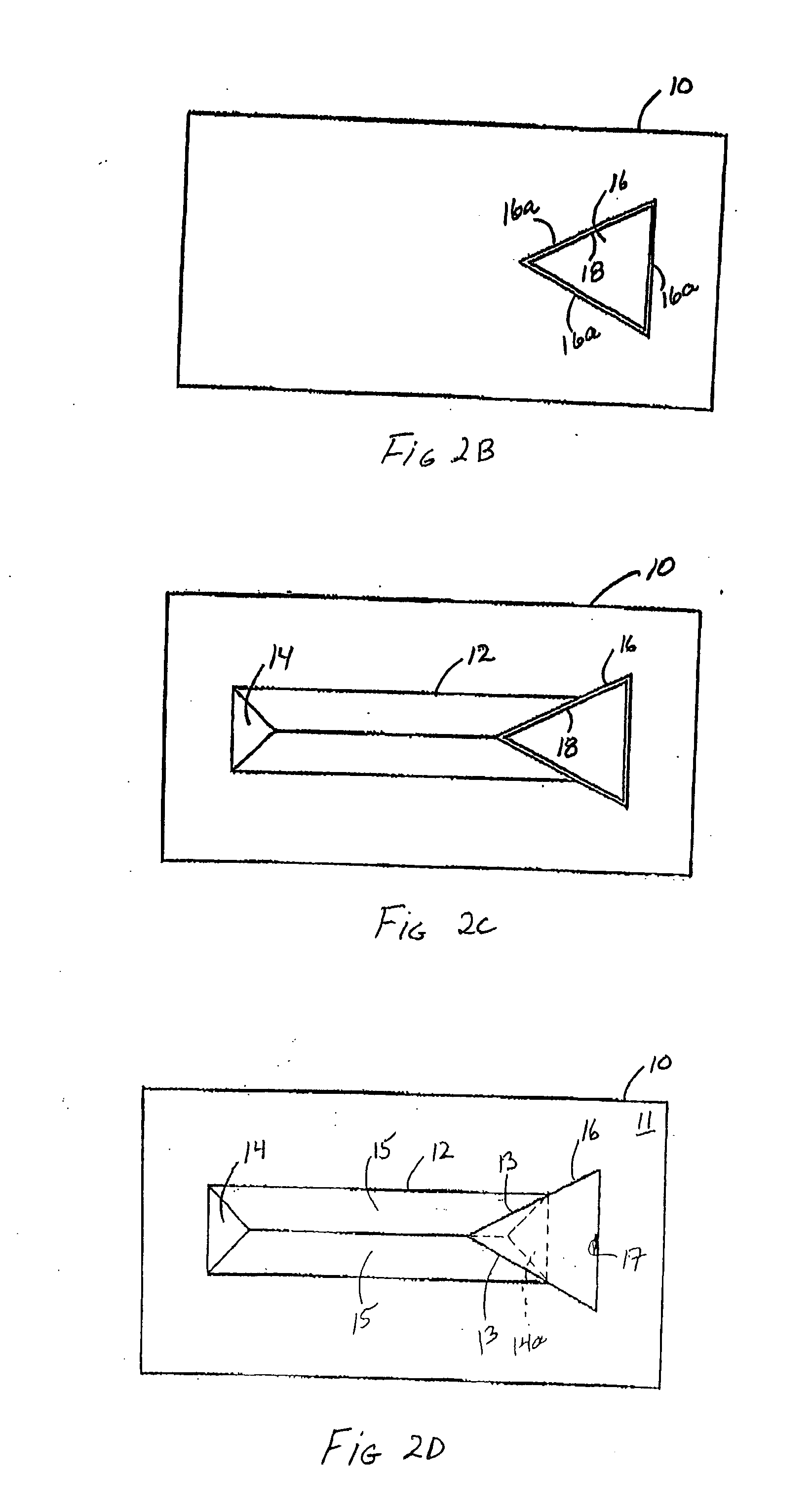

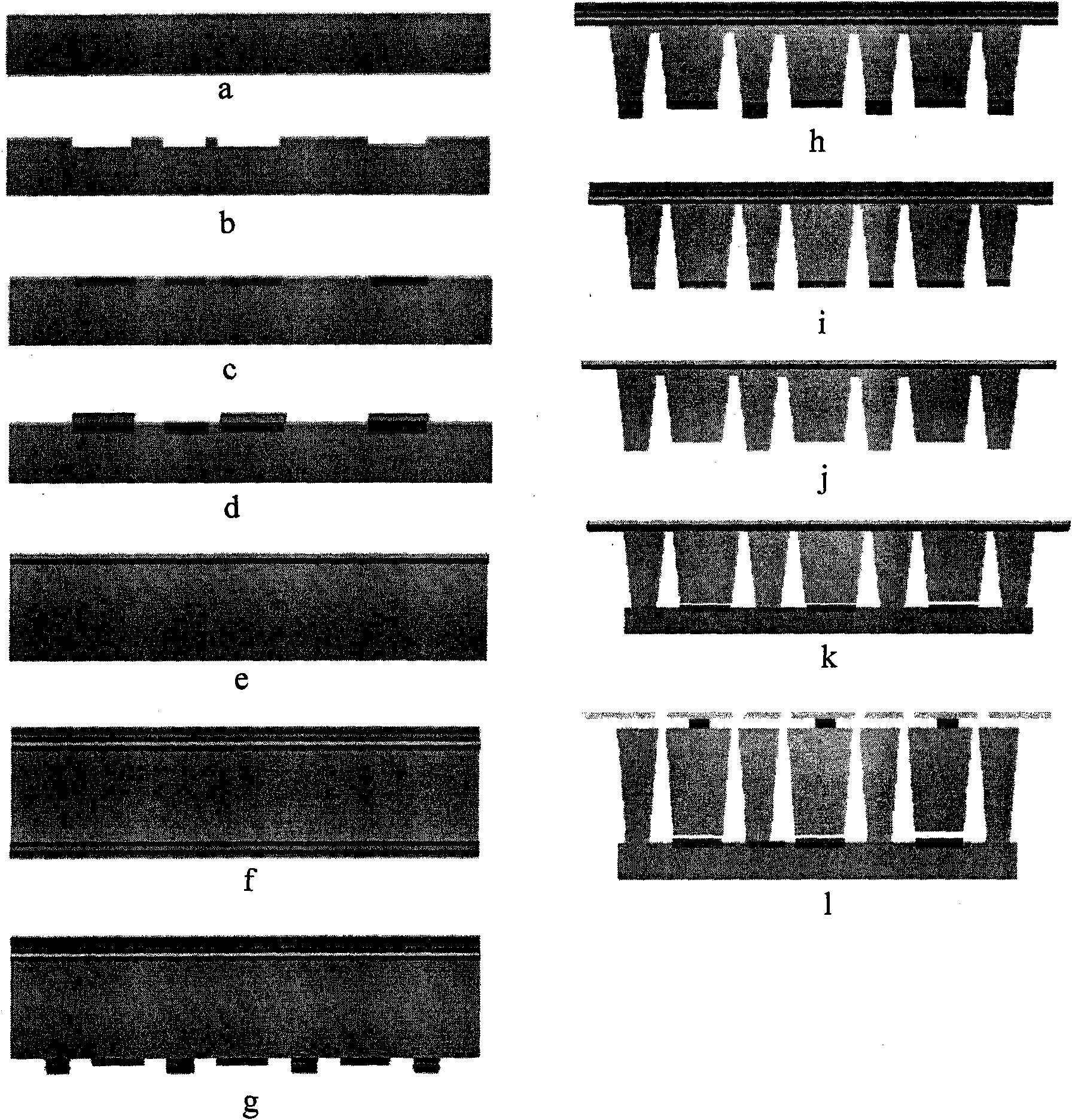

Etching process for micromachining crystalline materials and devices fabricated thereby

ActiveUS20050001282A1Volume/mass flow by thermal effectsFixed microstructural devicesCrystalline materialsMachining

The present invention relates generally to micromachining. More particularly, the present invention relates to a method for combining directional ion etching and anisotropic wet etching and devices and structures fabricated thereby. The present invention is particularly applicable to silicon micromachining and provides architectures that combine crystallographic surfaces and vertical dry etched surfaces together in the same structure.

Owner:SAMSUNG ELECTRONICS CO LTD

Etching process for micromachining crystalline materials and devices fabricated thereby

ActiveUS7157016B2Fixed microstructural devicesVolume/mass flow by thermal effectsCrystalline materialsMachining

The present invention relates generally to micromachining. More particularly, the present invention relates to a method for combining directional ion etching and anisotropic wet etching and devices and structures fabricated thereby. The present invention is particularly applicable to silicon micromachining and provides architectures that combine crystallographic surfaces and vertical dry etched surfaces together in the same structure.

Owner:SAMSUNG ELECTRONICS CO LTD

Dimesize dynamic piezoresistance, pressure sensor, and manufacturing method

InactiveCN1796956AGuaranteed dynamic frequency response characteristicsMeet the response frequencySemi-permeable membranesFluid pressure measurement using ohmic-resistance variationCooking & bakingEngineering

The invention is a method for manufacturing a micro dynamic pressure resistance pressure sensor, using MEMS silicon micromachining method to manufacture a micro pressure sensitive chip of an E-type silicon cup force sensitive structure; the back of the chip is welded with Pyrex or GG-17 glass ring plate to form a pressure sensitive component; the naked surface of the glass ring is pasted at the upper end of the a ceramic pipe provided with spline groove on the circumferential surface, which are provided with silver baking electrode; the lead of the pressure sensitive component is an inner lead welded on an inner pressure soldered dot on the right side of the chip, and the other end of the inner lead is welded to the upper end of the silver baking electrode, the outer lead is welded to the lower end of the silver baking electrode; the pressure sensitive component is put in the outer pipe of the sensor and seal-boned with the outer pipe; the top of the sensor is welded with a top cover, and a small hole is made in the center of the top cover corresponding the chip; a micro cable drawing out the outer lead is fixed by injection component with a micro air pipe connected with back pressure cavity of the chip and then they are bonded to the bottom end of the outer pipe of the sensor; and the manufactured sensor has very strong light resistance and electromagnetic interference resistance and prevents destructive impacts.

Owner:KUNSHAN SHUANGQIAO SENSOR MEASUREMENT CONTROLLING

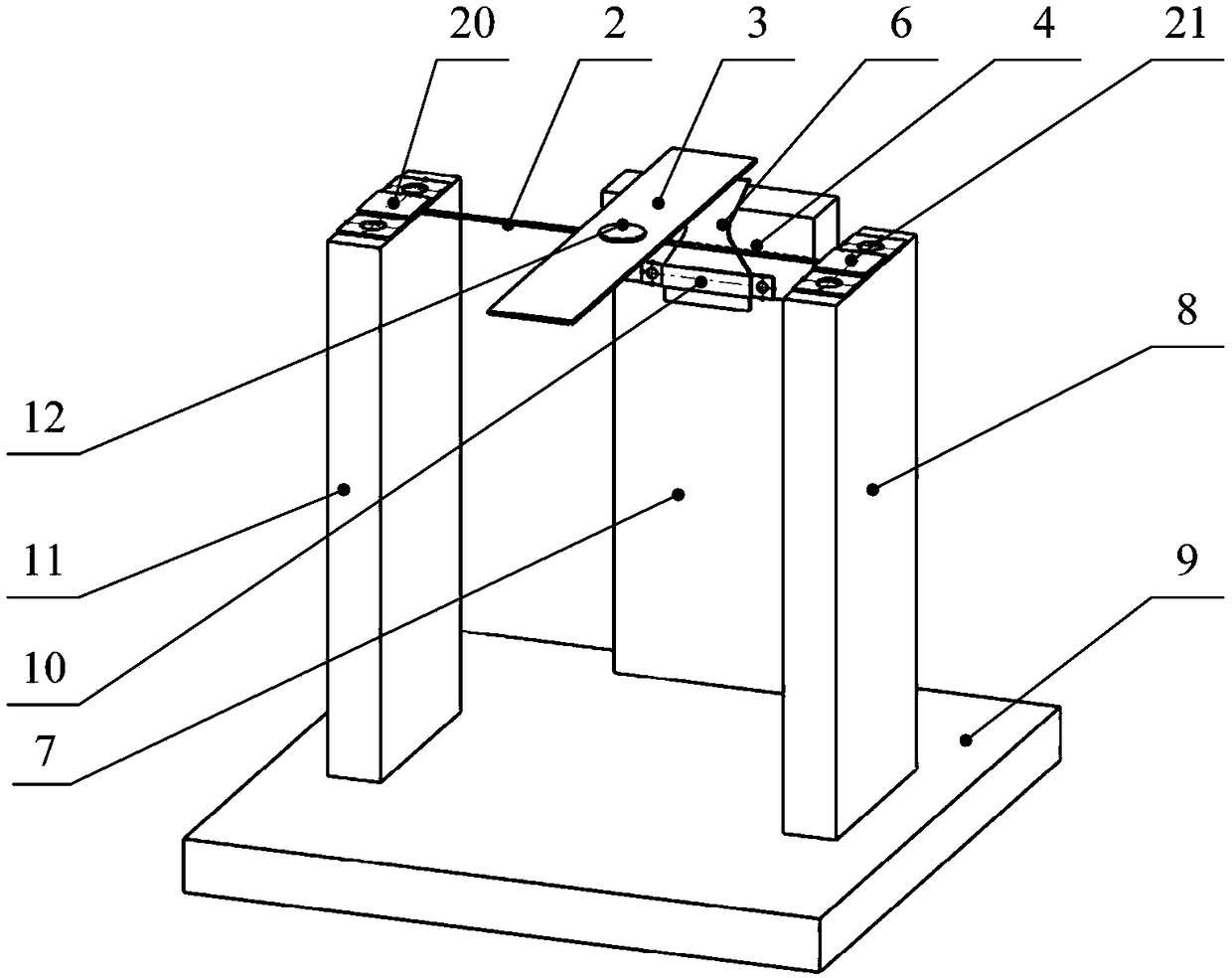

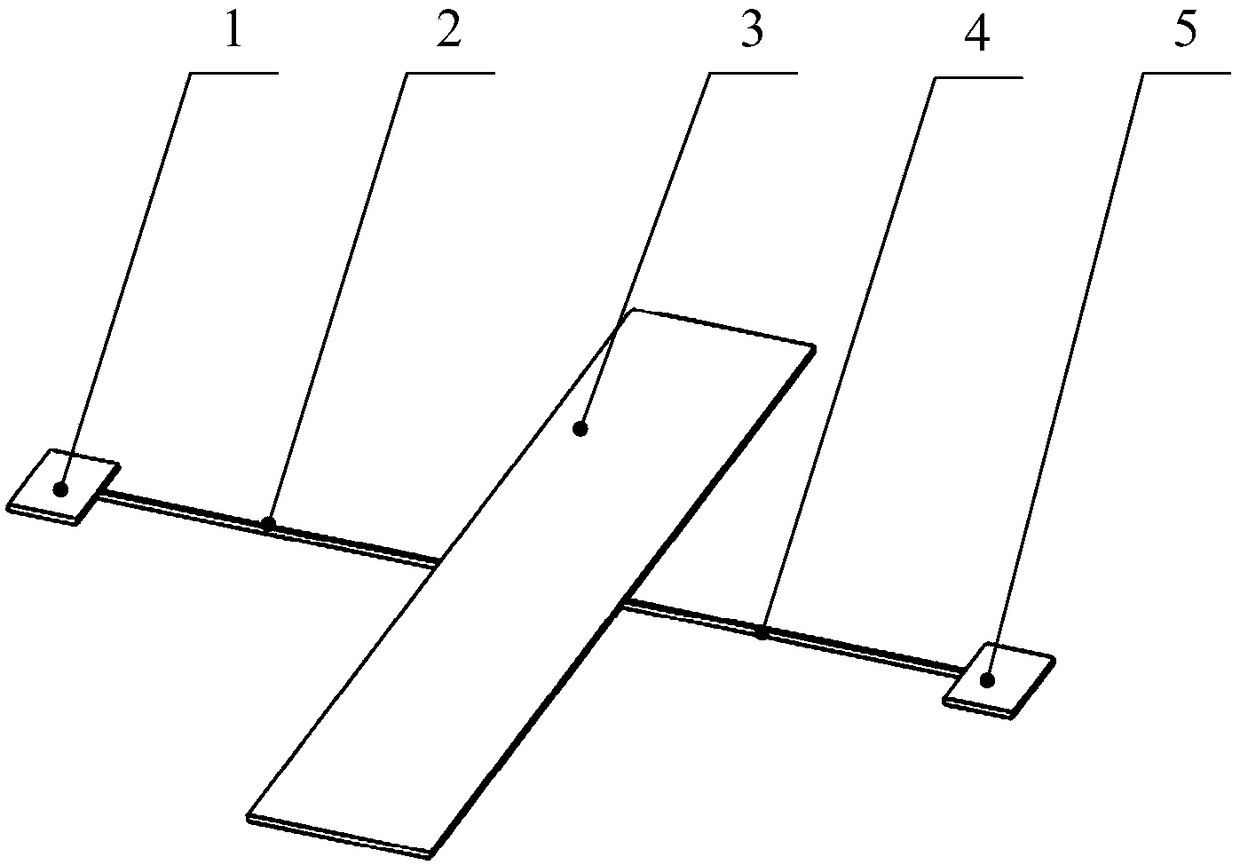

Micro-thrust measuring device that employs silicon torsion spring

ActiveCN108827512AAvoid influenceReduce the impactForce measurement by measuring optical property variationApparatus for force/torque/work measurementAviationMeasurement device

The invention relates to a micro-thrust measuring device that employs a silicon torsion spring, and specifically relates to a silicon torsion spring formed by a silicon micromachining technology; thesilicon torsion spring and an optical path can amplify the micro thrust displacement of a micro propeller, thus measuring micro thrust with high sensitivity; the micro-thrust measuring device can directly measure and evaluate the thrust performance of the micro propeller, thus providing important effects in micro propeller research and development and assessment. In addition, in some emerging fields, such as space satellite control technology, biomechanics, microrobot and bionics, have higher and higher requirements on the thrust measuring technology in a micro N level, Nano N level and even smaller level. The micro-thrust measuring device belongs to the aviation, spaceflight, micro force measurement, micro propulsion technology and micro mechanical fields.

Owner:BEIJING UNIV OF TECH

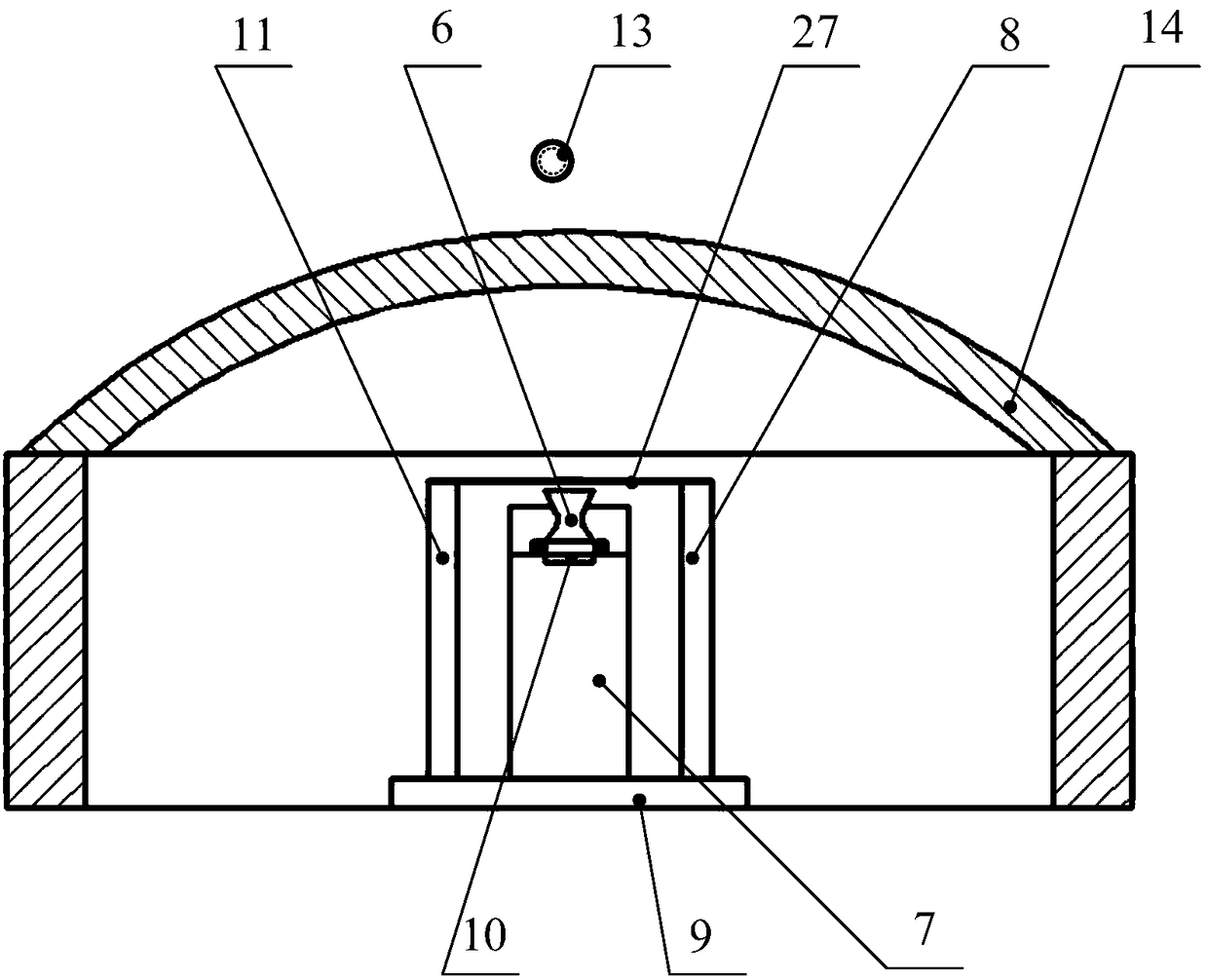

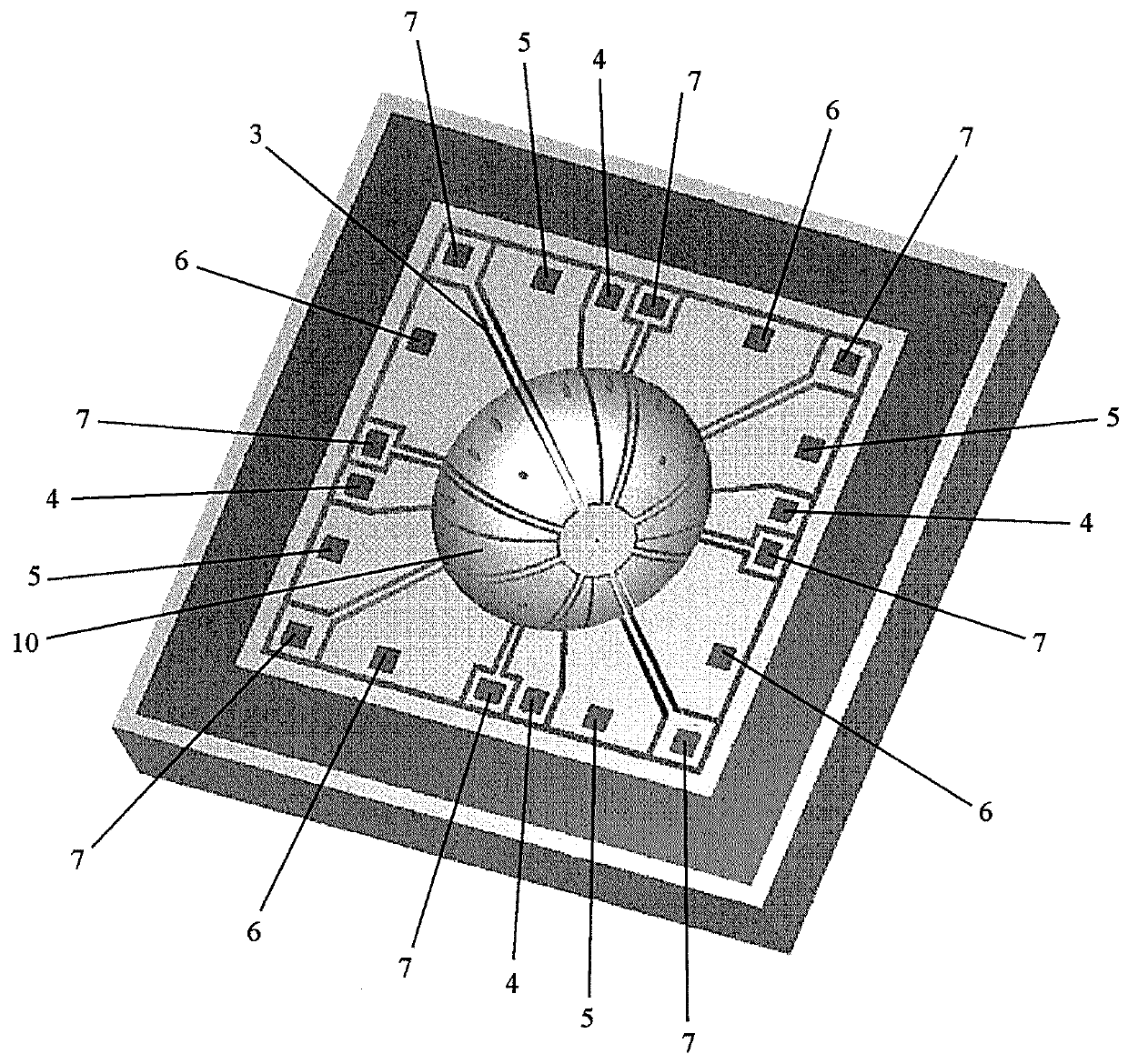

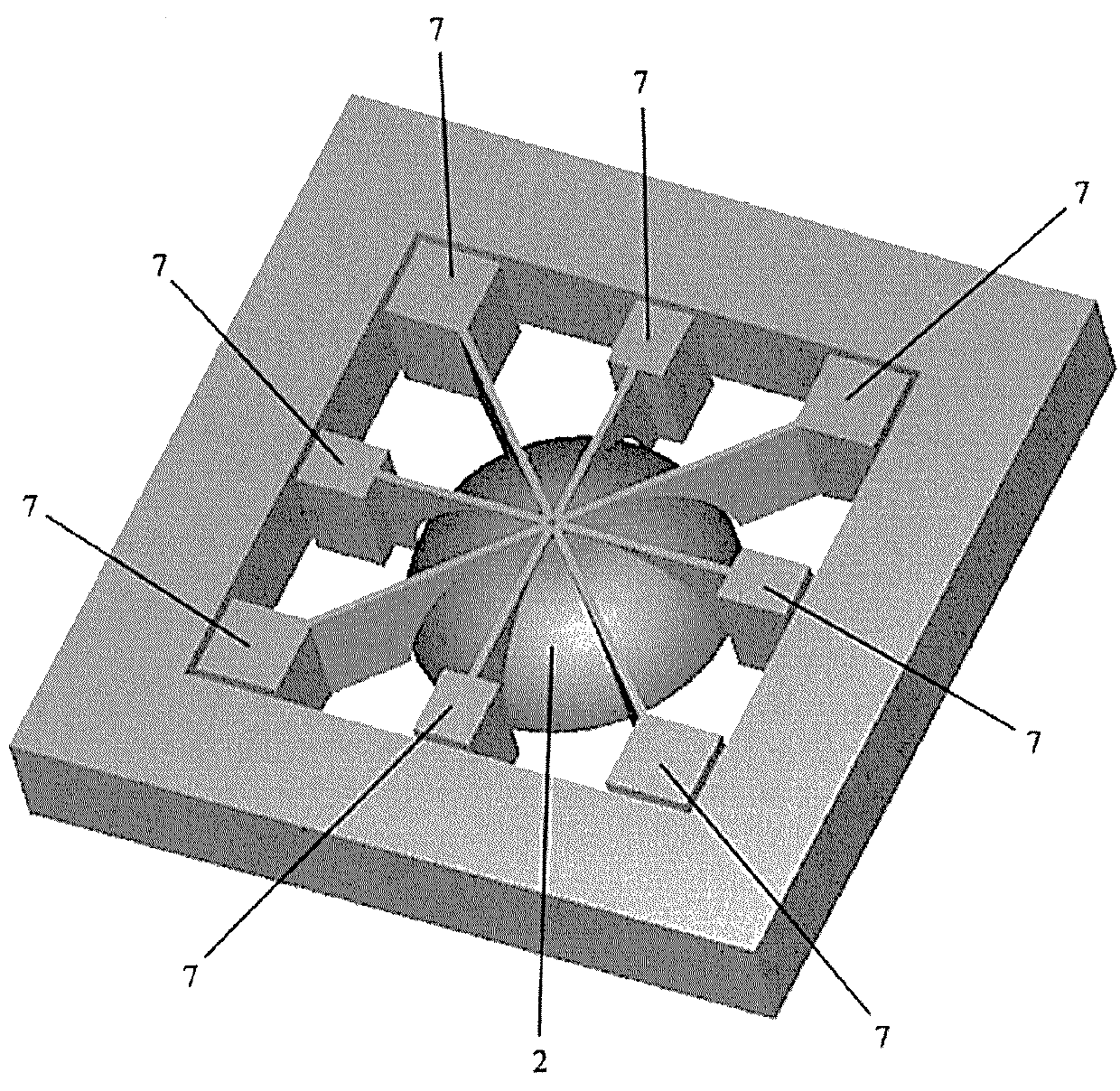

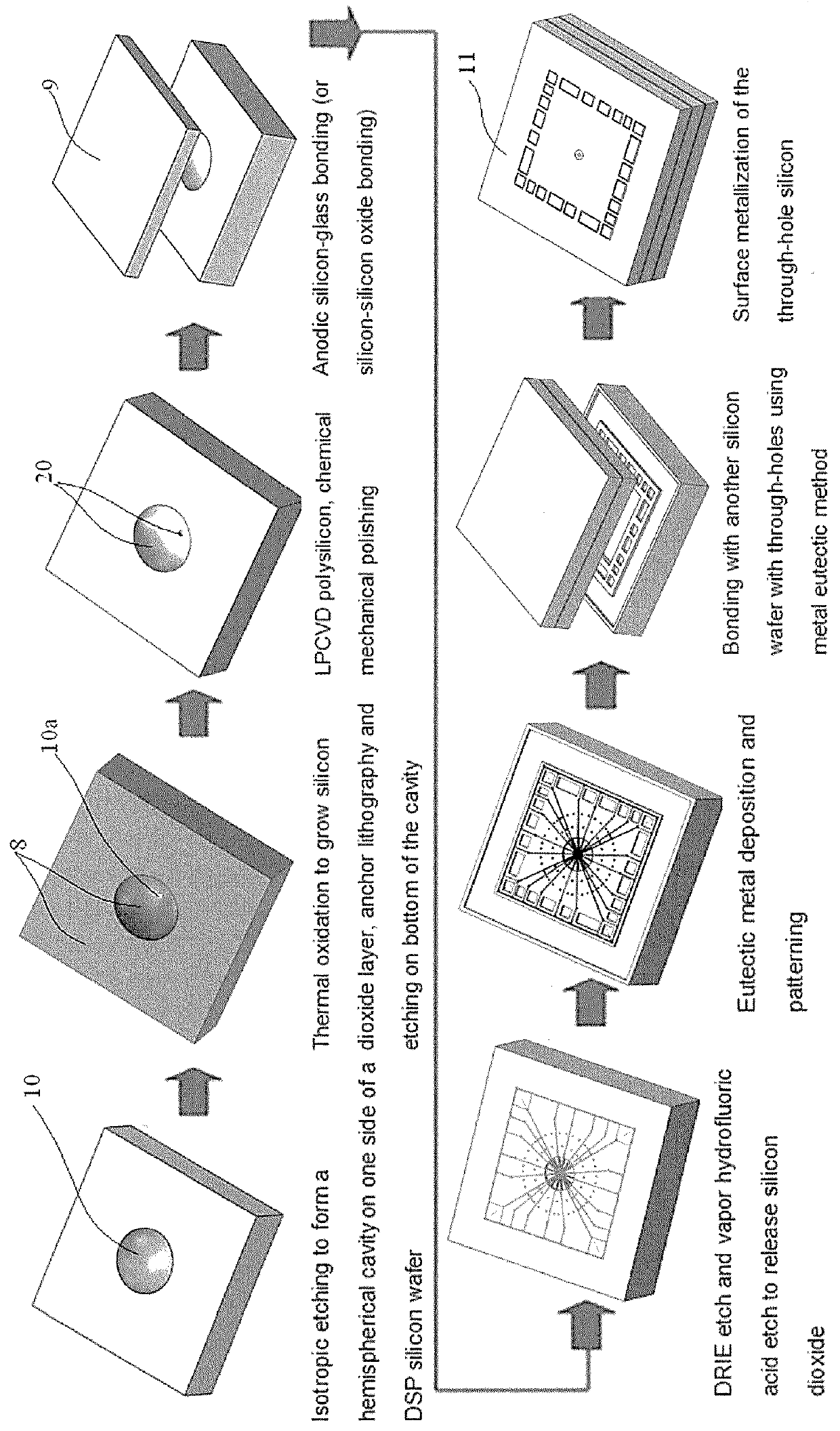

Hemispherical resonance micromechanical gyroscope and processing method thereof

ActiveUS20180164098A1Reduce the driving voltageReduce output noiseAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGyroscopeResonance

The present invention relates to a micromachined hemispherical resonance gyroscope, which includes a resonant layer, wherein the resonant layer comprises a hemispherical shell whose top point of the hemispherical shell is its anchor point; several silicon hemispherical electrodes are ananged around the hemispherical shell, the silicon hemispherical electrodes include driving electrodes, equilibrium electrodes, shielded electrodes and signal detection electrodes or quadrature correction electrodes, the hemispherical shell and the several silicon spherical electrodes which sunound the hemispherical shell constitute several capacitors. The hemispherical resonance micromechanical gyroscope utilizes a processing method on the basis of silicon micromachining, which leads to small size and low production cost, as well as batch production capacity, meanwhile its sensitivity is independent of amplitude and its driving voltage could be very low, as a result its output noise could be significantly reduced, and its accuracy is better than the gyroscope products in the prior art.

Owner:SUZHOU WENZHIXIN MICRO SYST TECH

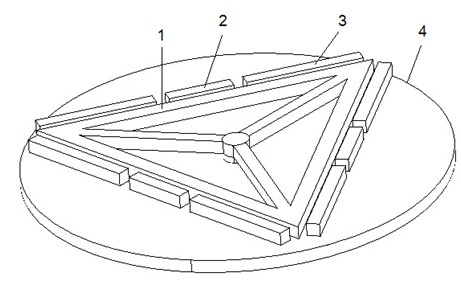

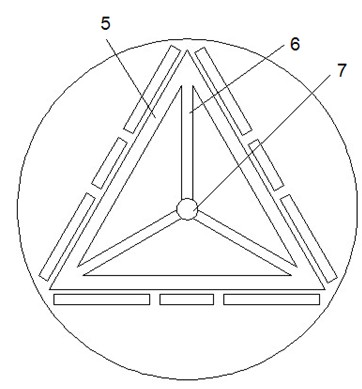

Silicon micro gyroscope with triangular vibrator and manufacturing method thereof

The invention relates to a silicon micro-gyroscope with a triangular oscillator and a manufacturing method thereof of the micro-electromechanical technical field, and the silicon micro-gyroscope comprises an equilateral triangle oscillator with three vibrating beams, driving electrodes which are parallel to the vibrating beams and have a certain interval, detection electrodes which are located at two sides of the driving electrode and are parallel to the vibrating beams, and a substrate. The manufacturing method of the micro-gyroscope adopts a bulk silicon micro-processing process, has a simple manufacturing process, high reliability, and can ensure low cost and high yield. The micro-gyroscope of the invention has a small volume, a simple structure, an easily-realized processing process, compatibility with CMOS technology, impact resistance, does no require vacuum packaging, and is applicable to batch production.

Owner:SHANGHAI JIAO TONG UNIV

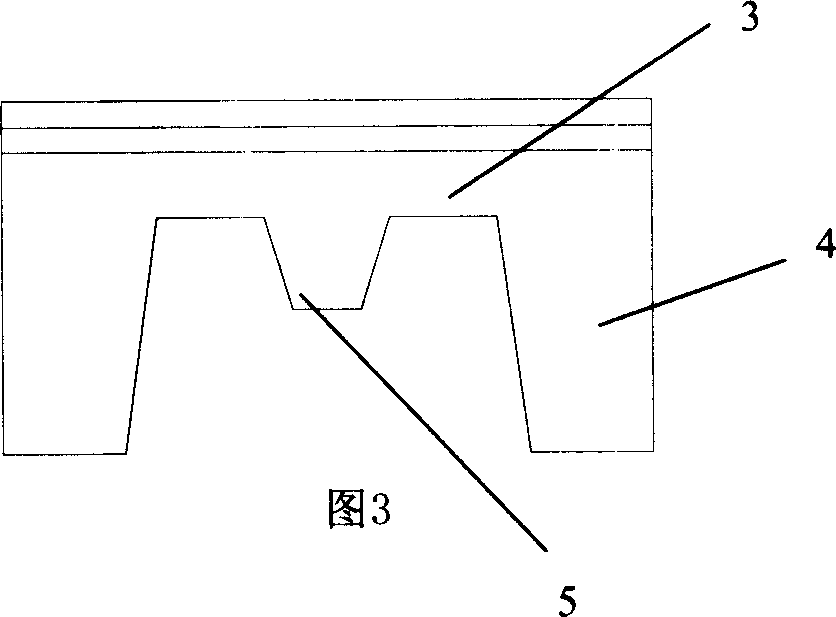

Micro machining method for bulk silicon for forming cavity structure of MEMS (micro-electromechanical systems) thermopile detector

ActiveCN103145094AStructural symmetryHigh controllability of the manufacturing processDecorative surface effectsChemical vapor deposition coatingThermopileMicroelectromechanical systems

The invention provides a micro machining method for bulk silicon for forming a cavity structure of an MEMS (micro-electromechanical systems) thermopile detector. The method comprises the following steps of: providing a silicon substrate, growing a silica membrane on the silicon substrate in a thermal oxidation manner, and forming a thermopile area and an infrared absorption area on the silica membrane. A thermal nodal area is arranged at one end of the thermopile area, close to the infrared absorption area, and a cold nodal area is arranged at the other end of the thermopile area, far away from the infrared absorption area. A silicon nitride and silica compound membrane structure is deposited on a thermopile structure layer, and a corrosion opening is formed in a compound membrane through photoetching. A release channel of the thermopile structure is formed by the corrosion opening. Through the release channel, a superficial layer on the surface of the bulk silicon is corroded by using an isotropy corrosion method so as to form a thin cavity of the superficial layer of the bulk silicon, and a bulk silicon deep layer below the thin cavity is corroded by using an anisotropy corrosion method so as to form a regular smooth ladder-shaped cavity structure, and therefore, the cavity structure in the bulk silicon is finally formed. The cavity structure formed by using the method has a regular and smooth inner surface and is good in structure symmetry.

Owner:中科芯未来微电子科技成都有限公司

Etching radical controlled gas chopped deep reactive ion etching

ActiveUS8546264B2Decorative surface effectsSemiconductor/solid-state device manufacturingInductively coupled plasmaPolymer

A method for silicon micromachining techniques based on high aspect ratio reactive ion etching with gas chopping has been developed capable of producing essentially scallop-free, smooth, sidewall surfaces. The method uses precisely controlled, alternated (or chopped) gas flow of the etching and deposition gas precursors to produce a controllable sidewall passivation capable of high anisotropy. The dynamic control of sidewall passivation is achieved by carefully controlling fluorine radical presence with moderator gasses, such as CH4 and controlling the passivation rate and stoichiometry using a CF2 source. In this manner, sidewall polymer deposition thicknesses are very well controlled, reducing sidewall ripples to very small levels. By combining inductively coupled plasmas with controlled fluorocarbon chemistry, good control of vertical structures with very low sidewall roughness may be produced. Results show silicon features with an aspect ratio of 20:1 for 10 nm features with applicability to nano-applications in the sub-50 nm regime. By comparison, previous traditional gas chopping techniques have produced rippled or scalloped sidewalls in a range of 50 to 100 nm roughness.

Owner:RGT UNIV OF CALIFORNIA

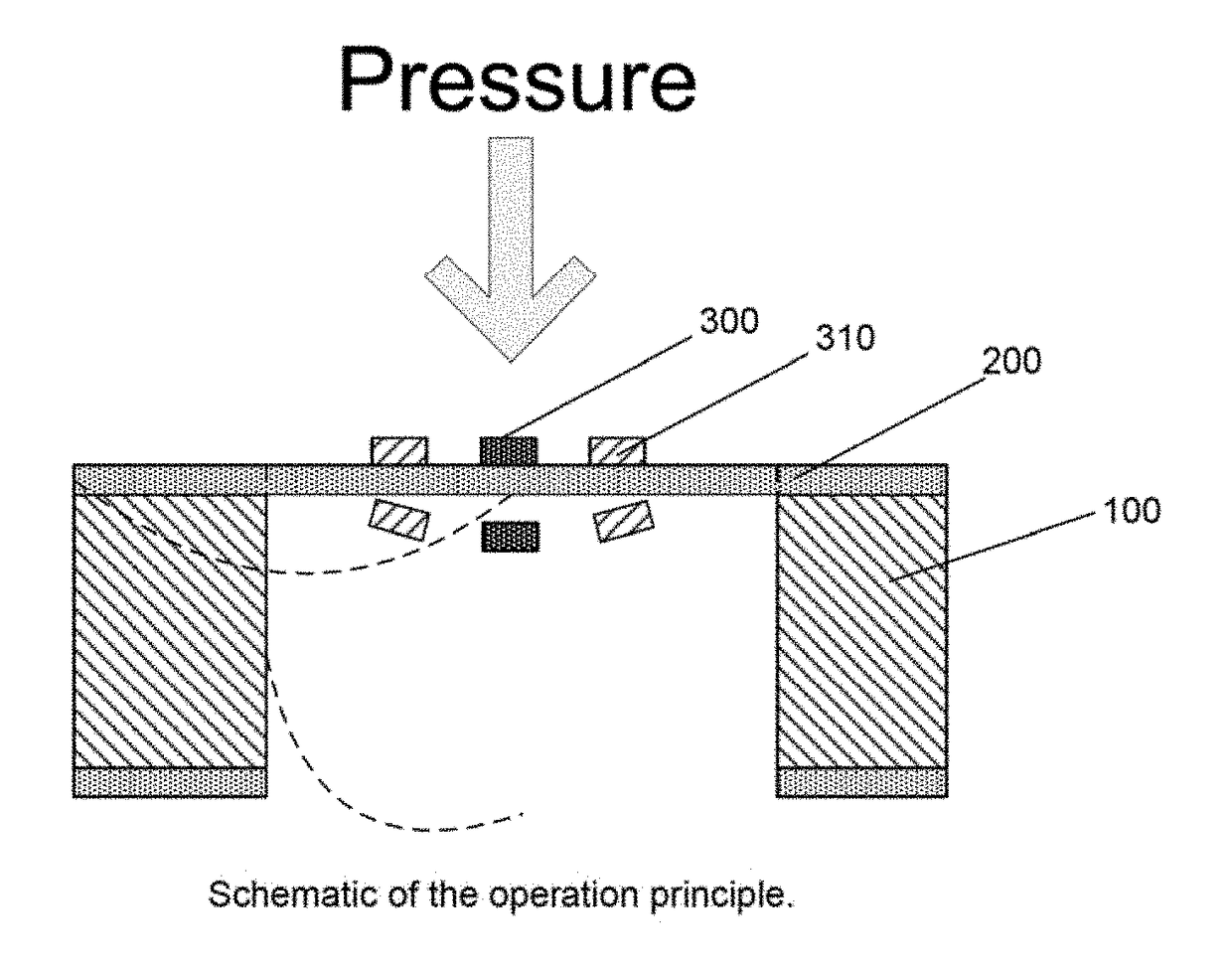

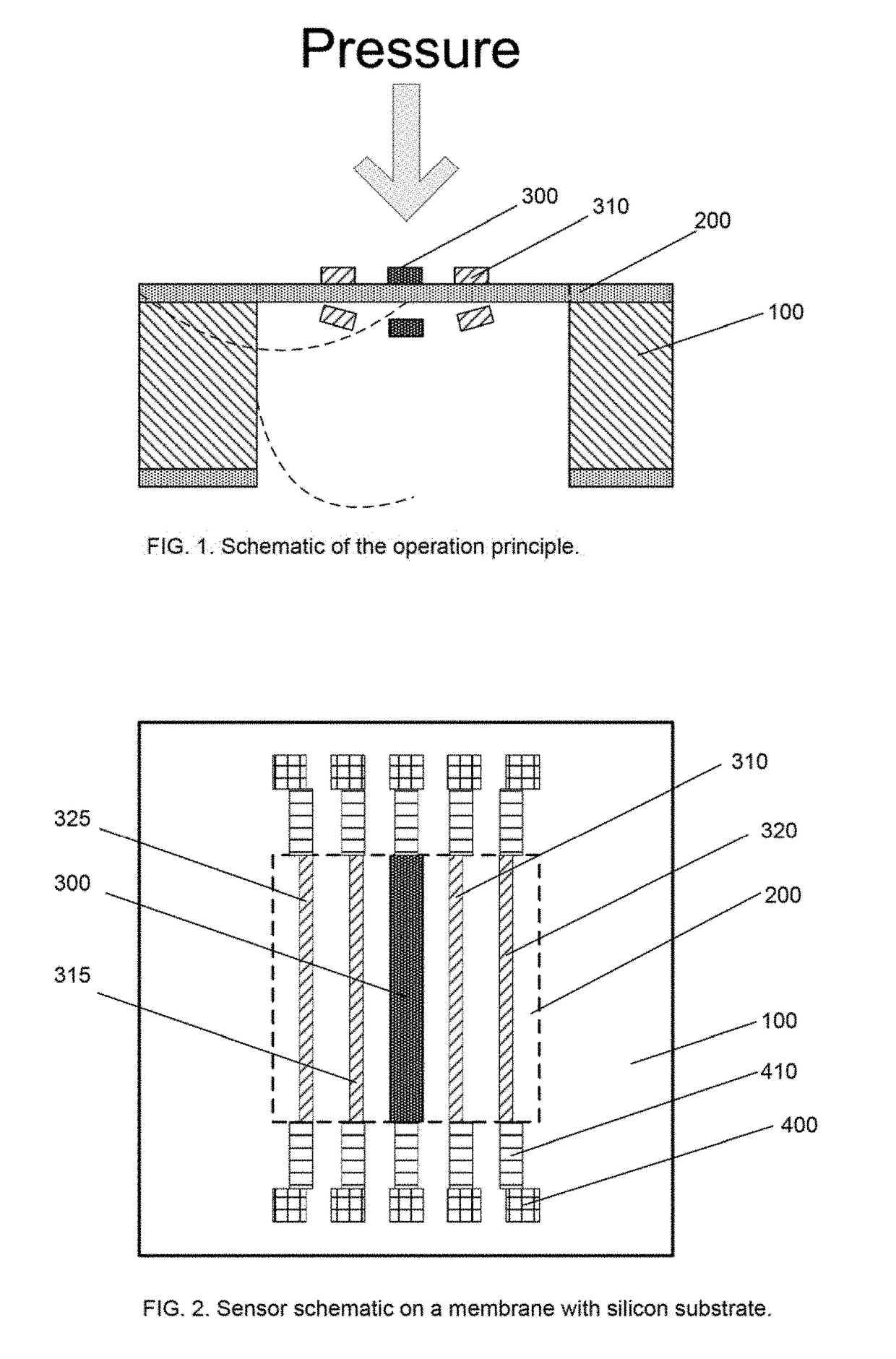

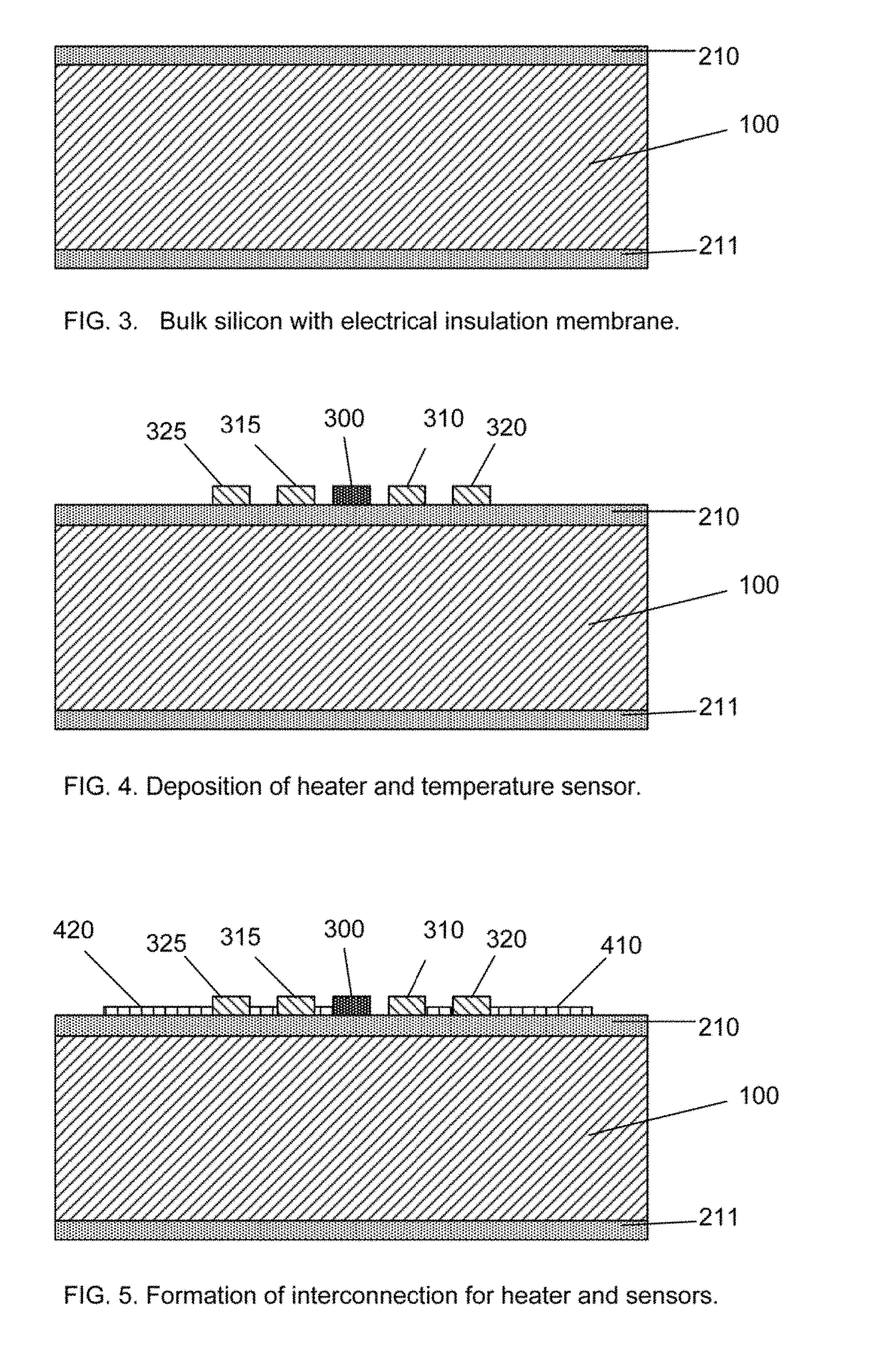

Micromachined pressure sensor and method of making the same

ActiveUS20180172532A1High accurate pressure dataLarge dynamic rangeFluid pressure measurement by electric/magnetic elementsFluid pressure measurement by thermal meansMetrologyDiaphragm structure

The design and manufacture method of a pressure sensor utilizing thermal field sensing with a thermal isolated membrane of a diaphragm structure is disclosed in the present invention. This device is made with silicon micromachining (a.k.a. MEMS, Micro Electro Mechanical Systems) process for applications of pressure measurement with large dynamic range, high accuracy and high stability during temperature variation. This device is applicable for all types of pressure metrology. The said thermal field pressure sensing device operates with thermistors on a membrane of the diaphragm structure made of silicon nitride with a heat isolation cavity underneath or a single side thermal isolated silicon nitride membrane with a reference cavity. This device can be seamlessly integrated with a thermal flow sensor with the same process.

Owner:WISENSTECH

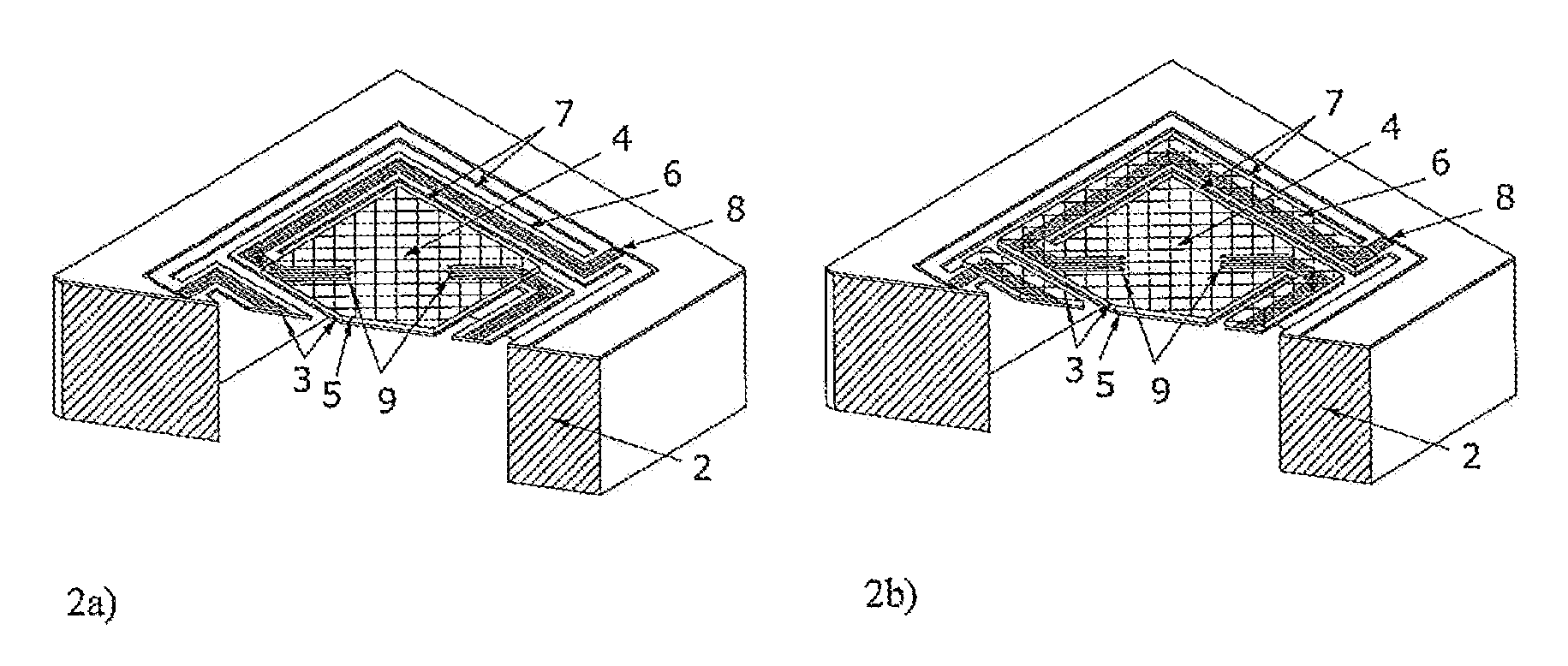

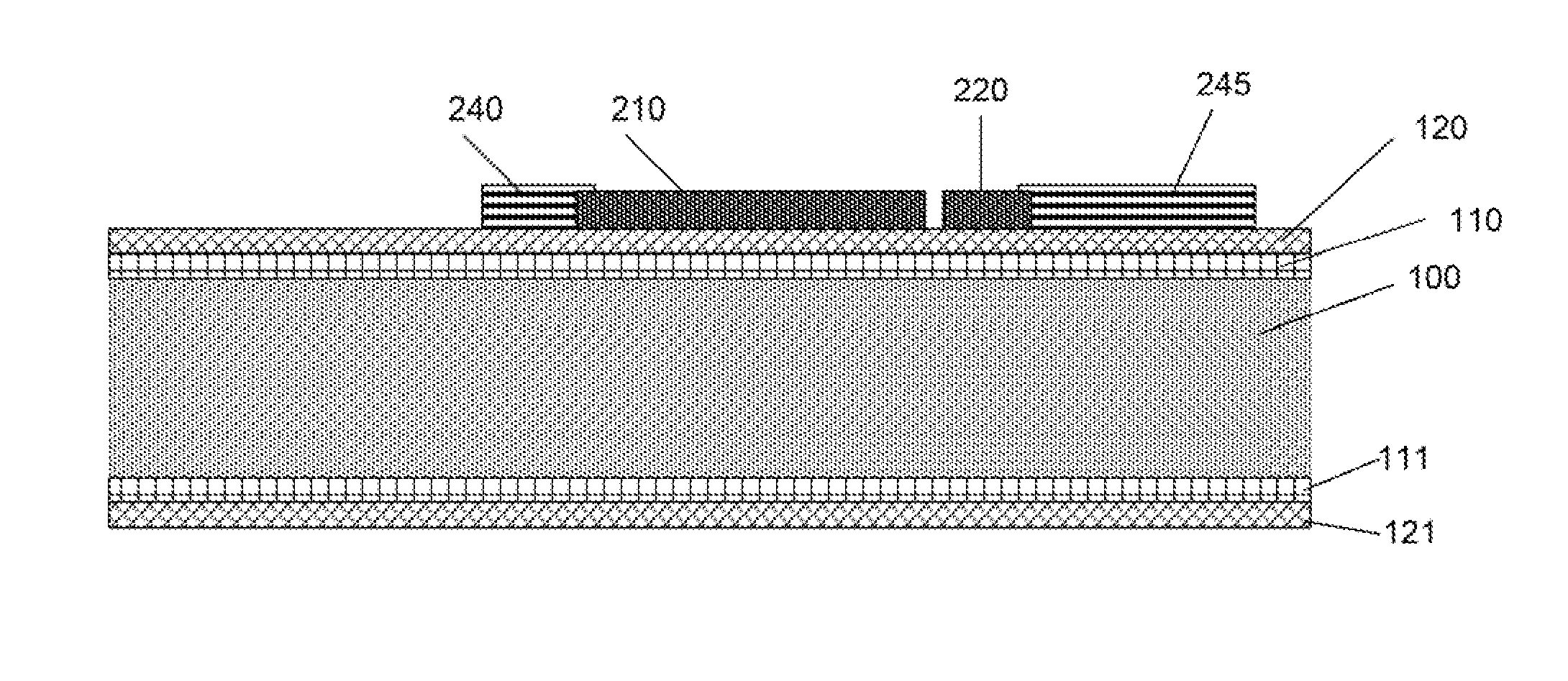

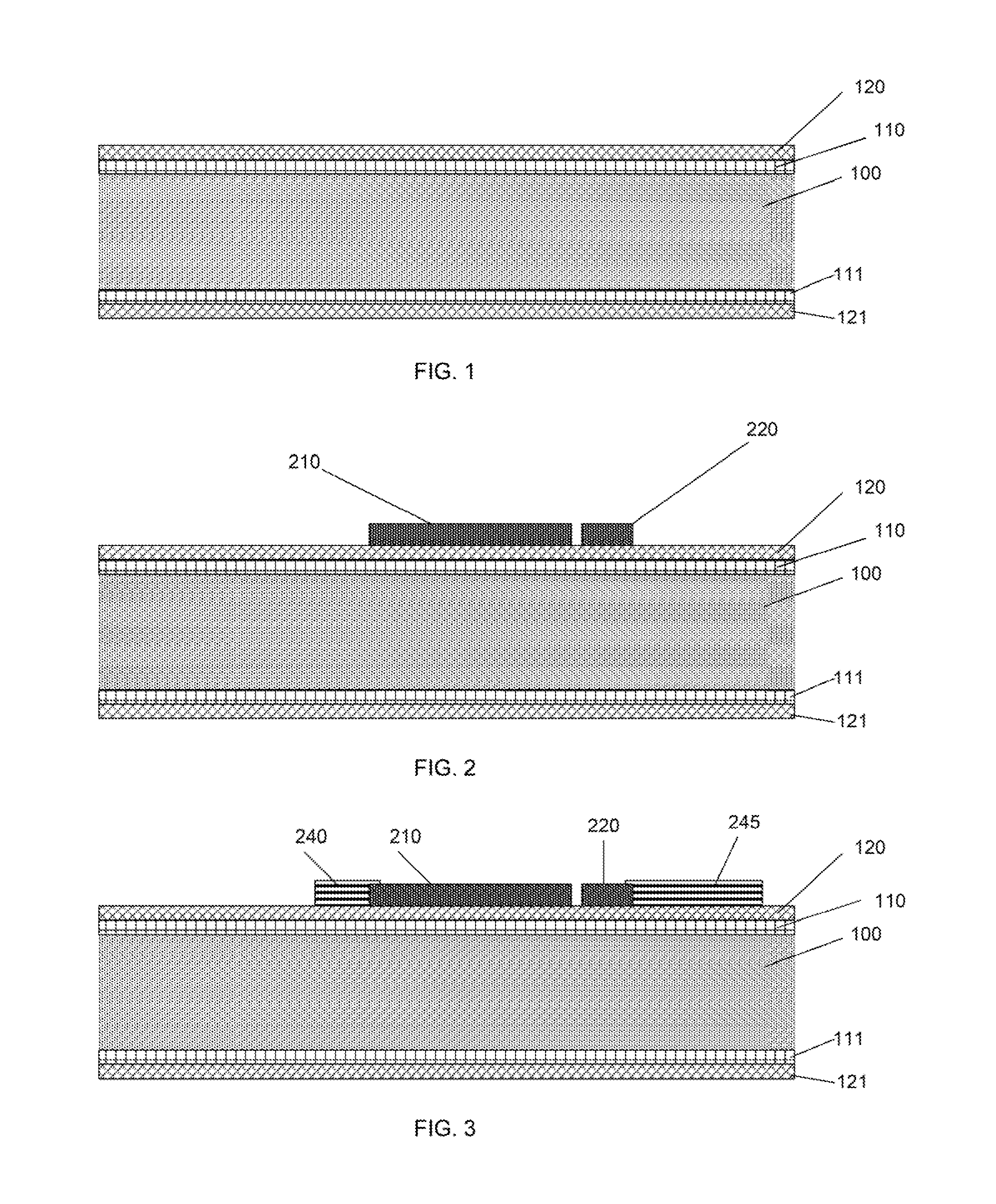

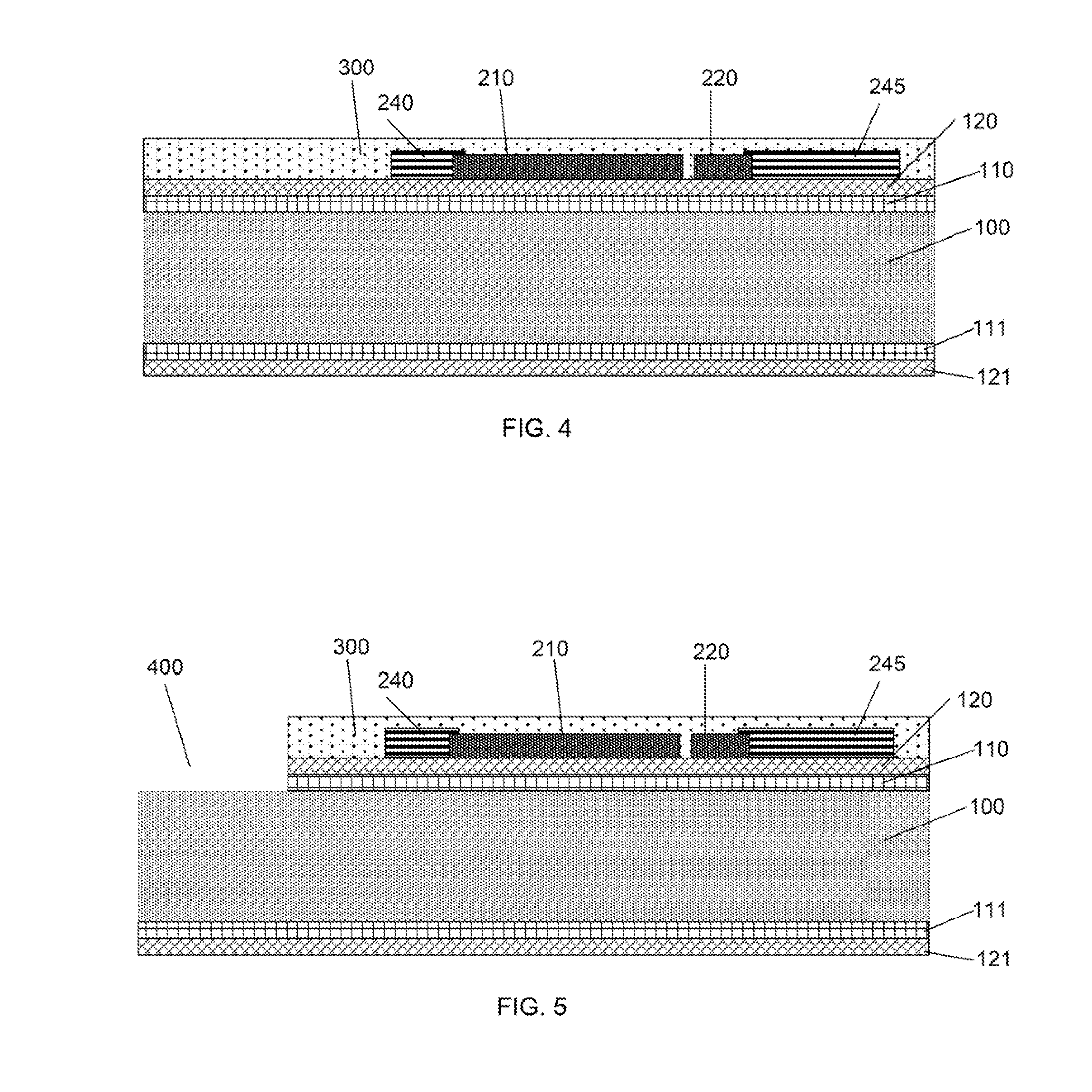

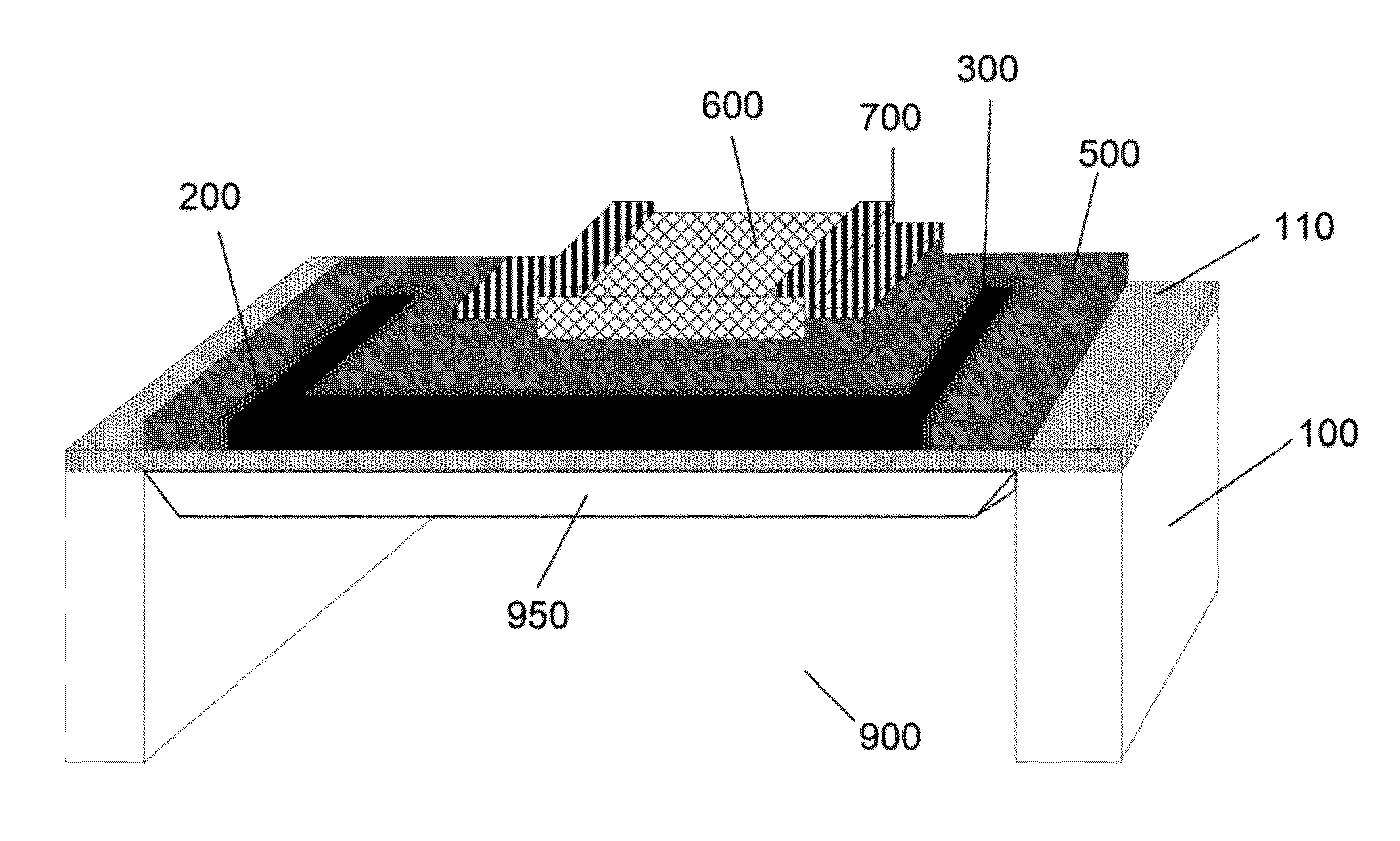

Process for manufacturing three-layer continuous surface type MEMS deformable mirror based on bonding process

InactiveCN101604069ASolve the disadvantages of difficult processingEliminates the effects of static pull-inOptical elementsBonding processOut of plane displacement

The invention discloses a process for manufacturing a three-layer continuous surface type MEMS deformable mirror based on a bonding process, which mainly comprises the following steps: performing dry-etching of a releasing hole on the upper surface of an SOI wafer, partially releasing a middle oxidation layer of the SOI wafer, performing wet-etching on the lower surface of the SOI wafer, depositing a metal on another substrate (silicon wafer or glass) as an electrode structure, and finally bonding the substrate and the SOI wafer. The process is characterized in that a bulk silicon micromachining process and a surface micromachining process are combined, and an upper two-layer structure obtained by adopting the bulk silicon process and a lower electrode structural layer obtained by adopting surface micromachining are bonded to form a three-layer micromechanical structure. The process for manufacturing the three-layer continuous surface type MEMS deformable mirror based on the bonding process has a relatively easy manufacturing process, overcomes the defect that the prior continuous surface micromechanical deformable mirror is difficult to process through three-layer surface micromachining, can eliminate the defect of short circuit due to electrostatic draw-in by adding a silicon nitride insulating layer, and can be widely applicable in the fields of optical communication and adaptive optics; and the machined deformable mirror can obtain large out-of-plane displacement.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Silicon substrate isotropic wet etching process

ActiveCN102931070AGood corrosion ratePhotomechanical apparatusSemiconductor/solid-state device manufacturingAcetic acidIce water

The invention provides a novel silicon substrate isotropic wet etching process. The process includes forming two sacrificial layers on the surfaces of silicon substrates by adding negative 450-CP photo-resists, forming graphs needed to be machined through a surface micromachining photolithography technique, and using isotropic etching to obtain two-dimensional machined graphs with small depth-to-width ratios. According to the silicon substrate isotropic wet etching process, a certain quantity of acetic acids and water are added in a corrosion system selecting reasonable proportioning to serve as buffer agents to stabilize corrosion rates, and a corrosion solution is placed in an ice water mixture to control the reaction temperature to obtain a silicon corrosion system with an optimum corrosion rate, depth-to-width ratio and surface quality.

Owner:TIANSHUI TIANGUANG SEMICON

Method for constructing metal-based surface with alternate hydrophilic and hydrophobic strips

ActiveCN108889575AControllable microscopic morphologyThickness is easy to controlPretreated surfacesCoatingsNanoparticleMetal

The invention discloses a method for constructing a metal-based surface with alternate hydrophilic and hydrophobic strips in the technical field of non-silicon micromachining and micronano functionalmaterial preparation. The method comprises the steps that a metal wire is tightly wound on a substrate, the wire and the substrate are integrally sintered under the pressure of weight, after the obtained sintered body is immersed in a hydrophobic nanoparticle turbid liquid, hydrophobic nanoparticles are deposited on the area, not covered by the metal wire, of the substrate, and the superhydrophobic strips are formed after high-temperature film hardening; the metal wire is peeled off from the substrate, and the exposed area forms the hydrophilic strips. The spacing and width of the strips of the constructed metal-based surface with the alternate hydrophilic and hydrophobic strips can be adjusted by adjusting the diameter of the metal wire and the pressure of the weight respectively; the method is simple and easy in operation, and has broad application prospects.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Micromachined mass flow sensor with condensation prevention and method of making the same

ActiveUS9360357B2Accurate measurementSave energyVolume/mass flow measurementElectrical resistance and conductanceEngineering

The design and manufacture method of a silicon mass flow sensor made with silicon micromachining (a.k.a. MEMS, Micro Electro Mechanical Systems) process for applications of gas flow measurement with highly humidified or liquid vapors is disclosed in the present invention. The said silicon mass flow sensor operates with an embedded heater and an adjacent control temperature sensor beneath the integrated calorimetric and thermal dissipative sensing thermistors. When the condensation takes place at the surface of the said silicon mass flow sensor, the embedded heater shall be turned on to elevate the temperature of the supporting membrane or substrate for the sensing thermistors. The elevated temperature shall be adjusted to above the vaporization temperature with the feedback data of the adjacent temperature sensor such that the surface condensation due to the presence of the liquid vapors in a gas flow can be effectively eliminated.

Owner:WISENSTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com