Process for manufacturing three-layer continuous surface type MEMS deformable mirror based on bonding process

A bonding process and manufacturing process technology, applied in the field of manufacturing process of three-layer continuous surface MEMS deformable mirror, to achieve the effect of eliminating electrostatic pull-in, wide application and large off-plane displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

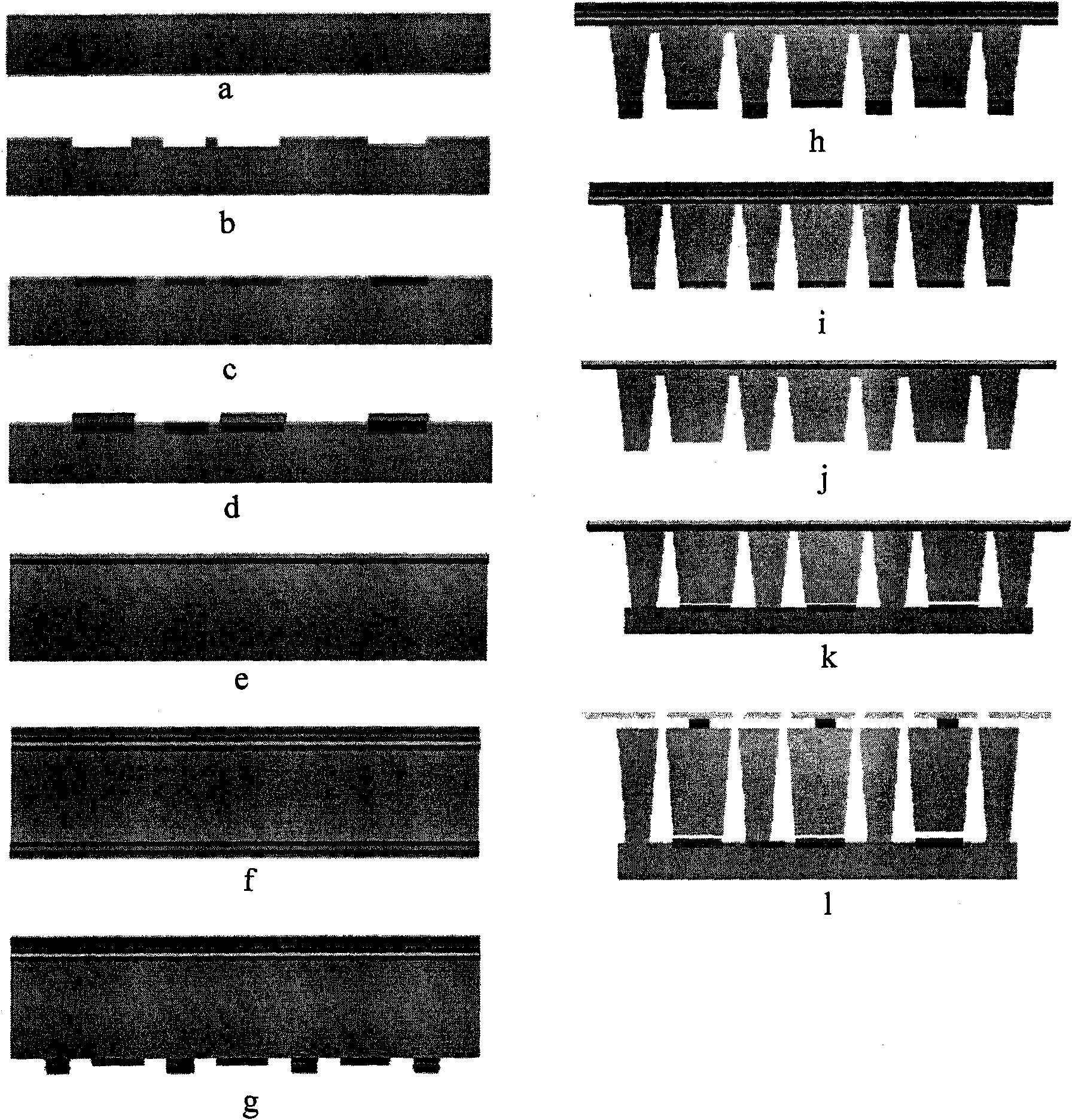

[0034] Taking the manufacturing process of a three-layer continuous surface-shaped micromechanical deformable mirror with 3 × 3 units as an example, the present invention will be described in detail in conjunction with the accompanying drawings. The specific steps are as follows: figure 1 shown.

[0035] 1. Take a piece of 5-inch Pyrex7740 glass with a thickness of 500 microns as the first substrate 1, such as figure 2 shown.

[0036] 2. Use the first mask photolithography and wet etching with buffered hydrofluoric acid to form a 0.5 micron deep groove to prepare for the deposition of the lower electrode, such as image 3 shown.

[0037] 3. Evaporate gold with a thickness of 0.5 microns on the upper surface of the glass substrate, then photolithography and dry etching, the etching depth is 0.5 microns, and form the lower electrode 3 and lead 2 of the deformable mirror, such as Figure 4 shown.

[0038] 4. Deposit a silicon nitride film 4 with a thickness of 0.5 microns by...

Embodiment 2

[0046] Taking the manufacturing process of the three-layer continuous surface-shaped micromechanical deformable mirror with 7×7 units as an example, the present invention will be described in detail in conjunction with the accompanying drawings. The specific steps are as follows: figure 1 shown.

[0047] 1. Take a 5-inch Corning 7070 glass with a thickness of 1000 microns as the first substrate 1, such as figure 2 shown.

[0048] 2. Use the first mask to lithography and wet-etch a 2 micron deep groove with buffered hydrofluoric acid to prepare for laying the lower electrode, such as image 3 shown.

[0049] 3. Evaporate gold with a thickness of 2.0 microns on the upper surface of the substrate, then photolithography and dry etching, the etching depth is 2 microns, and form the lower electrode 3 and lead 2 of the deformable mirror, such as Figure 4 shown.

[0050] 4. Deposit a silicon nitride film 4 with a thickness of 1 micron by LPCVD, then photolithography and dry etch...

Embodiment 3

[0058] Taking the manufacturing process of a 10×10 unit three-layer continuous surface-shaped micromechanical deformable mirror as an example, the present invention will be described in detail in conjunction with the accompanying drawings. The specific steps are as follows: figure 1 shown.

[0059] 1. Take a 4-inch N-type (100) double-sided polished Max silicon wafer with a thickness of 300 microns as the first substrate 1, with a resistivity of 10 5 ~2×10 5 Ω·cm, such as figure 2 shown.

[0060] 2. Use the first mask plate photolithography and wet-etch a 0.1 micron deep groove with 50% potassium hydroxide solution to prepare for laying the lower electrode, such as image 3 shown.

[0061] 3. Deposit polycrystalline silicon with a thickness of 0.1 micron by LPCVD, then photolithography and dry etching, the etching depth is 0.1 micron, to form the lower electrode 3 and lead 2 of the deformable mirror, as Figure 4 shown.

[0062] 4. Deposit a silicon nitride film 4 with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com