Organic photoelectric material, preparation method and application thereof

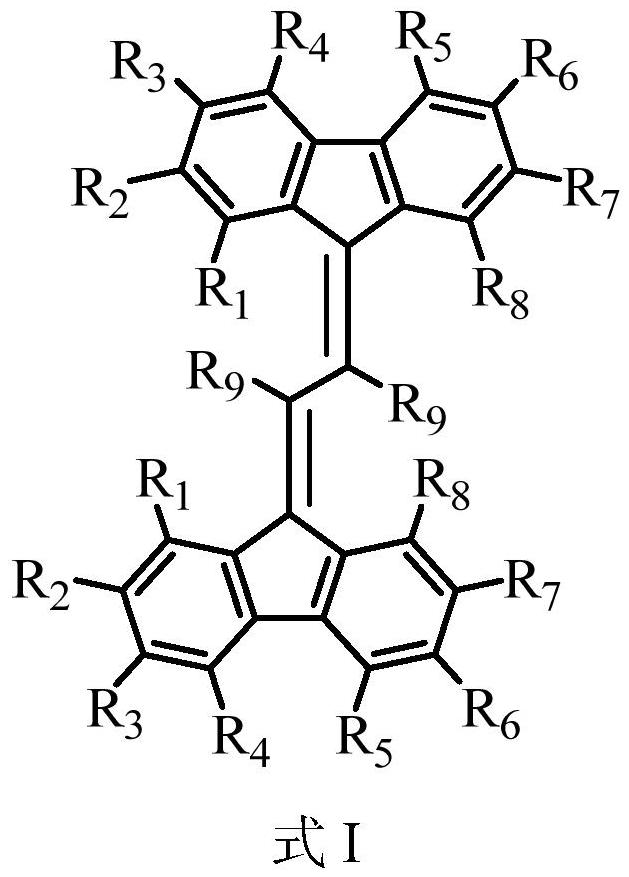

An organic optoelectronic material, an unreplaced technology, applied in the field of organic electroluminescence, which can solve the problems of high cost, many steps of axenic compounds, and poor stability of metal complexes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

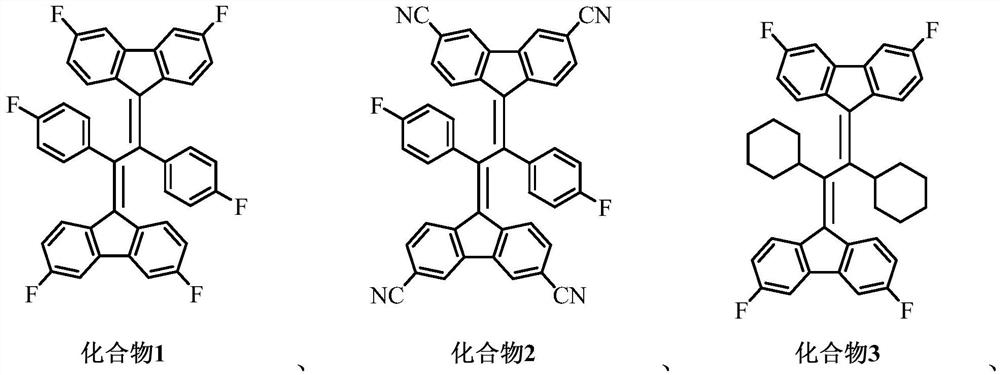

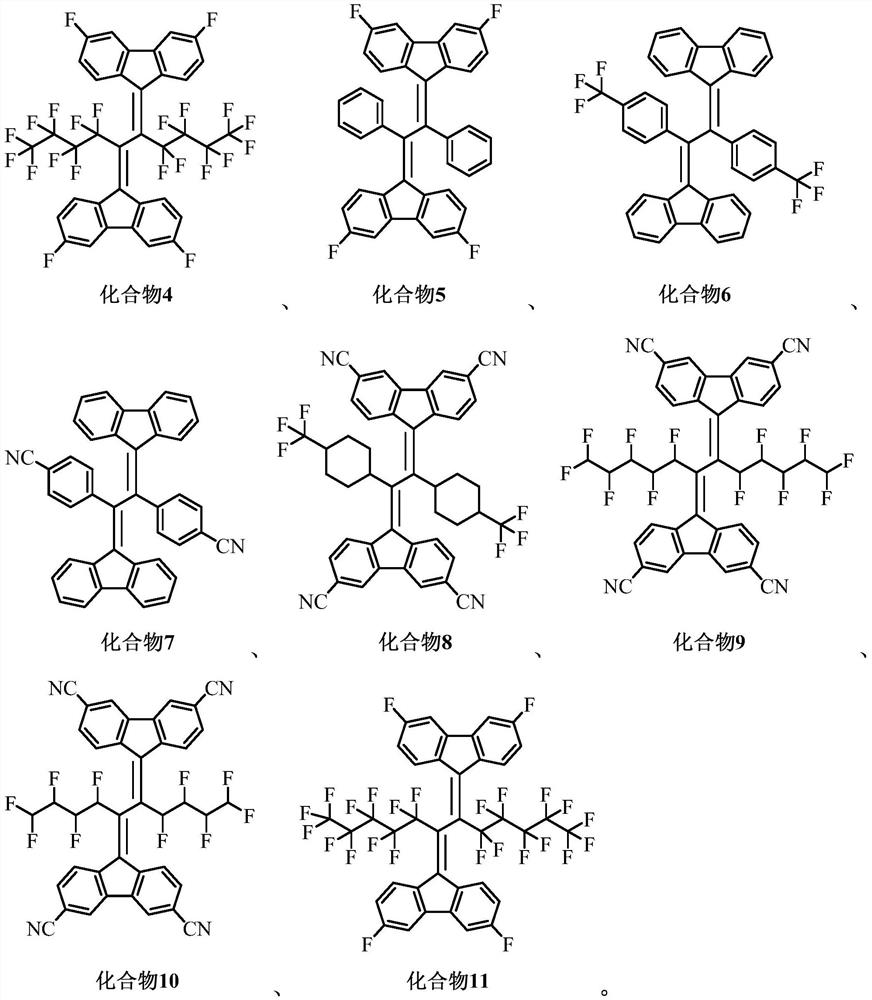

[0063] This embodiment provides an organic optoelectronic material compound 1, the structural formula of compound 1 is as follows The reaction formula for preparing compound 1 is:

[0064]

[0065] Concrete preparation method comprises the following steps:

[0066] (1) Add 2.17g of compound 1a (5mmol), 30mL of n-heptane and 20mL of diethyl ether into a Schelenk tube with nitrogen and oxygen isolation, and cool the solution to -78°C; then add 8.5mL, 1.3mol / L tert-butyllithium solution (solvent is n-heptane), stirred at -78°C for 8 minutes; removed the ice bath, and continued to stir for 15 minutes to obtain a reaction intermediate;

[0067] (2) 40.5mg FeCl 3 (0.25mmol) was dissolved in 2.5mL tetrahydrofuran to obtain a mixed solution, which was added to the reaction intermediate obtained in step (1); then di-tert-butyl peroxide (DTBP, 0.91mL, 5.0mmol) was added, and after stirring for 30min The reaction temperature was adjusted to room temperature, and the entire reacti...

Embodiment 2

[0071] This embodiment provides an organic optoelectronic material compound 2, the structural formula of compound 2 is as follows The reaction formula for preparing compound 2 is:

[0072]

[0073] Concrete preparation method comprises the following steps:

[0074] (1) Add 2.34g of compound 2a (5mmol), 30mL of n-heptane and 20mL of diethyl ether into a Schelenk tube with nitrogen to isolate oxygen, and cool the solution to -78°C; then add 8.5mL and 1.3mol of / L tert-butyllithium solution (solvent is n-heptane), stirred at -78°C for 8 minutes; removed the ice bath, and continued to stir for 15 minutes to obtain a reaction intermediate;

[0075] (2) 40.5mg FeCl 3(0.25mmol) was dissolved in 2.5mL tetrahydrofuran to obtain a mixed solution, which was added to the reaction intermediate obtained in step (1); then di-tert-butyl peroxide (DTBP, 0.91mL, 5.0mmol) was added, and after stirring for 30min The reaction temperature was adjusted to room temperature, and the entire reac...

Embodiment 3

[0079] This embodiment provides an organic optoelectronic material compound 3, the structural formula of compound 3 is as follows The reaction formula for preparing compound 3 is:

[0080]

[0081] Concrete preparation method comprises the following steps:

[0082] (1) Add 2.20g of compound 3a (5mmol), 30mL of n-heptane and 20mL of diethyl ether into a Schelenk tube with nitrogen to isolate oxygen, and cool the solution to -78°C; then add 8.5mL and 1.3mol of / L tert-butyllithium solution (solvent is n-heptane), stirred at -78°C for 8 minutes; removed the ice bath, and continued to stir for 15 minutes to obtain a reaction intermediate;

[0083] (2) 40.5mg FeCl 3 (0.25mmol) was dissolved in 2.5mL tetrahydrofuran to obtain a mixed solution, which was added to the reaction intermediate obtained in step (1); then di-tert-butyl peroxide (DTBP, 0.91mL, 5.0mmol) was added, and after stirring for 30min The reaction temperature was adjusted to room temperature, and the entire rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nmr | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com