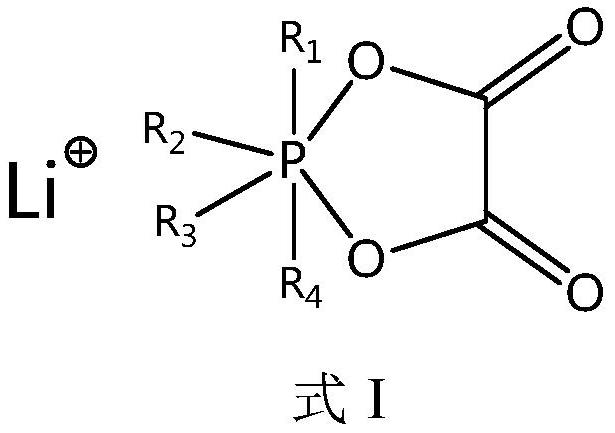

High-nickel ternary lithium ion battery electrolyte and ternary lithium ion battery

A lithium-ion battery and electrolyte technology, which is applied in secondary batteries, circuits, electrical components, etc., can solve problems such as hindering lithium ion migration, transition metal ion dissolution, and entering ion dissolution, so as to improve internal dynamic characteristics and inhibit Reduction reaction decomposition, the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

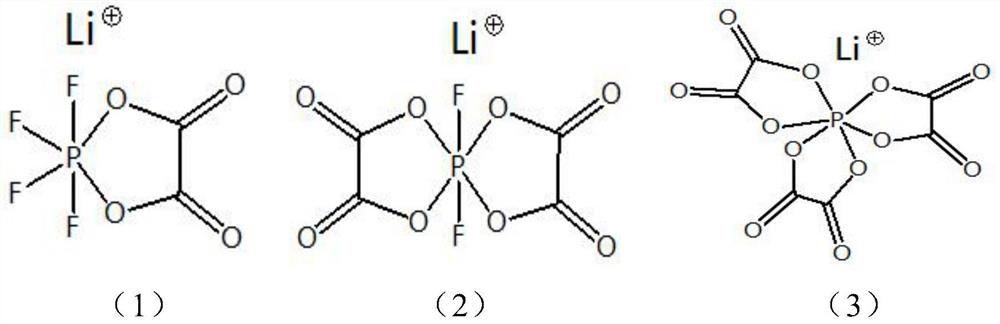

Embodiment 1

[0033] Electrolyte preparation: In a glove box filled with argon, ethylene carbonate, diethyl carbonate and ethyl methyl carbonate were mixed according to the mass ratio of EC:DEC:EMC=30:20:50, and then mixed Slowly add 12.5wt% lithium hexafluorophosphate and 0.8wt% lithium difluorophosphate to the solution, and finally add 1.0wt% lithium oxalate phosphate additive (compound 1) accounting for the total mass of the electrolyte, and stir evenly to obtain the lithium ion battery of Example 1 electrolyte.

[0034] Preparation of lithium-ion batteries:

[0035] The positive electrode active material LiNi 0.6 co 0.2 mn 0.2 o 2 , conductive agent acetylene black, binder polyvinylidene fluoride (PVDF) according to the mass ratio of 96:2:2 in the N-methylpyrrolidone solvent system after fully stirring and mixing evenly, coated on the aluminum foil and dried, cold pressed , to obtain the positive electrode sheet.

[0036] Negative electrode active material artificial graphite, con...

Embodiment 2-8

[0039] Embodiment 2-8 and comparative example 1-7

[0040] In Examples 2-8 and Comparative Examples 1-7, except that the composition ratio of the components of the electrolyte solution is added as shown in Table 1, the others are the same as in Example 1.

[0041] Table 1 embodiment 1-8 and the composition ratio of each component of the electrolyte of comparative example 1-7

[0042]

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com