Lithium-ion secondary battery

A secondary battery, lithium ion technology, used in secondary batteries, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of no protection device, high short-circuit power, and inability to completely remove impurities or particles, and achieve compensation for irreversible capacity. Loss, reduce the formation of lithium dendrites, and avoid the effect of short circuit inside the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

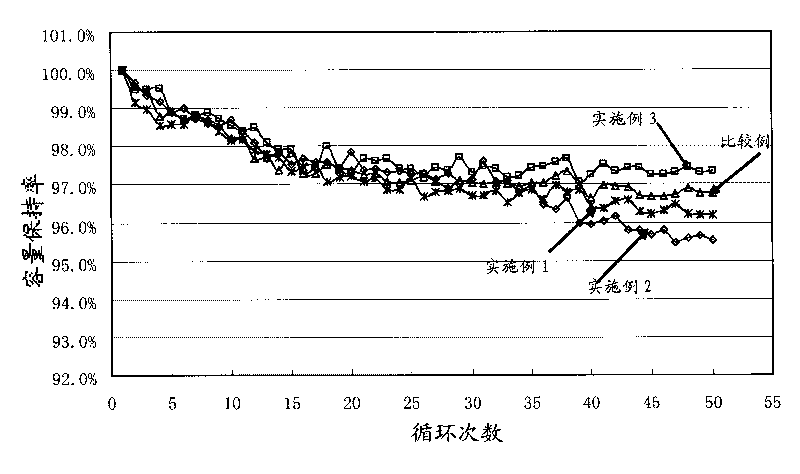

Embodiment 1

[0043] The preparation of the positive electrode plate: Lithium nickel cobalt manganese oxide (LiNiCoMnO 2 ), conductive carbon black (Super-P), polyvinylidene fluoride (PVDF) and N,N-dimethylpyrrolidone (NMP) at a weight ratio of 94:2:4, mix them evenly to obtain a slurry for coating the positive electrode sheet , The viscosity can be adjusted by NMP during the stirring process. Then, the slurry was uniformly coated with a certain width on both sides of a 14 μm thick positive current collector (aluminum foil), and then cold pressed and sliced (that is, the pole pieces were cut and cut to the required size) to prepare positive electrode sheets.

[0044] The preparation of the negative electrode sheet: the artificial graphite, conductive carbon black (Super-P), sodium carboxymethyl cellulose (water-based binder, CMC), and styrene butadiene rubber (Styrene Butadiene Rubber, SBR) at a weight ratio of 95:1 :1:3 is mixed with deionized water and stirred evenly to obtain a slurry for...

Embodiment 2

[0048] Preparation of the positive electrode plate: Lithium nickel cobalt manganate (LiNiCoMnO 2 ), conductive carbon black (Super-P), and polyvinylidene fluoride (PVDF) are mixed with N,N-dimethylpyrrolidone (NMP) at a weight ratio of 94:2:4, and stir to obtain a slurry for coating the positive electrode sheet. , The viscosity can be adjusted by NMP during the stirring process. Then, the slurry is uniformly coated with a certain width on both sides of a 14 μm thick positive current collector (aluminum foil), and then cold pressed and sliced (ie, the pole pieces are cut and cut to the required size) to prepare positive electrode sheets.

[0049] The preparation of the negative electrode sheet: the artificial graphite, conductive carbon black (Super-P), sodium carboxymethyl cellulose (water-based binder, CMC), and styrene butadiene rubber (Styrene Butadiene Rubber, SBR) at a weight ratio of 95:1 :1:3 is mixed with deionized water and stirred evenly to obtain a slurry for coating...

Embodiment 3

[0053] The preparation of the positive electrode plate: Lithium nickel cobalt manganese oxide (LiNiCoMnO 2 ), conductive carbon black (Super-P), and polyvinylidene fluoride (PVDF) are mixed with N,N-dimethylpyrrolidone (NMP) at a weight ratio of 94:2:4, and stir to obtain a slurry for coating the positive electrode sheet. , The viscosity can be adjusted by NMP during the stirring process. Then, the slurry is uniformly coated with a certain width on both sides of a 14 μm thick positive current collector (aluminum foil), and then cold pressed and sliced (ie, the pole pieces are cut and cut to the required size) to prepare positive electrode sheets.

[0054] The preparation of the negative electrode sheet: the artificial graphite, conductive carbon black (Super-P), sodium carboxymethyl cellulose (water-based binder, CMC), and styrene butadiene rubber (Styrene Butadiene Rubber, SBR) at a weight ratio of 95:1 :1:3 is mixed with deionized water and stirred evenly to obtain a slurry f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com