Microfluid centrifugal chip and its processing method

A microfluidic and chip technology, which is applied in the direction of centrifuges, separation of sediments by centrifugal force, instruments, etc., can solve the problems of no centrifugal application value and sample processing, etc., and achieve the advantages of easy on-chip integration, low cost, and good centrifugal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1. Processing of microfluidic centrifugal chip:

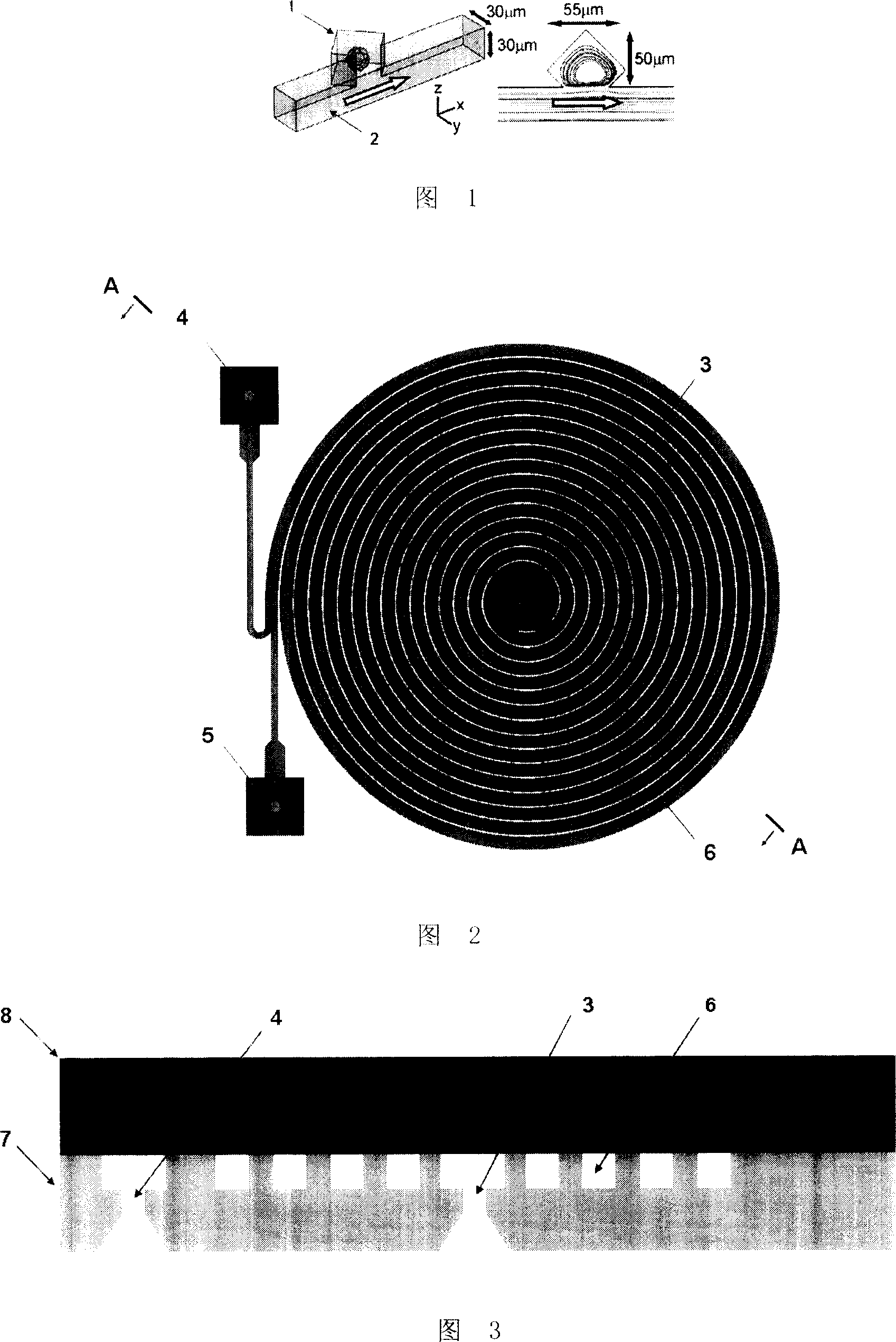

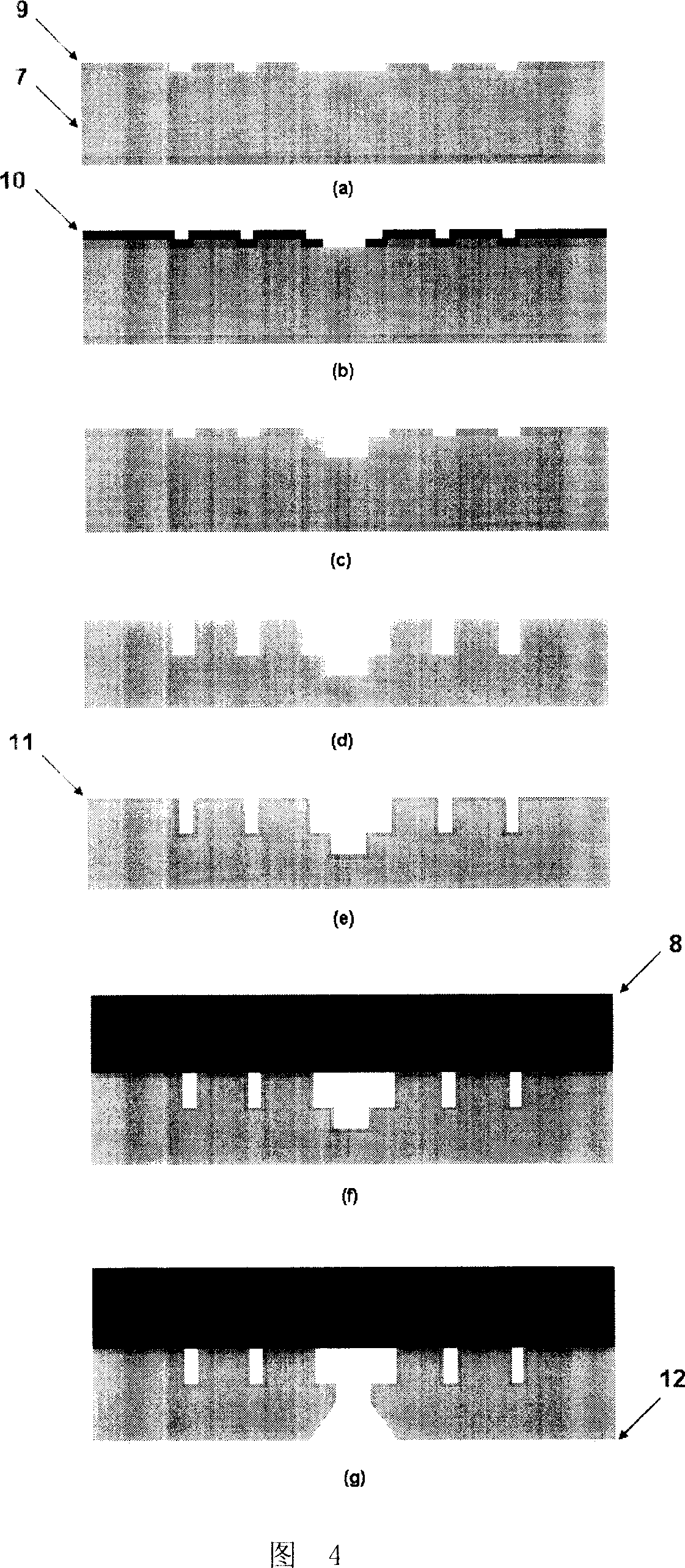

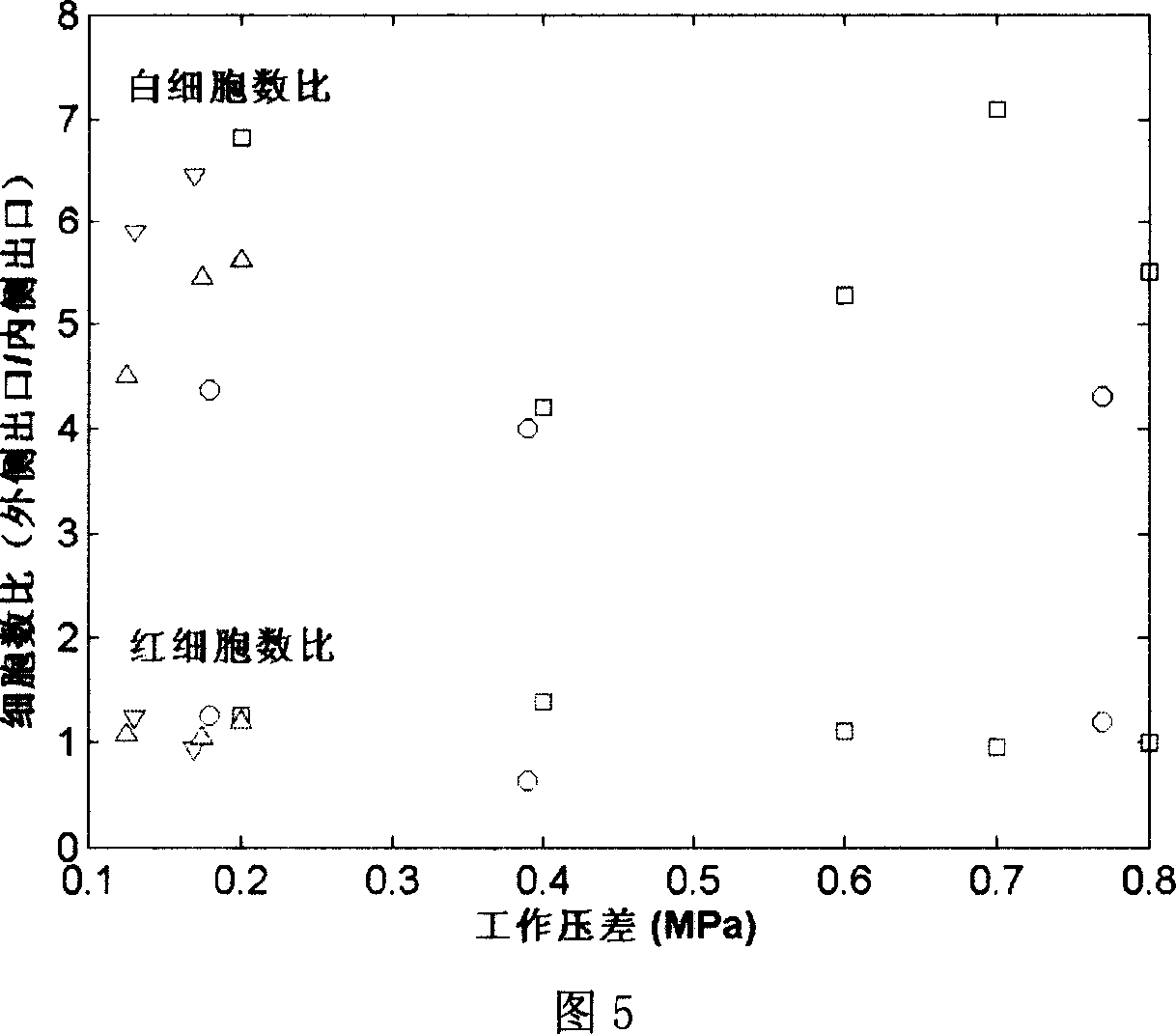

[0032] The structure of the microfluidic centrifugal chip of the present invention is shown in Figs. 2 and 3, wherein Fig. 3 is a cross-sectional view of A-A in Fig. 2. The chip mainly includes a spiral microchannel 6 (in which the sample to be centrifuged moves) etched on the silicon wafer 7 and closed by a glass cover 8; an inlet 3 in the center of the spiral channel is used for sample injection; The chip contains two outlets, an outer outlet 4 and an inner outlet 5, which are used to extract samples after centrifugation. The thickness of the silicon wafer 7 is 400 μm; the thickness of the cover glass 8 is 500 μm; the width of the spiral micro channel 6 is 120 μm, and the depth is 60 μm. 23μm, the angle of the helix changes from 4π to 37π; the inlet 3, the outer outlet 4 and the inner outlet 5 are all through holes with a flared cross section, the port width is 568μm, and the diameter of the through hole is 100μm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com