Paper board discolored by water and processing technology thereof

A technology that changes color when exposed to water and cardboard is applied in the direction of paper, anti-biological agent addition, pigment/opacifier addition, etc. It can solve the problems that children tend to lose patience in learning, the time for cardboard to develop color is short, and the time for learning is short. To achieve the effect of prolonging the reduction time, lasting discoloration time and good fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

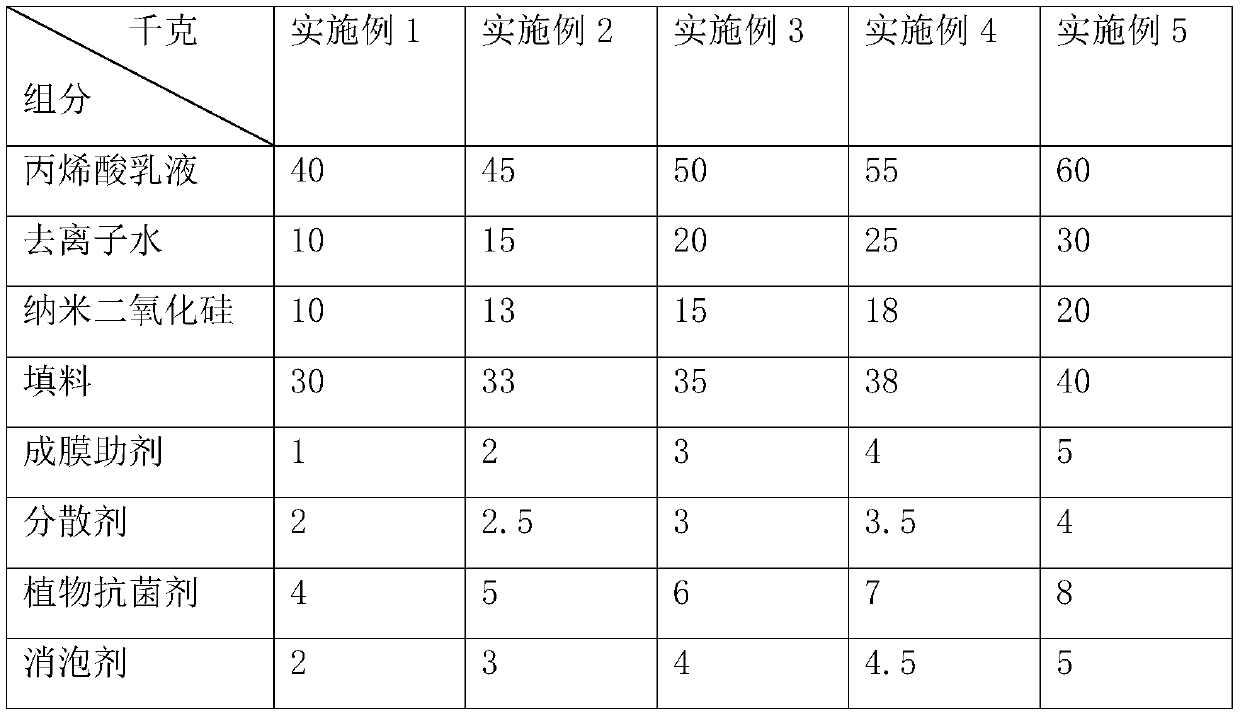

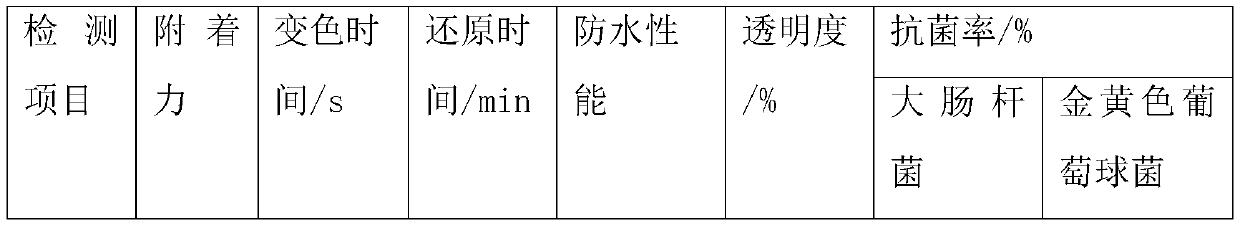

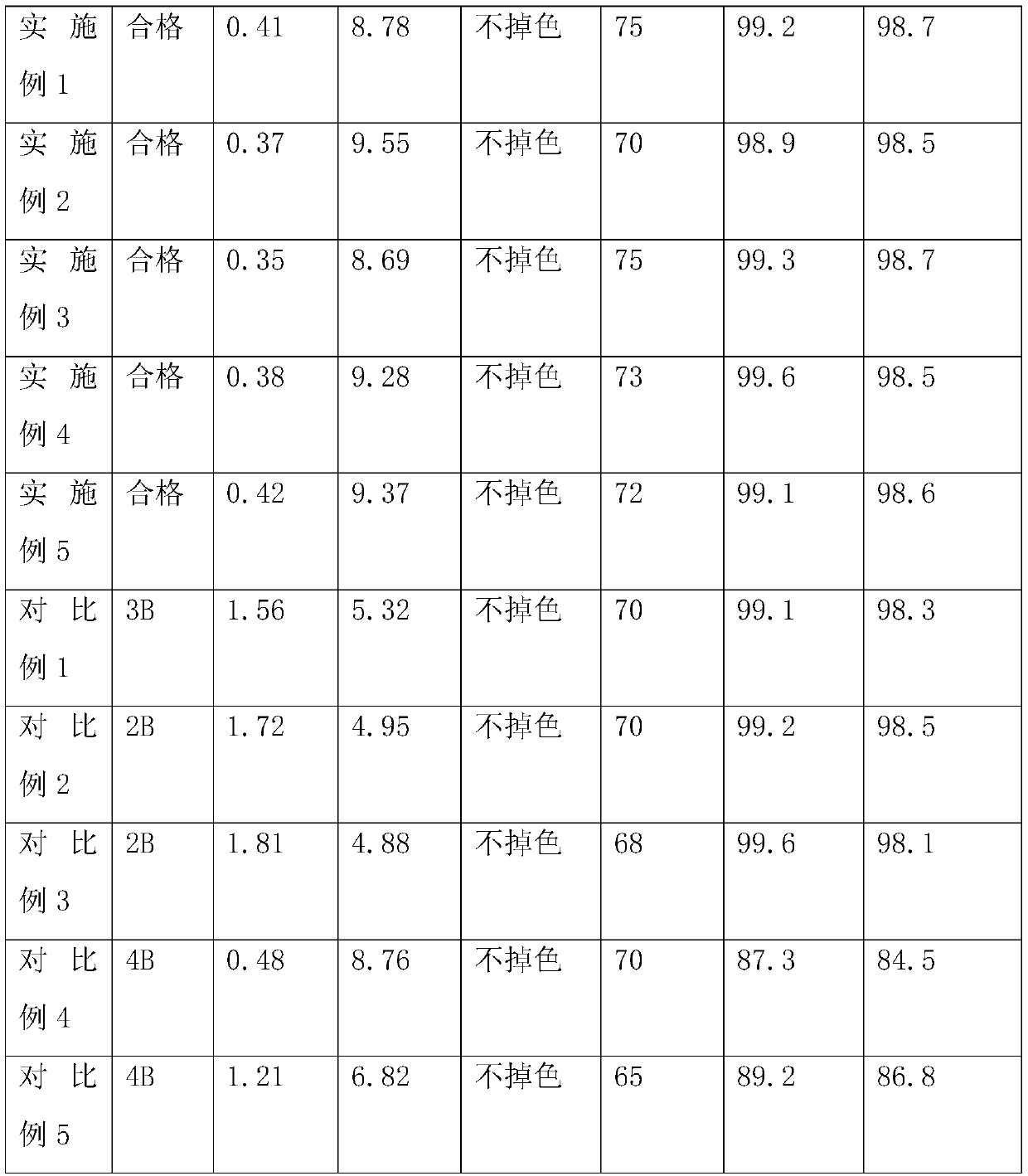

Examples

preparation example 1

[0035] Preparation example 1: (1) drying and dehydrating Phellodendron Phellodendri, Aloe Vera, and Rubia leaves until the water content is below 10%, and pulverizing them into a slurry, the mass ratio of Phellodendron Phellodendri, Aloe Vera, and Rubia is 1:1.2:0.8; (2) making the slurry The raw material is mixed with absolute ethanol to make a mixed solution, and the mixed solution is extracted at a constant temperature of 50°C for 1 hour. After the extraction is completed, it is centrifuged at a speed of 2800r / min, the residue is filtered, the filtrate is concentrated, and the ethanol is recovered to obtain a plant Antibacterial agent, the mass ratio of slurry and absolute ethanol is 1:20.

preparation example 2

[0036] Preparation example 2: (1) drying and dehydrating Phellodendron Phellodendri, Aloe Vera, and Rubia leaves until the moisture content is below 10%, and pulverizing them into a slurry, the mass ratio of Phellodendron Phellodendri, Aloe Vera, and Rubia leaves being 1:1.3:1; (2) making the slurry The raw material is mixed with absolute ethanol to make a mixed solution, and the mixed solution is extracted at a constant temperature of 50°C for 1 hour. After the extraction is completed, it is centrifuged at a speed of 2900r / min, the residue is filtered, the filtrate is concentrated, and the ethanol is recovered to obtain a plant Antibacterial agent, the mass ratio of slurry and absolute ethanol is 1:23.

preparation example 3

[0037] Preparation example 3: (1) drying and dehydrating Phellodendron Phellodendri, Aloe Vera, and Rubia leaves until the water content is below 10%, and pulverizing them into a slurry, the mass ratio of Phellodendron Phellodendri, Aloe Vera, and Rubia is 1:1.5:1.2; (2) making the slurry Mix the material with absolute ethanol to make a mixed solution, extract the mixed solution at a constant temperature of 50°C for 1 hour, centrifuge at a speed of 3000r / min after the extraction is completed, filter out the residue, concentrate the filtrate, recover the ethanol, and obtain the plant Antibacterial agent, the mass ratio of slurry and absolute ethanol is 1:25.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com