Efficient soldering flux formula

A flux and formula technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of single, reduce the efficiency of flux use, reduce the work efficiency of working users, etc., to improve the use efficiency, improve Welding efficiency and the effect of ensuring firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

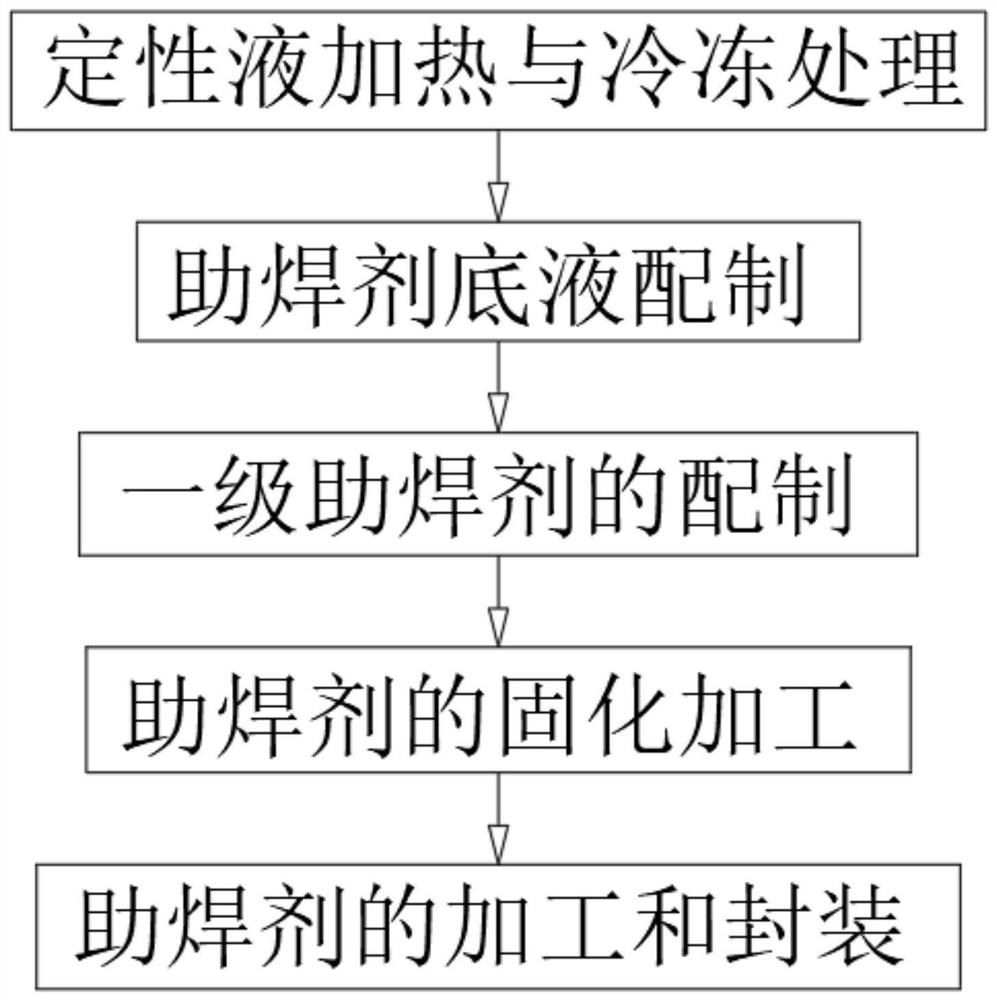

[0030] see figure 1 , the present invention provides a technical solution: a high-efficiency flux formula, characterized in that: the high-efficiency flux formula is realized according to the mass ratio of the following materials:

[0031] 25-30 parts of rosin, 2 parts of rosin-modified phenolic resin, 1 part of rosin glyceride, 1 part of acrylic resin, 15-20 parts of absolute ethanol, 2 parts of butyl ether, dimethyl sulfonate succinate 1 part, 1 part of benzotriazole, 30-35 parts of xylene, 10-15 parts of benzene, 35-40 parts of deionized water, 2 parts of qualitative solution.

[0032] This highly effective flux formulation includes the following production steps:

[0033] Step 1. Heating and freezing treatment of the qualitative solution. Place the qualitative solution in a clean vessel, and heat the qualitative solution in the vessel. The heating temperature is 150 degrees Celsius, and the heating time is 15-18 minutes. Place it in the environment of minus 18 degrees Ce...

Embodiment 2

[0047] see figure 1 , the present invention provides a technical solution: a high-efficiency flux formula, characterized in that: the high-efficiency flux formula is realized according to the mass ratio of the following materials:

[0048] Rosin 20-25 parts, rosin modified phenolic resin 1 part, rosin glyceride 2 parts, acrylic resin 1 part, absolute ethanol 20-25 parts, ethylene glycol butyl ether 2 parts, dimethyl sulfonate succinate 1 part, 1 part of benzotriazole, 35-40 parts of xylene, 10-15 parts of benzene, 30-35 parts of deionized water, 2 parts of qualitative solution.

[0049] This highly effective flux formulation includes the following production steps:

[0050] Step 1. Heating and freezing treatment of the qualitative solution. Place the qualitative solution in a clean vessel, and heat the qualitative solution in the vessel. The heating temperature is 150 degrees Celsius, and the heating time is 15-18 minutes. Place it in the environment of minus 18 degrees Cels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com