Battery electrolyte additive, and electrolyte and lithium ion battery using additive

A technology of electrolyte additive and lithium-ion battery, applied in the field of electrolyte and lithium-ion battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

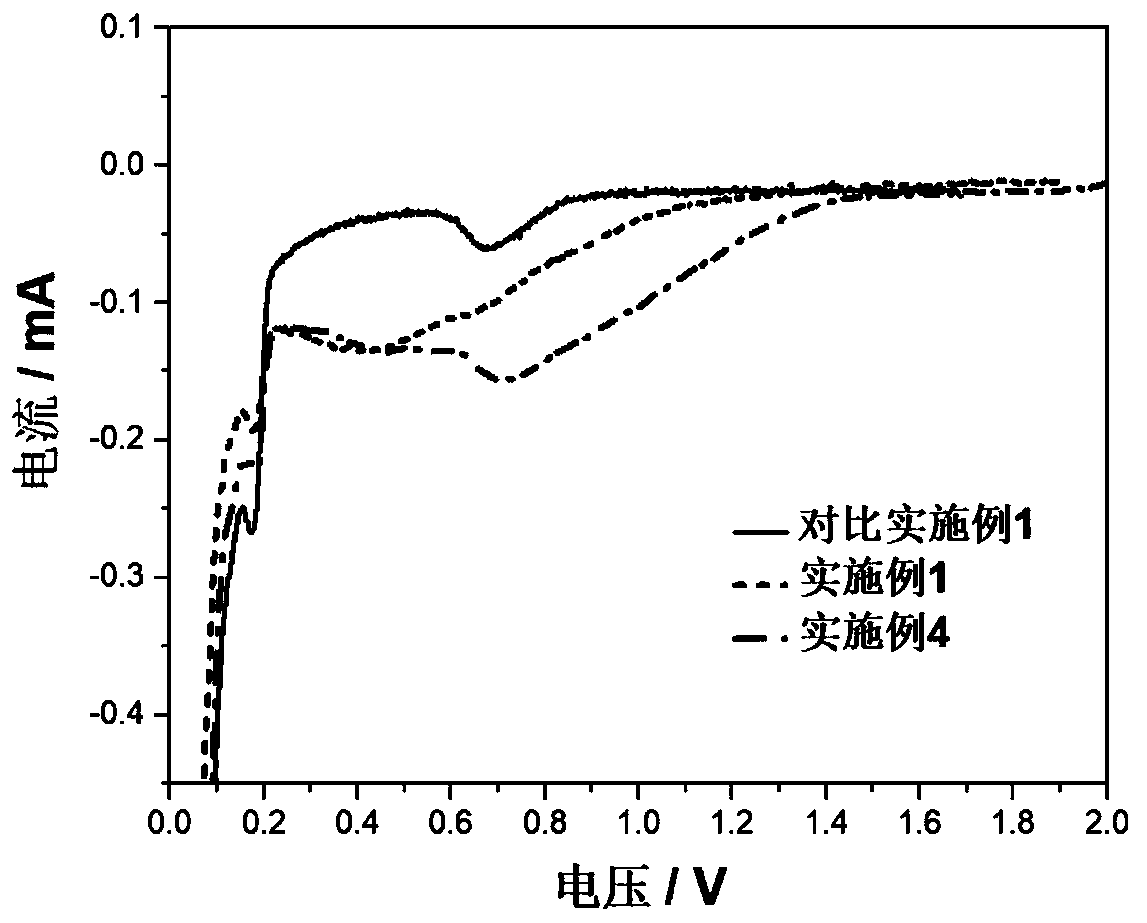

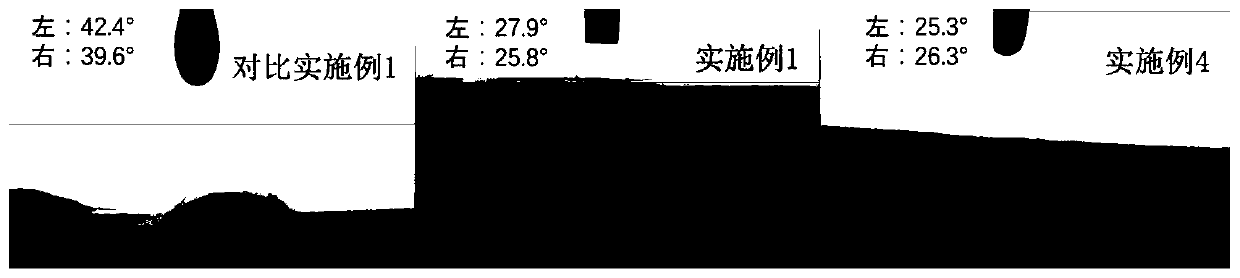

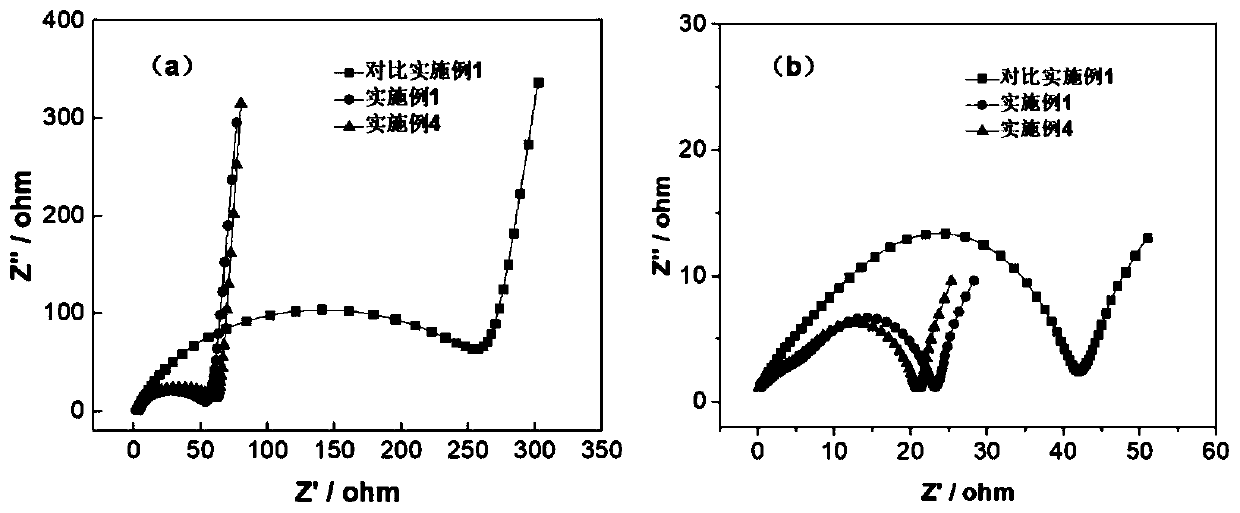

Embodiment 1

[0043] (1) Preparation of electrolyte

[0044]Mix ethylene carbonate (EC), diethyl carbonate (DEC) and ethyl methyl carbonate (EMC) according to the mass ratio of EC:DEC:EMC=3:2:5, and then add lithium hexafluorophosphate (LiPF 6 ) to a molar concentration of 1mol / L, and then add 1% lithium hexafluoroisopropoxide based on the total mass of the electrolyte.

[0045] (2) Preparation of positive plate

[0046] Mix positive electrode active material lithium nickel cobalt manganese oxide LiNi according to mass ratio 93:4:3 0.5 co 0.2 mn 0.3 o 2 , conductive carbon black Super-P and binder polyvinylidene fluoride (PVDF), and then disperse them in N-methyl-2-pyrrolidone (NMP) to obtain positive electrode slurry. The positive electrode slurry is uniformly coated on both sides of the aluminum foil, dried, calendered and vacuum dried, and the aluminum lead-out wire is welded with an ultrasonic welder to obtain the positive electrode plate.

[0047] (3) Preparation of negative plat...

Embodiment 2

[0058] Replace the 1% lithium hexafluoroisopropoxide in the electrolyte prepared in Example 1 with 0.05% lithium hexafluoroisopropoxide, and prepare the electrolyte, positive plate and negative plate according to the same operating conditions as in Example 1 , batteries, and conduct liquid injection and formation of batteries and cycle performance tests of batteries. The obtained room temperature cycle performance data are shown in Table 1.

Embodiment 3

[0060] Replace the 1% lithium hexafluoroisopropoxide in the electrolyte prepared in Example 1 with 0.1% lithium hexafluoroisopropoxide, and prepare the electrolyte, positive plate, and negative plate according to the same operating conditions as in Example 1 , batteries, and conduct liquid injection and formation of batteries and cycle performance tests of batteries. The obtained room temperature cycle performance data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com