High-rate and safe cylindrical lithium ion battery ad manufacturing method thereof

A lithium ion battery and a manufacturing method technology, which are applied in the manufacture of secondary batteries, cylindrical shell batteries/batteries, secondary batteries, etc., can solve the problem that the diaphragm cannot be completely eliminated, the perimeter of the punching edge of the positive and negative plates is lengthened, and the battery Problems such as large internal resistance, to avoid internal short circuit of the battery, reduce powder drop and burr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

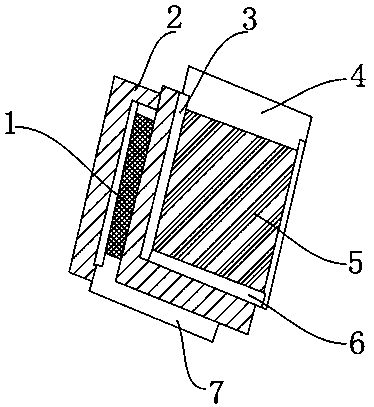

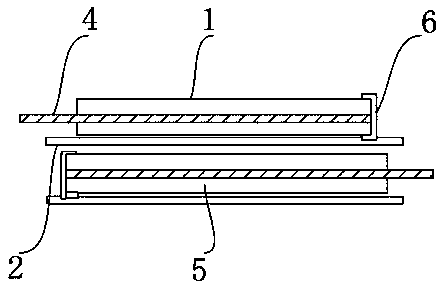

[0023] Step 1: Positive electrode sheet production: 93% by weight of nanoscale lithium iron phosphate, 2.5% carbon nanotube conductive agent 1 and 1.5% carbon powder conductive agent 2 and 3.0% PVDF binder are dissolved in N-formazan The positive electrode slurry was made in base pyrrolidone, and the 20µm thick carbon-coated aluminum foil was used as the current collector, and the positive electrode slurry was pressed figure 1 The coating shown is coated on the current collector and dried. After rolling, the side of the coating aligned with the carbon-coated aluminum foil is dipped in the polymer glue PVDF, taken out and dried; the PVDF binder has a molecular weight of 1 million The polyvinylidene fluoride polymer above.

[0024] Step 2: Negative electrode sheet production: Dissolve 10% graphite negative electrode material, 1.5% conductive graphite and 3.5% binder in deionized water to make negative electrode slurry with 12µm thick carbon coating Copper foil is used as a curr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com