Nickel-base high energy battery electrode tab welding process

A technology of battery tabs and welding process, applied in welding equipment, laser welding equipment, circuits, etc., can solve the problem of inability to solve the problem of high-rate and high-current charging and discharging, high-current startup and operation, and the inability to realize large-scale batches of nickel-based batteries. To solve problems such as low production and processing efficiency, it can enhance the ability of high-rate rapid charge and discharge, improve welding efficiency, and improve welding contact strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

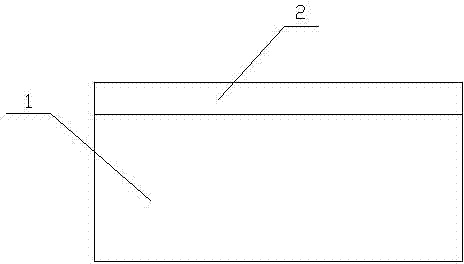

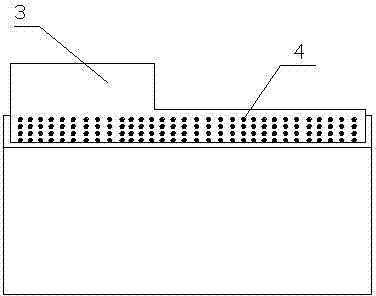

[0020] Combine below figure 1 and figure 2 , to further describe the technical solution of the present invention, but not limited to this description.

[0021] A nickel-based high-energy battery tab welding process, the steps comprising:

[0022] A. The nickel-based material strip is processed by slurry, drying, rolling, etc. to form the pole strip 1 of the nickel-based high-energy battery, and the unprocessed nickel-base strip welding zone 2 has been reserved on the pole strip 1. Easy to weld;

[0023] B. Send the pole strip 1 to the laser welding area of a laser welding machine by a mechanical positioning mechanism, a welding block for receiving the pole strip 1 is arranged in the laser welding area, and several welding blocks are arranged on the welding block. welding holes;

[0024] C. Place the tab 3 on the laser welding area with a manipulator;

[0025] D. placing the tab 3 corresponding to the welding zone 2 of the nickel base material, the width of the welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com