Patents

Literature

31results about How to "Long restore time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

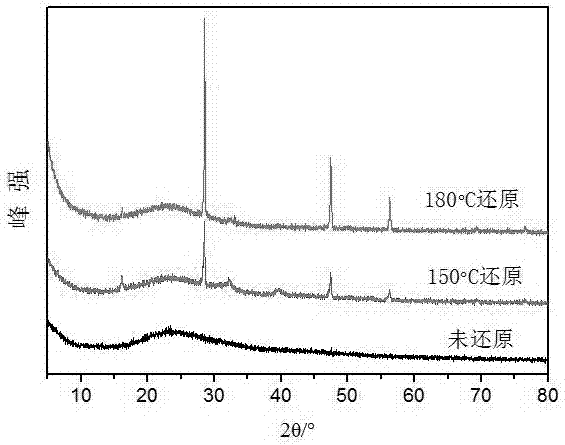

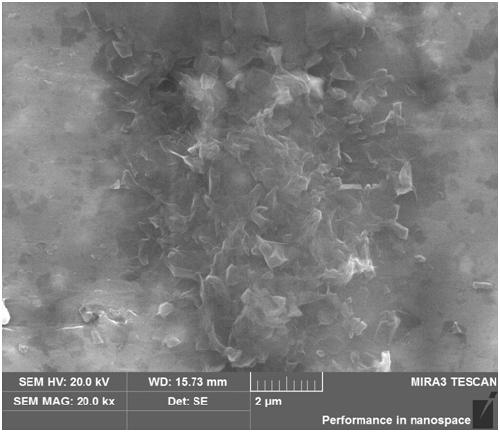

Graphene aerogel and preparation method and application thereof

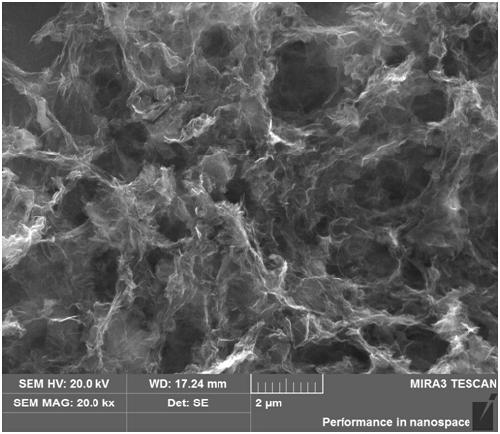

ActiveCN107585758ALow densityImprove integrityMagnetic/electric field screeningGrapheneReduction treatmentFreeze-drying

The invention discloses a graphene aerogel and a preparation method and an application thereof, wherein the aerogel is prepared from the following method: (1) pre-reduction treatment: adding a reducing agent to a graphene oxide solution, mixing, carrying out ultrasonic dispersion, and carrying out pre-reduction treatment, to obtain a semi-reduction graphene hydrogel; (2) final reduction treatment:adding a reducing agent, carrying out ultrasonic treatment, and then carrying out final reduction treatment, to obtain a graphene hydrogel; and (3) acid / alkali soaking: placing the graphene hydrogelin an acid or alkali aqueous solution, soaking, washing the hydrogel to be neutral, sucking out the excess liquid, and carrying out freeze drying, to obtain the graphene aerogel. The graphene aerogelis applied to electromagnetic wave absorption materials. The graphene aerogel obtained by the method has small density and good integrality, and has a certain mechanical strength and resillency; the prepared wave absorbing material has good electromagnetic wave absorption performance, and the wave absorbing performance can be adjusted; and the method has the advantages of simple process, short production cycle, low cost and good benefits, and is suitable for industrialized production.

Owner:苏州涤致良特种防护装备科技有限公司

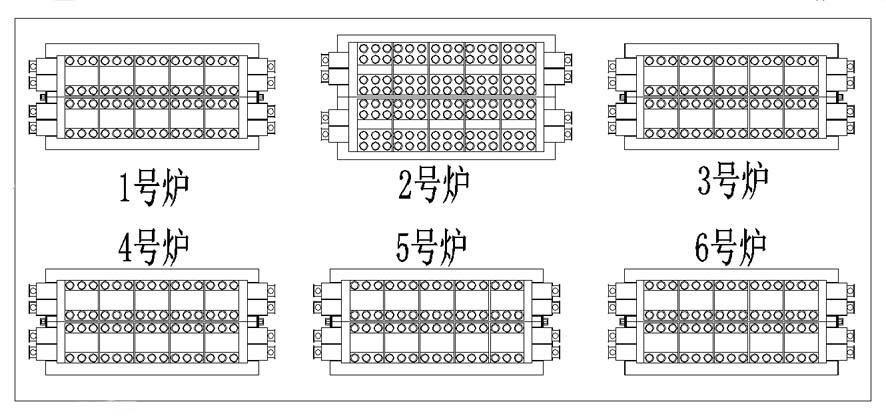

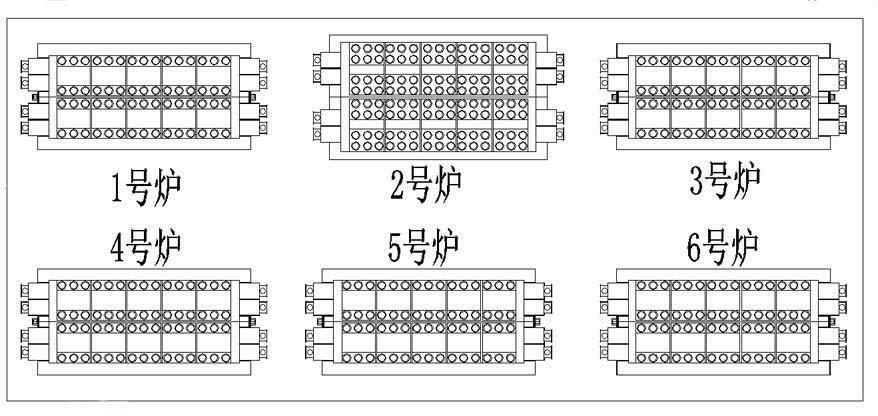

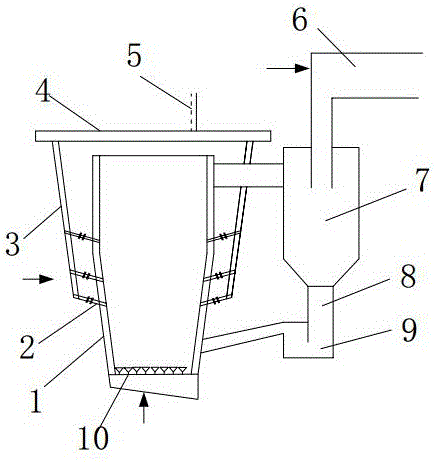

Low-nitrogen combustion technique based on circulating fluidized bed boiler

ActiveCN106051749ASolve the reduction of NOx emissionsSolve the high carbon content of fly ashFluidized bed combustionFluegas recirculationBurning outCirculating fluidized bed boiler

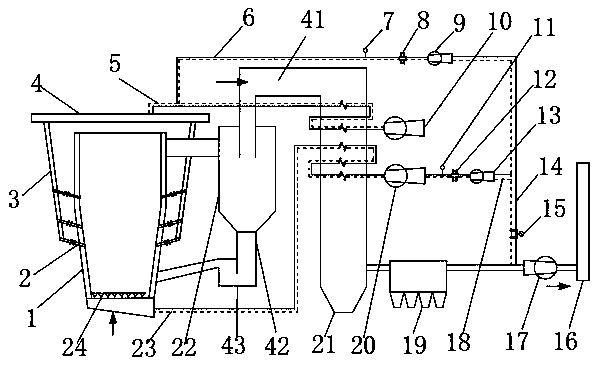

The invention discloses a low-nitrogen combustion technique based on circulating fluidized bed boiler. The circulating fluidized bed boiler comprises a boiler body, a cyclone separator, a deduster, an induced draft fan, a primary air supply system and a secondary air supply system which are connected in sequence. A smoke recirculation pipe is drawn out behind the induced draft fan. The primary air supply system and the secondary air supply system are connected to the smoke recirculation pipe in parallel. A burn-out chamber is arranged at an outlet of the cyclone separator. The low-nitrogen combustion technique based on the circulating fluidized bed boiler comprises the following steps that pulverized coal enters the boiler body under the action of primary air, specifically, the amount of smoke recirculation air in the primary air accounts for 8-10% the total air amount of the primary amount, and the amount of the primary air accounts for 40-45% of the total air amount; secondary air is introduced into the boiler body through the secondary air supply system, specifically, the amount of smoke recirculation air in the secondary air accounts for 12-14% the total air amount of the secondary air; fine flying ash enters the burn-out chamber; and over fire air is introduced into the burn-out chamber. According to the low-nitrogen combustion technique based on the circulating fluidized bed boiler, the burn-out chamber is arranged at the outlet of the separator, and part of smoke is mixed into the primary air and the secondary air, so that generation of NOx is reduced.

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

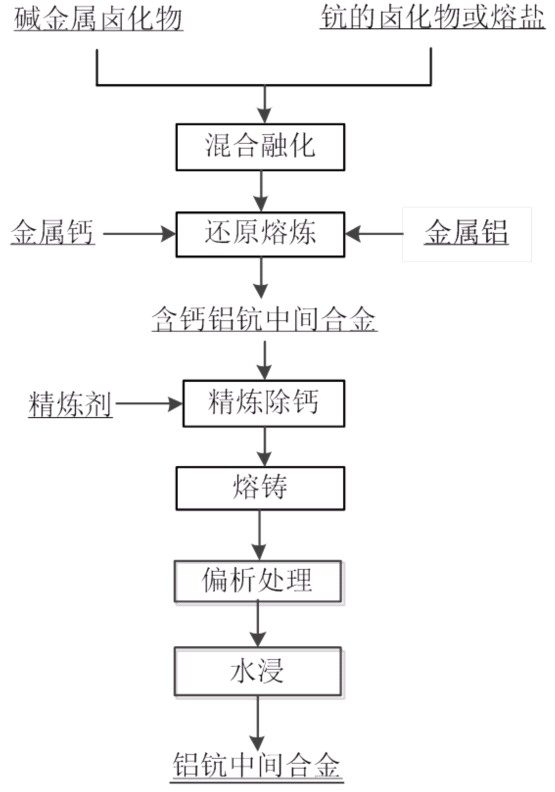

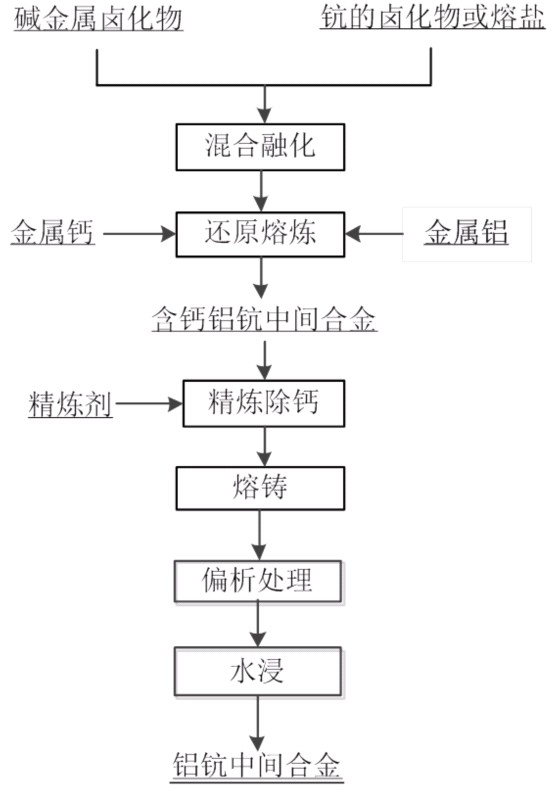

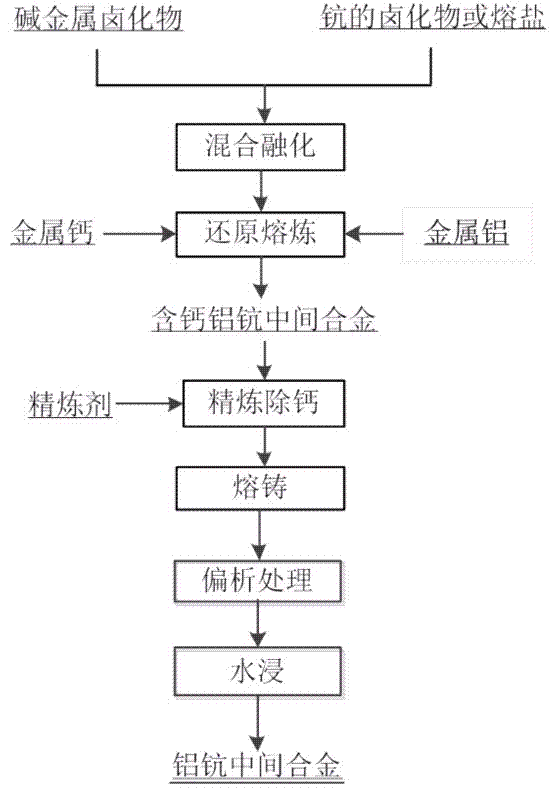

Method for preparing aluminum-scandium intermediate alloy by using calciothermy

The invention discloses a method for preparing an aluminum-scandium intermediate alloy by using calciothermy. The method comprises the following steps of: (1) calculating the weights of halides of aluminum, metal calcium and scandium serving as raw materials, or scandium-containing fused salt, anhydrous calcium chloride and alkali chloride required for smelting in each furnace according to the component content of the aluminum-scandium intermediate alloy; (2) after uniformly mixing a flux, adding the flux into a crucible to smelt; (3) when the flux is completely smelted, adding scandium halide and preserving the heat in a closed protective atmosphere; (4) adding aluminum and metal calcium into the smelted scandium-containing fused salt, preserving the heat and thermally reducing for 20 to 200 minutes; (5) after finishing the thermal reduction reaction, slagging off, and adding an excessive amount of refining agent to remove the calcium, when the calcium content in the alloy is less than 50ppm, casting an ingot and cooling, and performing water leaching to remove slag so as to obtain the aluminum-scandium intermediate alloy. The method disclosed by the invention has the advantages of low fluorine, micro discharge, easiness in operation, steady aluminum-scandium alloy product, novelty and economy.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

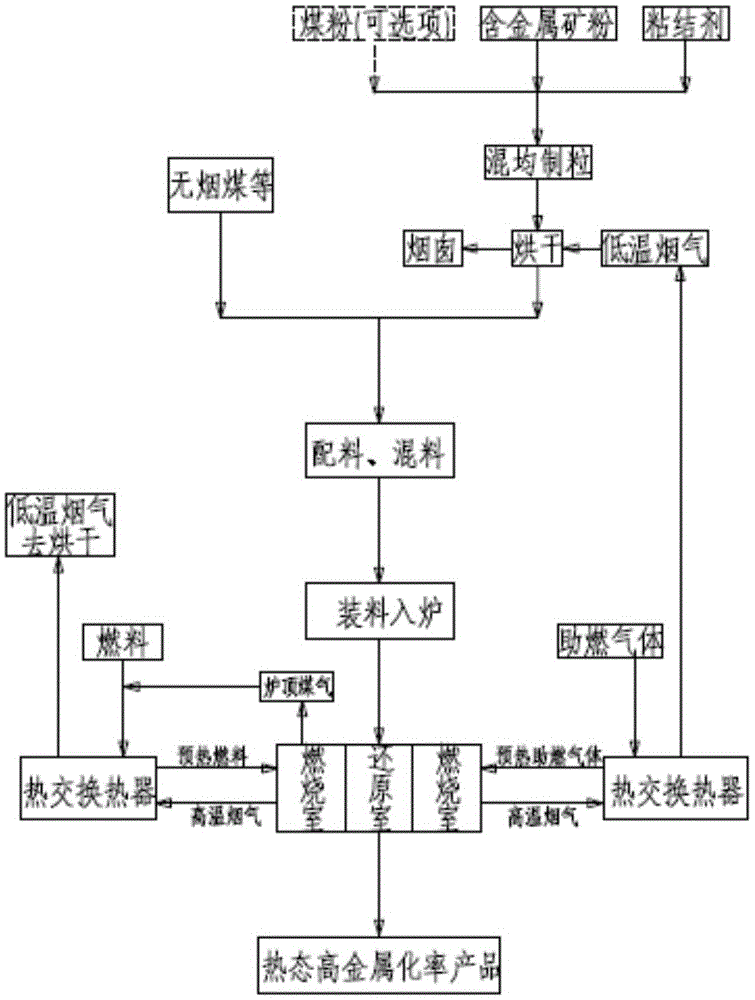

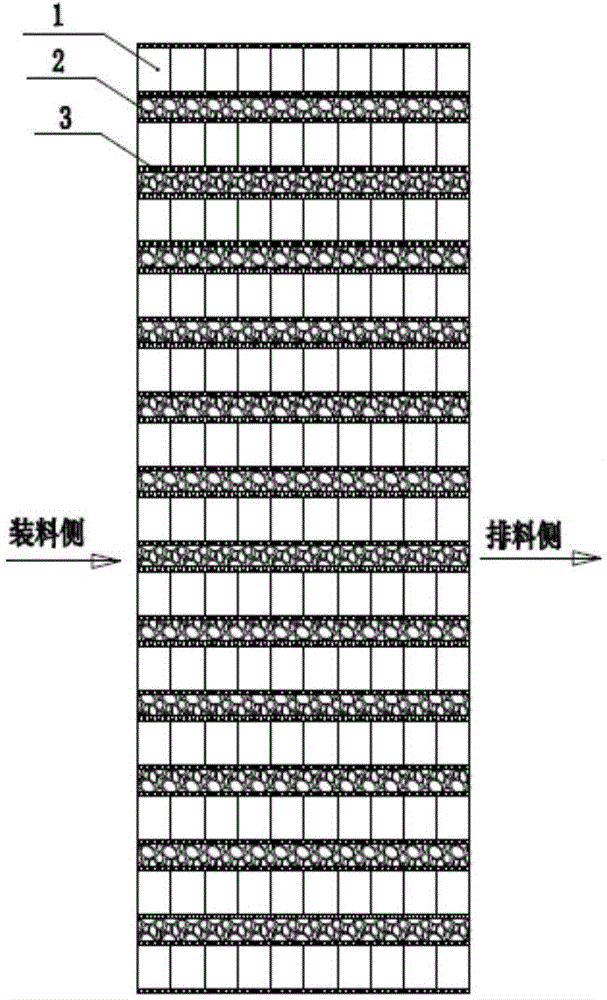

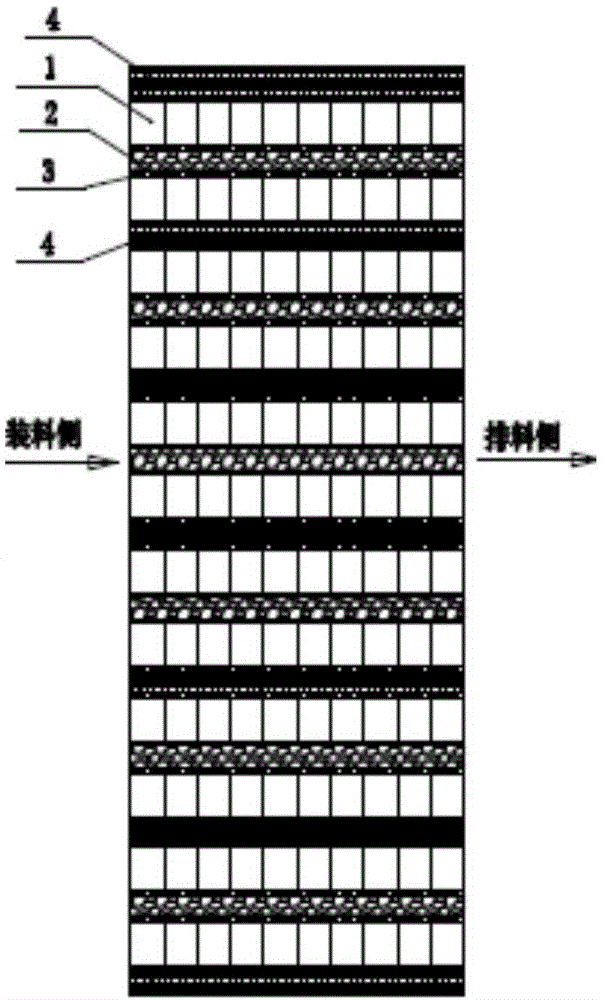

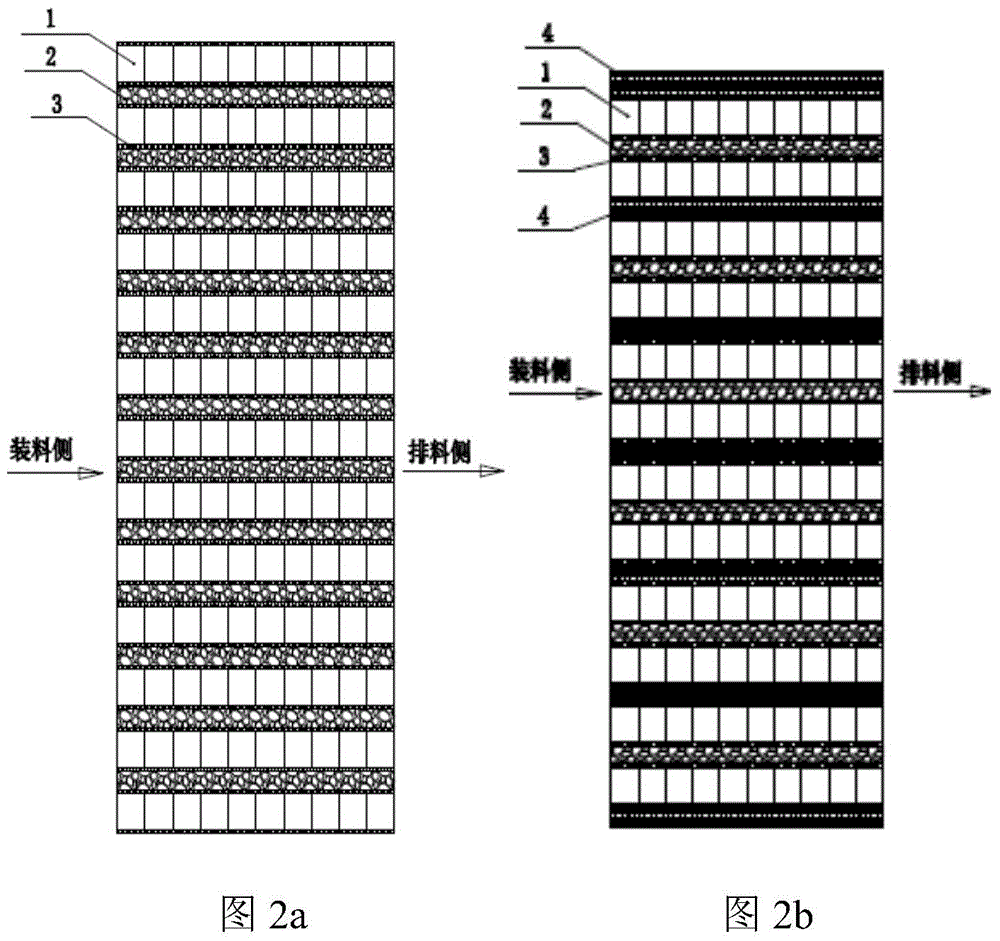

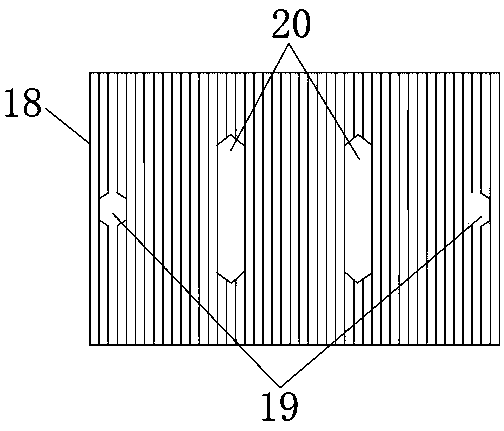

QDF (quiescent direct furnace) direct reduction technology

InactiveCN104630404AAchieve the desired effectReduced strength requirementsFluidised-bed furnacesCombustion chamberProduct gas

The invention relates to a QDF (quiescent direct furnace) direct reduction technology which comprises the following steps: uniformly mixing a metal-containing raw material and reducing agent powder, and putting into each reducing chamber, wherein in a reducing process, the reducing chambers and the reduced material are all kept in a stationary state; uniformly heating the materials in the reducing chambers by use of the heat generated by the combustion of the fuel in a combustion chamber and a combustion-supporting gas so as to perform a reduction reaction between the metal-containing raw material and the reducing agent, wherein each reducing chamber is a narrow long one-section reactor. According to the technology provided by the invention, the reducing chambers and the reduced material are all in a stationary state, the requirement on the strength of the granular raw material is reduced, and the production efficiency of a granulation process is improved; and the reducing time can be prolonged, and the metallization ratio of the reduction product is improved. The reducing chamber is not provided with a preheating area or a cooling area, the temperature is uniform, the atmosphere is uniform and consistent, and the overall quality of the reduction product is improved. The direct reduction technology has remarkable advantages of wide application range of raw materials, uniform temperature field, easy control on reduction process, high product metallization ratio, high yield and the like.

Owner:WISDRI ENG & RES INC LTD

Circulating fluidized bed boiler system for achieving low nitrogen oxide discharge

InactiveCN105805730AImprove fluidization characteristicsWell mixedFluidized bed combustionStaged combustionFlue gasEngineering

The invention discloses a circulating fluidized bed boiler system for achieving low nitrogen oxide discharge. The circulating fluidized bed boiler system comprises a boiler, a cyclone separator, a dust remover and an induced draft fan which are sequentially connected. The circulating fluidized bed boiler system further comprises a primary air supply system and a secondary air supply system. A flue gas recirculation pipe is guided out of the rear portion of the induced draft fan and connected with the primary air supply system and the secondary air supply system in parallel. The secondary air supply system comprises a secondary air fan, a secondary air pipe, a plurality of secondary air vertical pipes arranged on the outer sides of a front wall and a rear wall of the boiler and secondary air nozzles, wherein the secondary air nozzles are arranged on a water cooling wall, connected with the secondary air vertical pipes and arranged in a dilute phase area of the boiler in a layered manner. According to the circulating fluidized bed boiler system, part of flue gas is mixed into primary air, the fluidization characteristic of a dense phase area during low-load running is improved, part of flue gas is mixed into secondary air, the air speed of the secondary air nozzles can be increased easily, a local high-temperature area is avoided, and generated NOx is reduced. By means of the secondary air arrangement manner of the system, the disturbance function of the flue gas in a hearth is increased, fuel is combusted fully, and the generated NOx is reduced.

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

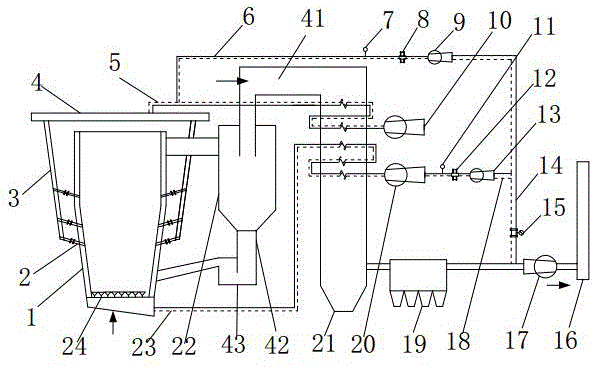

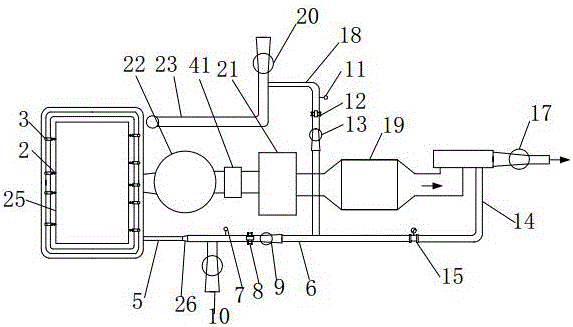

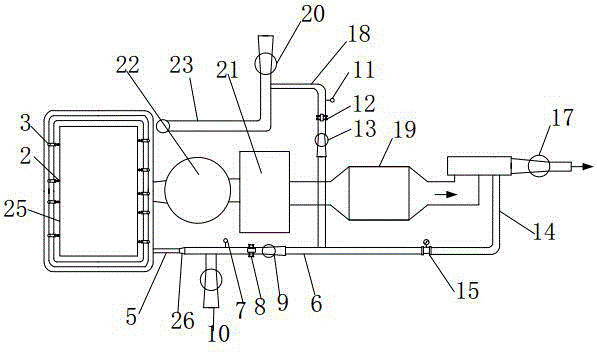

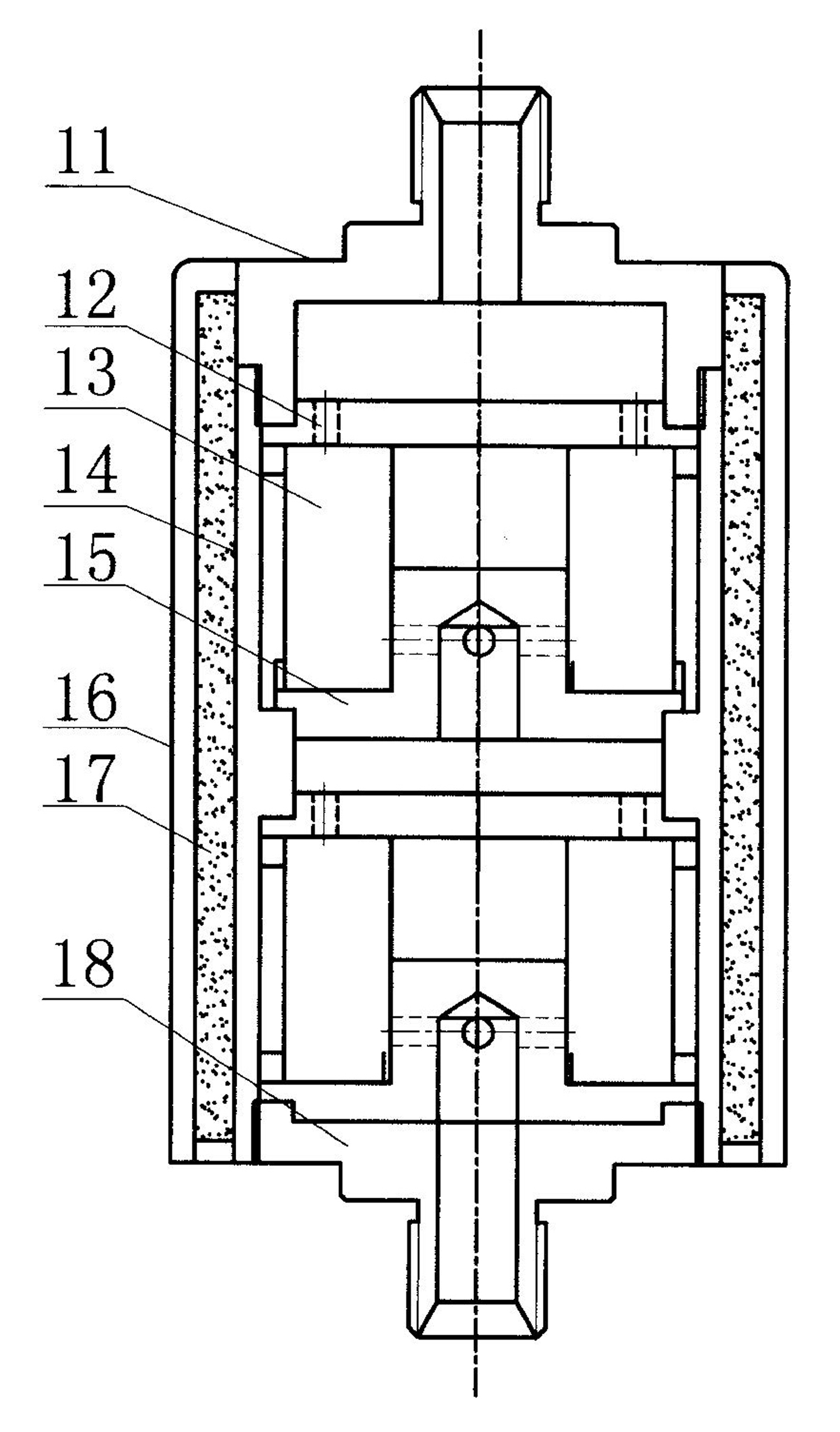

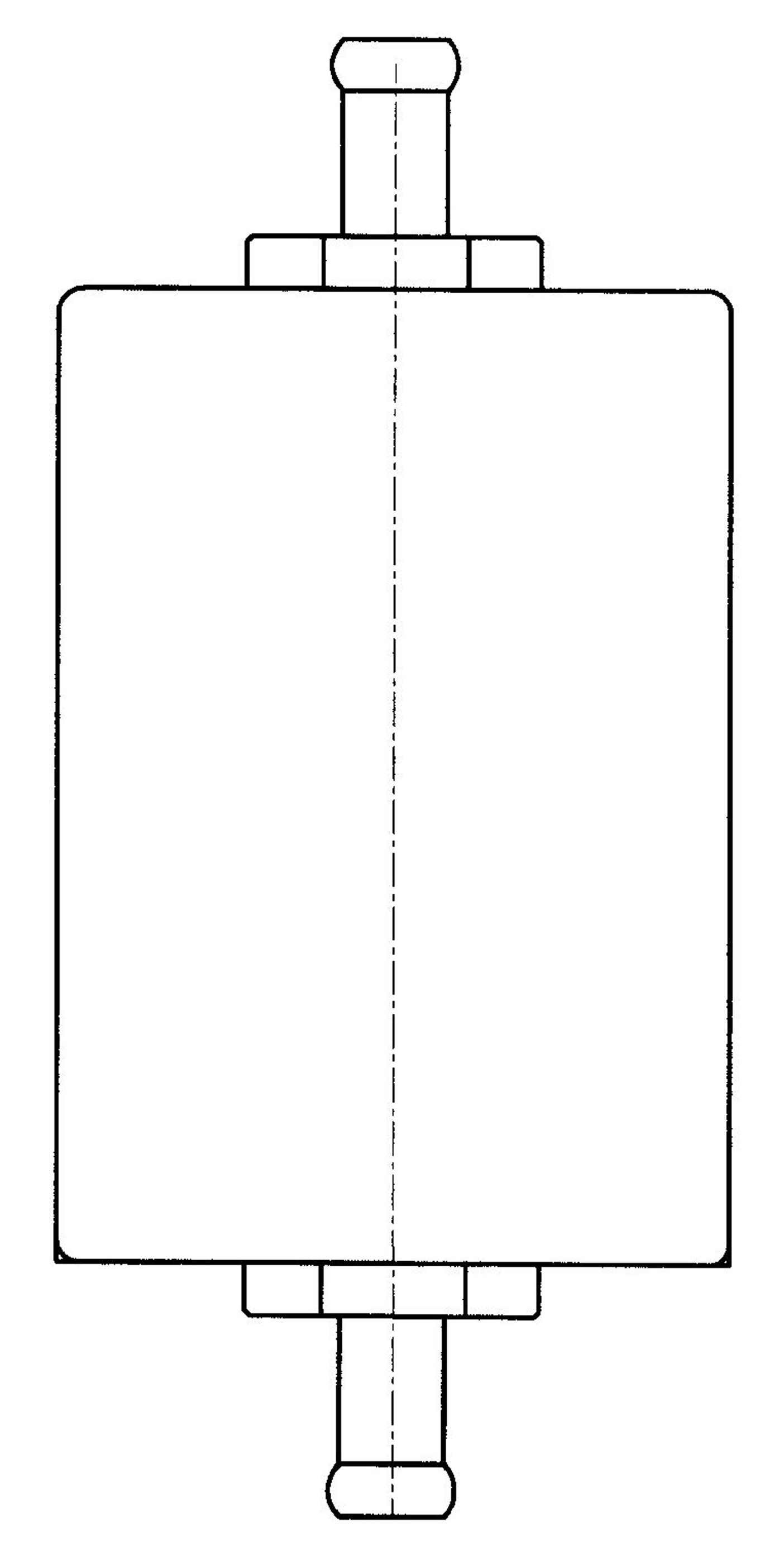

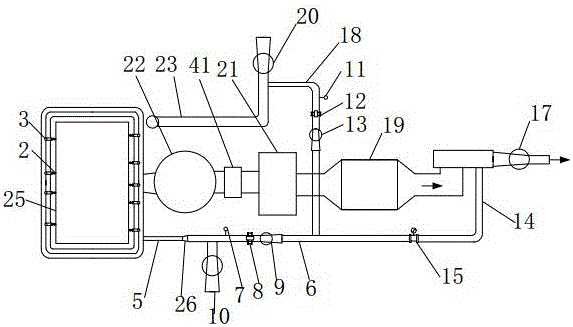

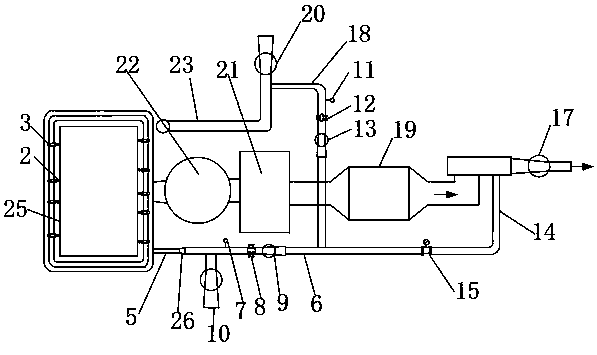

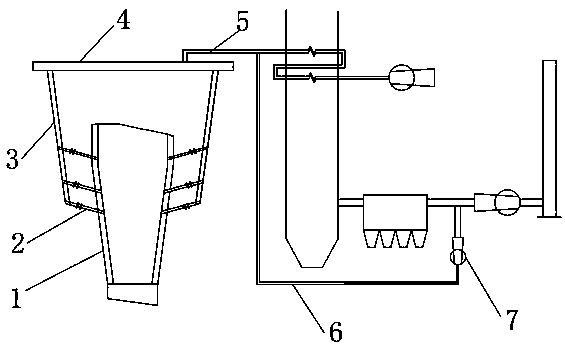

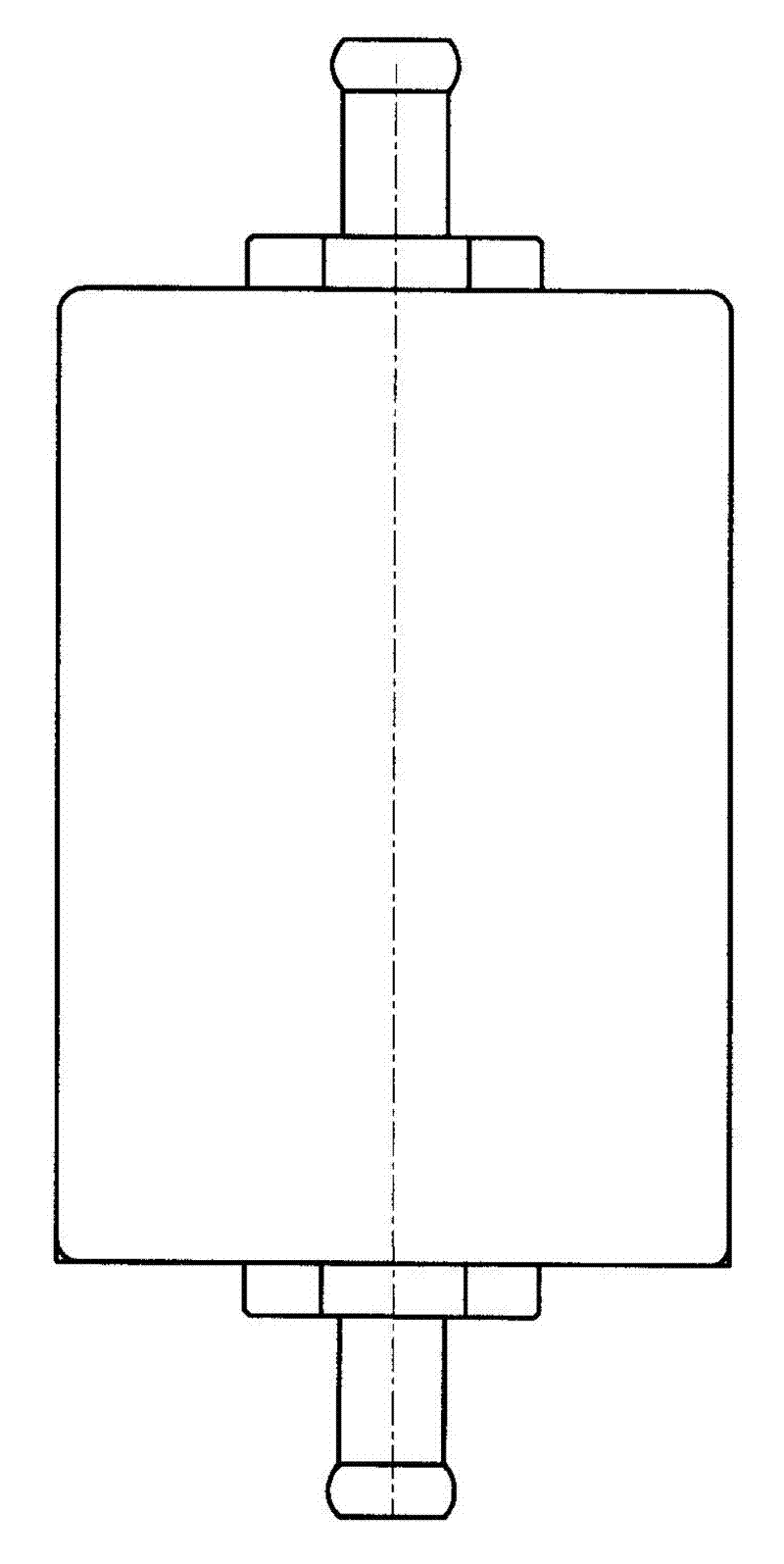

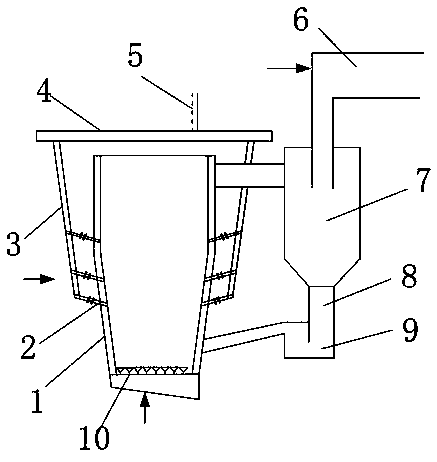

Fuel oil saving device of vehicle

InactiveCN101865053ALong restore timeAvoid peroxy combustionNon-fuel substance addition to fuelInternal combustion piston enginesMagnetic energyFuel oil

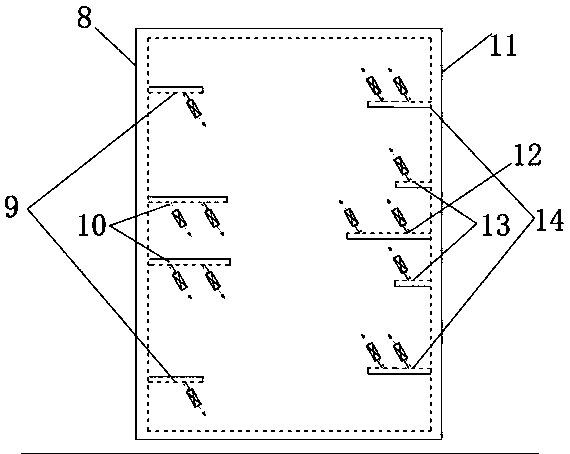

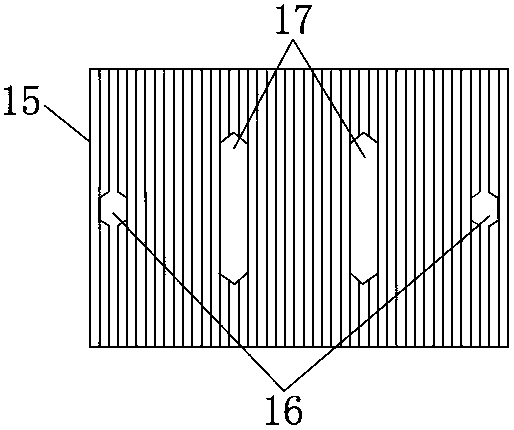

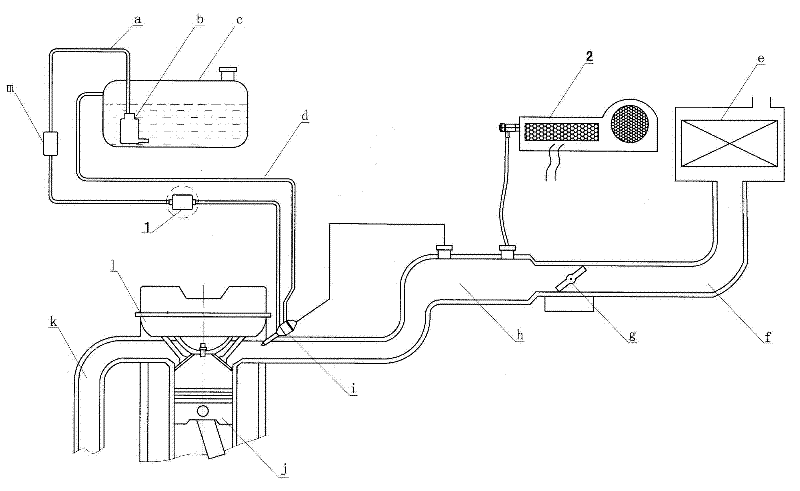

The invention relates to a fuel oil saving device of a vehicle, comprising two groups, i.e. a fuel oil magnetization processor and an oxygen increasing and supplementing device, wherein the fuel oil magnetization processor comprises two multi-gradient magnetization radiation areas, two stagnation areas and an output port, wherein each multi-gradient magnetization radiation area consists of a main body; each magnetic energy radiation area comprises an upper supporting plate, a lower supporting plate and a permanent magnet clamped between the upper supporting plate and the lower supporting plate, and the two magnetic energy radiation areas are arranged adjacently; the inlet end of the first magnetic energy radiation area is the first stagnation area, and a second stagnation area is positioned between the two magnetic energy radiation areas; the oxygen increasing and supplementing device comprises a space divider and an ozone generator, wherein the space divider comprises an air filter assembly, a fan assembly, a permanent magnet fastening end cover clamped between the upper supporting plate and the lower supporting plate, and the like and forms an integer with a shell; and a space divider assembly control power supply inside the ozone generator, a booster, a generating tube and a boosting pump are sequentially arranged on a base plate. The invention has high fuel oil saving efficiency and easy installation and debugging.

Owner:姚大华

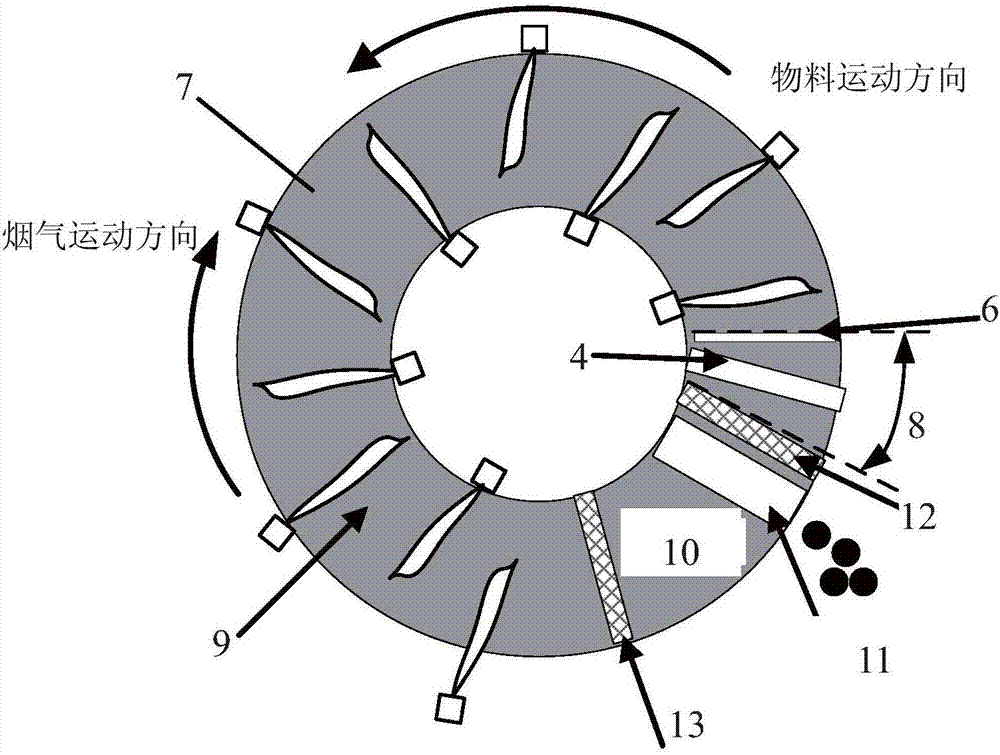

Rotary hearth furnace

The invention relates to a rotary hearth furnace. The rotary hearth furnace comprises an annular furnace body, an annular hearth, a heat power engineering system, a discharge mechanism, a distributionmechanism and a smoke discharge mechanism. The rotary hearth furnace effectively solves low CO utilization rate, and meanwhile, fully uses the smoke afterheat; more CO participates in indirect reduction; materials are preheated by the smoke afterheat; compared with a traditional rotary hearth furnace technology, the rotary hearth furnace can reduce adding of the material carbon dosage, effectively reduces the smelting energy consumption, and reduces the production cost; and the angle of a high-temperature reduction area is increased, so that the reduction time is prolonged, the reduction effect is improved, and meanwhile, the treatment capacity of the rotary hearth furnace is improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Preparation method for fuel oil desulfuration adsorbent

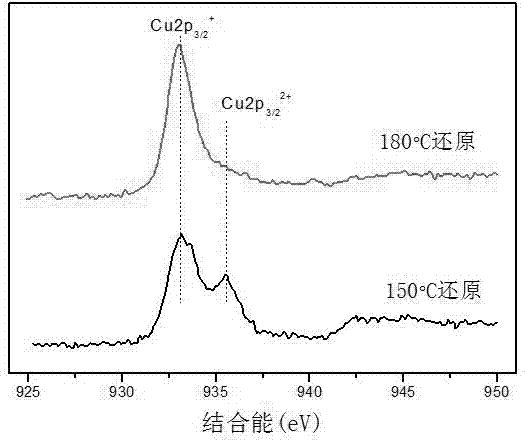

ActiveCN106984257AWeak reductionImprove adsorption capacityOther chemical processesHydrocarbon oils refiningSorbentFuel oil

The invention discloses a preparation method for a fuel oil desulfuration adsorbent, and belongs to the technical field of fuel oil desulfuration. The method comprises the steps of dispersing CuCl2 and a carrier into a solvent and stirring until a solvent evaporates to obtain a carrier material which is uniformly loaded with CuCl2; putting a quartz tube containing the carrier material which is uniformly loaded with the CuCl2 into a heating furnace, introducing a mixed gas prepared from ethylene and an inert gas into the heating furnace for reduction reaction and cooling to a room temperature after reaction is completed to obtain the CuCl2-loaded adsorbent. The method is high in reduction rate and short in reduction time; compared with hydrogen, the reducibility of ethylene is relatively weak and monovalent copper is not reduced into pure copper; the ratio of the monovalent copper in a copper component of the obtained sample is relatively high; and the adsorption effect on thiophene sulfide in fuel oil can be improved.

Owner:YANGZHOU UNIV

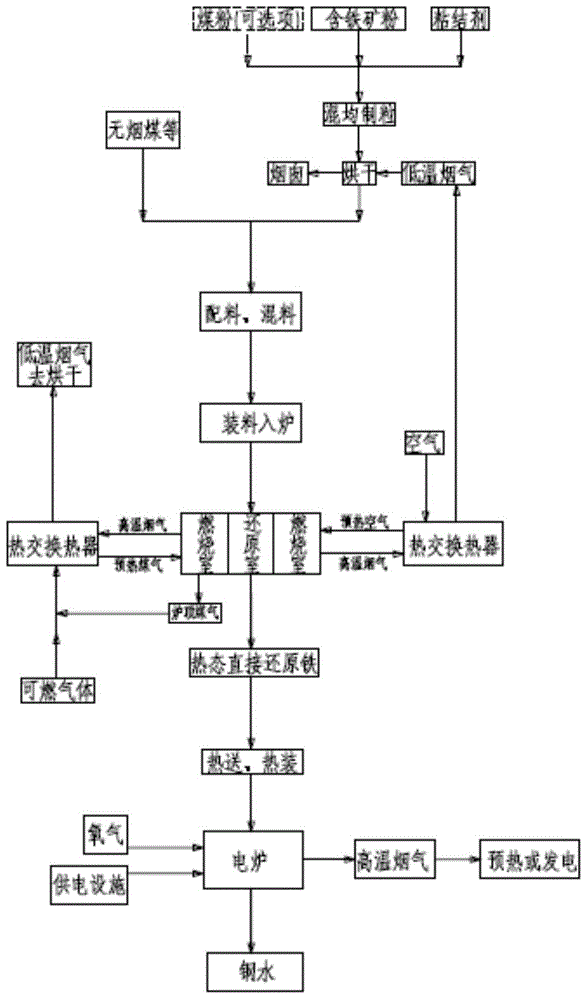

QDF electric steelmaking process

InactiveCN104630411AAchieve the desired effectReduced strength requirementsProcess efficiency improvementElectric furnaceSteelmakingCombustion

The invention relates to a QDF electric steelmaking process. The process comprises the following steps: uniformly mixing an iron-containing raw material and a powdery reducing agent, and filling each reducing room, wherein the materials are in disperse and uniformly distributed state in the reducing room, and the reducing rooms and the reduced materials are maintained in static states in the reduction process; uniformly heating the materials in the reducing room by using the heat produced by the combustion of fuel and combustion-supporting gas in a combustion room to preform the reduction reaction on the iron-containing raw material and the reducing agent, wherein the reducing room is a narrow one-part form reactor; obtaining heat-state directly reduced iron after the materials in the reducing room are completely reacted, conveying the heat-state directly reduced iron to a charging device through a hot-delivery mode, and hot-filling an electric furnace to obtain molten steel. The process has the obvious advantages of being short in flow, strong in raw material adaptability, non-coke smelting, easy in control of the reduction process, sufficient in inter-process energy utilization, and capable of obviously reducing CO2 discharge; the process is a steelmaking method with shorter process flow, lower investment, lower cost and better environment protection in comparison with a converter steelmaking process.

Owner:WISDRI ENG & RES INC LTD

High-efficiency denitration ionic liquid and application method thereof

ActiveCN109569240AHigh orientationReduce the degree of hydrolysisGas treatmentDispersed particle separationPeptideIon

The invention relates to high-efficiency denitration ionic liquid, which belongs to the technical field of smoke treatment. The high-efficiency denitration ionic liquid comprises the following components: 15 to 30 parts of urea-based organic peptide, 60 to 80 parts of deionized water, 5 to 10 parts of catalyst, 1 to 5 parts of stabilizers, and 1 to 5 parts of regulator. The components are added into a high-speed dispersion device to be dispersed at a high speed, and the stable high-efficiency denitration ionic liquid can be formed by virtue of the dispersion and reaction. An application methodof the high-efficiency denitration ionic liquid comprises the following steps: spraying the prepared ionic liquid into a denitration reactor by using a spray gun, wherein the application temperatureis 450 to 1250 DEG C. According to the high-efficiency denitration ionic liquid and the application method thereof, the high-efficiency denitration ionic liquid is colorless, tasteless and non-corrosive liquid, is safe in transportation and storage, convenient and simple to use, free from secondary pollution, wide in operating temperature range, and capable of being operated at 450 to 1250 DEG C;the method does not cause any crystallization and blockage when in operation; and after the product is put into the high temperature area, the smoke sufficiently contacts the denitration ionic liquid,so that the reduction time of the liquid catalyst and the smoke can be increased, and the escaping can be avoided.

Owner:山东汇之蓝环保科技有限公司

Waste electromagnetic wire copper refining agent and preparation method and application thereof

ActiveCN106636668ALow costPromote recycling industryProcess efficiency improvementNickelMaterials science

The invention relates to a waste electromagnetic wire copper refining agent and a preparation method and application thereof. The refining agent is preferably composed of, by mass, 1.0-5.0% of V, 1.0-5.0% of Sr, 0.5-2.5% of B, 5.5-7.5% of Mg, 5-10% of Y, 5-10% of Ce and the balance Cu. According to the preparation method of the refining agent, Cu-B-Y-Ce-Mg intermediate alloy and Cu-Sr intermediate alloy are crushed into fragments with the particle size being smaller than 10 mm, and the fragments and vanadium with the particle size being smaller than 10 mm are mixed evenly according to a set proportion and then wrapped with a high-purity oxygen-free copper sheet to obtain the refining agent. The refining agent can be used for refining oxygen-free copper from waste copper electromagnetic wires, and the adding amount is 0.1-0.65 percent of the melt mass. The refining agent of the design has the good effects on deoxidation, desulfurization, dealumination, deferrization, denickelefication and the like, and does not pollute copper liquid secondarily. The refining agent is reasonable in component design and simple in preparation process and can achieve large-scale industrial application conveniently.

Owner:CENT SOUTH UNIV +1

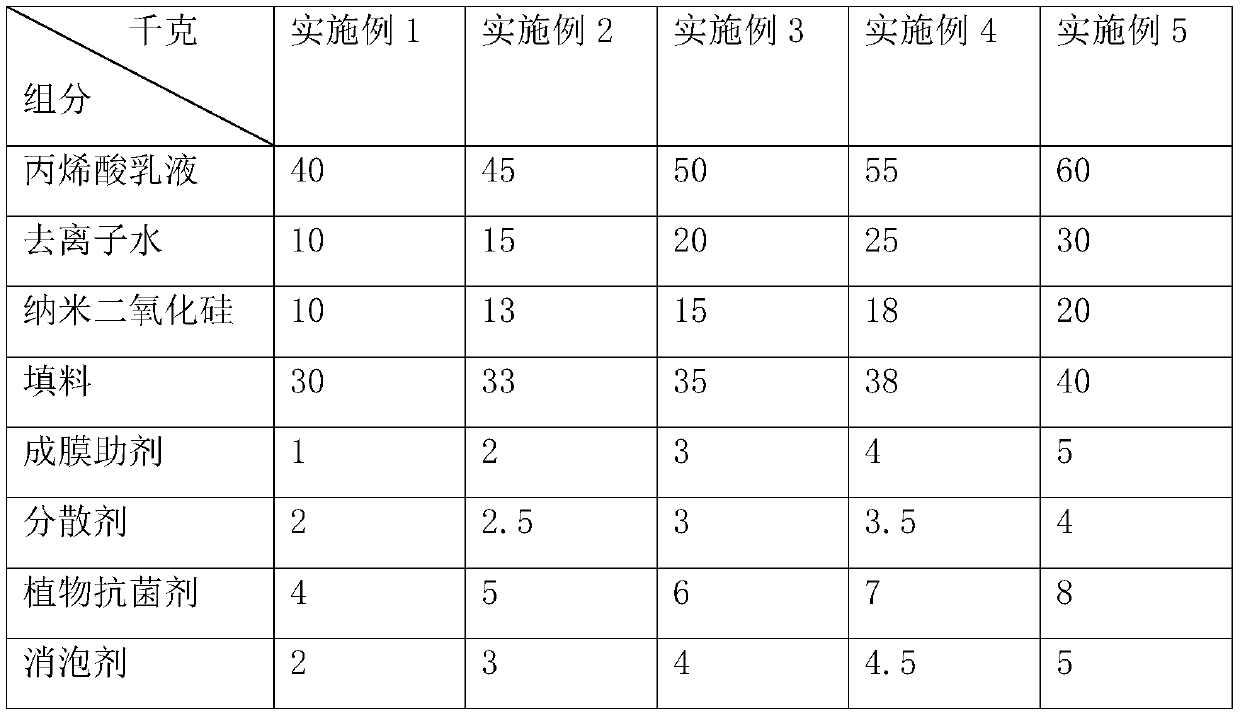

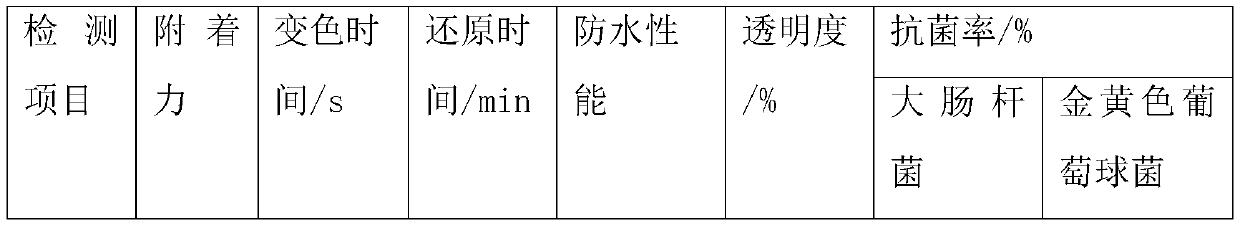

Paper board discolored by water and processing technology thereof

The invention discloses a paper board discolored by water and a processing technology thereof. The paper board discolored by water comprises a printing substrate, wherein one side of the printing substrate is sequentially provided with an ink layer, a light oil layer and a color-changing ink layer. The color-changing ink layer comprises color-changing ink and aqueous polyurethane emulsion with a mass ratio of 1: 0.1-0.3. The color-changing ink comprises the following components in parts by weight: 40-60 parts of acrylic emulsion, 10-20 parts of nano silicon dioxide, 1-5 parts of a film formingauxiliary agent, 2-5 parts of a defoaming agent, 10-30 parts of deionized water, 30-40 parts of a filler, 2-4 parts of a dispersant and 4-8 parts of a plant antibacterial agent. The processing technology comprises S1, selecting the printing substrate; S2, printing the ink; S3, brushing varnish; and S4, brushing the color-changing ink. The paper board discolored by water has the advantages of clear color development, fast color development, long reduction time and antibiosis. In addition, the preparation method has the advantage of simple preparation process.

Owner:青岛市贤俊龙彩印有限公司

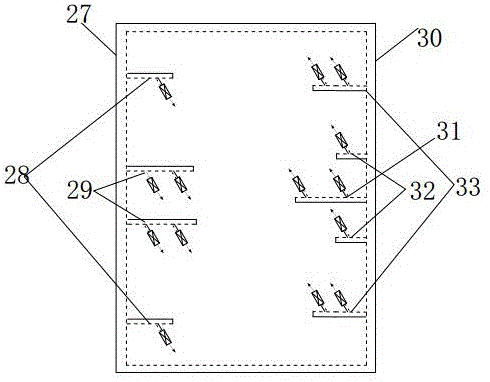

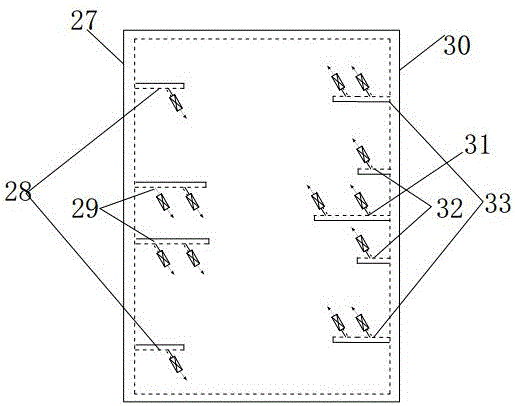

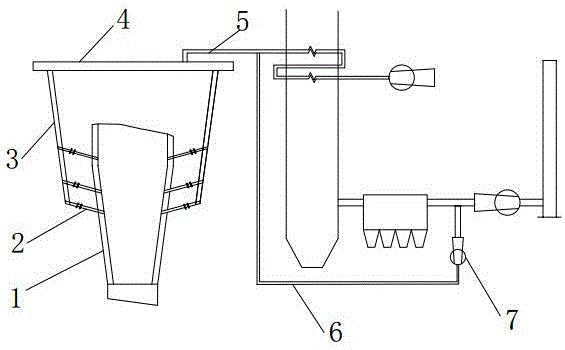

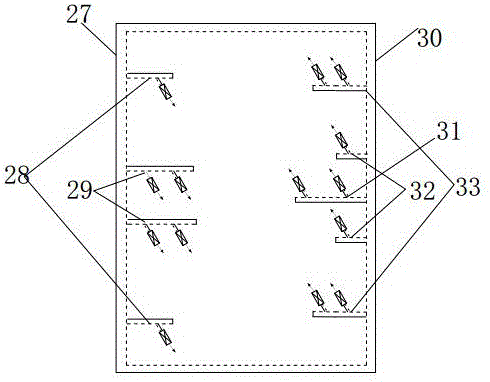

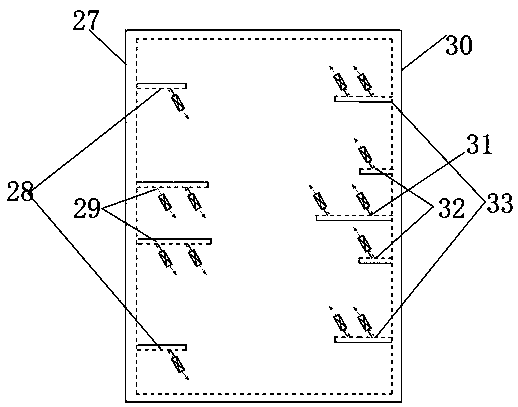

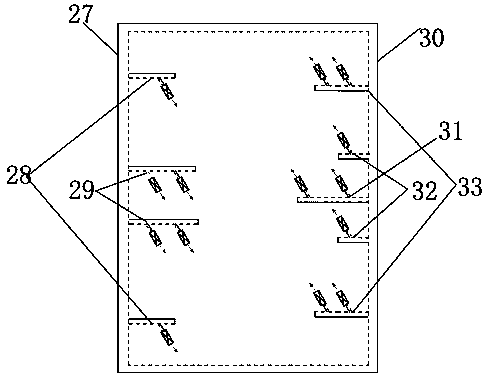

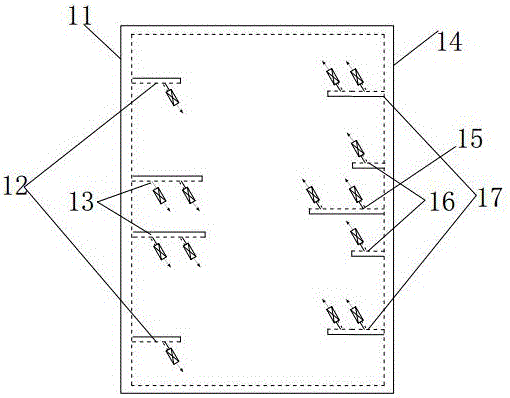

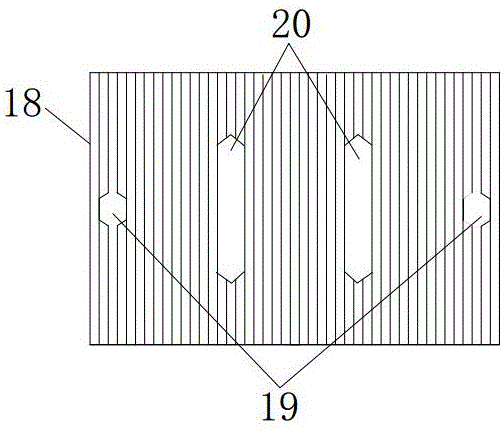

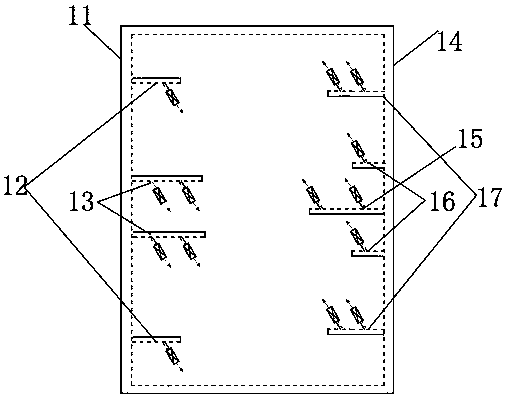

Secondary air distribution device used for circulating fluidized bed boiler

ActiveCN105864754AEvenly distributedIncrease disturbanceFluidized bed combustionApparatus for fluidised bed combustionSingle holeCirculating fluidized bed boiler

The invention discloses a secondary air distribution device used for a circulating fluidized bed boiler. The secondary air distribution device comprises the boiler, water walls arranged on the four walls of the interior of the boiler and provided with receding pipes and a secondary air system. The lower portion of the boiler is a dense-phase zone, and the upper portion of the boiler is a lean-phase zone. The secondary air system comprises a secondary air branch pipe, a plurality of secondary air stand pipes arranged on the outer side of the front wall of the boiler and the outer side of the rear wall of the boiler, and secondary air nozzles arranged on the water walls and connected with the secondary air stand pipes. The secondary air nozzles comprise the double nozzles and the single nozzles and are arranged in the lean-phase zone of the boiler in a layered mode. The receding pipes comprise the double-hole receding pipes and the single hole receding pipes. The disturbing effect of smoke in a boiler hearth is added through the secondary air distribution modes, fuel can be completely burnt, generation of NOx is reduced, grading of secondary air in the height direction is achieved, and grading of the secondary air in the horizontal direction is achieved.

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

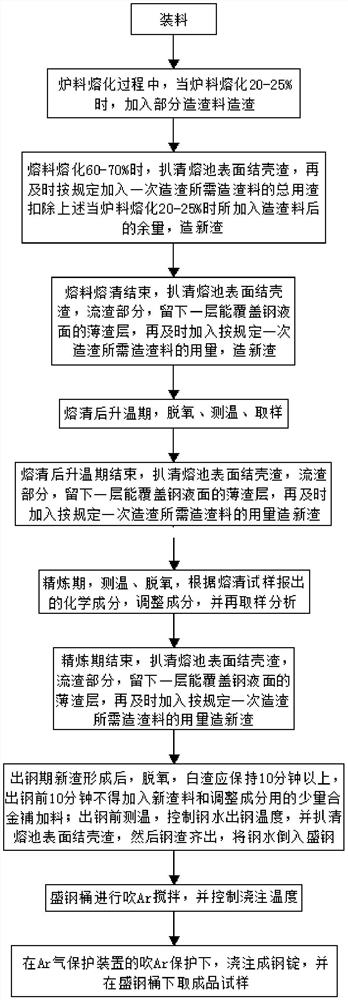

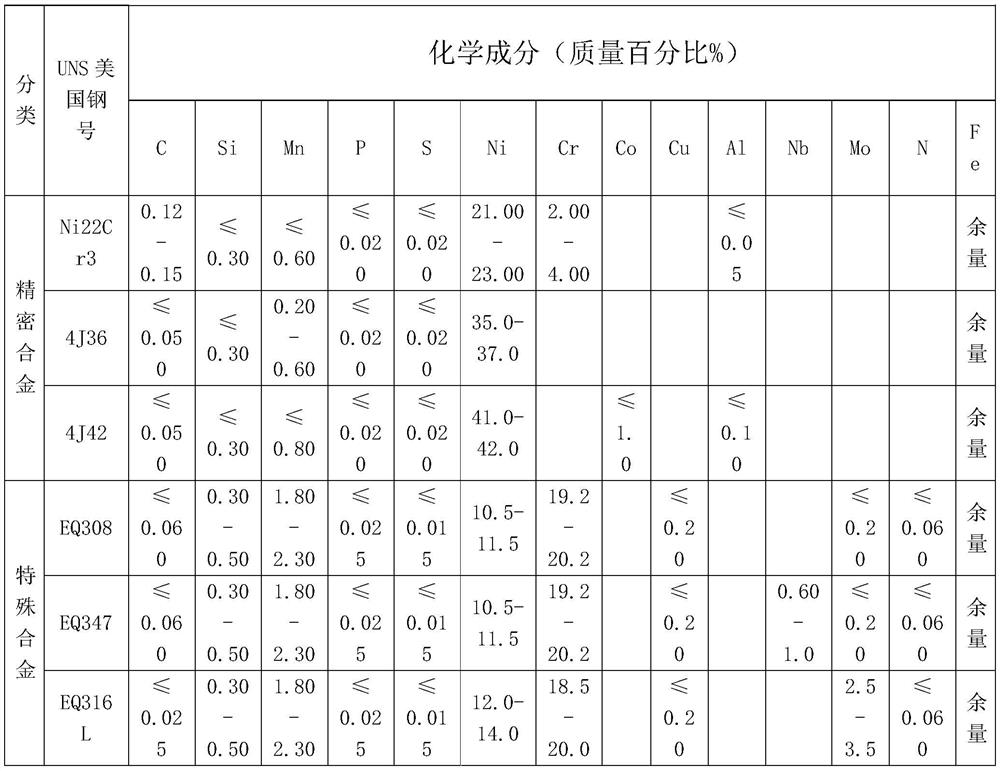

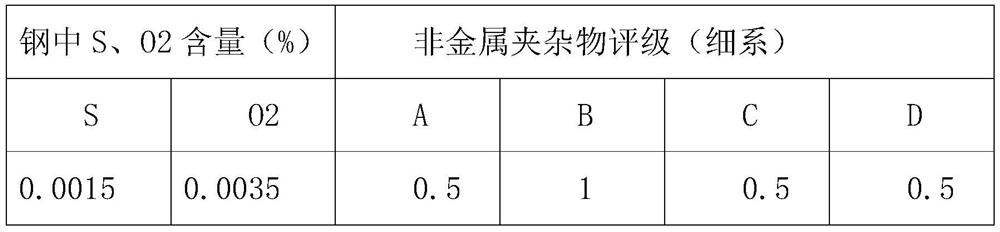

Desulfurization and deoxygenation process for smelting precise or special alloys by using medium-frequency induction furnace multi-slag method

InactiveCN111996330AGood desulfurization and deoxidationReduce power consumptionProcess efficiency improvementElectric furnaceDeoxygenationSlag

The invention discloses a desulfurization and deoxygenation process for smelting precise or special alloys by using a medium-frequency induction furnace multi-slag method. The process is characterizedin that the capacity of a medium-frequency induction furnace is less than or equal to 6 tons, metal raw materials loaded into the furnace must be clean and rust-free, and pure iron is inserted into the furnace in the form of a cast rod. During smelting of one heat steel, the total number of times of repeated new slag making reaches two or more, crusting slag and flowing slag on the surface of a molten pool need to be removed clearly every time slag making is conducted, and a thin slag layer capable of covering the molten steel surface is reserved, and then new slag is made in time. The alkalinity of the slag is 3-3.6, and precipitation and diffusion deoxidation are preformed according to requirements. In the refining period, the temperature of molten steel is controlled to be 1590-1610 DEG C, and the tapping temperature is controlled to be 1610-1630 DEG C. After the molten steel is poured into a steel containing barrel, Ar is blown and stirred, and then the molten steel is cast into asteel ingot under an Ar gas protection device. According to the process, the contents of sulfur and oxygen in the steel can be remarkably reduced, and high-end metal products such as precision or special alloys for cold or hot working can be successfully smelted.

Owner:HAIYAN ZHONGDA METAL ELECTRONIC MATERIAL CO LTD

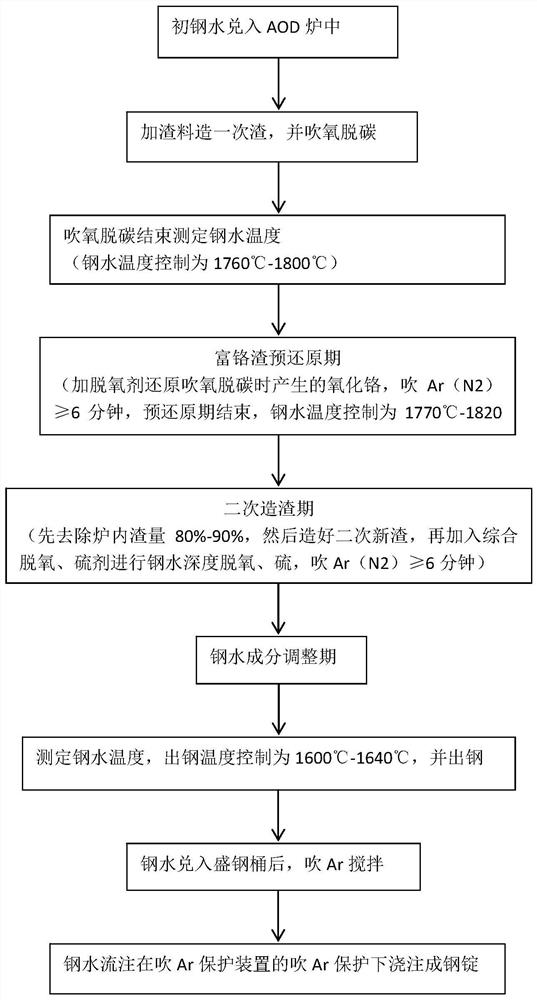

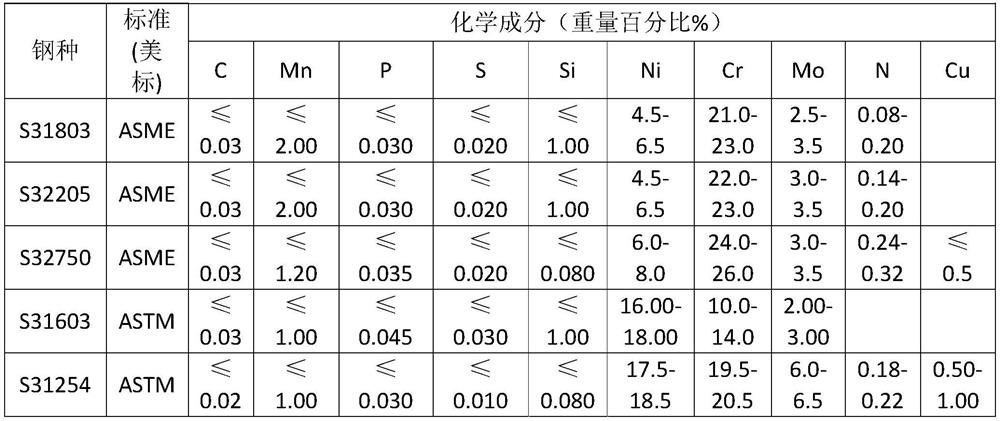

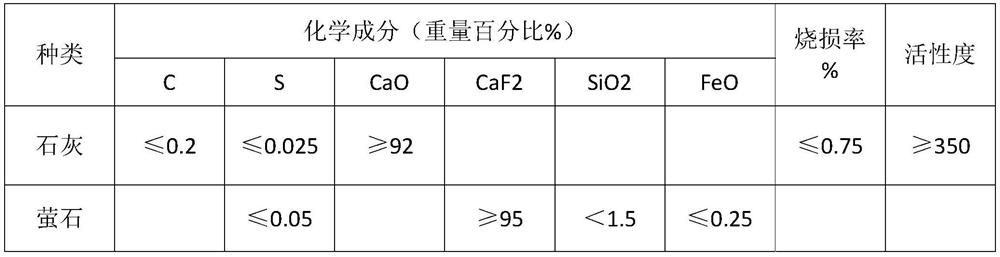

Comprehensive deoxidizing and desulfurizing process for smelting stainless steel by using small-capacity AOD (Argon Oxygen Decarburization) furnace

The invention discloses a comprehensive deoxidizing and desulfurizing process for smelting stainless steel by using a small-capacity AOD (Argon Oxygen Decarburization) furnace. The comprehensive deoxidizing and desulfurizing process is characterized in that the furnace capacity of the AOD furnace is less than or equal to 10 tons, and primary molten steel added into the AOD furnace meets the specified requirements. After the oxygen-blowing decarburization period ends, a chromium-rich slag pre-reduction period begins, Ar(N2) is blown for more than or equal to 6 minutes, and the temperature of the molten steel is controlled to be 1770-1820 DEG C. In the secondary slagging period, after 80 to 90 percent of slag in the furnace is removed, lime and fluorite meeting the specified requirements are added; and after secondary new slag is formed, a comprehensive deoxidizing and desulfurizing agent which is composed of a deoxidizing agent metal Al block, a composite deoxidizing and desulfurizing agent Si-Ca block and a composite deoxidizing and desulfurizing agent Si-Ca-Ba-Al block and meets the specified requirements is added, and Ar(N2) is blown for more than or equal to 6 minutes. The tapping temperature is 1600-1640 DEG C. According to the process, on the basis of the prior art, the oxygen content of steel is remarkably reduced, and the quality of high-end stainless steel for cold (hot) machining deformation is improved.

Owner:HAIYAN ZHONGDA METAL ELECTRONIC MATERIAL CO LTD

Circulating fluidized bed boiler device capable of effectively reducing emission of nitrogen oxide and particulate matter

InactiveCN106051750AReduce carbon contentSolve NO <sub>x<</sub> Fluidized bed combustionFluegas recirculationParticulatesHigh carbon

The invention discloses a circulating fluidized bed boiler device capable of effectively reducing emission of nitrogen oxide and particulate matter. The circulating fluidized bed boiler device comprises a boiler, a cyclone separator, a deduster, an induced draft fan, a primary air supply system and a secondary air supply system which are connected in sequence. A burn-out chamber is arranged at an outlet of the cyclone separator. Over fire air is introduced into the burn-out chamber. A smoke recirculation pipe is drawn out behind the induced draft fan. The primary air supply system and the secondary air supply system are connected to the smoke recirculation pipe in parallel. According to the circulating fluidized bed boiler device capable of effectively reducing emission of the nitrogen oxide and the particulate matter, a smoke recirculation mode is adopted, part of the smoke is mixed into primary air and secondary air, generation of NOx is effectively reduced, grading of the secondary air in the height direction and in the horizontal direction is achieved through the secondary air arrangement mode, the burn-out chamber is arranged at the outlet of the separator, the carbon content of flying ash is reduced, and the contradiction between NOx emission reduction and high carbon content of the flying ash due to the fact that oxygen content in a combustion furnace is reduced can be effectively solved.

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

Magnesium smelting method capable of shortening reduction period

ActiveCN102534252AShorten recovery cycleImprove the efficiency of magnesium smeltingDolomiteMagnesium

The invention relates to methods for smelting nonferrous metal and provides a magnesium smelting method capable of shortening a reduction period, aiming at solving the problem of long reduction period caused by the relatively-large temperature decreasing amplitude of a furnace after cold pellets enter a reduction pot. The method comprises the process steps of calcining dolomite, carrying out ballmilling, pelletizing and carrying out reduction, and the pellets formed by pelletizing are preheated prior to reduction, wherein the temperature for preheating is 600-780 DEG C and the time for preheating is 1.5-3 hours. Compared with the traditional method, the magnesium smelting method has the advantages that: the reduction period is shortened to 6-8 hours from 7-12 hours, the reduction period is obviously shortened, the efficiency for magnesium smelting can be increased, and the production cost is lowered.

Owner:WUTAI YUNHAI MAGNESIUM IND

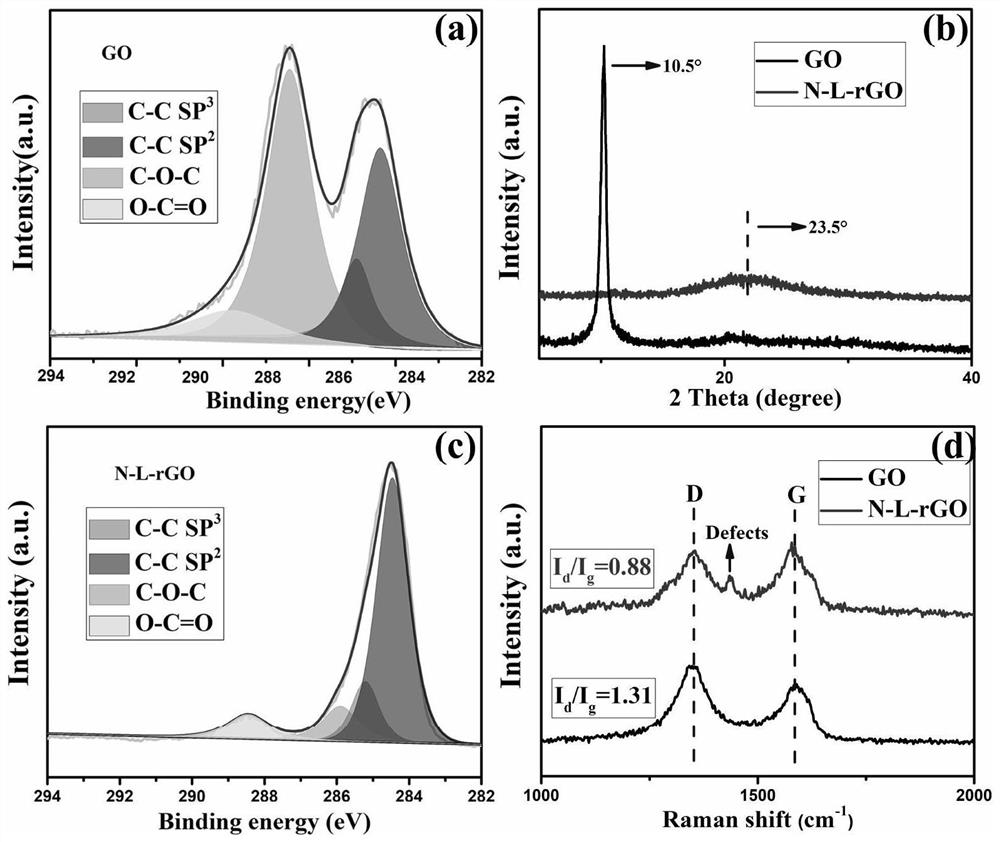

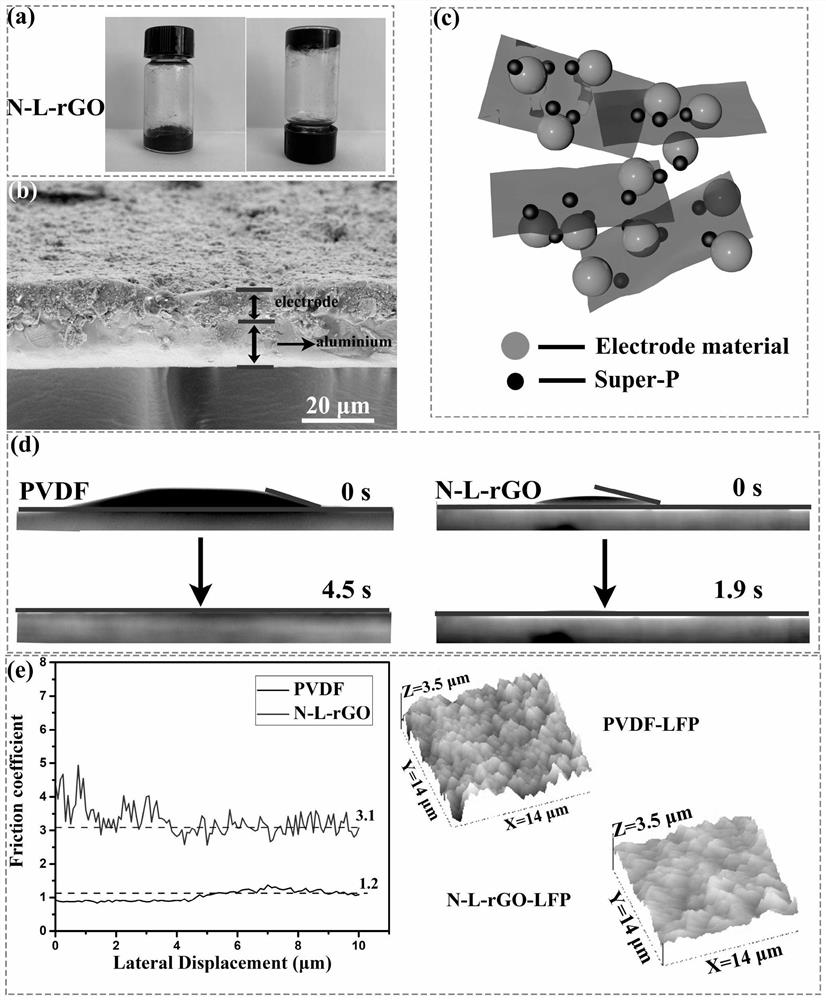

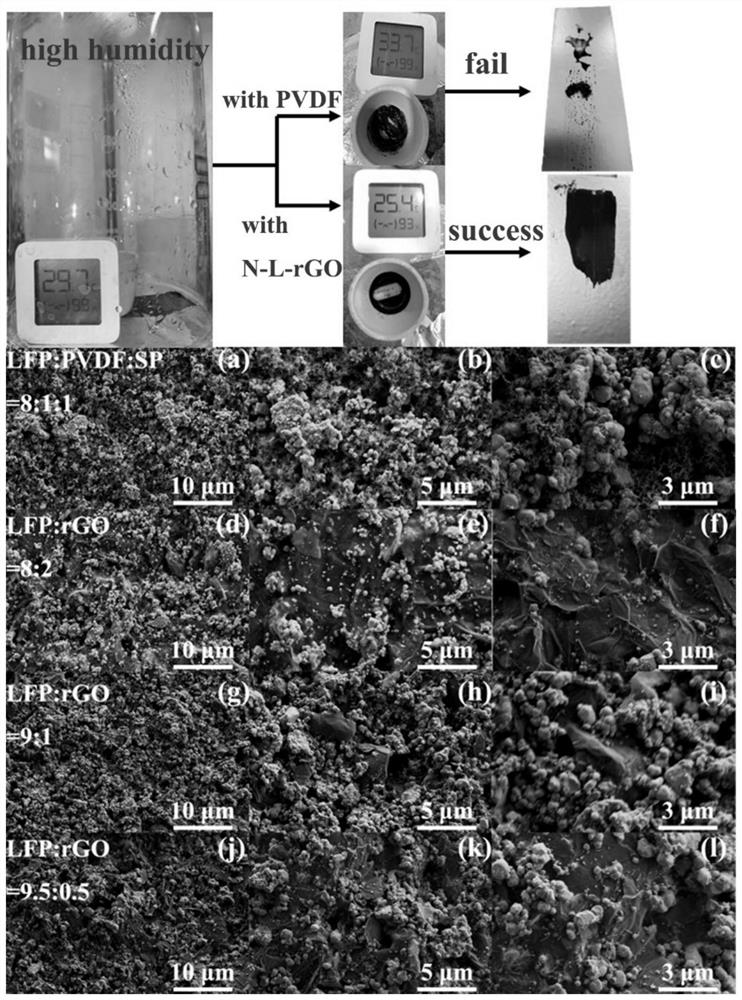

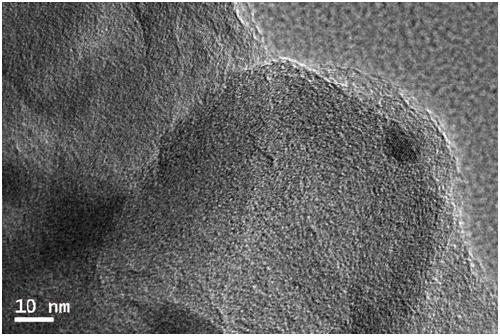

Modified reduced graphene oxide binder as well as preparation method and application thereof

PendingCN114864946AGood dispersionImprove conductivitySecondary cellsPositive electrodesHigh humidityPyrrolidinones

The invention provides a modified reduced graphene oxide binder and a preparation method and application thereof.The preparation method comprises the steps that graphene oxide is evenly dispersed in an N-methyl pyrrolidone (NMP) solution, then ascorbyl palmitate powder is added, or the ascorbyl palmitate powder is pre-dispersed in the NMP solution, the mixture is fully stirred for 2-5 h, and the modified reduced graphene oxide binder is obtained; and reacting for 3-5 minutes under the microwave energy of 500-800W, and carrying out suction filtration on redundant solution to obtain the modified reduced graphene oxide binder. According to the invention, grafting of ester bonds and excellent properties of graphene enable the graphene to have high mechanical stress and friction coefficient, high defect density and a multi-dimensional conductive network to facilitate transmission of lithium ions, N-L-rGO is used as a binder to reduce the requirements of production environment, and the materials are still uniformly mixed in a high-humidity environment; and in addition, excellent rate capability and cycling stability are shown in electrochemical performance.

Owner:HARBIN ENG UNIV

Circulating Fluidized Bed Boiler System Realizing Low NOx Emissions

InactiveCN105805730BImprove fluidization characteristicsWell mixedFluidized bed combustionStaged combustionFlue gasNitrogen oxide

The invention discloses a circulating fluidized bed boiler system for achieving low nitrogen oxide discharge. The circulating fluidized bed boiler system comprises a boiler, a cyclone separator, a dust remover and an induced draft fan which are sequentially connected. The circulating fluidized bed boiler system further comprises a primary air supply system and a secondary air supply system. A flue gas recirculation pipe is guided out of the rear portion of the induced draft fan and connected with the primary air supply system and the secondary air supply system in parallel. The secondary air supply system comprises a secondary air fan, a secondary air pipe, a plurality of secondary air vertical pipes arranged on the outer sides of a front wall and a rear wall of the boiler and secondary air nozzles, wherein the secondary air nozzles are arranged on a water cooling wall, connected with the secondary air vertical pipes and arranged in a dilute phase area of the boiler in a layered manner. According to the circulating fluidized bed boiler system, part of flue gas is mixed into primary air, the fluidization characteristic of a dense phase area during low-load running is improved, part of flue gas is mixed into secondary air, the air speed of the secondary air nozzles can be increased easily, a local high-temperature area is avoided, and generated NOx is reduced. By means of the secondary air arrangement manner of the system, the disturbance function of the flue gas in a hearth is increased, fuel is combusted fully, and the generated NOx is reduced.

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

A kind of graphene airgel and its preparation method and application

ActiveCN107585758BLow densityImprove integrityMagnetic/electric field screeningGrapheneReduction treatmentFreeze-drying

The invention discloses a graphene aerogel and a preparation method and an application thereof, wherein the aerogel is prepared from the following method: (1) pre-reduction treatment: adding a reducing agent to a graphene oxide solution, mixing, carrying out ultrasonic dispersion, and carrying out pre-reduction treatment, to obtain a semi-reduction graphene hydrogel; (2) final reduction treatment:adding a reducing agent, carrying out ultrasonic treatment, and then carrying out final reduction treatment, to obtain a graphene hydrogel; and (3) acid / alkali soaking: placing the graphene hydrogelin an acid or alkali aqueous solution, soaking, washing the hydrogel to be neutral, sucking out the excess liquid, and carrying out freeze drying, to obtain the graphene aerogel. The graphene aerogelis applied to electromagnetic wave absorption materials. The graphene aerogel obtained by the method has small density and good integrality, and has a certain mechanical strength and resillency; the prepared wave absorbing material has good electromagnetic wave absorption performance, and the wave absorbing performance can be adjusted; and the method has the advantages of simple process, short production cycle, low cost and good benefits, and is suitable for industrialized production.

Owner:苏州涤致良特种防护装备科技有限公司

Method for preparing aluminum-scandium intermediate alloy by using calciothermy

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

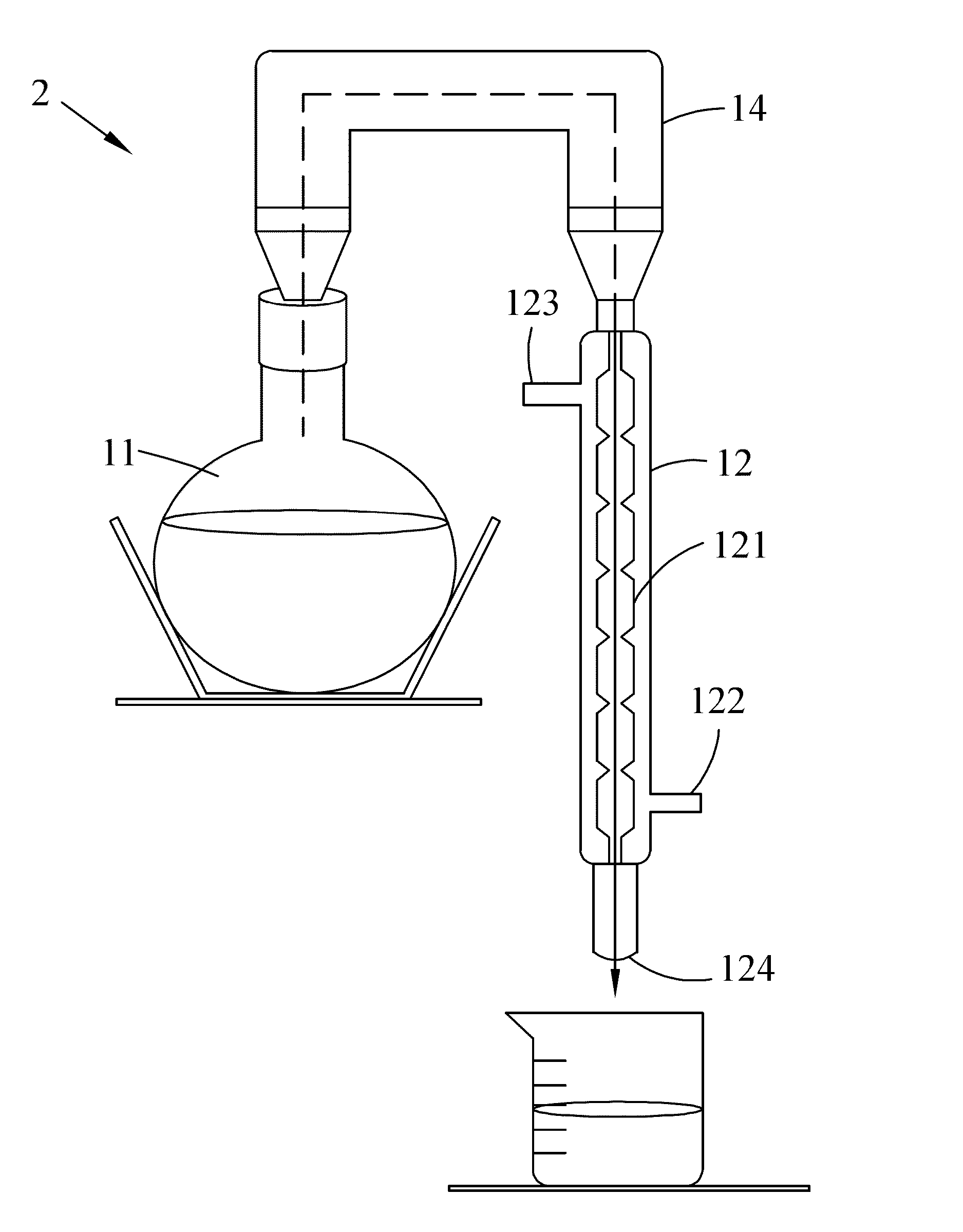

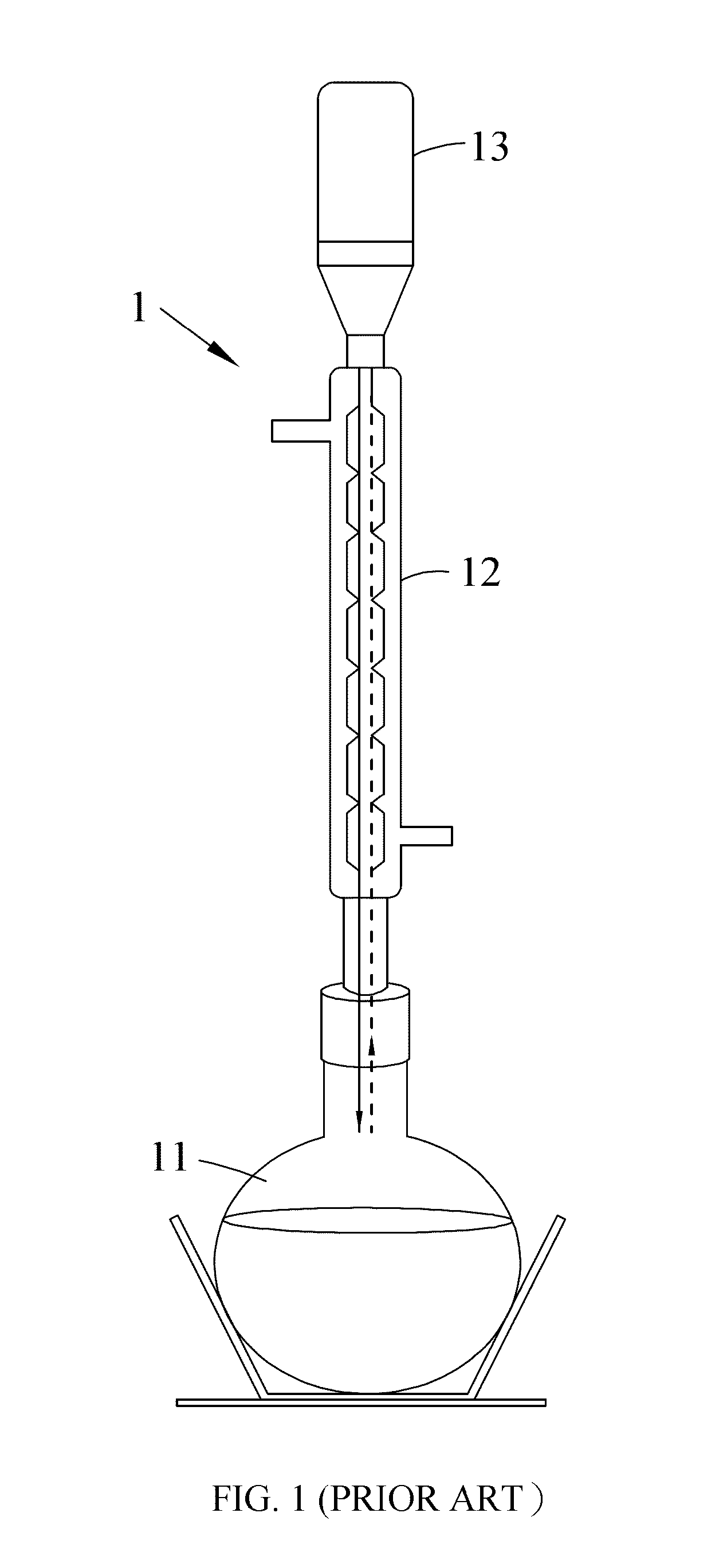

Method for preparing nano-scale platinum

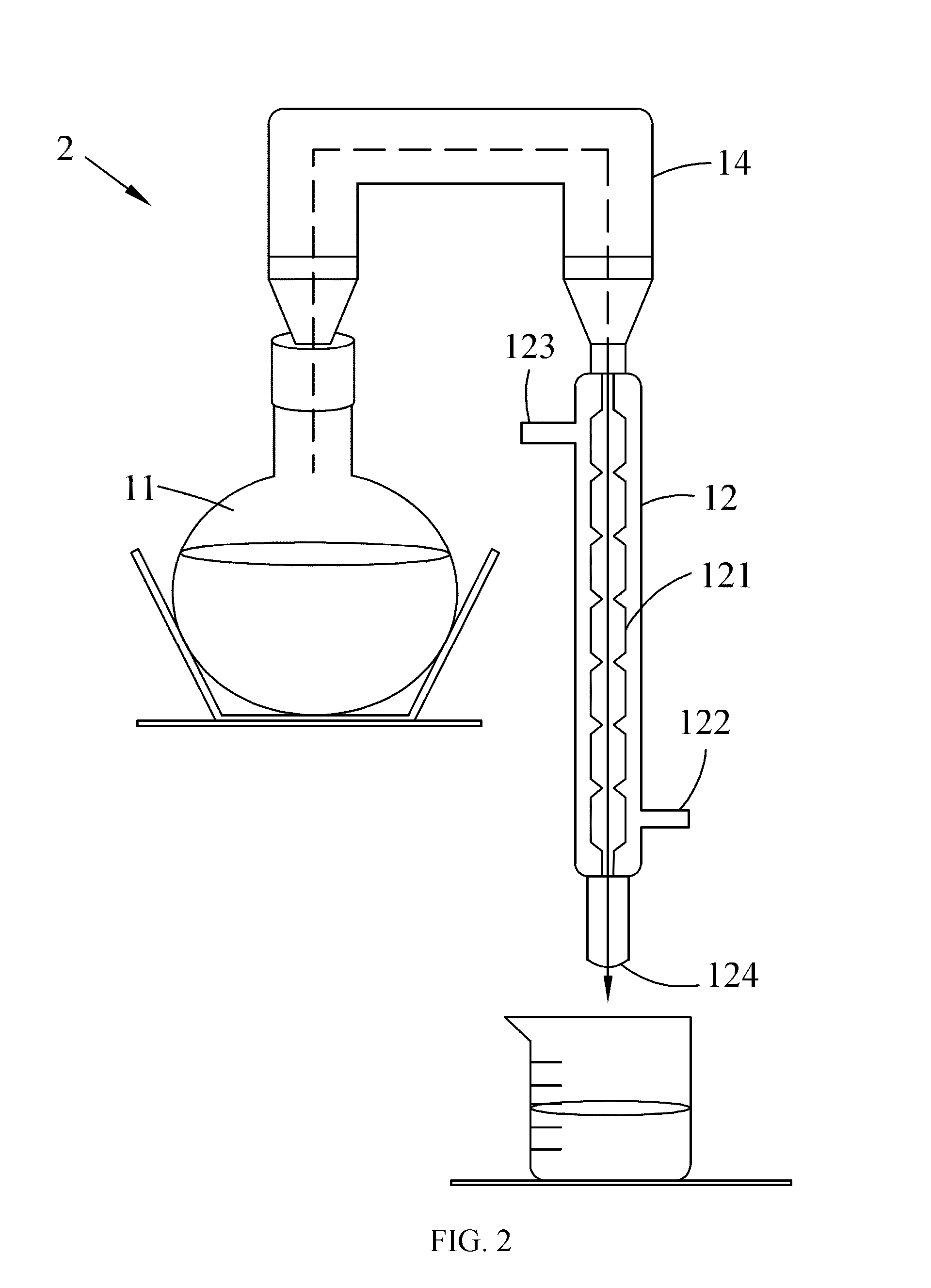

ActiveUS8703640B2Long restore timeEnhancement of poor electrochemical propertyMaterial nanotechnologyCatalyst activation/preparationPlatinum saltsLiquid water

The invention discloses a preparation method of nano-scale platinum (Pt) using an open-loop reduction system. The preparation method comprises the steps of: utilizing carbon nanotubes (CNTs) as a catalyst support; mixing platinum salt with a reducing agent and deionized water to form a precursor solution in a flask; heating the precursor solution in the flask at a predetermined temperature range to reduce nano-scale platinum nanoparticles on the carbon nanotubes by the process of water evaporation; allowing the water vapor to flow through a connection tube to a condenser; filling a cooling substance into the condenser via the first opening and draining the cooling substance from the condenser via the second opening to lower the temperature of the water vapor in the inner tube by the cooling substance and condense the water vapor into liquid water, which is collected with a beaker placed under the condenser.

Owner:NATIONAL TSING HUA UNIVERSITY

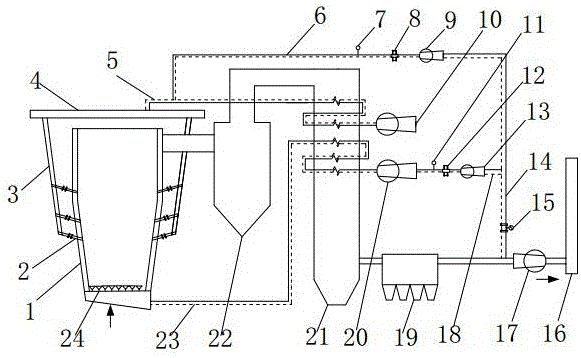

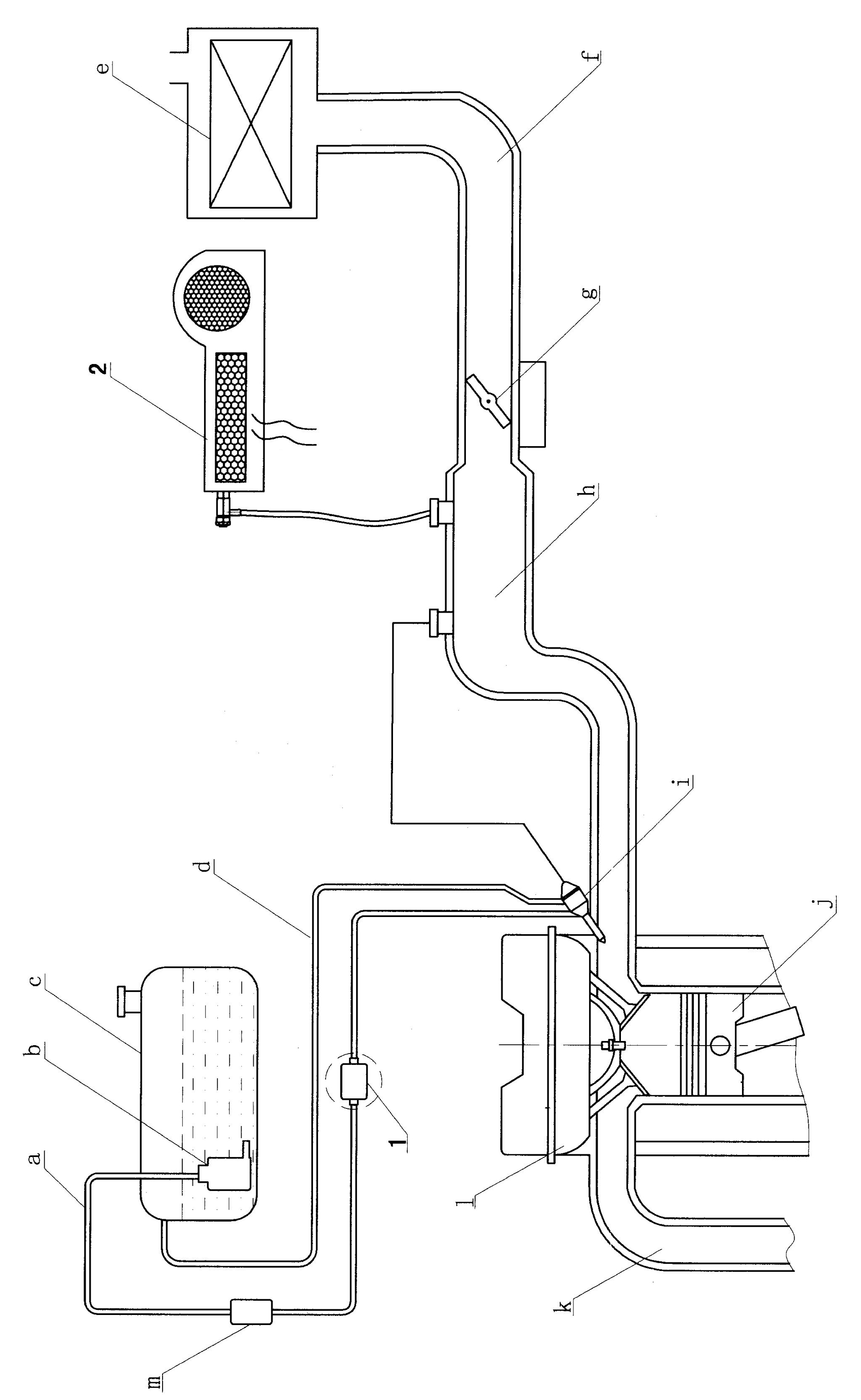

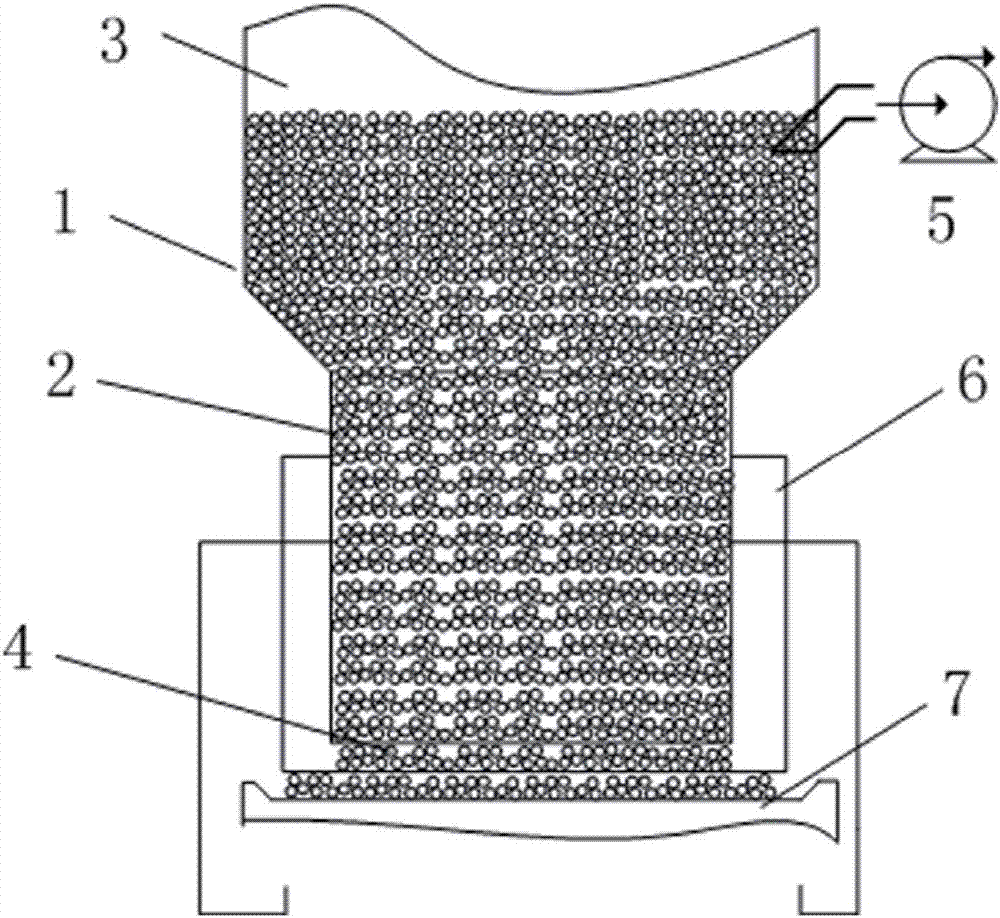

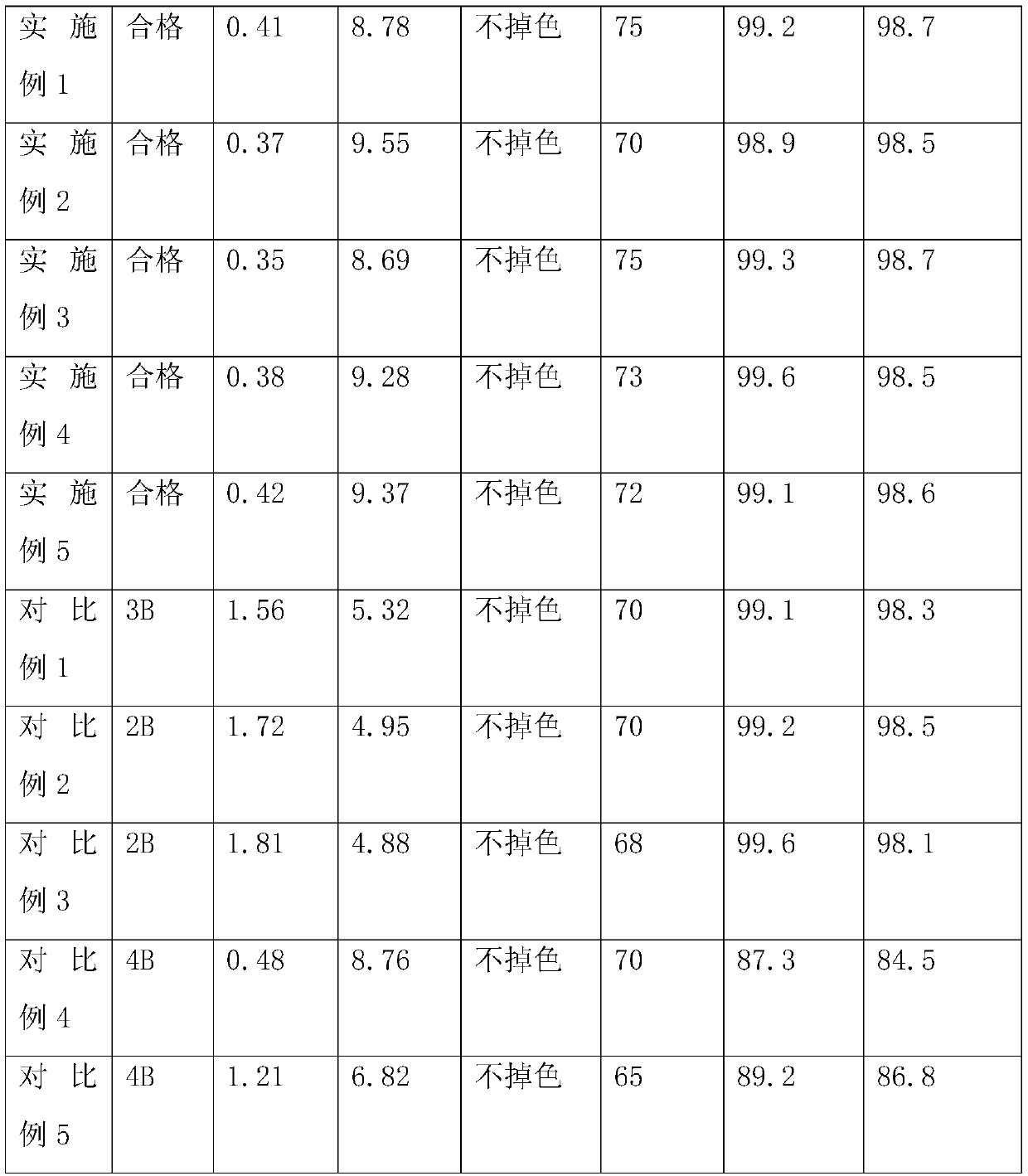

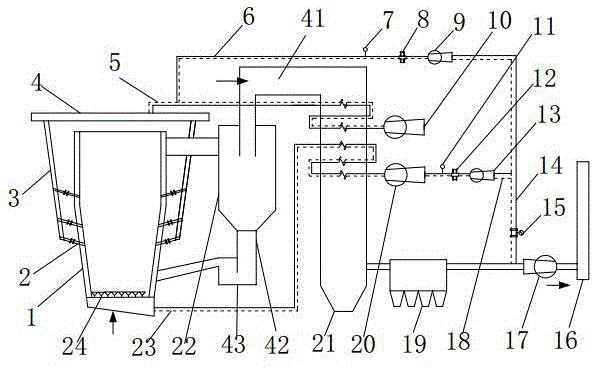

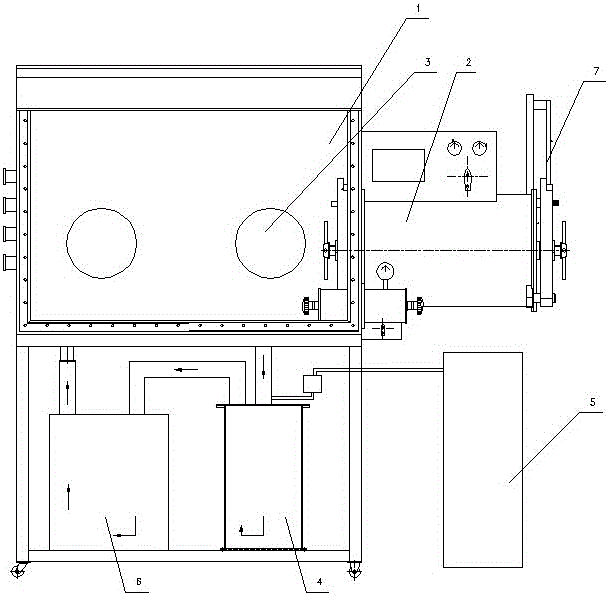

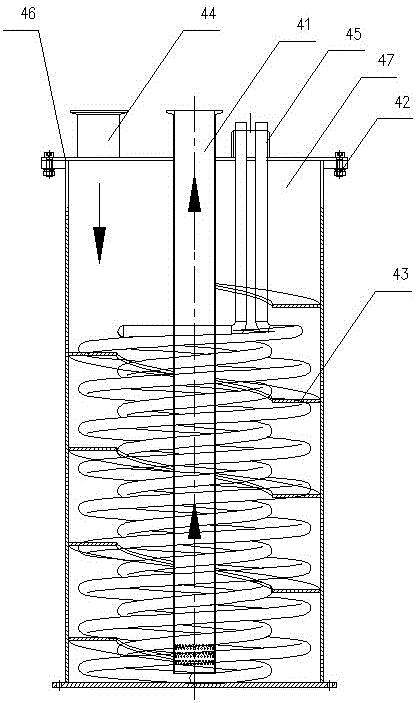

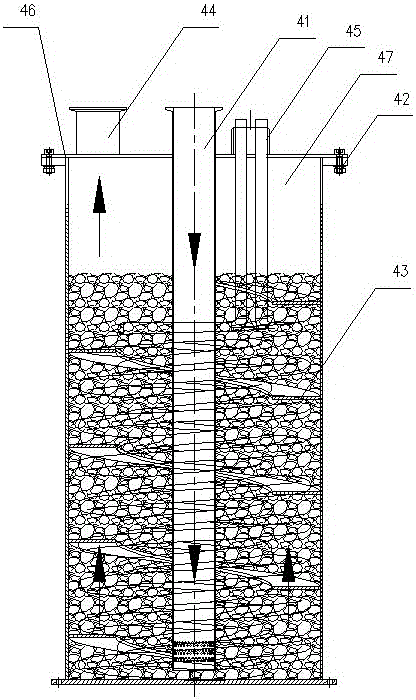

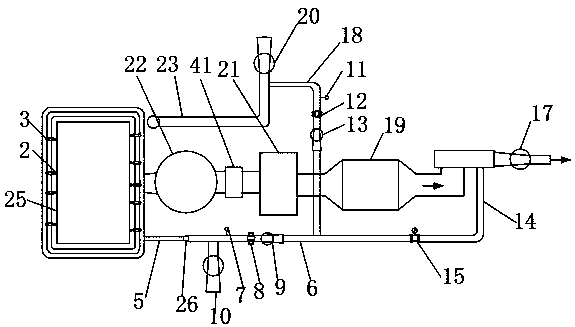

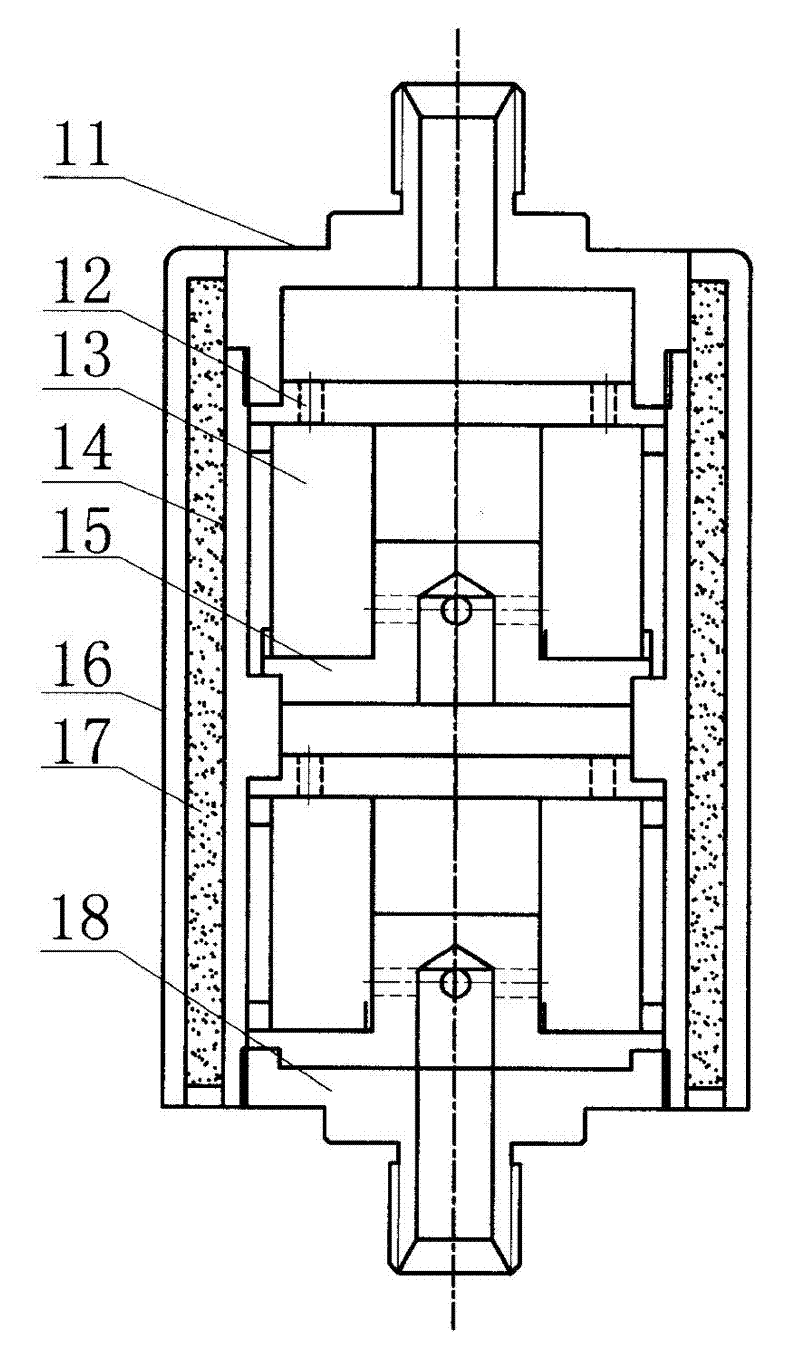

A method of using a glove box with a purification system

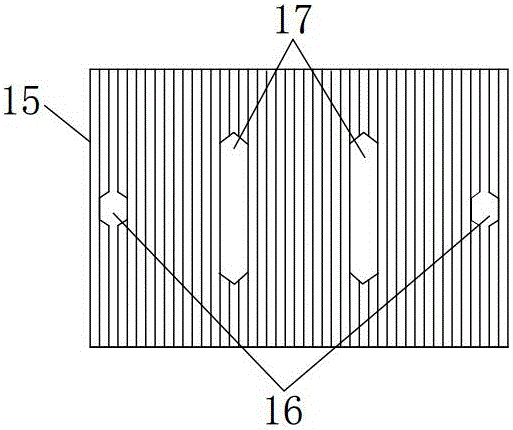

The invention relates to a glove box with a purification system and usage thereof. The glove box structurally comprises a main box body (1), a transition chamber (2), glove operation openings (3), the purification system (4) and a power system (6); the main box body (1) and the transition chamber (2) are respectively provided with a valve, and are connected with exhaust and charge ports; the glove box is characterized in that the purification system (4) comprises a sealing cover (46) and a purification cartridge (47), and the sealing cover (46) is connected with the purification cartridge (47) through bolts (42); a main air passage (41) and a heater (45) are fixedly arranged in the purification cartridge (47); a helical air passage (43) is arranged on the inner wall of the purification cartridge (47), and purification material fills the purification cartridge (47). The purification and regeneration effect of the glove box is good, and the utilization rate of the purification material is high.

Owner:长沙天创粉末技术有限公司

A kind of copper refining agent for waste electromagnetic wire and its preparation method and application

ActiveCN106636668BImprove refining effectLow costProcess efficiency improvementAlloyMaterials science

The invention relates to a waste electromagnetic wire copper refining agent and a preparation method and application thereof. The refining agent is preferably composed of, by mass, 1.0-5.0% of V, 1.0-5.0% of Sr, 0.5-2.5% of B, 5.5-7.5% of Mg, 5-10% of Y, 5-10% of Ce and the balance Cu. According to the preparation method of the refining agent, Cu-B-Y-Ce-Mg intermediate alloy and Cu-Sr intermediate alloy are crushed into fragments with the particle size being smaller than 10 mm, and the fragments and vanadium with the particle size being smaller than 10 mm are mixed evenly according to a set proportion and then wrapped with a high-purity oxygen-free copper sheet to obtain the refining agent. The refining agent can be used for refining oxygen-free copper from waste copper electromagnetic wires, and the adding amount is 0.1-0.65 percent of the melt mass. The refining agent of the design has the good effects on deoxidation, desulfurization, dealumination, deferrization, denickelefication and the like, and does not pollute copper liquid secondarily. The refining agent is reasonable in component design and simple in preparation process and can achieve large-scale industrial application conveniently.

Owner:CENT SOUTH UNIV +1

High-efficiency denitrification ionic liquid and method of using the same

ActiveCN109569240BImprove utilization efficiencyGood orientationGas treatmentDispersed particle separationPtru catalystFlue gas

The high-efficiency denitrification ionic liquid of the present invention belongs to the technical field of flue gas treatment, and comprises the following components: 15-30 parts of urea-based organic peptide, 60-80 parts of deionized water, 5-10 parts of catalyst, 1-5 parts of stabilizer, and regulator 1-5 parts, the above ingredients are added to the high-speed dispersion equipment for high-speed dispersion, and the dispersion reaction forms a stable and efficient denitrification ionic liquid; the method of using the high-efficiency denitrification ionic liquid is to spray the configured ionic liquid into the denitrification reactor with a spray gun , the operating temperature is 450-1250°C. The high-efficiency denitrification ionic liquid and its use method of the present invention, the high-efficiency ion denitration liquid is a colorless, odorless, non-corrosive liquid, which is safe in transportation and storage, convenient and simple to use, and has no secondary pollution. The product has a wide operating temperature range and can It operates at 450-1250°C; this method does not produce any crystallization and blockage; after the product is put into high temperature area, the flue gas is fully contacted with the denitrification ion liquid, which increases the reduction time of the liquid catalyst and flue gas to avoid escape.

Owner:山东汇之蓝环保科技有限公司

Circulating fluidized bed boiler device that effectively reduces emissions of nitrogen oxides and particulate matter

InactiveCN106051750BReduce carbon contentEmission reductionFluidized bed combustionFluegas recirculationParticulatesEngineering

The invention discloses a circulating fluidized bed boiler device capable of effectively reducing emission of nitrogen oxide and particulate matter. The circulating fluidized bed boiler device comprises a boiler, a cyclone separator, a deduster, an induced draft fan, a primary air supply system and a secondary air supply system which are connected in sequence. A burn-out chamber is arranged at an outlet of the cyclone separator. Over fire air is introduced into the burn-out chamber. A smoke recirculation pipe is drawn out behind the induced draft fan. The primary air supply system and the secondary air supply system are connected to the smoke recirculation pipe in parallel. According to the circulating fluidized bed boiler device capable of effectively reducing emission of the nitrogen oxide and the particulate matter, a smoke recirculation mode is adopted, part of the smoke is mixed into primary air and secondary air, generation of NOx is effectively reduced, grading of the secondary air in the height direction and in the horizontal direction is achieved through the secondary air arrangement mode, the burn-out chamber is arranged at the outlet of the separator, the carbon content of flying ash is reduced, and the contradiction between NOx emission reduction and high carbon content of the flying ash due to the fact that oxygen content in a combustion furnace is reduced can be effectively solved.

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

A secondary air distribution device for circulating fluidized bed boiler

InactiveCN105864754BEvenly distributedHierarchical implementationFluidized bed combustionApparatus for fluidised bed combustionFluidized bedHearth

The invention discloses a secondary air distribution device used for a circulating fluidized bed boiler. The secondary air distribution device comprises the boiler, water walls arranged on the four walls of the interior of the boiler and provided with receding pipes and a secondary air system. The lower portion of the boiler is a dense-phase zone, and the upper portion of the boiler is a lean-phase zone. The secondary air system comprises a secondary air branch pipe, a plurality of secondary air stand pipes arranged on the outer side of the front wall of the boiler and the outer side of the rear wall of the boiler, and secondary air nozzles arranged on the water walls and connected with the secondary air stand pipes. The secondary air nozzles comprise the double nozzles and the single nozzles and are arranged in the lean-phase zone of the boiler in a layered mode. The receding pipes comprise the double-hole receding pipes and the single hole receding pipes. The disturbing effect of smoke in a boiler hearth is added through the secondary air distribution modes, fuel can be completely burnt, generation of NOx is reduced, grading of secondary air in the height direction is achieved, and grading of the secondary air in the horizontal direction is achieved.

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

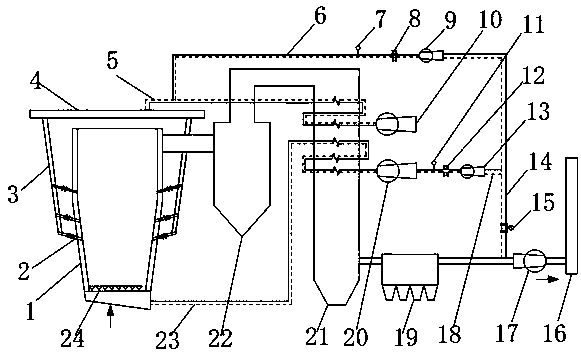

Fuel oil saving device of vehicle

InactiveCN101865053BLong restore timeImprove internal energyInternal combustion piston enginesNon-fuel substance addition to fuelOzone generatorControl power

The invention relates to a fuel oil saving device of a vehicle, comprising two groups, i.e. a fuel oil magnetization processor and an oxygen increasing and supplementing device, wherein the fuel oil magnetization processor comprises two multi-gradient magnetization radiation areas, two stagnation areas and an output port, wherein each multi-gradient magnetization radiation area consists of a mainbody; each magnetic energy radiation area comprises an upper supporting plate, a lower supporting plate and a permanent magnet clamped between the upper supporting plate and the lower supporting plate, and the two magnetic energy radiation areas are arranged adjacently; the inlet end of the first magnetic energy radiation area is the first stagnation area, and a second stagnation area is positioned between the two magnetic energy radiation areas; the oxygen increasing and supplementing device comprises a space divider and an ozone generator, wherein the space divider comprises an air filter assembly, a fan assembly, a permanent magnet fastening end cover clamped between the upper supporting plate and the lower supporting plate, and the like and forms an integer with a shell; and a space divider assembly control power supply inside the ozone generator, a booster, a generating tube and a boosting pump are sequentially arranged on a base plate. The invention has high fuel oil saving efficiency and easy installation and debugging.

Owner:姚大华

Circulating fluidized bed boiler for effectively reducing oxycarbide emission

InactiveCN105841144AReduce carbon contentEmission reductionFluidized bed combustionStaged combustionCombustionFluidized bed

The invention discloses a circulating fluidized bed boiler for effectively reducing oxycarbide emission. The circulating fluidized bed boiler for effectively reducing oxycarbide emission comprises a combustion furnace, a cyclone separator connected with the combustion furnace, and a secondary air system for arranging secondary air. An outlet of the combustion furnace is connected with an inlet of the cyclone separator, a burn-out chamber is arranged at an outlet of the cyclone separator, and overfire air is introduced into the burn-out chamber. The secondary air system comprises a secondary air pipe, a plurality of secondary air vertical pipes arranged on the outer sides of a front wall and a back wall of the combustion furnace, and secondary air nozzles arranged on a water-cooled wall and connected with the secondary air vertical pipes. According to the circulating fluidized bed boiler for effectively reducing oxycarbide emission, part of flue gas is mixed with primary air and secondary air, so that NOx emission is reduced; secondary air classification in the height direction and the horizontal direction is achieved through a secondary air arrangement mode; the burn-out chamber is arranged at the outlet of the separator, carbon in fine flying ash at the outlet of the separator is burned again in the burn-out chamber, the carbon content of the flying ash is reduced, and thus the contradiction caused by reduction of the oxygen content of the combustion furnace between NOx emission reduction and the high carbon content of the flying ash can be overcome effectively.

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

Circulating Fluidized Bed Boiler Effectively Reducing Carbon Oxide Emissions

InactiveCN105841144BReduce carbon contentEmission reductionFluidized bed combustionStaged combustionBurn outCirculating fluidized bed boiler

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com