Preparation method of molybdenum alloy

A technology of molybdenum alloy and molybdenum powder, which is applied in the field of molybdenum alloy material preparation, can solve problems such as the reduction of the purity of aluminum alloys, achieve the effects of increasing purity, improving plasticity, and solving low-temperature brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

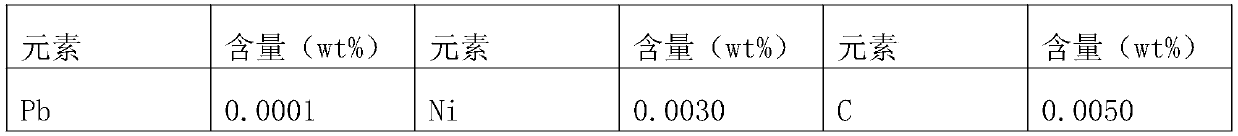

[0021] This case proposes a method for preparing a molybdenum alloy, which includes the following steps: uniformly mix molybdenum powder and strontium powder, press and form after isostatic pressing, and obtain a pressed green body; as an inventive point of the present invention, the pressed green body is then The body is put into a hot isostatic pressing device for sintering, and then cooled to obtain a molybdenum alloy; the mass ratio of the molybdenum powder and strontium powder is 1: (0.005-0.01), and the steps of the isostatic pressing molding process are as follows: Compact the dry mixture with a pressure of 800MPa ~ 1800MPa and hold the pressure for 15min ~ 30min to obtain a compacted block, and then put the compacted body into the mold of the hot isostatic pressing equipment for sintering. The sintering process is: holding, etc. The static pressure is 800MPa~1800MPa, and the temperature is continuously raised to 1500℃~2000℃ at a heating rate of 6.5℃ / min~8.5℃ / min, and th...

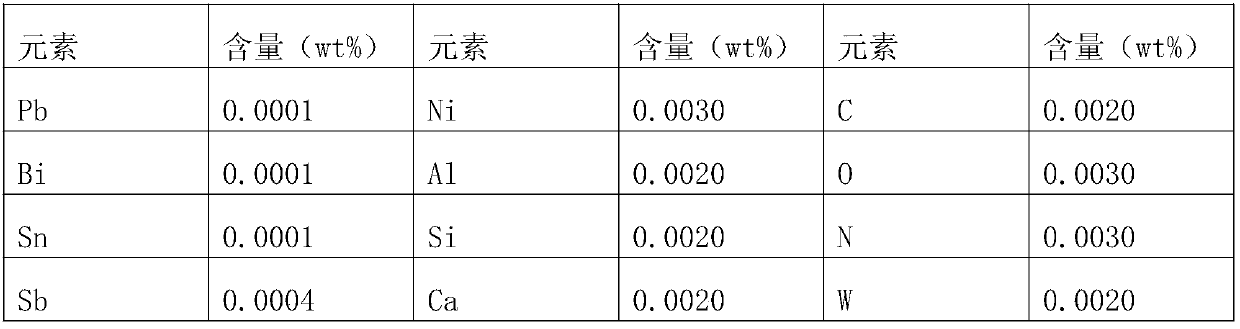

Embodiment 1

[0032] A method for preparing a molybdenum alloy comprises uniformly mixing molybdenum powder and strontium powder, and the particle size of the molybdenum powder and strontium powder is not greater than 300 mesh. Press molding after isostatic pressing to obtain a pressed green body; then put the pressed green body into a hot isostatic pressing device for sintering, and then cool to obtain a molybdenum alloy; the mass ratio of the molybdenum powder and strontium powder is 1 : 0.005, the step of the isostatic pressing molding process is to use 800MPa pressure to compact the dry mixture and hold the pressure for 15min to obtain a compacted block, and then put the pressed green body into the mold of the hot isostatic pressing equipment Sintering. The sintering process is as follows: keep the isostatic pressure at 800 MPa, continue to raise the temperature to 1500° C. at a heating rate of 6.5° C. / min, and keep the temperature for 3 hours to obtain a molybdenum alloy.

[0033] Spec...

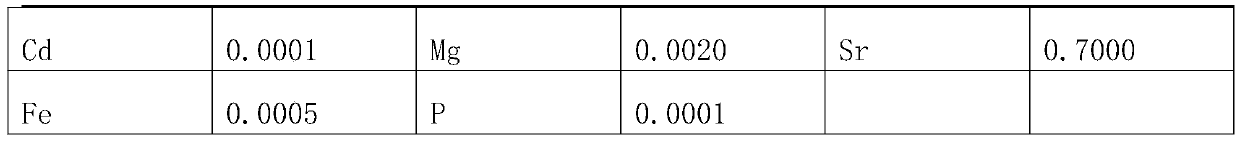

Embodiment 2

[0038] A method for preparing a molybdenum alloy comprises uniformly mixing molybdenum powder and strontium powder, and the particle size of the molybdenum powder and strontium powder is not greater than 300 mesh. Press molding after isostatic pressing to obtain a pressed green body; then put the pressed green body into a hot isostatic pressing device for sintering, and then cool to obtain a molybdenum alloy; the mass ratio of the molybdenum powder and strontium powder is 1 : 0.01, the step of the isostatic pressing molding process is to use 1800MPa pressure to compact the dry mixture and hold the pressure for 30min to obtain a compacted block, and then put the pressed green body into the mold of the hot isostatic pressing equipment Sintering, the sintering process is as follows: keep the isostatic pressure at 1800MPa, continue to raise the temperature to 2000°C at a heating rate of 8.5°C / min, and keep the temperature for 3h-4h to obtain a molybdenum alloy.

[0039] Specifical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com