Patents

Literature

61results about How to "Raise the reduction potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

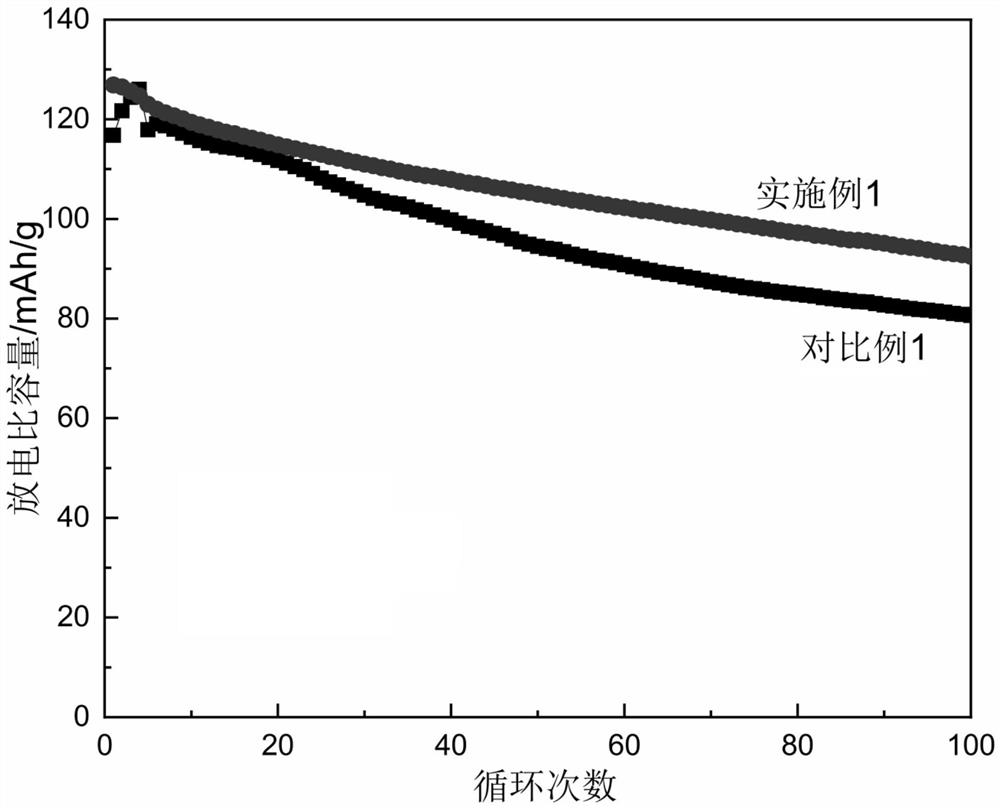

Novel lithium salt additive and non-aqueous electrolyte for lithium-ion batteries

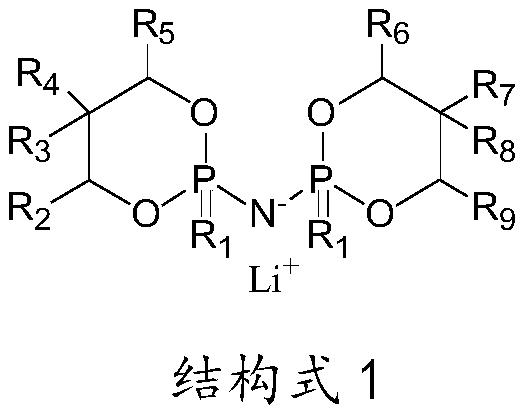

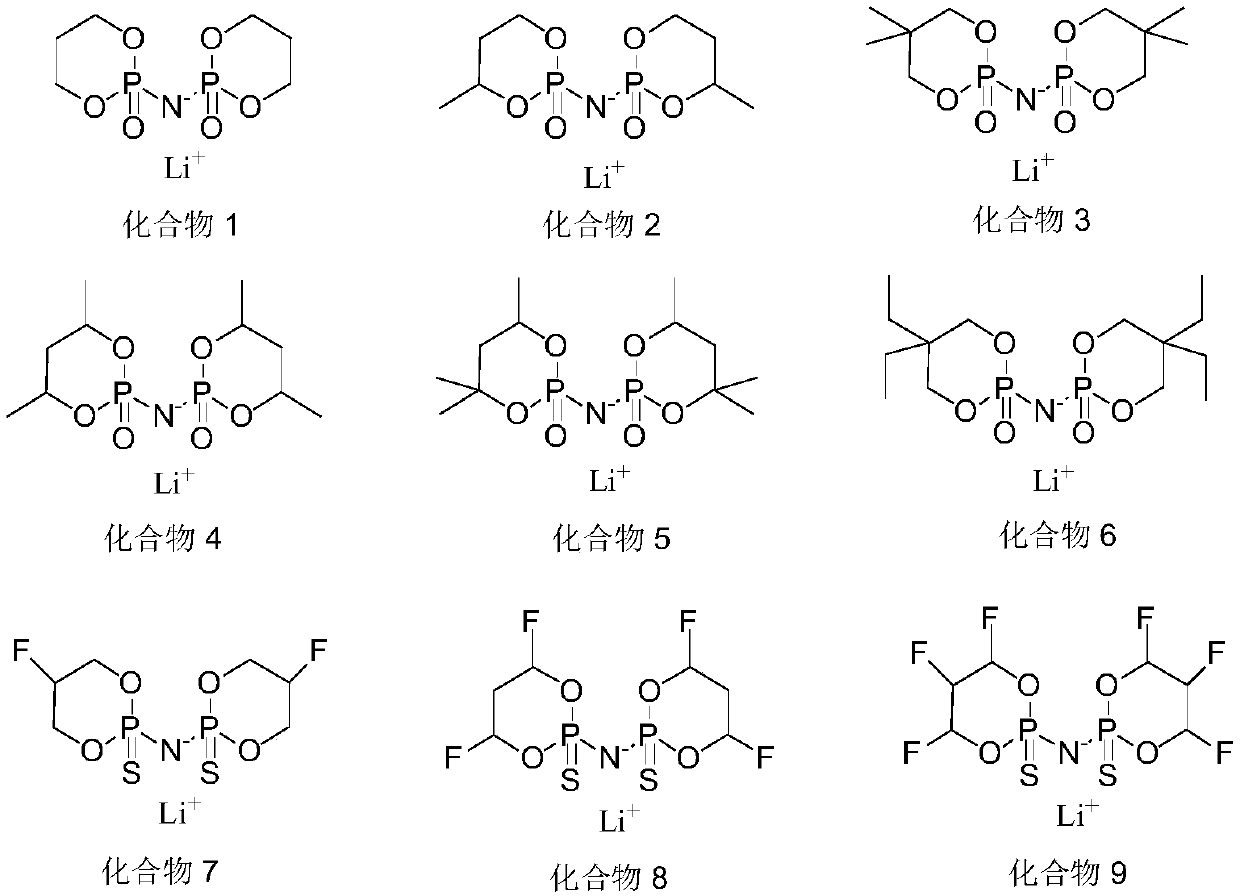

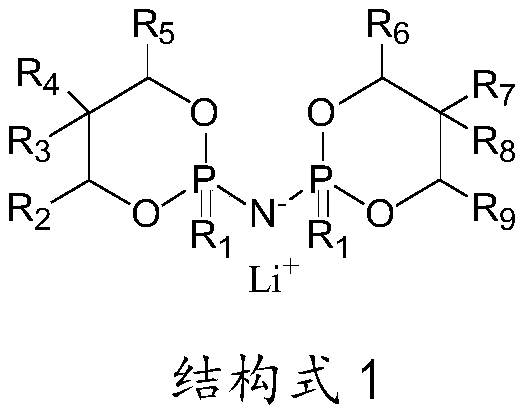

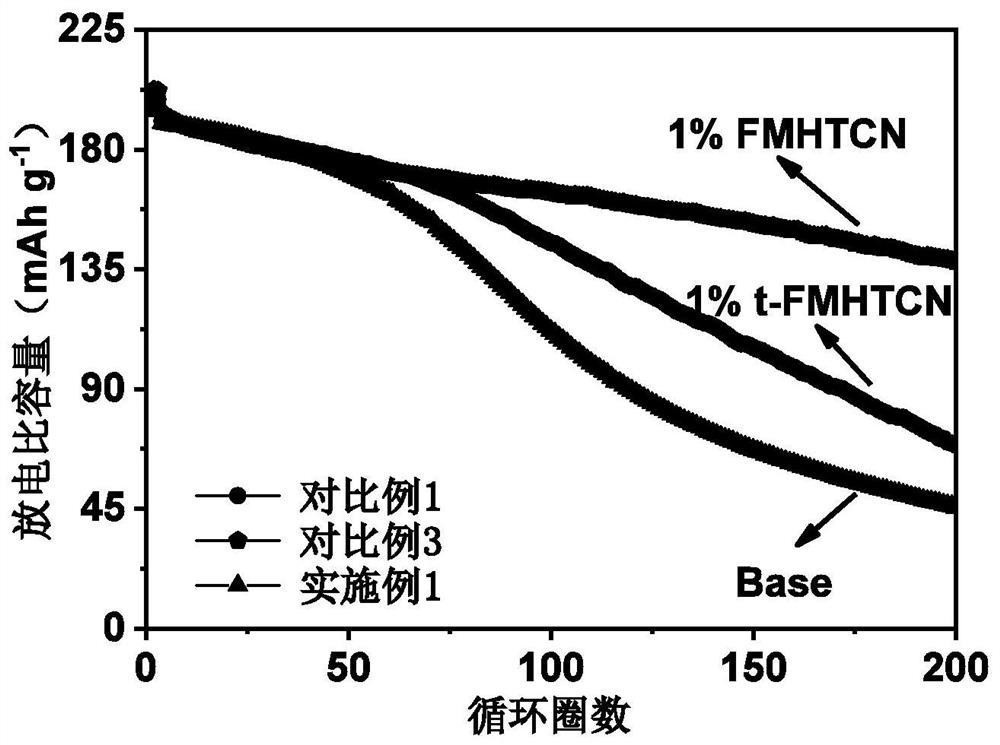

ActiveCN110299562ALower oxidation potentialLower reduction potentialSecondary cellsOrganic electrolytesOrganic solventPhosphate

The invention provides a lithium-ion battery electrolyte, which is composed of an organic solvent, lithium salt, a novel additive and other conventional additives. The novel additive is a dicyclophosphimide lithium salt or lithium dicyclothiophosphimide lithium salt compound shown in a structural formula 1. The compound shown in structural formula 1 of the invention has a high reduction potentialwhen used as an electrolyte additive, so that the novel additive can participate in the formation of a solid electrolyte film on the surface of a negative electrode in preference to the conventional additives and improve the composition of the interfacial film. Because the additive has a cyclic phosphate structure, the phosphorus-oxygen bond is easy to break under high voltage, and the additive can participate in the formation of a positive electrolyte film and improve the interface stability of the positive electrode material. Therefore, the introduction of the additive can improve the high temperature performance, low temperature performance and cycle performance of lithium-ion batteries.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

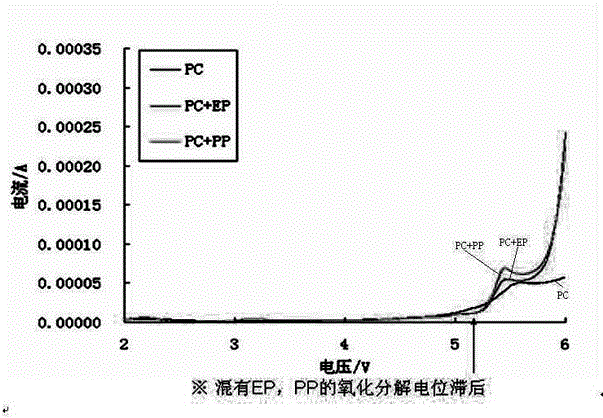

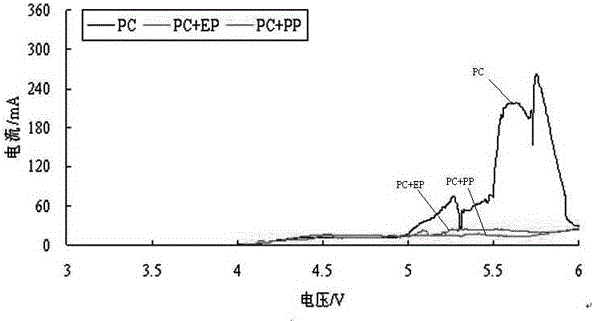

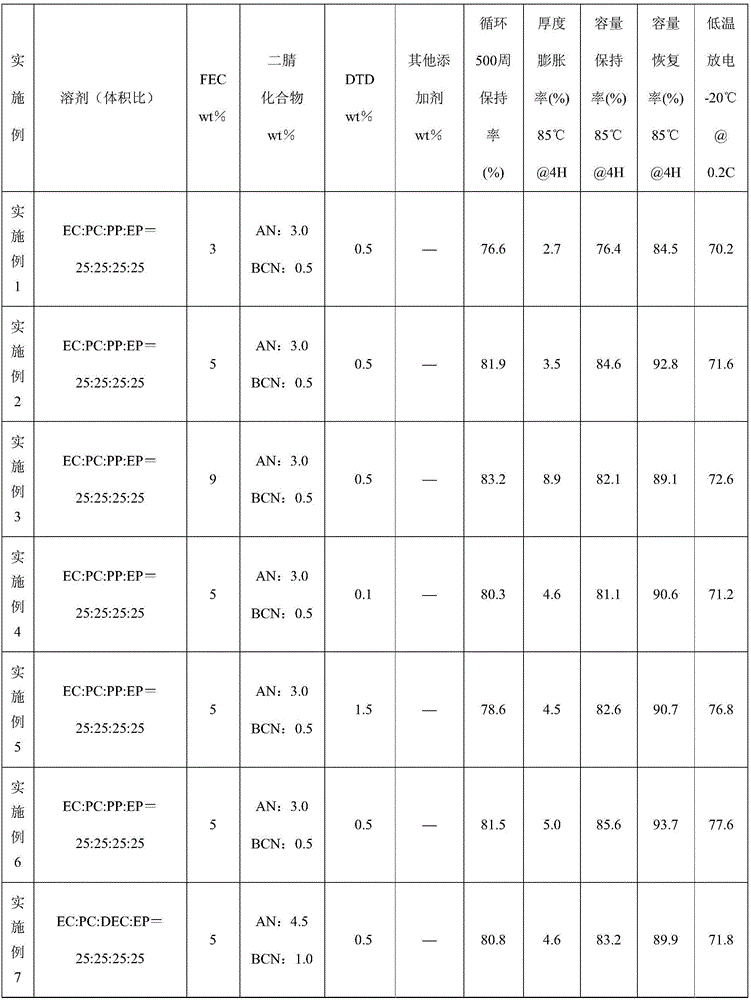

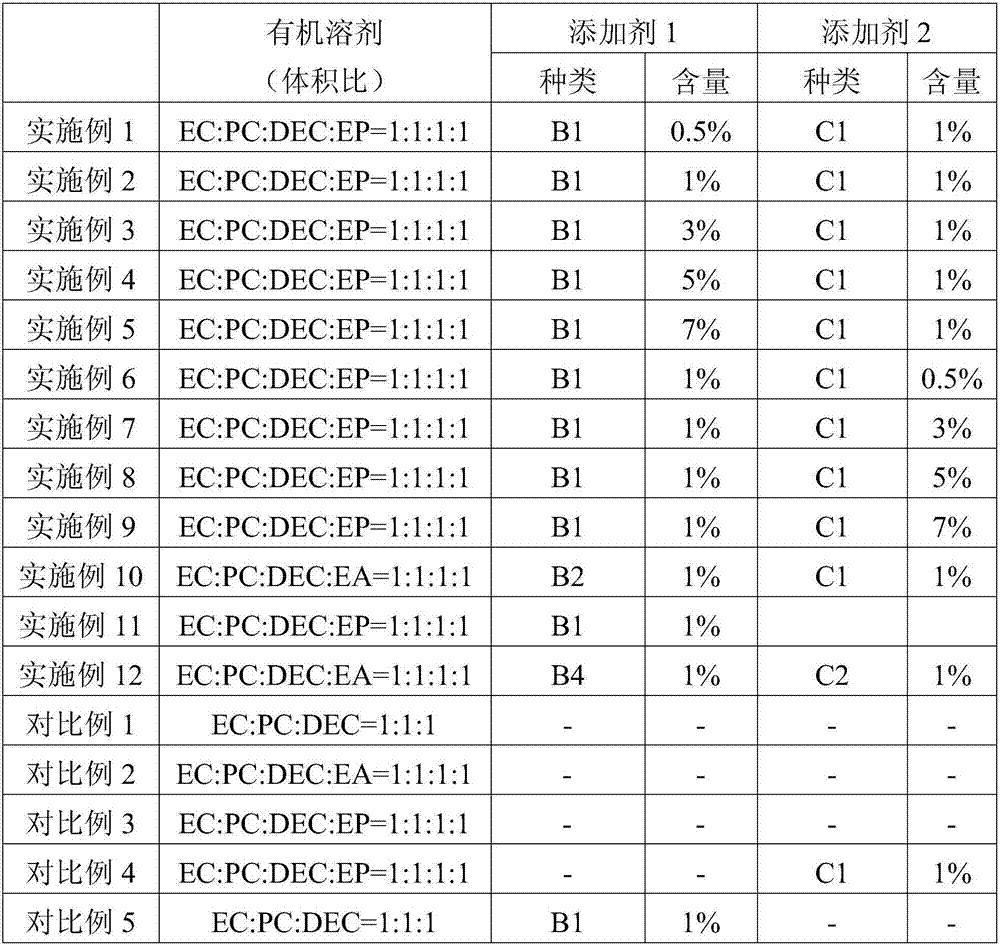

PC (Propylene Carbonate)-based high-voltage electrolyte and lithium ion battery

InactiveCN106159330APromote circulationAvoid co-insertionSecondary cellsHigh temperature storageElectrical battery

The invention provides PC (Propylene Carbonate)-based high-voltage electrolyte. The PC-based high-voltage electrolyte comprises a non-aqueous solvent, and a lithium salt and an additive which are dissolved into the non-aqueous solvent; the non-aqueous solvent comprises propylene carbonate (PC) and linear carboxylate; the mass percent content of the propylene carbonate (PC) in the electrolyte is 15%-50%; the additive comprises fluoroethylene carbonate, ethylene sulfate and a dinitrile compound. A solvent system and the additive are optimally combined and used to generate a cooperative effect and are used for a lithium ion battery, so that good cycle life, low-temperature discharging properties and high-temperature storage properties of the battery can still be kept under high voltage.

Owner:GUANGZHOU TINCI MATERIALS TECH

Modifying agent for bottom material of pond for breeding aquatic products

InactiveCN101050365ARaise the reduction potentialIncrease the oxygen content of the bottom of the poolClimate change adaptationPisciculture and aquariaChemistryDisease

This invention relates to a sediment improver for aquaculture pond. The sediment improver comprises sodium percarbonate, humus soil, poly (ferric sulfate), attapulgite soil, and zeolite powder. The sediment improver is produced by: weighing the above components, packaging sodium percarbonate alone, mixing the other components, packaging, and sealing the two packages in a big package. The net content of each big package is 1 kg. The sediment improver has such advantages as convenient usage, no environmental influence, low usage amount, rapid acting and stable effect. The sediment improver can obviously reduce the contents of harmful substances in pond bottom, improve the environmental quality of pond sediment and the living condition of aquaculture creatures, prevent diseases and abrupt death of aquaculture creatures, and increase the yield and quality of aquaculture creatures.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

Pure cotton fabric reduced dye dyeing method

InactiveCN104047186AImprove reducibilityMaintain resilienceBleaching apparatusDyeing processPolymer scienceDioxyethylene Ether

The invention relates to a pure cotton fabric reduced dye dyeing method which comprises the following steps: (1) textile preparation; (2) textile pretreatment; (3) preparation of reduced dye leuco body solution; (4) dip dyeing of reduced dye; (5) soap boiling and (6) after-finishing. The reduced dye leuco body solution is prepared by the following raw materials: 1-10g / L thiourea dioxide, 2-5g / L of iso-tridecanol polyoxyethylene ether, 1-2g / L of glucose, 2-5g / L of sodium silicate, and 1-2g / L of sodium sulfide. The K / S value of the dyed textile is obviously improved.

Owner:福建金苑服饰有限公司

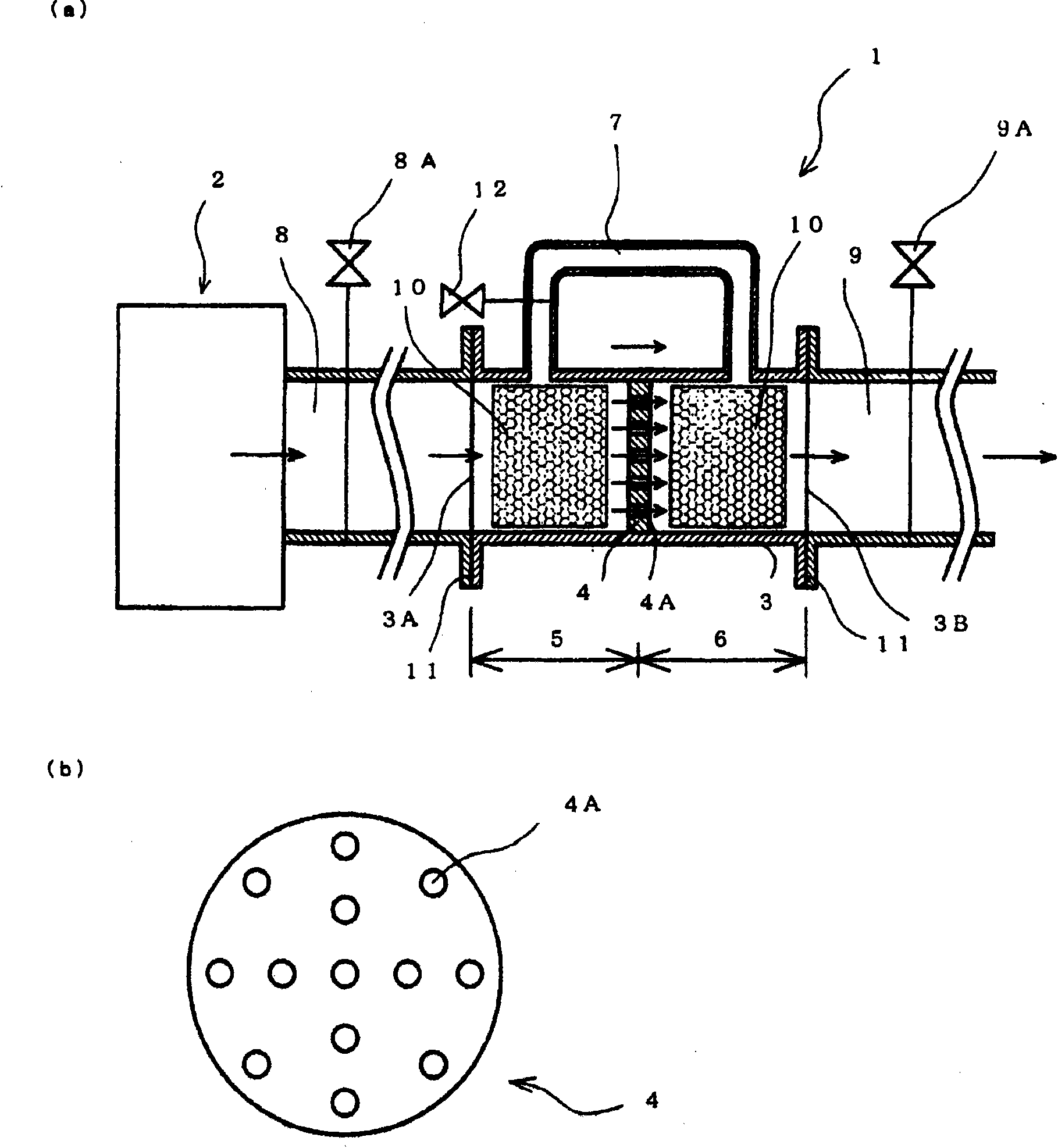

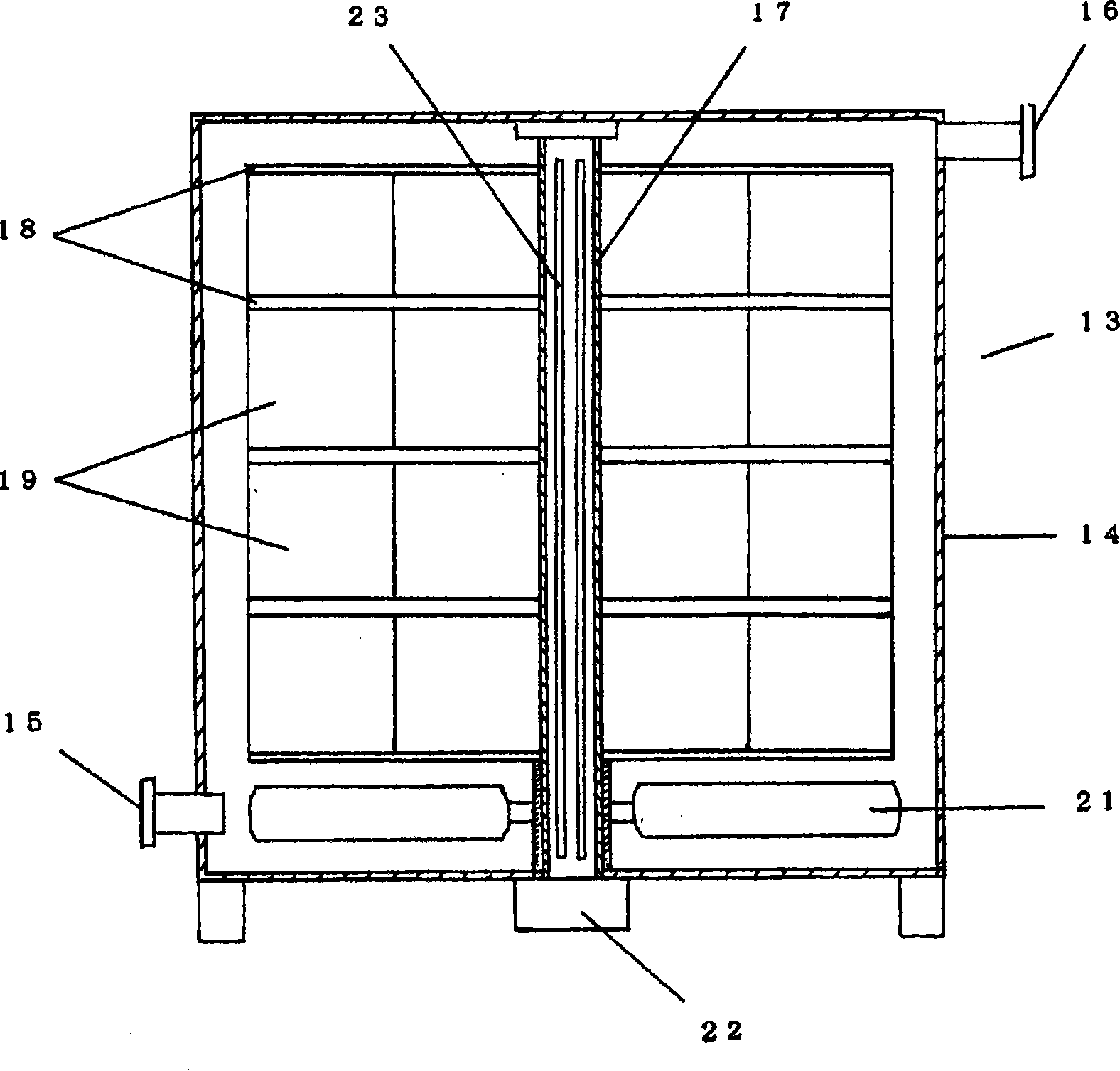

Overheated compressed hot air stream producing method and device, object processed by overheated compressed hot air stream, processing method, and processing apparatus

InactiveCN101910748ADry evenlyEven drying effectLiquid fuel feeder/distributionDrying solid materials with heatWater qualityEngineering

A method and device for producing a minus-ion air similar to a heated compressed hot air stream, electromagnetic waves in the far-infrared and submilimeter region (hereinafter referred to as ''terahertz wave'') by regulating the discharge pressure and the discharge temperature. The device is excellent in versatility, small in size, and low in cost. An object processed by using the method and device, a processing method, and a processing apparatus are also provided. Air is sent from a blower or an air compressor (2) through an air pipe (8) to a heated compressed air regulator (vessel (3)). The air sealed in the heated compressed airregulator (1) regulated under a predetermined discharge pressure (for example, 30 kPa to 150 kPa) and at a temperature (40 DEG C to 250 DEG C) is passed through a through hole (4A) of a circular plate (4) to produce a heated compressed air. In the produced hot air stream, a resonance electromagnetic wave resonating with the natural frequency of the water molecule is generated by a terahertz wave and a generated thermal shock wave, thereby the hydrogen bond of the water molecules in the air is cut, and electrons are released from hydrogen atoms, thus also producing a minus-ion air stream. A processed object, a processing method, and a processing apparatus are so constituted that the produced hot air stream is used for drying, production of a functional water by exposing water to the hot air stream, production of an aqueous fuel, beauty / health appliances, air / water quality improvement devices, combustion efficiency enhancement devices for internal combustion engines, and so forth.

Owner:SUZUYAELECTRIC SERVICE

A kind of PD/C catalyst and preparation method for TMBQ hydrogenation production TMHQ

InactiveCN102294240AEasy to makeHigh catalytic activityOrganic compound preparationQuinone preparationWater bathsActivated carbon

The invention relates to a Pd / C catalyst for producing 2,3,5-trimethylhydroquinone (TMHQ) by virtue of hydrogenation of 2,3,5-trimethylbenzoquinone (TMBQ) and a preparation method thereof. In the Pd / C catalyst provided by the invention, a noble metal Pd supported on a carrier activated carbon exists in a nano particle form, the dispersion degree of Pd is not less than 30%, and the carrier activated carbon has micropores and mesopores. The preparation method comprises the following steps: (1) carrying out acid treatment on the carrier activated carbon, and adding an acid solution in activated carbon for carrying out water bath reflux treatment; (2) washing activated carbon treated by the acid with deionized water to be neutral, and drying so as to obtain the activated carbon carrier; (3) infiltrating the activated carbon carrier with an infiltration liquid in advance; (4) slowly dropwise adding a 0.01-0.3mol / L Pd source solution in the activated carbon carrier which is infiltrated in advance, so that Pd is supported on the activated carbon, thus a catalyst precursor is obtained; and (5) drying the catalyst precursor and then treating the dried catalyst precursor by a reduction method so as to obtain the Pd / C catalyst for producing TMHQ by virtue of hydrogenation of TMBQ. The Pd / C catalyst provided by the invention has the characteristics of being simple and efficient, and having high catalysis property in BTOP (benzene to phenol) reaction.

Owner:ZHEJIANG NORMAL UNIVERSITY

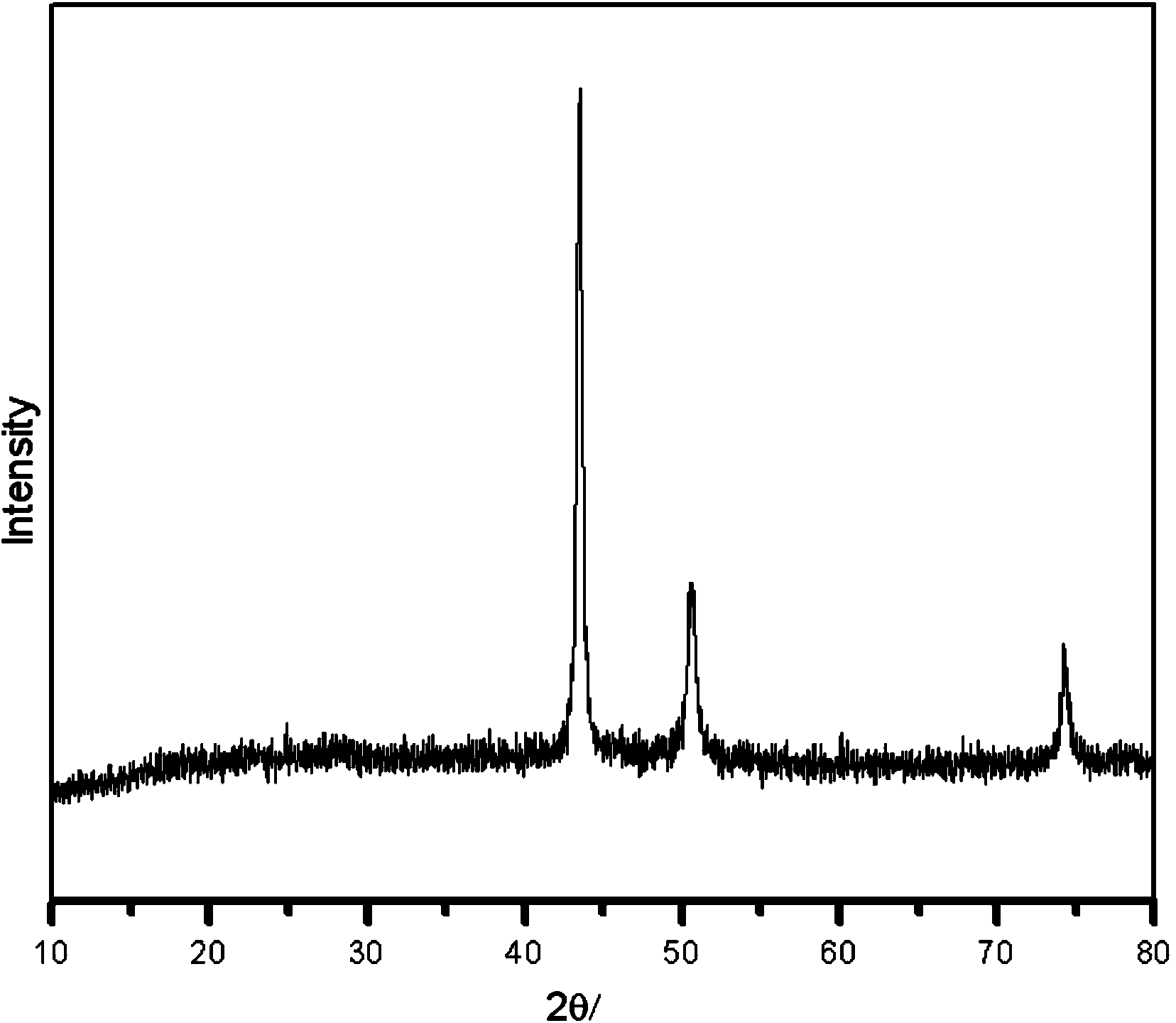

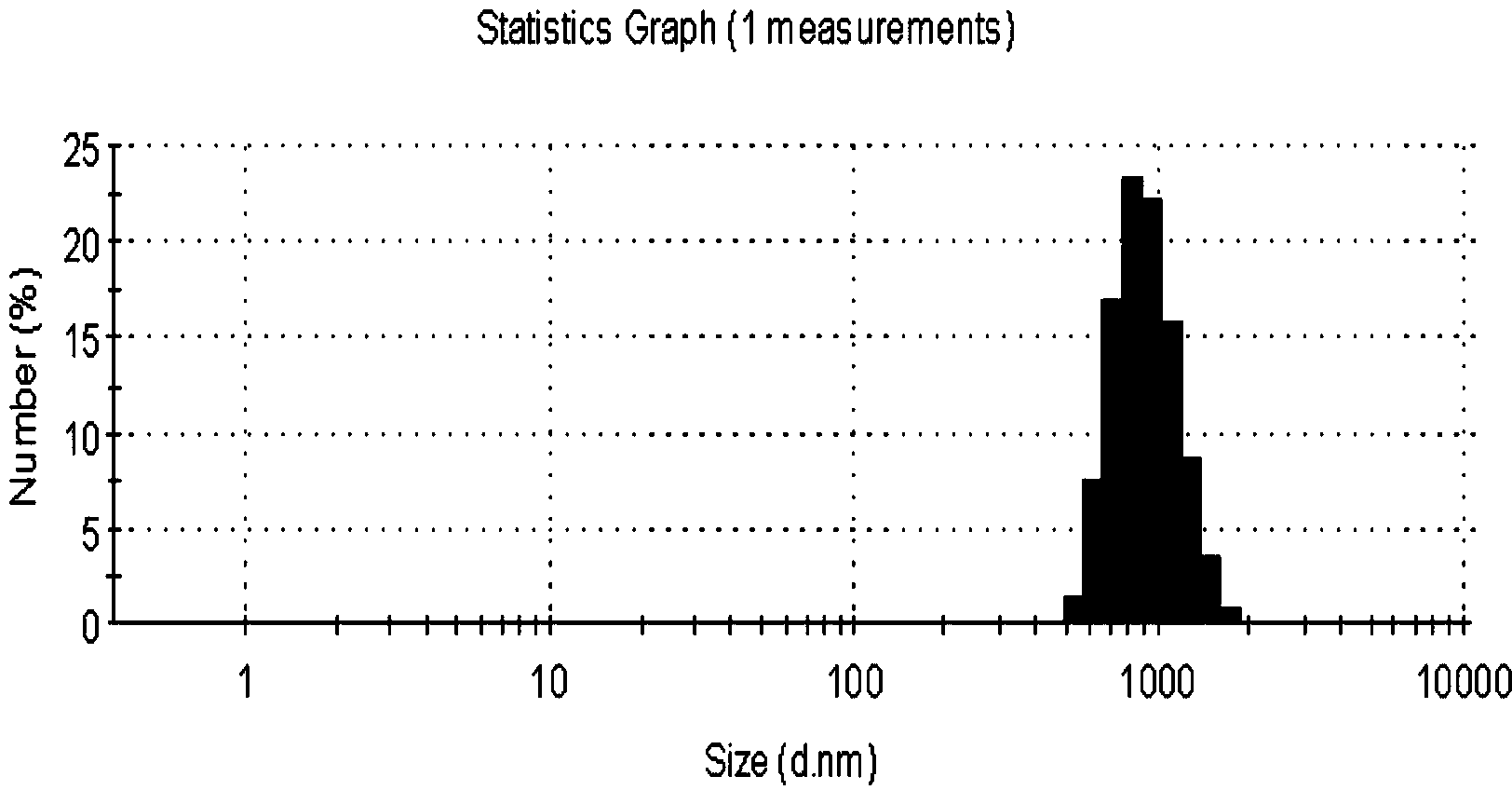

Method for recycling ultrafine copper powder from waste liquid containing complexing copper

ActiveCN103506632AImprove thermal conductivityImprove self-healing abilityRecovery methodLiquid waste

The invention discloses a method for recycling ultrafine copper powder from waste liquid containing complexing copper, and belongs to the technical field of chemical engineering recycling. According to the technical scheme, the method for recycling the ultrafine copper powder from waste liquid containing the complexing copper comprises the steps of adding a pvp dispersing agent in the waste liquid containing the copper, then adding glucose and NaOH, conducting heating and stirring to conduct a prereduction reaction, after the reaction, adding thiourea dioxide, conducting heating and stirring to conduct a reduction reaction, after the reaction is finished, conducting filtering, conducting washing for two times, conducting ethyl alcohol washing for two times, conducting vacuum drying, and obtaining the ultrafine copper powder. According to the method for recycling the ultrafine copper powder, the copper removal rate is 99%, the granularity of the recycled and obtained ultrafine copper powder can be 700nm-1500nm, the purity of the produced copper powder can be more than 99.95%, and the prepared ultrafine copper powder is applied to a plurality of fields of conducting resin, conductive coatings, conductive composite material raw materials, high-performance catalysts, lubricant additives, nanocrystalline copper, medicines and the like.

Owner:JINAN UNIVERSITY

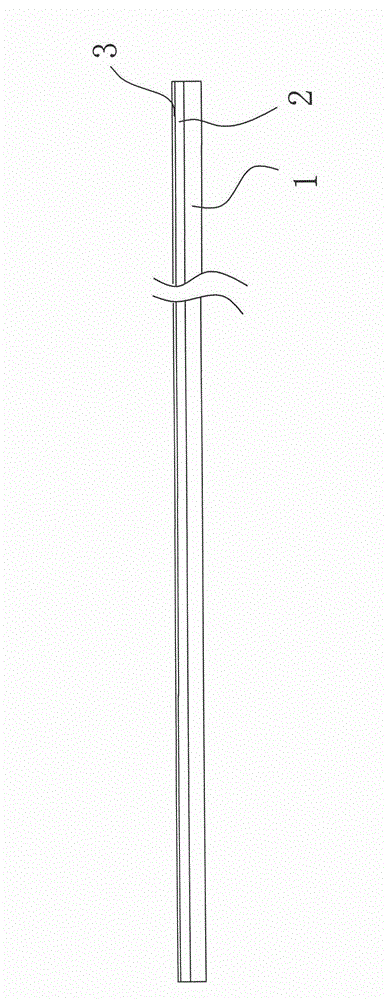

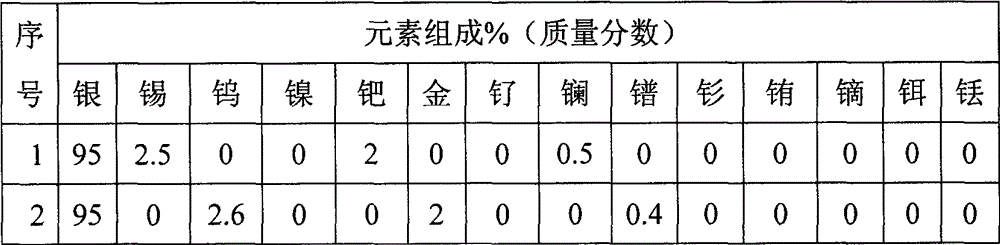

Silver alloy reflecting film with high conductivity and electrochemical corrosion resisting performance and manufacture method thereof

InactiveCN102943221AGood electrical conductivityRaise the reduction potentialMetallic material coating processesRare-earth elementIridium

A silver alloy reflecting film with high conductivity and electrochemical corrosion resisting performance and a manufacture method thereof are characterized in that the silver alloy reflecting film is an amorphous-state silver alloy reflecting film (3) and contains 0.0001-15 parts by mass of rare earth element and the balance silver element. 0.001-25 parts of one or more of ferrum, cobalt, nickel, tungsten, tin, palladium, gold, rhodium, iridium and ruthenium is further added into the silver alloy reflecting film. In preparation, a glass sheet serves as a substrate (1), chromium, aluminum, titanium, silicon dioxide, the nickel or the ferrum serves as a transition layer (2), and the amorphous-state silver alloy reflecting film (3) is manufactured through vacuum evaporation, magnetron sputtering, ion sputtering, chemical vapor deposition and an electroplating or chemical plating method. The amorphous-state silver alloy reflecting film has the high conductivity and the electrochemical corrosion resisting performance, is simple in manufacture process and is suitable for manufacture of liquid crystal display (LCD) devices, light-emitting diode (LED) devices, organic light emitting diode (OLED) devices, earth current (EC) devices or sensitized solar cell devices.

Owner:仝泽彬 +1

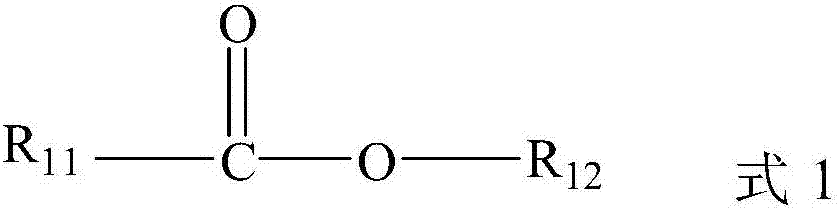

Non-aqueous electrolyte solution for lithium ion battery and lithium ion battery adopting non-aqueous electrolyte solution

InactiveCN105762413APromote circulationDissolution inhibitionSecondary cellsOrganic electrolytesDecompositionSolvent

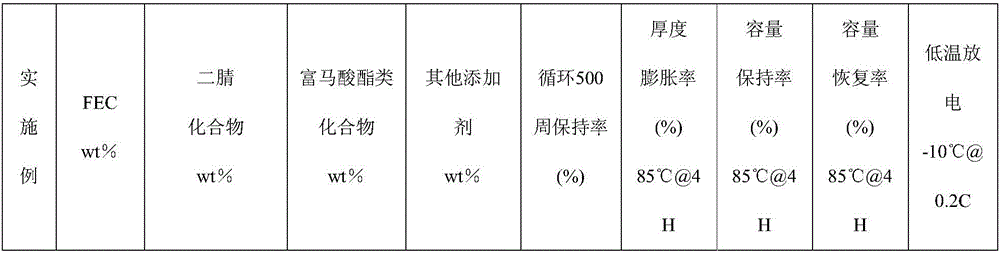

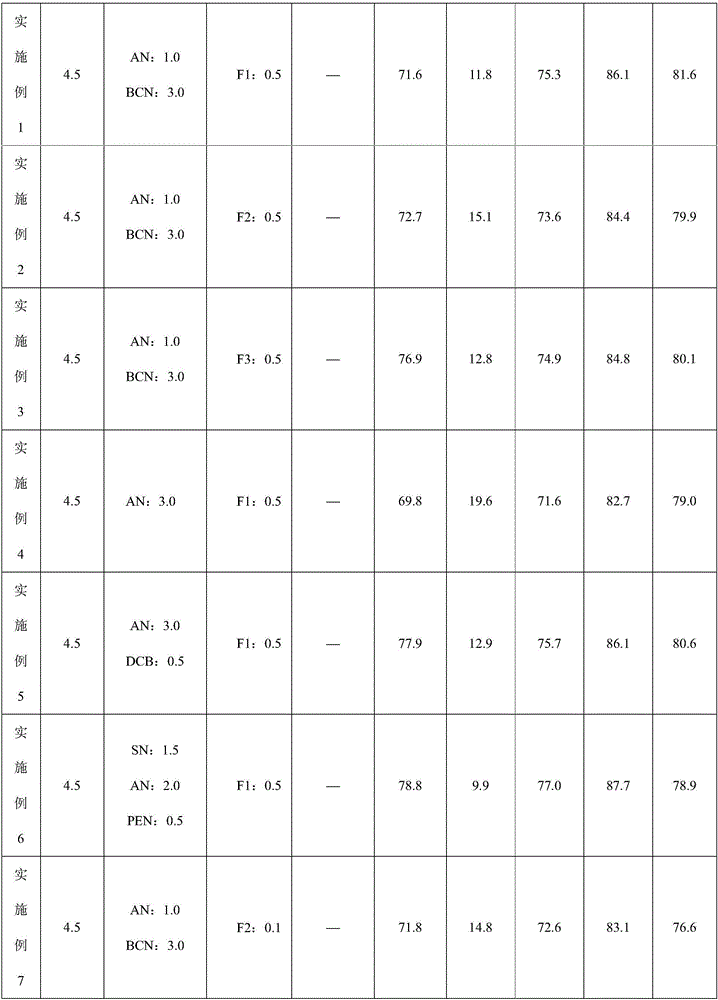

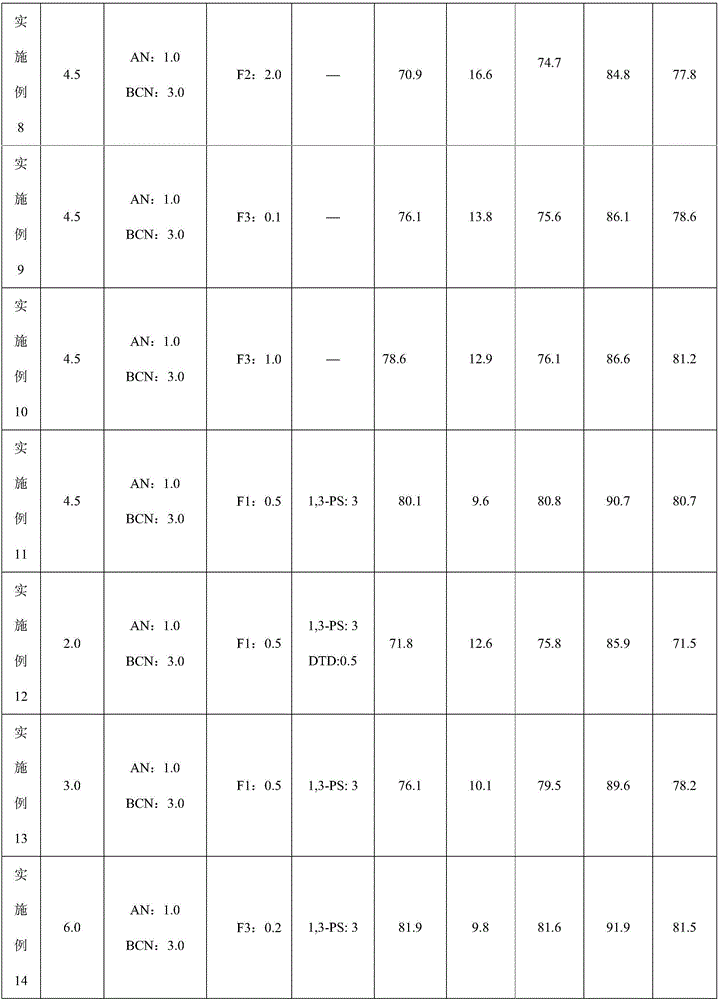

The invention provides a non-aqueous electrolyte solution for a lithium ion battery and a lithium ion battery adopting the non-aqueous electrolyte solution. The non-aqueous electrolyte solution comprises a non-aqueous solvent, lithium salt dissolved into the non-aqueous solvent and an additive, wherein the additive is prepared from fluoroethylene carbonate (FEC), a dinitrile compound and a fumarate type compound. 1 to 6 percent of FEC in the additive can form good SEI at a cathode, to make sure that the battery is high in cycle performance; 1 to 6 percent of the dinitrile compound in the additive can be complexed with metal ions to reduce decomposition of the electrolyte solution and suppress dissolving out of the metal ions as well as protect an anode and improve the battery performance; 0.1 to 2 percent of the fumarate type compound in the additive can form good SEI at the cathode, to improve the low-temperature discharging performance of the battery.

Owner:GUANGZHOU TINCI MATERIALS TECH

Lithium-ion electrolyte for improving interface of lithium ion pole piece

InactiveCN107579279AImprove thermal stabilityImprove securitySecondary cells servicing/maintenanceOrganic solventPhysical chemistry

The invention provides a lithium-ion electrolyte for improving an interface of a lithium ion pole piece, and relates to the technical field of lithium ion batteries. The lithium-ion electrolyte for improving the interface of the lithium ion pole piece comprises the following components in percentage by total mass:15%-27% of a lithium salt, 1.5%-6% of an additive and the balance of an organic solvent. The lithium-ion electrolyte for improving the interface of the lithium ion pole piece improves the heat stability of an SEI (Solid Electrolyte Interphase) film formed in the primary charge-discharge process of a lithium battery, and prolongs the charge-discharge cycle life of the lithium battery at the low temperature, the probability of swelling of the lithium battery is reduced, so that thesafety performance and the electrochemical performance of the lithium battery are improved, and the potential safety hazard of the lithium ion battery is reduced.

Owner:长沙小新新能源科技有限公司

High temperature resistant electrolyte for lithium ion battery

ActiveCN103825049BImprove cycle stabilitySmall capacity attenuationSecondary cellsOrganic baseTemperature resistance

The invention provides a high temperature-resistant electrolyte solution of a lithium ion battery. The high temperature-resistant electrolyte solution of the lithium ion battery comprises the raw materials of lithium electrolyte salt, an organic solvent, a high temperature-resistant additive, a film forming additive and a circulatory stability additive, wherein the concentration of the lithium electrolyte salt in the organic solvent is 0.5-2 mol / L; the organic solvent comprises the following components in parts by volume: 5-30 parts of a high-dielectric-constant organic base solvent, 40-65 parts of a high-boiling-point organic solvent, and 5-55 parts of a low-viscosity organic solvent; the high temperature-resistant additive is at least one of lithium tetrafluoroborate, lithium difluoroborate, lithium bis(malonato)borate, lithium bis(oxalate)borate and lithium malonato oxalate borate, the mass of the high temperature-resistant additive accounts for 0.1-8% of the total mass of the electrolyte solution, the mass of the film forming additive accounts for 0.2-4% of the total mass of the electrolyte solution, and the mass of the circulatory stability additive accounts for 0.5-5% of the total mass of the electrolyte solution. According to the invention, the high temperature resistance and circulatory stability of the lithium ion battery are effectively improved.

Owner:DONGFENG COMML VEHICLE CO LTD

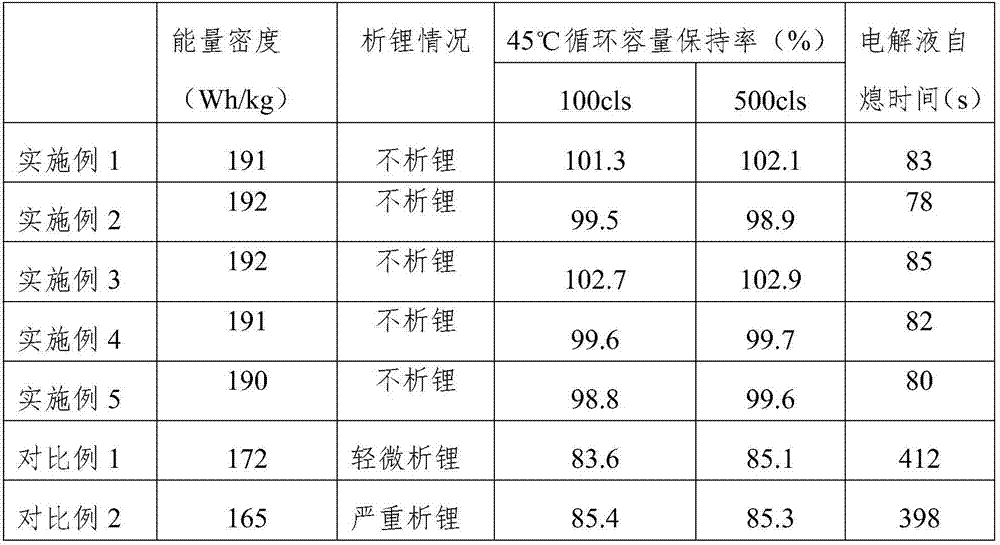

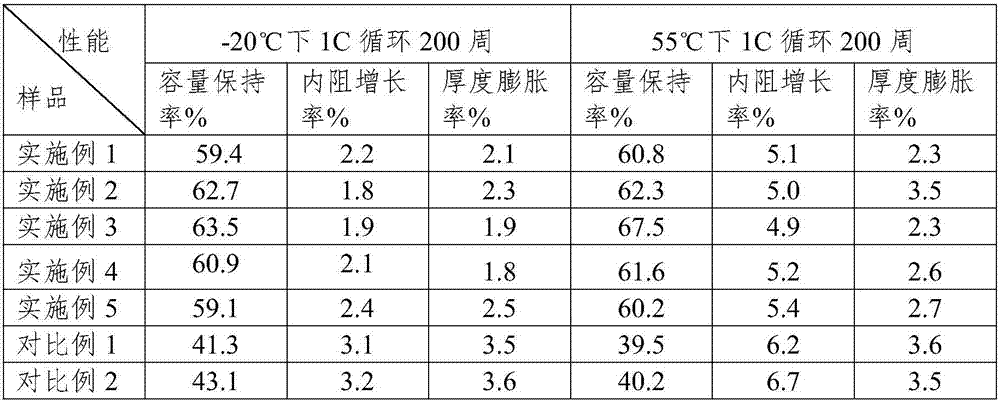

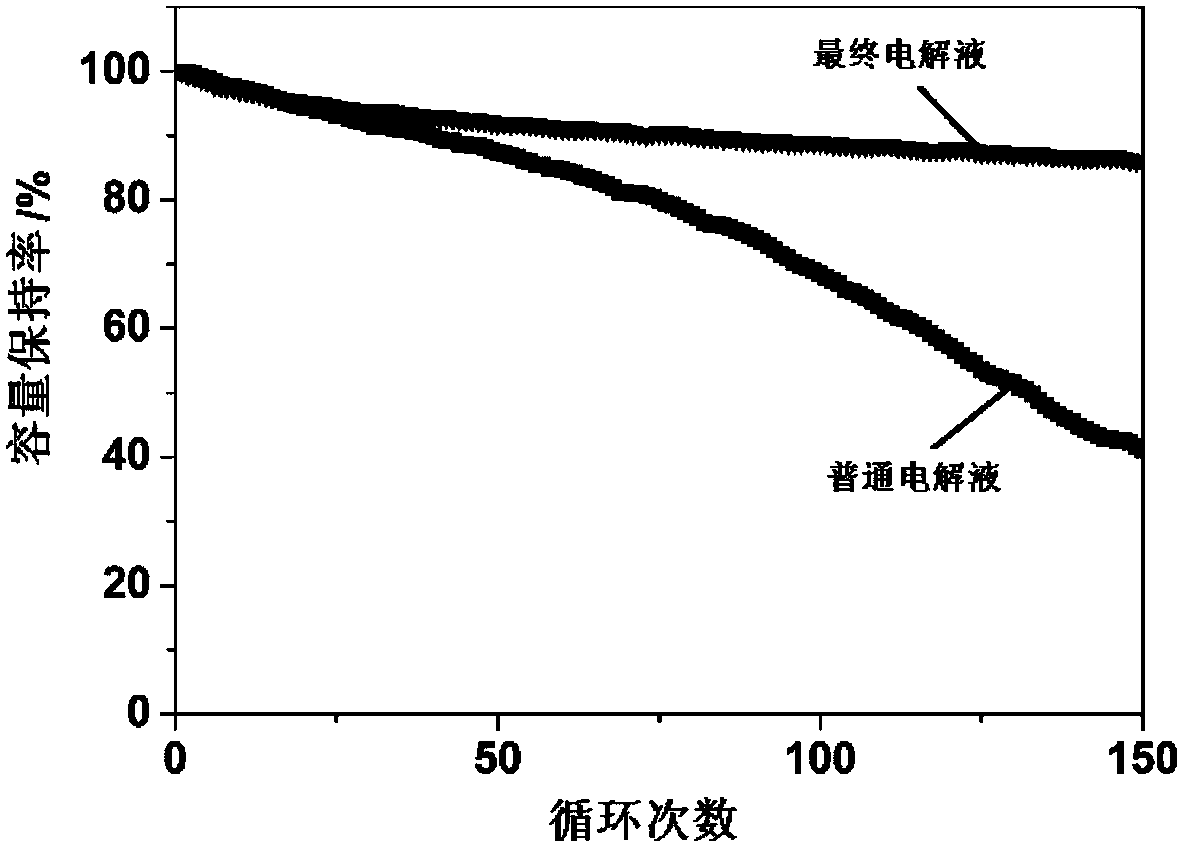

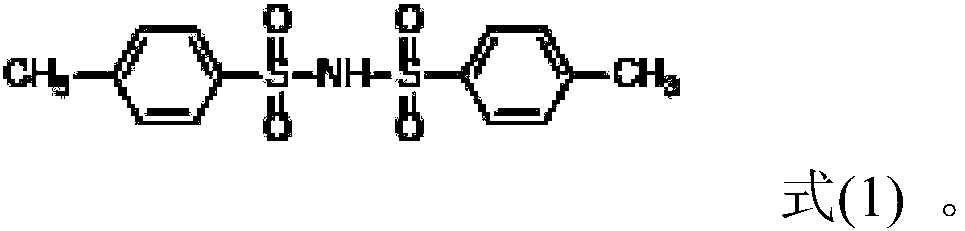

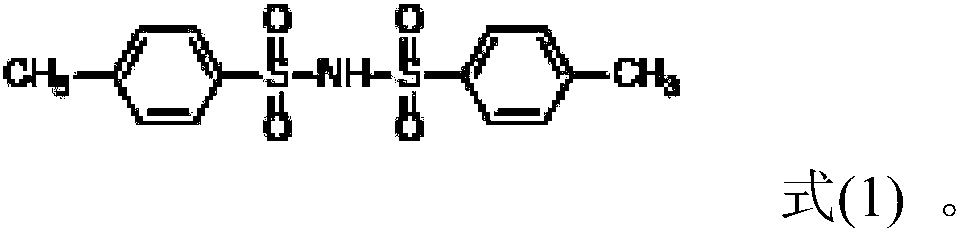

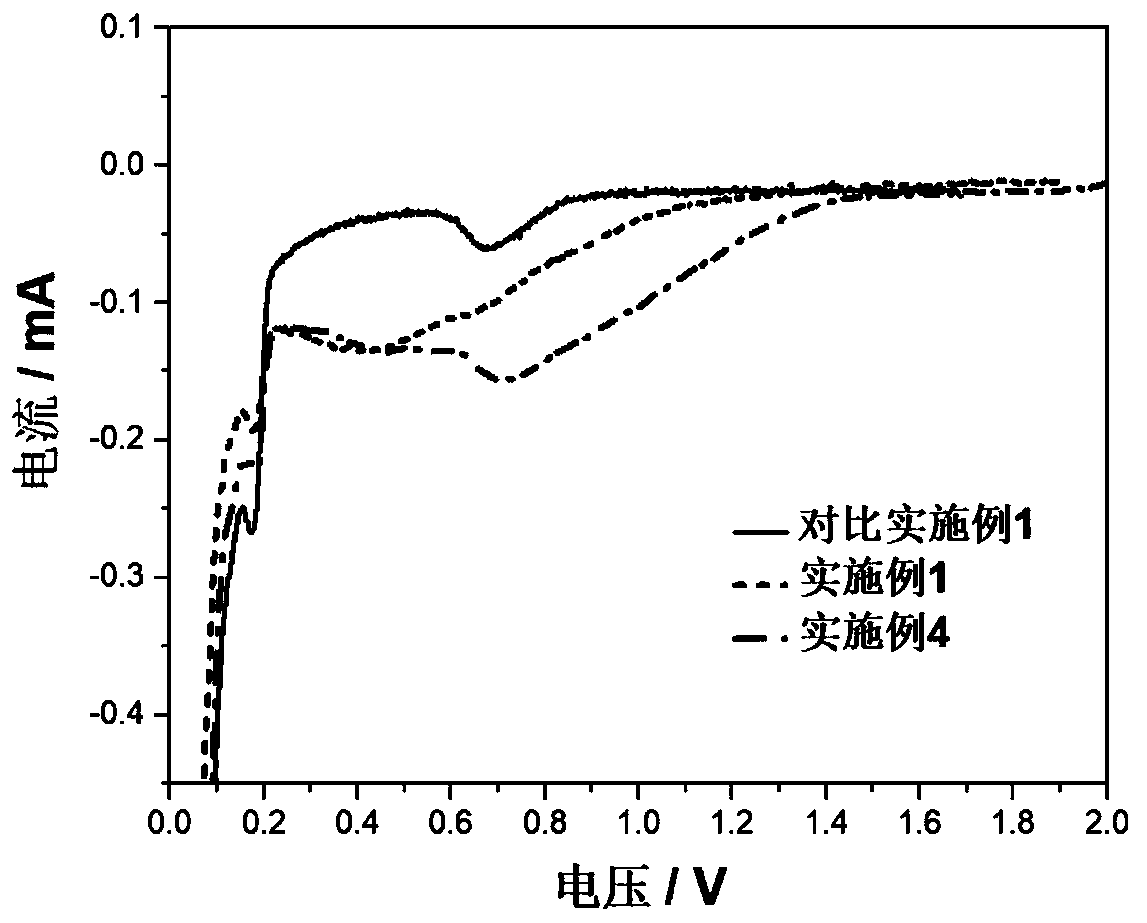

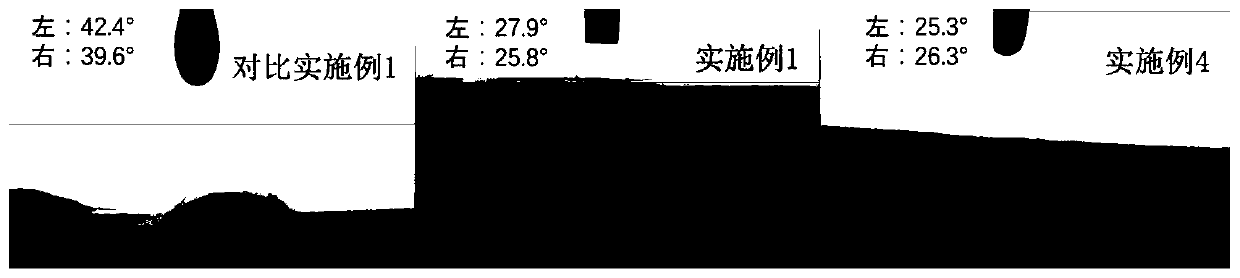

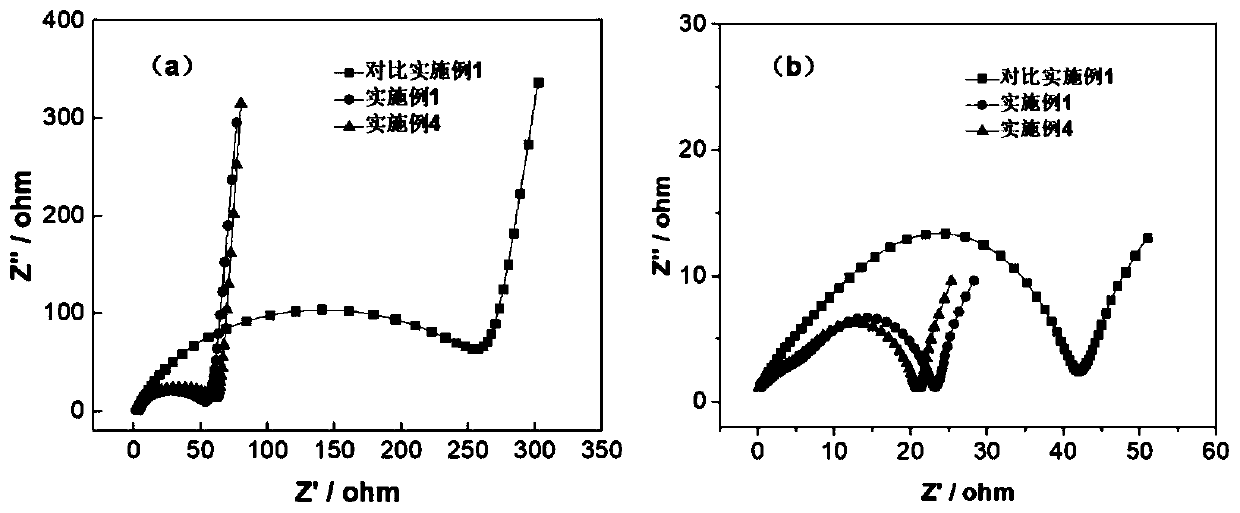

Electrolyte additive and electrolyte comprising additive, and lithium secondary battery

ActiveCN107799823ALower oxidation potentialRaise the reduction potentialSecondary cellsPhysical chemistryRoom temperature

The invention belongs to the field of a lithium ion battery material, and discloses an electrolyte additive and an electrolyte comprising the additive, and a lithium secondary battery. The electrolyteadditive is 4-methyl-N-tosyl benzene sulfonamide. A cyclic carbonate solvent and a linear carbonate solvent are mixed, and then are subjected to purification, impurity removal and dewatering, and a conductive lithium salt is added in the room temperature condition to obtain a common electrolyte; and next, an additive which accounts for 0.5-3.0% of the mass of the common electrolyte is added to the common electrolyte to obtain the final electrolyte. By taking 4-methyl-N-tosyl benzene sulfonamide as the additive of the lithium ion electrolyte, the cycle performance of the lithium secondary battery at a high pressure is improved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

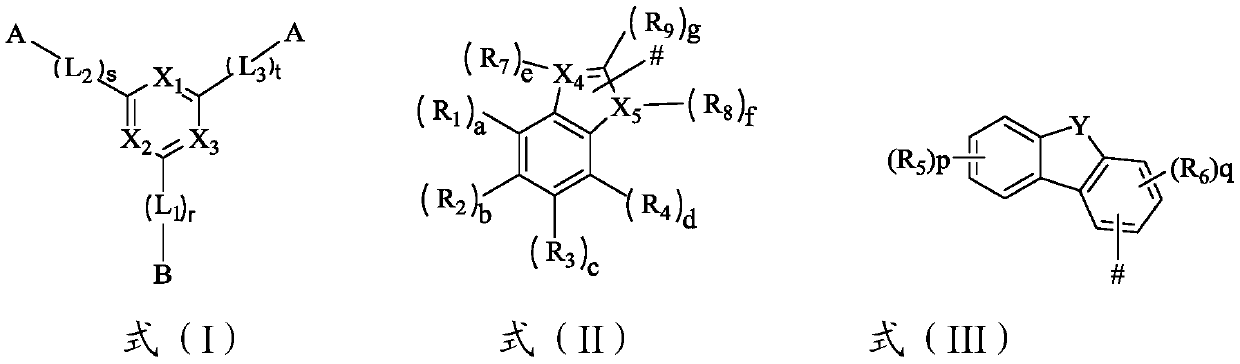

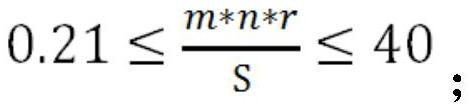

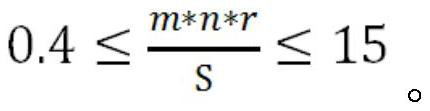

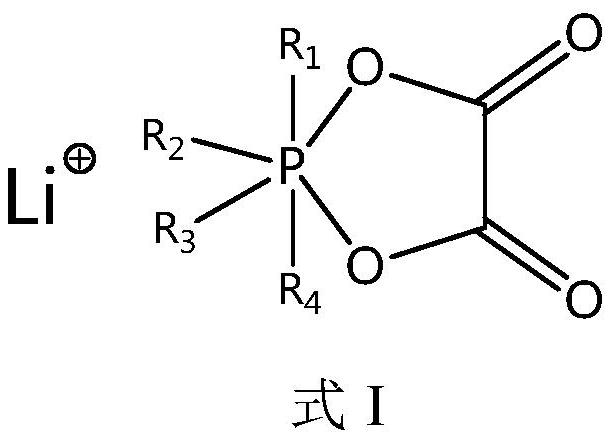

Battery electrolyte additive, and electrolyte and lithium ion battery using additive

PendingCN111384443AImprove interfacial wettabilityReduce interface contact resistanceSecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentInterface impedance

The invention provides an additive applied to a battery electrolyte, which has a structure as shown in the following (I), and a substituent group is shown in the specification. The invention also provides an electrolyte and a battery using the additive. The additive provided by the invention can effectively reduce the interface impedance and charge transfer impedance between graphite, silicon carbon and other negative electrode materials and an electrolyte, thereby effectively improving the cycle stability and rate capability of the negative electrode materials.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

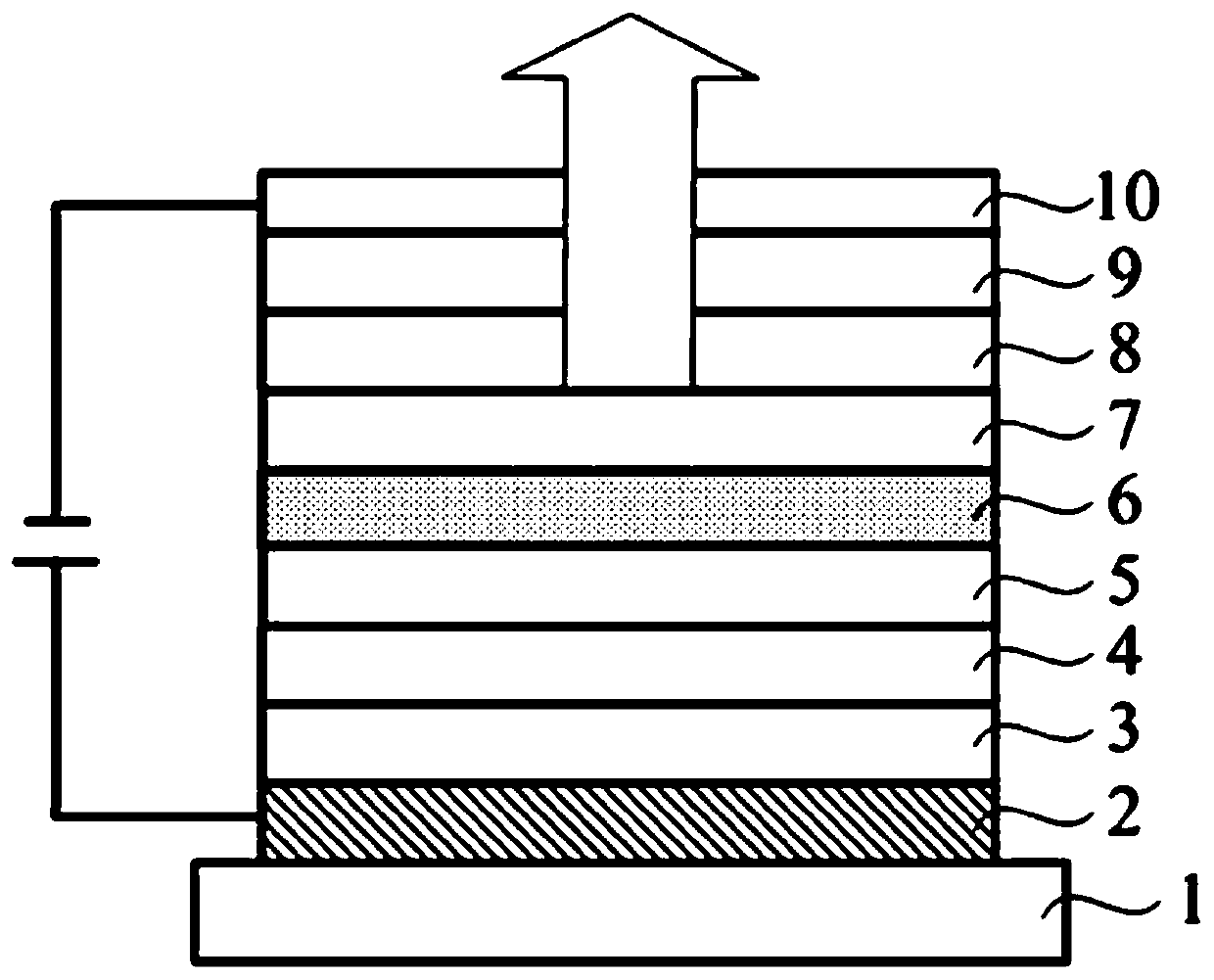

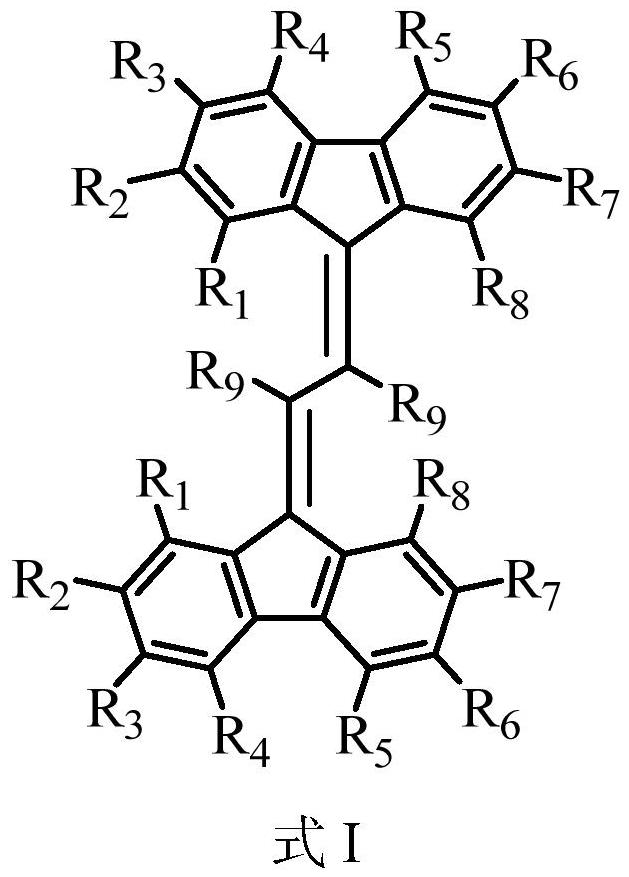

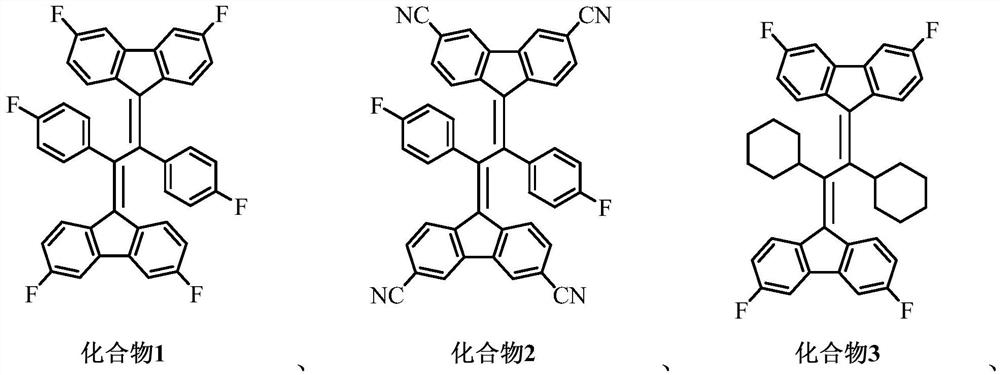

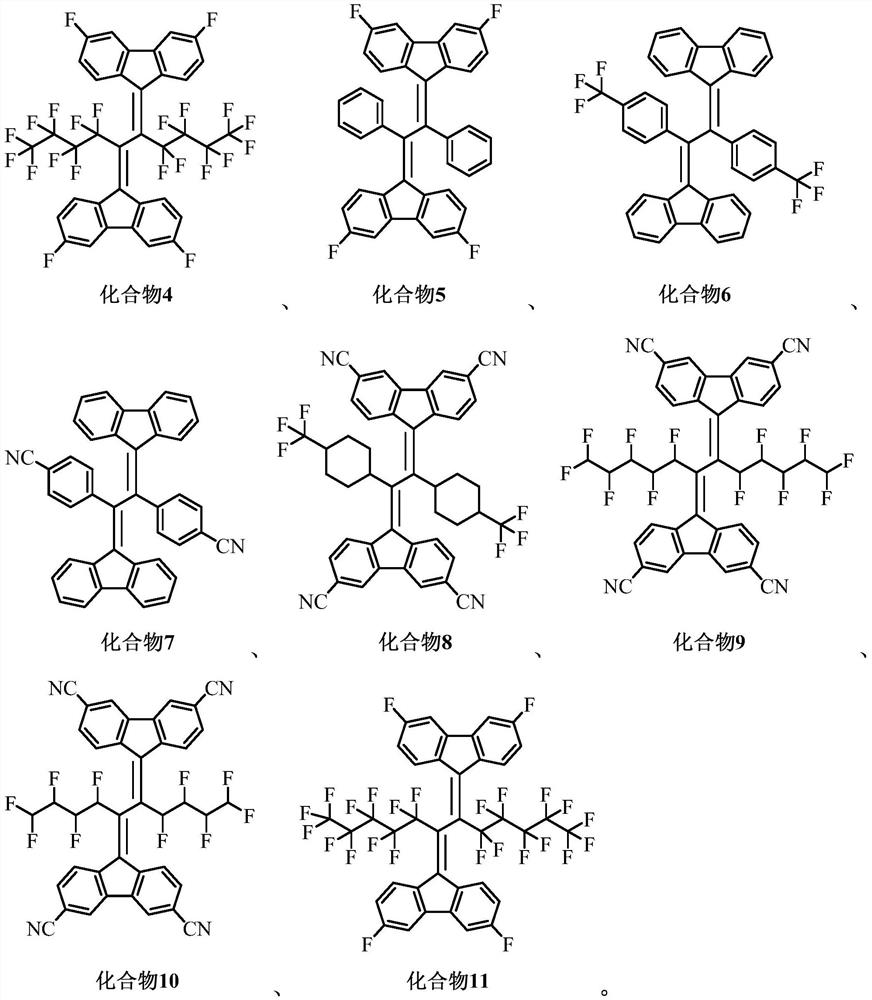

Compound, organic light-emitting device and display device

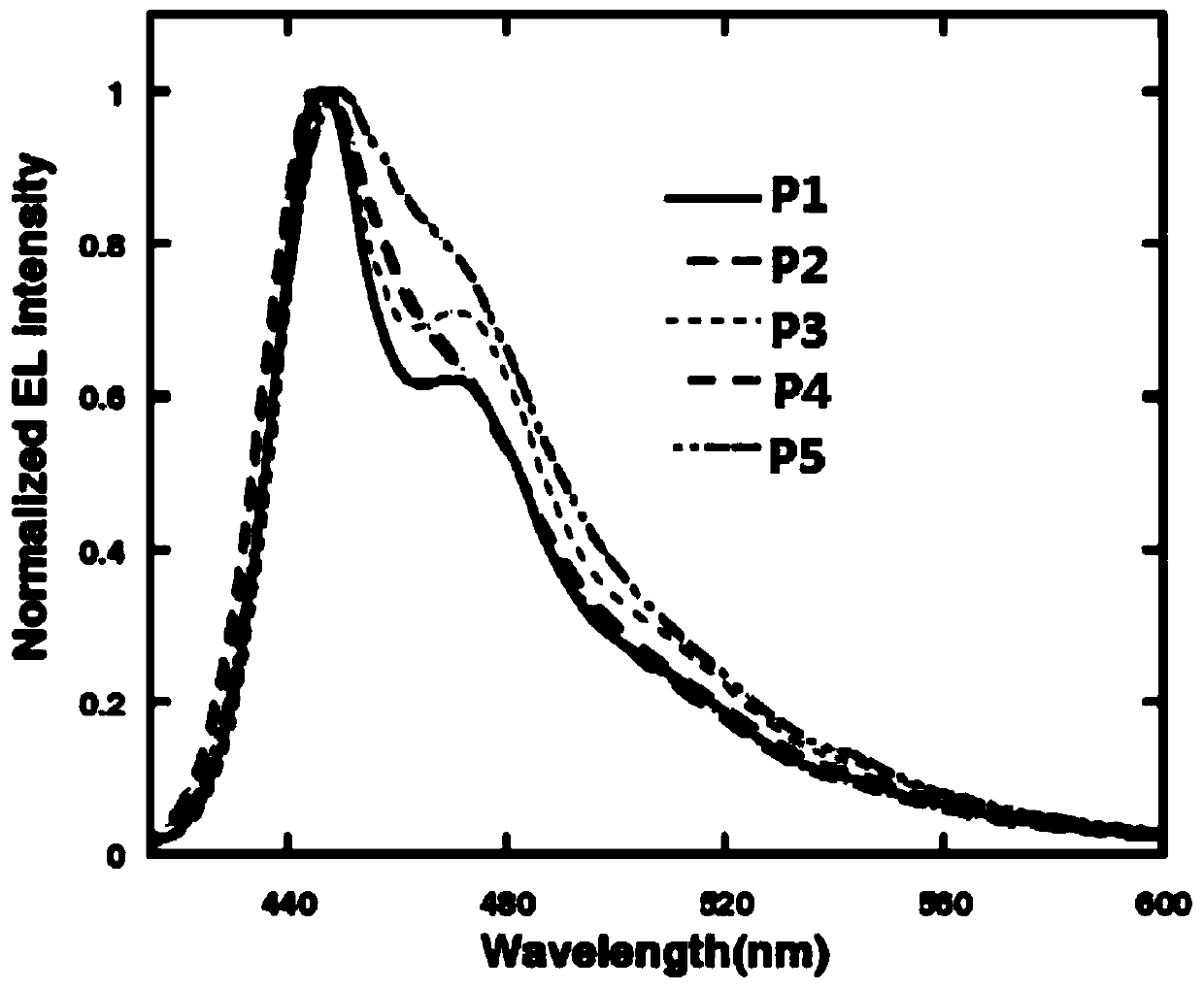

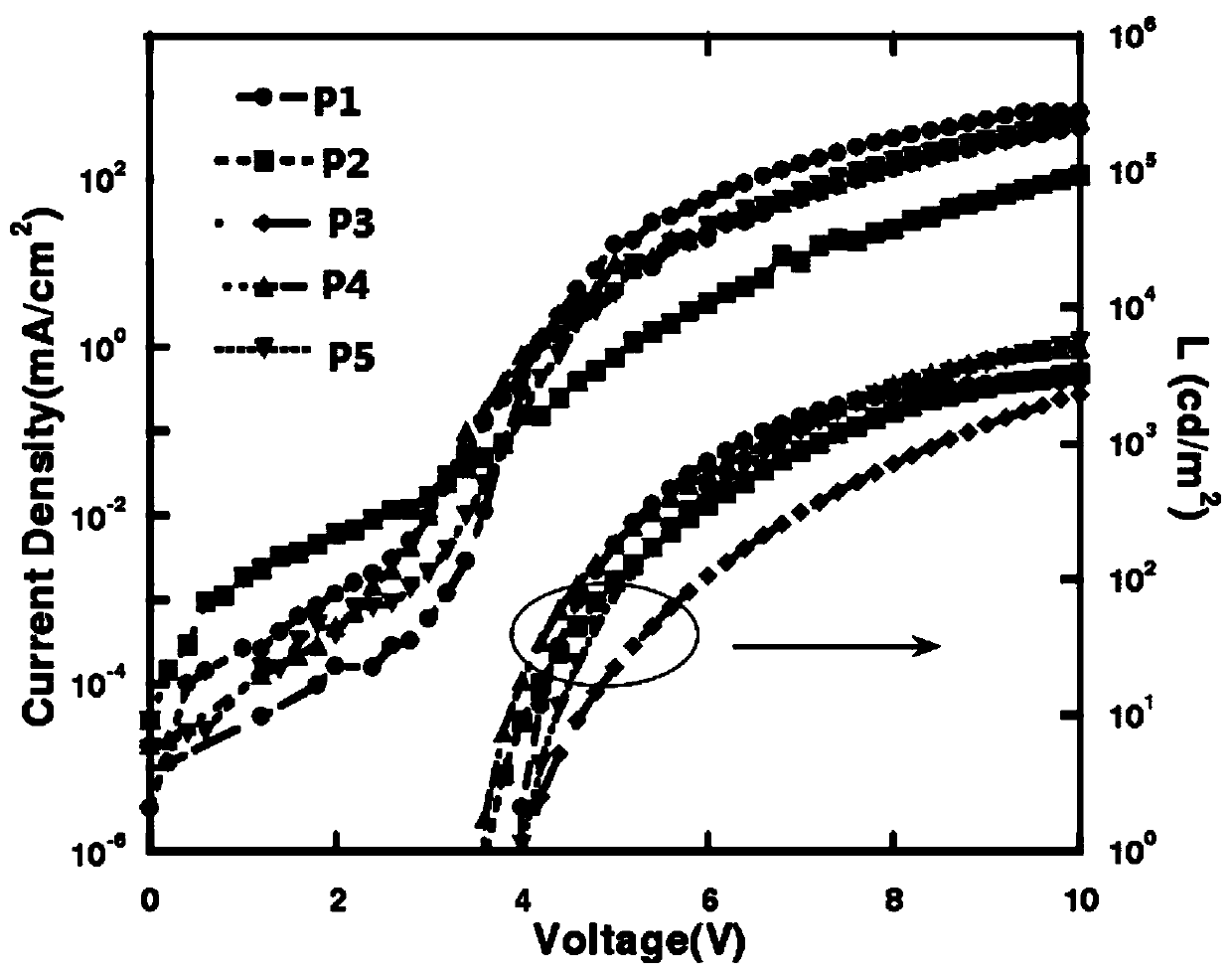

InactiveCN110642841ALower HOMO levelIncrease spawn rateOrganic chemistrySolid-state devicesDisplay deviceOrganic electroluminescence

The invention relates to the technical field of organic electroluminescence, and especially relates to a compound, an organic light-emitting device and a display device. The compound has a structure represented by formula (I).

Owner:SHANGHAI TIANMA AM OLED

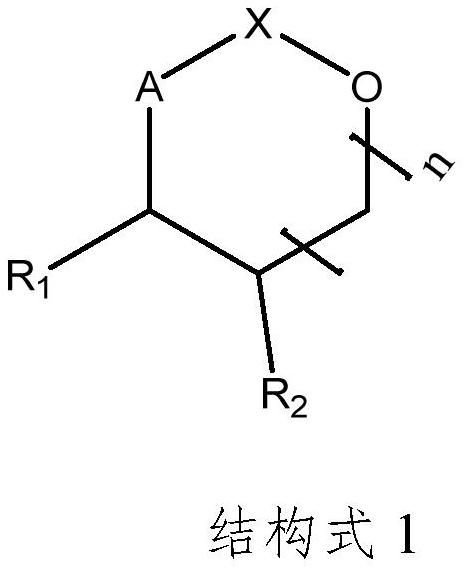

Secondary battery

ActiveCN114497692AIncrease energy densityRaise the reduction potentialNegative electrodesLi-accumulatorsElectrolytic agentElectrical battery

In order to overcome the problem of insufficient high-temperature storage performance of an existing battery containing a silicon-based material, the invention provides a secondary battery which comprises a positive electrode, a negative electrode with a negative electrode material layer and a non-aqueous electrolyte, the negative electrode material layer comprises a negative electrode active material, and the negative electrode active material comprises a silicon-based material; the non-aqueous electrolyte comprises a solvent, an electrolyte salt and an additive, and the additive comprises a compound as shown in a structural formula 1; wherein n is 0 or 1, A is selected from C or O, X is selected from R1 and R2, or R1 and R2 are independently selected from H, or R1 and R2 are not selected from H at the same time, and X, R1 and R2 at least contain one sulfur atom; the secondary battery satisfies the following conditions: 40% < = m < = 90%, 0.05% < = n < = 2%, 1.2 g / cm < 3 > < = r < = 1.8 g / cm < 3 >, and 5% < = S < = 30%. According to the secondary battery provided by the invention, the high-temperature storage performance of the battery can be improved on the premise of ensuring that the battery has excellent energy density.

Owner:SHENZHEN CAPCHEM TECH CO LTD

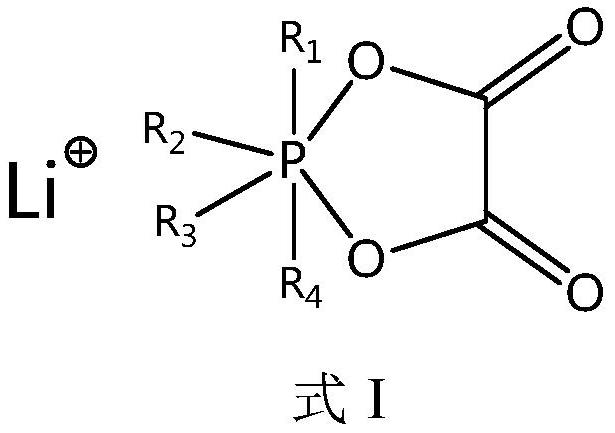

High-nickel ternary lithium ion battery electrolyte and ternary lithium ion battery

InactiveCN112216862AReduce reactivityImprove electrochemical performanceSecondary cellsHigh temperature storageElectrolytic agent

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a ternary lithium ion battery non-aqueous electrolyte and a lithium ion battery. The ternary lithiumion battery electrolyte comprises a non-aqueous organic solvent, an electrolyte lithium salt and an additive, the additive comprises an oxalic acid lithium phosphate additive with a structure shown ina formula (I), and can also comprise conventional additives such as vinylene carbonate (VC), 4-vinyl-1,3-dioxolan-2-one (VEC), 1, 3-propane sultone (PS), ethylene sulfate (DTD), tris (trimethylsilane) phosphate (TMSP) and the like. Under the combined action of the uniquely combined conventional additive and the oxalic acid lithium phosphate additive with the structure shown in the formula (I), the generation of cracks in positive electrode material particles in the circulation process can be inhibited, the dissolution of transition metal elements at high temperature can be reduced, the reduction reaction decomposition of a solvent on a negative electrode interface can be inhibited, the cycle performance, the high-temperature storage performance and the low-temperature performance of the ternary lithium ion battery are effectively improved.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

High-voltage lithium ion battery

PendingCN112186190AGuaranteed oxidation resistanceInterface Modification ConsolidationCell electrodesSecondary cellsElectrolytic agentLithium-ion battery

The invention discloses a high-voltage lithium ion battery, which comprises a positive electrode, a negative electrode and an electrolyte, wherein the positive electrode is a high-voltage fluorinatedpositive electrode, the negative electrode is a carbonaceous negative electrode, and the electrolyte uses fluorinated ether as a cosolvent and uses fluorinated carbonate and a boron-containing substance as additives. According to the battery disclosed in the invention, the oxidation resistance of the positive electrode material and the electrolyte can be improved, and the high-voltage stability ofan interface constructed by the positive electrode, the negative electrode and the electrolyte can be ensured, so that the key problem of the lithium ion battery under a high-voltage working condition is effectively solved, and the high-voltage cycle performance of the lithium ion battery is integrally improved.

Owner:XIAN UNIV OF SCI & TECH

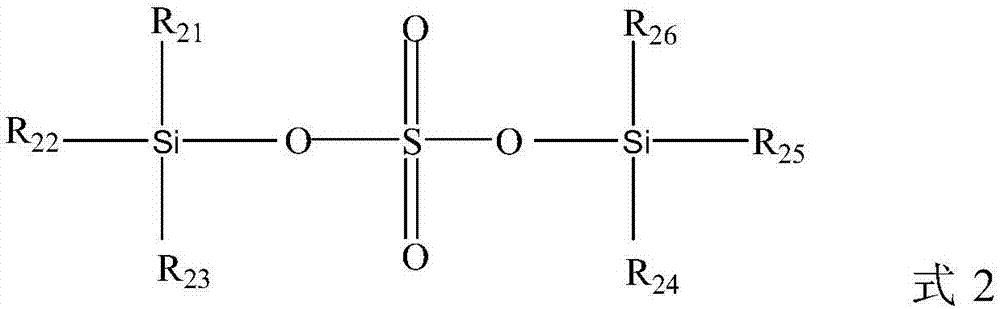

Electrolyte and lithium ion battery

InactiveCN107403957AInhibit oxidative decompositionExcellent rate performanceSecondary cellsOrganic electrolytesOrganic solventSulfate

The invention provides electrolyte and a lithium ion battery. The electrolyte contains lithium salt, an organic solvent and an additive, wherein the organic solvent contains a carboxylic ester compound; and the additive contains a silicon alkyl sulfate compound. By applying the electrolyte to the lithium ion battery, the rate capability and high-temperature cycle performance of the lithium ion battery can be improved.

Owner:NINGDE AMPEREX TECH

Pure cotton fabric vat dye dyeing method

A pure cotton fabric vat dye dyeing method includes the following steps of firstly, preparing fabric; secondly, conducting pretreatment on the fabric; thirdly, preparing a vat dye leuco body solution; fourthly, conducting dip dyeing on vat dye; fifthly, conducting soaping; sixthly, conducting after treatment, wherein dip dyeing is conducted on vat dye in the fourth step, deoxygenation is conducted in a dyeing device, nitrogen is introduced into the dyeing device, the dyeing device is then sealed, pure cotton fabric where pretreatment is conducted is placed in the leuco body solution of vat dye, the temperature is raised to 60 DEG C at the temperature rise speed of 1 DEG C per minute, heat preservation is conducted for 12minutes, 2.5 g / L salt is added, dyeing continues to be conducted for 12 minutes, dyeing is finished, and dyed pure cotton fabric is oxidized in air and then washed through cold water.

Owner:耿云花

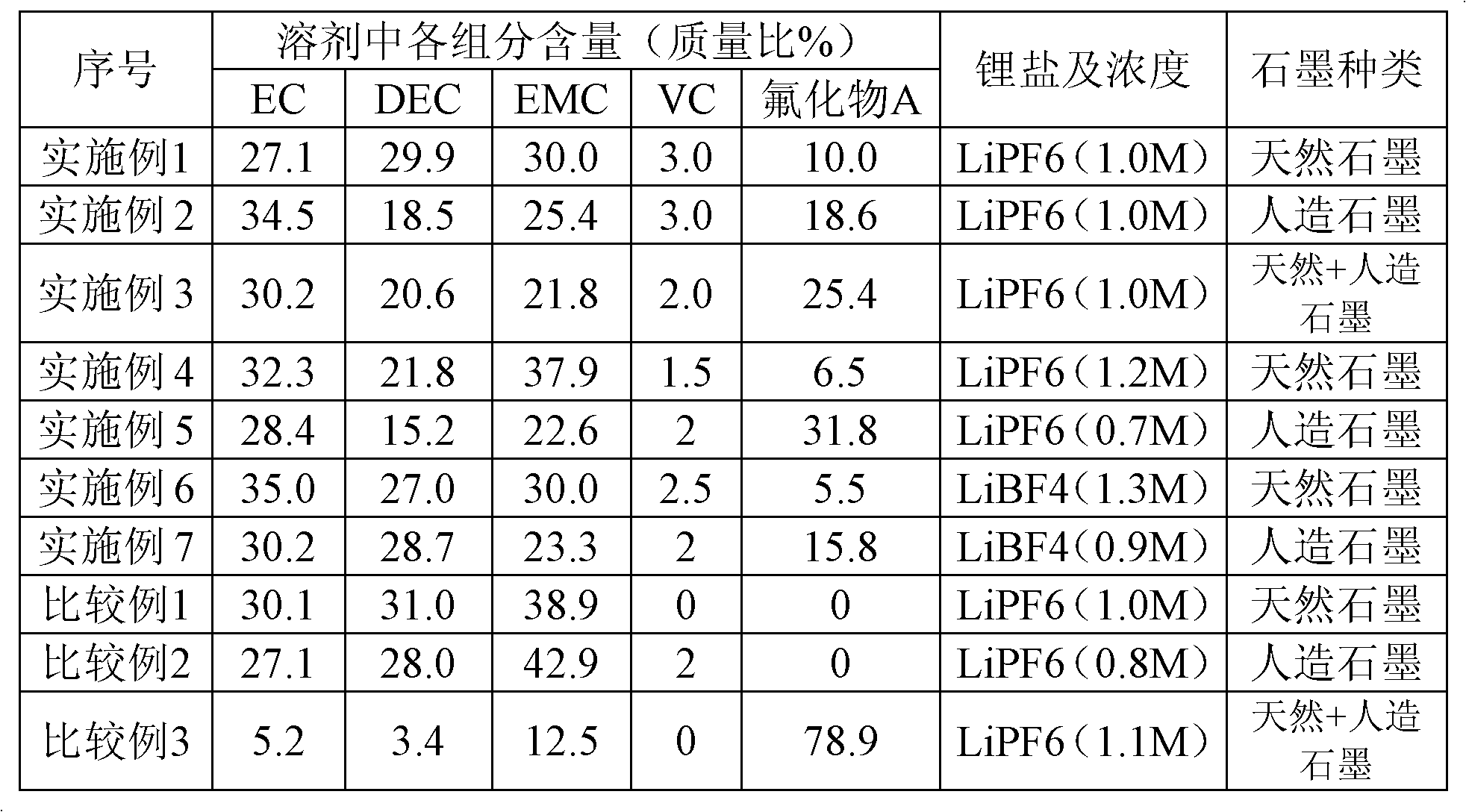

Non-aqueous electrolyte, preparation method of non-aqueous electrolyte and lithium ion secondary battery containing non-aqueous electrolyte

InactiveCN102522592AGood chemical stabilityImprove thermal stabilitySecondary cellsSolventEthyl acetate

The invention relates to non-aqueous electrolyte, a preparation method of the non-aqueous electrolyte and a lithium ion secondary battery containing the non-aqueous electrolyte. The non-aqueous electrolyte is characterized by consisting of a non-aqueous solvent and electrolyte, wherein the electrolyte comprises at least one of LiBOB, LiCF3SO3, Li(CF3SO2)2N, LiPF6, LiBF4, LiClO4, LiAsF6, lithium halide and lower aliphatic acid lithium carbonate; lithium salt in the electrolyte has the concentration of 0.5 to 2.0M; the non-aqueous solvent comprises at least one of ethylene carbonate, diethyl carbonate, dimethyl carbonate, methyl ethyl carbonate, propylene carbonate, methyl formate, methyl acrylate, methyl butyrate, ethyl acetate, dimethyl sulfide, acetic ester and propionate, and another fluoride; and the weight percentage of the fluoride in the non-aqueous solvent is 0.1 to 70 percent. The electrolyte provided by the invention not only has high chemical stability, but also does not influence the service life of the battery.

Owner:IRICO

Negative electrode slurry, negative electrode plate, lithium ion soft package battery cell, lithium ion battery pack and application of lithium ion battery pack

InactiveCN112563465AAct as passivationIncrease energy densityElectrode carriers/collectorsSecondary cells servicing/maintenanceElectrochemical responseElectrolytic agent

The invention discloses negative electrode slurry, a negative electrode plate, a lithium ion soft package battery cell, a lithium ion battery pack and application thereof. The negative electrode slurry comprises a negative electrode active material, an additive and a solvent, the negative electrode active material comprises a silicon-based composite material, and the additive comprises lithium nitrate. The negative electrode active material comprising the silicon composite material is high in energy density, lithium nitrate has relatively high reduction potential and is easy to reduce and decompose, and the decomposition product can stably coat the surface of the negative electrode active material, plays a role in passivating the negative electrode active material, can effectively inhibitcontinuous side reaction between electrolyte and the negative electrode active material, such as electrochemical reactions, so that the cycle performance of the lithium ion soft package battery cell can be improved, and the cycle life is long.

Owner:GAC AION NEW ENERGY AUTOMOBILE CO LTD

Application of nitrile compound in preparation of electrolyte for high-voltage battery system

ActiveCN111682263AImprove high pressure stabilityRaise the reduction potentialCarboxylic acid nitrile preparationOrganic compound preparationElectrical batteryReduction potential

The invention discloses an application of a nitrile compound in preparation of an electrolyte for a high-voltage battery system. The structural formula of the nitrile compound is shown in the specification, n1, n2 and n3 are integers from 0 to 10 respectively, but are not 0 at the same time, and Rf is a fluorine-containing functional group. The substitution of the F-containing electron withdrawingfunctional group can cooperate with the nitrile functional group to well modify the positive electrode interface layer, thereby further enhancing the high-voltage stability of the battery, F-containing functional groups are substituted, so that the reduction potential of nitrile molecules can be effectively improved, a stable LiF-rich interface layer is formed on a graphite or lithium metal negative electrode, the incompatibility of a nitrile additive to the negative electrode is further improved, and the overall high-voltage stability of the soft package total battery is improved.

Owner:XIAMEN UNIV

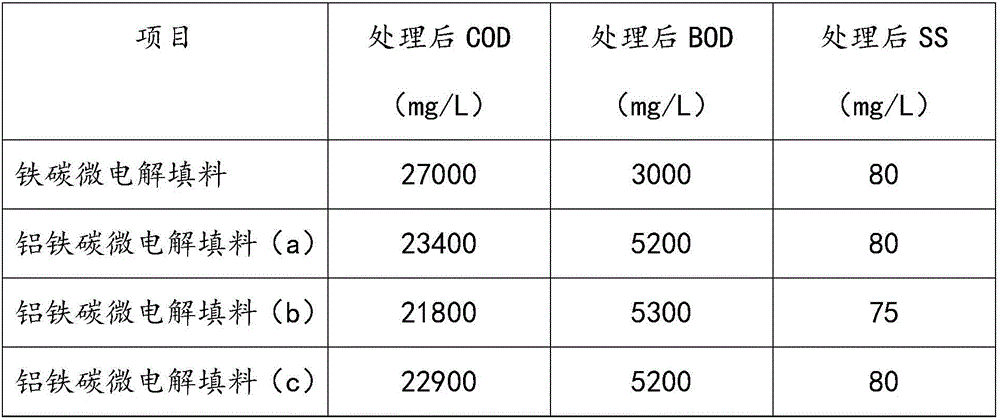

Method for preparing aluminum-iron-carbon micro-electrolysis filler

InactiveCN106186209AHigh removal rateRaise the reduction potentialWater/sewage treatmentIron powderElectrolysis

The invention discloses a method for preparing aluminum-iron-carbon micro-electrolysis filler. The method includes the following steps that 1, fine iron powder and coal coke powder are mixed; 2, the mixture is calcined to obtain high-carbon iron; 3, the high-carbon iron is smashed into fine particles; 4, an aluminum ingot is melted in protective gas; 5, the melted aluminum ingot and the high-carbon iron powder are jointly mixed in the protective gas, the mixture is cooled and coagulated, and an aluminum-iron-carbon micro-pore block is formed; 6, the aluminum-iron-carbon micro-pore block is cut ready for use. By means of the method, the reduction potential is improved, the removing rate of COD is increased, reaction time is shortened, and the pH application range is wide.

Owner:浙江合众环保科技有限公司

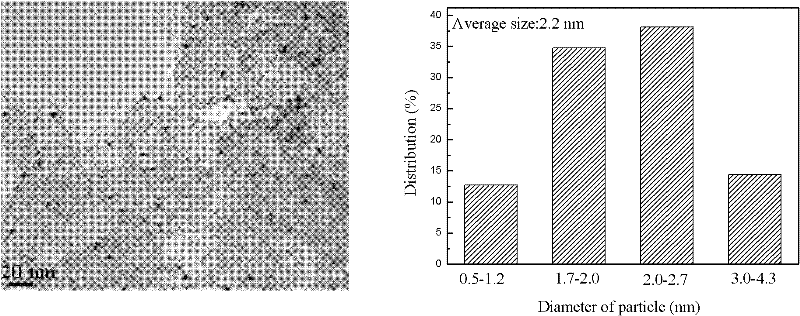

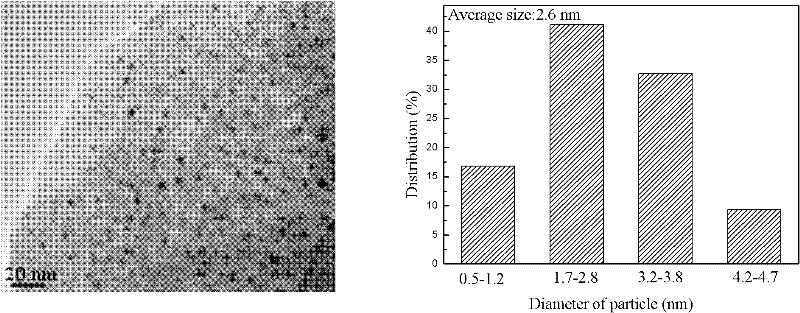

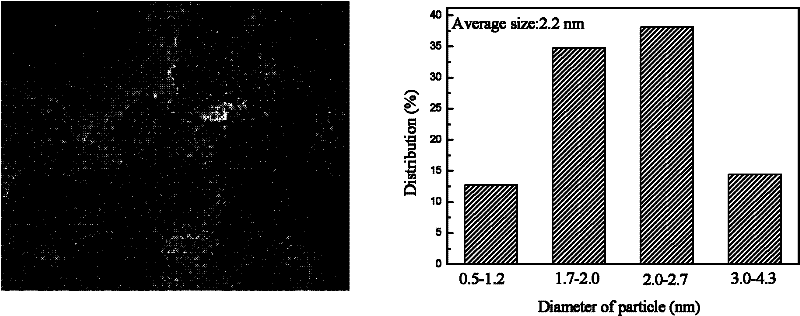

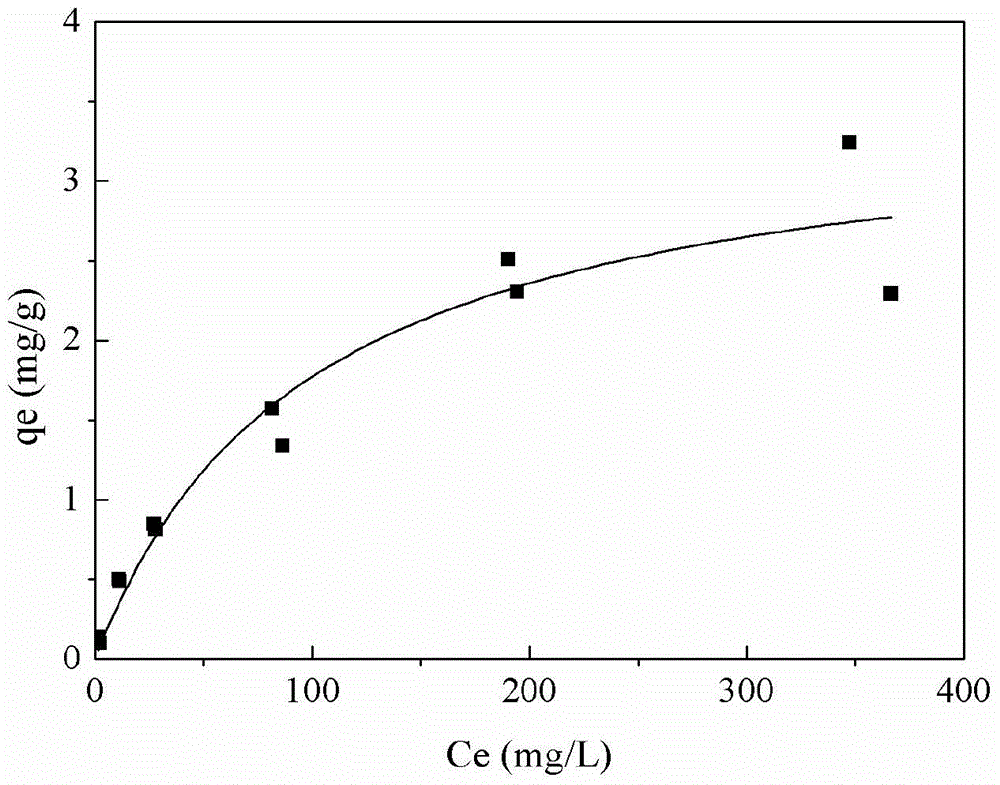

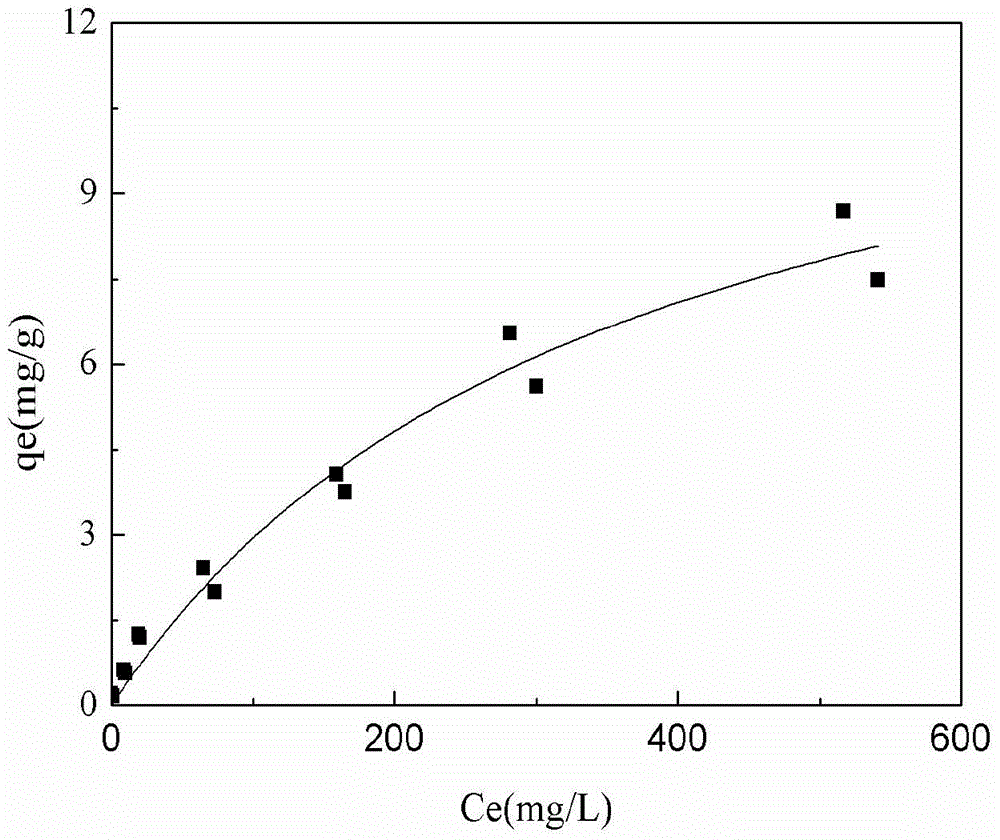

A zeolite-loaded nano-iron material for removing heavy metals in water and its preparation method

InactiveCN104174355BGood dispersionUniform particle size distributionOther chemical processesWater/sewage treatment by sorptionReaction rateFreeze-drying

The invention relates to a zeolite-loaded nano-iron material and a preparation method thereof. It is composed of zeolite and nano-iron loaded on the pores and surfaces of zeolite particles. The average particle size of the zeolite is 80-100 mesh, and the loading amount of nano-iron is 1 wt%. ~1.3wt%, the particle size is 50~200nm. It is made by soaking and rinsing zeolite particles with HCl solution, 3 Shake the reaction in the solution until the zeolite is saturated to adsorb Fe 3+ , rinsed with deionized water and then added NaBH 4 The solution shakes and reacts, removes the supernatant, freezes and dries to obtain the finished product. The zeolite-loaded nano-iron prepared by the present invention has strong adsorption capacity and reduction ability for pollutants. Tests have shown that the zeolite-loaded nano-iron material of the present invention can realize various heavy metal ions such as Pb in water bodies. 2+ 、Cd 2+ and Cr 6+ The removal rate can reach more than 99%. It has the advantages of high removal rate and fast reaction rate. The preparation process is simple and controllable, and the cost is low. It provides a better technical approach for solving heavy metal pollution in water.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

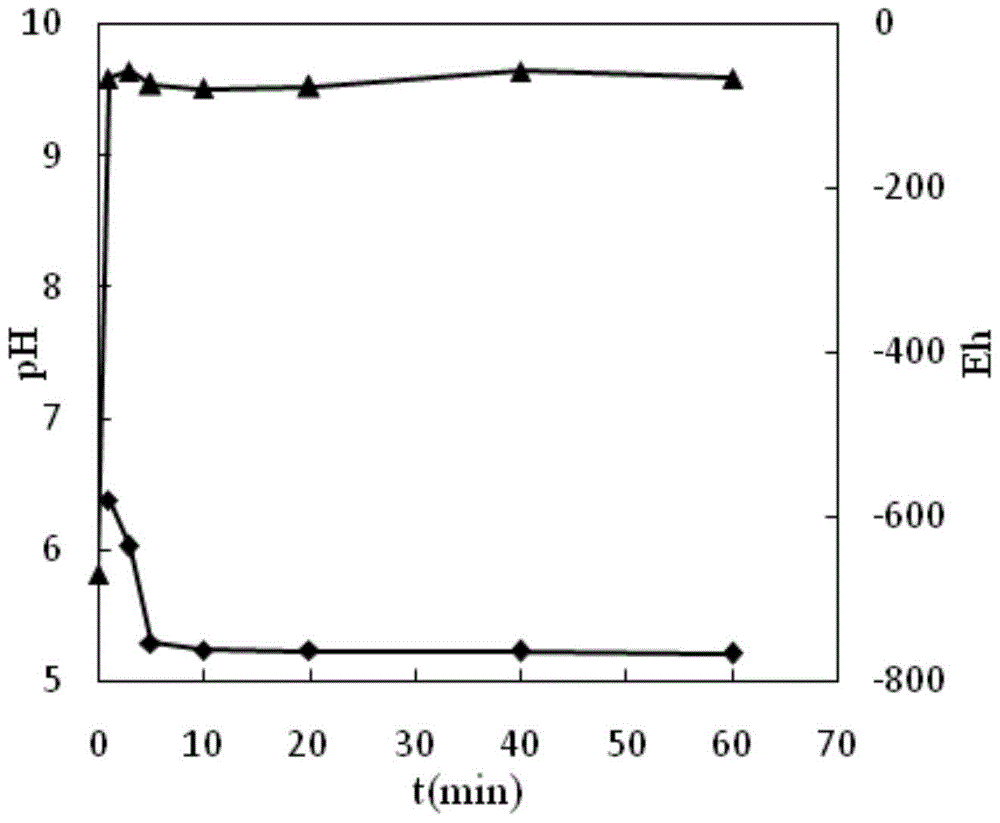

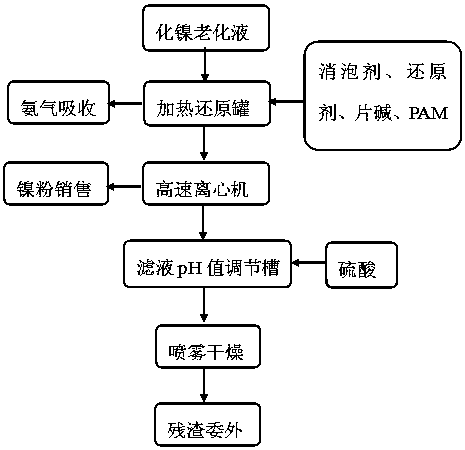

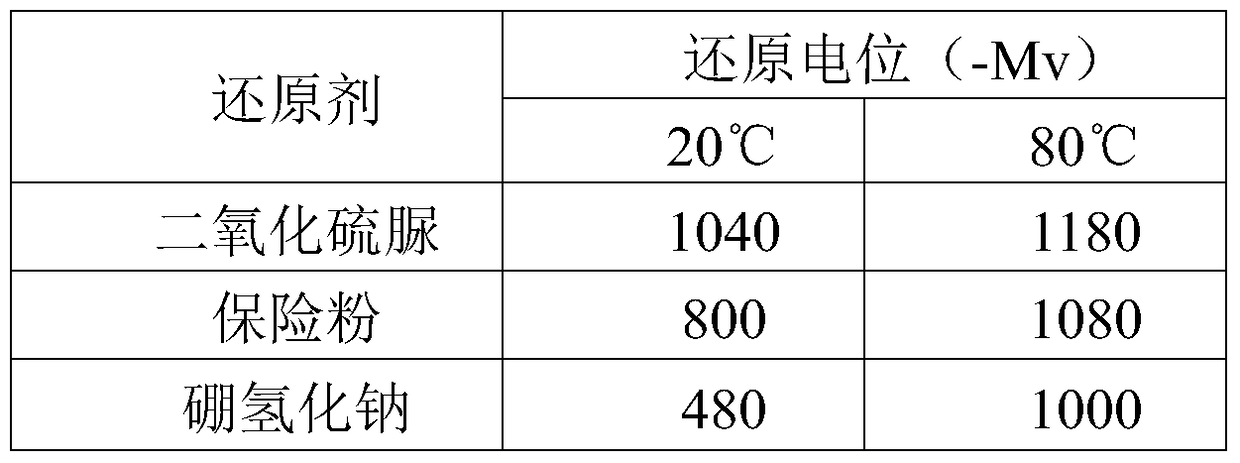

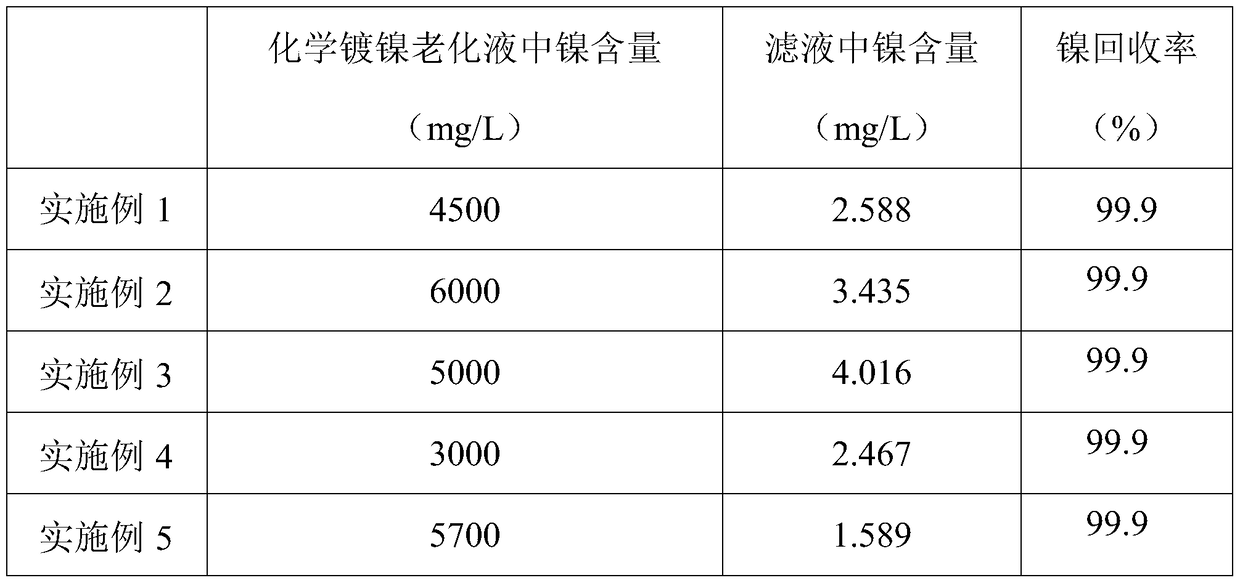

A kind of electroless nickel plating aging solution treatment process

ActiveCN105149610BWon't happenEffective protectionLiquid/solution decomposition chemical coatingElectroless nickelReaction temperature

The invention provides a process for treating chemical nickel-plating ageing solution. The process comprises the following steps: simultaneously adding an antifoaming agent and a reducing agent to a heating reduction tank, adopting steam heating; when the temperature rises to 70-100 DEG C, adding caustic soda flakes to perform a reduction reaction, making the reaction temperature be 70-100 DEG C, making the pH be 12-14, and making the reaction time be 20-30 min; purifying ammonia generated in the reaction process through an ammonia absorption tower, adding polyacrylamide after the reaction is ended, obtaining nickel powder and filtrate through high-speed centrifugation, recycling the nickel powder, adjusting the pH of the filtrate to 5-6 and then performing spraying drying, wherein obtained residue belongs to ordinary solid waste, performing outsourcing processing, and finishing treatment of the chemical nickel-plating ageing solution. The nickel concentration of the process filtrate is measured to be smaller than 5 mg / L, acid is added to regulate the PH of the filtrate to the suitable conditions to perform spraying drying, the dried residue undergoes outsourcing treatment, and the whole process is free of waste water discharge.

Owner:中新联科环境科技(安徽)有限公司

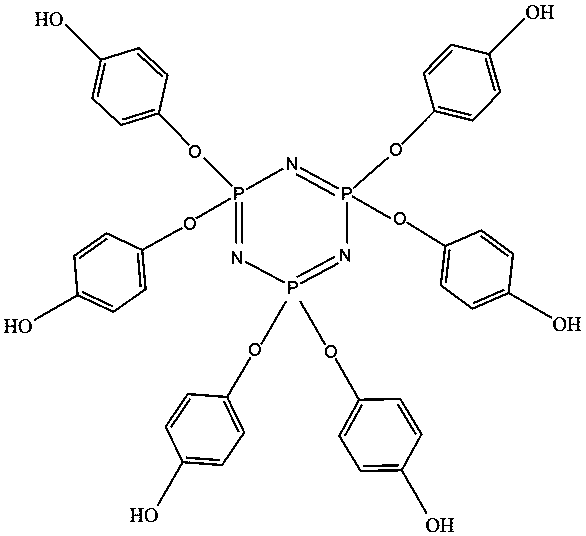

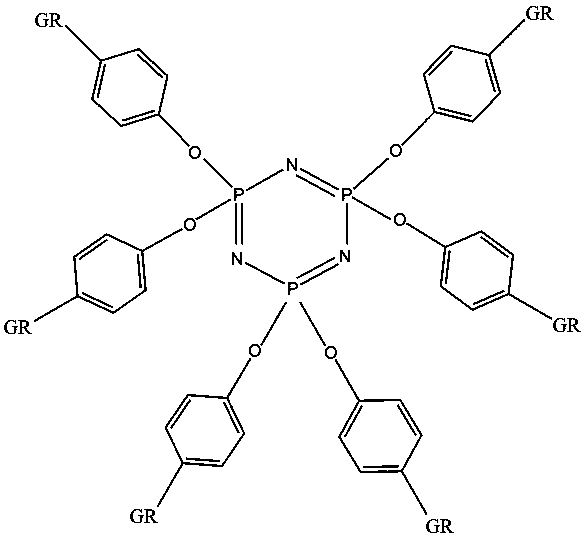

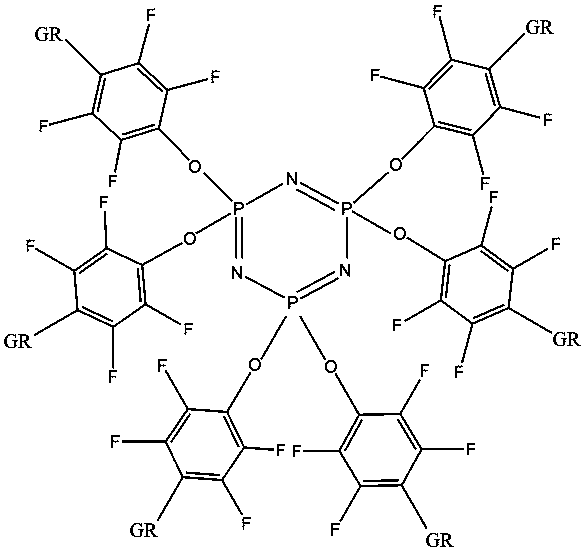

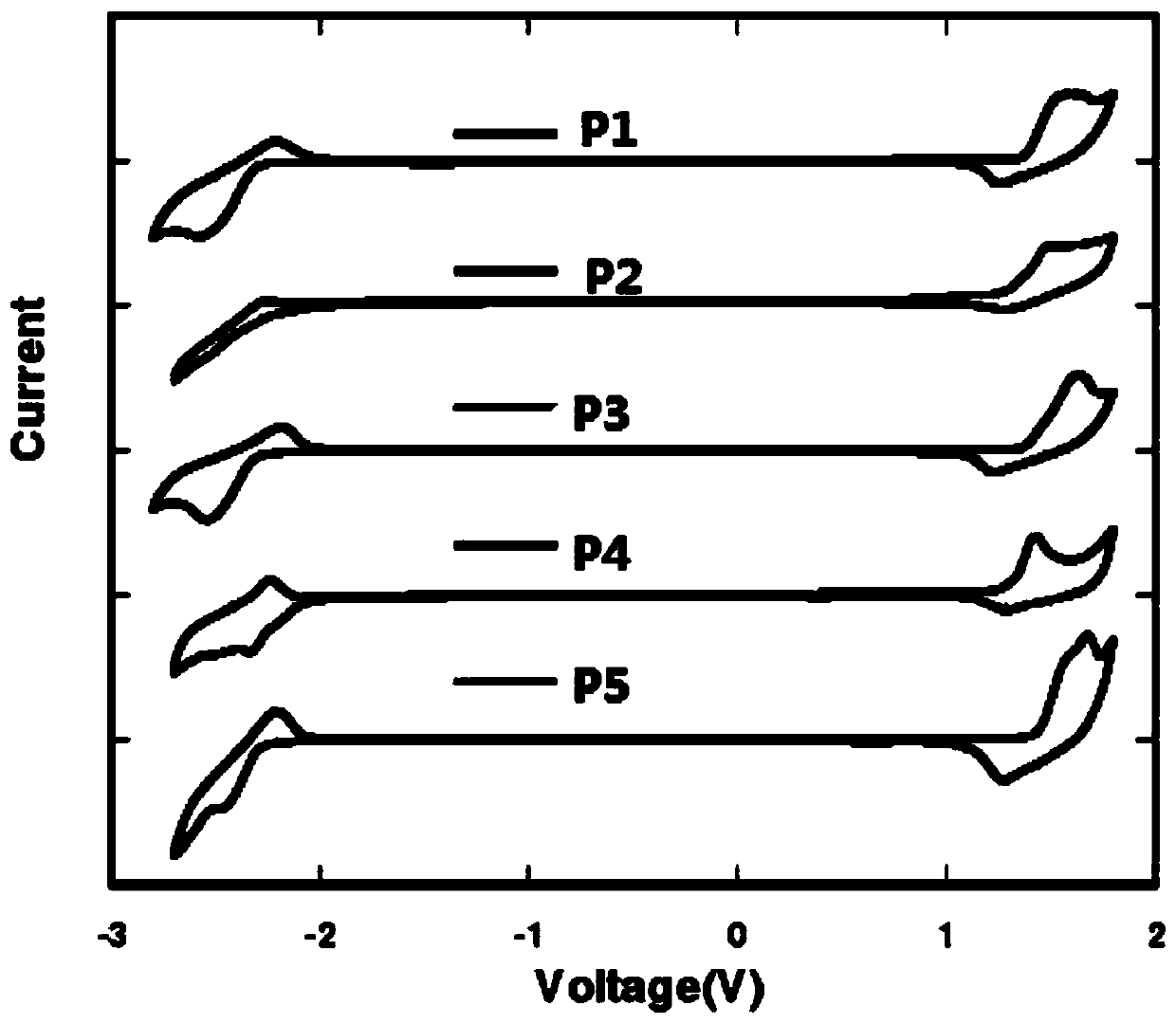

Modified cyclic phosphazene flame-retardant additive for lithium battery electrolyte and preparation method

ActiveCN111153939AGood effectReduce migration resistanceGroup 5/15 element organic compoundsOrganic chemistry methodsElectrolytic agentSide chain

The invention relates to the technical field of lithium batteries, and provides a modified cyclic phosphazene flame-retardant additive for a lithium battery electrolyte and a preparation method. The method comprises the following steps: preparing hexa(4-hydroxyphenoxy) cyclotriphosphazene by taking hexachlorocyclotriphosphazene and hydroquinone as raw materials; then carrying out mixing and ball milling on graphene nanosheets and oxalic acid, and grafting a carboxyl group on the surface of the graphene; then grafting the carboxylated graphene onto a side chain of hexa(4-hydroxyphenoxy) cyclotriphosphazene, so as to prepare graphene grafted phenoxy cyclotriphosphazene; and finally, performing substitution reaction on phenoxy on the side chain of cyclotriphosphazene by using fluorine gas toprepare graphene grafted perfluorophenoxy cyclotriphosphazene. Compared with the traditional method, the flame-retardant additive prepared by the invention not only can enable a lithium battery to have good flame-retardant performance, but also can improve the conductivity of the electrolyte.

Owner:SHUANGDENG GRP

Thiazole-based organic electroluminescent material and preparation method thereof

InactiveCN111560113AIncrease HOMO levelLower oxidation potentialSolid-state devicesSemiconductor/solid-state device manufacturingDisplay devicePhenyl group

The invention belongs to the technical field of photoelectric display devices, and particularly relates to a thiazole-based organic electroluminescent material and a preparation method thereof. The thiazole-based organic electroluminescent material provided by the invention has a structure as shown in a formula (I). The invention also provides a preparation method of the thiazole-based organic electroluminescent material. The method comprises the step of subjecting a compound as shown in the formula (II), 3,10-dibromo-14-(3-(5-phenyl-1,3,10-oxadiazol-2-yl)phenyl)-14H-bis(S,S-dioxo-dibenzothiophene)pyrrole and 2-(3-(3,10-bis(4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)-14H-bis(S,S-dioxo-dibenzothiophene)pyrrole-1, 5-phenyl-1,3,4-oxadiazole to a Suzuki coupling reaction so as to obtain a polymer as shown in a formula (I). The thiazole-based organic electroluminescent material and the preparation method thereof solve the technical problem that existing organic electroluminescent materialsare difficult to guarantee both hole and electron transport efficiency and are thus poor in electroluminescent efficiency.

Owner:胡金超

Organic photoelectric material, preparation method and application thereof

PendingCN111825522AReduce internal energyImprove thermal stabilityCarboxylic acid nitrile preparationOrganic compound preparationCharge injectionElectron hole

The invention provides an organic photoelectric material, which has a structure represented by a formula I. According to the invention, the organic photoelectric material contains a substituted butadiene skeleton structure, and two double bonds form a conjugated system, so that the thermal stability of the material is improved, and the film-forming property of the organic photoelectric material inthe processing process is further improved; under the combined action of the cross conjugate structure in the molecule and the electron withdrawing group in the substituent group, the molecule has high reduction potential so as to assist the hole transport layer to perform efficient hole injection; and the organic photoelectric material is used as a hole injection layer object material of an OLEDdevice, so that charge injection can be effectively increased, the driving voltage of the OLED device is reduced, the service life of the device is prolonged, and the overall efficiency of the deviceis improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

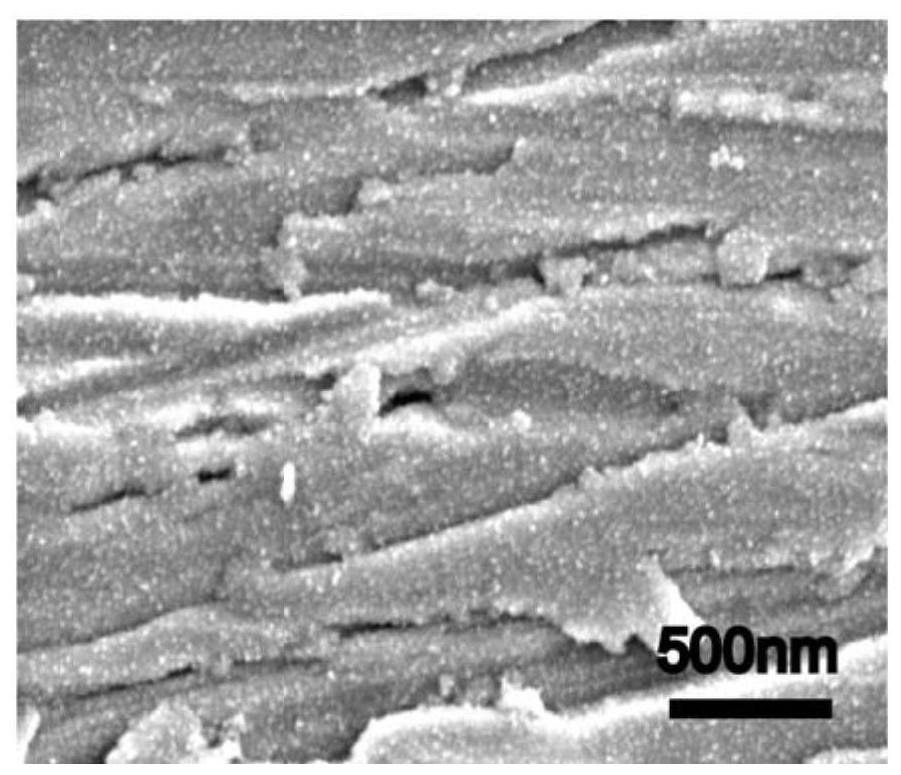

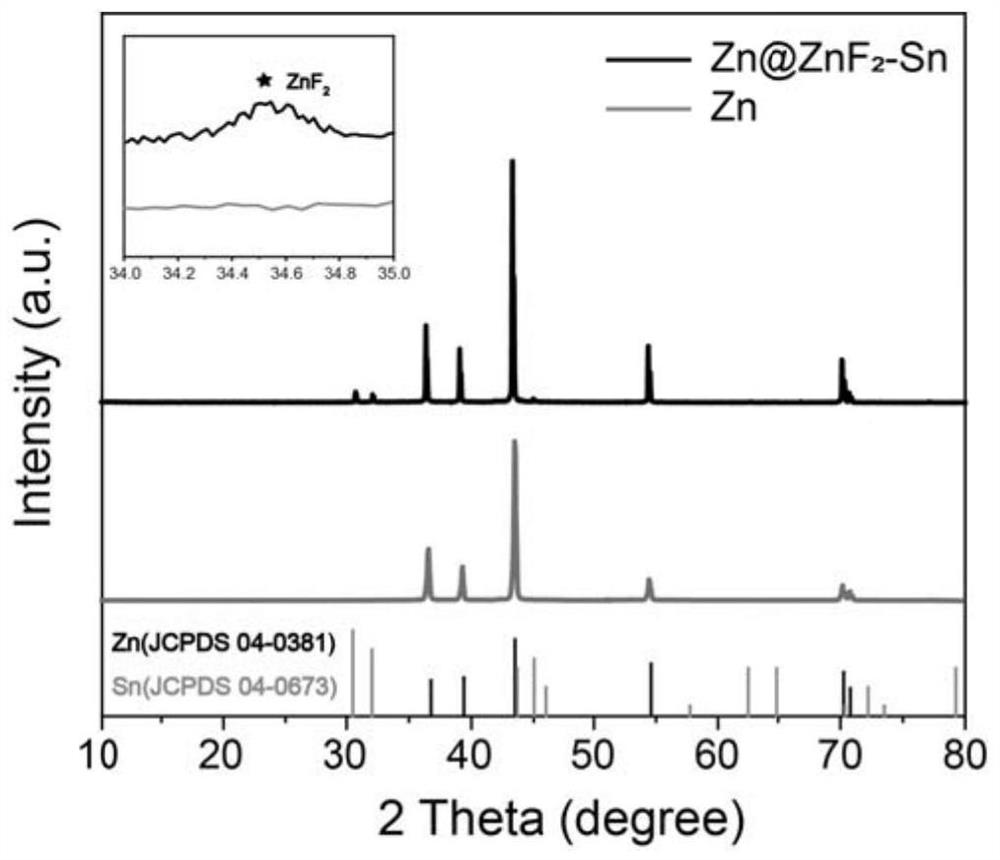

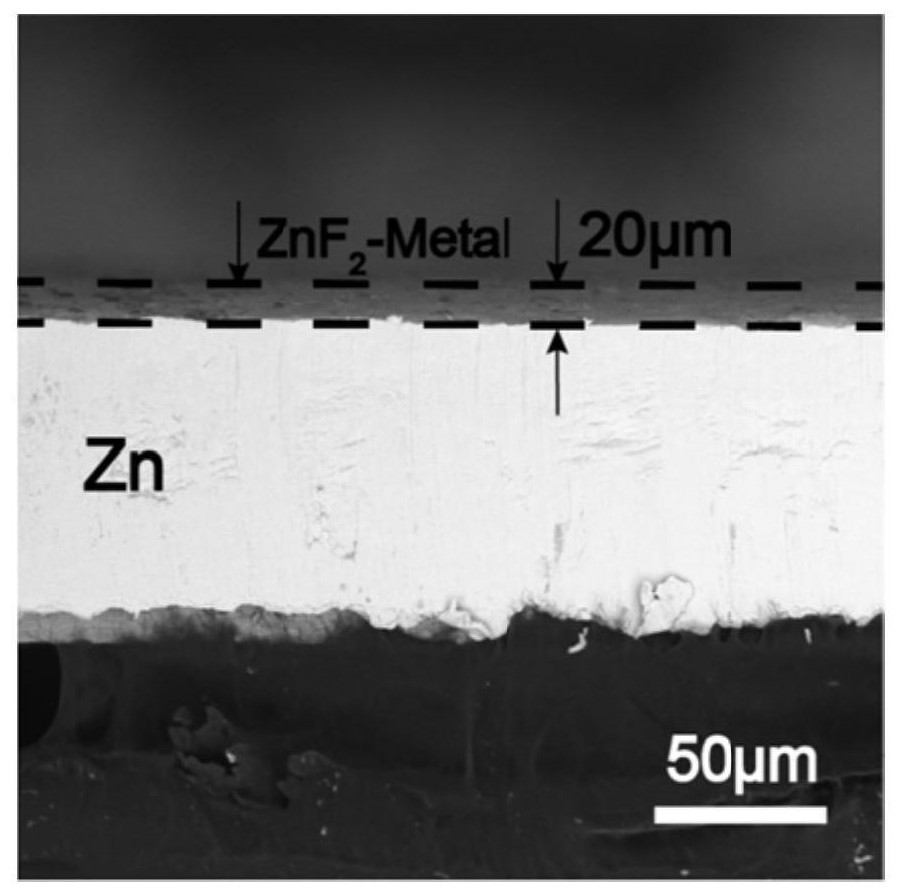

Double-phase interface protected metal zinc negative electrode and preparation method and application thereof

PendingCN114551775AUniform nucleation growthImprove adsorption capacityFinal product manufactureActive material electrodesZinc ionElectrical battery

The invention discloses a double-phase interface protected metal zinc negative electrode and a preparation method and application thereof.A zinc sheet is placed in a metal fluoride solution through a simple and rapid treatment method to form an artificial double-phase interface of ZnF2 and a metal simple substance, and uniform nucleation and efficient deposition of zinc ions are promoted through the metal simple substance in the double-phase interface, so that the metal zinc negative electrode is obtained. And meanwhile, the ZnF2 protective layer reduces side reactions of polarization and hydrogen evolution corrosion, successfully inhibits growth of zinc dendrites, improves the interface stability between the zinc negative electrode and the electrolyte, and remarkably improves the electrochemical performance of the zinc ion battery.

Owner:XI AN JIAOTONG UNIV

Lithium ion secondary battery electrolyte

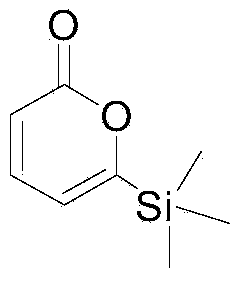

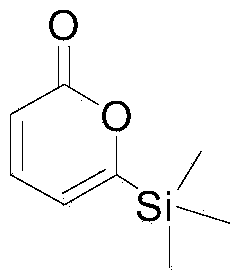

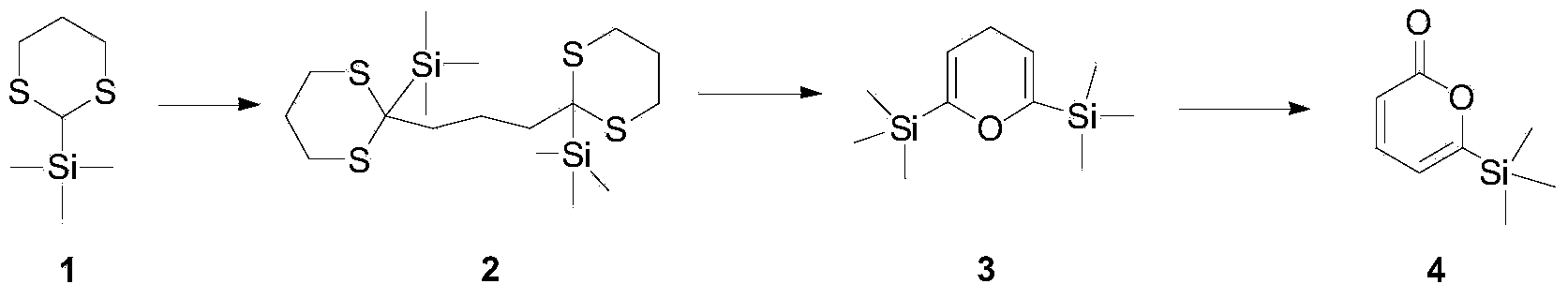

ActiveCN104078709AImprove initial discharge capacityImprove cycle lifeSilicon organic compoundsSecondary cellsSolid state electrolyteOrganic solvent

The invention discloses lithium ion secondary battery electrolyte which comprises a non-aqueous organic solvent and lithium salt dissolved in the non-aqueous organic solvent, wherein the non-aqueous organic solvent contains 6-trimethyl silicon-based pyrone which accounts for 0.5%-5% of the non-aqueous organic solvent in total mass; the structure formula of the 6-trimethyl silicon-based pyrone is described in the specification. An additive containing the 6-trimethyl silicon-based pyrone described in the molecular structural formula is added into the lithium ion secondary battery electrolyte; since the additive has a high reduction potential, a compact and stable solid electrolyte passivation membrane (SEI) can be formed in the process of charging for the first time, so that the co-embedding of propylene carbonate (PC) on graphite can be effectively suppressed, the initial discharge capacity of the battery can be effectively increased, the cycle life of the battery is prolonged, the high and low temperature performance of the battery can be effectively improved, and the problem of the stripping of the graphite in the battery in the charging process can be effectively avoided.

Owner:XIAMEN SHOUNENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com