Solid electrolyte composite layer and lithium ion battery

A solid-state electrolyte and lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve the problems of large grain boundary resistance, poor physical contact, and low ionic conductivity at room temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

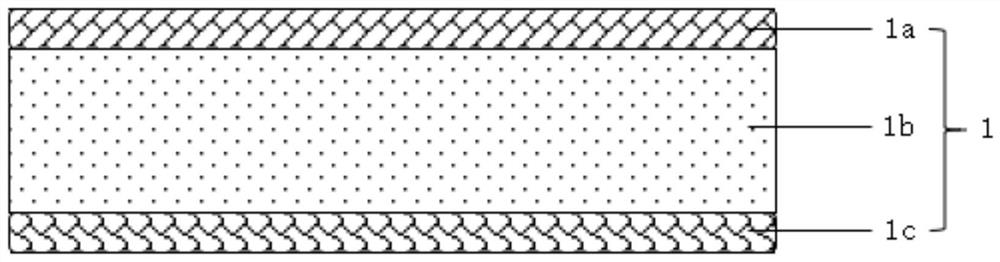

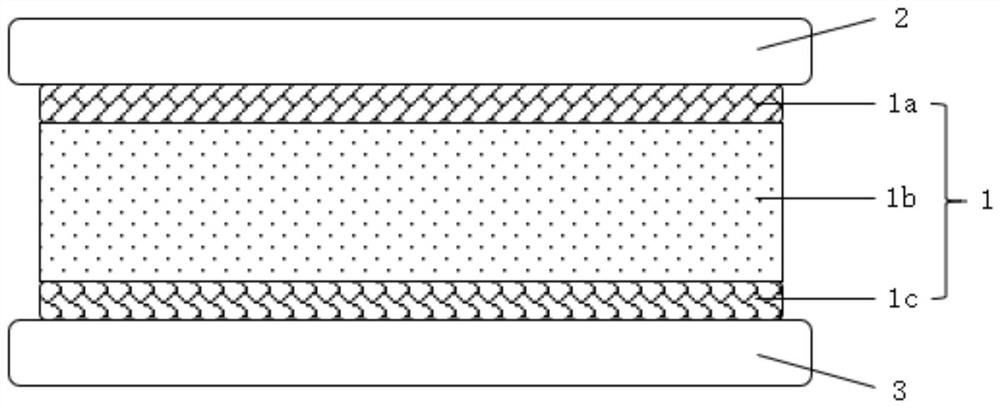

[0070] The solid electrolyte composite layer and lithium-ion battery structure of this embodiment refer to figure 1 with figure 2 , the preparation method is as follows:

[0071] 1. Preparation of solid electrolyte composite layer 1

[0072] 1) According to the traditional solid-state sintering method, the NASICON-type electrolyte Li 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3 , after drying, put it into a mold and press it into a thin sheet, sinter at 900°C for 6 hours and then cool to obtain the intermediate solid electrolyte layer 1b.

[0073] 2) Polyacrylonitrile (PAN), LiClO 4 Dissolve in DMF according to the mass ratio of 2:1, stir evenly at a rotating speed of 600rpm to obtain a slurry near the positive electrode side with a solid content of 11%, and apply the positive electrode side slurry to the middle solid electrolyte layer 1b near the positive electrode sheet 2 On the functional surface, fully vacuum-dry the positive electrode side solid electrolyte 1a at 80°C for 10h, wh...

Embodiment 2

[0080] The solid electrolyte composite layer and lithium-ion battery structure of this embodiment refer to figure 1 with figure 2 , the preparation method is as follows:

[0081] 1. Preparation of solid electrolyte composite layer 1

[0082] 1) The commercially available perovskite electrolyte Li 3x La 2 / 3-x TiO 3 (x=0.11) after drying, put it into a mold and press it into a thin sheet, sinter at 950° C. for 4 hours and then cool to obtain the intermediate solid electrolyte layer 1b.

[0083] 2) Dissolve polycaprolactone (PCL), LiDTI, and succinonitrile in THF at a mass ratio of 7:3:1.1, and stir evenly at 400 rpm to obtain a slurry near the positive electrode with a solid content of 23%, which is close to the positive electrode. The side slurry is coated on the functional surface of the intermediate solid electrolyte layer 1b close to the positive electrode sheet 2, and fully vacuum-dried at 50°C for 3 hours to obtain the solid electrolyte 1a near the positive electrode...

Embodiment 3

[0090] The solid electrolyte composite layer and lithium-ion battery structure of this embodiment refer to figure 1 with figure 2 , the preparation method is as follows:

[0091] 1. Preparation of solid electrolyte composite layer 1

[0092] 1) According to the traditional solid-state sintering method, the garnet-type electrolyte Li 6.6 La 3 Zr 1.6 Ta 0.4 o 12 , after drying, put it into a mold and press it into a thin sheet, sinter at 1200°C for 3 hours and then cool to obtain the intermediate solid electrolyte layer 1b.

[0093] 2) Polyvinylene carbonate (PVCA) and LiFSI were dissolved in chloroform according to the mass ratio of 5:3, and stirred evenly at 900rpm to obtain a slurry near the positive side with a solid content of 12%. The material is coated on the functional surface of the intermediate solid electrolyte layer 1b close to the positive electrode sheet 2, and fully vacuum-dried at 25°C for 6 hours to obtain the solid electrolyte layer 1a near the positive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com