Lithium ion battery core and preparation method thereof

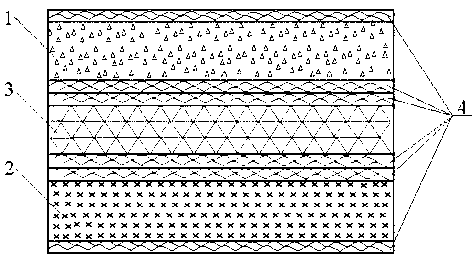

A lithium-ion battery and cell technology, which is applied in the field of new energy materials, can solve the problem that parameters such as battery internal resistance, life, energy density and capacity cannot be substantially improved, and limit the structure and shape of curly batteries, small curvature changes, etc. problems, to achieve the effect of slowing the peeling phenomenon, improving cycle stability and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Dissolve 7g of polyvinylidene fluoride in 180g of N-methylpyrrolidone, fully stir and dissolve to form polyvinylidene fluoride glue with a certain concentration;

[0027] (2) Dissolve 7g of polyvinylidene fluoride binder in 180g of N-methylpyrrolidone, stir and dissolve to form a colloidal solution, then add 140g of LiFePO 4and 2.8g superfine carbon powder into the colloidal solution, and stir evenly with a mixer to make a paste-like positive electrode slurry. Fill the obtained positive electrode slurry into the multi-permeable pores of the current collector with a porosity of 90% by using the scraping method. The metal foam is made of aluminum material, and the current collector filled with the positive electrode material is placed in an oven at a temperature of 110°C. Dry for 4h. Take out and die-cast with a calender, with a thickness of 300 μm, wherein the thickness is determined according to the size of the battery. The die-cast material was calcined at 700° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com