Patents

Literature

103results about How to "Lower battery internal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

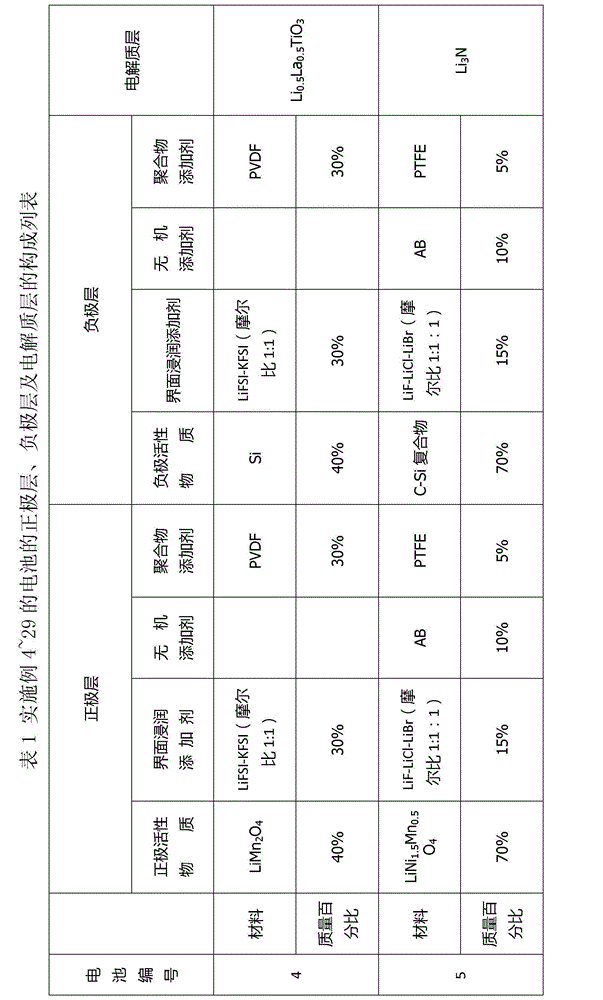

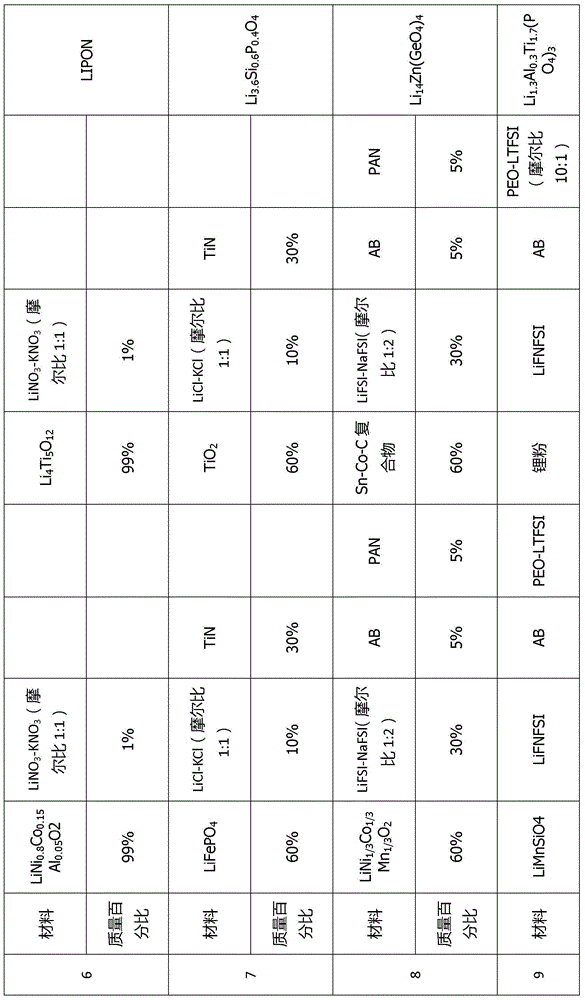

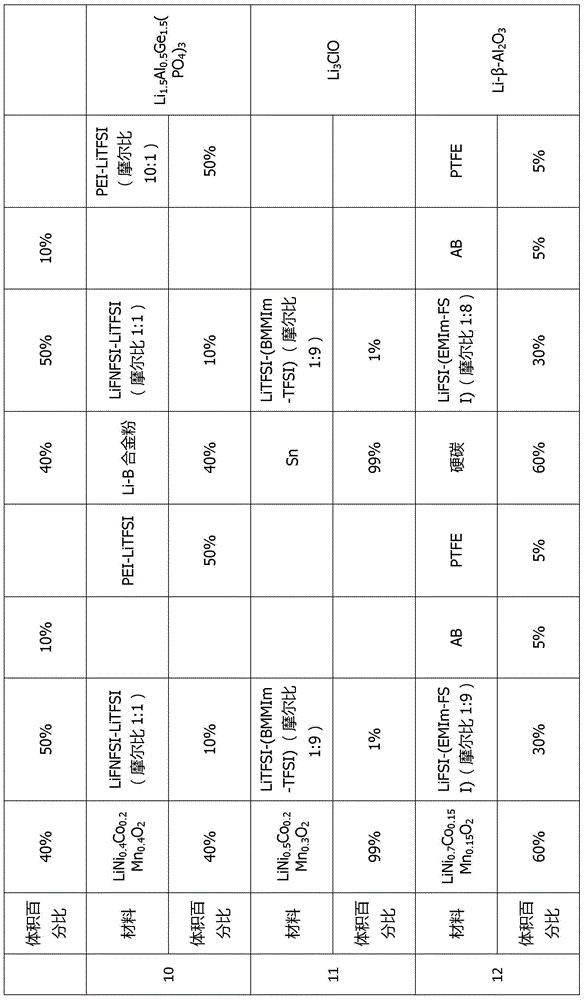

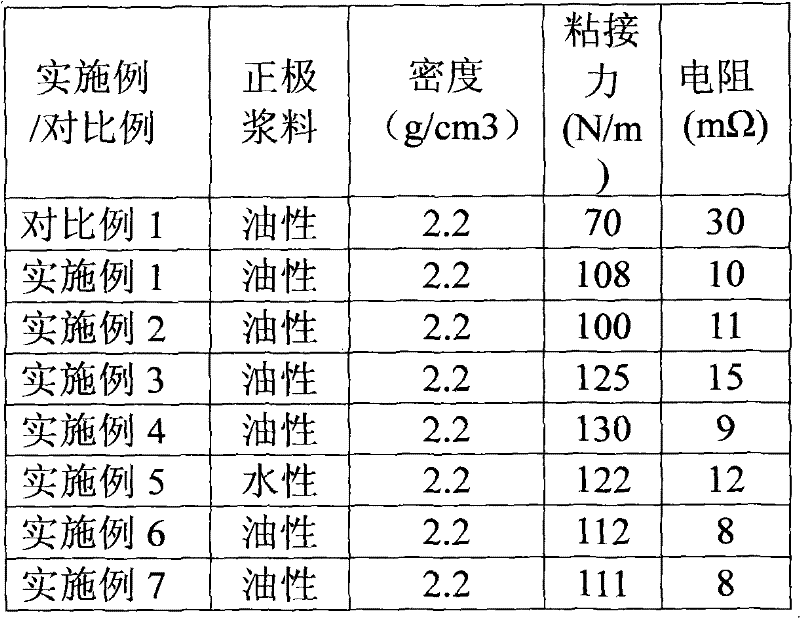

An interface infiltrated quasi-solid alkali metal cell, electrodes of the cell and a preparing method of the cell

ActiveCN105374980AImprove security featuresIncrease the output voltageNon-aqueous electrolyte accumulator electrodesLi-accumulatorsElectrolysisWorking temperature

An interface infiltrated quasi-solid alkali metal cell is provided by the invention and comprises a cathode layer, an anode layer and an electrolyte layer. The electrolyte layer is a solid electrolyte. The cathode layer and / or the anode layer comprise electrode active compounds and an interface infiltrating additive. The interface infiltrating additive is of a liquid state in a work temperature range, can conduct ions and can infiltrate the electrode active compounds and the solid electrolyte. Electrodes of the cell and a preparing method of the cell are also provided by the invention. The cell is high in safety characteristics and wide in voltage window and can work in a wide temperature range.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

Water-based conductive ink of a lithium-ion battery

ActiveCN102329538ASimple interfaceIncrease contact areaElectrode carriers/collectorsInksWater basedSolubility

The invention relates to the technical field of a lithium-ion battery, in particular to water-based conductive ink of the lithium-ion battery. Dry materials mainly comprise (by weight percentage): 0.2-2 percent of water-soluble polymer thickener, 5-25 percent of water-based dispersant, 30-70 percent of conductive carbon black and 20-50 percent of non-polar high polymer water-based latex with the solubility parameter delta less than or equal to 18(J / cm3)1 / 2. The solvent adopts water and accounts for 60-90 percent of the total weight of the pulp. The adhesive properties of the adhesive can be enhanced, the adhesive also has the characteristics of water resistance, NMP (nuclear matrix protein) resistance and electrolyte resistance, a conductive network is formed on a current collector under the effect of the adhesive after adding the conductive carbon black, the contact area between the current collector and a film is increased, and the effect of reducing the contact resistance can be achieved. The current collector after printing of the water-based conductive ink is not only suitable for pulp coating of water-based systems, but also suitable for pulp coating of NMP systems. Moreover, the lithium-ion battery has lower internal resistance and longer cycle life.

Owner:DONGGUAN AMPEREX TECH +1

Method for solving gas expansion failure of lithium titanate battery

ActiveCN105449301ALower excitation resistanceLower battery internal resistanceSecondary cells charging/dischargingElectrical batteryEngineering

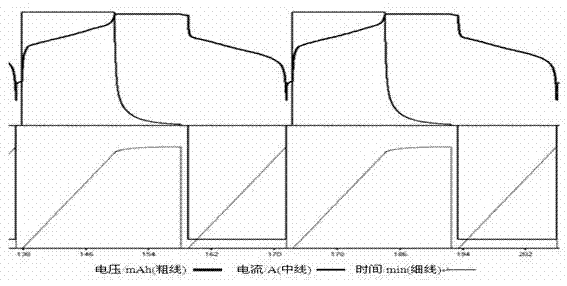

The invention provides a method for solving gas expansion failure of a lithium titanate battery. The method comprises a formation process and an aging process; the formation process comprises the following steps: firstly, charging for 2 to 20 hours in a constant-current mode by current of 0.01C to 0.1C, charging for 1 to 7 hours in a constant-current mode by current of 0.1C to 0.2C and charging for 0.5 to 1 hour in a constant-current mode by current of 0.2C to 0.5C; secondly, discharging for 3 hours in a constant-current mode by current of 0.5C to 1C, then charging for 3 hours and discharging for 3 hours in a constant-current and constant-voltage mode by current of 0.5C, and repeating the steps of charging for 3 hours and discharging for 3 hours in a constant-current and constant-voltage mode by current of 0.5Cfor 3 to 6 times; and finally, charging for 2 hours and discharging for 2 hours in a constant-current and constant-voltage mode by current of 1C, and repeating final two steps for 3 to 6 times. With such a design, batteries are prevented from expanding, the discharge power of the batteries is increased and a quick charge capacity and good service are realized. The production probability of defective products is low and the process cycle is short.

Owner:DONGFENG COMML VEHICLE CO LTD

Vanadium phosphate sodium composite nano porous cathode material and method for preparing material by using freeze drying method

InactiveCN106025275ALarge specific surface areaHigh specific capacityMaterial nanotechnologyCell electrodesElectrochemical responseFreeze-drying

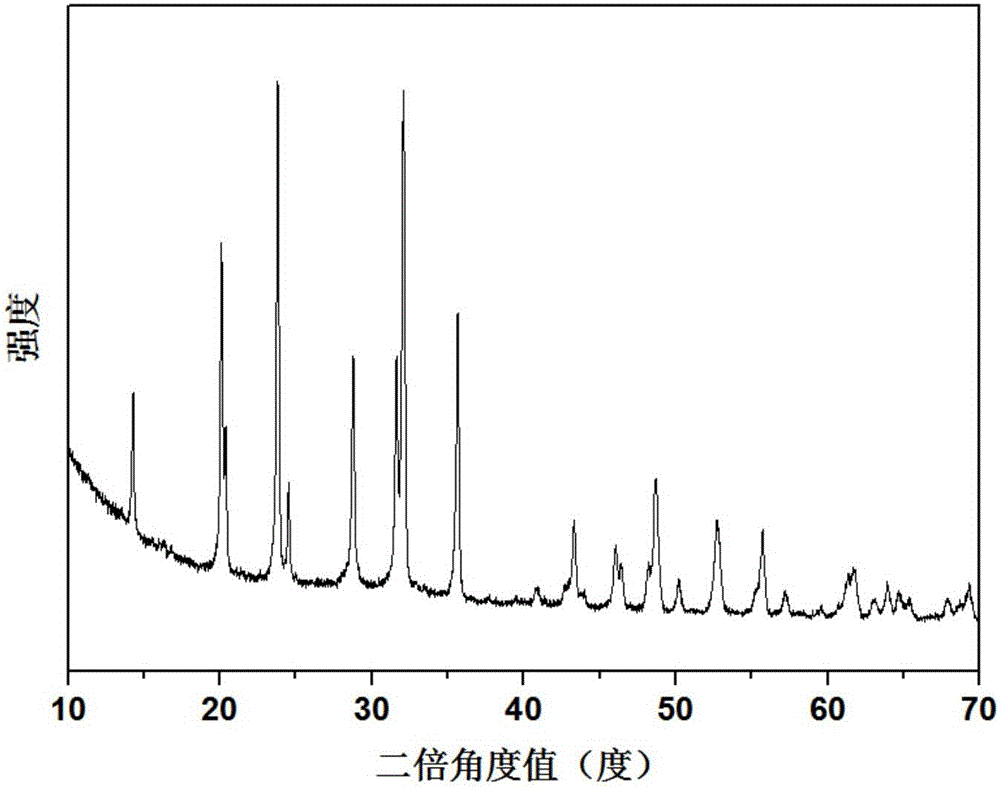

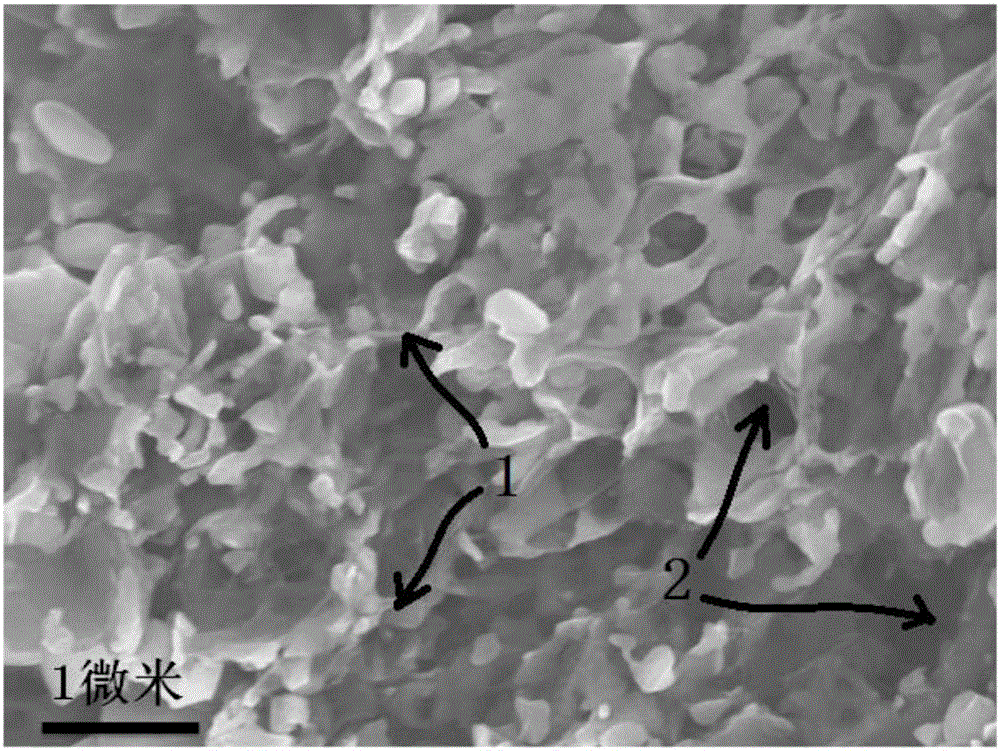

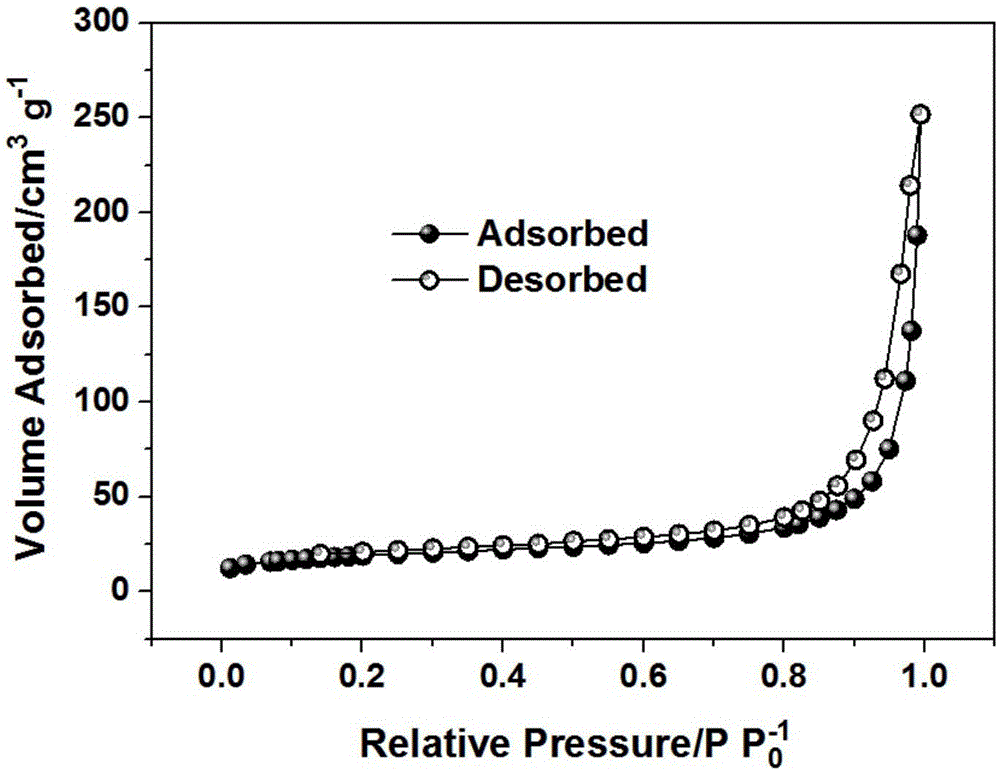

The invention discloses a vanadium phosphate sodium composite nano porous cathode material and a method for preparing the material by using a freeze drying method, which belong to the technical fields of a cell material and its preparation method. The method comprises the following steps: adding a certain amount of a vanadium source in a mixed solvent of deionized water and hydrogen peroxide, after stirring the materials and dissolving the materials, adding a sodium source, a phosphorus source and a carbon source with a stoichiometric ratio to form a mixing solution; then refrigerating the prepared mixing solution in liquid nitrogen to a solid, then performing vacuum drying on the material in a vacuum freeze drier; and finally putting a precursor obtained after freeze drying in mixing gas of argon and hydrogen for calcining to obtain the vanadium phosphate sodium composite nano porous cathode material. The prepared vanadium phosphate sodium composite nano porous cathode material has a three-dimensional porous structure and large specific surface area, and thereby is in favor of infiltration and transmission of an electrolyte, active sites of an electrochemical reaction are multiple, and high specific capacity and good multiplying power performance can be displayed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Cylinder type lithium ion battery with high power rate and high safety performance

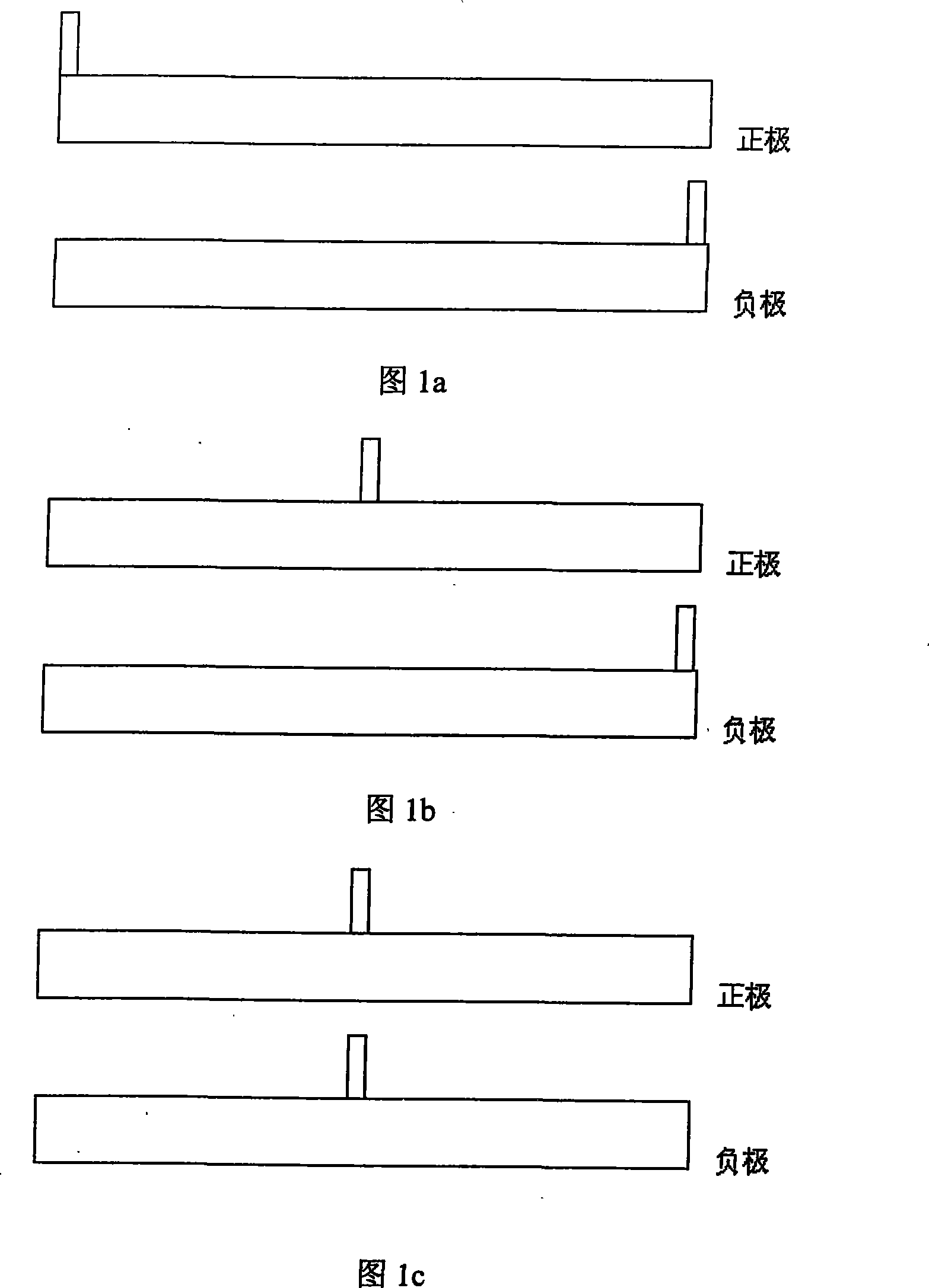

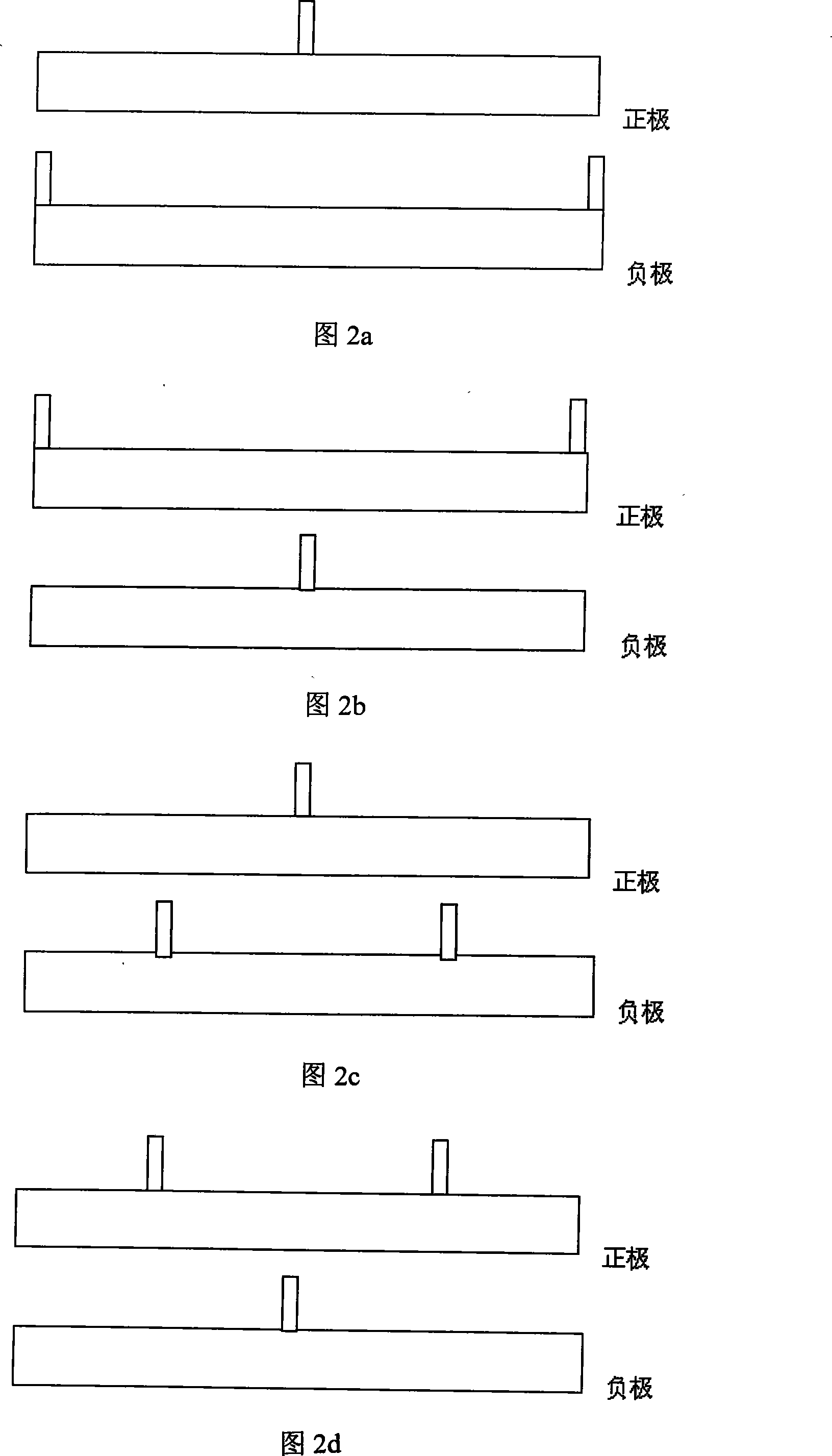

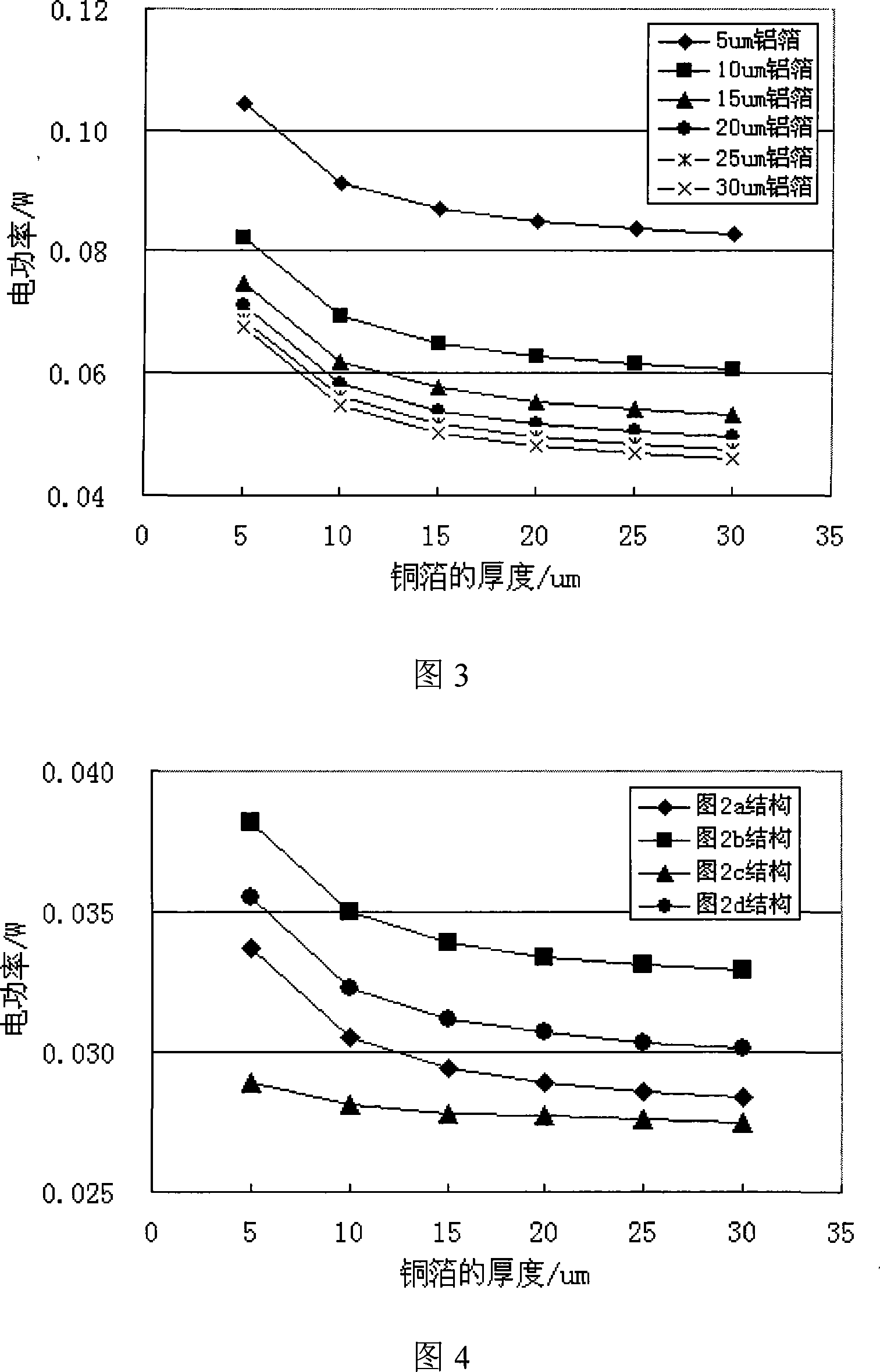

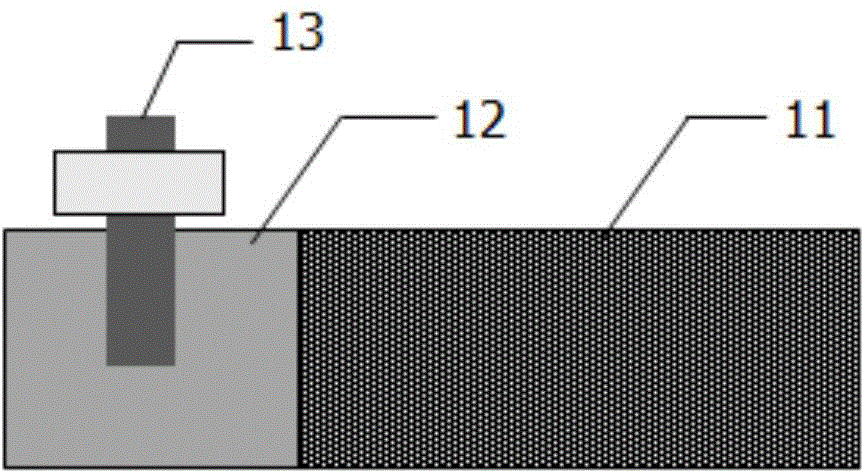

InactiveCN101227015ALower battery internal resistanceImproved rate performance and safety performanceElectrode carriers/collectorsSecondary cellsPolyvinylidene fluorideClutch

The invention relates to a circular lithium ion battery with high multiplying power and high safety, which is characterized in adopting LiMn2O4 or LiFePO4 as active materials of positive plate, adopting aqueous polyethylene oxide and oily polyvinylidene fluoride as agglomerant of the positive plate, wherein current collector of the positive plate is aluminum foil whose the thickness is 10-30 mum, adopting aluminum ear whose the thickness is 0.07-0.2mm as a positive ear, adopting the positive ear as the positive plate which is located in center corresponding the current collector, adopting graphitic carbon material as active material of a cathode plate, adopting aqueousbutadiene styrene rubber and oily polyvinylidene fluoride as the agglomerant, current collector of the cathode is clutch gold whose the thickness is 10-30 mum, adopting copper or nickel cathode ear whose the thickness is 0.07-0.20mm as cathode ear, two electrode ears of the cathode are respectively positioned on quarter and three quarter position of the cathode plate. Compared with the traditional positive and cathode plate which adopts structure design of monopole ear, the invention is capable of dramatically reducing internal resistance, improving multiplying power property and safety property of the battery, and having simple structure, rational design and reliable performance.

Owner:TIANJIN LISHEN BATTERY

Preparation method of lithium ion battery pole piece

ActiveCN106159206AIncrease volumetric energy densityLower battery internal resistanceElectrode thermal treatmentElectrode collector coatingInternal resistanceElectrical battery

The invention provides a preparation method of a lithium ion battery pole piece. The preparation method comprises the following steps: 1) providing a current collector, and sticking a thermal expansion foaming pressure sensitive adhesive tape or coating a thermal expansion forming adhesive at the preset position of a plug on the current collector, and forming a peelable adhesive sheet; 2) coating an active substance sizing agent on the current collector, and forming an active substance diaphragm layer; 3) drying the active substance diaphragm layer under the foaming expansion temperature of the adhesive sheet, carrying out thermal expansion foaming on the adhesive sheet in a drying process so as to be separated from the current collector, and forming an active substance hollow-out area in which the diaphragm layer is not covered with active substances on the current collector; and 4) fixing the lug on the current collector that the active substance hollow-out area is exposed out to obtain the required pole piece. Compared with the prior art, the pole piece prepared by the preparation method makes full use of the area of the current collector, and the increase of battery thickness is reduced, so that a lithium ion battery prepared by using the pole piece has relatively high volume energy density and relatively low battery internal resistance.

Owner:NINGDE AMPEREX TECH +1

Method for making electric core of lithium ion battery

InactiveCN101267050AGood discharge performanceLower battery internal resistanceFinal product manufactureElectrolyte accumulators manufactureAirplaneWrinkle

The present invention is an improvement of the preparing method of a lithium ion battery electrical core, characterized in that a diaphragm and / or electrode plate binding face has adhesive which is capable of resisting electrolyte, redox reaction and solid content is 2-30%, voltage attaching after mutually stacking, and the diaphragm voidage is above 30%. A gap does not exist between the diaphragm and the electrode pate, the battery has large rate discharge ability, especially for a battery product of a power battery, an electrical tool battery, a model airplane battery which has requirement to large rate discharge; the battery has a small internal resistance, small self-consumption power. The diaphragm is patched with the electrode plate at the same time, not only reducing the alignment degree adjustment of the diaphragm and the electrode plate under the winding or overlapping course, greatly enhancing the battery preparing production efficiency; the diaphragm and the electrode plate not easy wrinkle, benefit to improve the battery life service, the capability is more stable and credible.

Owner:JIANGSU DIO ENERGY SCI TECH

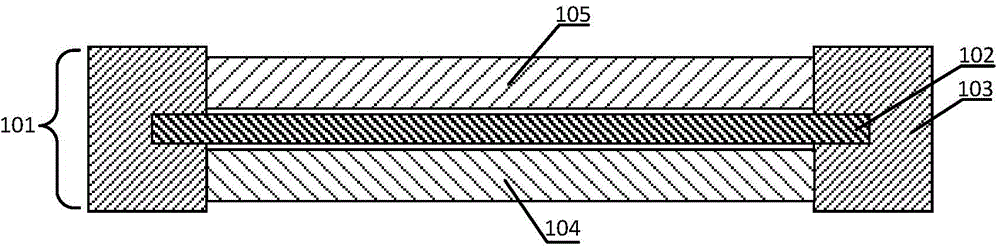

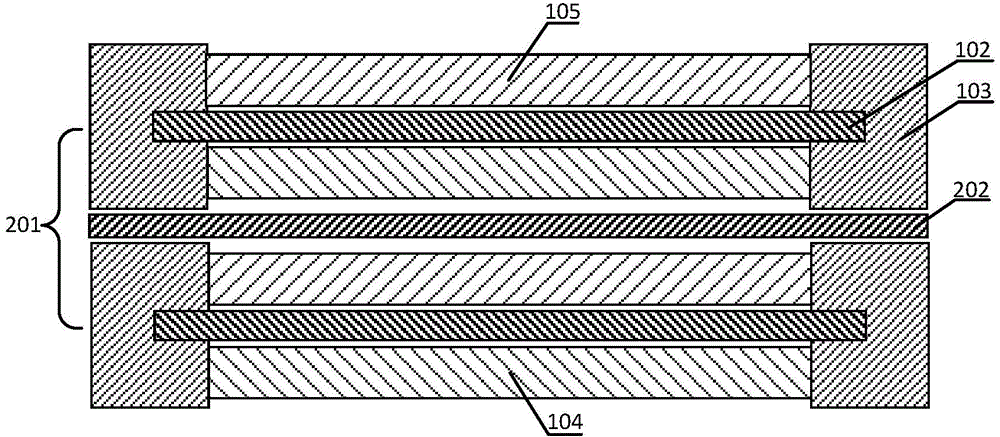

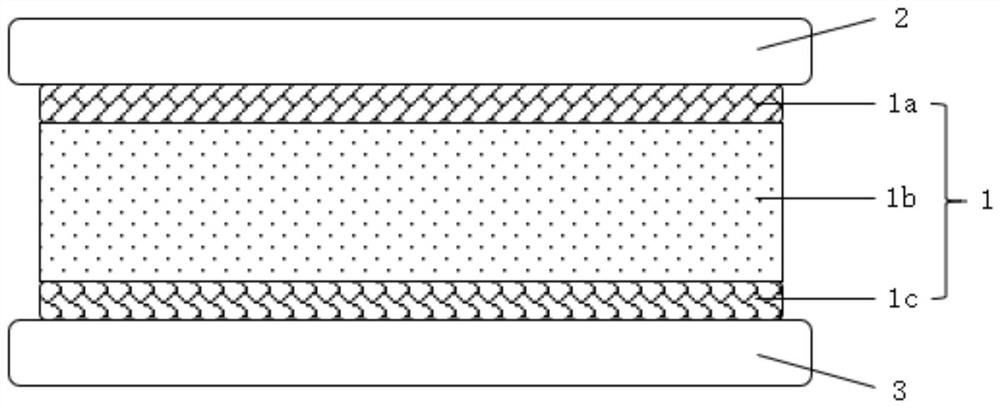

High-voltage power battery

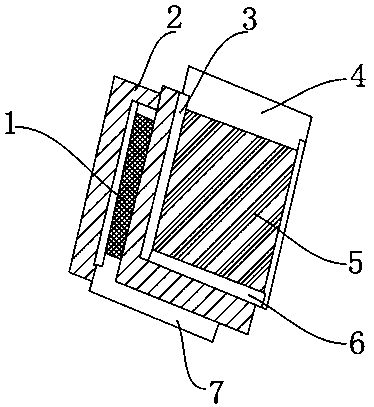

ActiveCN104577184AClose contactLower battery internal resistanceFinal product manufactureCell component detailsElectrical batteryCurrent collector

The invention provides a high-voltage power battery. The high-voltage power battery comprises a cell, elastic spacers, a battery concave seat, a battery cover, an insulation shell and a flexible current collector wire. The cell is formed by superimposing two or more than two battery units, an annular seal ring on the side edge of the cell and the elastic spacers on the upper surface and lower surface of the cell are elastically extruded mutually under the effect of an extrusion force produced by a flanging area of a battery shell, so that the insulation sealing performance of the cell and the tight connection among battery units inside the cell can be guaranteed, the inner resistance of the battery is reduced, the power battery is ensured to have relatively high impact resistance in the application process, and the interior of the cell can be prevented from being damaged due to the severe extrusion. The appearance of the high-voltage power battery is in a cake shape, the diameter of the battery is 8cm to 150cm, the height of the battery is 0.5cm to 16cm, and the ratio of the battery diameter to the batter height is more than 1 and preferably 5 to 20. By adopting the structure, the high voltage and high magnification output characteristic of the power battery can be realized, and the battery is integrally simple in structure, good in safety and high in reliability.

Owner:BEIJING HAWAGA POWER STORAGE TECH

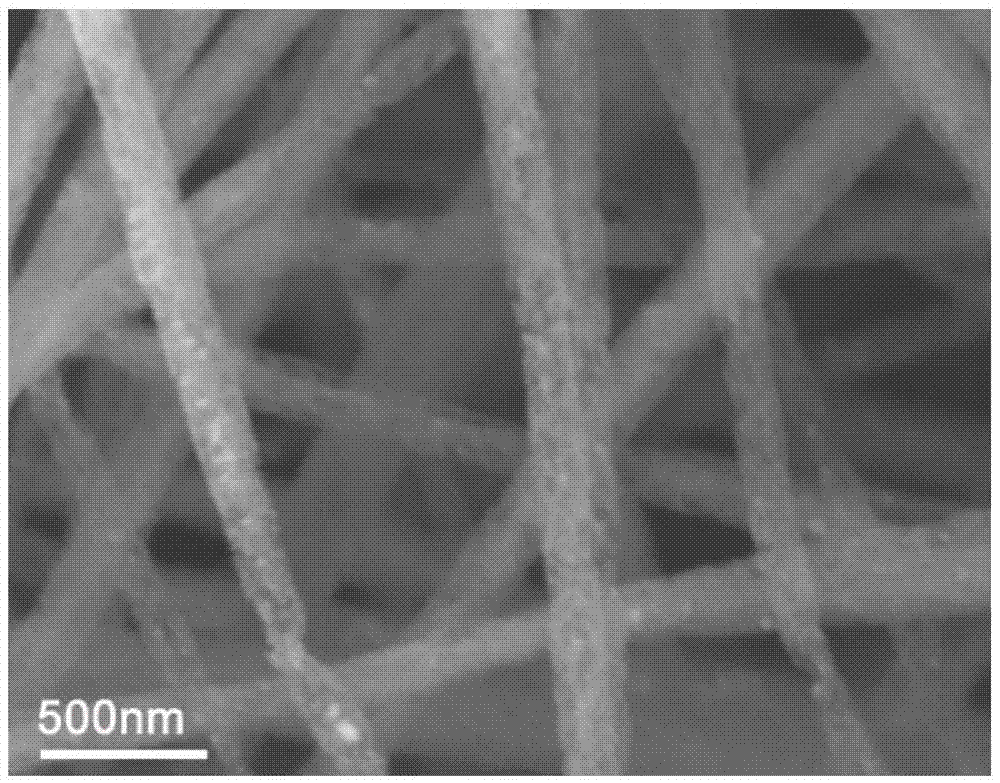

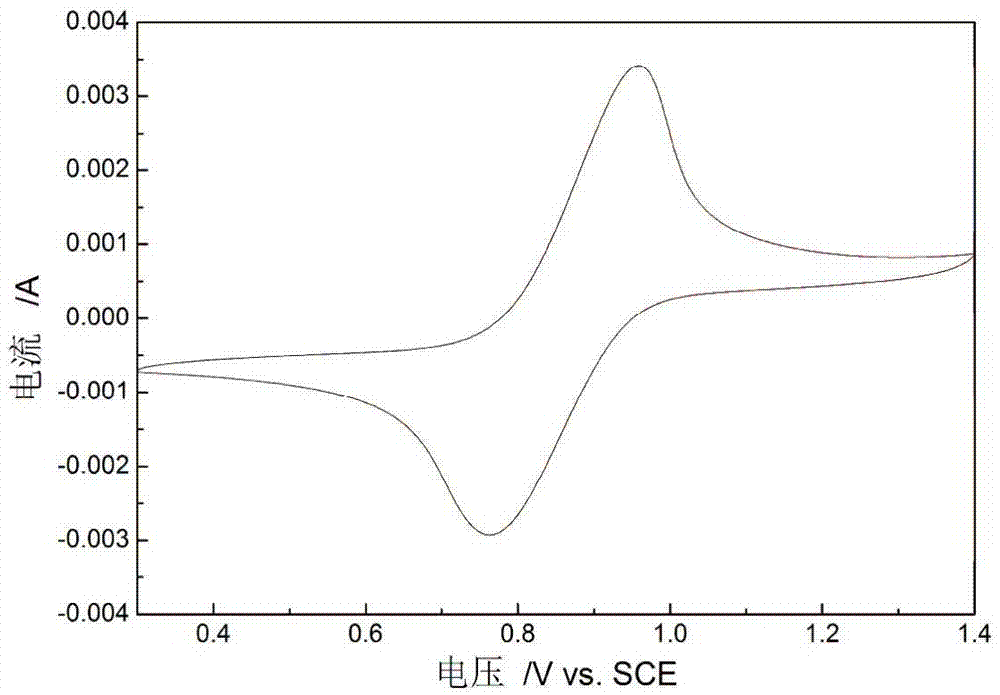

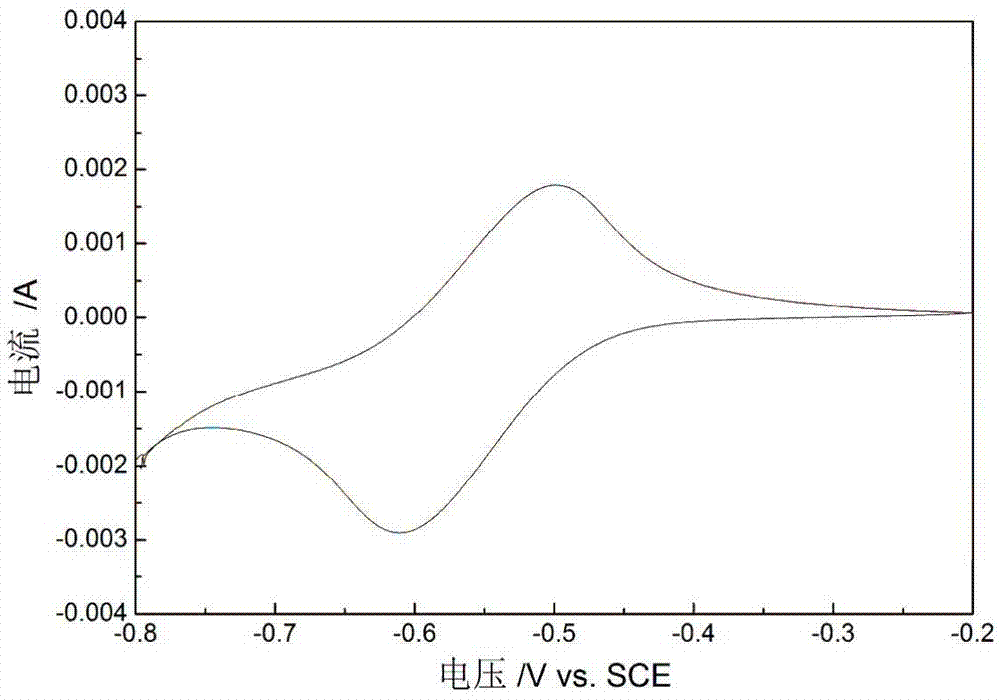

Porous carbon nanofiber electrode used for all-vanadium redox flow battery, and preparation method and application of porous carbon nanofiber electrode

InactiveCN106876721ALower battery internal resistanceLower resistanceCell electrodesRegenerative fuel cellsFiberPorous carbon

The invention discloses a porous carbon nanofiber electrode used for a redox flow battery, and a preparation method of the porous carbon nanofiber electrode. The electrode is 20-500[mu]m in thickness and formed by porous carbon nanofibers with diameter of 50-500nm; the porous carbon nanofiber electrode is prepared by the steps of taking a high-molecular polymer as a precursor, preparing into nanofibers through electrostatic spinning, and then performing high temperature carbonization and next, carrying out high-temperature activation through CO<2> or vapor. The prepared porous carbon nanofiber electrode, with obviously enlarged specific surface area and improved oxygen-containing functional group, has high electrocatalytic activity and electrochemical reversibility when the porous carbon nanofiber electrode is used for the redox flow battery; the redox flow battery has the advantages of simple preparation method, easily available raw material, low cost and the like; the electrode material is applicable to the redox flow battery; due to the ultra-thin electrode thickness, space between electrodes of the battery can be reduced, and internal resistance of the battery can be lowered; and in addition, charge transfer resistance can be lowered, the voltage efficiency and energy efficiency of the all-vanadium redox flow battery are improved, and the weight and the volume of the battery are reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

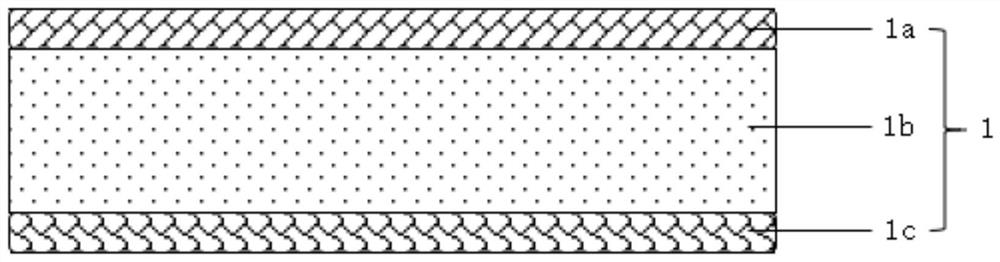

Solid electrolyte composite layer and lithium ion battery

InactiveCN112599850AImprove interfacial wettabilityHigh mechanical strengthSecondary cells servicing/maintenanceElectrolyte immobilisation/gelificationSolid state electrolyteMetallic lithium

The invention provides a solid electrolyte composite layer and a lithium ion battery. The solid-state electrolyte composite layer comprises a near-positive-electrode-side solid-state electrolyte layer, a middle solid-state electrolyte layer and a near-negative-electrode-side solid-state electrolyte layer which are sequentially arranged in a stacked mode. The middle solid-state electrolyte layer comprises the inorganic ceramic electrolyte, the near-positive-electrode-side solid electrolyte layer comprises near-positive-electrode-side polymer with high oxidation resistance, and the near-negative-electrode-side solid electrolyte layer comprises a near-negative-electrode-side compound stable with metal lithium, so that the solid electrolyte composite layer is high in mechanical strength, and lithium dendrites are prevented from piercing the electrolyte; the requirements of high-voltage resistance of a positive electrode side and stability of a negative electrode side and metal lithium aremet, and meanwhile, the interface wettability of the solid electrolyte composite layer is good. The lithium ion battery comprises the solid electrolyte composite layer, and due to the fact that the solid electrolyte composite layer is high in mechanical strength, excellent in wettability and good in stability with positive and negative electrode interfaces, the lithium ion battery has the advantages of being small in battery internal resistance, good in cycle performance and high in safety.

Owner:ZHUHAI COSMX BATTERY CO LTD

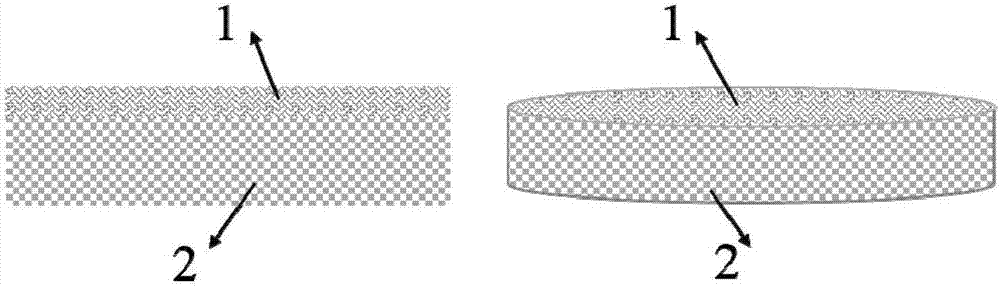

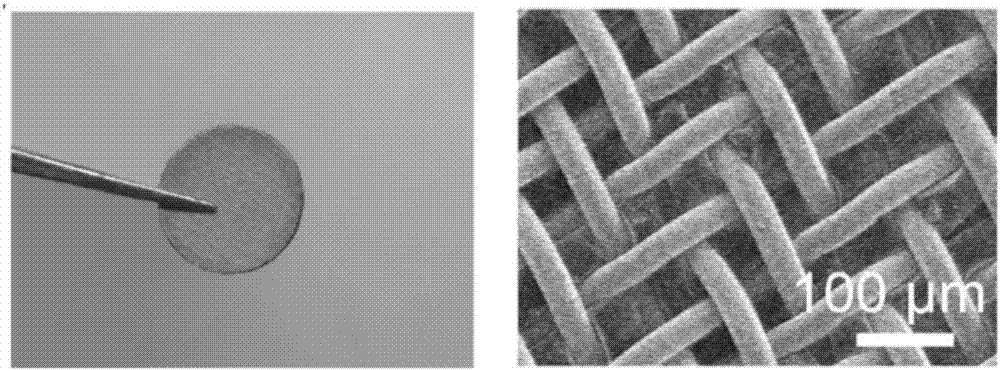

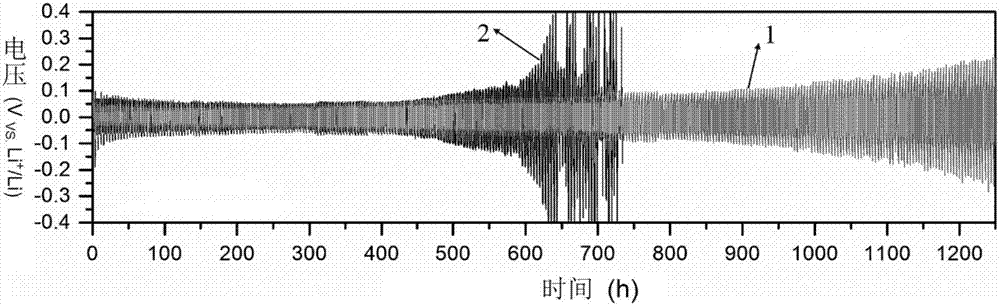

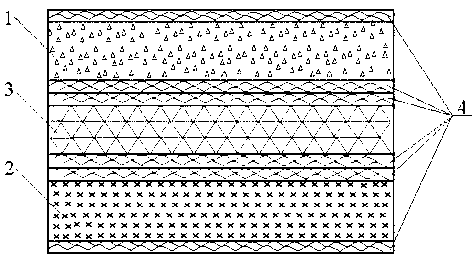

Metal electrode with three-dimensional structure

The invention discloses a metal electrode with a three-dimensional structure. The metal electrode comprises a substrate, wherein at least one surface of the substrate is provided with an embedded layer with a netlike structure; the substrate is selected from metal lithium, sodium, magnesium or aluminum, or an alloy consisting of at least two of the metal lithium, sodium, magnesium and aluminum; the embedded layer with the netlike structure is of a single-layer or multi-layer structure, and is selected from at least one of a metal layer, a polymer layer, a semiconductor layer and an insulator layer; the netlike structure is a planar netlike structure or a three-dimensional netlike structure; and the embedded layer is made of a material different from the material of the substrate. Through adoption of the metal electrode with the three-dimensional structure provided by the invention, the aims of restraining dendritic crystal growth and reducing volume expansion can be fulfilled, thereby increasing the coulombic efficiency of a battery and prolonging the service life the battery.

Owner:ZHEJIANG UNIV

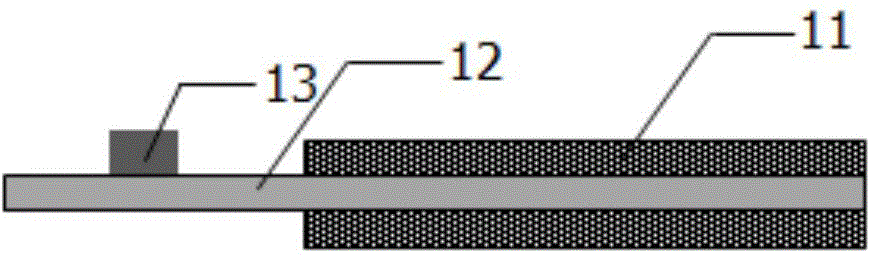

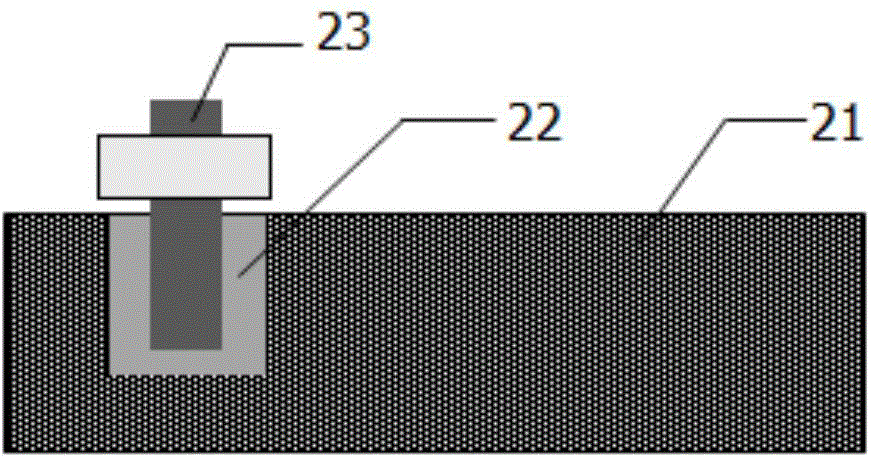

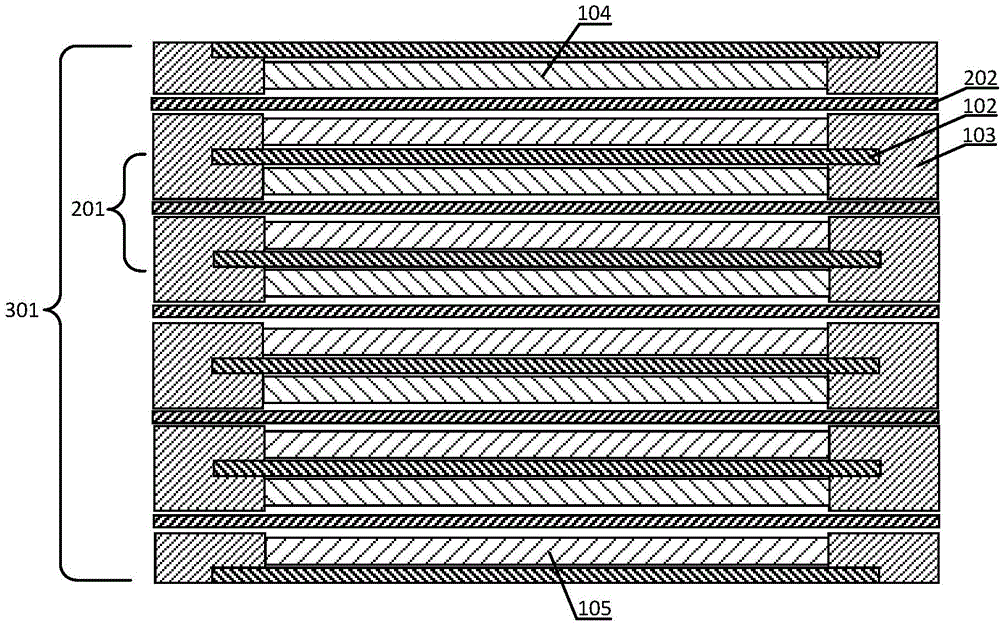

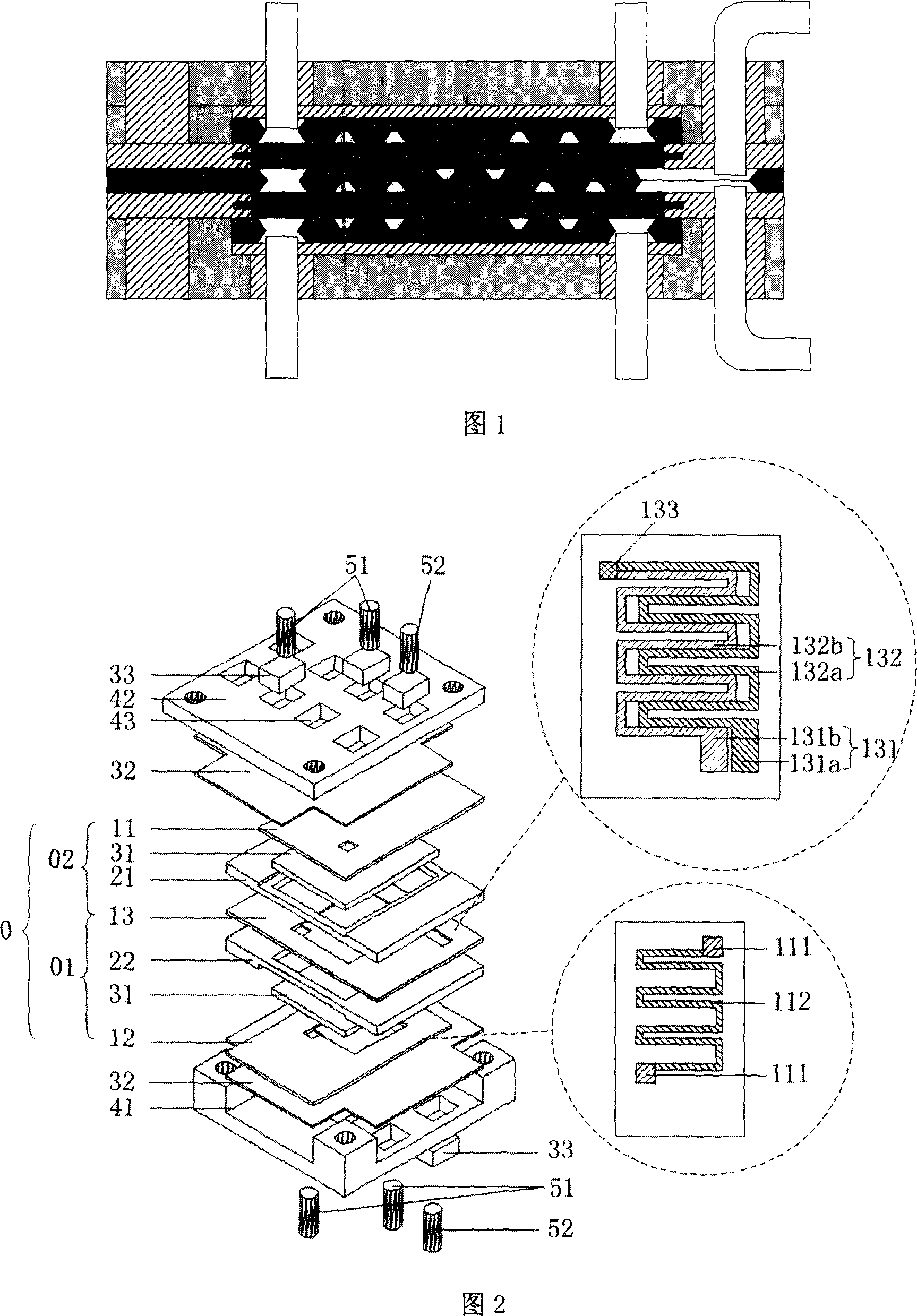

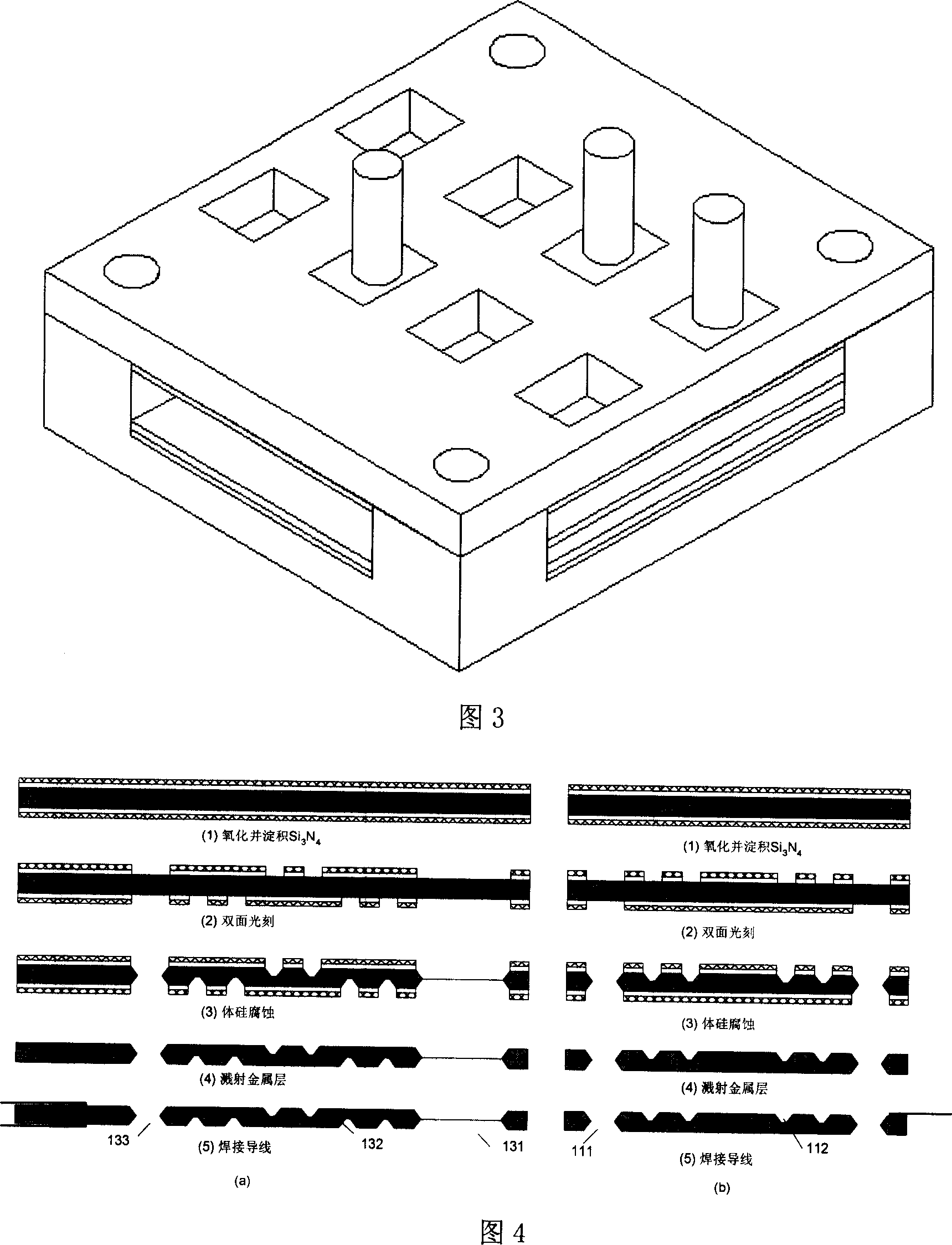

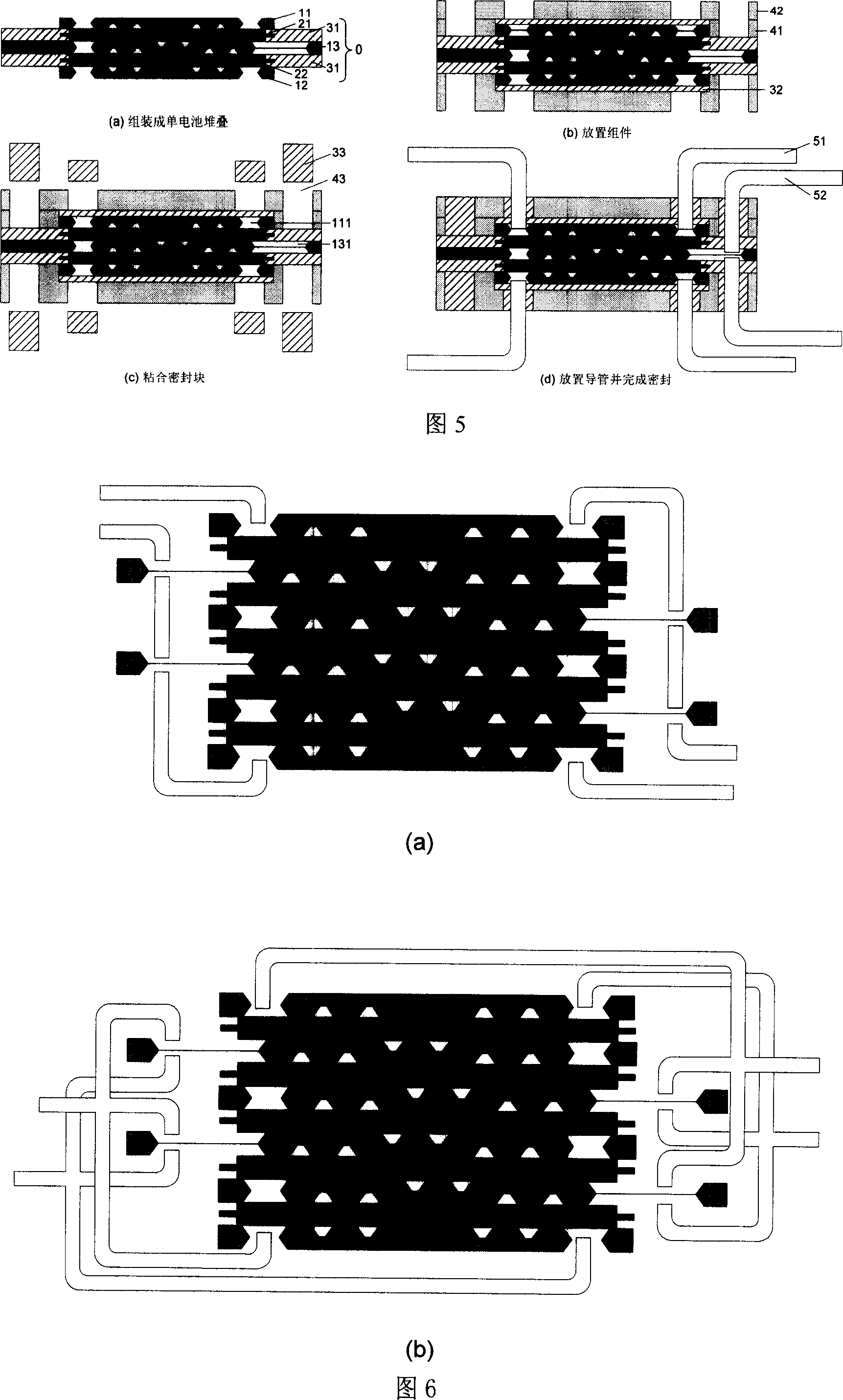

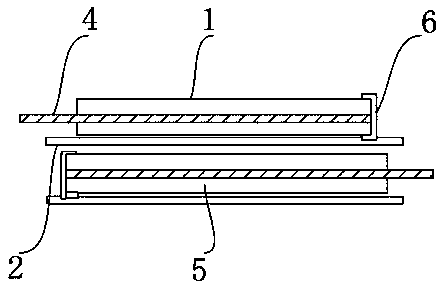

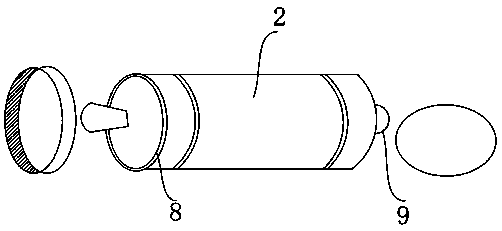

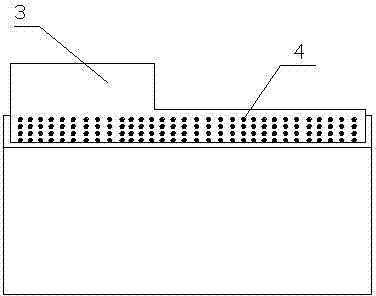

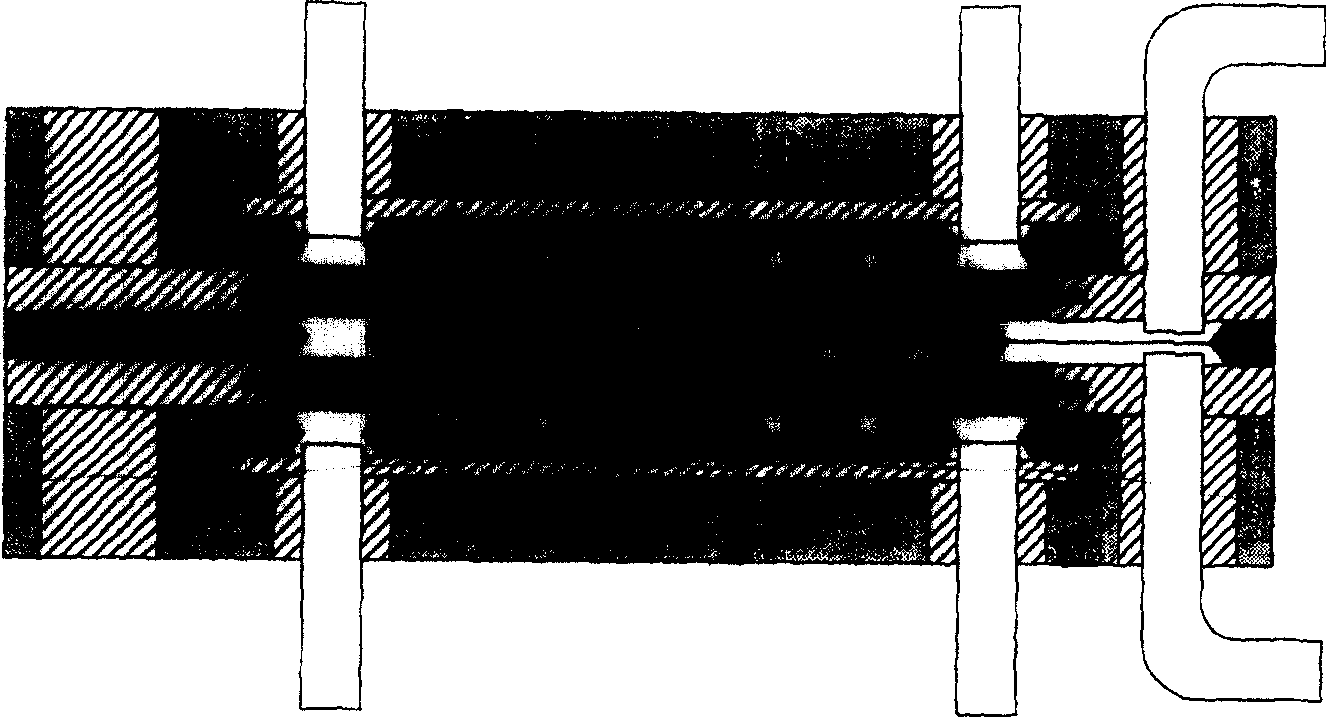

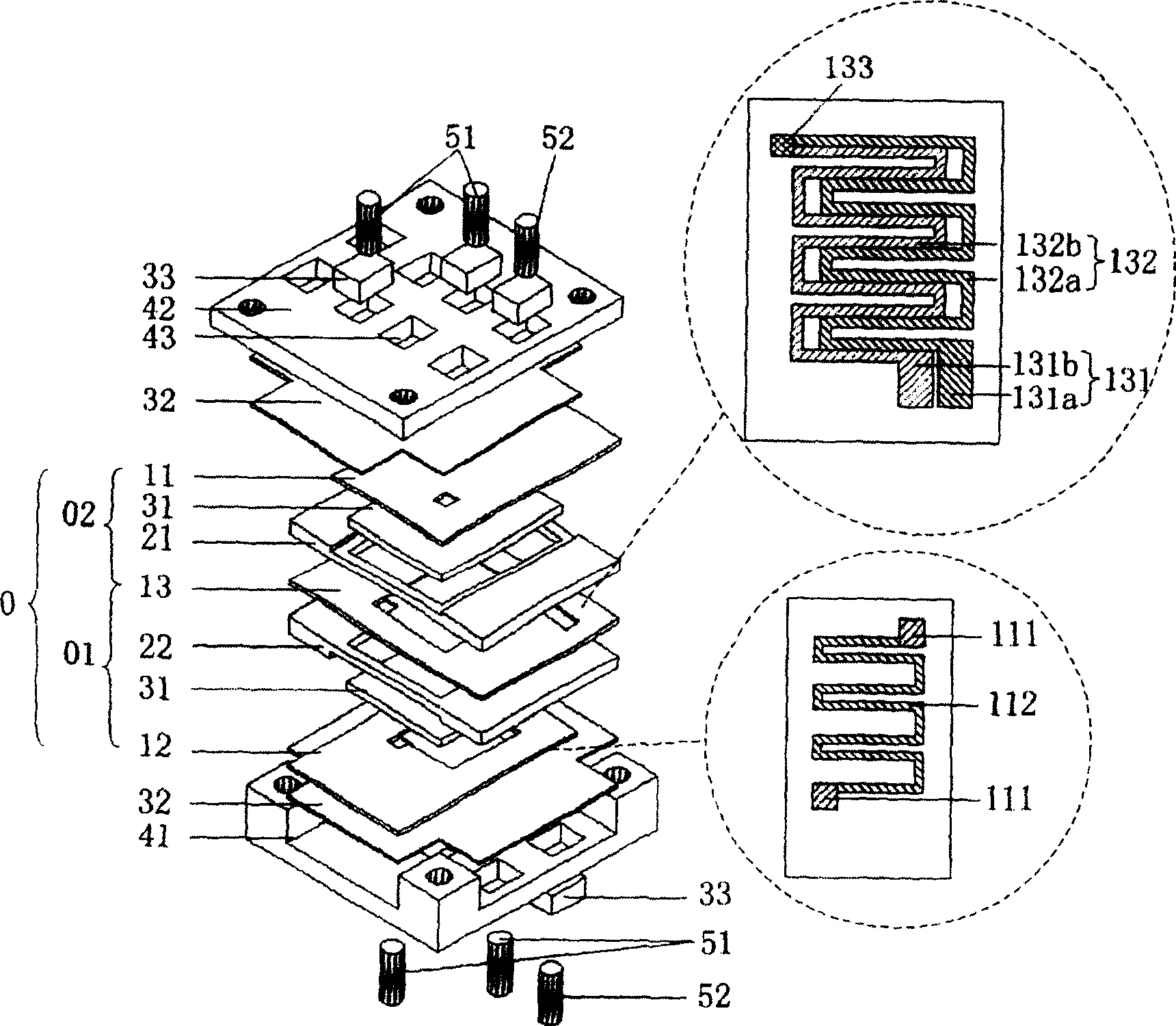

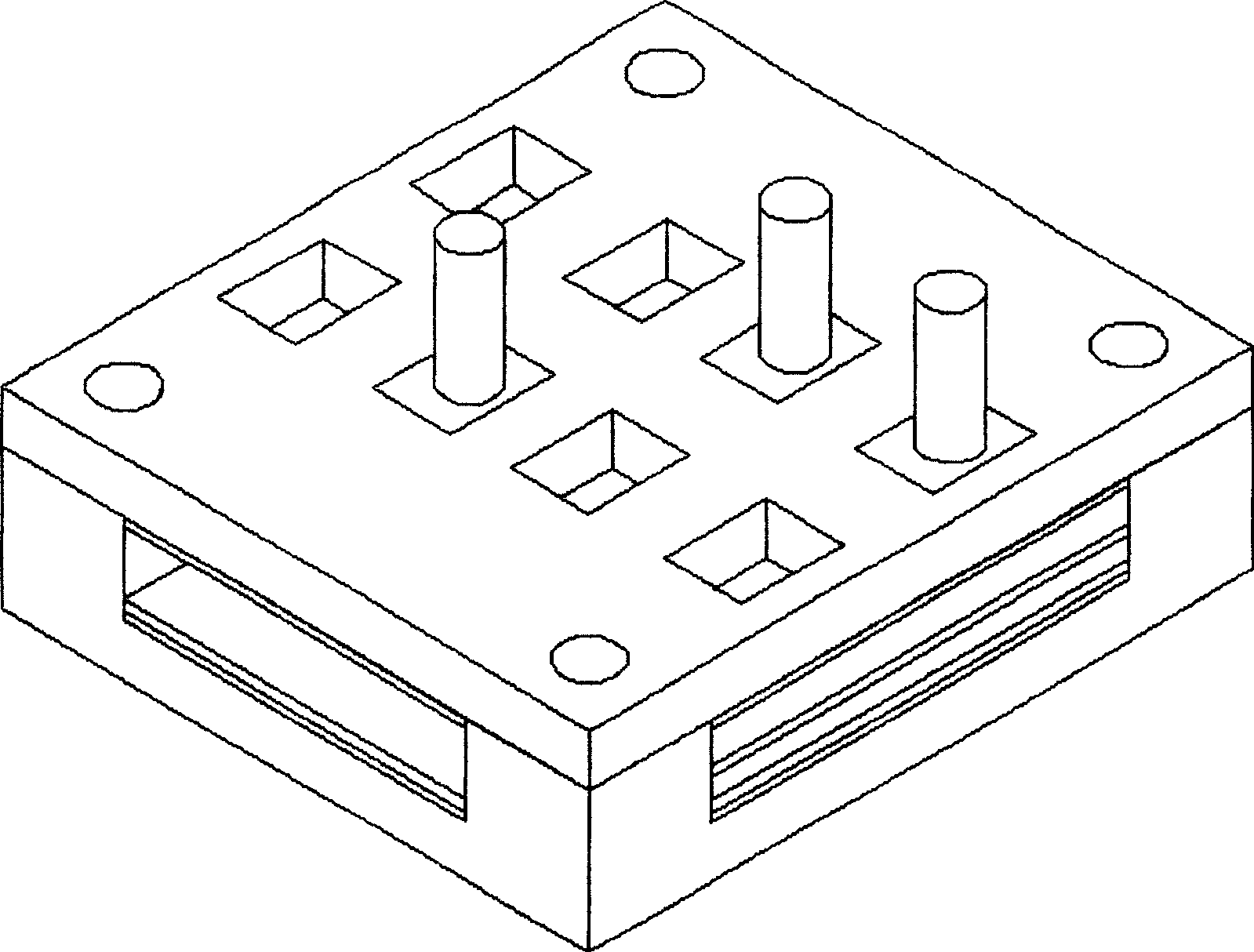

Stack silicon-base miniature fuel celles and manufacturing method

InactiveCN101000968AFlexible designLower battery internal resistanceSemi-permeable membranesFuel cells groupingElectrical batteryInternal resistance

Stacked silicon-based micro fuel cell group and its production method belong to the field of micro-energy and micro-machining areas. It includes the single cell stacking, sealing component, claming component and fluid catheter. Two or more fuel cell single batteries form stack, which order is: the second outer plate (12), the second membrane electrode (22), the inner plate (13), the first membrane electrode (21) and the first outer plate (11), and use the clamping and sealing components to seal package. The production method includes processing silicon plate and seal packaging of different component parts, using silicon micro-machined to produce a drainage channel, packaging the single cell stack. The invention has small resistance of battery, small package size, flexible flow graphic design, various series and parallel forms, which can get a larger output current and voltage when a small increase in the volume of cases.

Owner:TSINGHUA UNIV

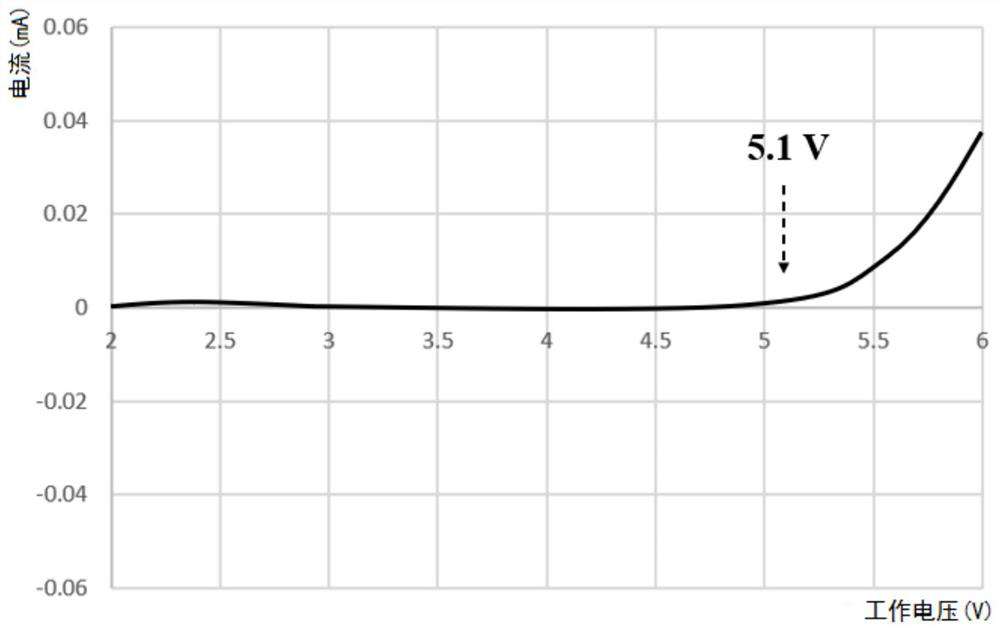

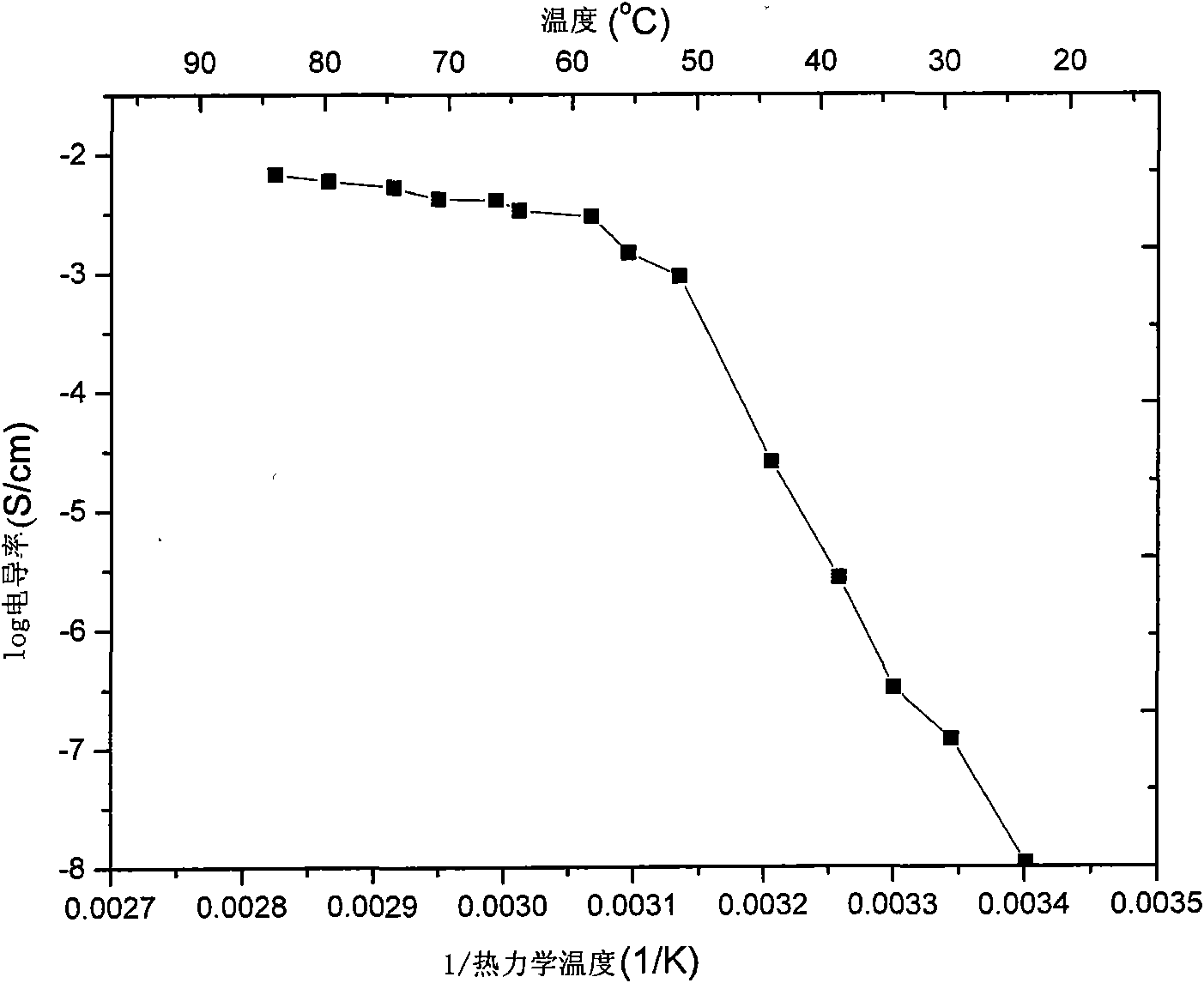

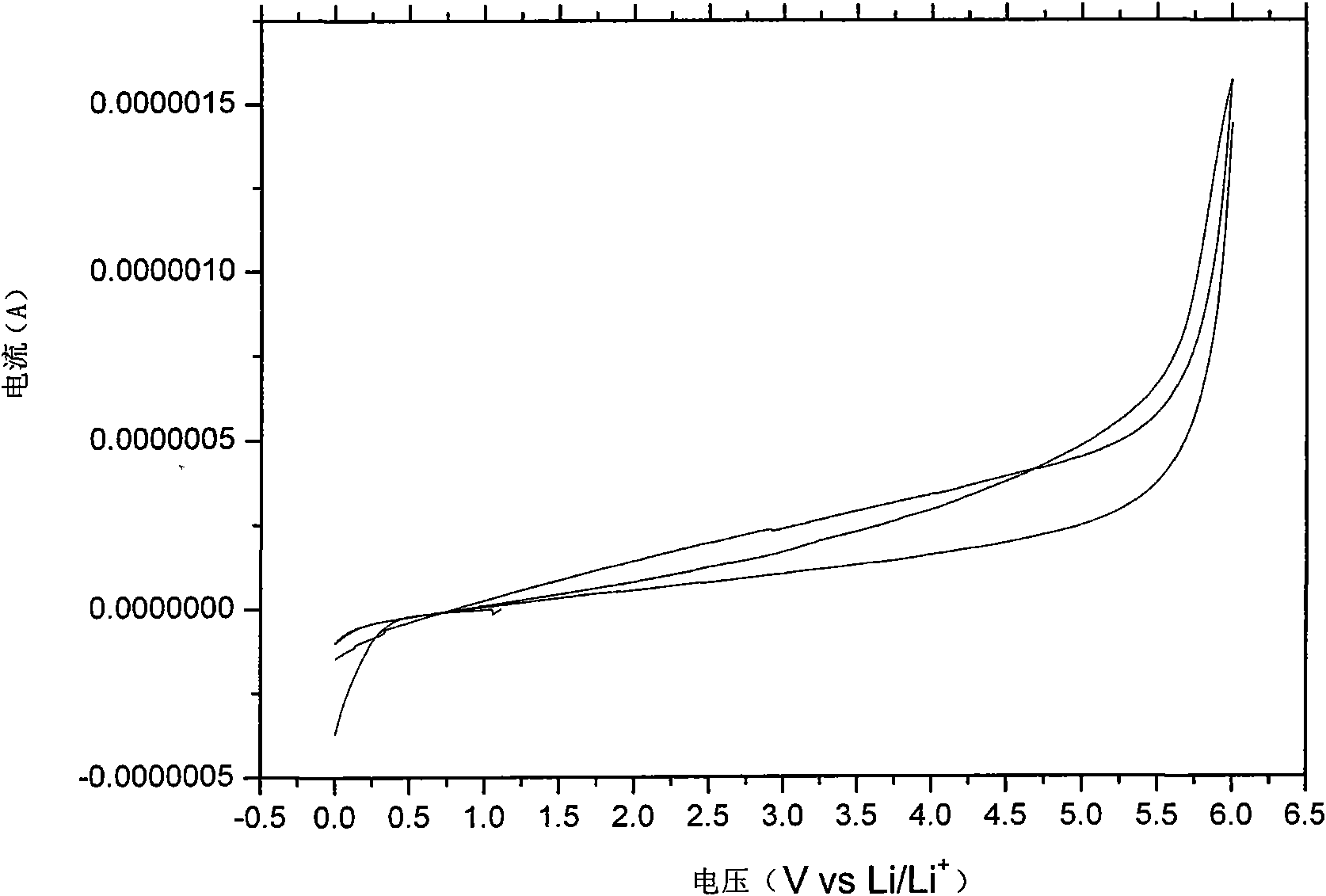

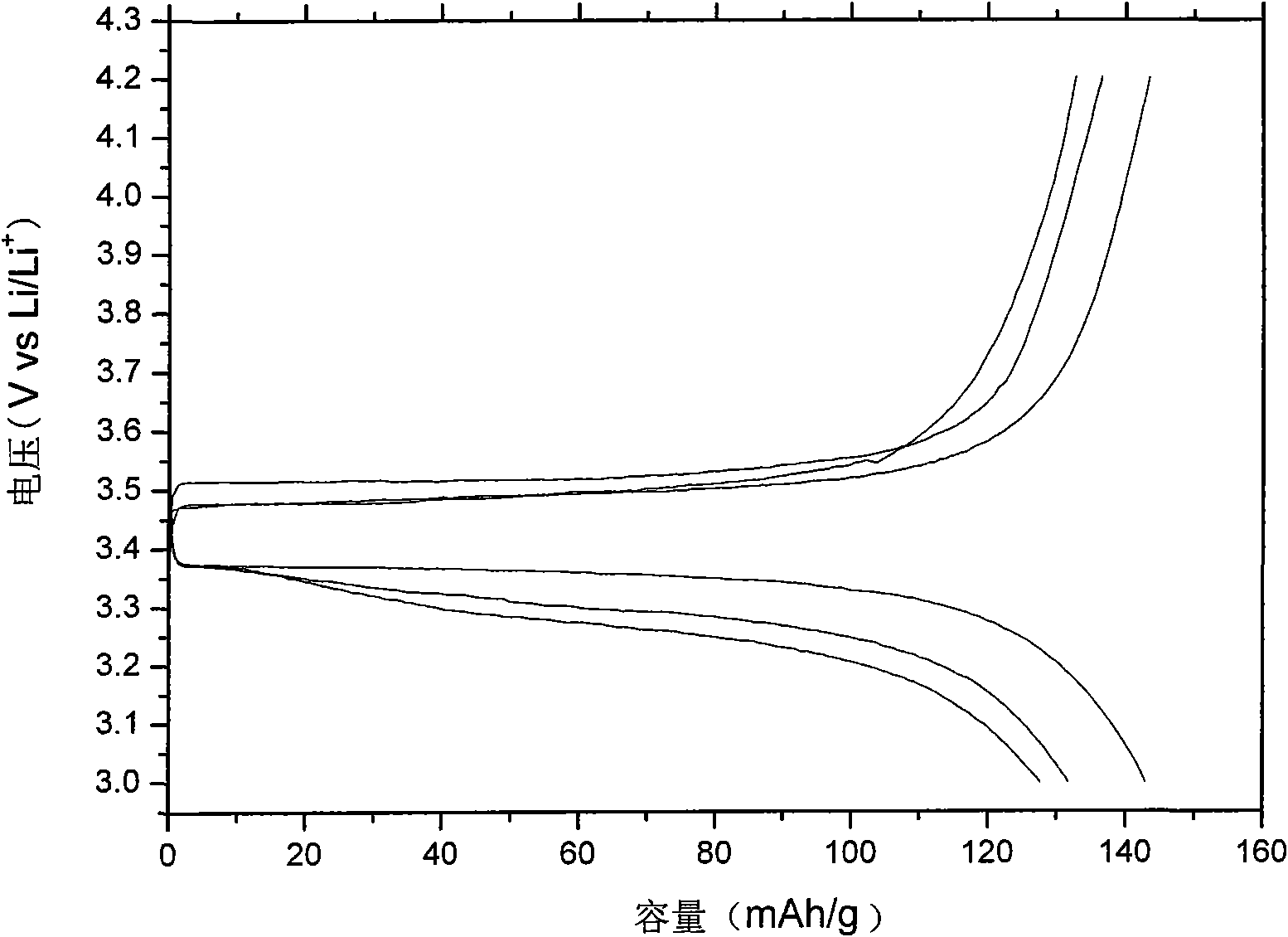

Phase variation electrolyte as well as preparation method and application thereof

The invention provides a phase variation lithium ion electrolyte comprising the following components of lithium salts and organic compounds containing acid amide functional groups. The invention also provides a preparation method of the electrolyte, comprising the following steps: a. mixing the lithium salts and the organic compounds containing acid amide functional groups; b. heating the mixture and melting the mixture to obtain transparency liquid; and c. cooling the transparency liquid to obtain the electrolyte, wherein the steps a, b and c are operated in dry environments. The phase variation lithium ion electrolyte is applied to chargeable and dischargeable lithium batteries. In addition, the invention also provides a chargeable and dischargeable lithium battery comprising the electrolyte. The electrolyte has lower electrical conductivity and higher thermal and chemical stability when being a solid under the condition that the temperature is lower than a phase variation temperature and has higher electrical conductivity when being liquid under the condition that the temperature is higher than the phase variation temperature.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

All-solid-state lithium battery and preparation method thereof

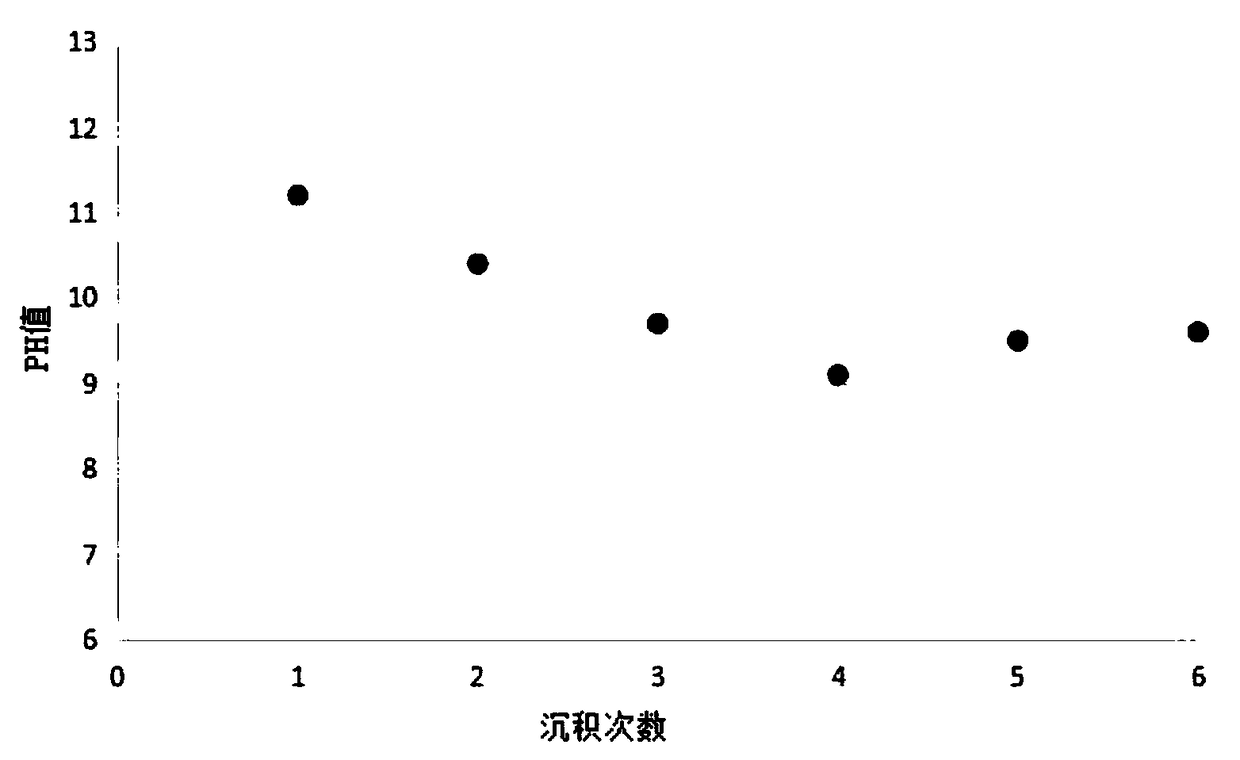

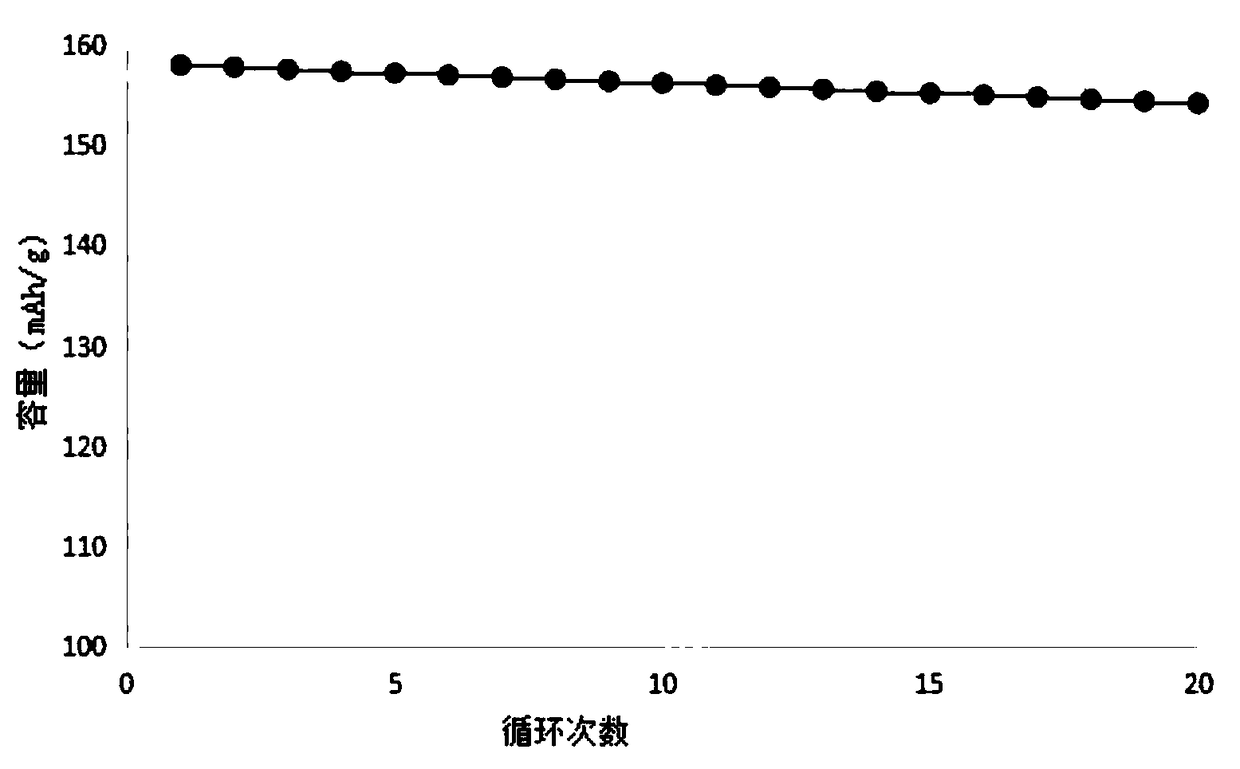

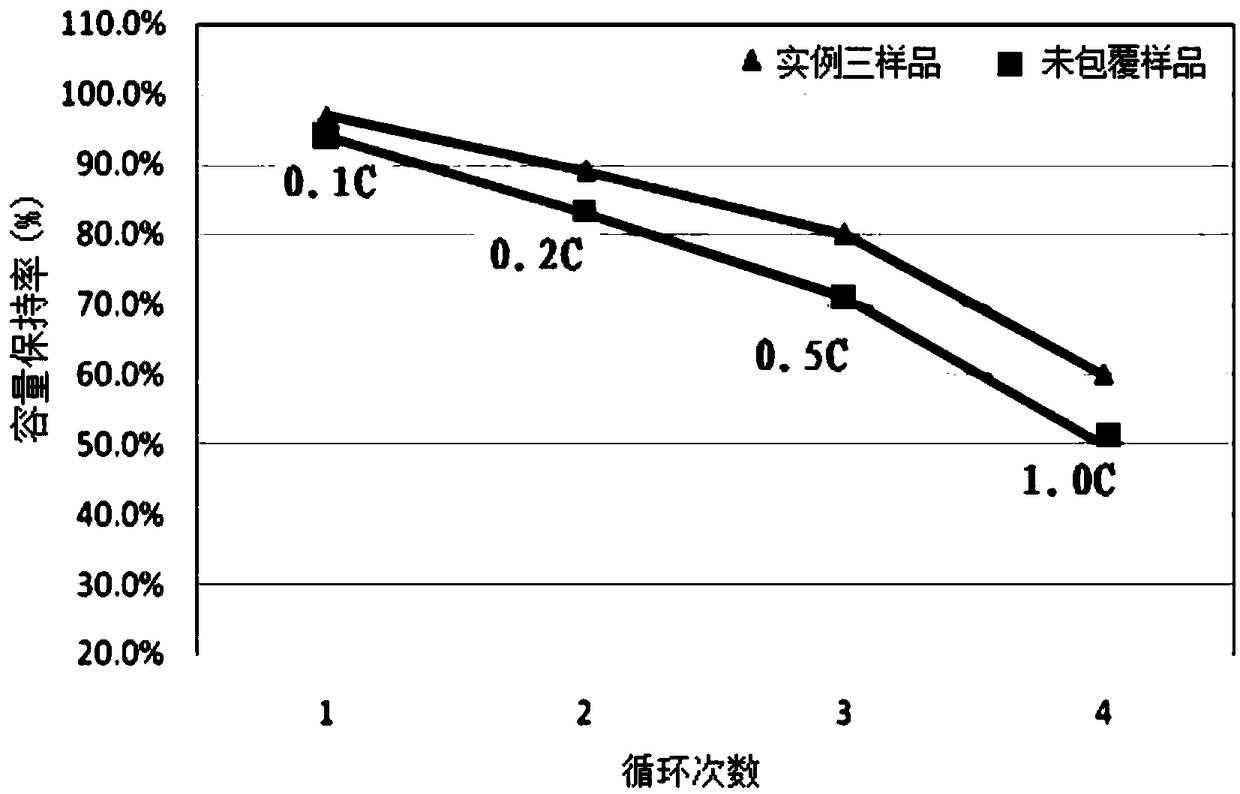

InactiveCN108539250AImprove cycle performanceImproved magnification performanceFinal product manufactureLi-accumulatorsSolid state electrolyteInternal resistance

The invention belongs to the technical field of lithium batteries and particularly relates to a preparation method of an all-solid-state lithium battery, comprising the steps of S1, forming a coatinglayer on the surface of cathodic material powder by means of atomic layer deposition; S2, sintering the cathodic material powder of the coating layer at 300-1000 DEG C for 2-10 h, and forming LiXaYb solid-state electrolyte layer on the surface of the cathodic material powder; S3, preparing a cathode with a cathodic material surface-coated with the LiXaYb solid-state electrolyte layer, and assembling an anode, the solid-state electrolyte layer and the cathode into the all-solid-state lithium battery. The invention also provides an all-solid-state lithium battery prepared via the preparation method. The surface of the cathodic material is coated with metallic oxides, metallic phosphates, metallic fluorides or metallic sulfides via ALD (atomic layer deposition); after heating, reaction with the surface residue, alkaline matters, on the cathodic material occurs so as to form the LiXaYb solid-state electrolyte layer; therefore, PH value of the cathodic material is reduced, internal resistance of the solid-state battery is improved, and the cycle performance and rate performance of the battery are improved.

Owner:武汉艾特米克超能新材料科技有限公司

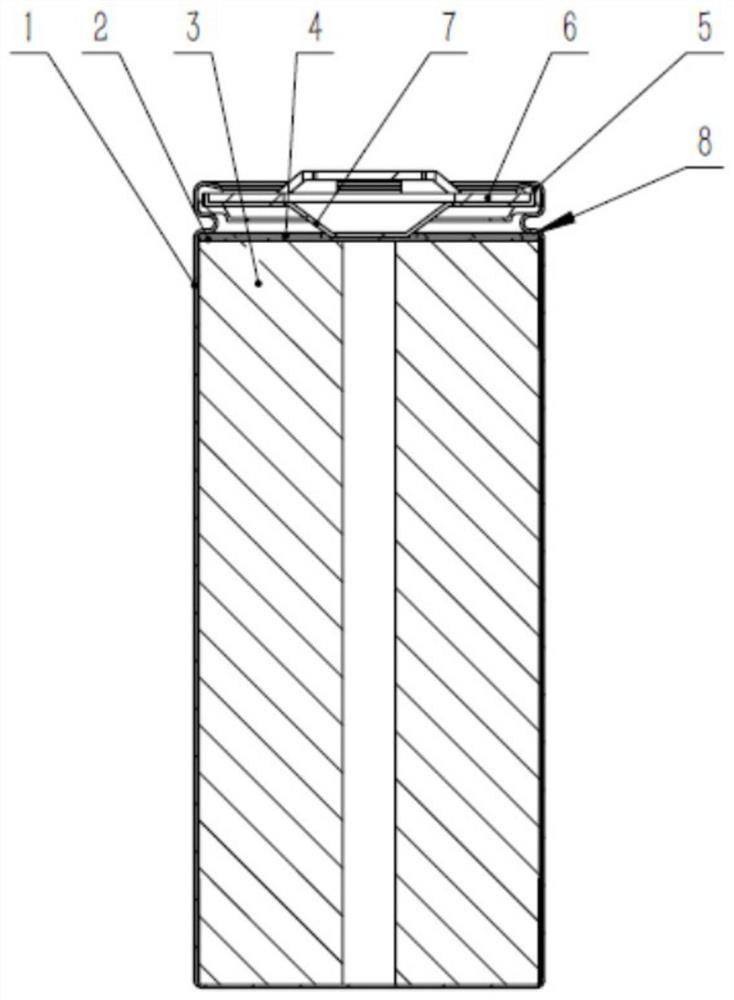

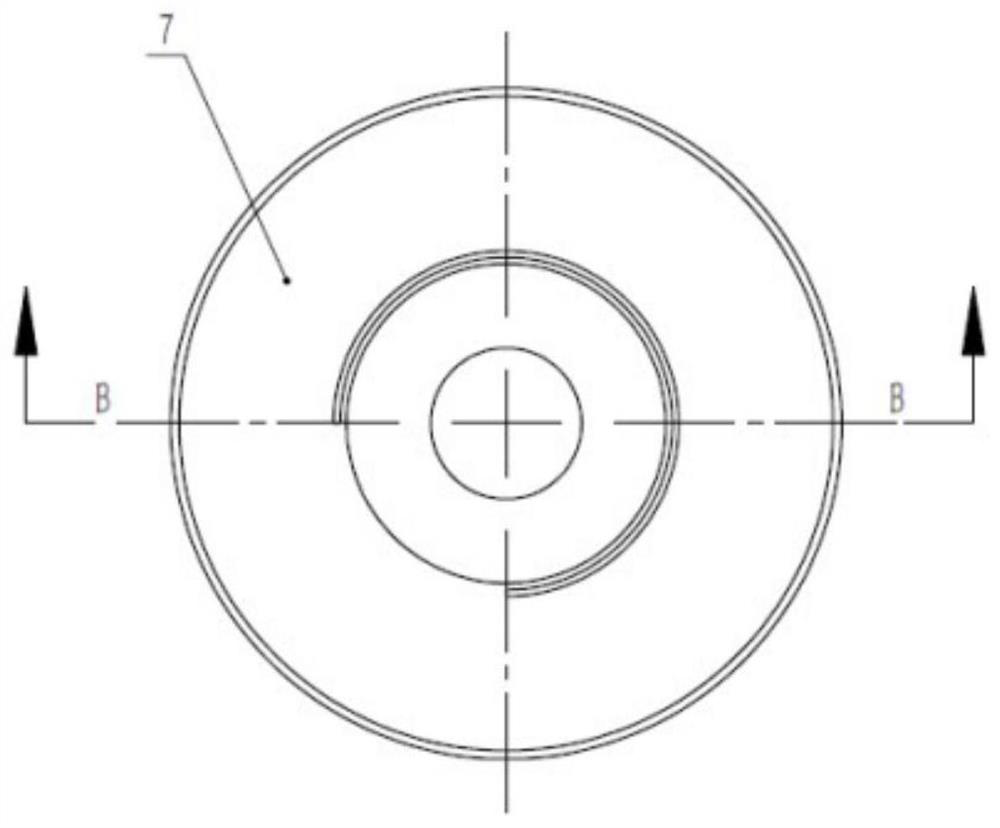

High-rate and safe cylindrical lithium ion battery ad manufacturing method thereof

PendingCN110739437APrevent short circuit inside the batteryReduce dust and burrsFinal product manufactureCylindrical casing cells/batteryCopper foilCurrent collector

The invention discloses a high-rate and safe cylindrical lithium ion battery. The battery comprises a positive pole piece and a negative pole piece, wherein a ceramic diaphragm is arranged between thepositive pole piece and the negative pole piece, a positive coating is arranged on a surface of the positive pole piece, a negative coating is arranged on a surface of the negative pole piece, an aluminum foil is arranged on the positive pole piece, a copper foil is arranged on the negative pole piece, high-temperature insulating adhesive tapes are arranged on the outer side surfaces of the positive coating and the negative coating, and polymer adhesives are arranged on surfaces of high-temperature insulating adhesive tapes. The battery is advantaged in that gathered multiple tabs are weldedwith a planar metal sheet current collector to form a full tab, so internal resistance is greatly reduced, and the high-current charging and discharging capacity of the battery is improved. The dry battery cell is subjected to electrolyte injection, packaging, formation and capacity grading, so the high-rate and safe lithium ion battery is assembled, the manufacturing process is simple and convenient, and the lithium ion battery is particularly suitable for new energy application fields of electric vehicles, large-scale energy storage and the like.

Owner:珈伟隆能固态储能科技如皋有限公司

Nickel-base high energy battery electrode tab welding process

InactiveCN104722918AImprove welding efficiencyAchieve weldingConductorsMetal working apparatusProduction lineInternal resistance

The invention relates to a nickel-base high energy battery electrode tab welding process, a laser welding technique is adopted, and a welding production line is achieved. By means of the nickel-base high energy battery electrode tab welding process, the welding between each electrode tab and a nickel-based high energy battery electrode strip can be effectively achieved, the laser welding technique is adopted for increasing the contact area between a battery electrode plate and each electrode tab, the welding strength is enhanced, the battery electrode plate is in close connection with the electrode tags, the internal resistance of a battery is reduced, the conductivity is improved, the high magnification rapid charging and discharging capabilities of a product are enhanced, meanwhile, the welding efficiency of the electrode tabs is raised, the operation is simple, the welding process is applicable to large-scale production and application, and a great production and practice significance is achieved.

Owner:徐象华

Stack silicon-base miniature fuel celles and manufacturing method

InactiveCN100483829CFlexible designLower battery internal resistanceSemi-permeable membranesFuel cells groupingElectrical batteryInternal resistance

Stacked silicon-based micro fuel cell group and its production method belong to the field of micro-energy and micro-machining areas. It includes the single cell stacking, sealing component, claming component and fluid catheter. Two or more fuel cell single batteries form stack, which order is: the second outer plate (12), the second membrane electrode (22), the inner plate (13), the first membrane electrode (21) and the first outer plate (11), and use the clamping and sealing components to seal package. The production method includes processing silicon plate and seal packaging of different component parts, using silicon micro-machined to produce a drainage channel, packaging the single cell stack. The invention has small resistance of battery, small package size, flexible flow graphic design, various series and parallel forms, which can get a larger output current and voltage when a small increase in the volume of cases.

Owner:TSINGHUA UNIV

Composite coating diaphragm with consistent pore diameter and preparation method thereof

ActiveCN111244365AImprove heat resistanceLower battery internal resistanceLi-accumulatorsCell component detailsCeramic particleCharge and discharge

The invention belongs to the technical field of lithium battery diaphragms, and particularly relates to a composite coating diaphragm with consistent pore diameters and a preparation method thereof. The composite coating diaphragm comprises a base membrane and a composite coating coated on the surface of the base membrane, and the composite coating contains polymer combined particles and ceramic particles, so that the pore diameter of micropores in the composite coating is kept consistent with that of the base membrane. The composite coating comprises polymer combined particles and ceramic particles in a specific proportion, the pore diameter of the composite coating is consistent with that of a base membrane, the heat resistance, electrolyte affinity and binding power with a positive plate and a negative plate of the battery are improved, the internal resistance of the battery is reduced, the cycle life of the battery is prolonged, and the charging and discharging efficiency of the battery is improved.

Owner:JIANGSU HORIZON NEW ENERGY TECH CO LTD

Zinc cathode and preparation method thereof as well as zinc secondary battery using zinc cathode

InactiveCN101740762AEasy to prepareLower battery internal resistanceAlkaline accumulatorsAlkaline accumulator electrodesChemistryCurrent collector

The invention relates to a zinc cathode which comprises a current collector and a cathode material, wherein the cathode material is attached to the current collector and comprises a cathode active substance and cathode adhesive; the cathode active substance is zinc-contained substance particles of which the surface is coated with hydrophobic silicon resin; the zinc-contained substance particles are selected from one or more of zinc compounds, zinc alloy and zinc elementary substances; and the cathode adhesive is hydrophilic adhesive. The secondary zinc-nickel battery prepared by the zinc cathode has lower internal resistance; and when large current discharge is carried out, a discharge platform is high, and the requirement of a product needing a high discharge platform can be favorably met.

Owner:BYD CO LTD

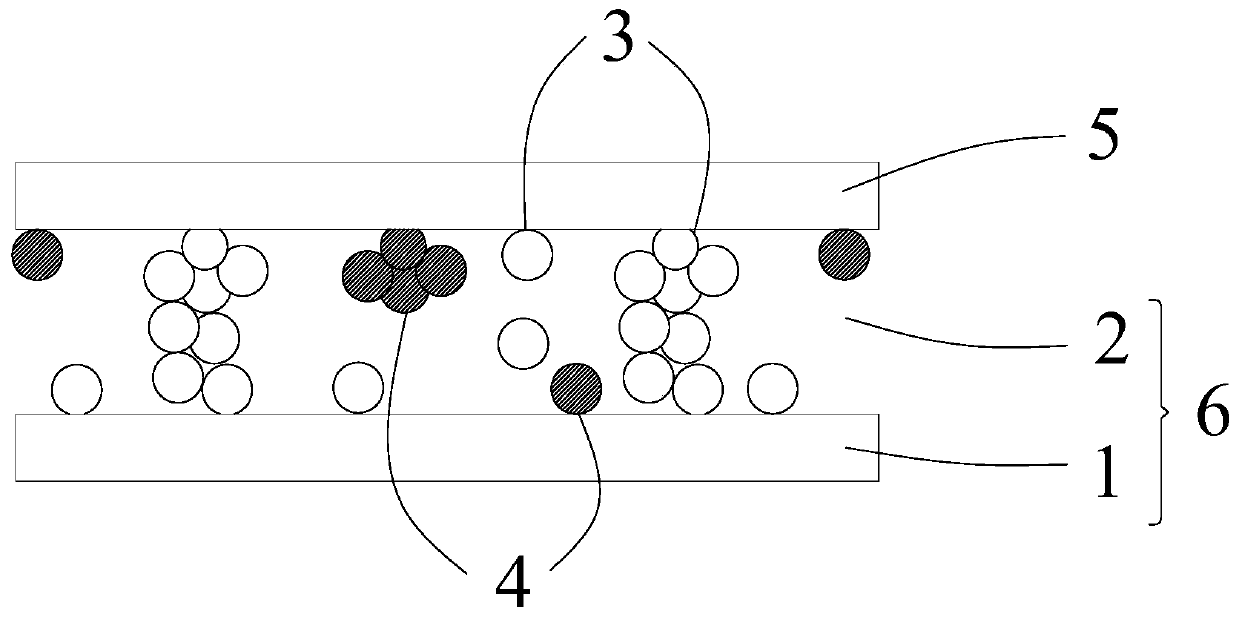

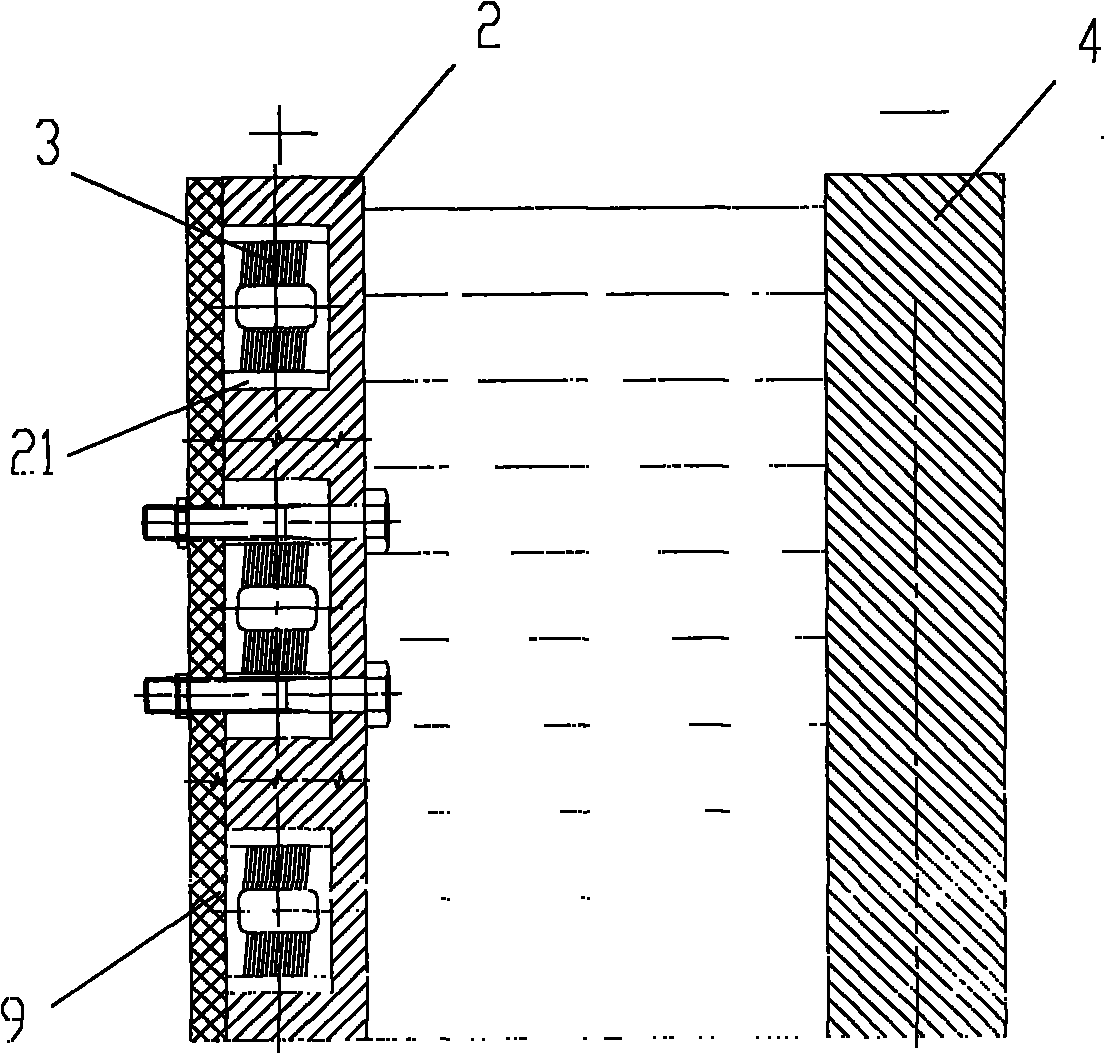

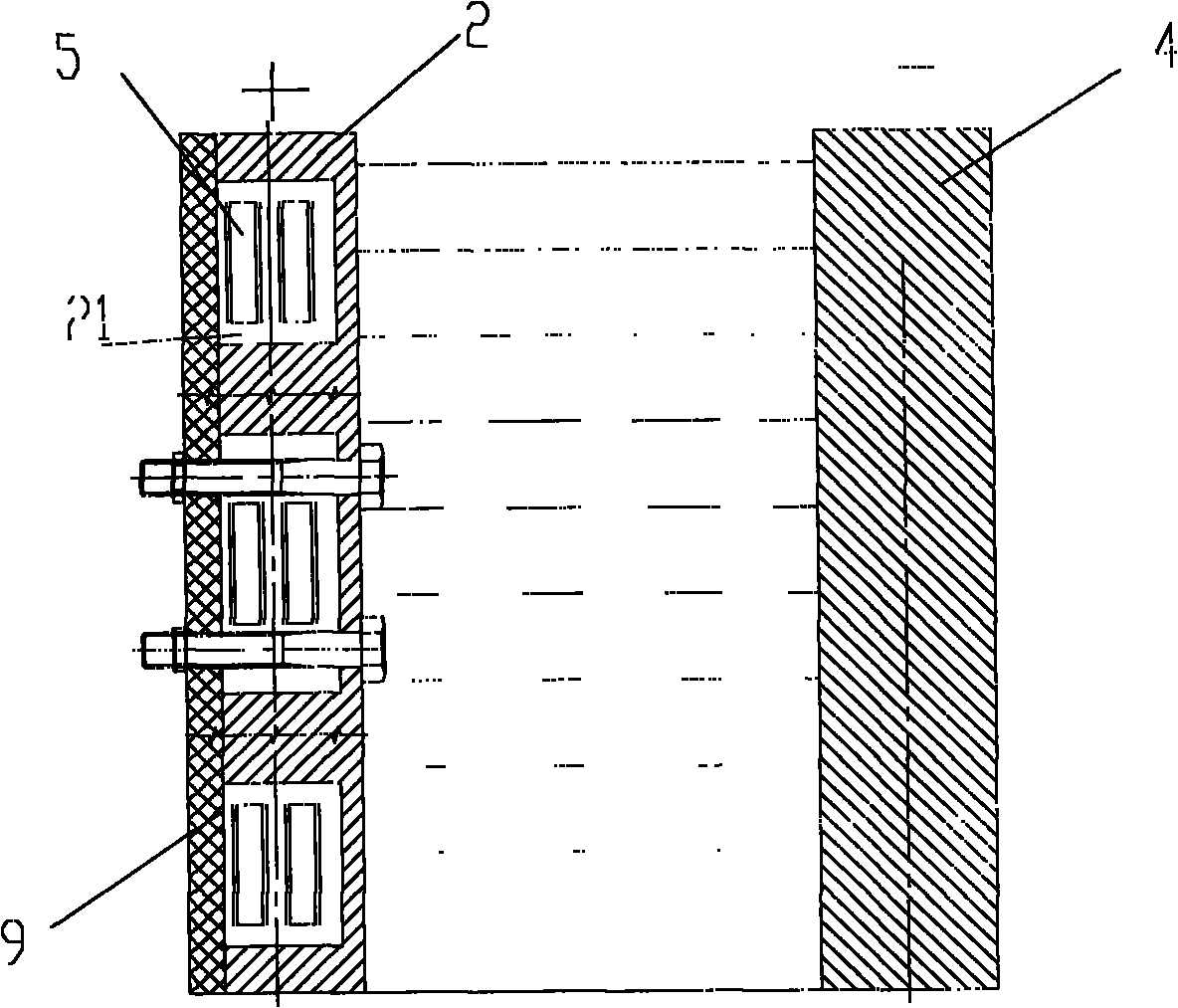

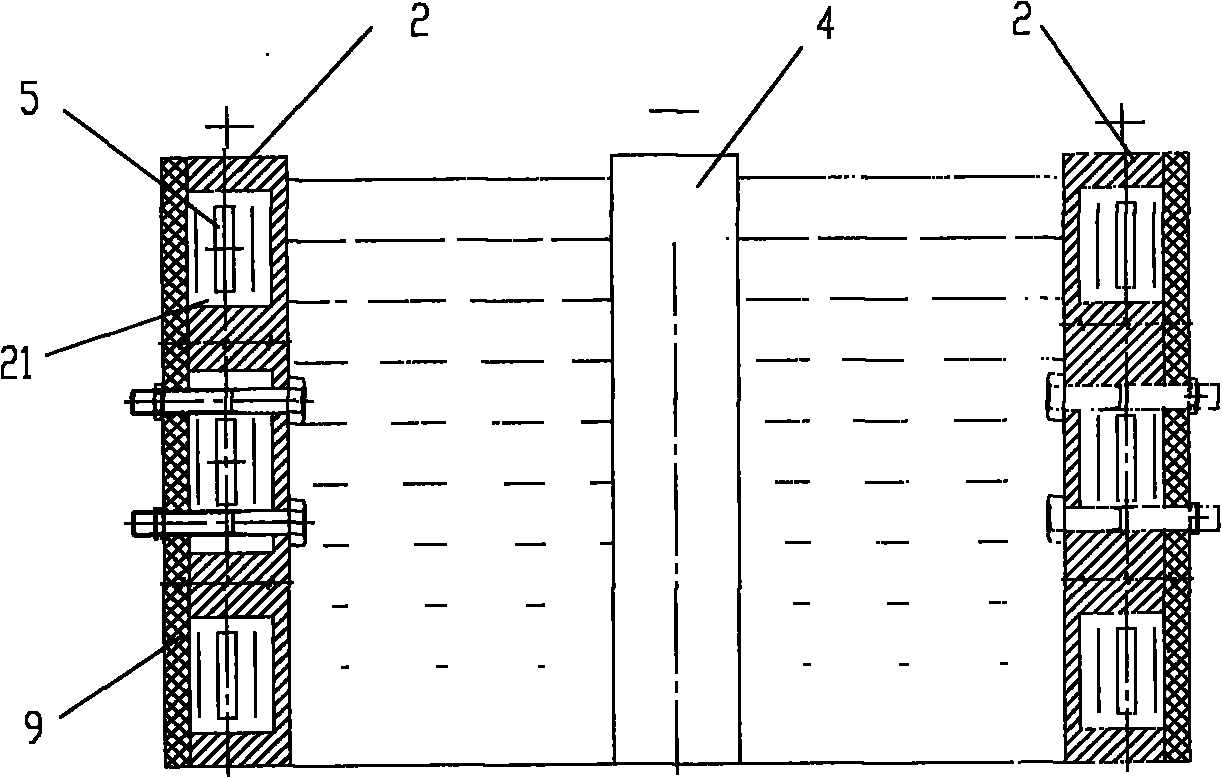

Battery

InactiveCN102593499AIncrease energy densityLower battery internal resistanceFuel and primary cellsPrimary cell maintainance/servicingElectrochemical responseHigher Power

The invention provides a battery, which is provided with electrodes immersed into an electrolyte, wherein the contact area of the electrodes and the electrolyte is an electrochemical reaction area, each of the electrodes is provided with an anode (2) and a cathode (4), the battery is further provided with ultra-sound components (3, 5, and 6) exerting sound field of ultrasonic waves on the electrochemical reaction area and / or the electrodes, wherein the ultra-sound components (3, 5, and 6) are fixedly connected with the electrodes. By using ultra-sound components for exerting sound field of ultrasonic waves on the electrodes, the power density that is times or tens of times higher than that of the current battery is provided, the energy density and the speed of charging and discharging are obviously improved, and the inner resistance of the battery is reduced and the power battery can be used in various occasions which require power batteries with high power densities and high energy densities, the power density of the current various battery techniques can be greatly increased to three times or even tens of times of the original power density.

Owner:常州信雷迪特电子系统工程有限公司

Preparation technology of photovoltaic battery front-face electrode

InactiveCN103367546AReduce fragmentationImprove conductivityFinal product manufactureSemiconductor devicesSilver pasteScreen printing

The invention discloses a preparation technology of a photovoltaic battery front-face electrode. The preparation technology includes the following steps that firstly, a conductive paste body is prepared; secondly, composite electrode material is prepared; thirdly, a battery piece or the composite electrode material is heated, the viscosity of the composite electrode material is made to recover, the composite electrode material is paved according to a designed pattern and connected to the front surface of the battery piece in an adhesive mode, and the adhesion processing is completed; fourthly, main grid lines are prepared on the front face of the battery piece; fifthly, the battery piece is placed into a drying furnace and a sintering furnace, the battery piece is dried at 200-500 DEG C and sintered at 500-900 DEG C, the bonding processing is completed, and the front-face electrode is formed. The composite electrode material different from traditional screen printing electrode material silver paste is applied, the electric combination of a composite electrode and alloy on the front face of the battery piece is finally achieved through the two processes of the adhesion processing and the bonding processing, and preparation of the battery front-face electrode is completed. The battery front-face electrode capable of being manufactured with the preparation technology is small in shading area, higher in conductivity and lower in cost.

Owner:余小翠

Lithium battery and preparation method thereof

PendingCN111668534ALower internal resistanceThe production process is simpleFinal product manufactureLi-accumulatorsEngineeringStructural engineering

The invention relates to the field of batteries, and provides a lithium battery and a preparation method thereof. The lithium battery comprises a positive current collecting disc, a roll core, a shelland an explosion-proof sheet, wherein the positive current collecting disc comprises a disc body, a first boss and a first groove; the roll core is formed by winding a positive plate, a negative plate and a diaphragm, so that the positive plate is wrapped by the negative plate, the negative plate is wrapped by the diaphragm, the back surface of the first groove is pressed into the positive exposed foil of the roll core, and the joint of the first groove and the positive electrode is welded; the bottom of the shell is provided with a plurality of second grooves which are formed at intervals and are sunken towards the opening of the shell, and the roll core is arranged in the shell, so that the negative electrode of the roll core is attached to the second grooves, and the attachment positions of the negative electrode of the roll core and the second grooves are welded; the explosion-proof sheet comprises a platform protruding outwards towards one side of the positive current collectingdisc and a pressing sheet surrounding the periphery of the platform, nicks are formed at the joint of the pressing sheet and the platform, and the bottom surface of the platform makes contact with andis welded to the first boss. According to the invention, super-high-rate charging and discharging can be carried out, and the required high-current discharging requirement is met.

Owner:大连中比能源科技有限公司

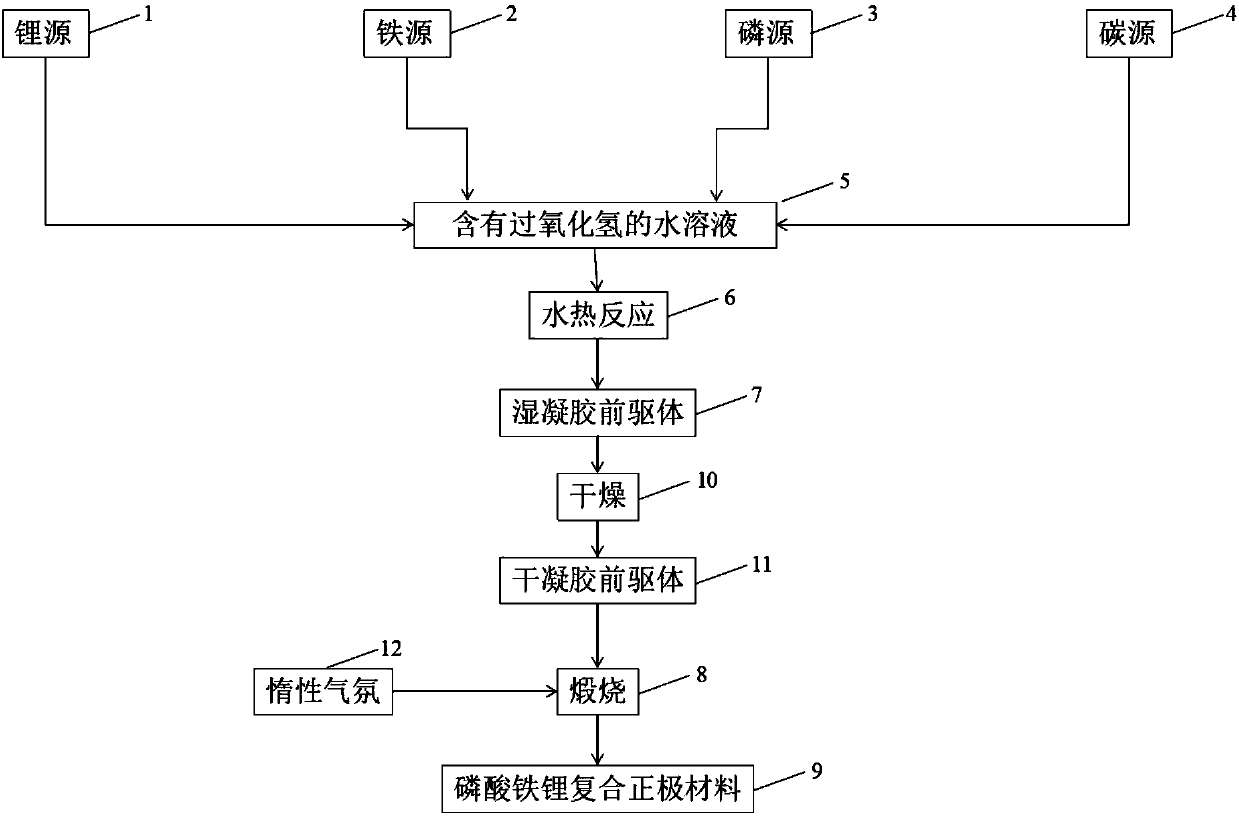

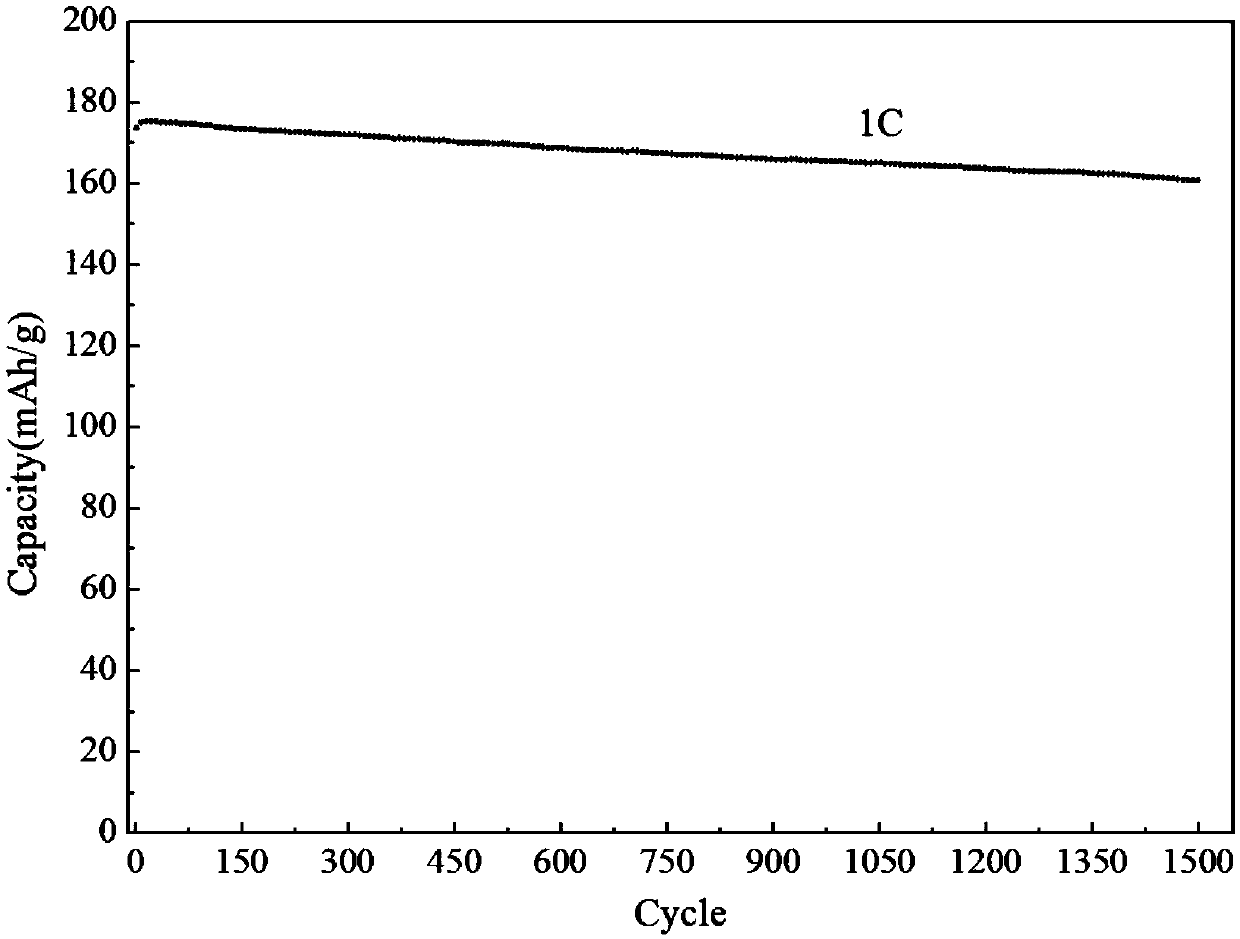

Composite lithium iron phosphate anode material and preparation method thereof

InactiveCN107768641AInhibition of volume changeAvoid reunionCell electrodesSecondary cellsState of artLithium iron phosphate

The invention belongs to the technical field of battery materials, and particularly relates to a composite lithium iron phosphate anode material and a preparation method thereof. The composite lithiumiron phosphate anode material is obtained by successively drying and calcining wet gel precursors; and the preparation method of the wet gel precursor comprises the following steps: dissolving a lithium source, an iron source, a phosphorus source and a carbon source in an aqueous solution containing hydrogen peroxide, performing the hydrothermal reaction, wherein the hydrothermal reaction temperature is 100 to 250 DEG C, the reaction time is 1 to 48h, and the pressure in the reaction kettle is 0.1 to 10MPa. The composite lithium iron phosphate anode material and the preparation method thereofsolve the technical defects in the prior art that particle size of the battery material obtained by utilizing carbon to wrap the lithium iron phosphate is wide in range, the sintering time is long, and the homogeneity is poor. By adopting the anode material of the invention, the electrochemical performance such as the reversible capacity, the rate capacity and the cycling performance can be significantly improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Graphene conductive agent

InactiveCN105118998AIncrease capacityLower battery internal resistanceCell electrodesSolventCvd graphene

The invention relates to a graphene conductive agent. The graphene conductive agent comprises, by mass, 18 to 23 parts of graphene, 5 to 10 parts of polyacrylonitrile fiber, 3 to 6 parts of triethylene tetramine, 100 to 160 parts of a solvent, 1 to 5 parts of rare earth oxide and 0.5 to 1 part of titanium carbide. The invention has the following beneficial effects: through adoption of the graphene conductive agent and excellent conductivity of graphene, the capacity of an electrode material is improved, internal resistance of a battery is reduced, and cycle life of the battery is prolonged; and the usage amount of the graphene conductive agent in preparation of a lithium ion battery is 50 to 60% of the usage amount of a conventional conductive agent, the usage amount of a binder is reduced by 18%, but 2C rate is increased by 6 to 10%, so cost is saved and the lithium ion battery is more competitive.

Owner:NINGBO POLYTECHNIC

Graphene composite lithium cobalt oxide cathode material and preparation method thereof

InactiveCN107742705AIncrease battery capacityThe battery conducts electricity wellCell electrodesGrapheneWater basedCopper

The invention discloses a graphene composite lithium cobalt oxide cathode material and a preparation method thereof. The graphene composite lithium cobalt oxide cathode material comprises the following raw materials: lithium cobalt oxide, water-based acrylic polyurethane, copper, grapheme, fluoroalkyl polyether, chlorinated polyethylene, ketjenblack, a chloroethylene vinyl acetate copolymer, ethylene distearic amide, an acrylate regulator, silver powder and a dispersing agent POLYRON. The graphene composite lithium cobalt oxide cathode material is prepared by the steps of graphene modification, powder grinding, solution preparation, calcining, grinding and the like. The graphene composite lithium cobalt oxide cathode material disclosed by the invention has the benefits that the battery capacity can be significantly improved, the battery internal resistance is reduced, and the battery conductivity is improved.

Owner:长沙仲善新能源科技有限公司

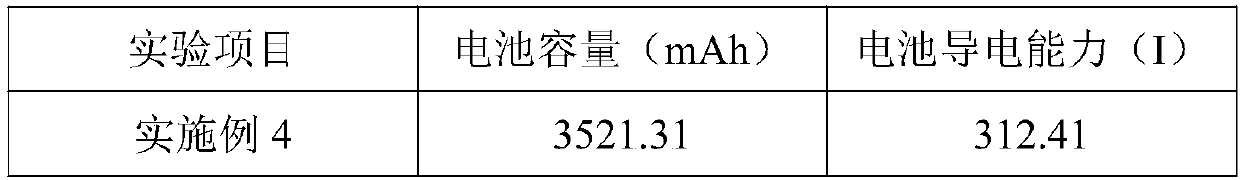

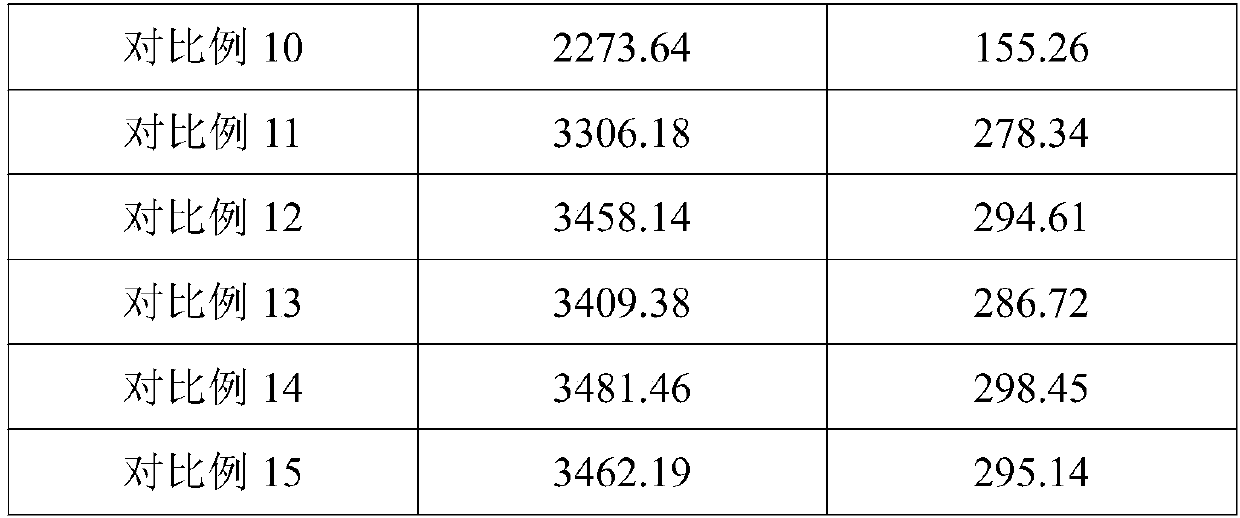

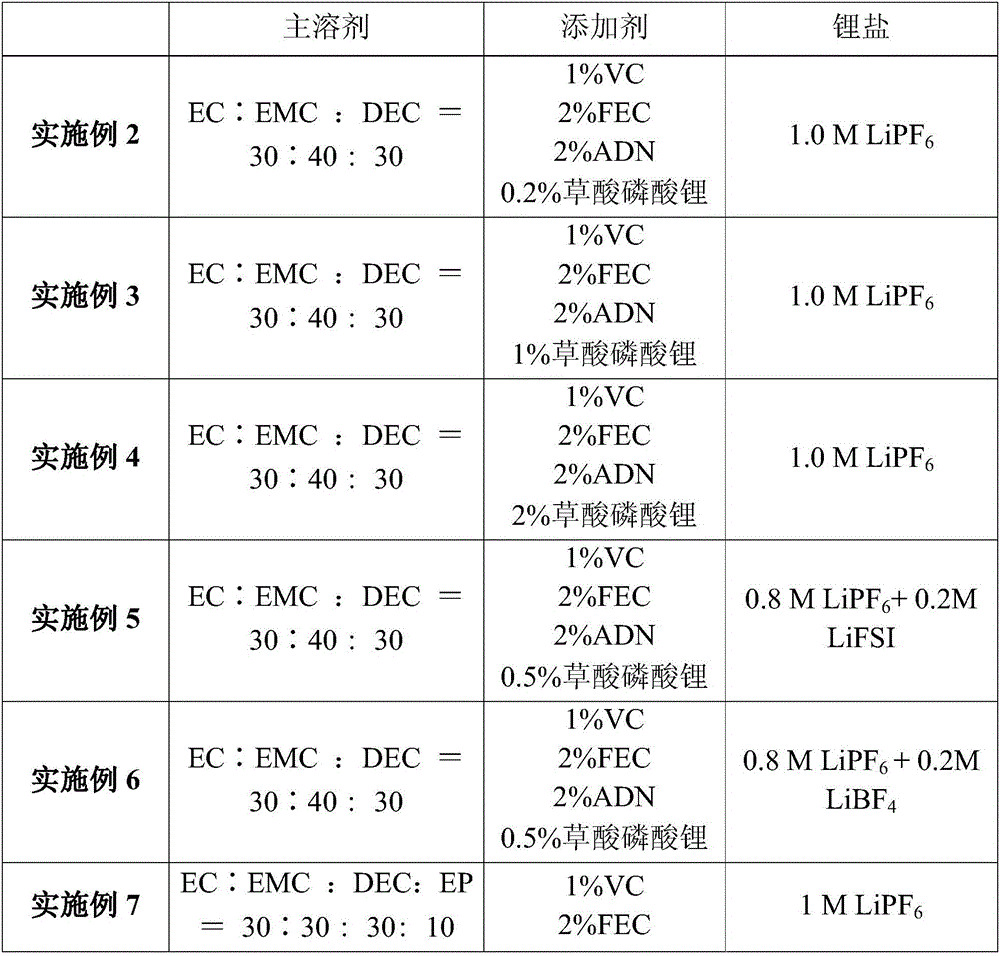

Electrolyte containing oxalic acid lithium phosphate and lithium ion battery adopting electrolyte

ActiveCN106450427AExtended service lifeLower battery internal resistanceSecondary cellsChemistryLithium electrode

The invention relates to an electrolyte containing oxalic acid lithium phosphate. The electrolyte is mainly prepared from the following components: an electrolyte lithium salt, oxalic acid lithium phosphate, a non-aqueous organic solvent and other additives, wherein the structural formula of the oxalic acid lithium phosphate is as shown in the specification: FORMUAL (I). The invention provides a novel lithium ion battery electrolyte, namely the electrolyte containing oxalic acid lithium phosphate. When the oxalic acid lithium phosphate is applied to the lithium ion battery electrolyte, formation of a more stable passivation film on the surface of a negative electrode and a positive electrode can be facilitated; and it is specifically embodied that the battery has high cycle performance and capacity recovery rate at the room temperature and a high temperature, as well as relatively low internal resistance.

Owner:宁德市凯欣电池材料有限公司

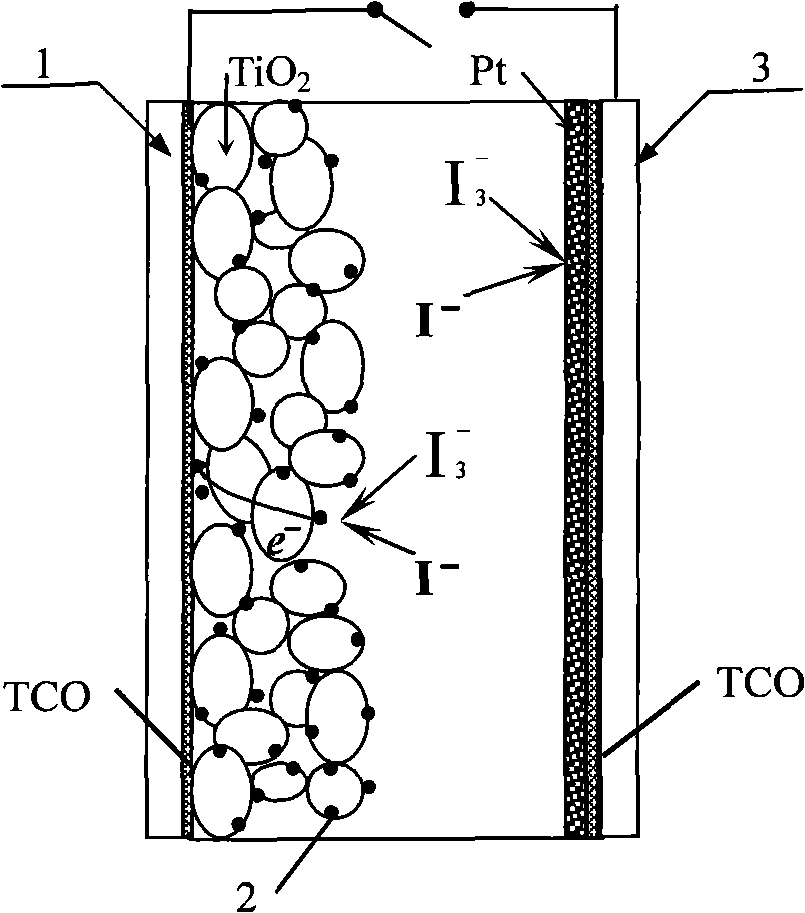

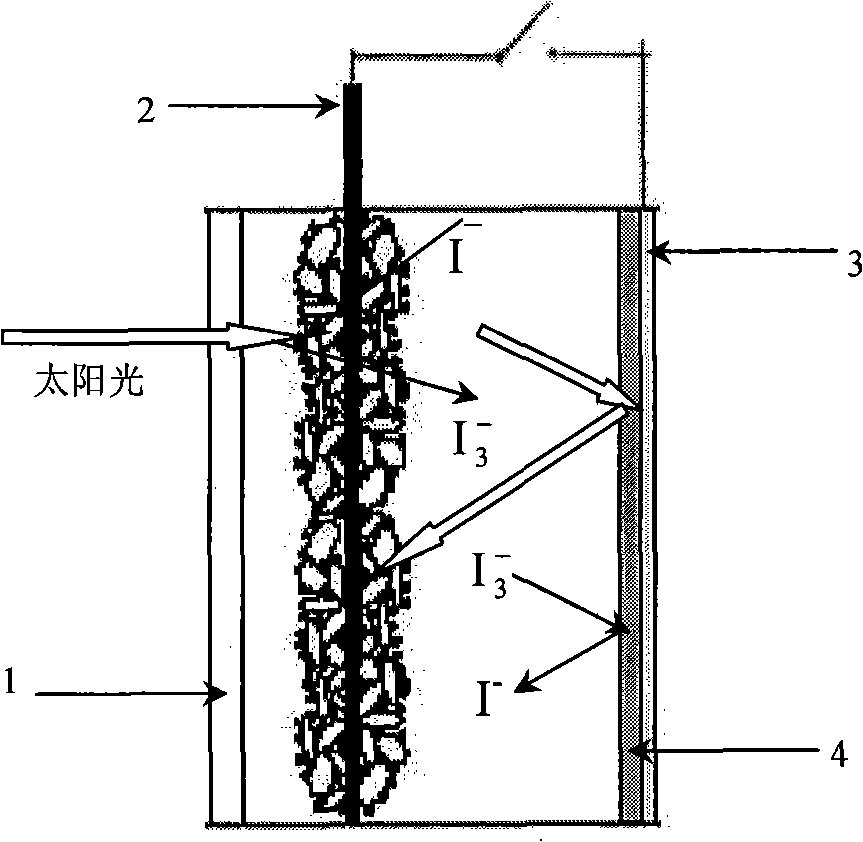

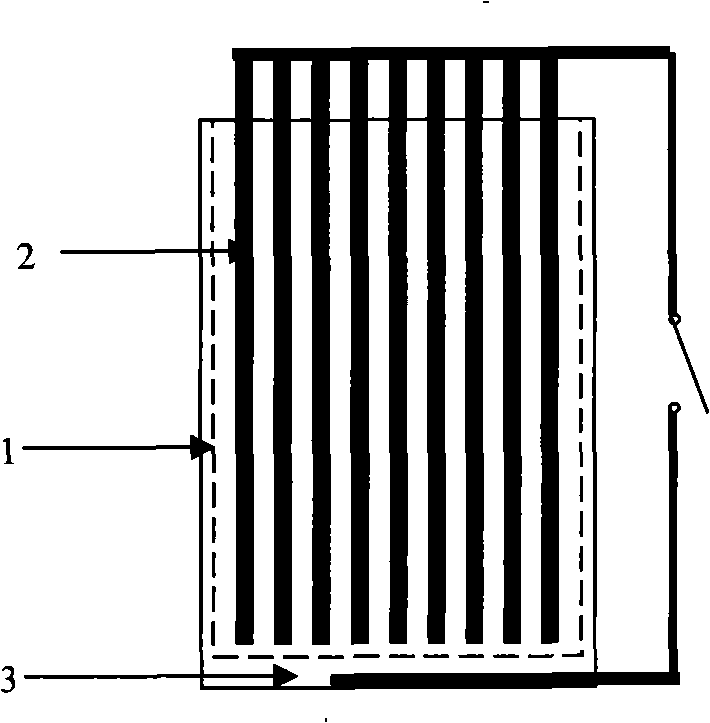

Silk light anode integrated efficient electronic collection dye sensitized solar battery

InactiveCN101266885ALower battery internal resistanceGood for collecting electronsLight-sensitive devicesSolid-state devicesCorrosionNanocrystalline semiconductors

The invention discloses a dye sensitized solar battery integrated by a threadlike light anode for efficiently collecting electrons, the solar battery is composed of three layers of structures, wherein the first layer is a super-white glass for packaging a cover board, the second layer is a plurality of coating metallic wires of the light anode which are interconnected in parallel, the coating metallic wires are the metallic wires which resist the corrosion of electrolyte or bandwidth gap nanometer crystal semiconductor oxide thin film that a conducting fiber is coated through coating procedure as charge separation effect; after heat treatment, the sensitized dye is adsorbed to prepare the second layer; the third layer is a coating metal sheet as pair electrodes; the gap between the super-white glass and the coating metal sheet is packaged to form a sealed space which is replete with the electrolyte having the redox. The solar battery of the invention can efficiently collect the electrons and adsorbs more dye to further improve the light absorption of the light anode, solving the problems of large resistance of the conduction glass substrate which limits the battery efficiency, of preparation in large area and of serial, parallel connections of the assemblies, and further enhancing the efficiency of battery.

Owner:SUN YAT SEN UNIV

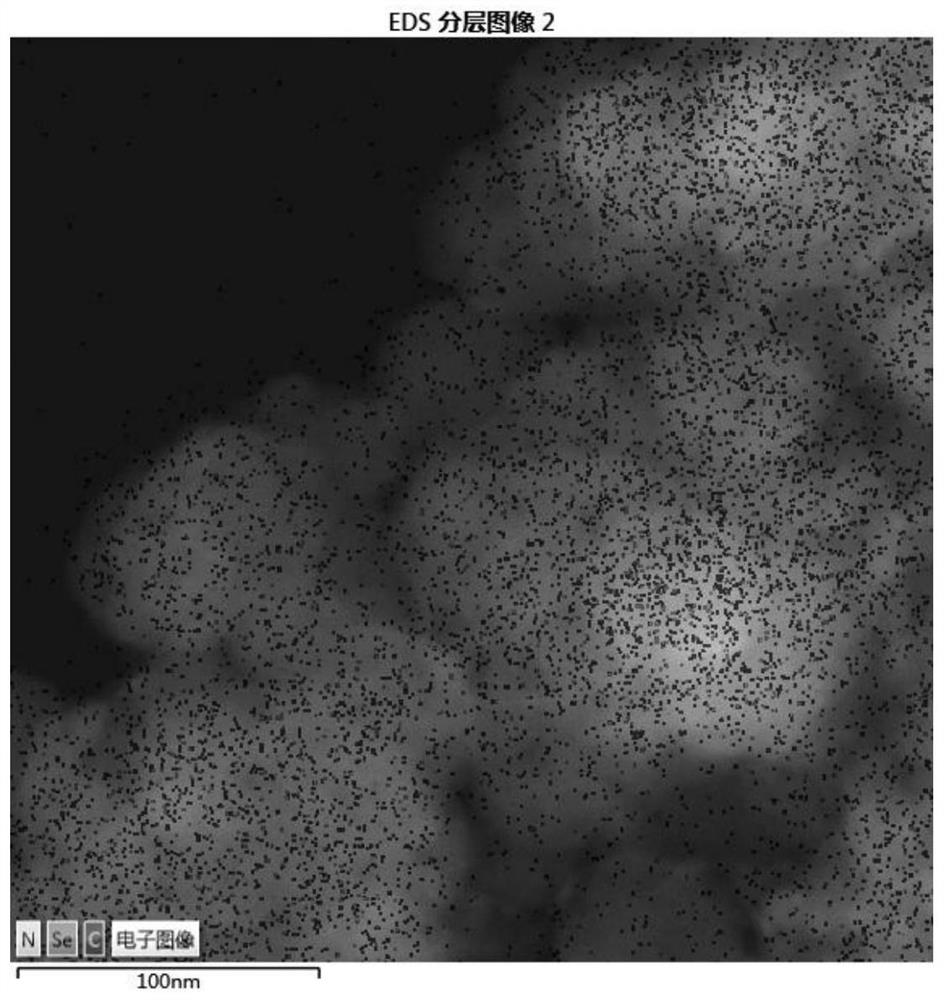

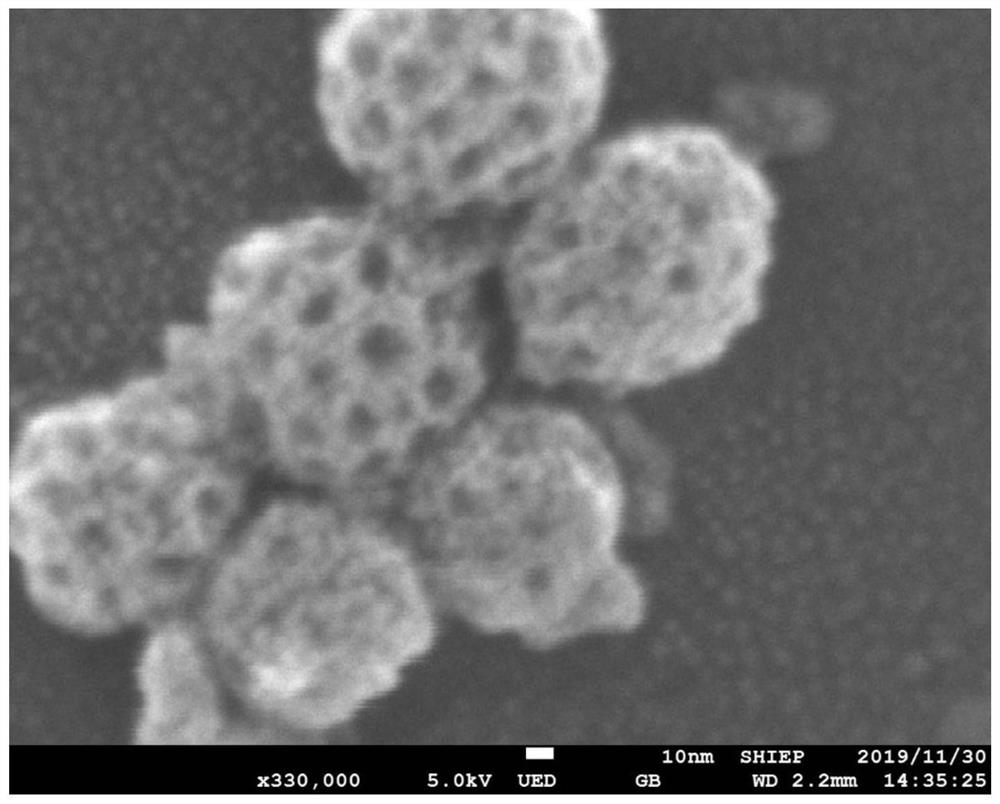

Nitrogen-selenium co-doped porous carbon sphere, sodium ion battery negative electrode material, and preparation methods and applications thereof

PendingCN112582617AAvoid etchingSimple methodNegative electrodesSecondary cellsElectrical batteryPorous carbon

The invention belongs to the technical field of material science, and provides a nitrogen-selenium co-doped porous carbon sphere, a sodium ion battery negative electrode material, a preparation methodand applications thereof. The method comprises the steps of dissolving F127 and dopamine hydrochloride in a mixed solution of water and ethanol to obtain a structure adopting a block copolymer F127 as a template, removing impurities through ethanol centrifugation washing to obtain the porous structure taking dopamine as a skeleton; calcining the precipitate, and carbonizing to obtain the nitrogen-doped porous carbon sphere; respectively placing the nitrogen-doped porous carbon sphere and selenium powder at the two ends of a porcelain boat, and calcining to obtain the nitrogen-selenium co-doped porous carbon sphere; and preparing the porous material into the battery negative electrode material, and applying the battery negative electrode material to a sodium ion battery to obtain the sodium ion battery. According to the present invention, selenium is deposited on a three-dimensional framework constructed by the porous carbon sphere, so that sodium ions have better cycle performance andrate capability under the porous framework, and metal selenium serving as a real commercial stable negative electrode material is pushed forwards by one step.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Lithium ion battery core and preparation method thereof

ActiveCN102916219AProtectImprove performanceFinal product manufactureNon-aqueous electrolyte accumulator electrodesDie castingLithium-ion battery

The invention discloses a lithium ion battery core and a preparation method thereof. The lithium ion battery core comprises a current collector, anode or cathode material, carbonizing medium, diaphragm composite material and porous polymer glue. The preparation method comprises the following steps: mixing and filling bonding agent, electrode material and conducting agent in the multi-penetration hole of the current collector; drying, die-casting and calcining; coating the porous polymer glue on the surface of the current collector after cooling; drying to obtain anode or cathode composite material; coating the porous polymer glue on the surface of the diaphragm composite material; drying; overlapping and casting the porous polymer glue, the anode or cathode composite material and the porous polymer glue to obtain the lithium ion battery core. Through adopting the above manner, according to the lithium ion battery core and the preparation method thereof provided by the invention, the cyclical stability is improved, the lithium ion battery core has better mechanical property and bending-resistant performance, the stripping phenomenon of electrode material is efficiently retarded, the communication and the electric conduction between electrode materials and isolated layers are promoted, each surface of the electrode layer is well protected, and the service life of the battery is prolonged.

Owner:江苏海基新能源股份有限公司

Electrode pad for graphene-based supercapacitor and preparation method of electrode pad

ActiveCN105679548AReduce weightImprove high rate discharge performanceHybrid capacitor electrodesHybrid/EDL manufactureFiberPorous graphene

The invention provides an electrode pad for a graphene-based supercapacitor and a preparation method of the electrode pad. The electrode pad comprises a current collector layer and an active material layer, wherein the current collector layer is a stacked graphene layer; and the active material layer is a porous graphene layer. The preparation method comprises the following steps: (1) preparing mixed slurry containing physically stripped graphene and a carbon nanotube or / and carbon fiber; (2) preparing mixed slurry containing the graphene which is prepared by a chemical oxidation method, a pore-forming agent and the carbon nanotube or / and carbon fiber; and (3) sequentially painting the mixed slurry obtained in the step (1) and the mixed slurry obtained in the step (2) on a substrate, carrying out heating in an inert atmosphere, carrying out pickling and washing in sequence, and drying and rolling the mixed slurry to obtain the electrode pad. The active material layer of the electrode pad is in tight contact with the current collector layer, so that the interface resistance and the internal resistance of a battery can be effectively reduced; and the electrode pad has high electrolyte adsorption and storage capacities and improves the high-rate discharge performance and the energy density of the capacitor.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com