Preparation method of titanium-graphene composite material with matched reinforced-plasticity

A composite material and graphene technology, applied in chemical instruments and methods, carbon compounds, metal processing equipment, etc., can solve problems such as sacrificial plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

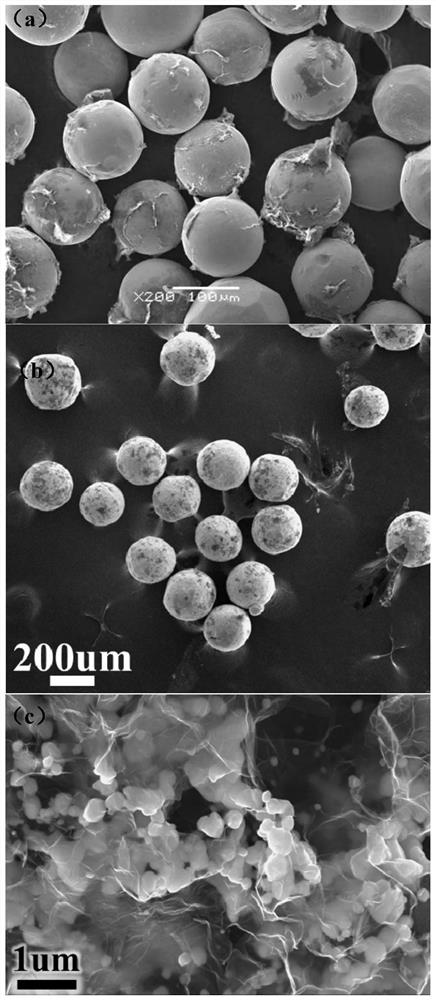

Method used

Image

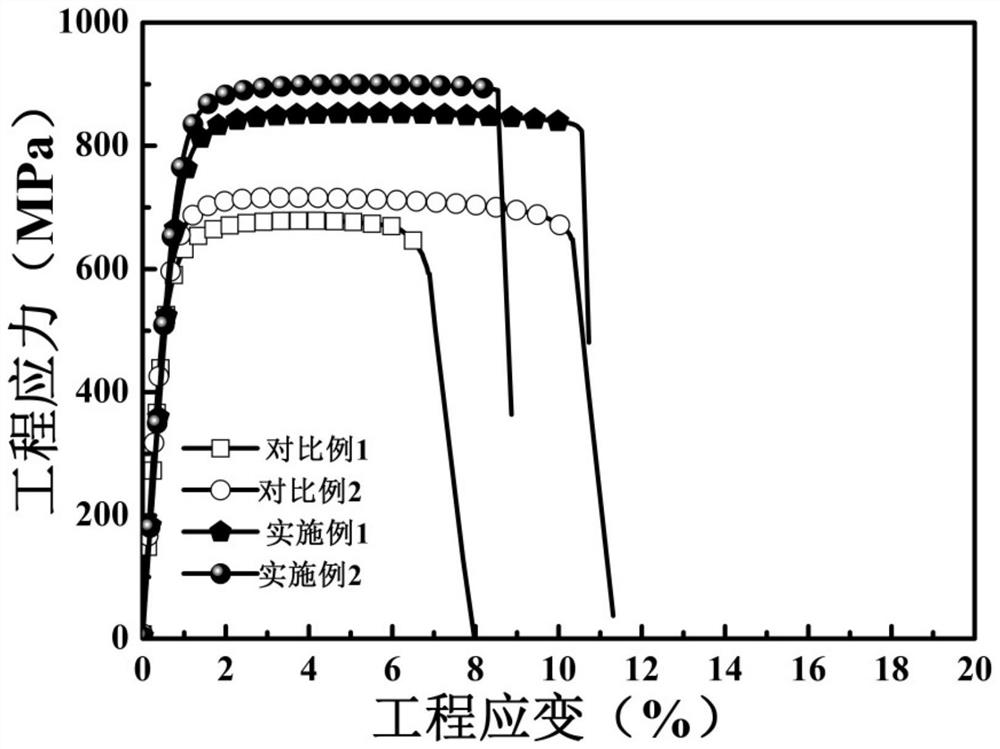

Examples

Embodiment 1

[0015] (1) Preparation of eutectoid Cu-modified graphene nanopowders (Cu@rGO)

[0016] 1) Disperse 0.5 g of graphene oxide in a mixed solvent of 300 mL of deionized water and 200 mL of alcohol, and disperse with ultrasonic stirring for 3 hours to form a uniform graphene oxide dispersion;

[0017] 2) Disperse 10g of copper chloride salt in 100mL of deionized water, stir and disperse until the solution has no suspended matter, forming a metal Cu ion salt solution;

[0018] 3) Add the graphene oxide dispersion liquid obtained in step 1) dropwise to the metal ion salt solution obtained in step 2), stir ultrasonically, stir for 2h, and add 1mL glacial acetic acid dropwise to improve the dispersibility; after stirring, add Add 0.2mol / L sodium hydroxide solution to adjust the pH to above 10, then add 30mL ascorbic acid with a concentration of 0.56mol / L and stir until the solution is uniform;

[0019] 4) Put the mixed solution obtained in step 3) into a 90° C. water bath for heating ...

Embodiment 2

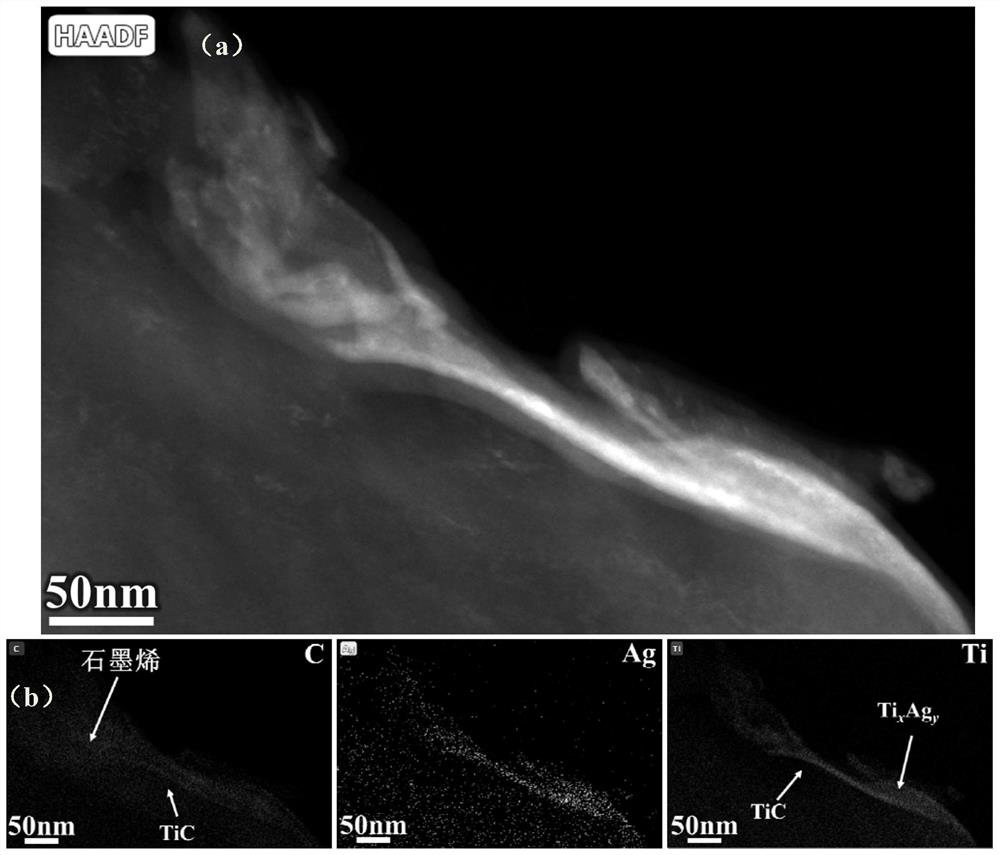

[0029] (1) Preparation of eutectoid metal element Ag-modified graphene nanopowder (Ag@rGO)

[0030] 1) Disperse 1 g of graphene oxide in a mixed solvent of 300 mL of deionized water and 200 mL of alcohol, and disperse with ultrasonic stirring for 3.5 hours to form a uniform graphene oxide dispersion;

[0031] 2) Disperse 10 g of silver nitrate salt in 100 mL of deionized water, stir and disperse until the solution has no suspended matter, and form a metal Ag ion salt solution;

[0032] 3) The graphene oxide dispersion obtained in step 1) is added dropwise to the metal ion salt solution obtained in step 2), stirred ultrasonically for 2 h, while adding 3 mL of glacial acetic acid dropwise to improve dispersibility; after stirring, add Add 0.2mol / L sodium hydroxide solution to adjust the pH to above 10, then add 30mL ascorbic acid with a concentration of 0.56mol / L and stir until the solution is uniform;

[0033]4) Put the mixed solution obtained in step 3) into a 90° C. water ba...

Embodiment 3

[0043] (1) Preparation of eutectoid metal element Fe-modified graphene nanopowder (Fe@rGO)

[0044] 1) Disperse 0.1 g of graphene oxide in a mixed solvent of 300 mL of deionized water and 200 mL of alcohol, and disperse with ultrasonic stirring for 5 hours to form a uniform graphene oxide dispersion;

[0045] 2) Disperse 30 g of ferrous chloride salt in 100 mL of deionized water, stir and disperse until the solution has no suspended matter, and form a metal Fe ion salt solution;

[0046] 3) The graphene oxide dispersion obtained in step 1) is added dropwise to the metal ion salt solution obtained in step 2), ultrasonically stirred, stirred for 2h, and 5mL of glacial acetic acid is added dropwise at the same time to improve dispersibility; after stirring, add to the mixed solution Add 0.2mol / L sodium hydroxide solution to adjust the pH to above 10, then add 30mL ascorbic acid with a concentration of 0.56mol / L and stir until the solution is uniform;

[0047] 4) Put the mixed so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com