All-solid-state lithium battery and preparation method thereof

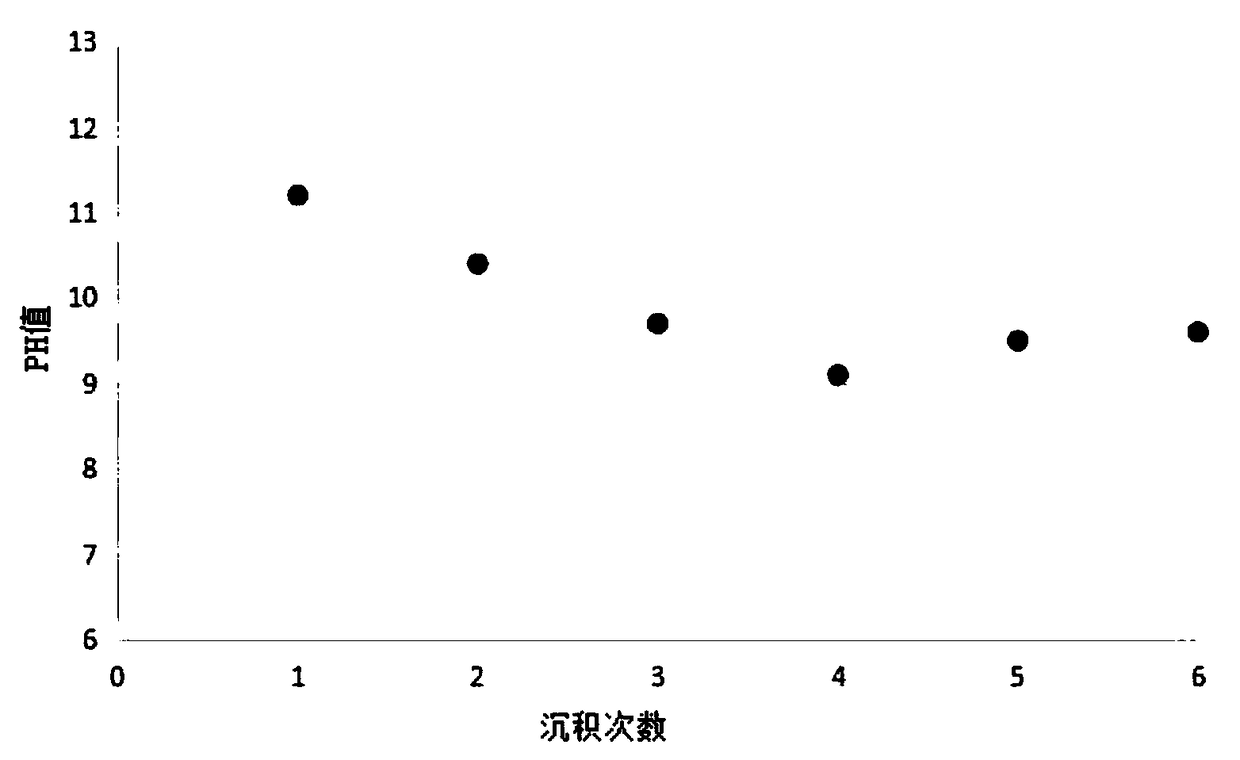

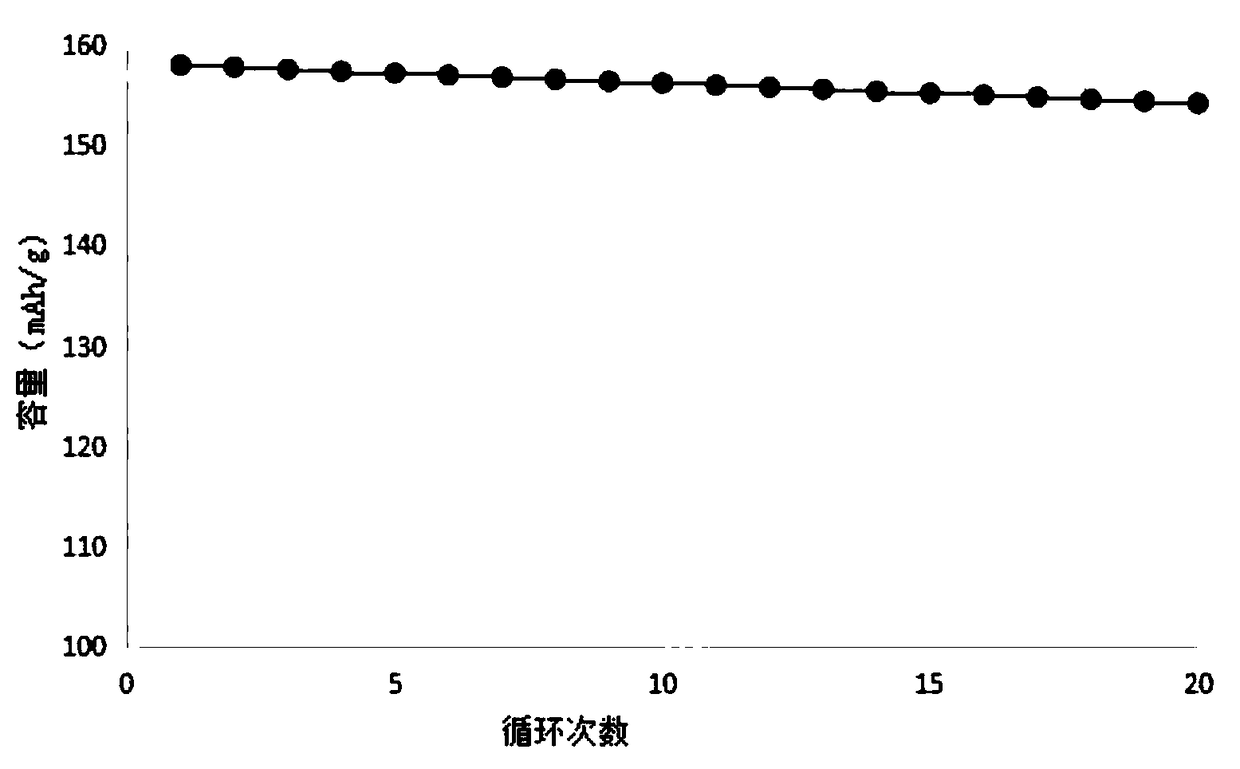

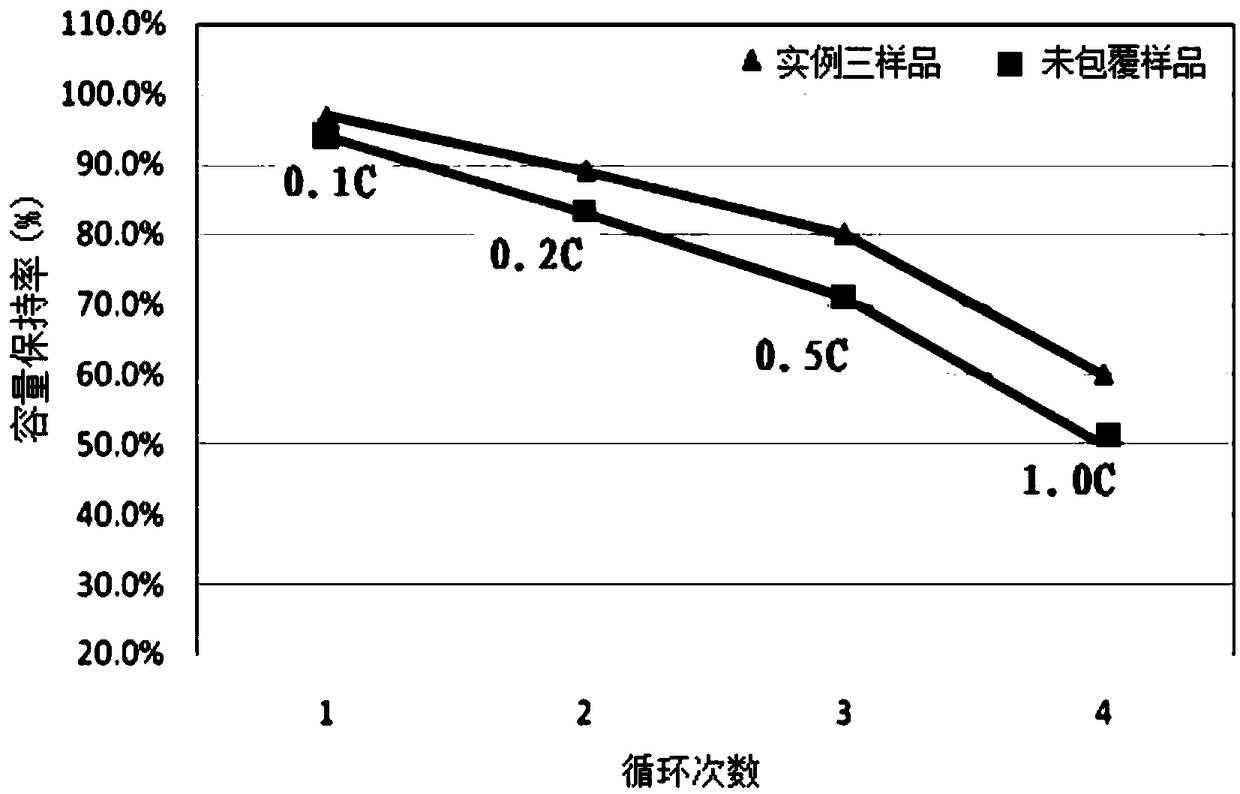

A lithium battery, all-solid-state technology, applied in the field of all-solid-state lithium battery and its preparation, can solve the problems of increased difficulty in lithium ion deintercalation, failure to reduce interface resistance, failure to reduce residual alkali, etc., to improve cycle performance and rate performance , reduce the pH value and internal resistance of the battery, and improve the effect of the rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] An embodiment of the present invention provides a method for preparing an all-solid lithium battery. The all-solid lithium battery includes a positive electrode, a negative electrode, and a solid electrolyte disposed between the positive electrode and the negative electrode. The positive electrode includes a positive electrode material. The preparation method includes Follow the steps below:

[0040] S1, forming a coating layer on the surface of the positive electrode material powder by atomic layer deposition, and the coating layer is any one of metal oxide, metal phosphate, metal fluoride or metal sulfide;

[0041] S2, sinter the positive electrode material powder with coating layer at 300-1000°C for 2-10h, and form LiX on the surface of the positive electrode material powder a Y b Solid electrolyte layer, that is, the surface is coated with LiX a Y bThe positive electrode material of the solid electrolyte layer; the sintering temperature should not exceed 1000°C. ...

Embodiment 1

[0064] 1) Put the LCO powder sample into a porous container;

[0065] 2) Put the porous container into the ALD reaction chamber, then repeatedly evacuate and replace nitrogen for at least three times;

[0066] 3) Fluidize the LCO powder sample in an atmosphere of nitrogen or argon or rotate the porous container to achieve the powder dispersion effect; wherein the fluidization pressure is 100torr;

[0067] 4) Vacuumize and heat the reaction chamber to bring the temperature to 400 Kelvin, keep the LCO powder sample at the set temperature for 25 minutes, and the air pressure in the reaction chamber is 10 mTorr;

[0068] 5) Open the air outlet valve, pulse the cleaning air, and clean for 15 seconds;

[0069] 6) Close the outlet valve, pulse gaseous trimethylaluminum for 0.01 second, and then keep it for 60 seconds;

[0070] 7) Then open the gas outlet valve, pulse sweeping gas argon, and sweep for 1 minute; close the gas outlet valve, vacuumize, and remove excess reaction by-pro...

Embodiment 2

[0077] 1) NMC powder sample is put into porous container;

[0078] 2) Put the porous container into the ALD reaction chamber, then repeatedly evacuate and replace nitrogen for at least three times;

[0079] 3) Fluidize the NMC powder sample under an atmosphere of nitrogen or argon or achieve the powder dispersion effect by rotating the porous container; wherein the fluidization pressure is 50torr;

[0080] 4) evacuate and heat the reaction chamber to bring the temperature to 450 Kelvin, keep the NMC powder sample at the set temperature for 5 minutes, and the air pressure in the reaction chamber is 10 millitorr;

[0081] 5) Open the air outlet valve, pulse sweeping gas nitrogen, and sweep for 3s;

[0082] 6) Close the outlet valve, pulse gaseous titanium chloride for 10 seconds, and then keep for a period of 1 second;

[0083] 7) Then open the air outlet valve, pulse sweeping gas nitrogen, and sweep for 0.1 minute; close the air outlet valve, vacuumize, and remove excess reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com