A secondary air distribution device for circulating fluidized bed boiler

A circulating fluidized bed and secondary air technology, applied in the field of boiler combustion, can solve the problems of poor flue gas disturbance, inability to achieve grading in the horizontal direction, and unfavorable full combustion of fuel, so as to prolong the residence time, facilitate reburning, improve The effect of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

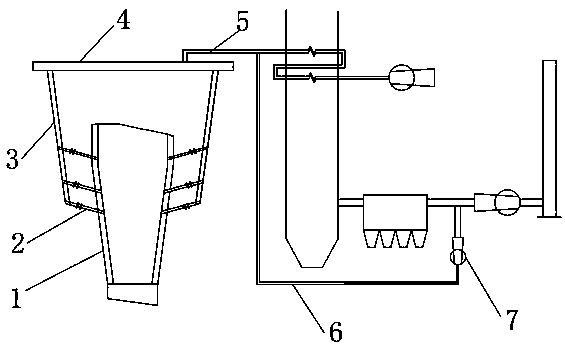

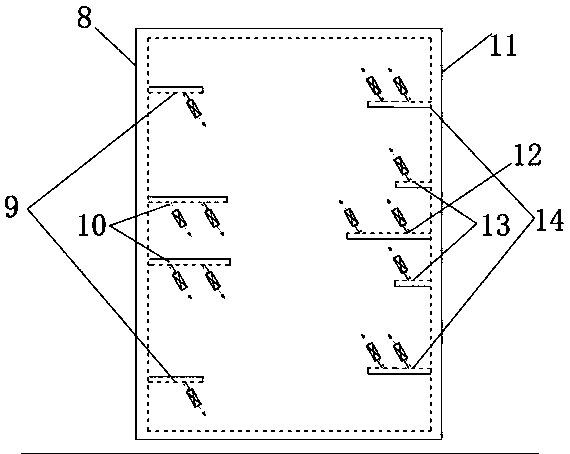

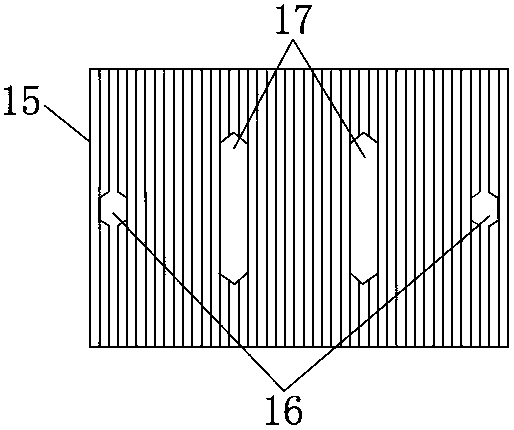

[0024] A secondary air distribution device for a circulating fluidized bed boiler, comprising a boiler 1, a water-cooled wall and a secondary air system arranged on four walls in the boiler 1 with letting pipes, and the lower part of the boiler 1 is a dense phase area, The upper part is the dilute phase area, and the secondary air system includes secondary air branch pipes 3, a plurality of secondary air risers 3 placed on the outside of the boiler front wall 8 and the boiler rear wall 11, and the secondary air risers arranged on the water wall and the secondary air risers. 3 connected secondary air nozzles 2, the secondary air nozzles 2 include double nozzles and single nozzles, the secondary air nozzles 2 are arranged in layers in the dilute phase area of the boiler 1, and the let pipes include double-hole let-down pipes and single-h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com