Patents

Literature

92results about How to "Improve internal energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of Manufacturing Anti-Bacteria Polyamide Fiber via High Speed Spinning

InactiveUS20080164628A1Increase length diameter ratePromote swellingArtifical filament manufactureMonocomponent polyamides artificial filamentYarnLow speed

A method of manufacturing anti-bacteria polyamide fiber via high speed spinning disclosed a kind of method, which can make manufacturing anti-bacteria polyamide fiber via high-speed spinning realized, including the preparation of anti-bacteria particles and process of high-speed spinning. The preparation of anti-bacteria particles includes surface treatment of anti-bacteria agent and its process of preparation. Choose nano zeolite carrying silver ion as anti-bacteria agent, mix the anti-bacteria particles and polymer chips, after melting, produce anti-bacteria yarns via high speed spinning. The surface treatment to the anti-bacteria agent the invention can improve the spinnability of raw material and place foundation for realizing high speed spinning. Further more, for the spinning pack, adopt good quality mental powder as filtering and pressuring material and increase length diameter rate of hole of spinneret to lengthen the friction distance that the melt passing the spinneret holes in order to eliminate the inner energy of polymer, which prevent the melt from breaking cause by released inner energy while polymer bursting from the spinneret holes. The method described in the invention is simple and easy to implemented. High speed spinning realized by adopting this method, solve the problems of long process rout, low output and lower grade products caused by existing low-speed spinning and greatly increase the beneficial result of enterprise.

Owner:LIAONING YINZHU CHEMTEX GROUP

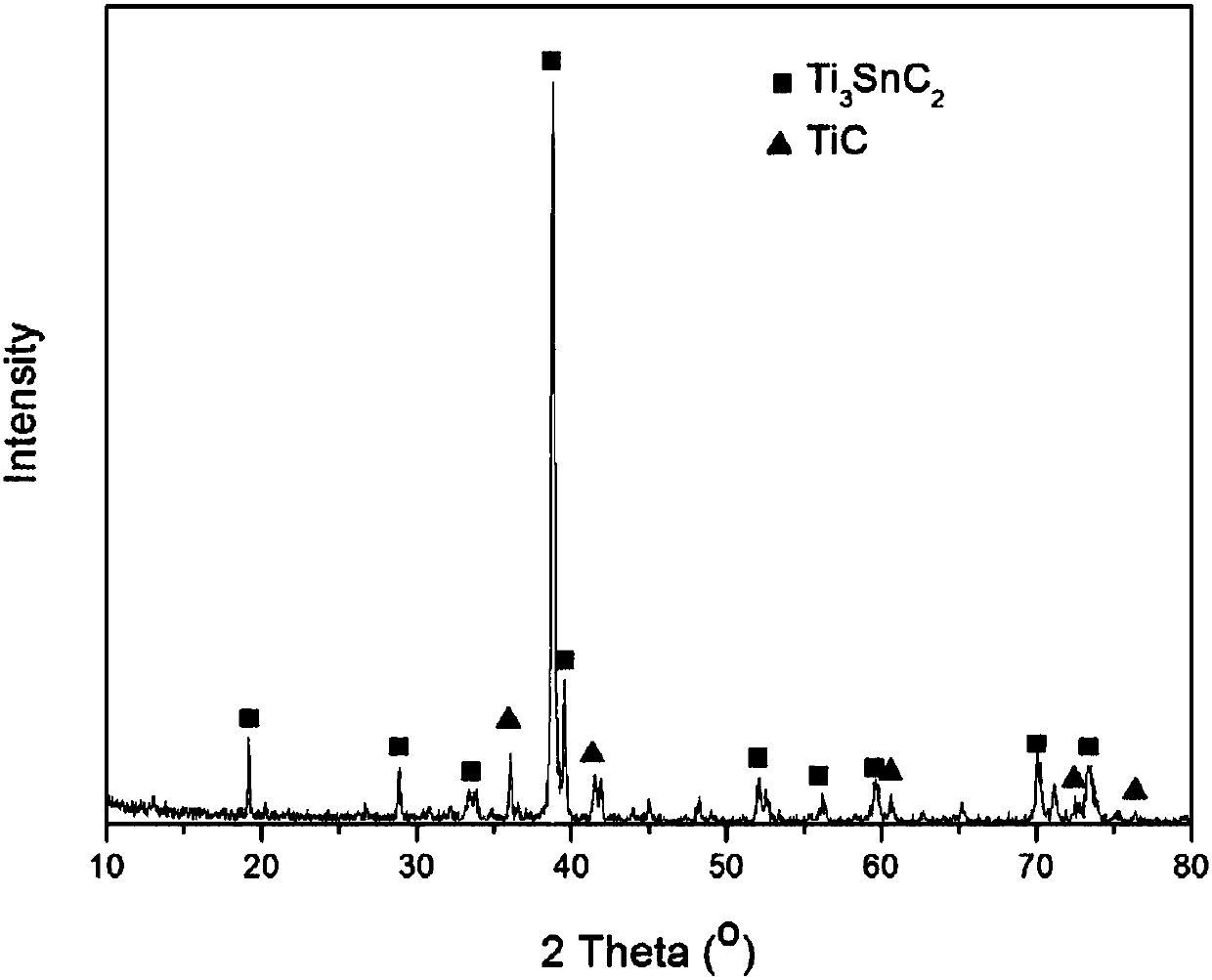

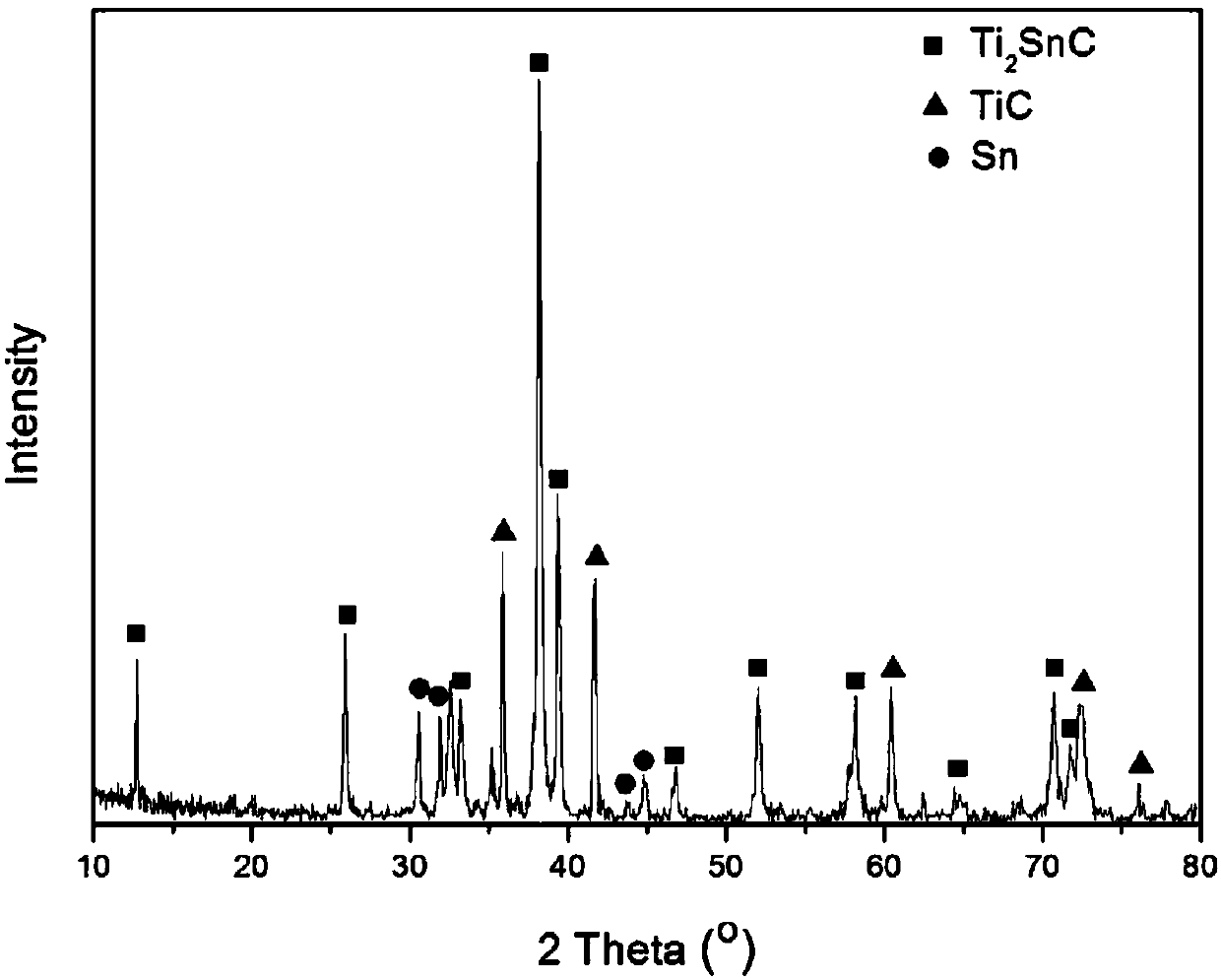

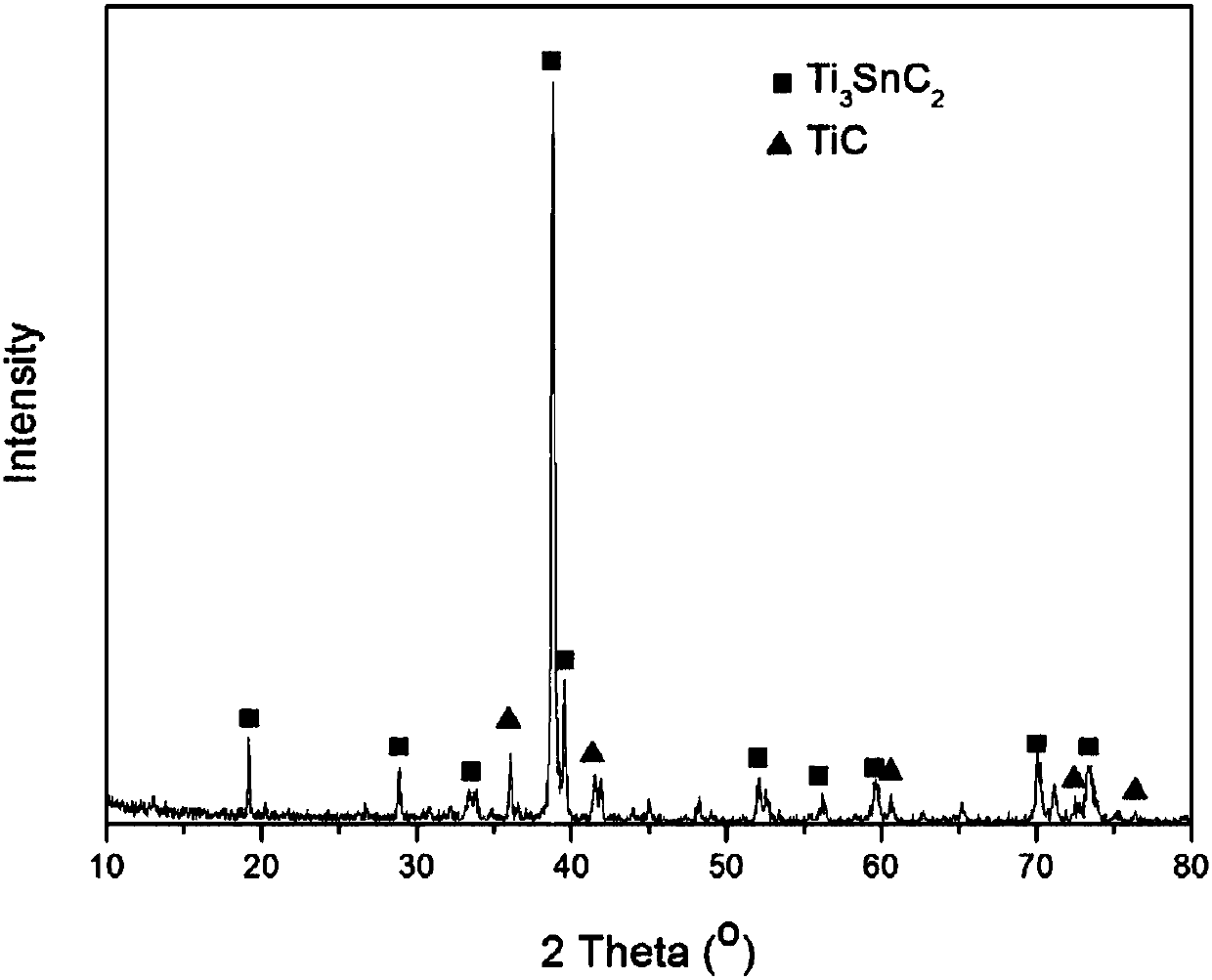

Preparation method for Ti3SnC2 ceramic powder and prepared ceramic powder

The invention provides a preparation method for a Ti3SnC2 ceramic powder and the prepared ceramic powder, and belongs to the field of ceramic materials. The preparation method comprises the steps: mixing raw materials evenly, and carrying out ball milling for a first time for 2.5-3.5 h at a speed of 400-800 r / min, to obtain a ball-milled activated powder; carrying out a self-propagating reaction of the ball-milled activated powder to obtain a massive product; and carrying out ball milling of the massive product for a second time for 2.5-3.5 h at a speed of 250-350 r / min. The raw materials comprise, in parts by weight, 2.95-3.05 parts of a Ti powder, 0.6-1 part of an Sn powder, 0.2-0.6 part of an Al powder and 1.95-2.05 parts of a C powder. The preparation method has the advantages of simple process, low energy consumption and rapid reaction. The ceramic powder prepared by the preparation method has the advantages of low cost, high purity, high activity, large hardness, small particle size, good electric conductivity, good thermal conductivity and the like, and is suitable for industrialized production.

Owner:YANCHENG INST OF TECH

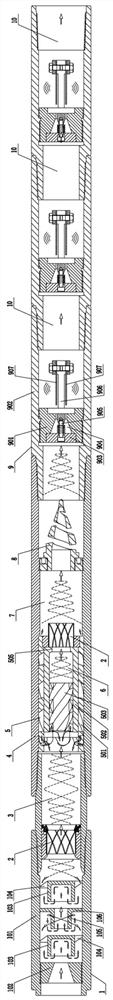

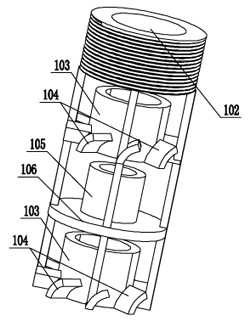

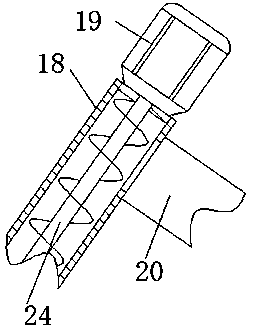

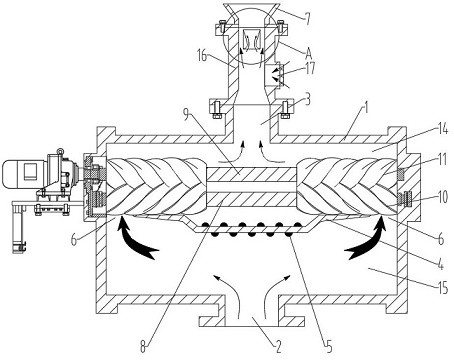

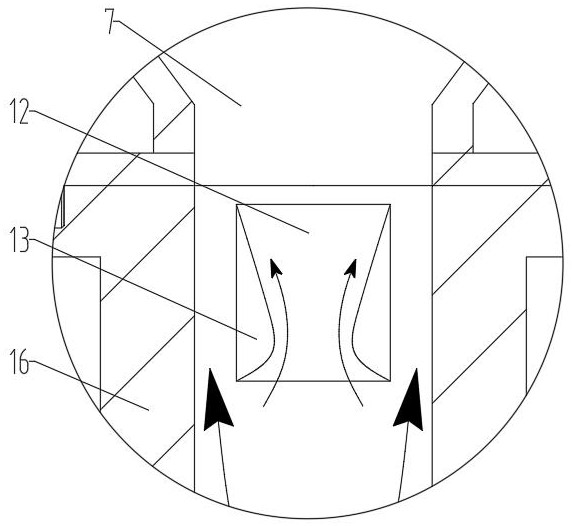

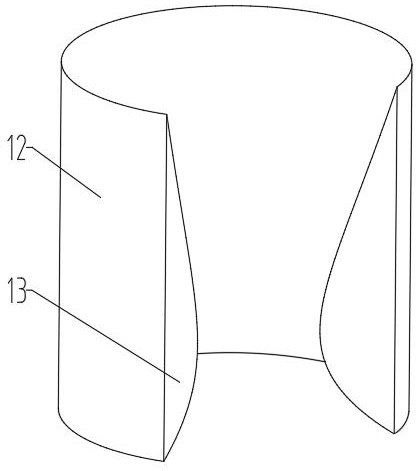

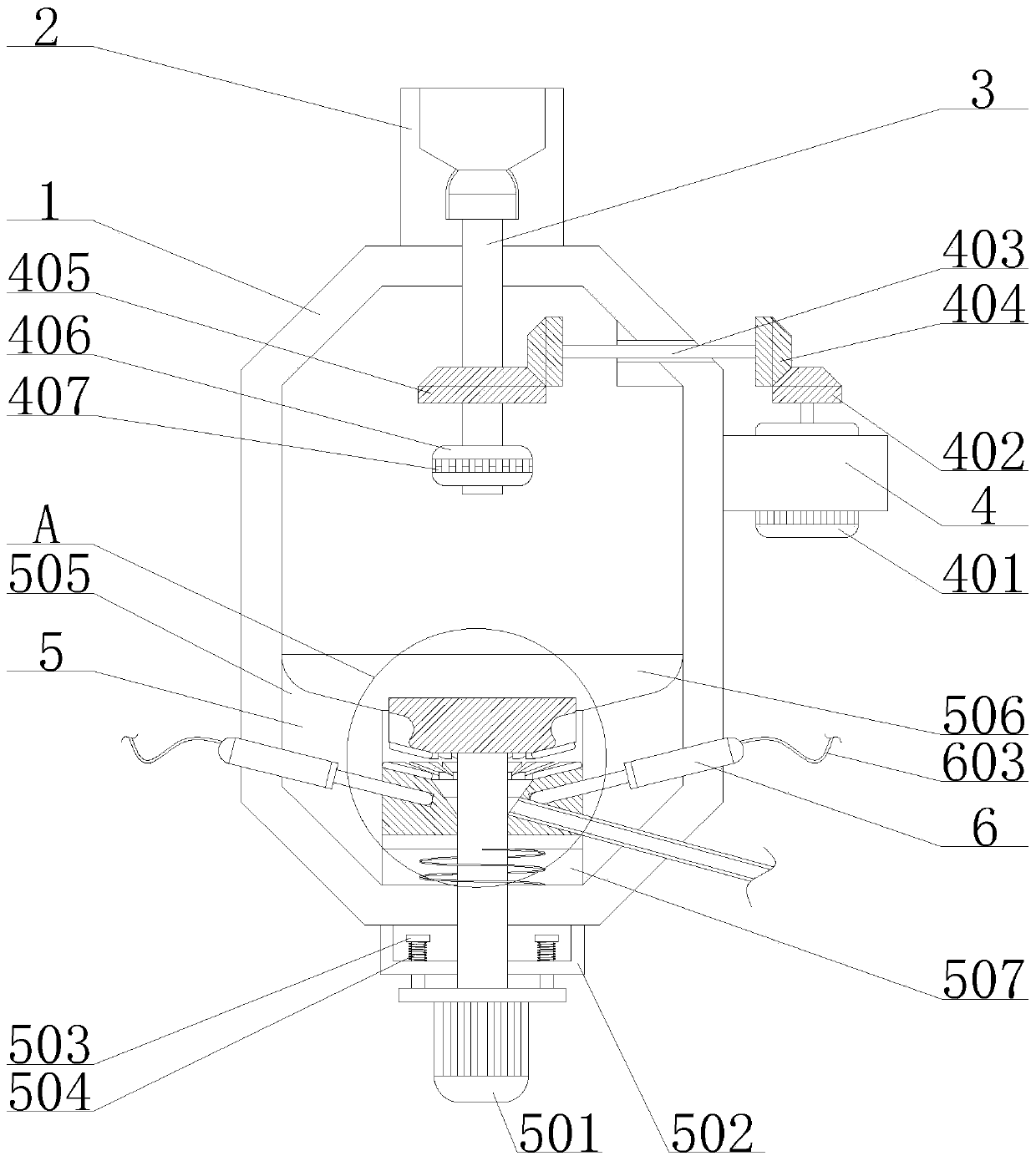

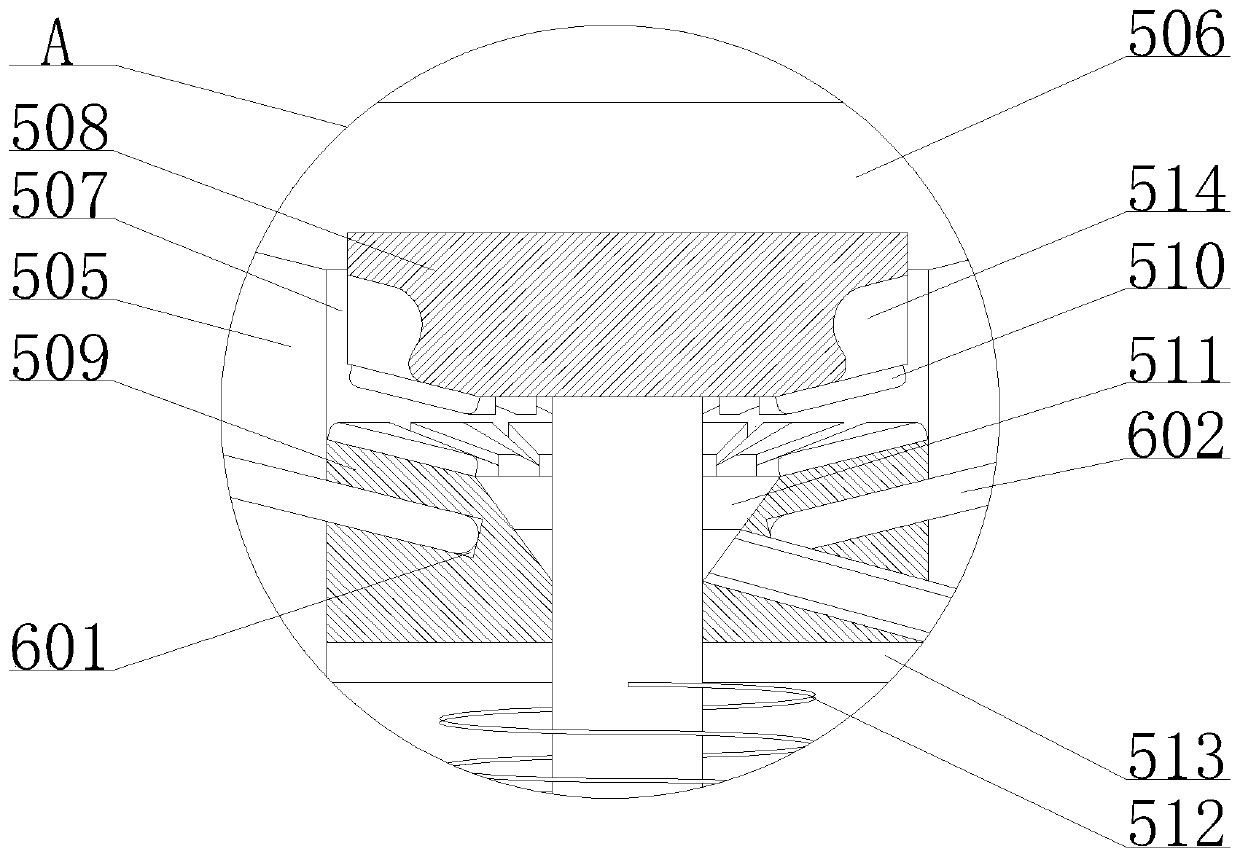

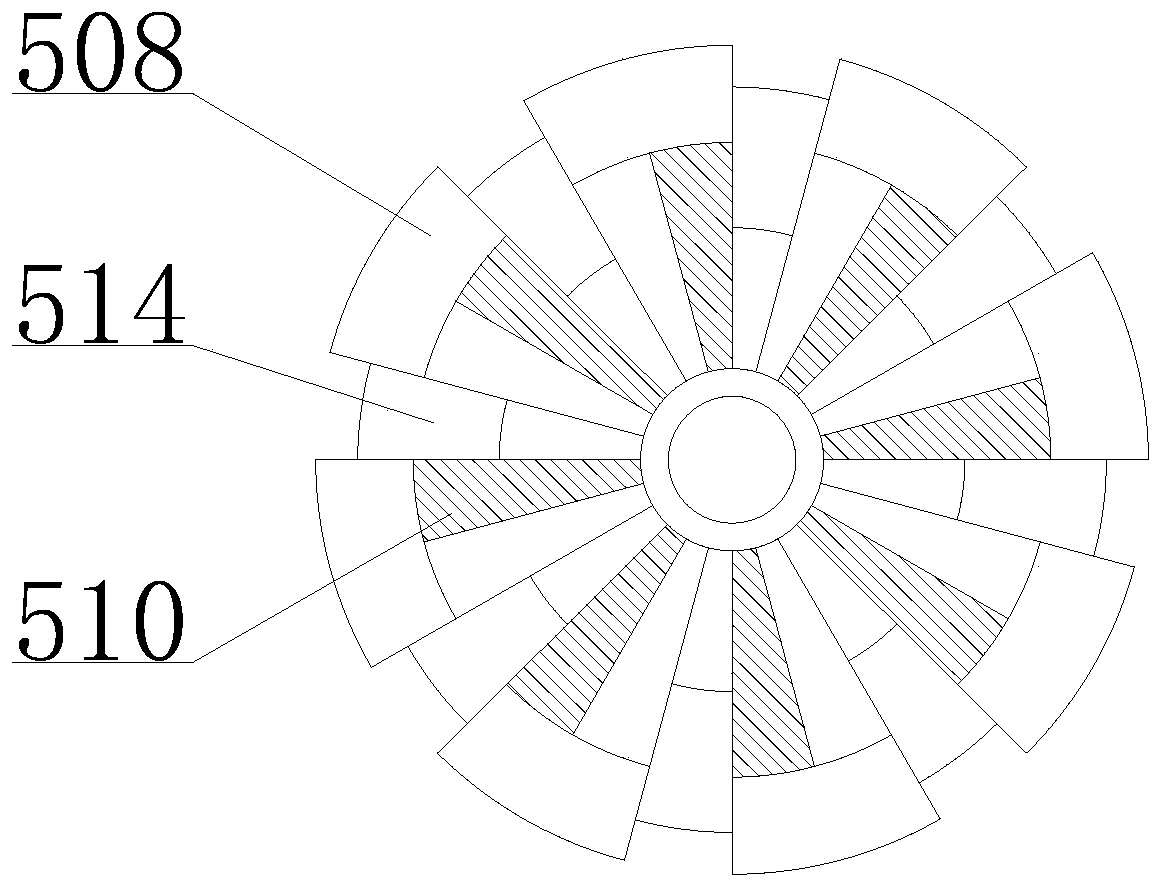

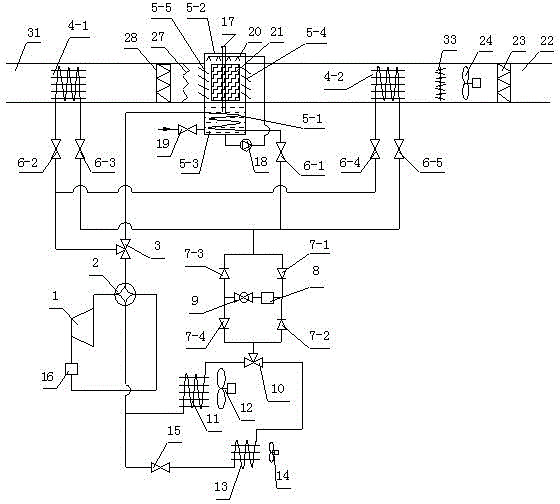

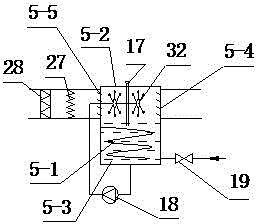

Multi-stage composite rotational flow and turbulent flow sound wave super-strong viscosity reduction, paraffin control and oil increasing device

ActiveCN112096346ASolve the problem of easy blockageImprove liquidityCleaning apparatusFluid removalAtomizer nozzleEngineering

The invention provides a multi-stage composite rotational flow and turbulent flow sound wave super-strong viscosity reduction, paraffin control and oil increasing device. The multi-stage composite rotational flow and turbulent flow sound wave super-strong viscosity reduction, paraffin control and oil increasing device comprises a pipe shell; an oil inlet is formed in the front end of the pipe shell; an oil outlet is formed in the rear end of the pipe shell; a layered rotational flow mechanism is mounted in the position, located behind the oil inlet, in the pipe shell and comprises an outer-layer rotational flow sleeve mounted on the inner wall of the pipe shell; a middle spacer sleeve is fixedly arranged on the inner wall of the outer-layer rotational flow sleeve; an inner-layer rotationalflow column core is arranged in the middle spacer sleeve; the middle spacer sleeve is used for separating an inner-layer oil passage from outer outer-layer oil passage; an atomizing nozzle is arranged in the position, located on the inner side of the oil outlet, in the pipe shell; a multi-stage turbulent flow mechanism is arranged at the outer end of the oil inlet in the pipe shell; a first-stageturbulent flow chamber is formed between the multi-stage turbulent flow mechanism and the layered rotational flow mechanism; a second-stage turbulent flow chamber is formed between the rear end of the middle spacer sleeve and the end part of the inner-layer rotational flow column core; and a third-stage turbulent flow chamber is formed between the layered rotational flow mechanism and the atomizing nozzle. According to the multi-stage composite rotational flow and turbulent flow sound wave super-strong viscosity reduction, paraffin control and oil increasing device, the paraffin control and viscosity reduction effects are greatly improved, the efficiency of an oil well pump is improved, an oil pipe almost cannot be blocked, and the yield of an oil well is increased.

Owner:HUANGSHI BOHUI TECH CO LTD

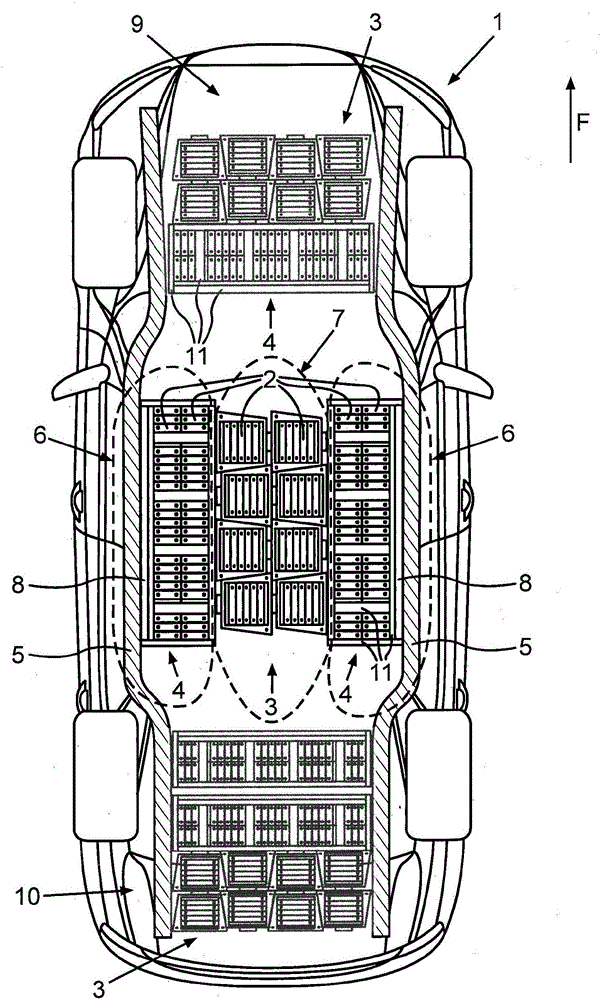

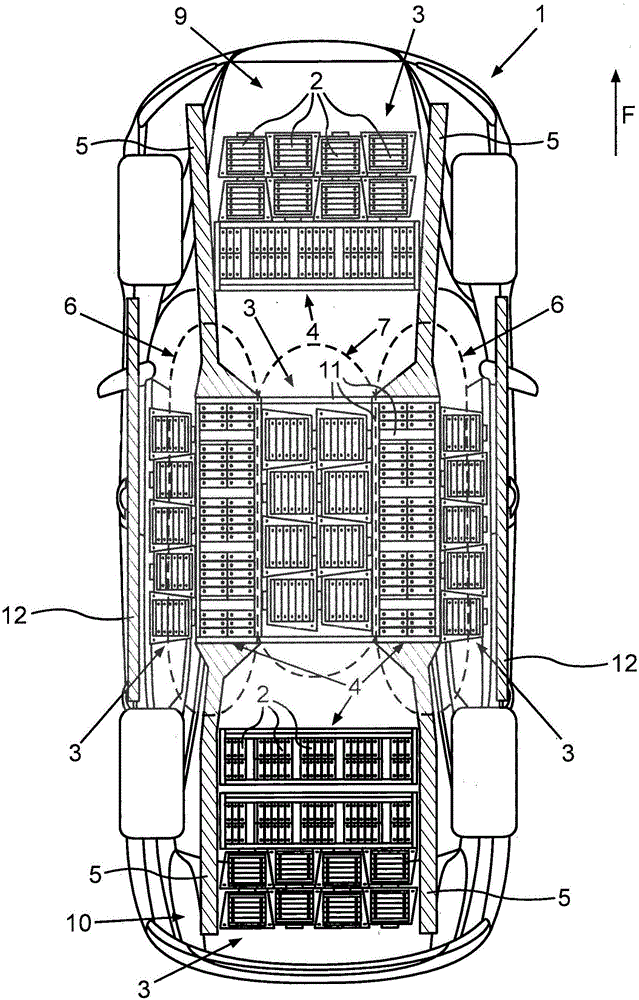

Motor vehicle having battery elements integrated in the structure

ActiveCN105939877AAvoid damageEnsure safetyElectric devicesElectric propulsion mountingOperational safetyElectrical and Electronics engineering

Owner:AUDI AG

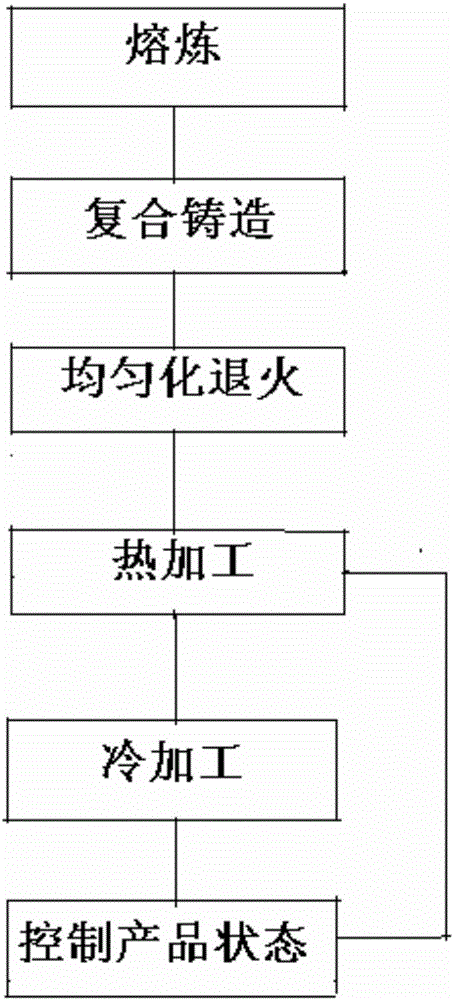

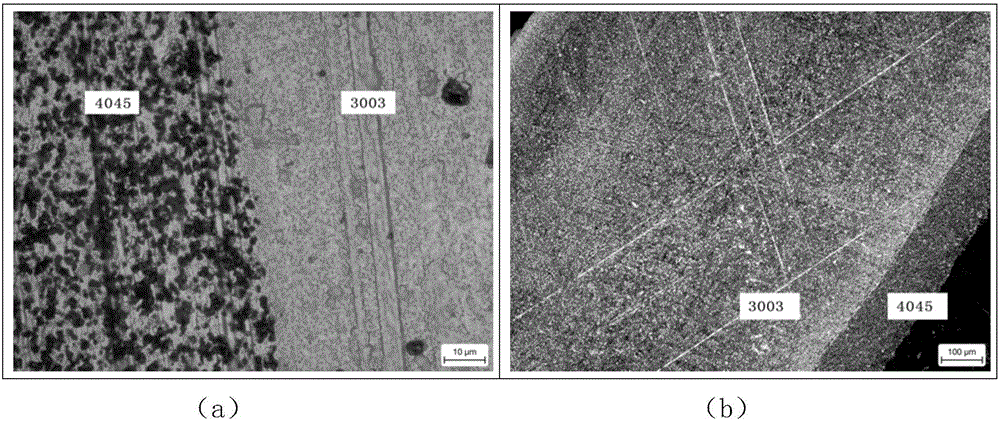

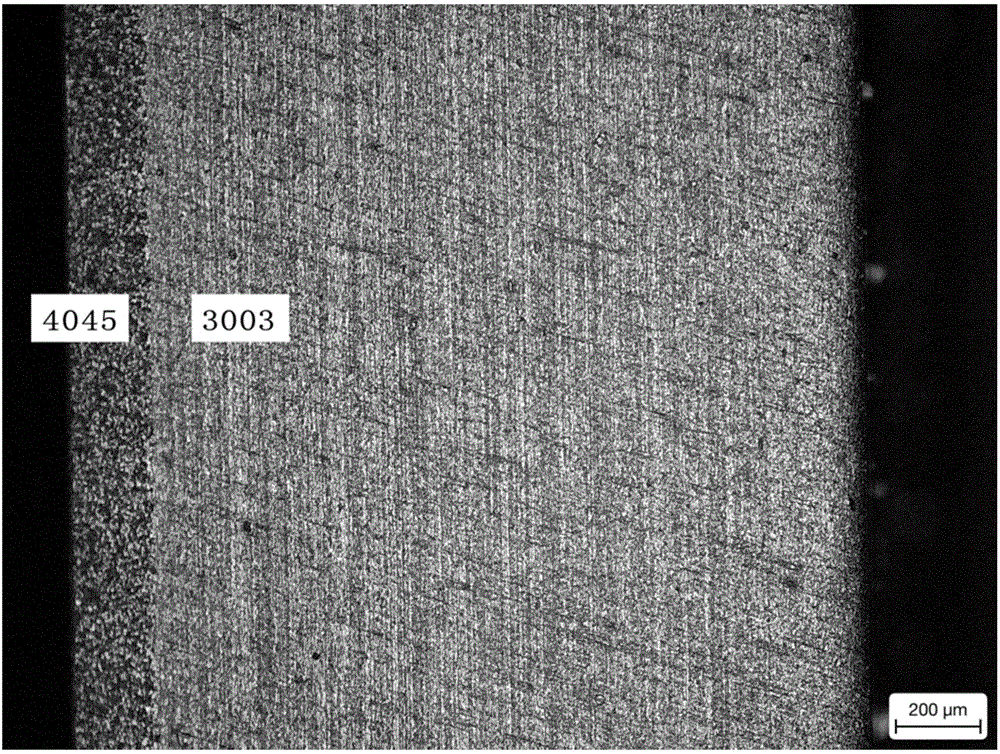

Method for producing aluminium alloy composite tube, bar and wire rod

The invention relates to the technical field of non-ferrous metal processing. A method for producing an aluminium alloy composite tube, bar and wire rod comprises the following steps: 1, smelting, which comprises preparing aluminium alloy raw materials according to chemical compositions of a core material and a sheath and performing smelting in two smelting furnaces; 2, compounding and casting, which comprises pouring a core material melt to a core material crystallizer, pouring a sheath melt in a chamber formed between a core material solidification shell and a sheath crystallizer, and starting a machine for casting to obtain a composite cast rod or a tube blank; 3, homogenizing annealing, which comprises heating the composite cast rod or the tube blank to a homogenizing temperature; 4, hot working, in which the composite cast rod or the tube blank is subjected to saw cutting, skin turning, and heating, and performing backward extrusion to obtain the composite bar or performing piercing and backward extrusion to obtain the composite tube; 5, cold working, which comprises heating and drawing the composite tube or bar to obtain a composite tube or bar in an H state; and 6, controlling the product state, which comprises performing annealing heating to the composite tube or bar obtained in the step 4 to obtain a composite tube or bar in an O state. According to the method, the production cost is reduced, and the stability of product quality is ensured.

Owner:大连黄海铝业有限公司

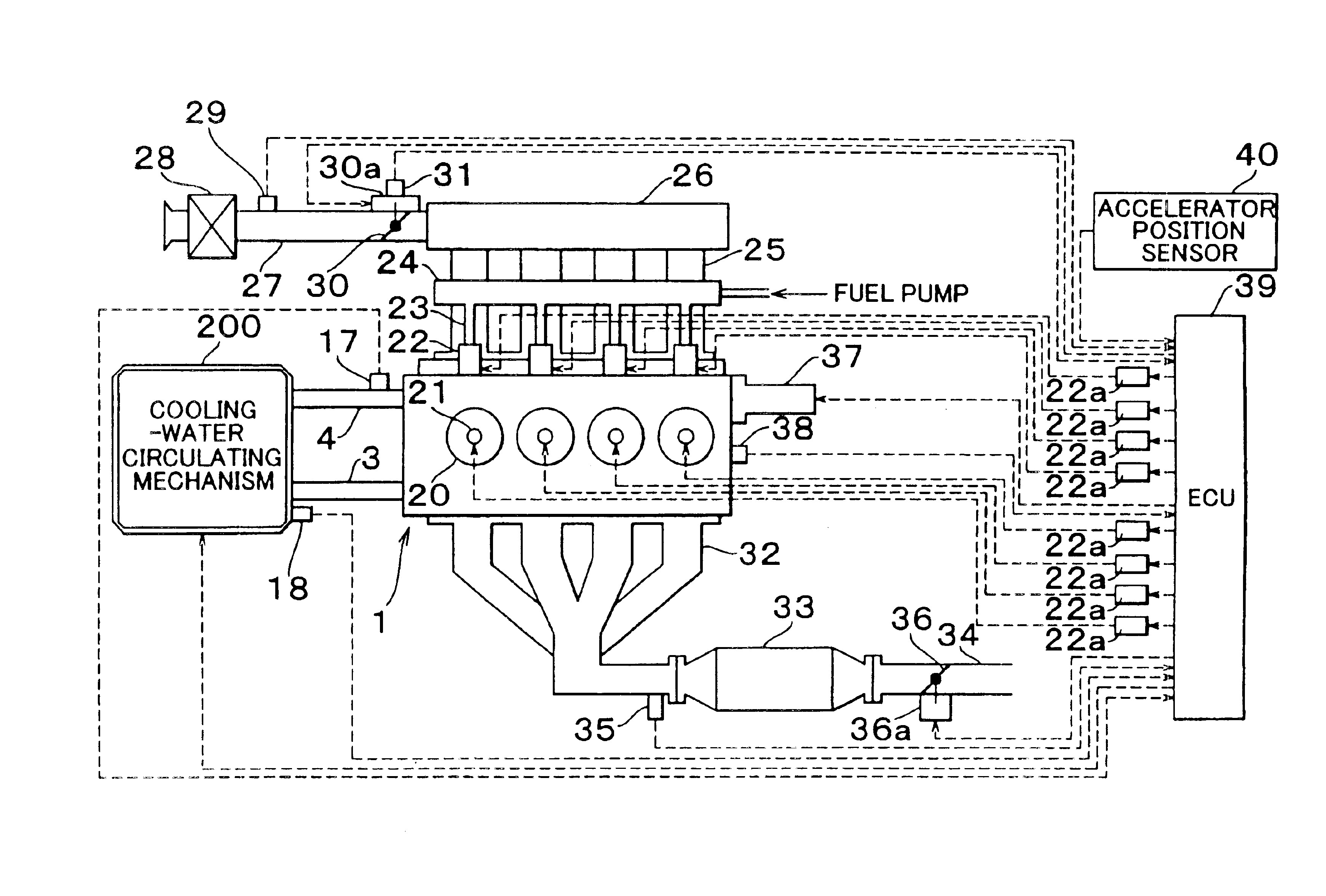

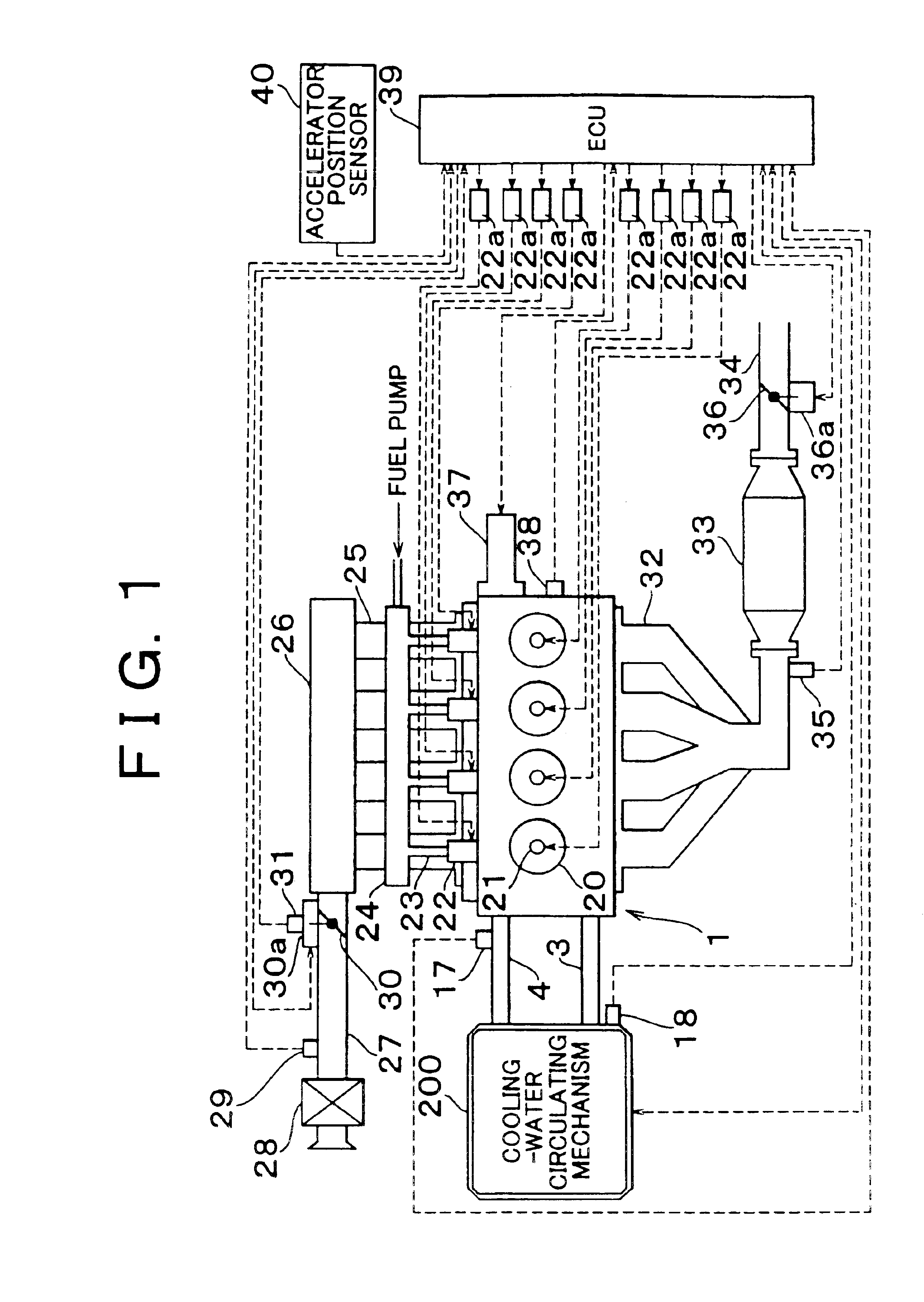

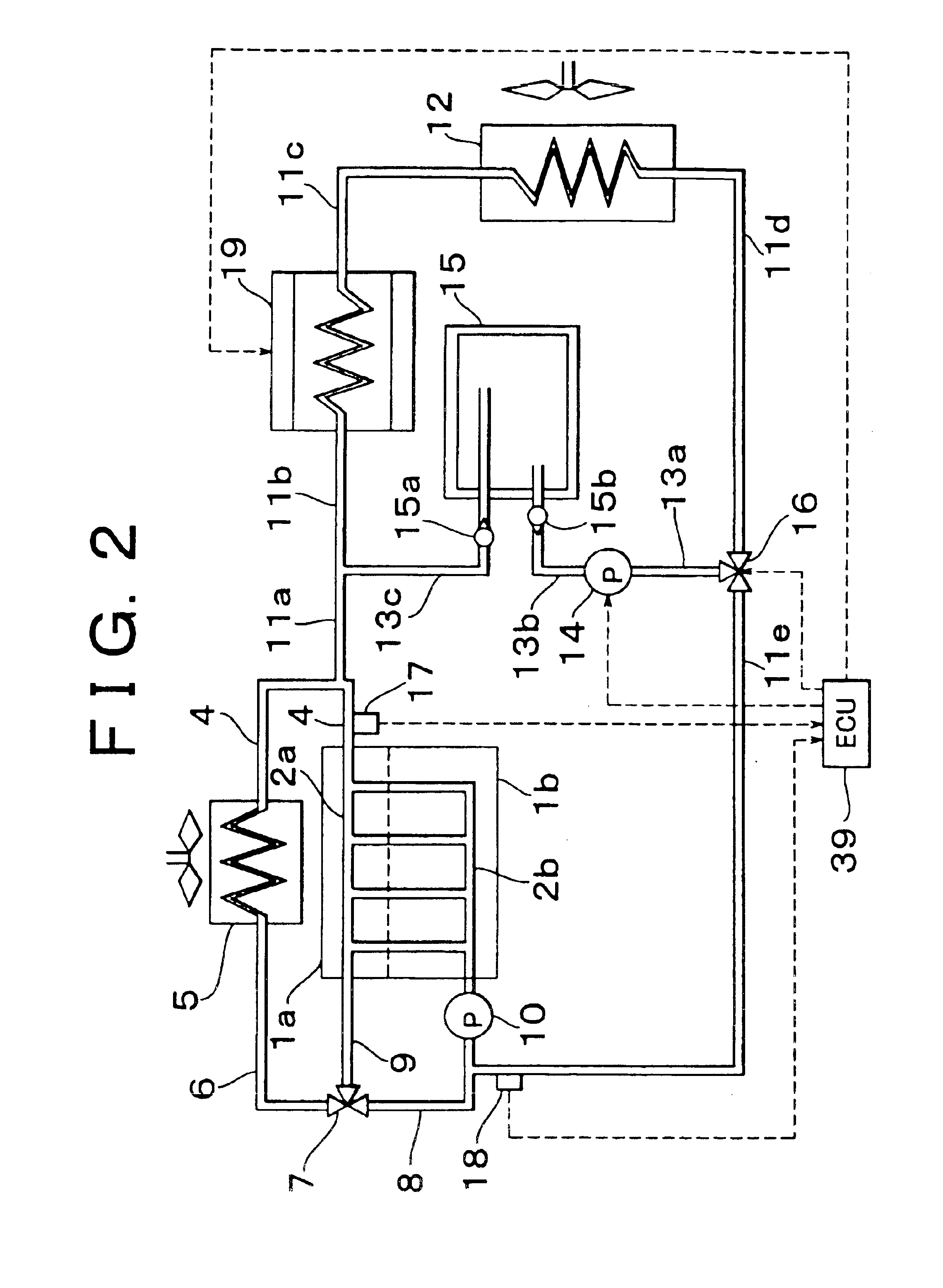

Internal combustion engine and control method of the same

InactiveUS6843216B2Prevent degradationEnable activationLiquid coolingAir-treating devicesAir–fuel ratioEngineering

The internal combustion engine includes an engine preheating apparatus for preheating the internal combustion engine upon or before starting thereof. This internal combustion engine further includes an air-fuel ratio controller for setting an air-fuel ratio of the internal combustion engine that is preheated, to a value higher than that of the internal combustion engine that is not preheated, and / or an ignition-timing controller for retarding an ignition timing of the internal combustion engine that is preheated as compared with the ignition timing of the internal combustion engine that is not preheated.

Owner:TOYOTA JIDOSHA KK

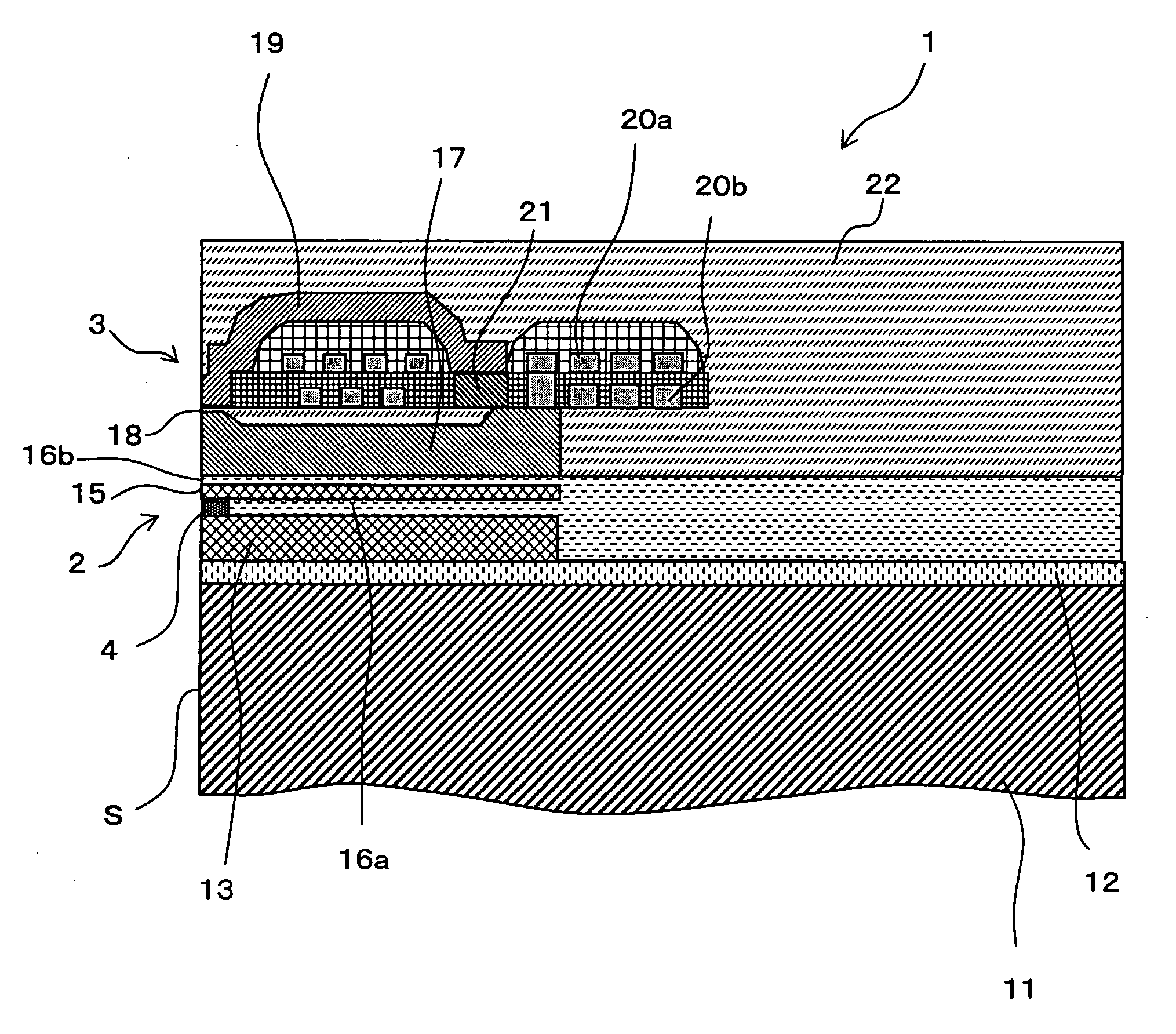

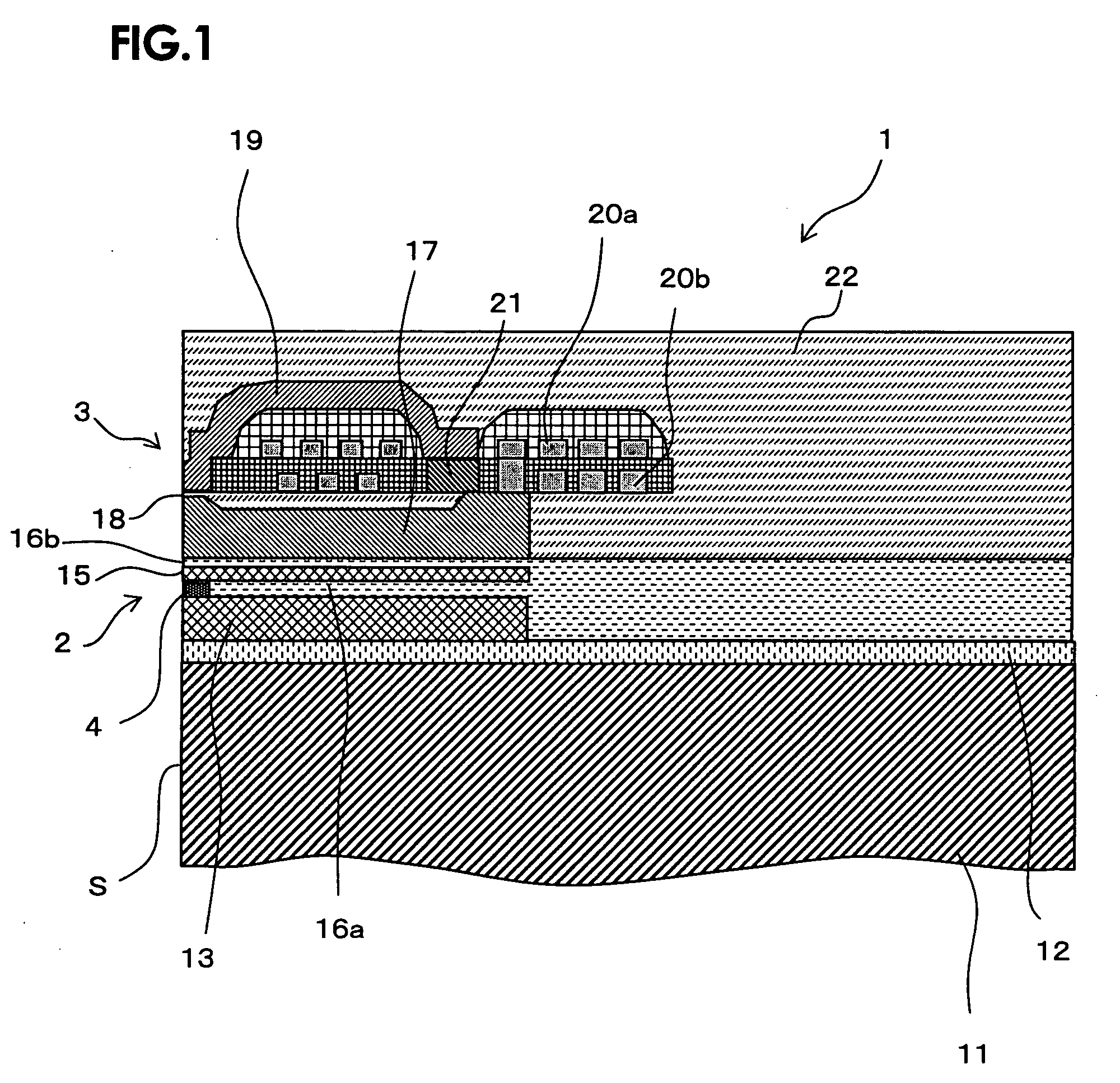

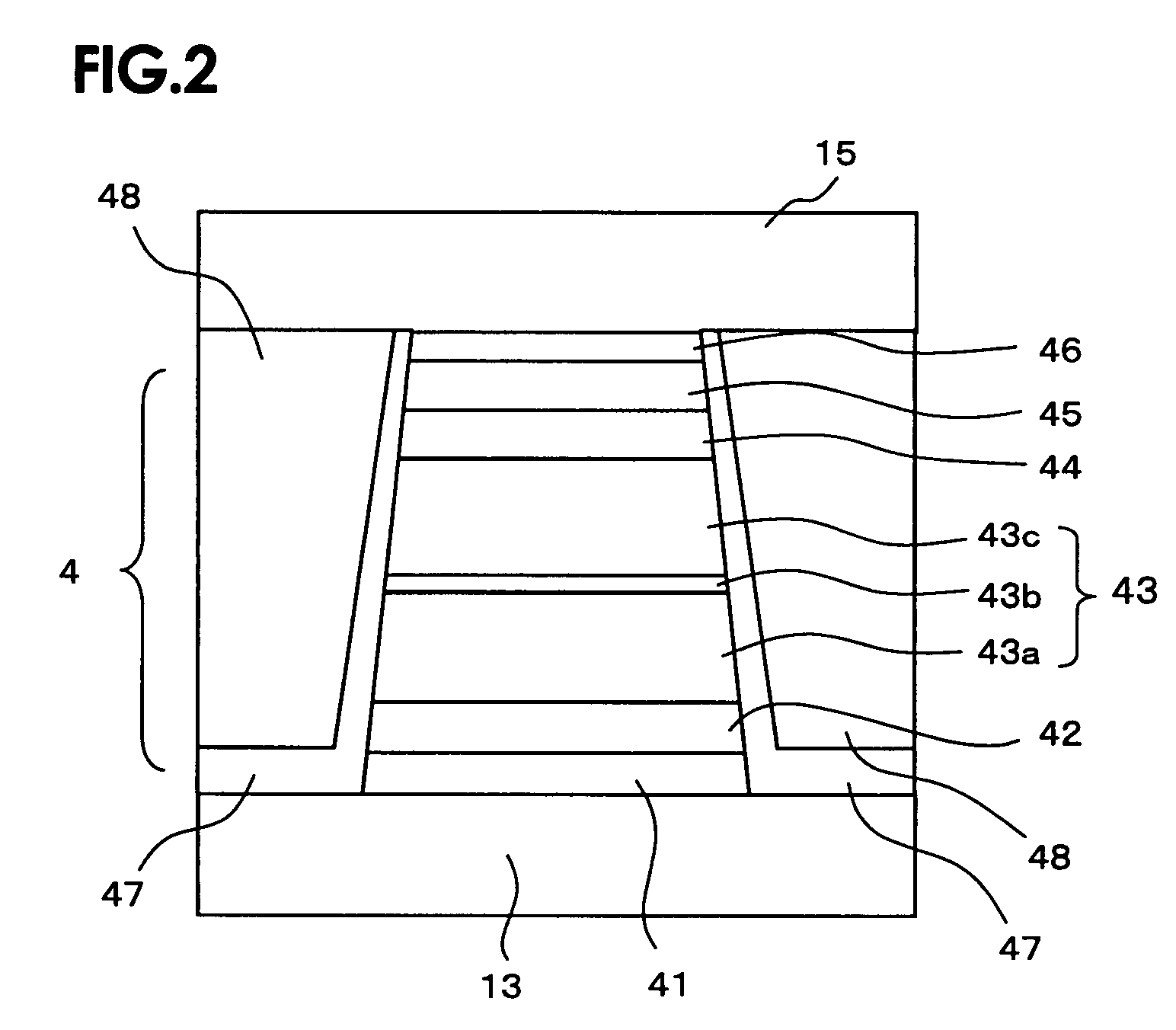

Magnetic thin film and magnetoresistance effect element having a heusler alloy layer containing an additive element

InactiveUS20070217087A1Reduce disadvantagesReduce processNanomagnetismMagnetic measurementsCrystal structureAlloy

A magnetic thin film has a layer which is formed of an alloy having a ordered crystal structure whose composition formula is represented by XYZ or X2YZ (where X is one or more than one of the elements selected from the group consisting of Co, Ir, Rh, Pt, and Cu, Y is one or more than one of the elements selected from the group consisting of V, Cr, Mn, and Fe, and Z is one or more than one of the elements selected the group consisting of Al, Si, Ge, As, Sb, Bi, In, Ti, and Pb). The alloy contains at least one additive element which is not included in the composition formula of the alloy and which has a Debye temperature that is equal to or less than 300K.

Owner:TDK CORPARATION

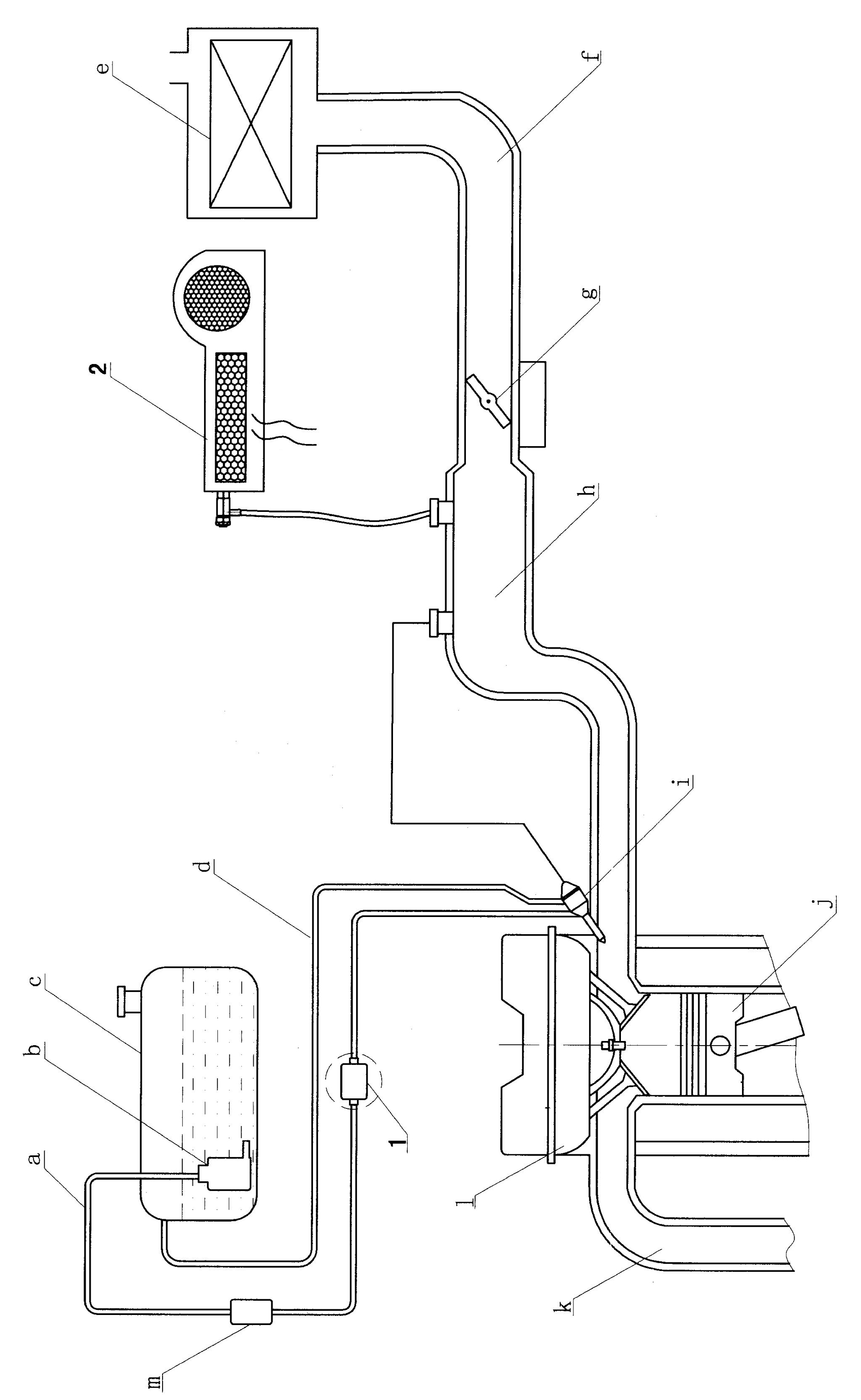

Fuel oil saving device of vehicle

InactiveCN101865053ALong restore timeAvoid peroxy combustionNon-fuel substance addition to fuelInternal combustion piston enginesMagnetic energyFuel oil

The invention relates to a fuel oil saving device of a vehicle, comprising two groups, i.e. a fuel oil magnetization processor and an oxygen increasing and supplementing device, wherein the fuel oil magnetization processor comprises two multi-gradient magnetization radiation areas, two stagnation areas and an output port, wherein each multi-gradient magnetization radiation area consists of a main body; each magnetic energy radiation area comprises an upper supporting plate, a lower supporting plate and a permanent magnet clamped between the upper supporting plate and the lower supporting plate, and the two magnetic energy radiation areas are arranged adjacently; the inlet end of the first magnetic energy radiation area is the first stagnation area, and a second stagnation area is positioned between the two magnetic energy radiation areas; the oxygen increasing and supplementing device comprises a space divider and an ozone generator, wherein the space divider comprises an air filter assembly, a fan assembly, a permanent magnet fastening end cover clamped between the upper supporting plate and the lower supporting plate, and the like and forms an integer with a shell; and a space divider assembly control power supply inside the ozone generator, a booster, a generating tube and a boosting pump are sequentially arranged on a base plate. The invention has high fuel oil saving efficiency and easy installation and debugging.

Owner:姚大华

Nonmetallic gasoline additive and method for preparing same

ActiveCN107916147ASimple stepsSave raw materials and energy consumptionLiquid carbonaceous fuelsFuel additivesNitrogen oxidesNOx

The invention discloses a nonmetallic gasoline additive and a method for preparing the same. The nonmetallic gasoline additive comprises, by weight, 0.5-12% of polyether, 0.5-12% of polyether polyol,0.5-10% of poly-alcohol, 0.1-15% of catalysts, 0.1-15% of stabilizers, 1-16% of soluble silicic acid and 55.9-92% of polyol. The method includes adding the polyether, the polyether polyol, the poly-alcohol and the catalysts into the polyol; carrying out stirring reaction to obtain transparent oily liquid; adding the soluble silicic acid into the liquid; carrying out stirring reaction at the temperature of 80-110 DEG C until solution turns clear; filtering the clear solution to obtain the nonmetallic gasoline additive. The nonmetallic gasoline additive and the method have the advantages that more than 18% of gasoline can be saved by the aid of the nonmetallic gasoline additive under identical conditions, emission of hydrocarbon HC, carbon monoxide CO, PM (particulate matters) and nitrogen oxide NOx can be reduced to a great extent, the smoke intensity can be lowered to a great extent, and effects of inhibiting carbon deposit generation and eliminating carbon deposits can be realized; the nonmetallic gasoline additive is stable in property, can be safely stored and transported and is free of damage to gasoline cylinders and engines, the nonmetallic gasoline additive and gasoline arecompletely mutually soluble, precipitation and layering can be prevented.

Owner:保定市瑞方生物科技有限公司

Preparation method of flue gas denitration agent

InactiveCN108939857AReduce partial pressureFacilitated DiffusionGas treatmentDispersed particle separationDislocationFermentation

The invention discloses a preparation method of a flue gas denitration agent and belongs to the technical field of flue gas treatment. According to the preparation method, limestone powder is used asa raw material, and the limestone and an auxiliary agent are subjected to operations of refrigeration, ball milling, microwave treatment, freezing and drying and the like, and diffusion of nitrogen oxide to a reaction interface in a denitration process can be effectively improved, so that the denitration efficiency is improved. According to the preparation method, steel dreg is activated by adopting ball milling treatment, the size of steel dreg grains are reduced, and physicochemical properties of a crystal structure and a surface are changed, so that the specific surface area of the steel dreg is enlarged, inner energy and surface energy are increased and crystal lattices can be reduced; crystal lattice dislocation and defects are generated, and an amorphous-state structure which is soluble in water is formed on the surface of the steel dreg; the size of the crystal lattices is reduced and the contact area with the water is enlarged, and the activity can be improved; active substances which can participate in hydration in a system can be sufficiently exposed, so that the activity of the steel dreg is improved; and a concentration and fermentation material component is used to improve the denitration effect very well. By adopting the preparation method, the problem that the denitration efficiency of a current common flue gas denitration agent is low is solved.

Owner:刘凡领

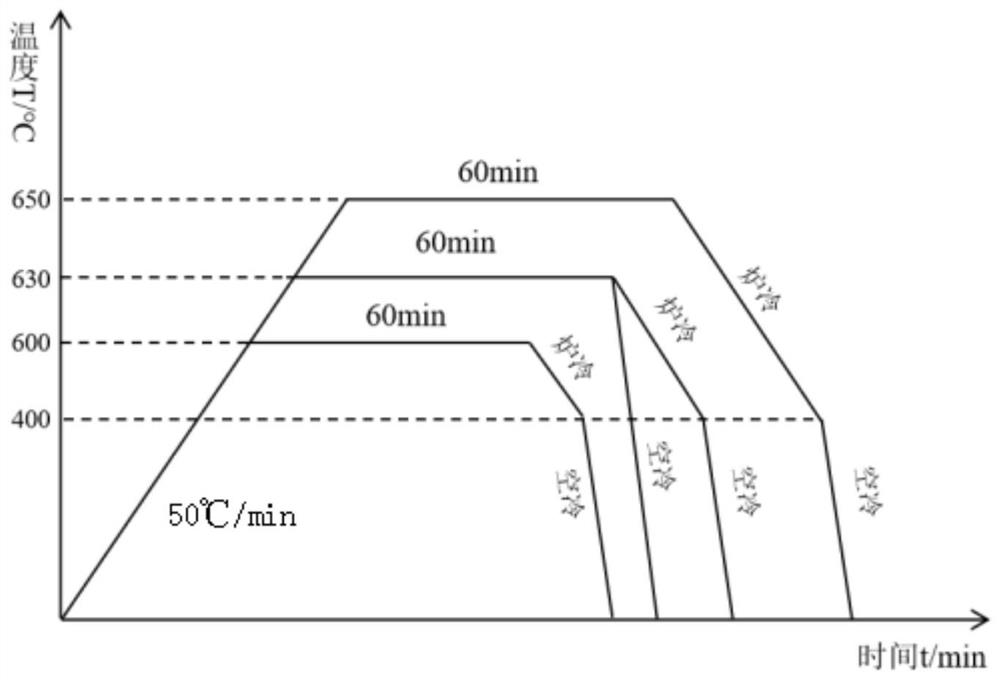

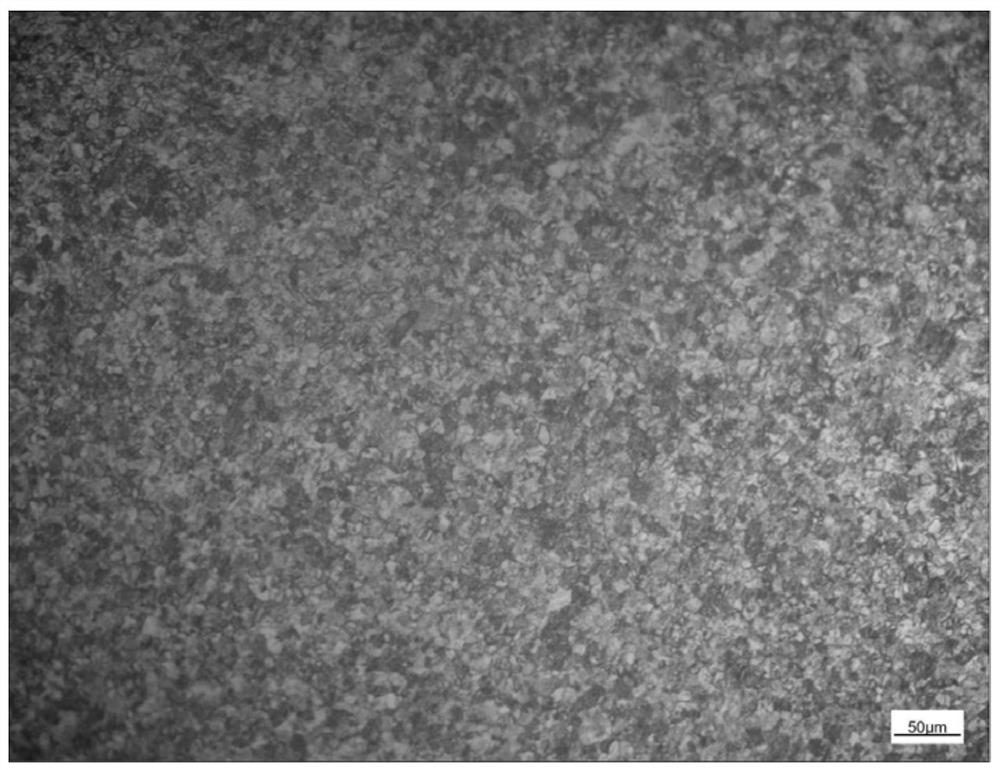

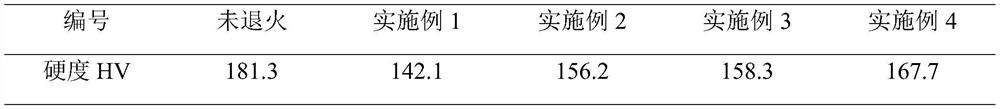

Method for eliminating residual stress of titanium part subjected to powerful spinning deformation

PendingCN112921259AEliminate residual internal stressReduced risk of deformationSpinningHeat conservation

A method for eliminating residual stress of a titanium part subjected to powerful spinning deformation comprises the following steps that 1, the titanium part subjected to spinning is placed in a heat treatment furnace, the temperature is increased to the target temperature of 530-560 DEG C at the heating speed of 10-52 DEG C / min, and the heat preservation time is 60-100 min; and 2, after heat preservation is conducted, cooling is conducted to 380-410 DEG C in a furnace cooling manner, and then discharging and air cooling are conducted to the room temperature. According to the process, the residual internal stress of the TA1 part after the powerful spinning deformation can be eliminated, so that the risk of deformation of a thin-walled cylinder part due to the release of the residual stress in the subsequent machining process is reduced, and the microstructure excellence and the use performance of the material are improved.

Owner:XIAN TAIJIN INDAL ELECTROCHEM TECH

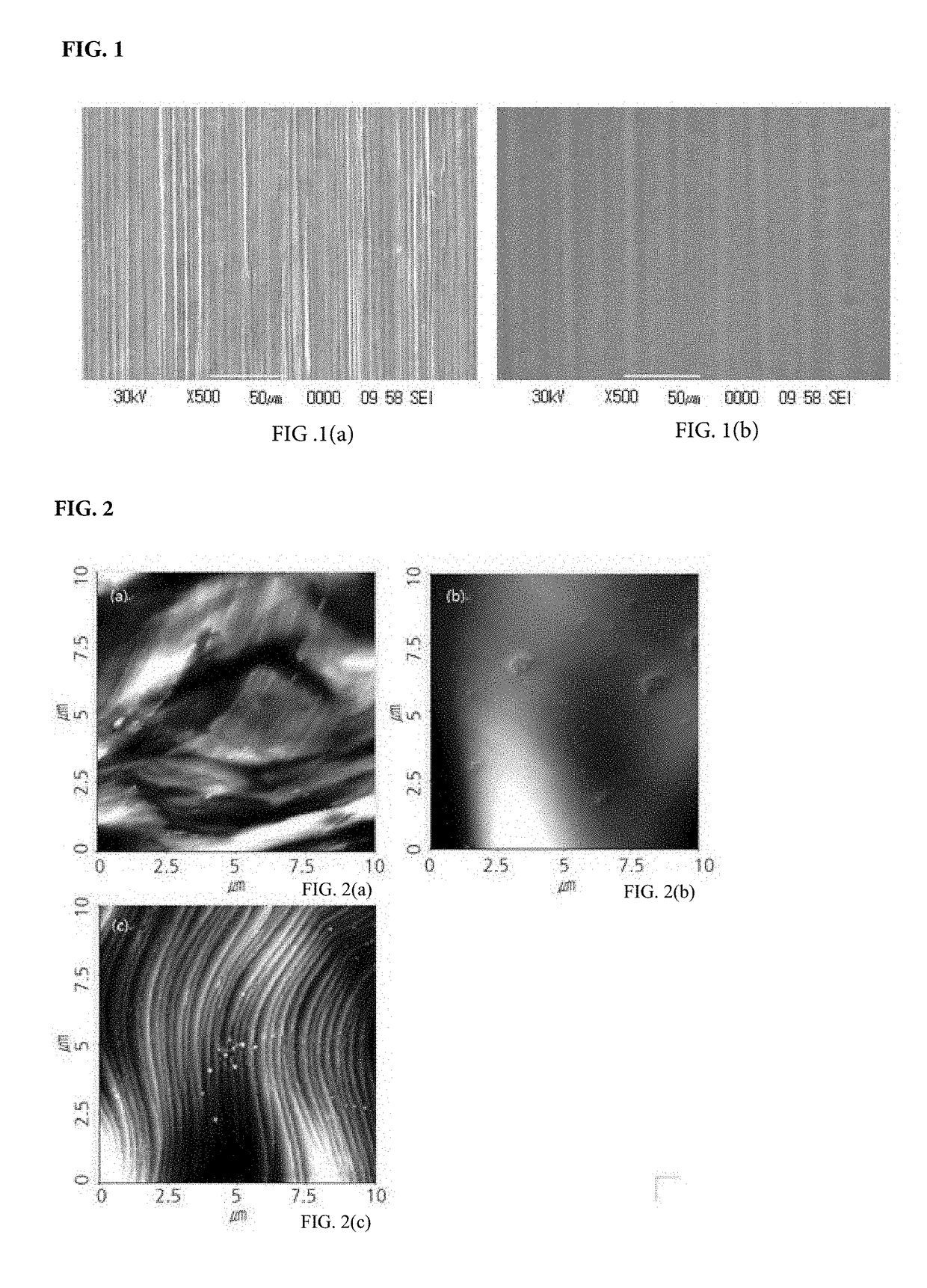

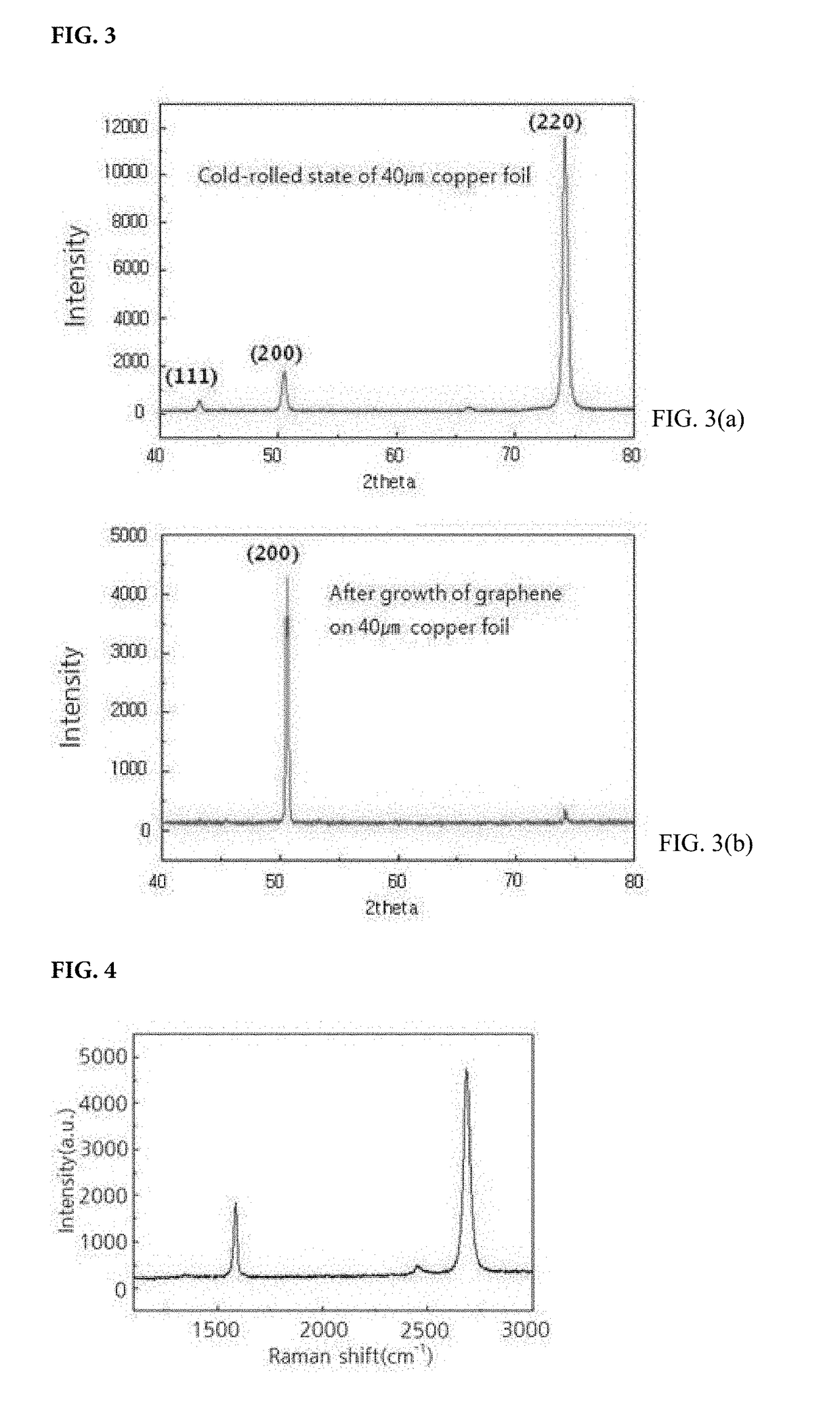

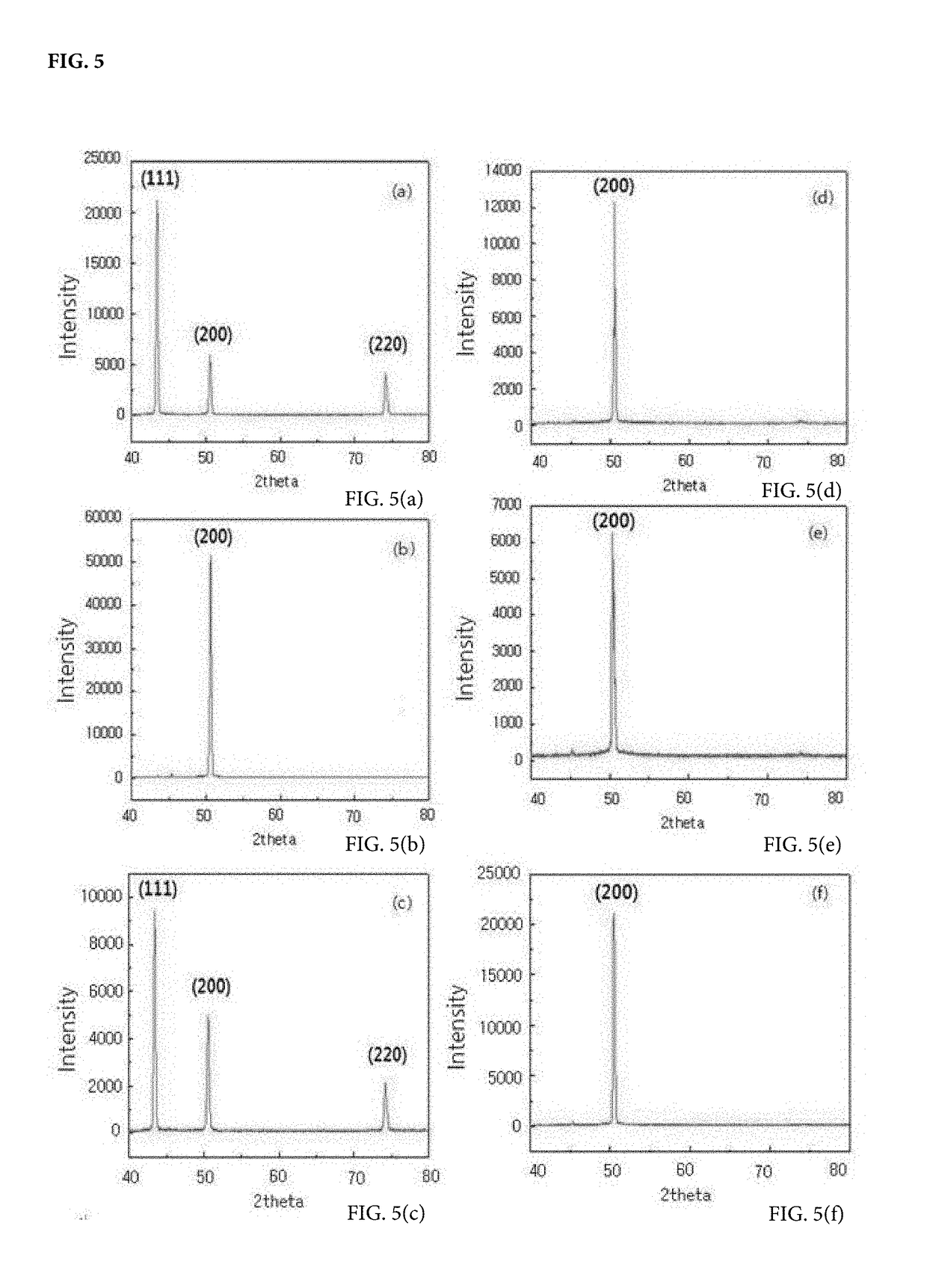

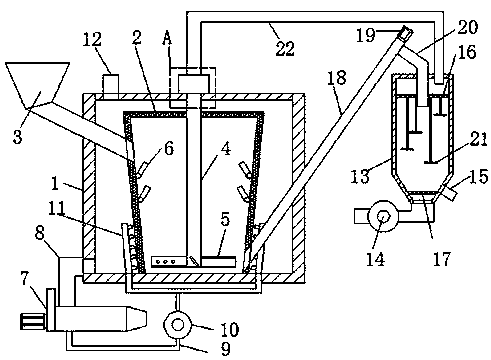

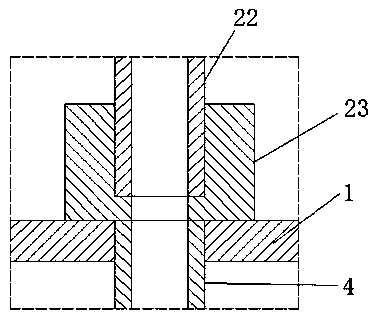

Method of manufacturing graphene using metal catalyst

The present invention relates to a method for producing graphene on a face-centered cubic metal catalyst having a plane oriented in one direction, and more particularly to a method of producing graphene on a metal catalyst having the (100) or (111) crystal structure and a method of producing graphene using a catalyst metal foil having a single orientation, obtained by electroplating a metal catalyst by a pulse wave current and annealing the metal catalyst. The invention also relates to a method of producing graphene using a metal catalyst, and more particularly to a method of producing graphene, comprising the steps of: alloying a metal catalyst with an alloying element; forming step structures on the metal catalyst substrate in an atmosphere of a gas having a molecular weight of carbon; and supplying hydrocarbon and hydrogen gases to the substrate. On unidirectionally oriented metal catalyst prepared according to the present invention, graphene can be grown uniformly and epitaxially. Moreover, a method for producing graphene according to the present invention can form monolayer graphene by epitaxially growing graphene while increasing the growth rate of graphene.

Owner:SRC INC

Environment-friendly plastic recovery equipment

ActiveCN111113723AEasy to cleanImprove water saving performancePlastic recyclingWater savingProcess engineering

The invention relates to the technical field of environment-friendly plastic recovery, in particular to environment-friendly plastic recovery equipment. The environment-friendly plastic recovery equipment comprises a cleaning box, and further comprises a fluidization barrel. A filter barrel is fixed in the cleaning box. A feeding hopper used for feeding materials into the filter barrel is fixed tothe outer side of the cleaning box. The filter barrel feeds materials into the fluidization barrel through a feeding pipe. A purification and backflow mechanism is arranged on one side of the cleaning box. A stirring and mixing mechanism is arranged in the filter barrel. The fluidization barrel is in drive connection with the stirring and mixing mechanism through an air guide pipe. According to the environment-friendly plastic recovery equipment, the cleaning effect and efficiency to plastic particles are improved, and energy and water are saved.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

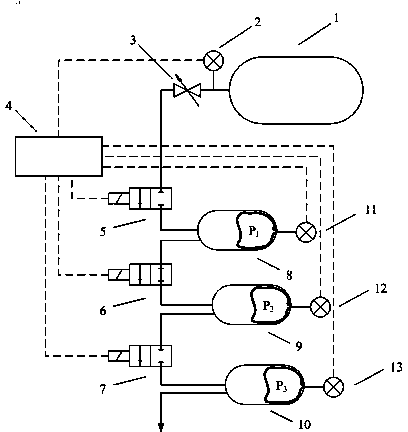

Constant pressure high-pressure gas decompression system

InactiveCN103867896AReduce energy lossImprove internal energyPipeline systemsProcess engineeringHigh pressure

The invention discloses a constant pressure high-pressure gas decompression system. The outlet of a high-pressure gas storage tank is connected with a fourth pressure sensor and a gas inlet of a gas switch valve; a gas outlet of the gas switch valve is connected with a gas inlet of a first level decompression system by a gas guide pipe; the gas outlet of the first level decompression system is connected with the gas inlet of a second level decompression system by a gas guide pipe; the outlet of the second level decompression system is connected with the gas inlet of a third level decompression system by a gas guide pipe; the gas outlet of the third level decompression system is connected with a gas guide pipe as the gas outlet of decompressed gas; a controller is respectively connected with the fourth pressure sensor and the first, second and third decompression systems. By using the fixed pressure high-pressure gas decompression system, high-pressure gas can be decompressed, the energy loss of the gas in the decompression process is effectively reduced while the stable pressure of the decompressed gas is ensured, the energy use rate of the gas is improved, and the gas internal energy can be increased by the heat exchange with the external environment in the decompression process.

Owner:NANJING UNIV OF SCI & TECH

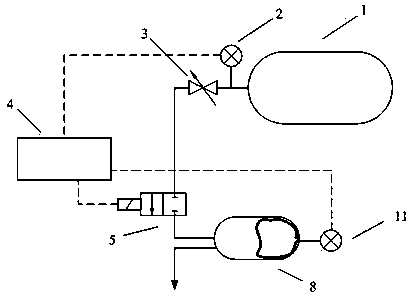

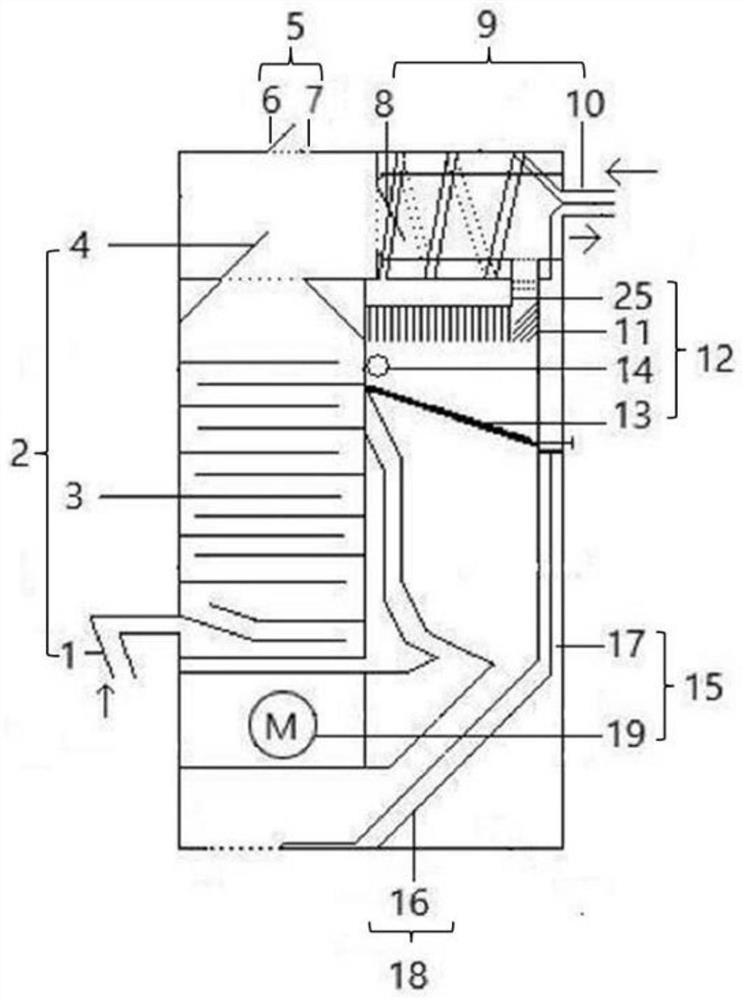

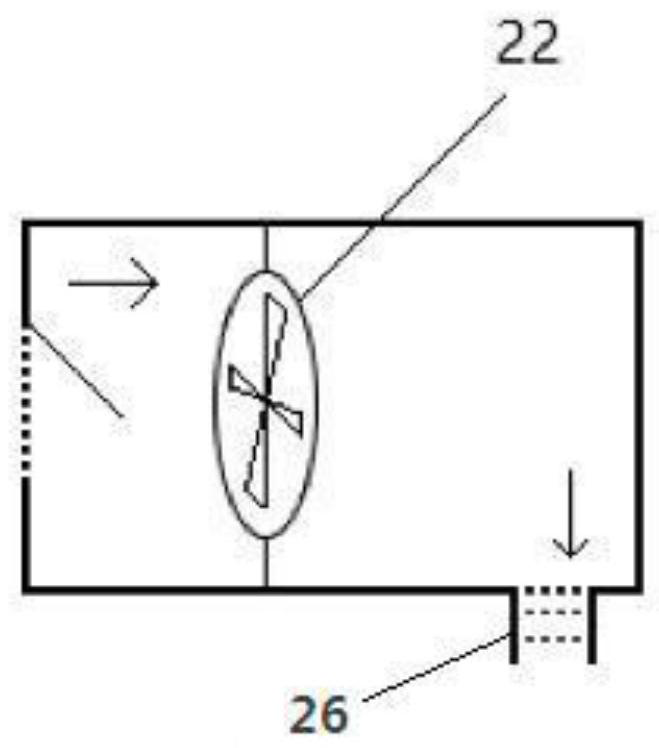

Recycling method of hydrogen peroxide oxidized tail gas

ActiveCN106145052AImprove internal energyReduce unit consumptionPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical industryAromatic hydrocarbonRefrigeration

The invention relates to a recycling method of hydrogen peroxide oxidized tail gas. The recycling method comprises the following steps of: (a) cooling the oxidized tail gas with the temperature of about 50 DEG C to 25-28 DEG C by virtue of a cold box and a cooler, introducing the oxidized tail gas into separators 1# and 2#, separating heavy aromatic hydrocarbon, returning the oxidized tail gas to the cold box, heating to 30-35 DEG C, and introducing the oxidized tail gas into an expansion refrigeration generator set for power generation; (c) after the power generation acting of the oxidized tail gas through an expansion machine, cooling to 0-5 DEG C, introducing the oxidized tail gas into a separator 3#, discharging oxidized tail gas into a low-temperature water generator to exchange heat with freeze inlet water so as to obtain freeze outlet water with a low temperature of 5-10 DEG C for other use, and evacuating residual oxidized tail gas; and (d) recycling heavy aromatic hydrocarbon liquid separated from the separators 1#, 2# and 3# into a system. According to the recycling method, the cooling capacity of outlet gas of the expansion machine is recycled by virtue of the low-temperature water generator; the cold box is used for cooling high-temperature oxidized tail gas, heating cooled low-temperature oxidized tail gas, heavy aromatic hydrocarbon in the oxidized tail gas is recycled, and the pressure and the internal energy of the oxidized tail gas are adequately utilized for carrying out expansion refrigeration for power generation, so that the production cost is lowered.

Owner:ANHUI JINGHE IND

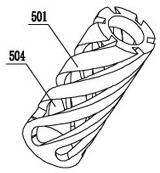

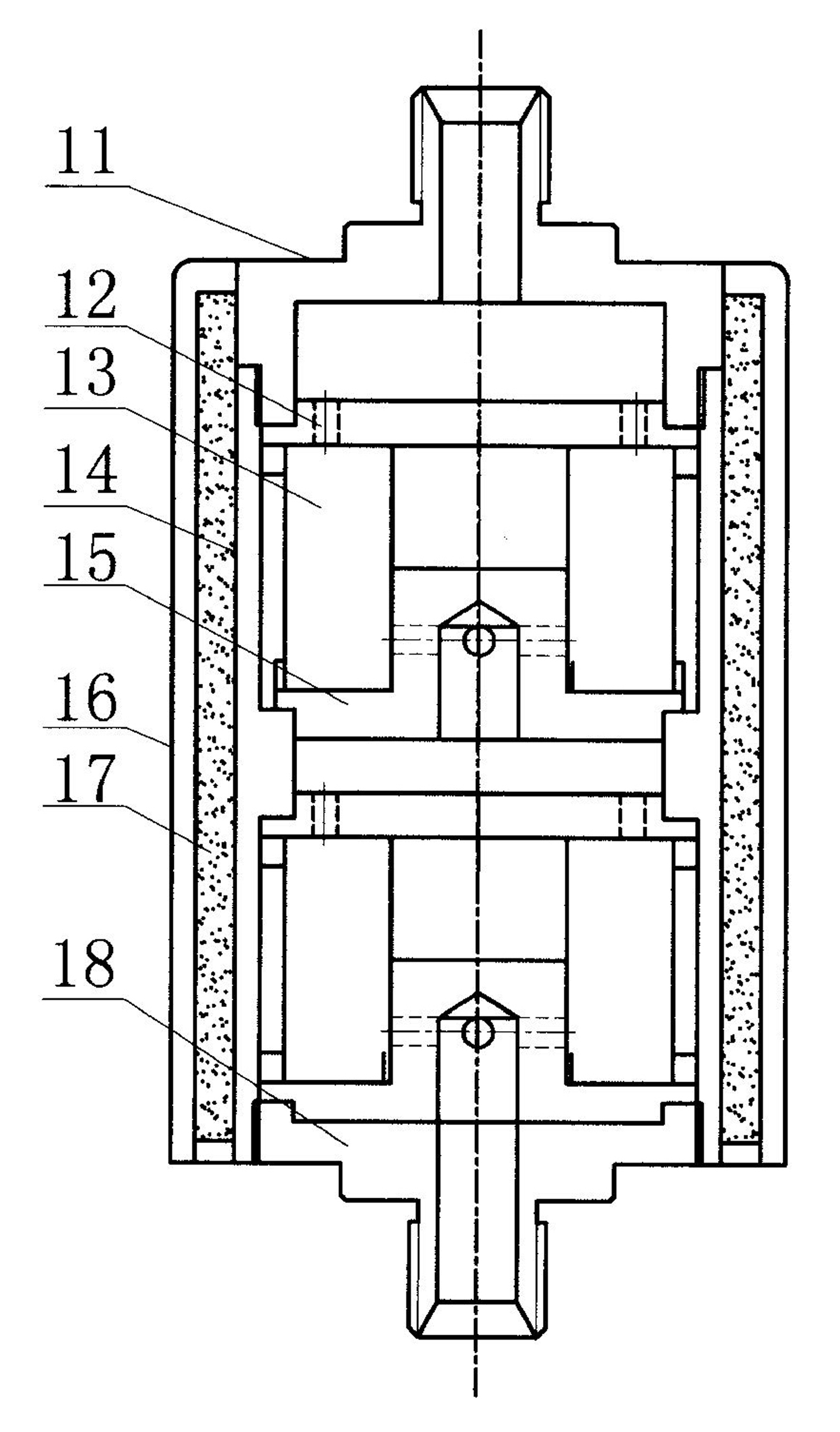

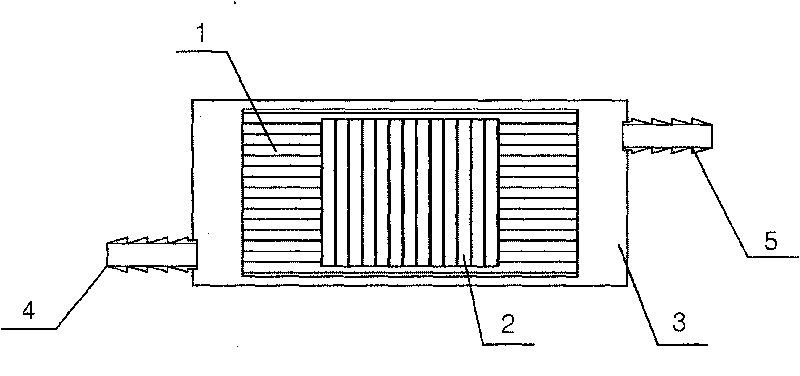

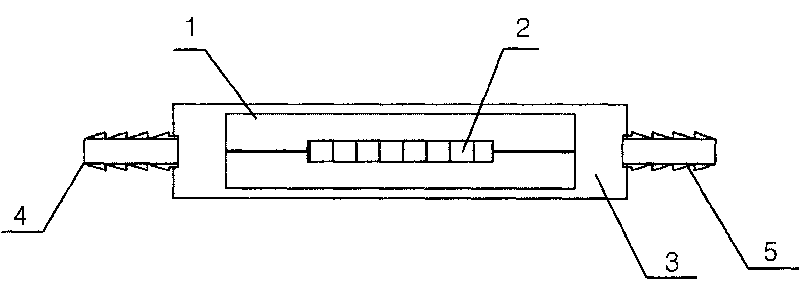

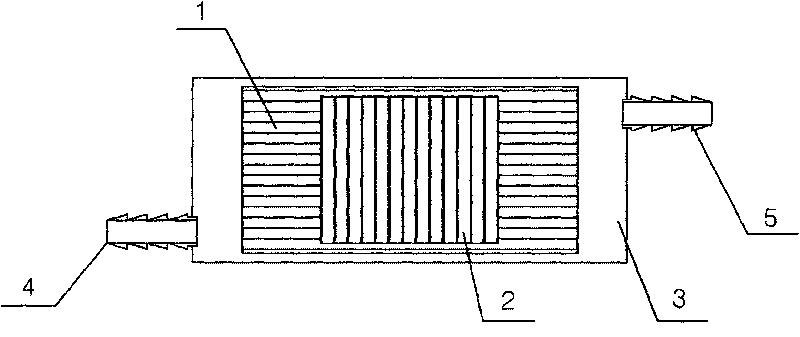

Spectrum function honeycomb ceramic fuel oil internal energy increasing device and manufacturing method thereof

InactiveCN101761426AIncrease disturbanceImprove internal energyInternal combustion piston enginesCombustion-air/fuel-air treatmentPolyvinyl alcoholAdhesive

The invention relates to fuel oil saving technology, in particular to a spectrum function honeycomb ceramic fuel oil internal energy increasing device and a manufacturing method thereof. The device comprises an oil inlet and an oil outlet arranged on a shell, a honeycomb ceramic body is arranged in the shell, and a rare earth permanent magnet energy block is arranged in the middle of the honeycomb ceramic body, wherein the honeycomb ceramic body is formed from 15-20% of chloritoid phyllite, 25-30% of alumina, 5-10% of calcite, 25-30% of tourmaline, 10-15% of iron oxide and 2% of polyvinyl alcohol adhesive by smashing, milling, hot mixing, vacuum refining, extrusion molding into a honeycomb micropore shape and firing at a high temperature of 1300 DEG C. The device can increase the utilization rate of the fuel oil, reduces the emission of hydrocarbon and particles in automobile exhaust, maintains an internal combustion engine and protects the atmospheric environment.

Owner:李永军

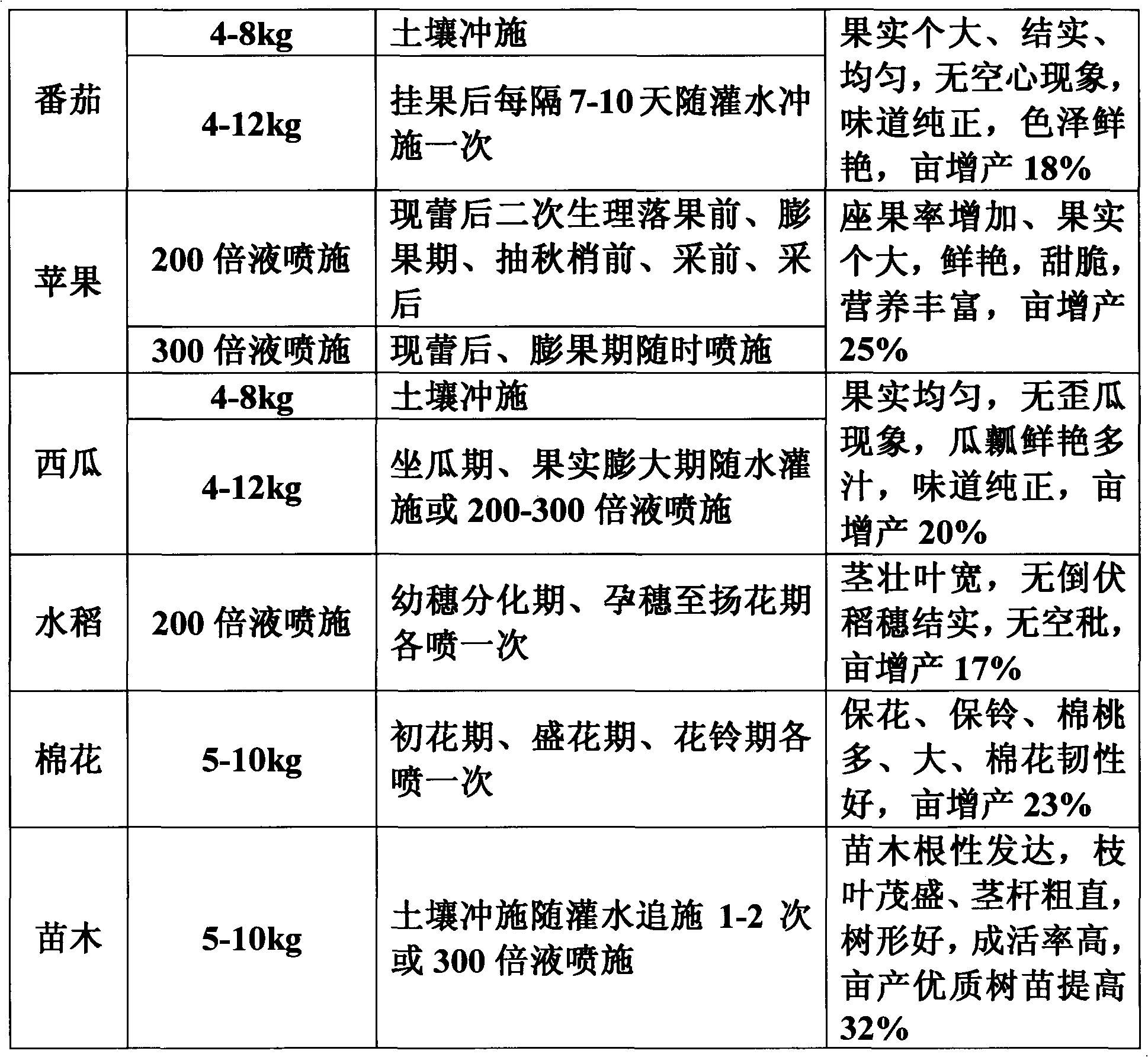

Multifunctional organic fertilizer

The invention relates to multifunctional organic fertilizer which comprises the following active ingredients in parts by weight: 20%-30% of nitrogen, 18%-22% of active calcium, 12%-18% of organic matters, 1%-5% of microelements, 3%-6% of rare earth, 0.1%-2% of swelling agent, 0.1%-2% of vegetable protein and 0.1%-3% of chitin. The multifunctional organic fertilizer is capable of fully improving the response speed and activity of probiotic groups of soil, changing the activity cycles of crops, improving the absorption rate of nitrogen and potassium in the soil and the utilization rate of the nitrogen and potassium in later top dressing, and achieving the effects of cold resistance, drought resistance, plant disease and insect pest resistance and phytotoxicity remission of the crops so as to improve the internal energy of the crops and further achieve the effects of improving the quality of the crops, increasing the yield of the crops and increasing the income of users.

Owner:王彬

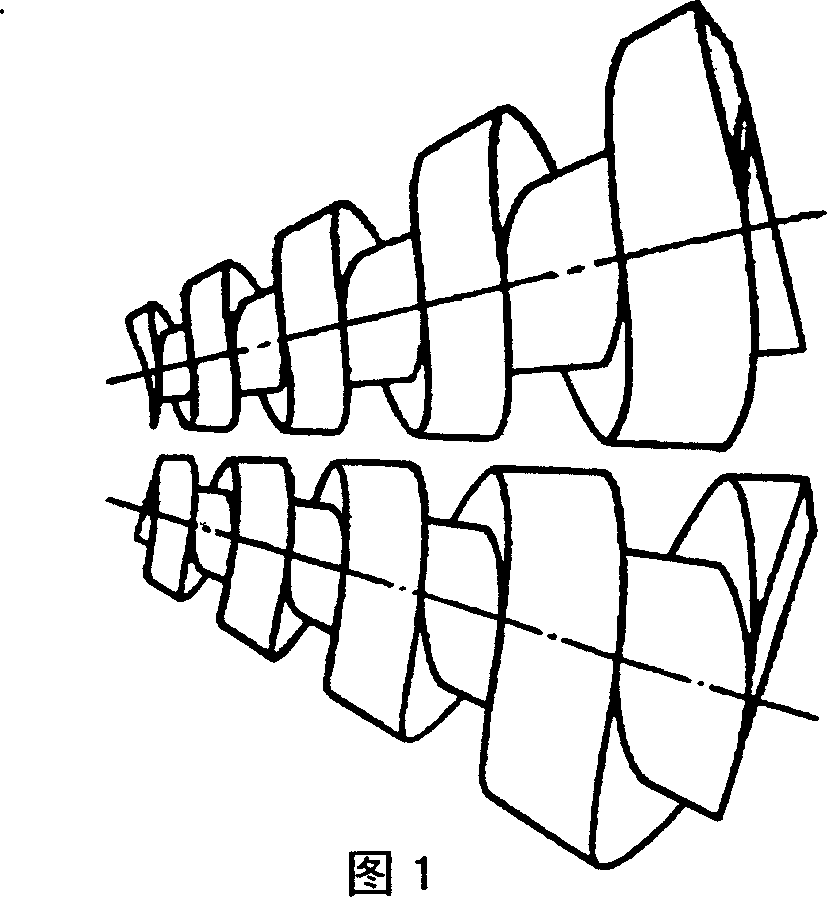

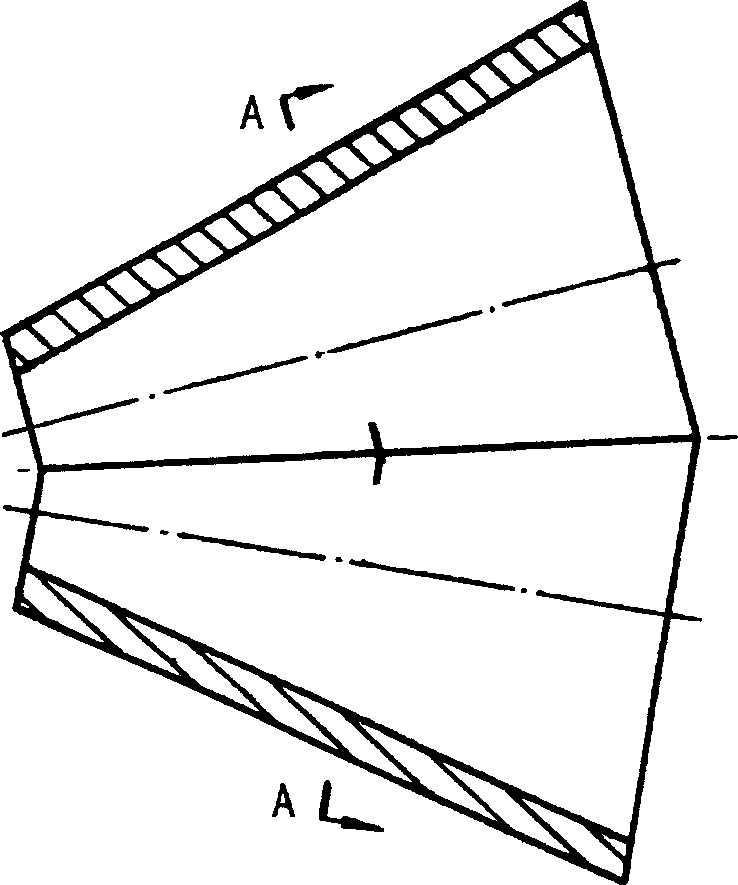

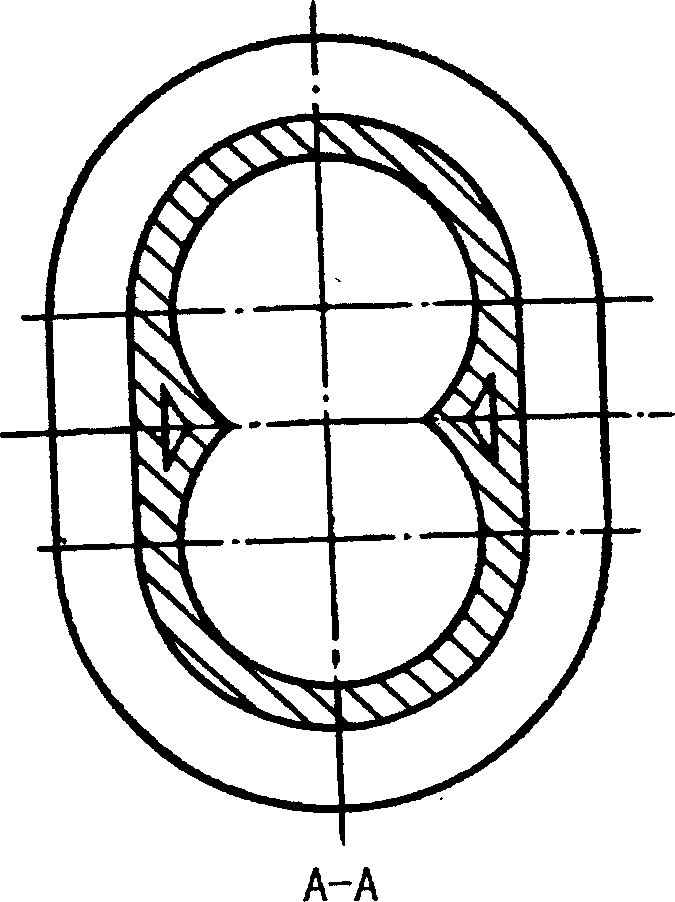

Capacity variable rotary internal combustion engine

InactiveCN1721658ASimple structureEliminate vibrationInternal combustion piston enginesEngine of intermeshing engagement typeCombustion chamberMechanical energy

This invention relates to a volume variable rotor generator, which is located with crank bar like piston generator and drainage gate. The generator is to use the rotor with increasing screw distance in cylinder for gear to form the volume cylinder to provide the conversion from heat energy to mechanic energy. The rotors output dynamic force as rotor and the generator compressed air uses the rotor or other same compressor.

Owner:葛开茂

High-efficiency spraying device

ActiveCN114589023AIngenious ideaIncrease water pressureLiquid spraying apparatusWater storageWater flow

The invention provides a high-efficiency spraying device which is characterized in that the high-efficiency spraying device comprises a closed water storage bin provided with a water inlet and a water outlet, a water baffle is arranged in the water storage bin, and a heating assembly is arranged on the water baffle; water flow channels are formed between the left side and the right side of the water baffle and the inner wall of the water storage bin. A pressurizing assembly is arranged at the position, located above the water flow channel, in the water storage bin. A spraying head is mounted on the water outlet, and a pressurizing plate is mounted in the spraying head; according to the scheme, the large-range spraying requirement is met, heat loss in a pipeline is avoided, the energy efficiency is effectively improved, it can be guaranteed that the water pressure in the water outlet cavity is kept constant, it is guaranteed that the water outlet amount is uniform in the spraying process, and spraying is more orderly.

Owner:SHANDONG VOCATIONAL ANIMAL SCI & VETERINARY COLLEGE

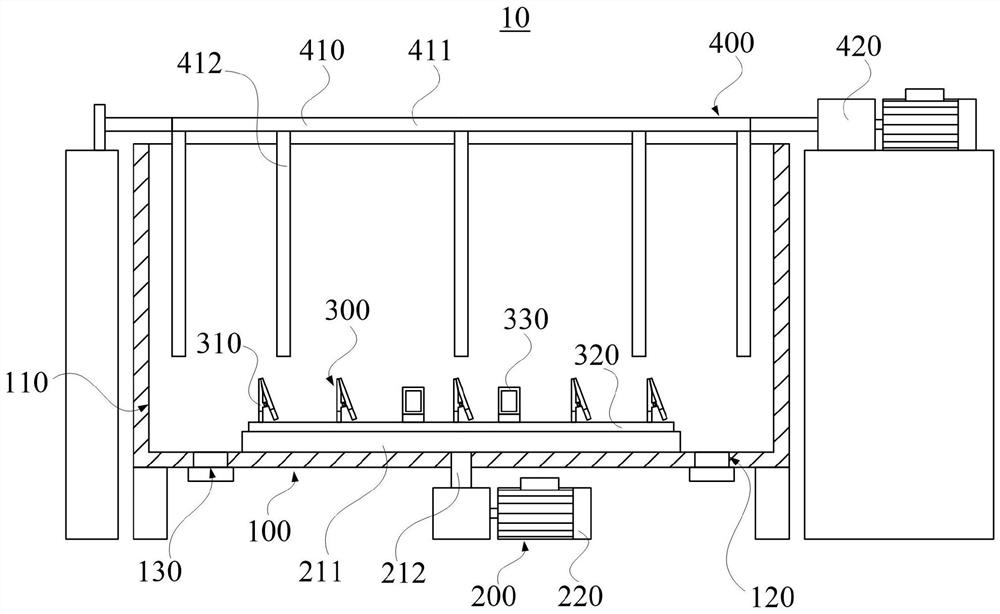

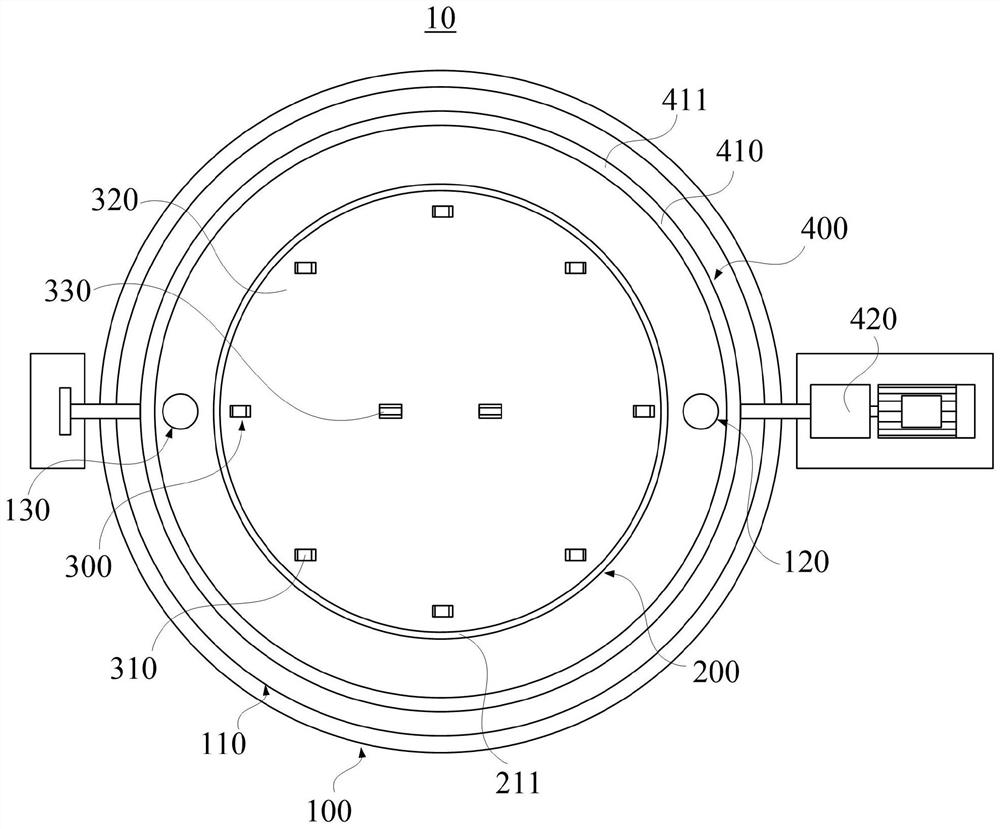

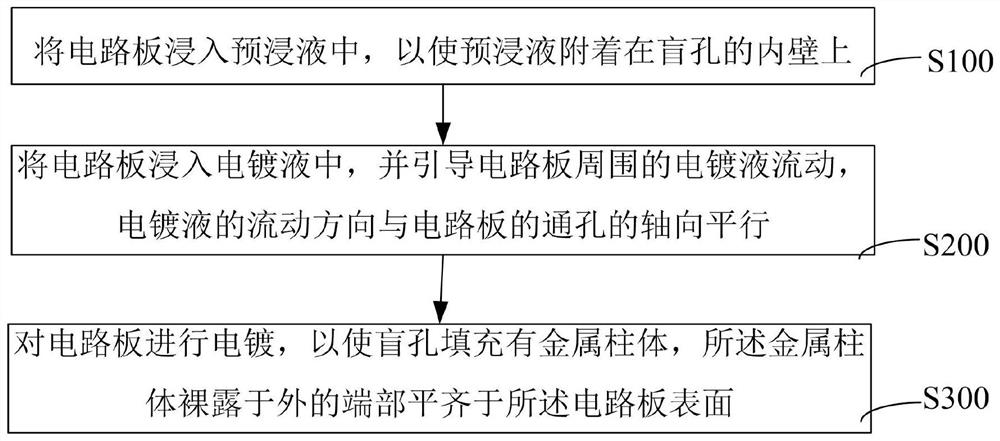

Circuit board soaking device and circuit board processing equipment

ActiveCN112533398AImprove surface cleanlinessSignal transmission is convenientPrinted circuit liquid treatmentCleaning using liquidsMotor vibrationElectric machinery

The invention provides a circuit board soaking device and circuit board processing equipment. The circuit board soaking device comprises a soaking machine body, a rotating mechanism, a clamping mechanism and a vibrating mechanism, wherein the soaking machine body is provided with a soaking cavity; the rotating mechanism comprises a rotating seat and a rotating motor, the rotating seat is arrangedin the soaking cavity, and the rotating motor is connected with the rotating seat to enable the rotating seat to rotate; the clamping mechanism comprises a plurality of clamping parts, and the clamping parts are all connected with the rotating seat; the vibration mechanism comprises a vibration part and a vibration motor, the vibration part is arranged in the soaking cavity, and the vibration motor is connected with the vibration part. As the circuit board moves relative to the electroplating liquid in the soaking machine body, the electroplating liquid can continuously scour the circuit board, metal cations and an electroplating accelerator in the electroplating liquid can continuously scour into the blind holes of the circuit board, and the blind holes of the circuit board are fully infiltrated, so the quality of the circuit board is improved; concentration of metal cations and electroplating accelerators in the blind holes of the circuit board is increased, and then the subsequent blind hole electroplating filling effect is improved.

Owner:HUAIAN TECHUANG TECH CO LTD

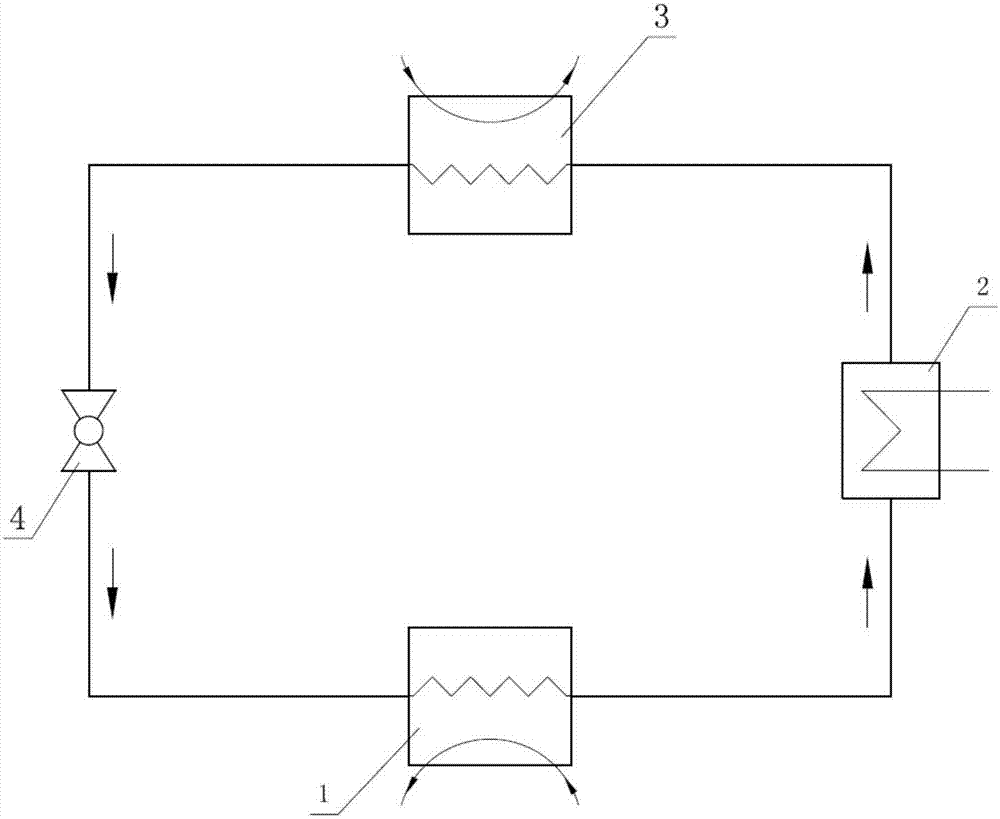

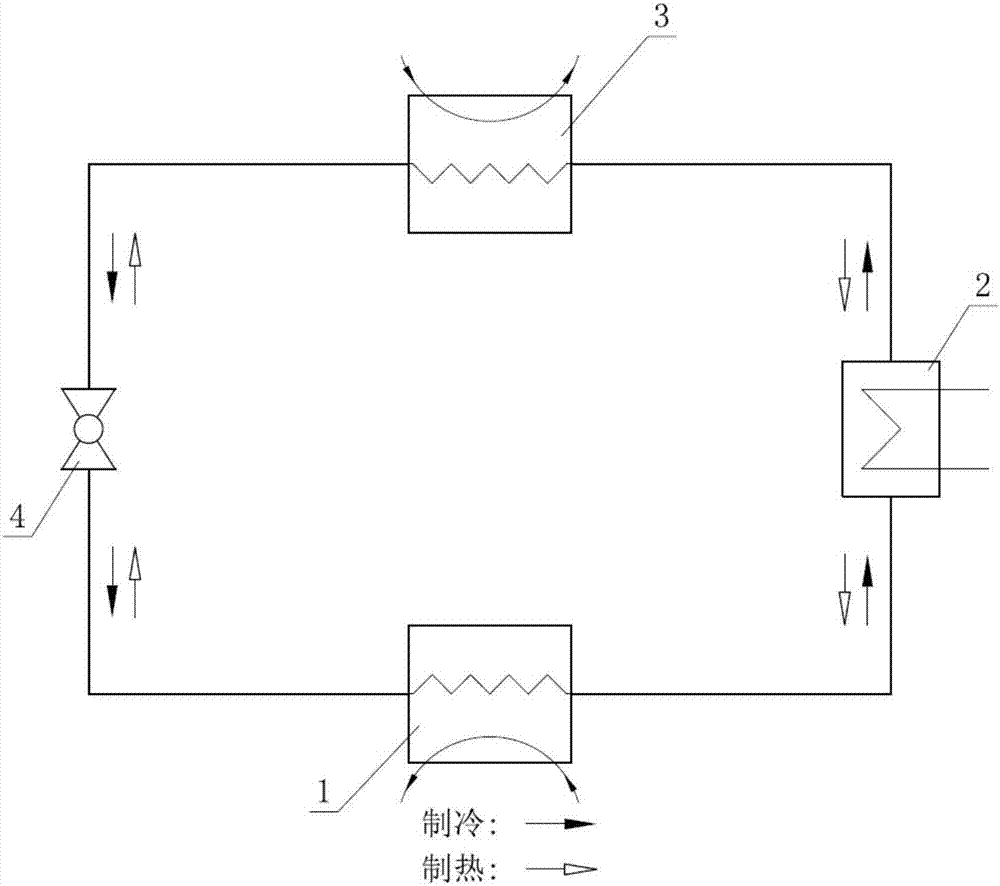

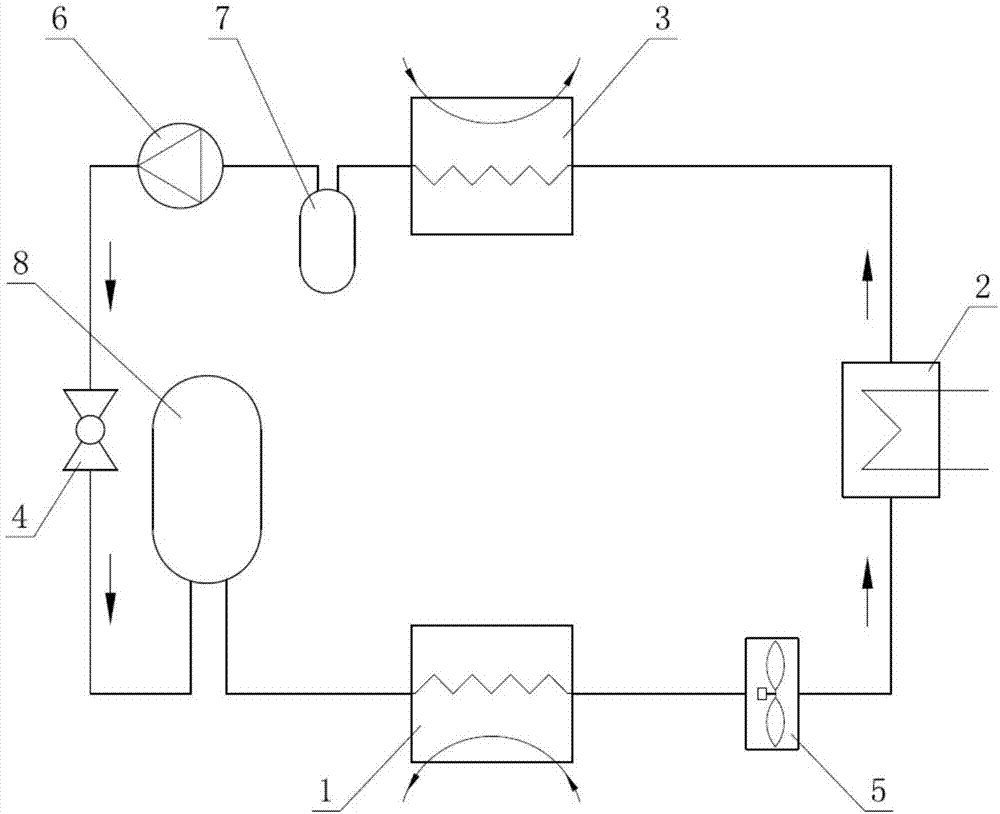

Heating type refrigerating circulation system

InactiveCN107477912AReduce energy consumptionNo energy consumptionRefrigeration componentsHigh energyMechanical energy

The invention relates to the technical field of refrigerating, and discloses a heating type refrigerating circulation system. The heating type refrigerating circulation system comprises an evaporator, a heater, a condenser and a throttling device. An outlet of the evaporator is connected with an inlet of the heater. An outlet of the heater is connected with an inlet of the condenser. An outlet of the condenser is connected with an inlet of the throttling device. An outlet of the throttling device is connected with an inlet of the evaporator. According to the heating type refrigerating circulation system, a compressor in a vapor-compression type refrigerating circulation system is replaced with the heater, the mode of providing mechanical energy power through mechanical compression is replaced with the mode of providing heat energy power through direct heating for acting on the system for increasing inner energy of the system, transmitting and exchanging of heat between the evaporator and the condenser are completed, and the high-energy-consumption problem of the vapor-compression type refrigerating circulation system is solved.

Owner:吴伟营

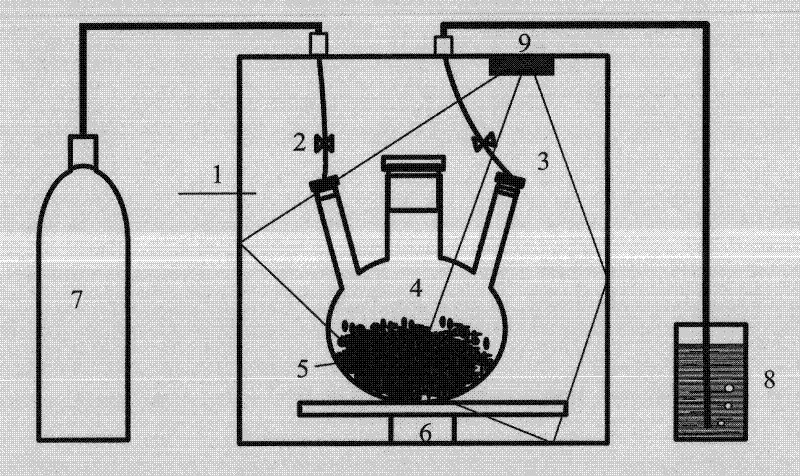

Preparation method of high-purity nano-powder Mg2-xSiTMx thermoelectric materials

InactiveCN102583391AHigh surface energyImprove internal energyChemical industryMetal silicidesThermoelectric materialsMicrowave oven

Disclosed is a preparation method of high-purity nano-powder Mg2-xSiTMx thermoelectric materials, which belongs to the field of thermoelectric material preparation and particularly relates to a technical scheme of preparation method of high-purity nano-powder Mg2-xSiTMx thermoelectric materials through a microwave reaction method. The preparation method is characterized in that magnesium hydride(MgH2) power, silicon powder and transition metal hydride TMHy powder are reacted under the protection of flowing argon air in a microwave oven, a decomposition temperature of the magnesium hydride powder and a decomposition temperature of the TMHy powder are both under 350 DEG C, reactants are easy to be decomposed and distributed in a substrate uniformly during the reaction process, the strong reducibility of the reactants can inhibit a substrate surface from absorbing oxygen and avoid further forming of oxidation products, and high-purity nano-powder Mg2-xSiTMx powder with a purity of not less than 99.95% is obtained. According to method, the process is simple, efficiency is high, energy is saved, and the prepared Mg2-xSiTMx thermoelectric materials have good thermoelectric performance.

Owner:TAIYUAN UNIV OF TECH

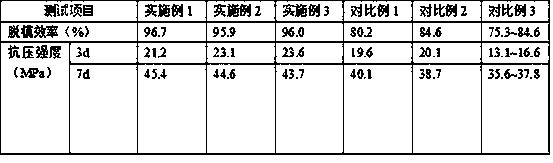

Concrete de-molding agent

ActiveCN108865330ALarge specific surface areaImprove internal energyCeramic shaping apparatusAdditivesHydration reactionMicro structure

The invention discloses a concrete de-molding agent and belongs to the field of concrete. According to the concrete de-molding agent, polyether polyol, mannitol and the like are used as raw materials,and are dehydrated and crossly linked to prepare a pre-polymer; the pre-polymer is matched with activated steel slag, gaps of slurry can be filled and a micro-structure at a transition period is improved; a hydration process is accelerated; kerosene and a grinding aid are matched to use so that the ball milling efficiency can be improved, the porosity in the steel slag is further enriched and thespecific surface area is enlarged; then active substances, which can participate in hydration, in a system can be sufficiently exposed; the de-molding effect is remarkably improved and the surface strength of the concrete is enhanced. Added carbomer can form gel under an alkaline environment of the system and excellent water retention and water holding performance of the gel can ensure that hydration reaction is sufficient and complete in a utilization process; CO2 is introduced so that the pH (Potential of Hydrogen) of the system is reduced and part of the carbomer is transformed into a dissolved state from a gel state again, and furthermore, the de-molding effect in an acting process of the concrete is facilitated. By adopting the concrete de-molding agent, the problem that the strengthof the concrete is reduced after an existing concrete de-molding agent is used is solved.

Owner:西安龙宾立强环保科技有限公司

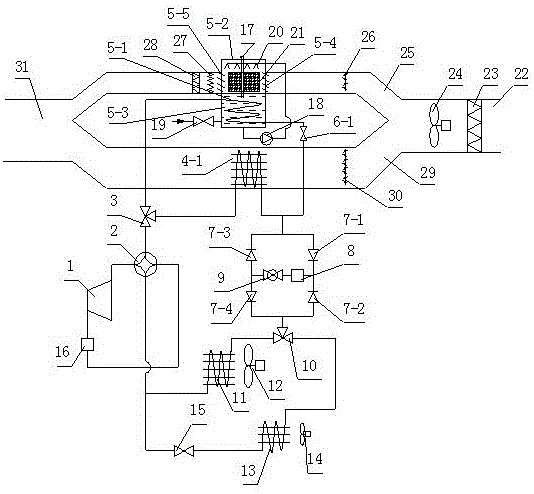

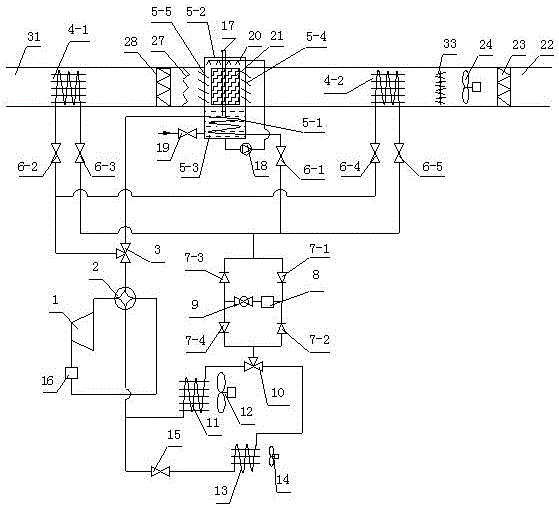

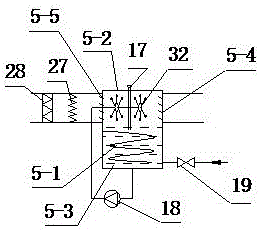

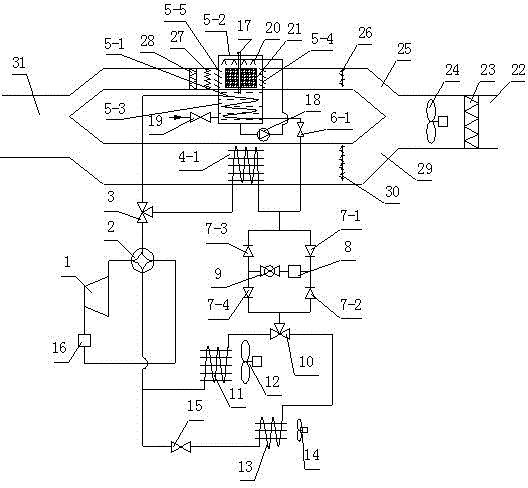

An integrated heat pump device for heating, humidification and cooling

ActiveCN104406321BPlenty of spaceReduce gasificationCompression machines with reversible cycleHeating and refrigeration combinationsFour-way valveActivated carbon filtration

The invention discloses a novel heating, humidifying and cooling integrated heat pump device. The device is characterized by comprising three parts, namely, a heat pump system, a water circuit and an air circuit; the heat pump system comprises a compressor, a four-way valve, an indoor heat exchanger, a secondary indoor heat exchanger, an one-way valve, a three-way valve, a throttling valve, an outdoor unit, an outdoor assisting heat exchanger, a liquid storing device, an air-liquid separator and an air blower; the water circuit comprises a dispenser, a water pump, a water distributor, a transfer packing layer, a water tank, a water supplementing valve, etc.; the air circuit comprises a main air returning pipeline, a branch pipeline, a primary filter, a water baffle, an activated carbon filter screen, a main air supplying pipeline, an air regulation valve, an air blower, etc. The heat pump system can be operated to heat and humidity indoor air at the same time in winter, and cool and dehumidify indoor air by evaporating a refrigerant to absorb heat and evaporating water in summer; therefore, the functions of heating, humidifying, cooling, sterilizing and the like are realized through one unit; the comfort is improved, and the energy consumption in heating and cooling is decreased.

Owner:YANTAI UNIV

Plastic material quick melting device

The invention discloses a plastic material quick melting device and relates to the field of plastic production equipment. The plastic material quick melting device comprises a melting tank. The top ofthe melting tank is fixedly connected with a feed hopper. A feed pipe movably penetrates through the bottom end of the feed hopper. The top end of the feed pipe is in interference fit with the feed hopper through a bearing. The bottom end of the feed pipe penetrates through the top of the melting tank to extend into the melting tank. The top of the inner wall of the melting tank is movably connected with a feeding mechanism. The bottom of the inner wall of the melting tank is movably connected with a squeeze mechanism. The plastic material quick melting device applies pressure to cause deformation of plastic particles through the squeeze mechanism to enhance the internal energy of the plastic particles during melting while heating the plastic particles, increases the heating area of the plastic particles, is higher in melting rate, uniformly feeds materials through centrifugal force of a hollow projecting disc and avoids incomplete melting of the raw materials. The problem that the rate of plastic melting equipment is not high is solved.

Owner:佛山博发智能科技有限公司

Method for producing anti-freeze swelling coloring biological fertilizer by using fulvic acid potassium

The invention discloses a method for producing an anti-freeze swelling coloring biological fertilizer by using fulvic acid potassium. The method comprises the following steps of: preparing a biological fermentation bacteria agent, selecting materials and mixing. The method has the advantages that the anti-freeze swelling coloring biological fertilizer is good in anti-frost property, significant in swelling coloring effect, strong in fertilizer efficiency and lasting in effect; soil hardening is not caused by long-time application; the preparation method is simple; the reaction speed and activity of a soil probiotic group can be fully improved; the activity cycle of a crop is changed; the absorption rate of nitrogen, phosphorus and potassium in soil and the utilization rate of a later additional fertilizer are improved; the cold resistance, the drought resistance, the pest resistance, remission of phytotoxicity and the like are achieved, so that internal energy of a crop body is improved; the effects of improving the quality, and increasing production and income are achieved.

Owner:湖北宏全生物科技有限公司

Novel heating, humidifying and cooling integrated heat pump device

ActiveCN104406321APlenty of spaceReduce gasificationCompression machines with reversible cycleHeating and refrigeration combinationsFour-way valveActivated carbon filtration

The invention discloses a novel heating, humidifying and cooling integrated heat pump device. The device is characterized by comprising three parts, namely, a heat pump system, a water circuit and an air circuit; the heat pump system comprises a compressor, a four-way valve, an indoor heat exchanger, a secondary indoor heat exchanger, an one-way valve, a three-way valve, a throttling valve, an outdoor unit, an outdoor assisting heat exchanger, a liquid storing device, an air-liquid separator and an air blower; the water circuit comprises a dispenser, a water pump, a water distributor, a transfer packing layer, a water tank, a water supplementing valve, etc.; the air circuit comprises a main air returning pipeline, a branch pipeline, a primary filter, a water baffle, an activated carbon filter screen, a main air supplying pipeline, an air regulation valve, an air blower, etc. The heat pump system can be operated to heat and humidity indoor air at the same time in winter, and cool and dehumidify indoor air by evaporating a refrigerant to absorb heat and evaporating water in summer; therefore, the functions of heating, humidifying, cooling, sterilizing and the like are realized through one unit; the comfort is improved, and the energy consumption in heating and cooling is decreased.

Owner:YANTAI UNIV

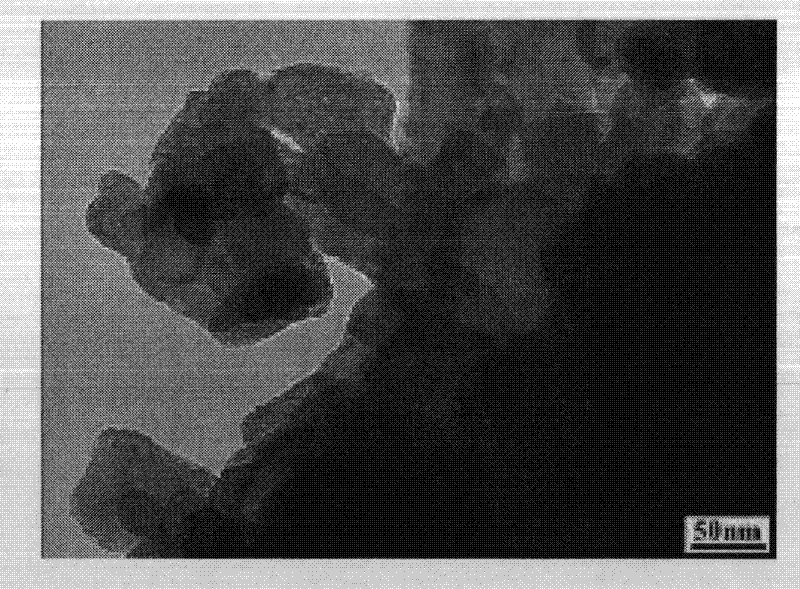

Infrared stealth coating containing rare-earth-doped nano Al2O3 powder

ActiveCN108841311AImprove powder internal energyImprove internal energyAluminium hydroxide preparationAnti-corrosive paintsNano al2o3Rare earth

The invention relates to an infrared stealth coating containing rare-earth-doped nano Al2O3 powder. The rare-earth-doped nano Al2O3 powder with the particle size ranging from 20 nm to 50 nm is prepared from AlCl3*6H2O, ErCl3 and Na2CO3 which are in the mole ratio being (2.5-4):(0.025-0.038):5 with the direct precipitation method; then the rare-earth-doped nano Al2O3 powder is modified by a silanecoupling agent KH570 which accounts for 6%-12% of the rare-earth-doped nano Al2O3 powder in mass; the modified rare-earth-doped nano Al2O3 powder is dispersed in absolute ethyl alcohol in the proportion of 1 g / mL, the solution is mixed with polyurethane, then the solution is sprayed to an aluminum substrate, the infrared stealth coating containing the rare-earth-doped nano Al2O3 powder is obtainedthrough curing, and the mass ratio of rare-earth-doped nano Al2O3 to the polyurethane is (1-2):3. The preparation technology is simple, and the infrared stealth coating is low in density, low in infrared reflectivity and high in transparency and has the good physical, mechanical and chemical properties.

Owner:NANCHANG HANGKONG UNIVERSITY

Low-temperature solidification, concentration and collection aerosol device and operation method thereof

ActiveCN112781971AEasy gas-solid separationThorough gas-solid separationPreparing sample for investigationAerosolizeWater flow

The invention discloses a low-temperature solidification, concentration and collection aerosol device and an operation method thereof. The low-temperature solidification, concentration and collection aerosol device comprises a gas deceleration cabin, a gas retention cabin, an aerosol acceleration cabin, a gas wet and hot flow atomization cabin, a gas freezing cabin and a collection cabin; folding channel collision plates which are mutually staggered are arranged in the gas deceleration cabin; the gas retention cabin is provided with a vibratable filter membrane covering an air vent; the aerosol acceleration cabin is of an interlayer structure, hot water flow circulation is arranged in an interlayer, and an air blower is arranged in a cavity; needle tube type atomizing nozzles are arranged on the upper side and an inlet of the gas wet and hot flow atomization cabin; and the gas freezing cabin circularly refrigerates, so that the concentrated aerosol-containing liquid drops are solidified into ice particles. Aerosol-containing ice particles and airflow are thoroughly separated through low-temperature solidification, the dilution effect of moisture on the aerosol is reduced by improving the mixing efficiency of the aerosol and spray vapor and controlling the vapor concentration, and concentrated aerosol is formed and is convenient to collect, analyze and detect.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

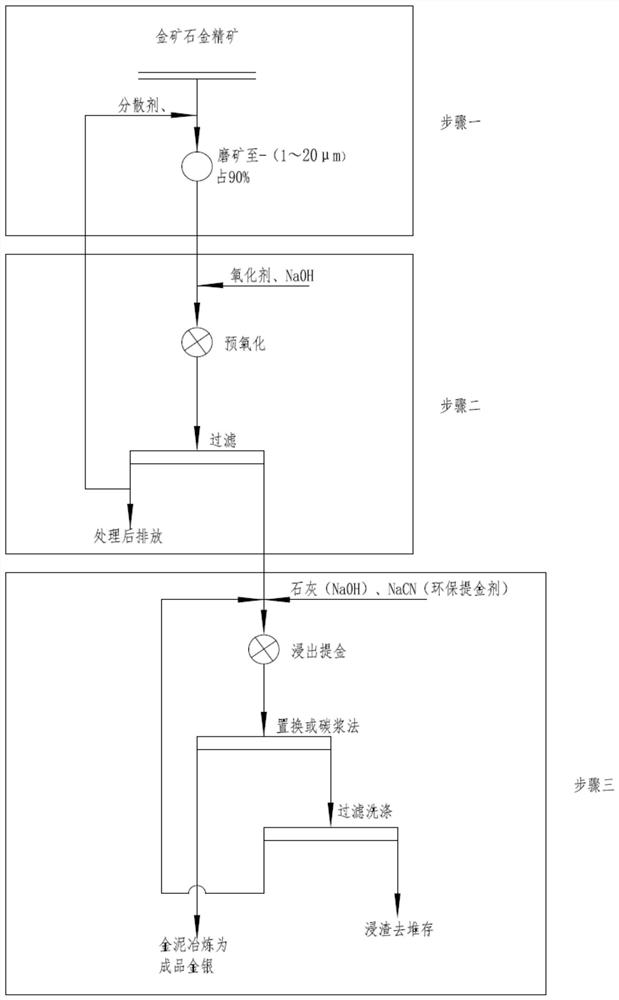

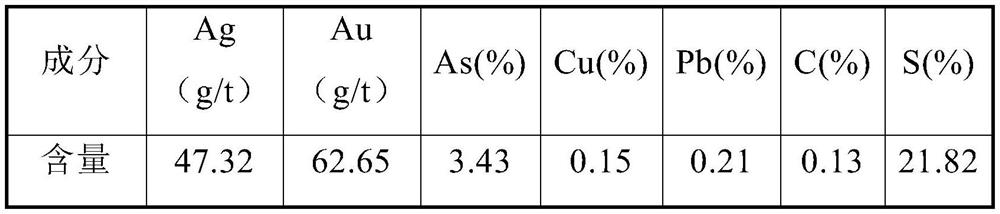

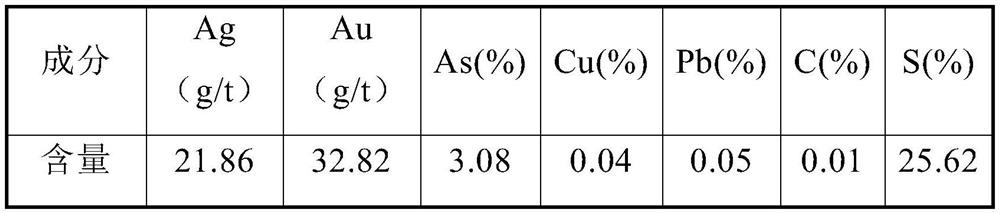

Efficient pretreatment method for refractory metallurgical ore

PendingCN113088720AEfficient recyclingImprove internal energyProcess efficiency improvementPretreatment methodChemical reaction

The invention relates to an efficient pretreatment method of refractory metallurgical ore. The efficient pretreatment method comprises the steps that water is added into the refractory metallurgical ore for size mixing, a dispersing agent is added for mechanical activation, ore grinding is conducted till 90 percent by mass of particles are less than 1-20 microns, and the chemical reaction activity of the refractory metallurgical ore is increased; an oxidizing agent is added into the mechanically-activated system for pre-oxidation, associated mineral wrapping gold is dissolved to expose the gold, and filtering is conducted after pre-oxidation; and a filter cake obtained through filtering is subjected to size mixing, gold is extracted through leaching, and the gold and silver in the filter cake are recycled. According to the efficient pretreatment method, mechanical activation and chemical pre-oxidation are adopted, the difficulty of oxidation reaction of the wrapping mineral of the refractory gold ore is reduced, the oxidation reaction can be conducted at the normal temperature and under the normal pressure, and the equipment investment and the operation cost are reduced and meanwhile, harmful gas and waste residues are not generated, environment friendliness is achieved, large-scale manufacturing of equipment is easy, large-scale production and application can be achieved, and the efficient pretreatment method has great popularization value.

Owner:张伟晓

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com