High-voltage lithium ion battery

A lithium-ion battery, high-voltage technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high-voltage oxidation and decomposition of high-voltage cathode materials, such as structural damage, to improve high-voltage cycle performance, ensure stability, and contact interface quality. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

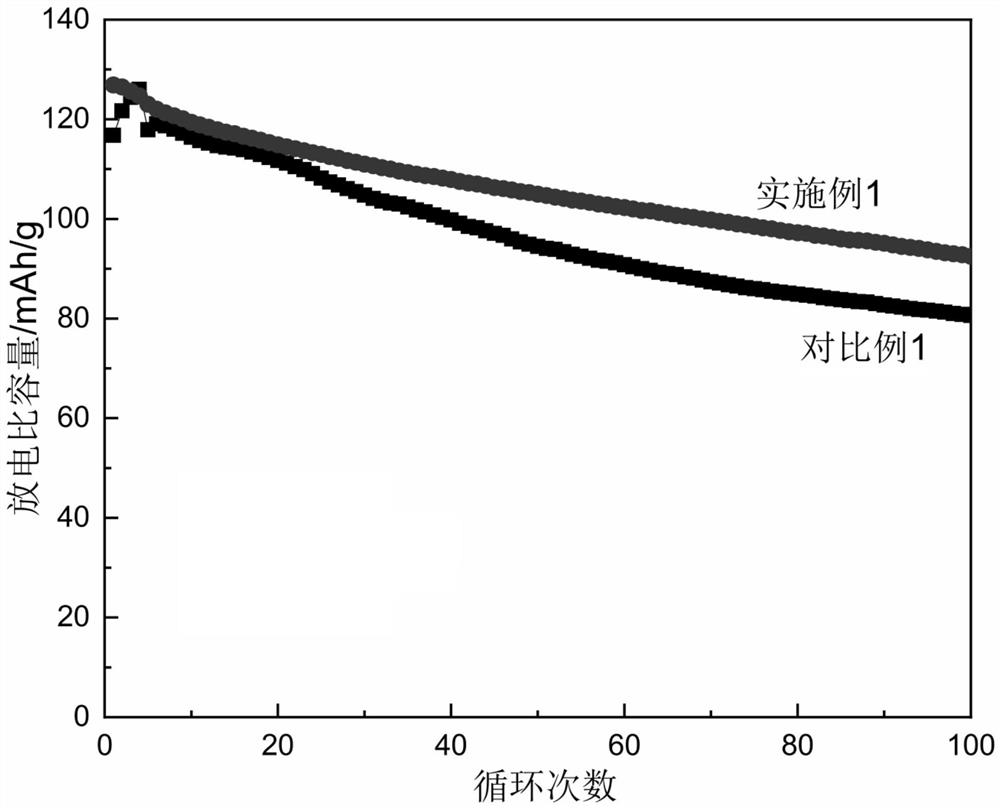

Embodiment 1

[0058] Spinel LiNi 0.5 mn 1.5 o 4 with NH 4 F was mixed by ball milling and heat-treated at 450 °C for 5 h to prepare high-pressure fluorinated cathode materials. After the material is uniformly mixed with conductive agent SP and binder PVDF in NMP solvent, it is coated on the surface of aluminum foil to prepare a high-voltage fluorinated positive electrode sheet.

[0059] After mixing the artificial graphite, the conductive agent SP, and the binder CMC+SBR in a deionized water solvent, they are coated on the surface of copper foil to prepare a carbonaceous negative electrode sheet.

[0060] lithium salt LiPF 6 Dissolve in a mixed solvent composed of 1H,1H,5H-octafluoropentyl-1,1,2,2-tetrafluoroethyl ether and EC, EMC (volume ratio 2:4:4), and add a mass ratio of 2% FEC and 1% lithium difluorooxalate borate to prepare a fluorinated electrolyte.

[0061] In a glove box filled with argon gas, the high-pressure fluorinated positive electrode, polyolefin separator and carbon...

Embodiment 2

[0063] Spinel LiNi 0.5 mn 1.5 o 4 Access to F 2 In the atmosphere, the high-pressure fluorinated cathode material was prepared after being kept at room temperature for 2 hours. After the material is uniformly mixed with conductive agent SP and binder PVDF in NMP solvent, it is coated on the surface of aluminum foil to prepare a high-voltage fluorinated positive electrode sheet.

[0064] lithium salt LiPF 6 Dissolve in a mixed solvent composed of 1,3-bis(1,1,2,2-tetrafluoroethoxy)propane, EC and DMC (volume ratio 1:1:1), and add a mass ratio of 5% Ethyl-(2,2,2-trifluoroethyl)carbonate and 0.5% tris(trimethylsilyl)borate to prepare a fluorinated electrolyte.

[0065] The carbonaceous negative electrode and the button lithium ion battery are made with the same embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com