Patents

Literature

306results about How to "Improve the perturbation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

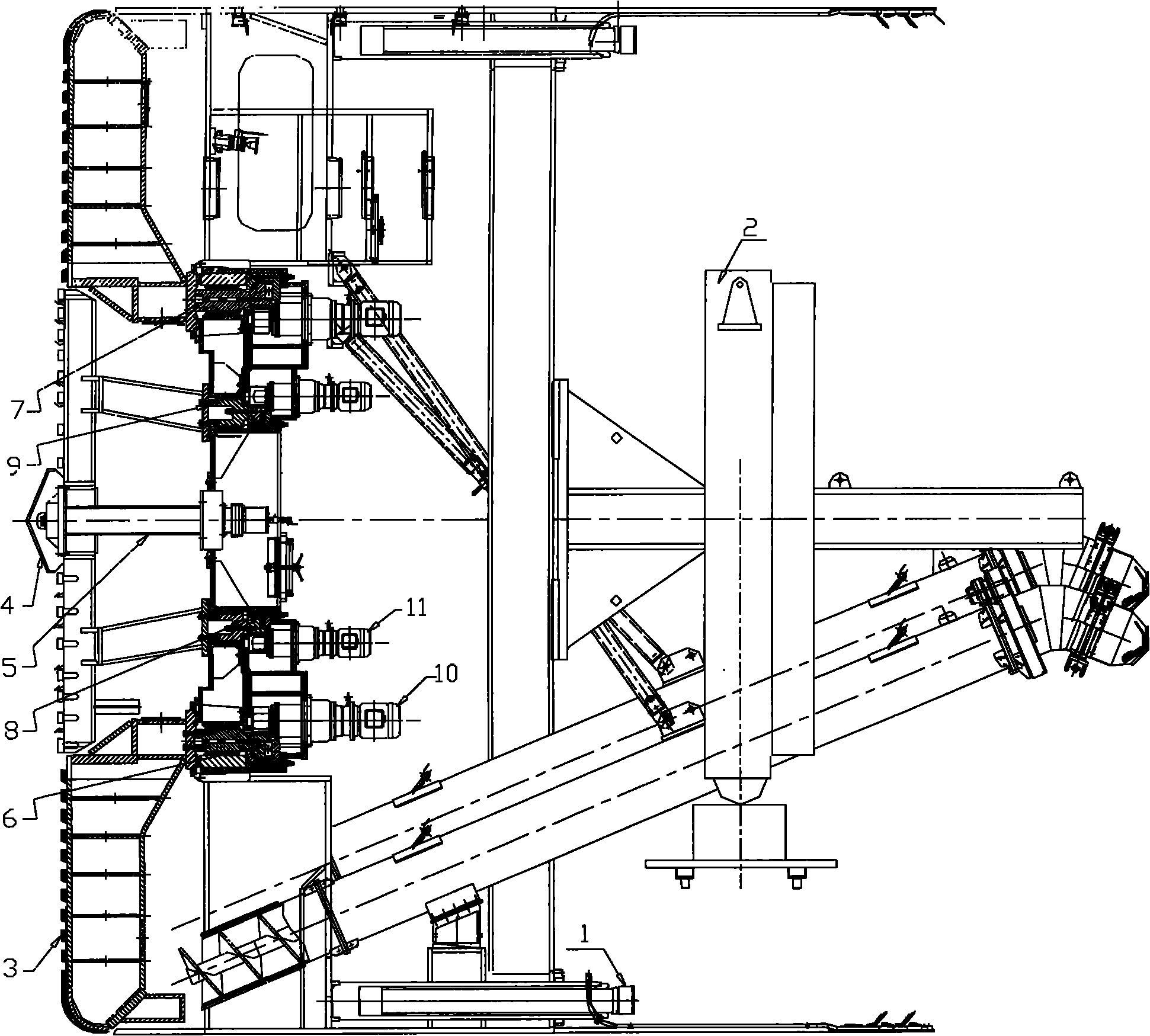

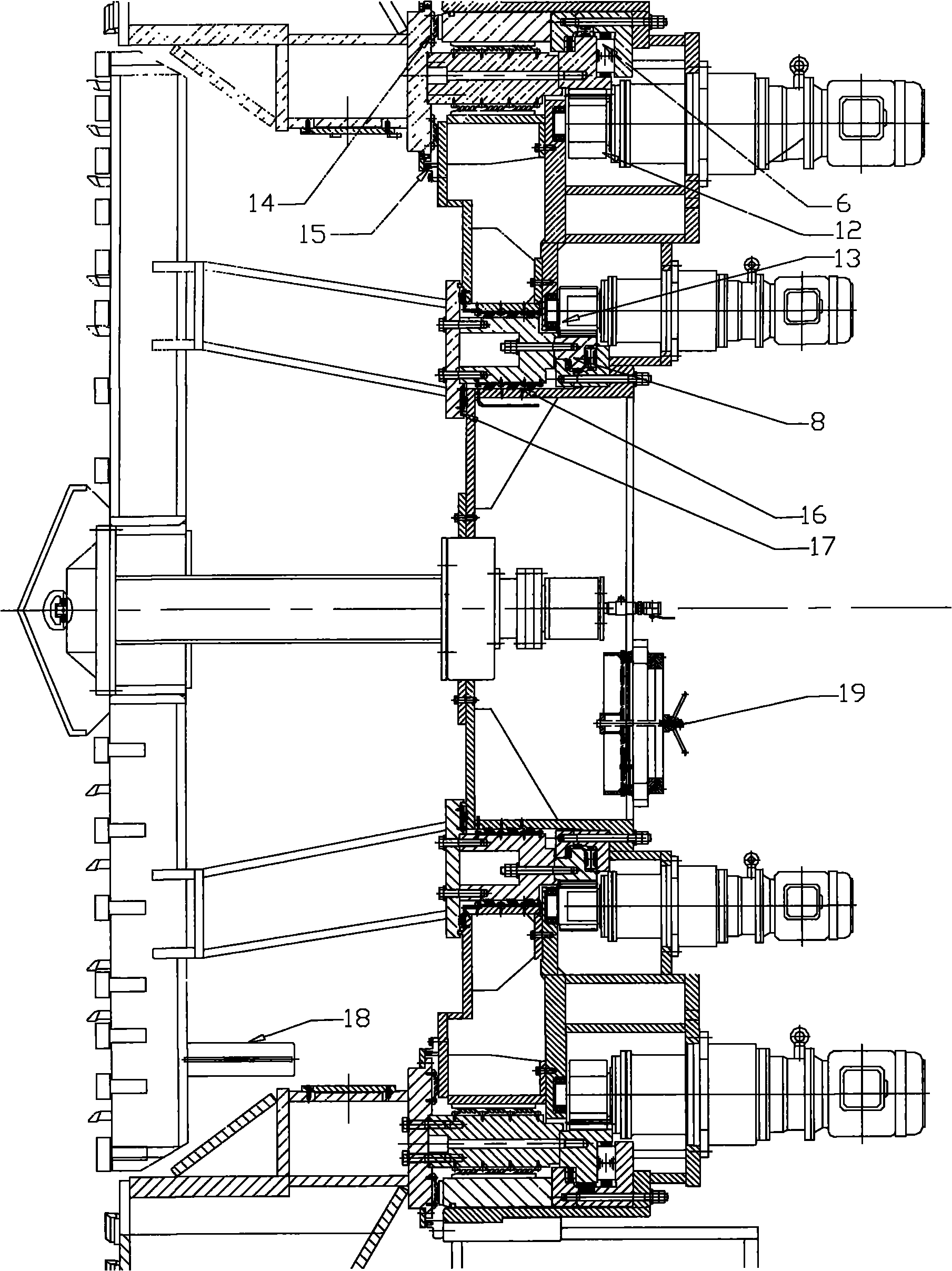

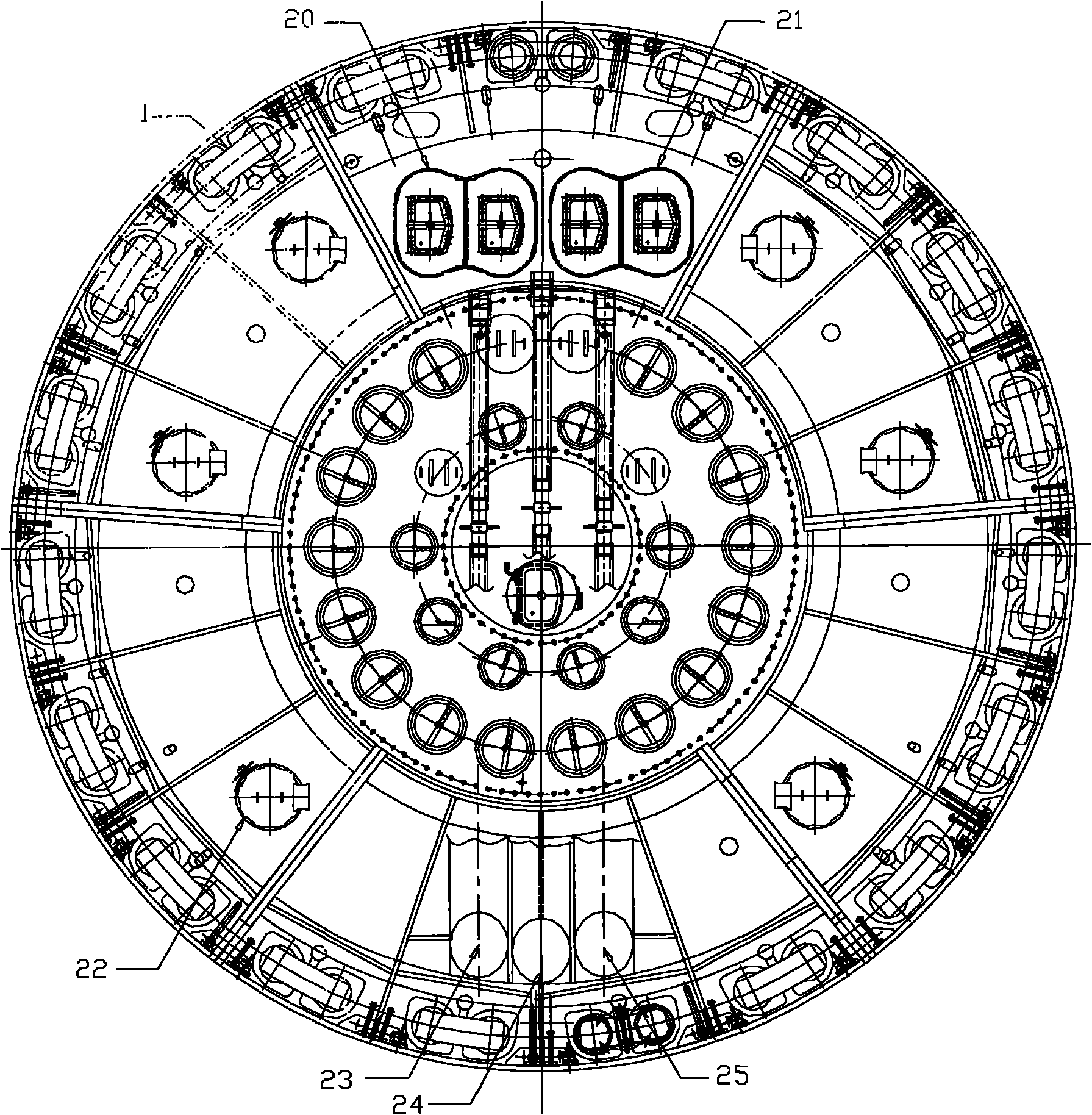

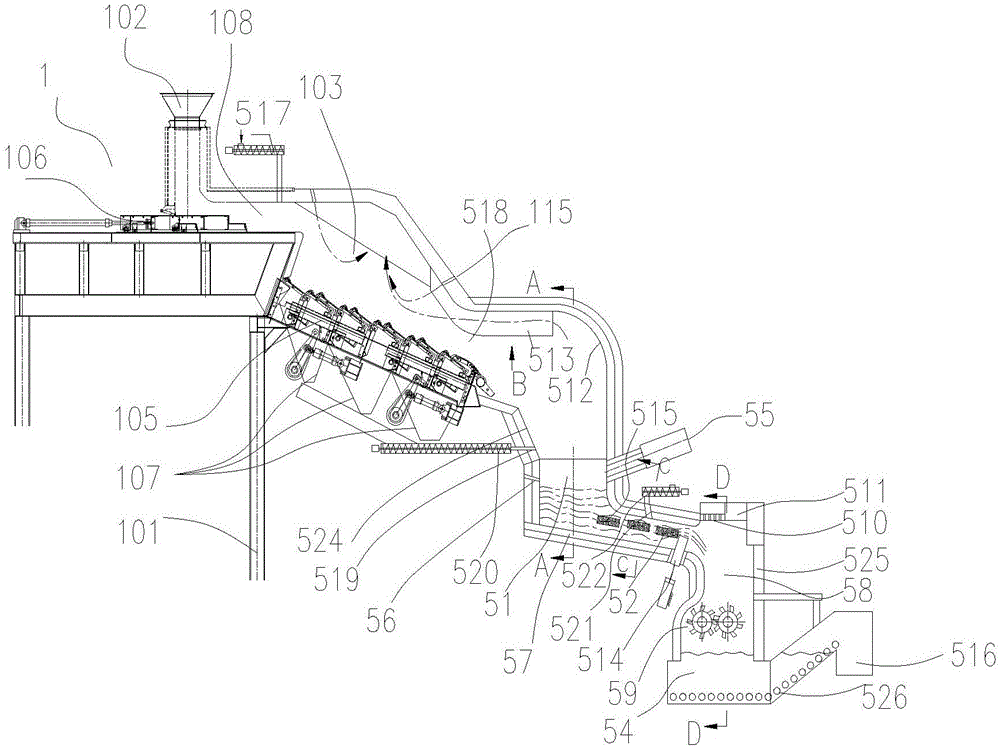

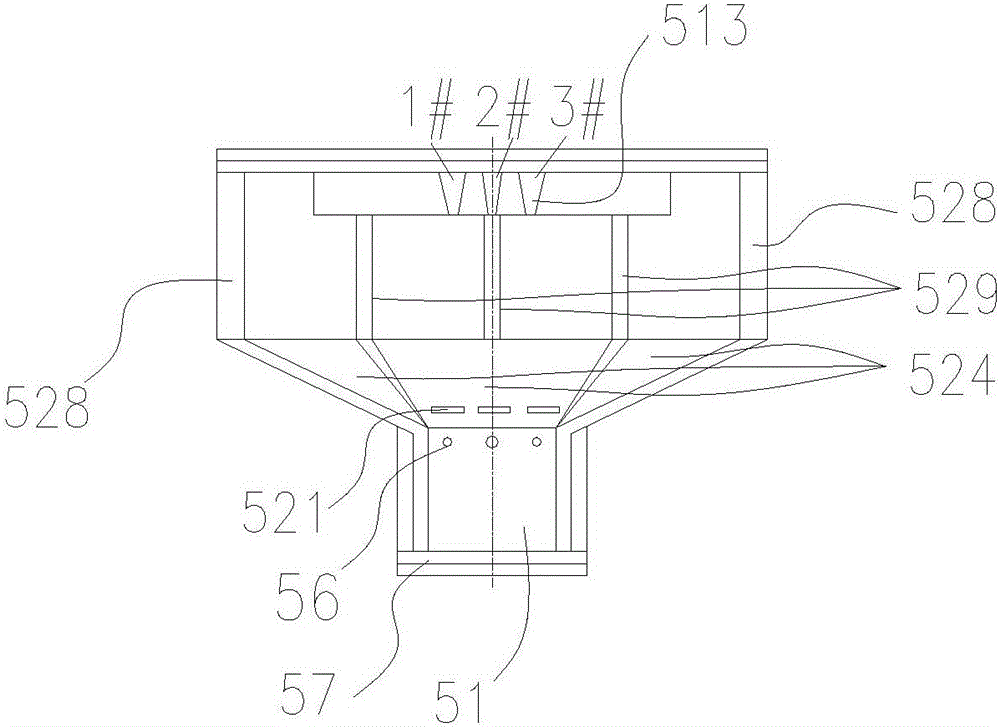

Large-diameter earth pressure balance shield machine

InactiveCN101798928AReduce wear rateChange the situation of uneven damageTunnelsControl theoryEarth pressure balance

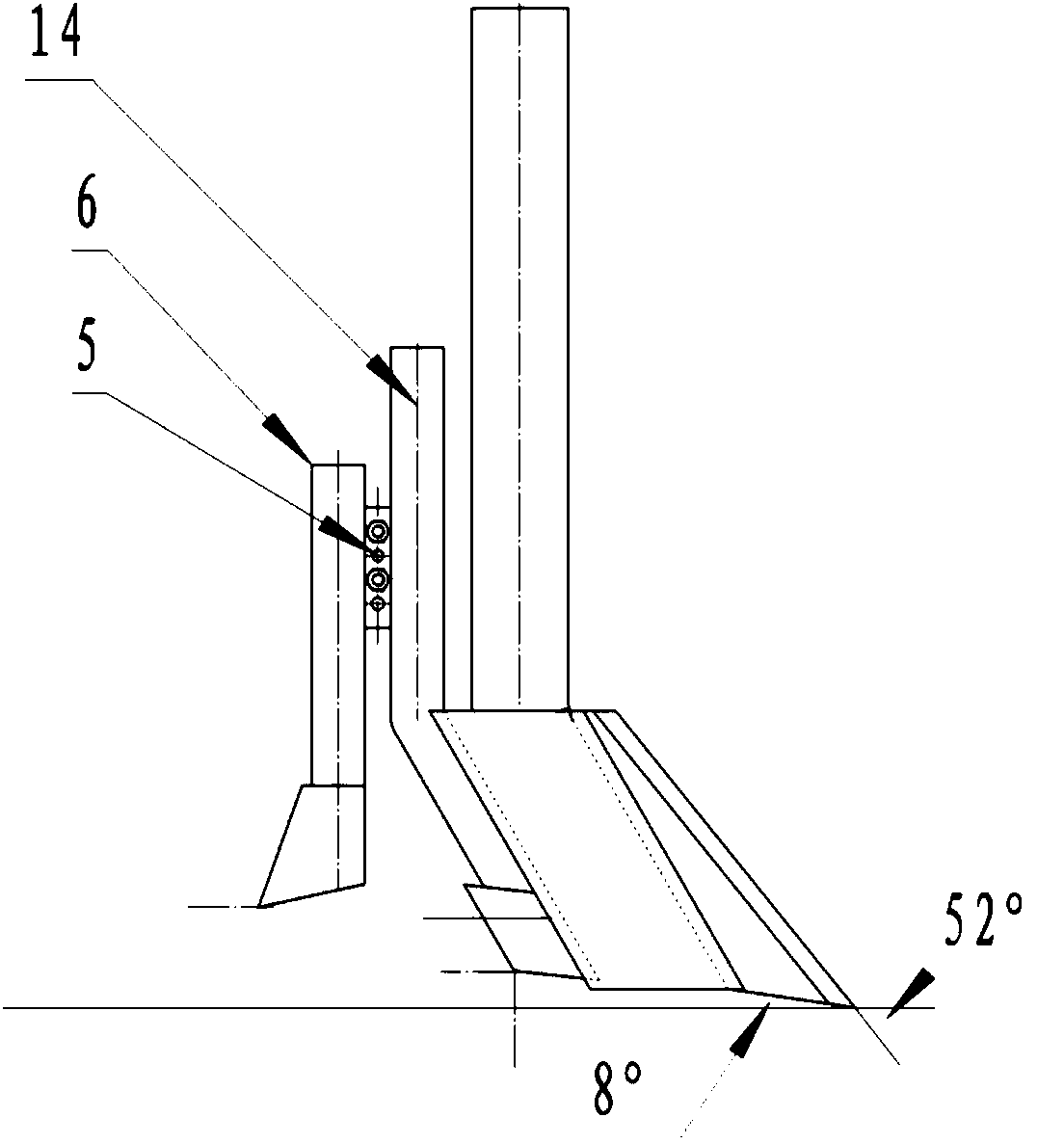

The invention relates to a large-diameter earth pressure balance shield machine. The machine comprises a cutterhead, a cutterhead drive part, a propulsion oil cylinder, an erector, spiral conveyors and a frame; the cutterhead is a double-cutterhead which comprises a peripheral large cutterhead and an independent central cutterhead; the cutterhead drive part comprises two driving mechanisms which drive the peripheral large cutterhead and the independent central cutterhead respectively; and the peripheral large cutterhead and the independent central cutterhead rotate independently and bidirectionally. Compared with the prior art, the shield machine adopts the double-cutterhead design, greatly optimizes a cutting speed of the cutterhead on a soil body, further improves a propulsion speed of the shield, optimizes the disturbance effect of the cutterhead on the soil body, and prevents the rolling of a shield machine body; different opening rates are designed on the cutterhead and are suitable for different situations of a central part and a peripheral part when a tunnel is advanced; and three spiral conveyors discharge soil, effectively control the posture of the shield, and prevent the deviation of a tunnel axis.

Owner:SHANGHAI LIXING ENG TECH DEV

Lacunaris metal carrier and manufacturing method thereof

ActiveCN101229699AOvercome the defect of not resistance to oxidationImprove high temperature oxidation resistanceMolten spray coatingMetal layered productsPorous substrateRare-earth element

The invention discloses a porous metal carrier and a preparation method thereof. The porous metal carrier has a continuous micro-porous structure formed through mutual connection of polyhedron cabinets; a first layer is a substrate metal layer which comprises one or a plurality of the compositions: nickel, iron or copper; metal quantity of the substrate metal layer is more than or equal to 100g / m<2>; a function metal coating of MCrAl or MCrAlR is arranged on the substrate metal layer and M refers to Fe, Ni and Co or alloy of Fe, Ni and Co and R is rare earth element. The preparation method includes the following steps: first, metallization pretreatment is carried out for nonmetal porous substrate to form the substrate metal layer; second, the function metal layer with chromium and aluminum are sprayed on the substrate metal layer by adopting a thermal spraying process; at last, flame remelt and induction remelt are carried out for the function coating. The material provided by the invention has high porosity, large surface area, high strength, favorable flow disturbance, excellent high temperature and oxidization resistance, simple preparation method and process and low cost.

Owner:先进储能材料国家工程研究中心有限责任公司

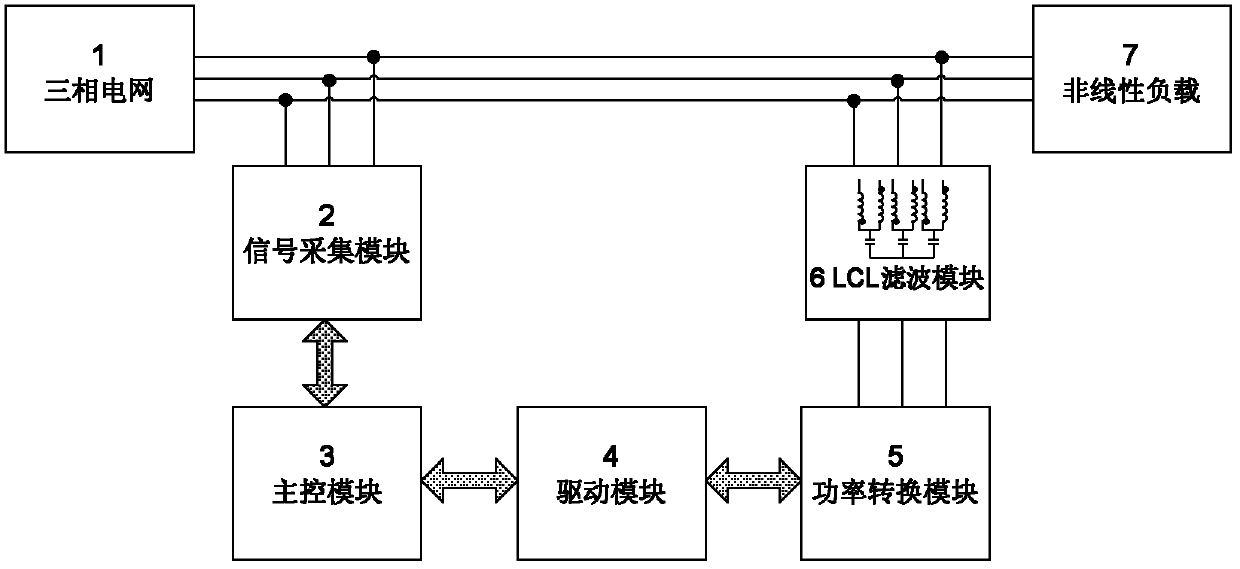

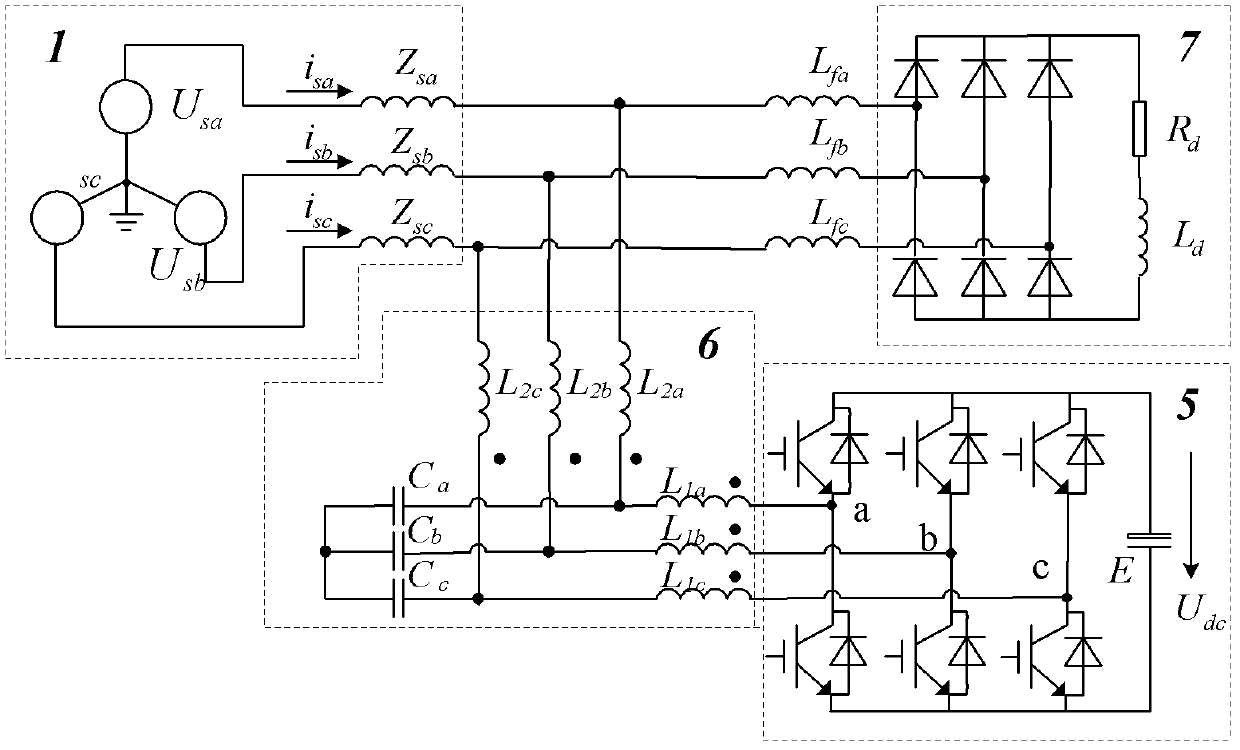

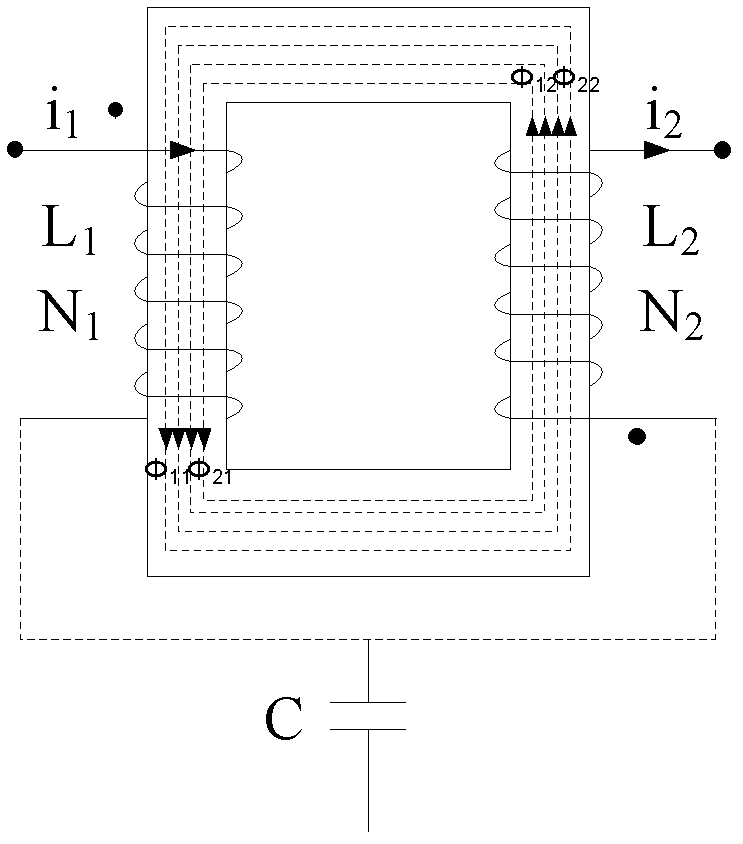

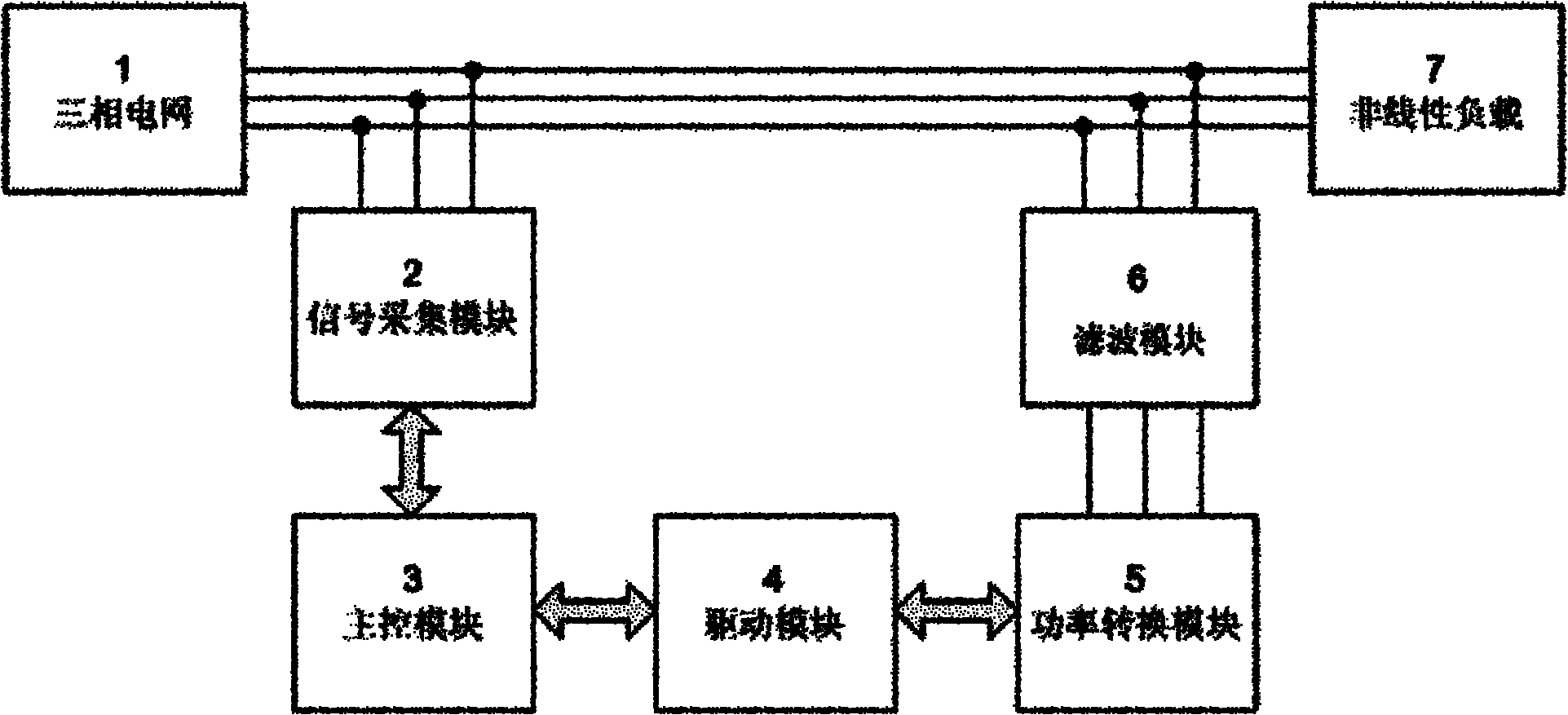

An Active Power Filter Device Based on Coupled Inductor

InactiveCN102290815AReduce volumeReduce weightActive power filteringReactive power adjustment/elimination/compensationPower gridEngineering

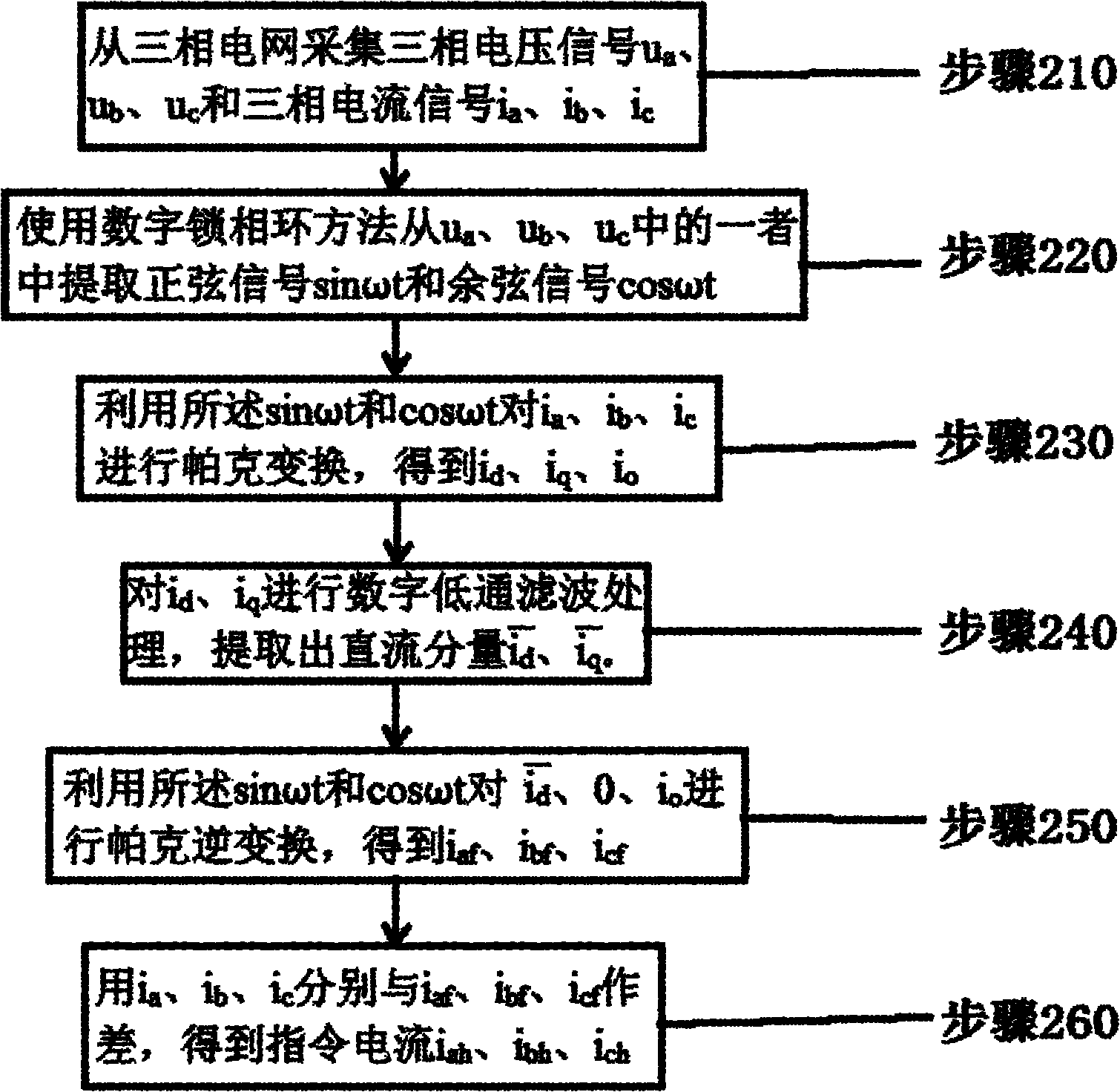

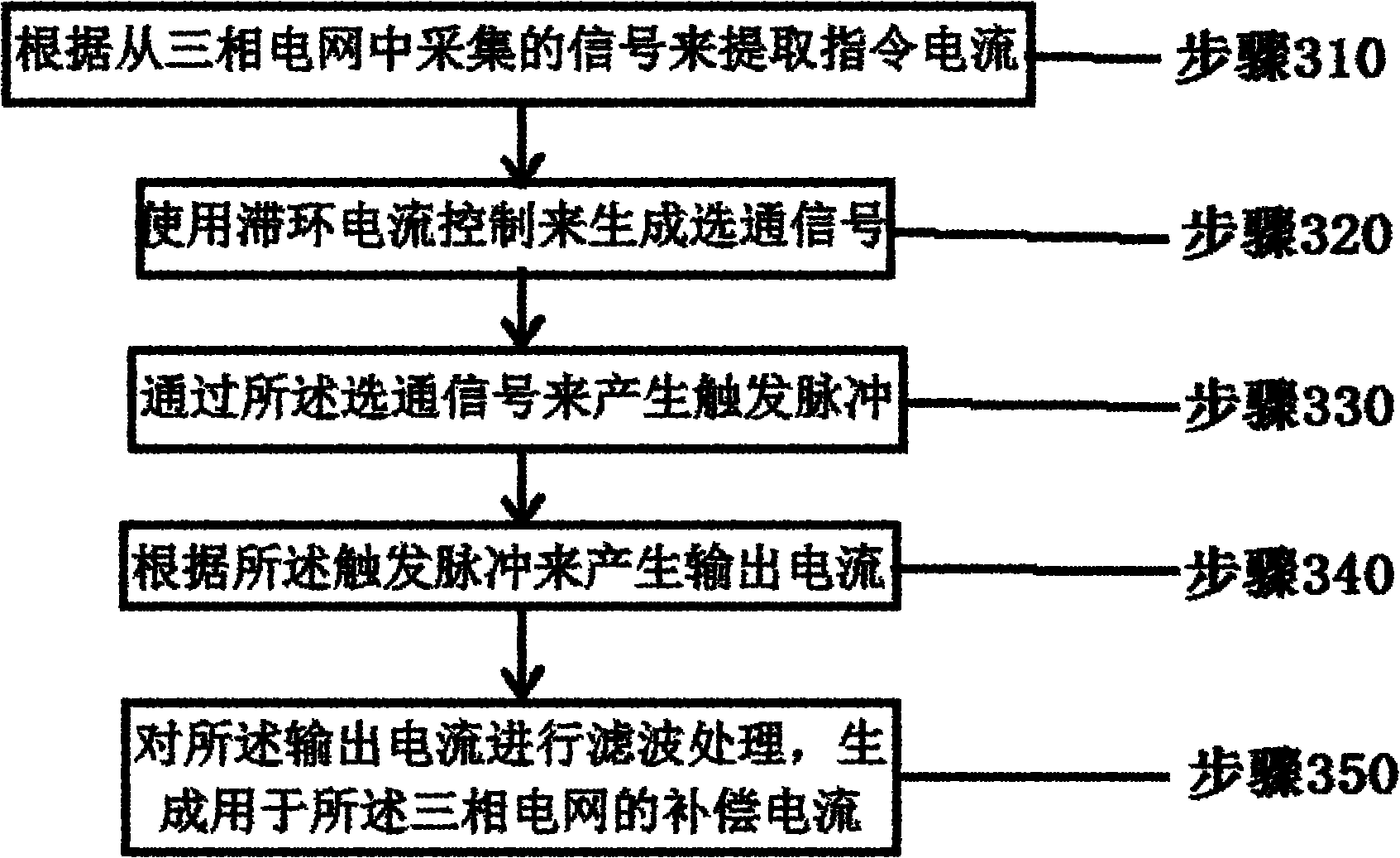

The invention discloses an active power filter device based on a coupled inductance, which is composed of a signal acquisition module, a main control module, a drive module, a power conversion module and an LCL filter module based on a coupled inductance. The steps of extracting command current are as follows: first, extract sinωt and cosωt which are synchronized with grid A-phase voltage ua through digital phase-locked loop; secondly, transform the three-phase grid current into dqo coordinates to obtain current id, iq in dqo coordinate system , io; the third is to perform digital low-pass filtering on id and iq to extract their DC components; the fourth is to inversely transform io, sinωt and cosωt to dqo coordinates; the fifth is to perform subtraction to obtain the three-phase grid current The fundamental reactive and harmonic currents in . After hysteresis comparison control, PWM gating signals and trigger pulses are generated to control the orderly on-off of each IGBT in the power conversion module to generate PWM voltage, which is filtered by the filter module and then injected into the grid for compensation.

Owner:HUBEI SANHUAN DEV

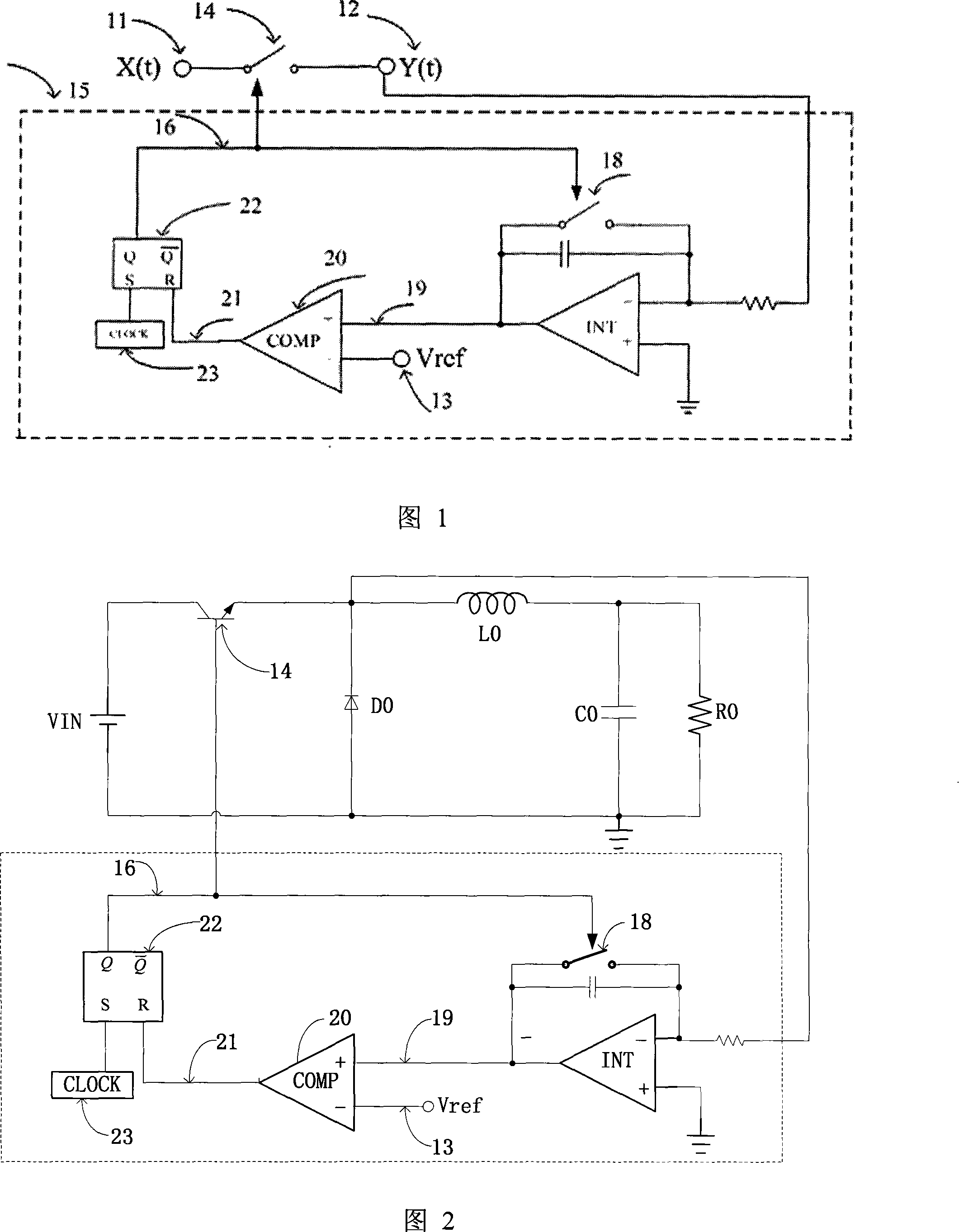

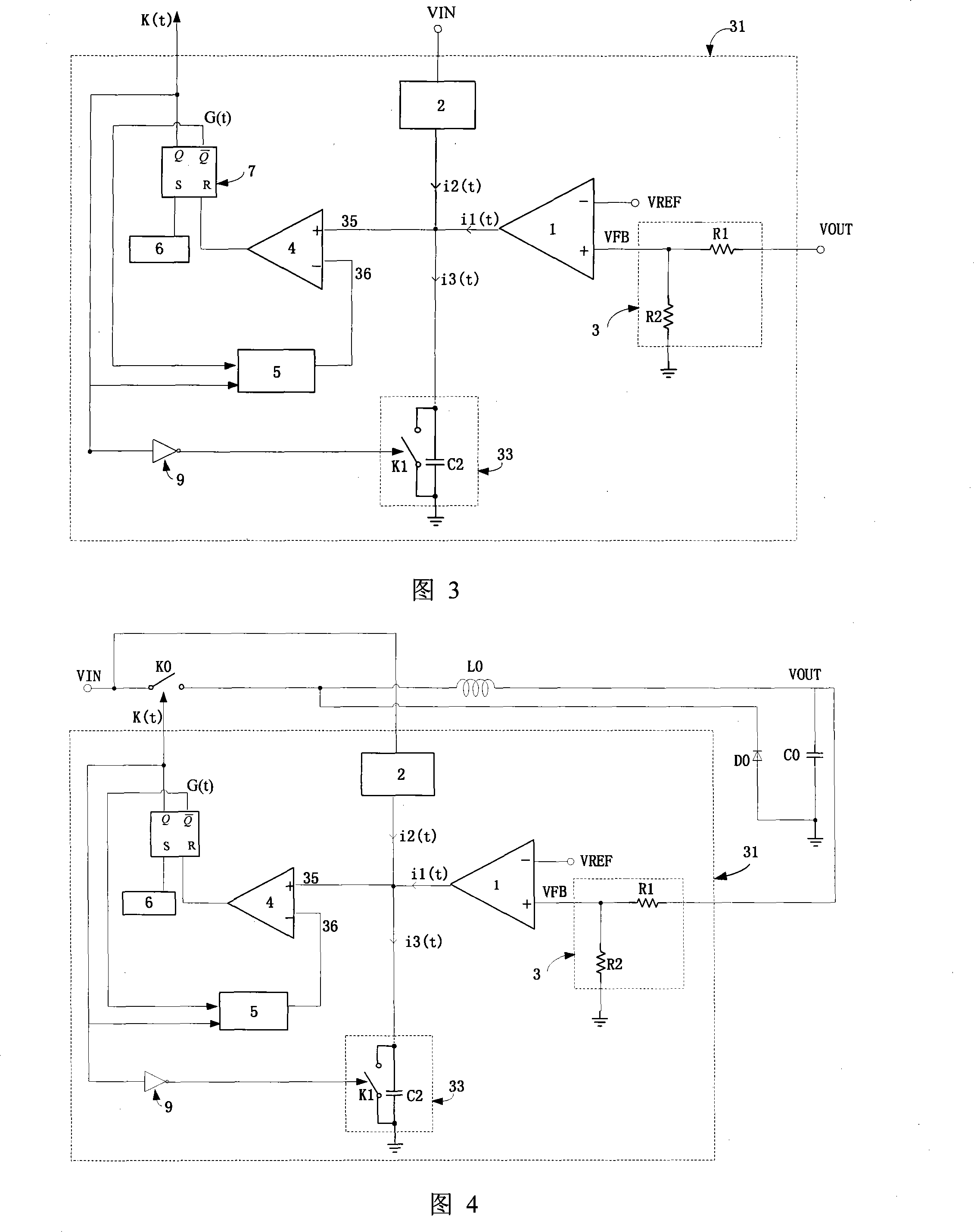

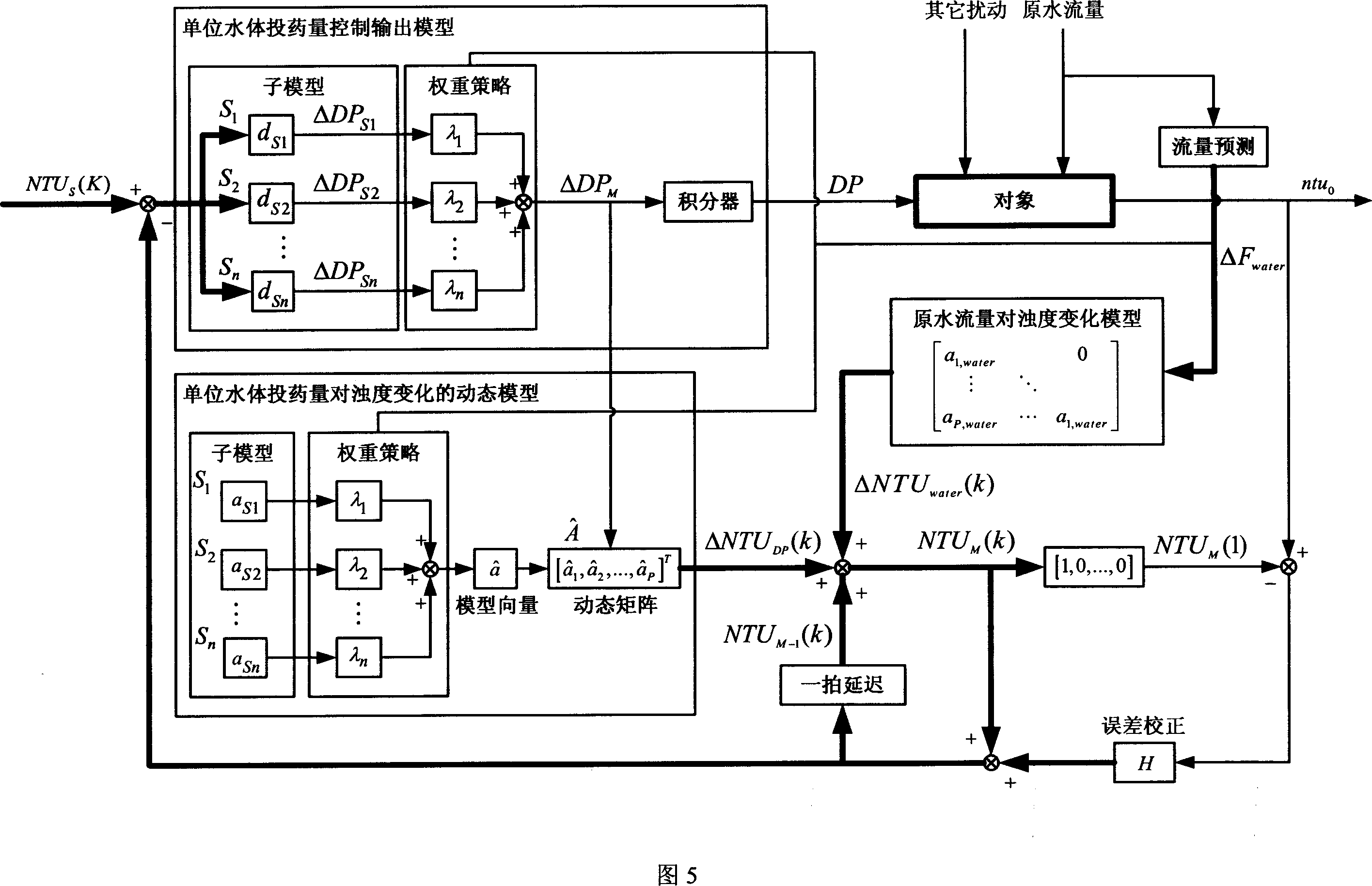

A monocycle feedforward switch control circuit

InactiveCN101217251AAchieving single-cycle nonlinear controlAchieving single-cycle controlDc-dc conversionSolid-state devicesControl signalVoltage reference

The invention discloses a single period feed forward switch control circuit, comprising a trans-conductance amplifier, a comparator, a clock, an RS trigger, an integrating network, a voltage and current converting circuit, a controllable voltage threshold module, a not gate and a resistor dividing network. In a switch period, an output signal of the switch circuit is integrated, and produces a feedback signal which represents the mean of the output signal in a switch period. The feedback signal and a reference voltage are compared by the comparator, and when the value of the feedback signal is equal to that of the reference voltage, the comparator produces a switch control signal to regulate the duty ratio of the switch circuit so as to stabilize the output voltage. A feed forward path which increases the sampling input voltage is added to the feedback control circuit. In the mode, the control circuit can sample both the output signal and the input signal at the same time and change the duty ratio of the switch circuit according to the sampling signal. The invention can enhance the disturbance rejection and optimize the dynamic performance of the switch power output.

Owner:HUAZHONG UNIV OF SCI & TECH

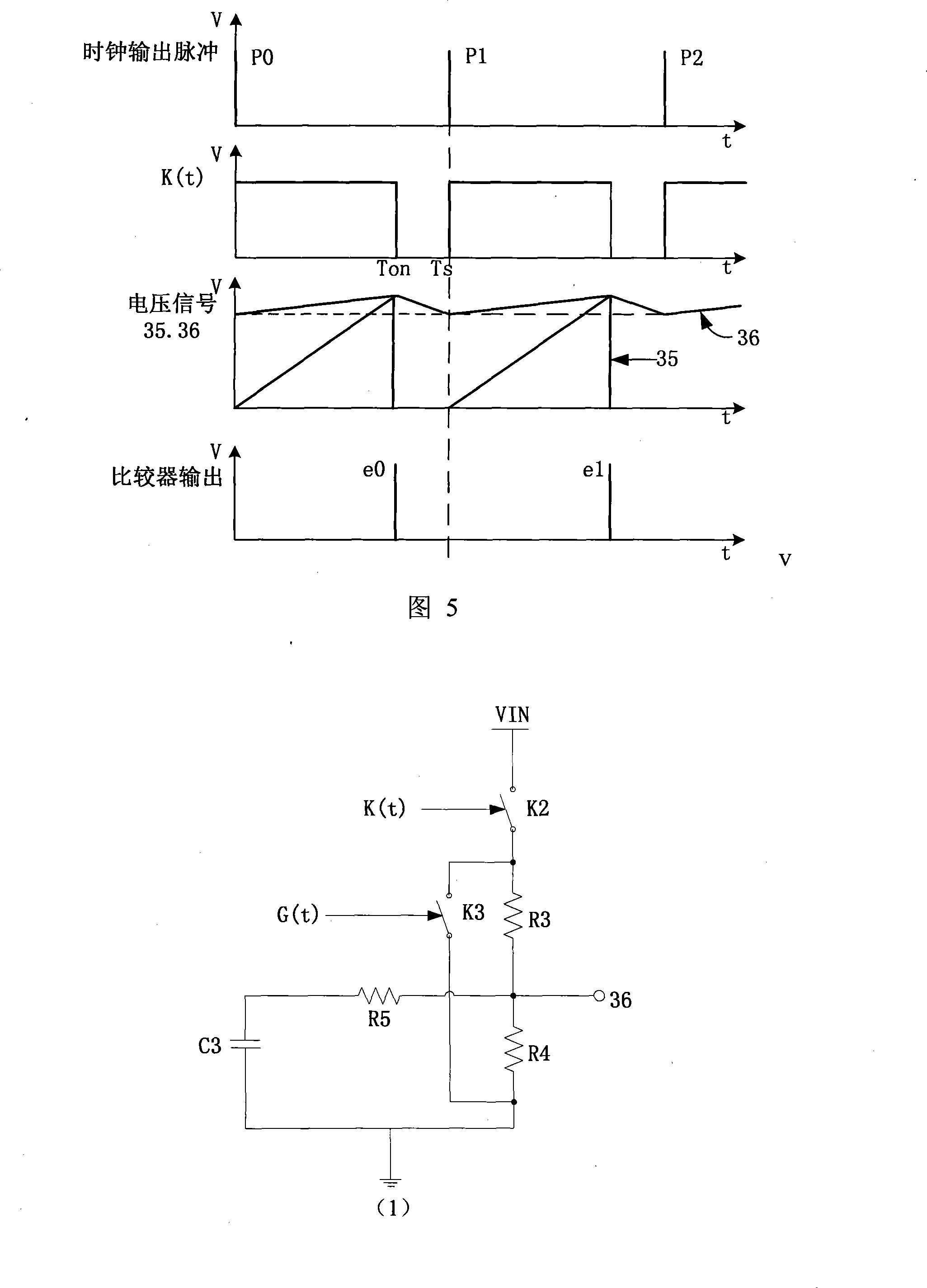

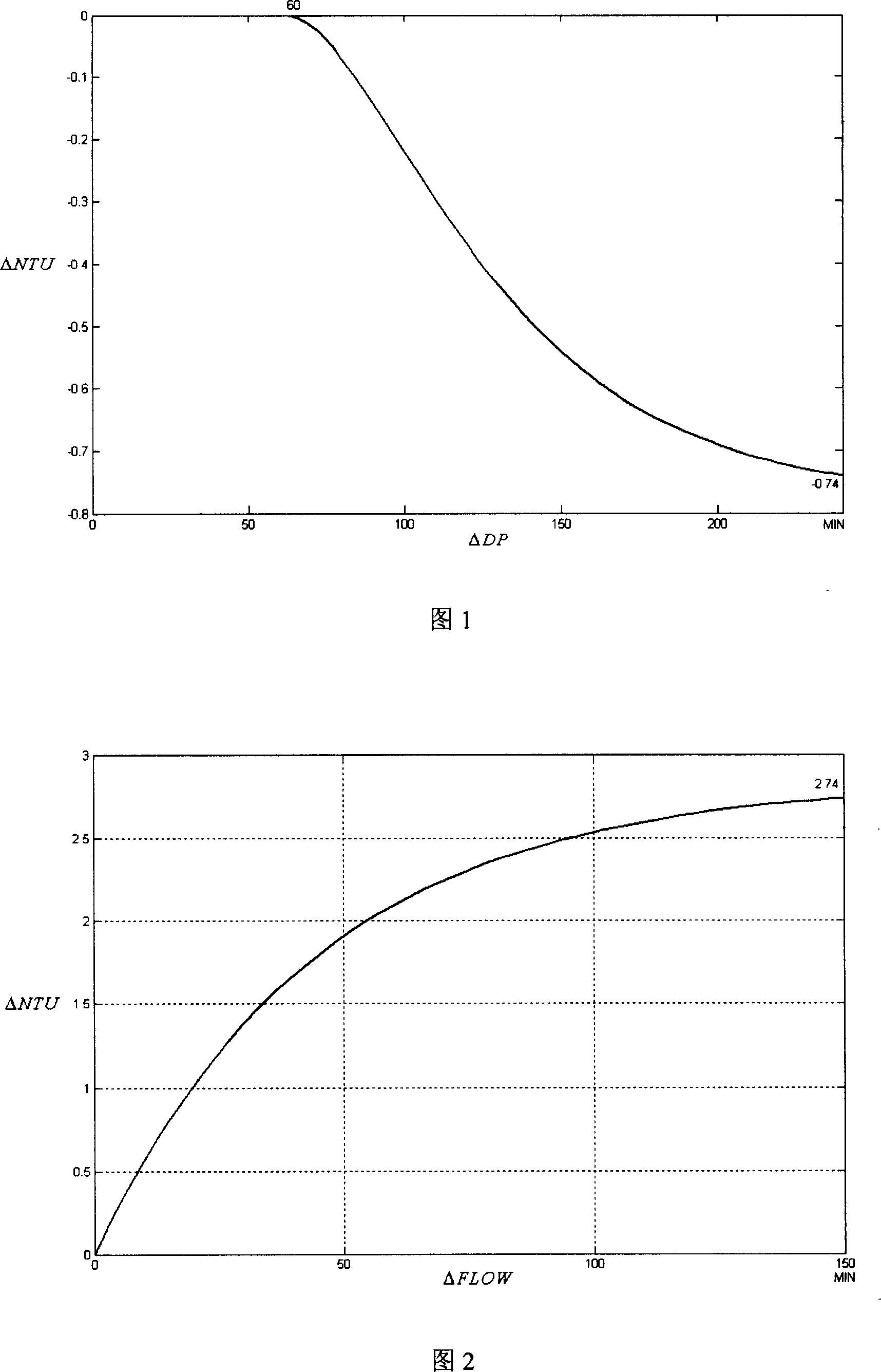

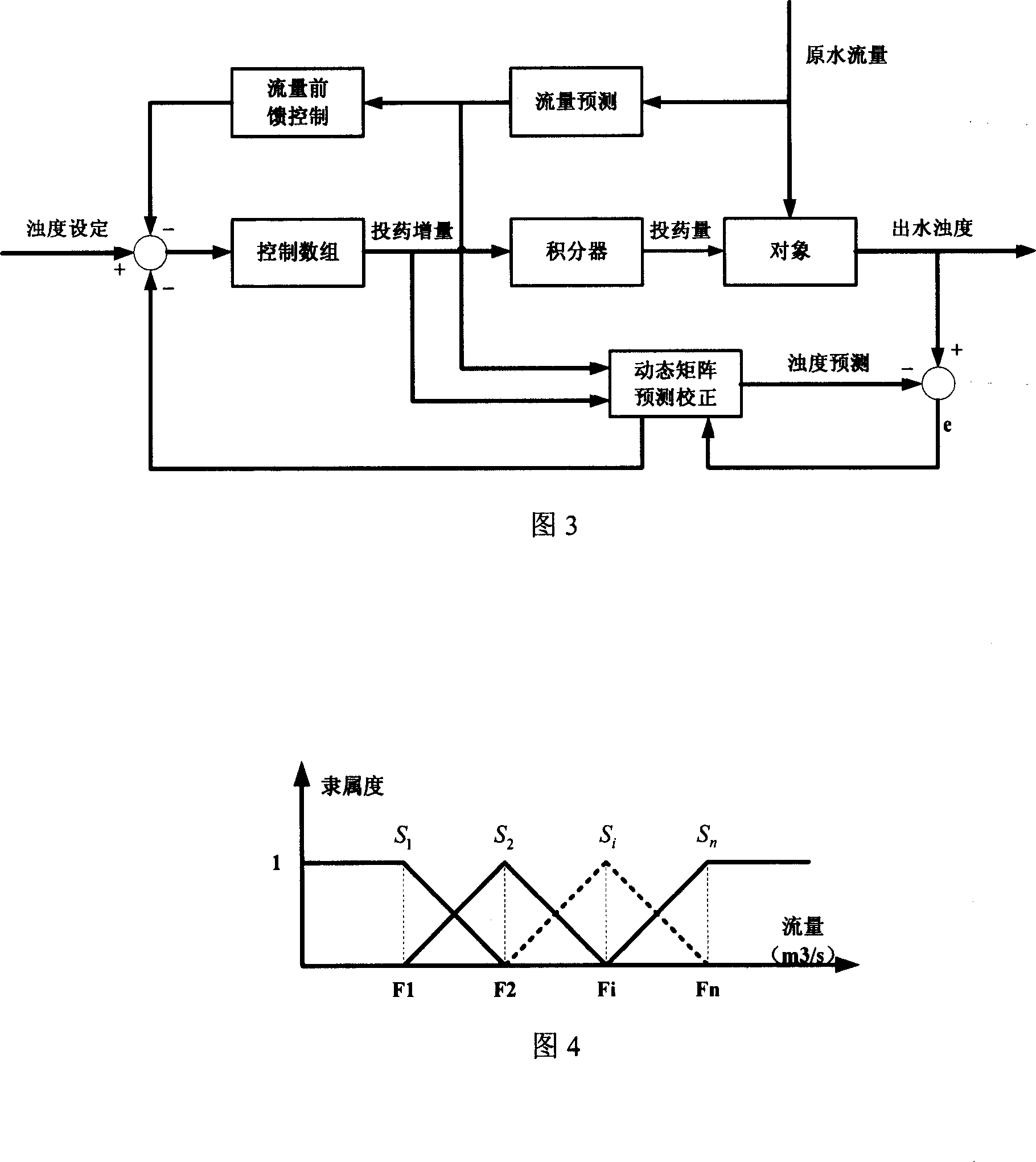

Multi-model dynamic matrix feeding amount control method for coagulation system in waterworks

InactiveCN101020128AApplicable to coagulation dosing controlSmall amount of calculationSedimentation separationWater/sewage treatment by flocculation/precipitationModel dynamicsDynamic models

The multi-model dynamic matrix feeding amount control method for coagulation system in waterworks features that dynamic matrix predicting controller is constituted based on comprehensive multi-model dynamic matrix control theory and by means of using raw water flow rate as the control target, separating the whole system into several subspaces and separate experiments to obtain sectional linear models of the subspaces; and that outflow water turbidity is controlled through determining the dynamic model of the system, predicting the outflow water turbidity, weighting treatment to obtain overall control increment and regulating the feeding amount based on the current work conditions, practical water flow rate and certain weighting police. The present invention can ensure smooth outflow water turbidity, system running economic performance, high robustness and low cost.

Owner:SOUTHEAST UNIV +1

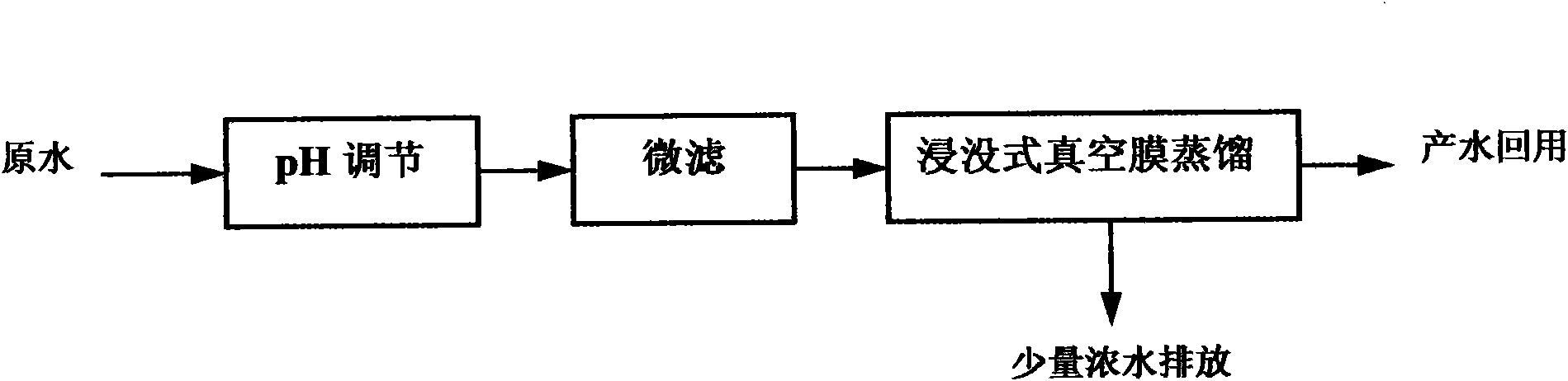

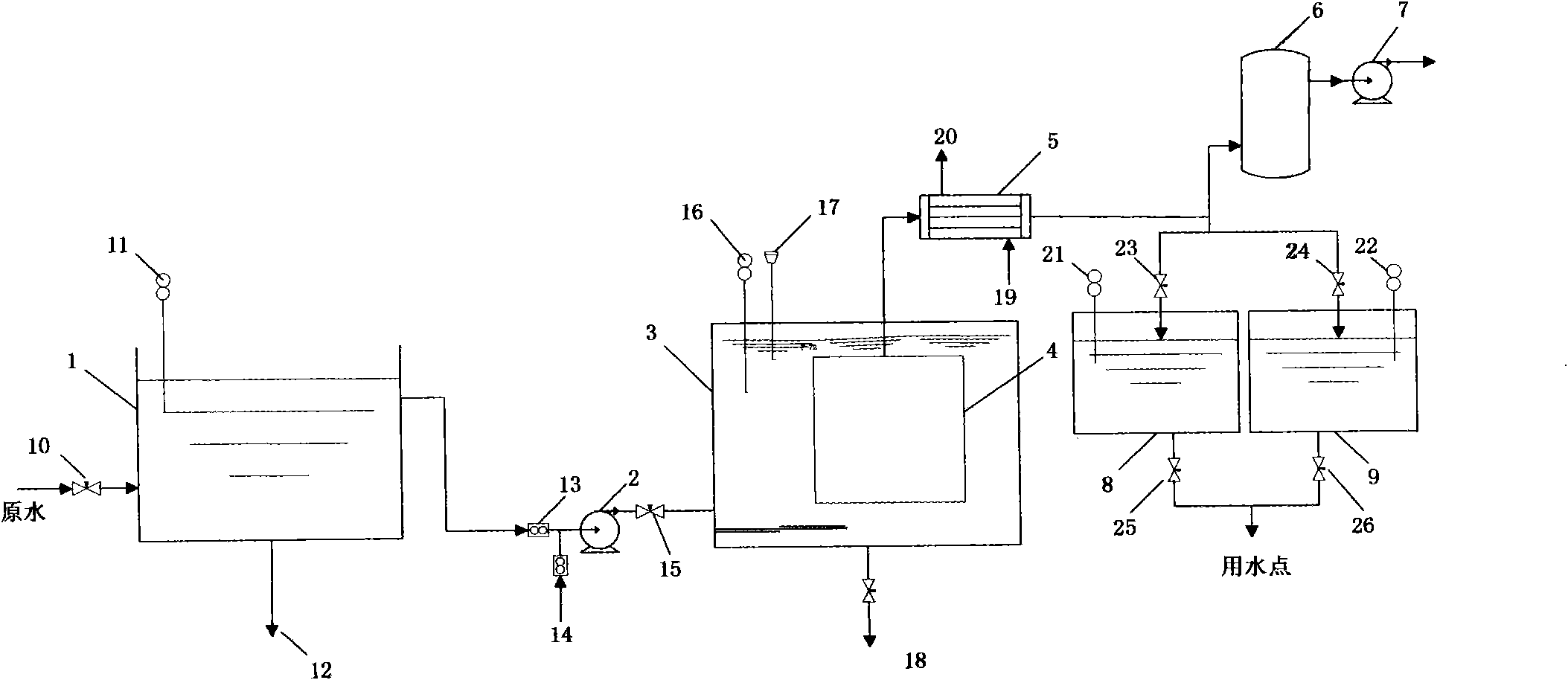

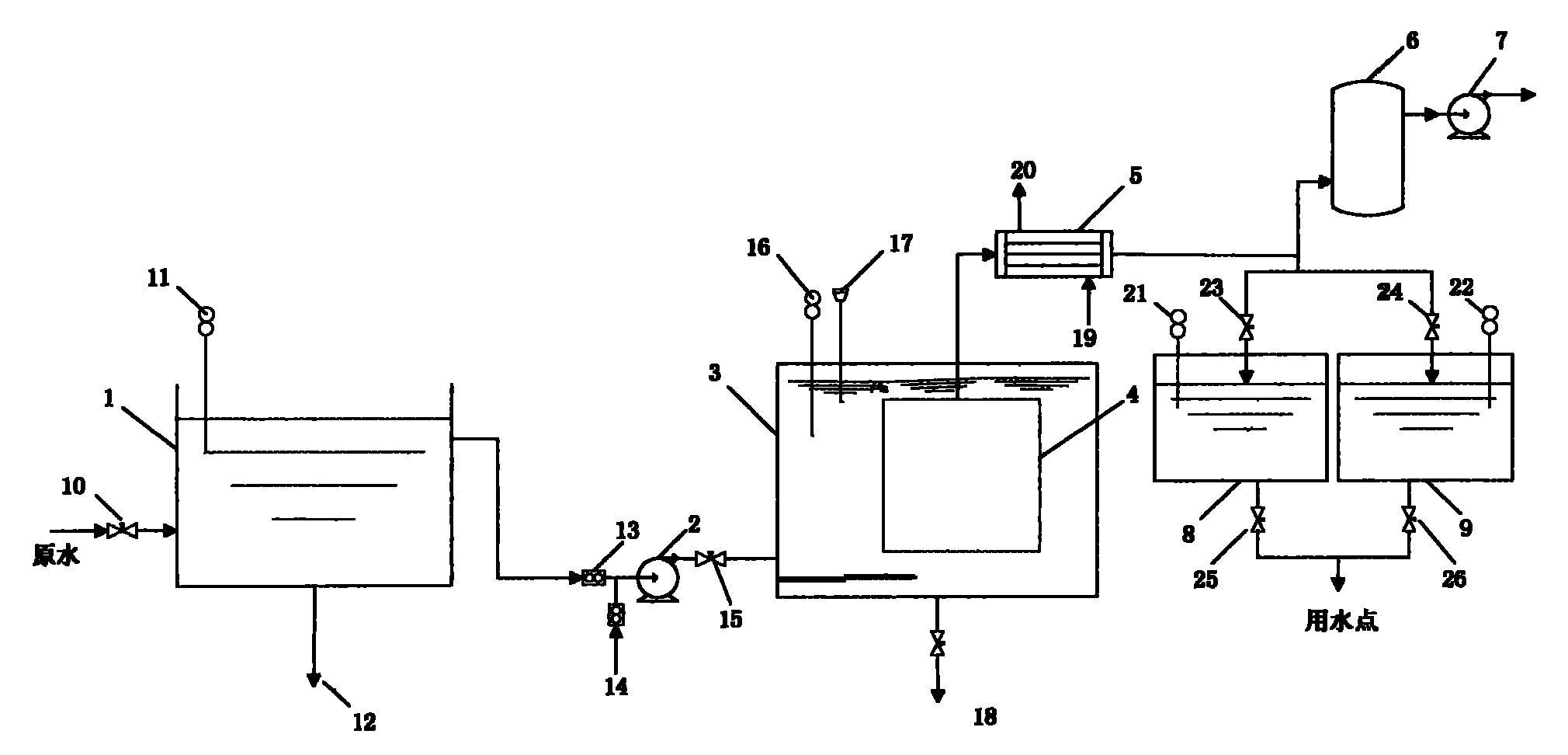

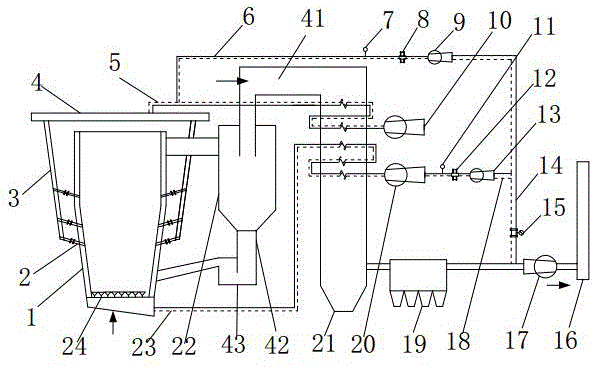

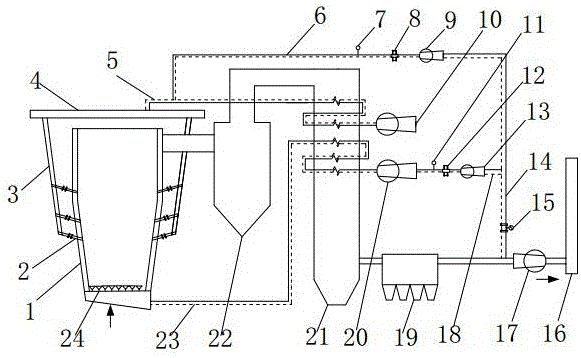

Immersed vacuum membrane distillation plant and sewage treatment technology using the same

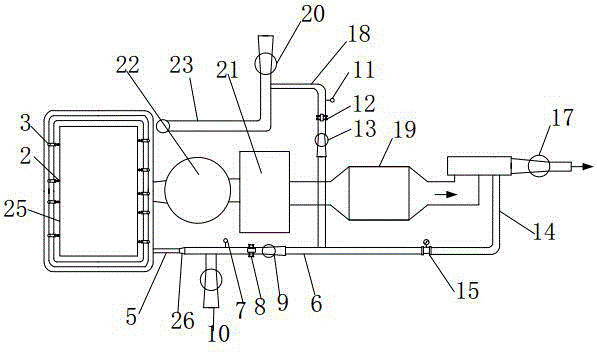

ActiveCN102417210AIncreased distillation throughputReduce pollutionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentConcentration polarizationMeasuring instrument

The invention relates to an immersed vacuum membrane distillation plant and a sewage treatment technology using the same. The immersed vacuum membrane distillation plant comprises a raw water storage tank, a gas dissolving pump, a raw water heating water tank, a membrane distillation hydrophobic membrane module, a condenser, a vacuum buffer tank, a vacuum pump, a water producing tank, a valve, a measuring instrument, and an automatic controller. The sewage treatment technology is characterized in that: raw water is subject to pH regulation, microfiltration and other pretreatment, then the pretreated raw water enters into the raw water storage tank, the sewage in the raw water storage tank is subject to gas-water mixing through the gas dissolving pump, and then the gas-water mixture enters into the raw water storage tank for heating to a specific temperature, membrane distillation is carried out at the specific temperature, the produced water after membrane distillation is directly reused, and a little thick water is treated concentrately. According to the invention, the use of the plant in sewage treatment reduces the effect of concentration polarization and temperature difference polarization in the sewage, reduces membrane pollution, increases the membrane distillation flux, prolongs the operation period of the membrane module, reduces the heat loss of the pipeline, and increases the heat utilization rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

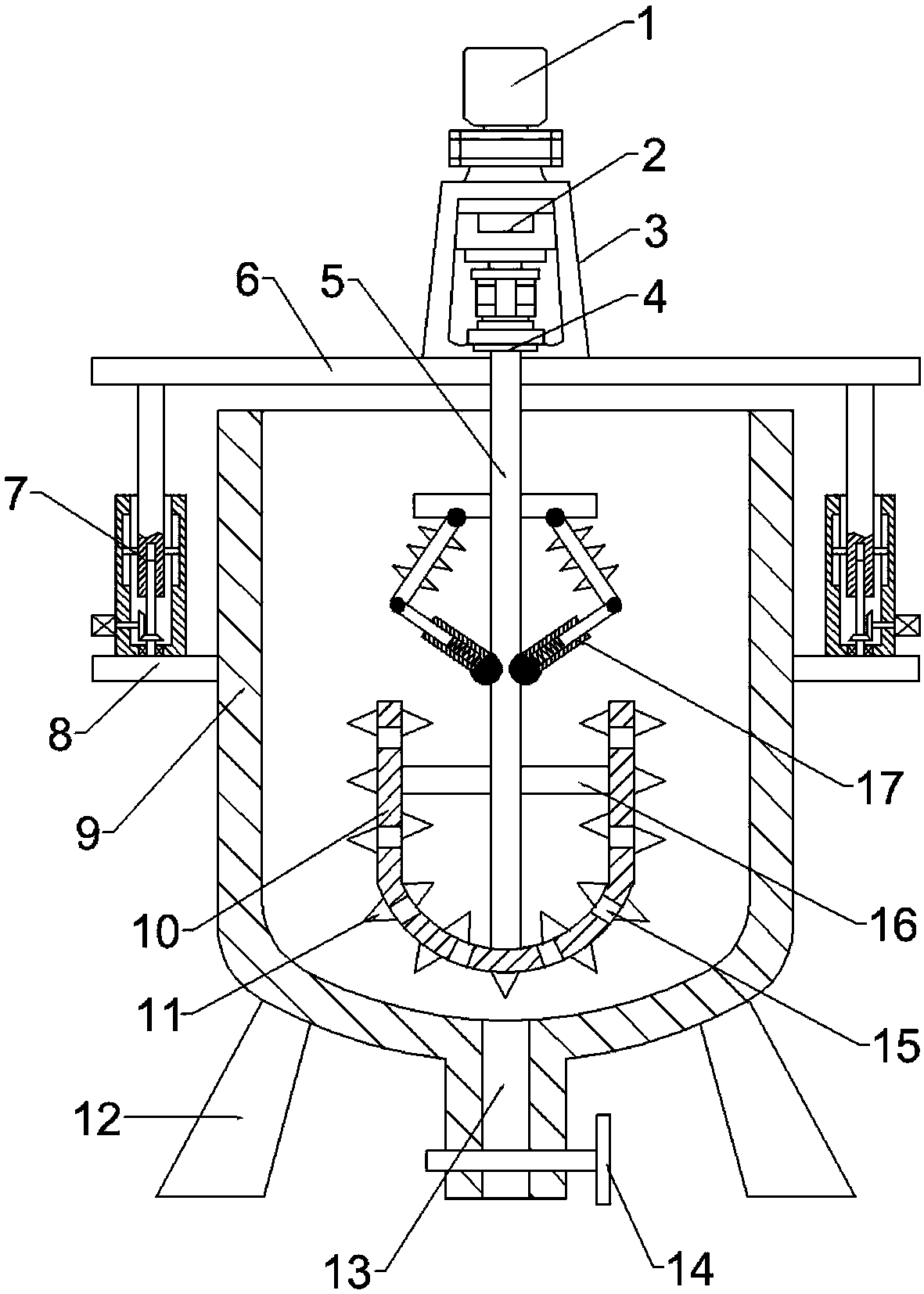

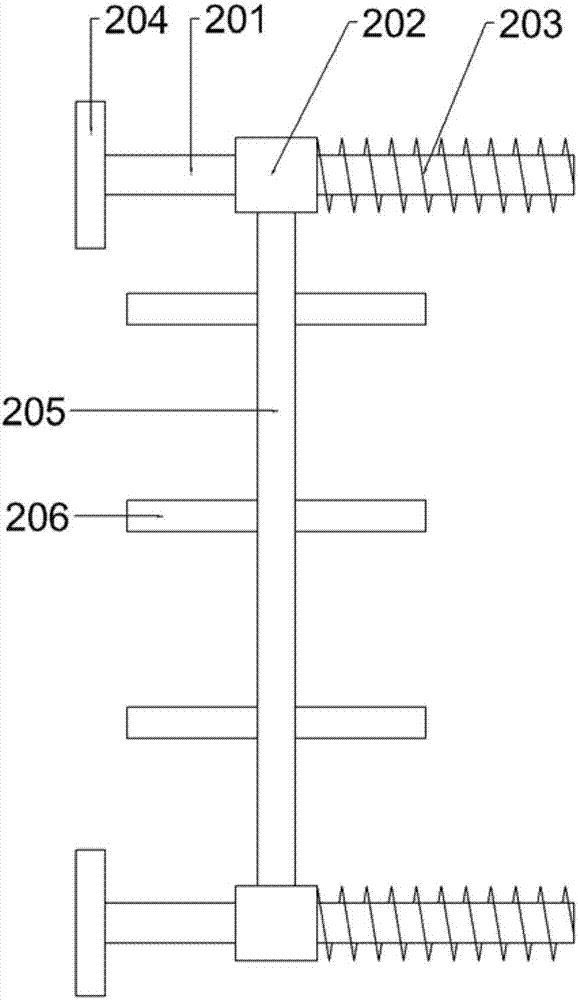

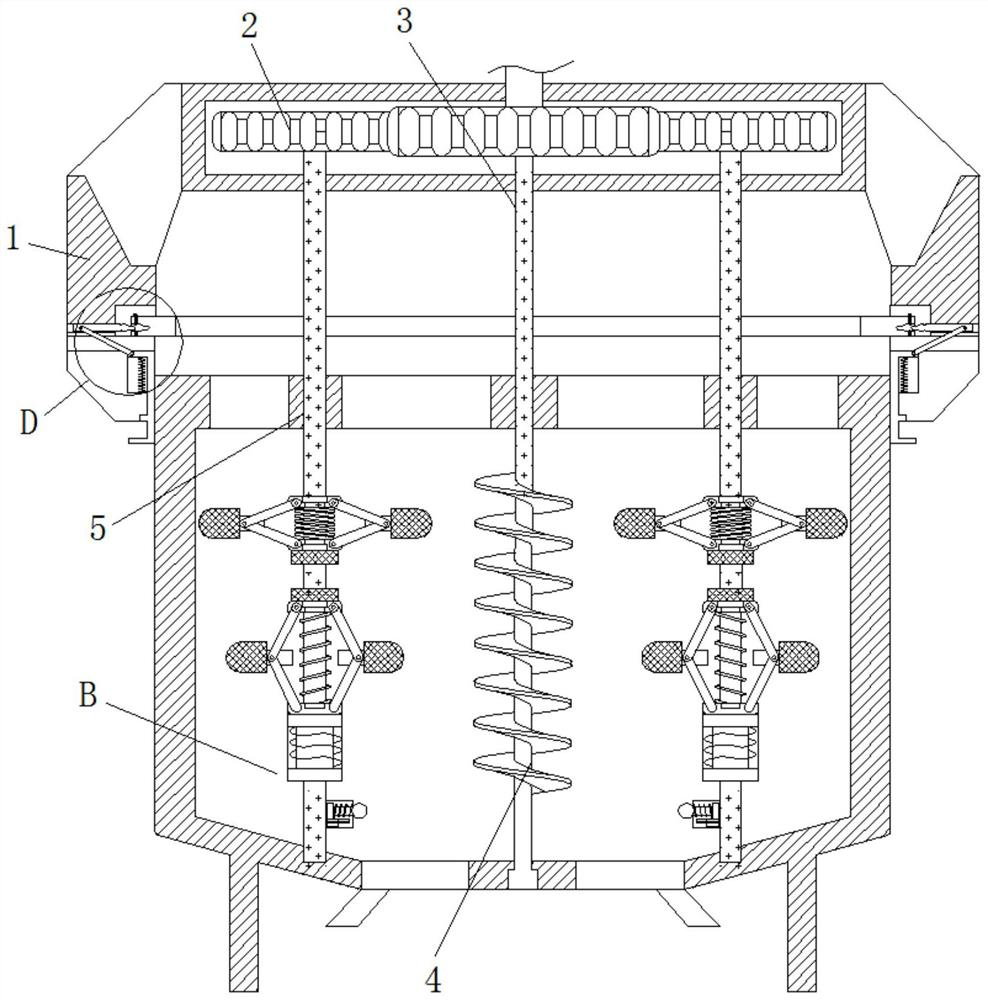

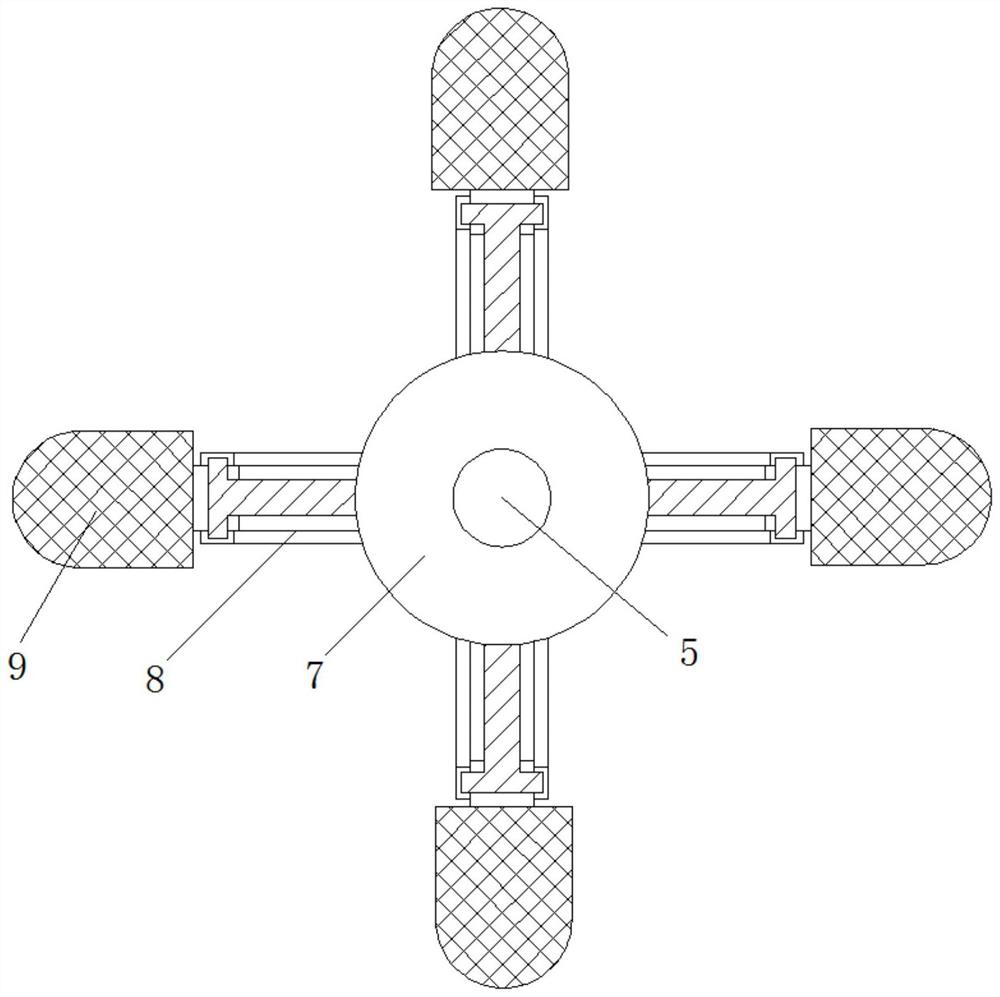

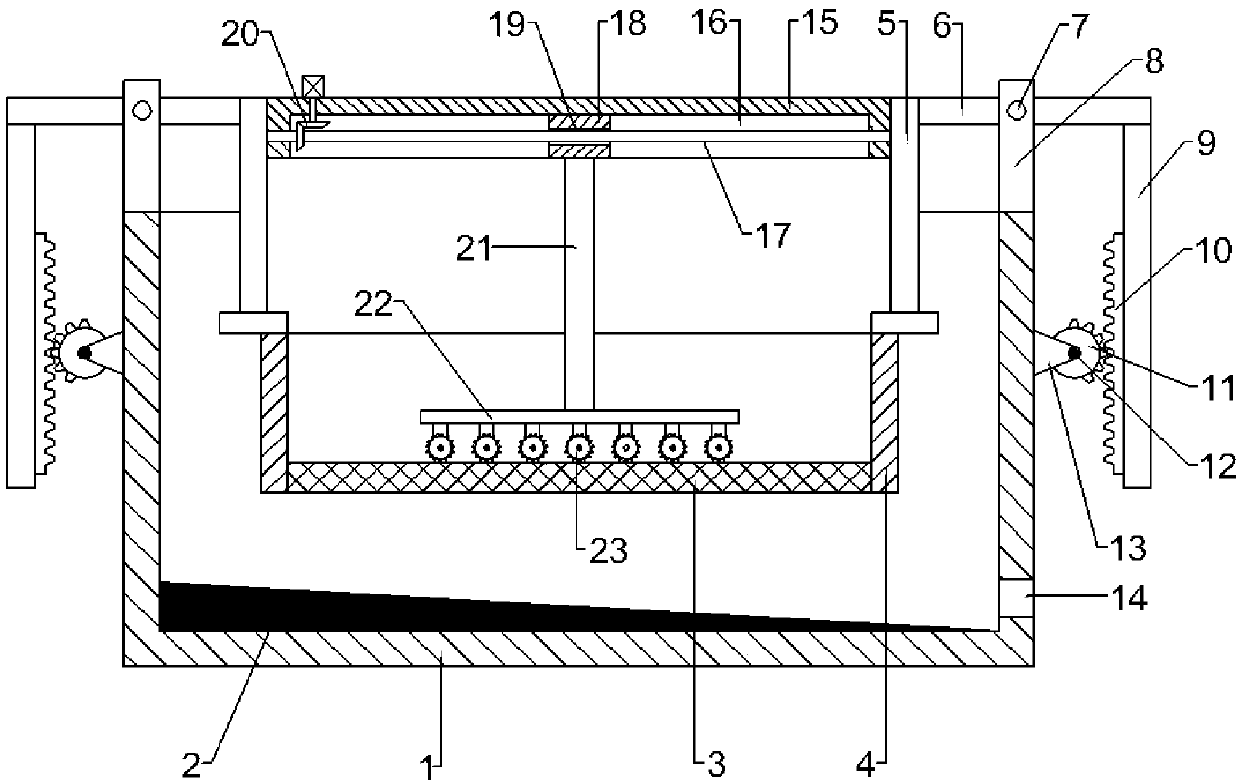

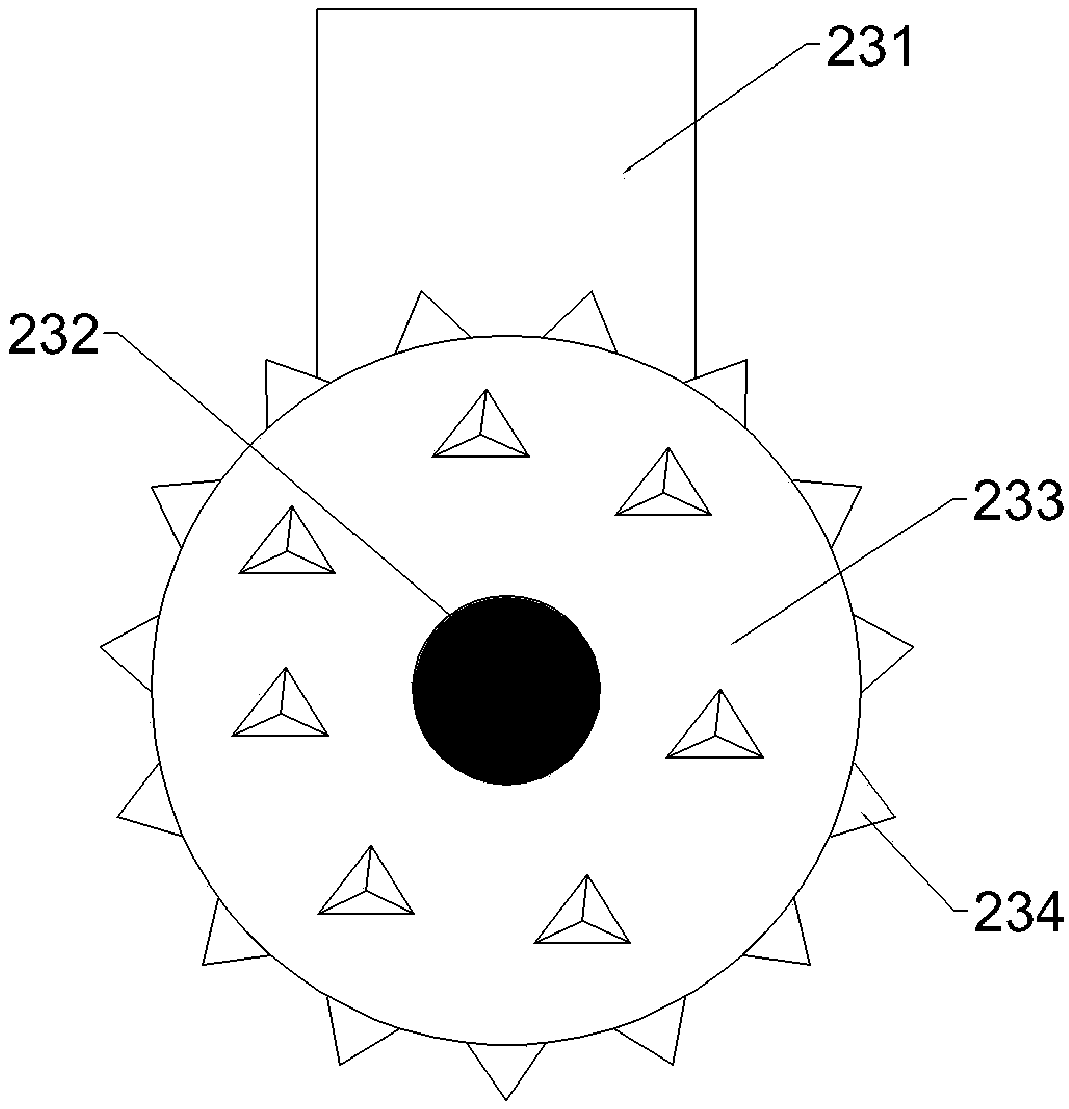

Variable-disturbance range polycarboxylate superplasticizer preparing equipment

InactiveCN107617358AChange the mixing rangeImprove mixing effectShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringSuperplasticizer

Variable-disturbance range polycarboxylate superplasticizer preparing equipment comprises a kettle body, a transmission device, a machine frame and a first rotating shaft, wherein mounting bases are symmetrically arranged on the outer side wall of the kettle body; lifting bodies are fixedly mounted on the mounting bases; the free ends of the two lifting bodies are jointly fixedly connected with amounting plate; the transmission device is fixed to the mounting plate through the machine frame; the transmission device is connected with the first rotating shaft positioned inside the kettle body.The variable-disturbance range polycarboxylate superplasticizer preparing equipment has the beneficial effects as follows: through stretch and retraction of the lifting bodies, lifting of the mountingplate is driven so as to drive the first rotating shaft to lift in the kettle body, and the first rotating shaft drives a stirring body to lift, so that the stirring range is changed and the stirringeffect is effectively improved; the first rotating shaft drives the stirring body to rotate, stirring bulges arranged on the stirring body stir and mix materials, and during rotation of the stirringbody, the materials enter and exit from through holes to form a turbulent flow, so that the mixing effect is further improved.

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

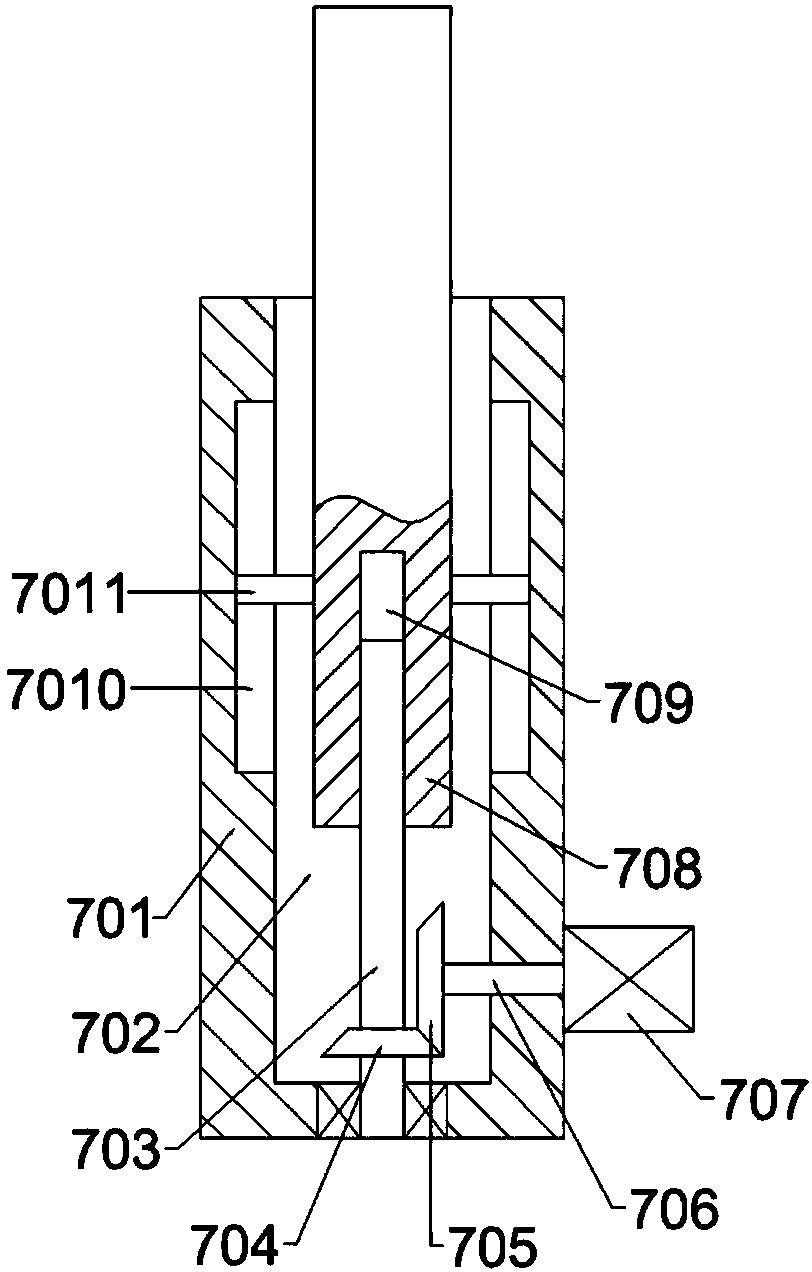

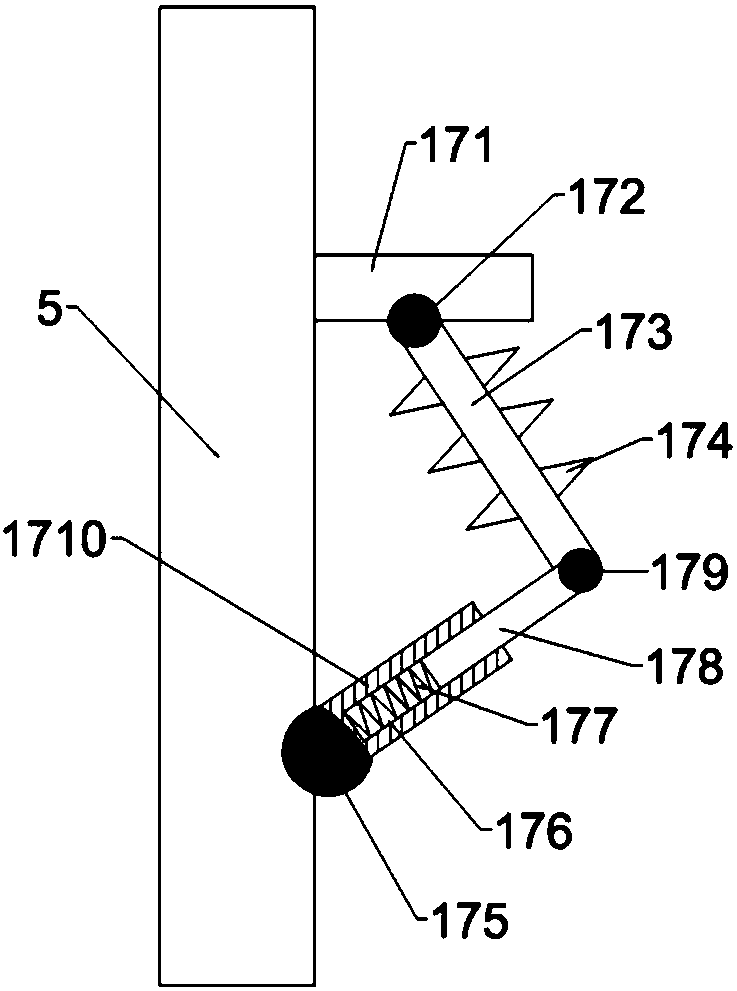

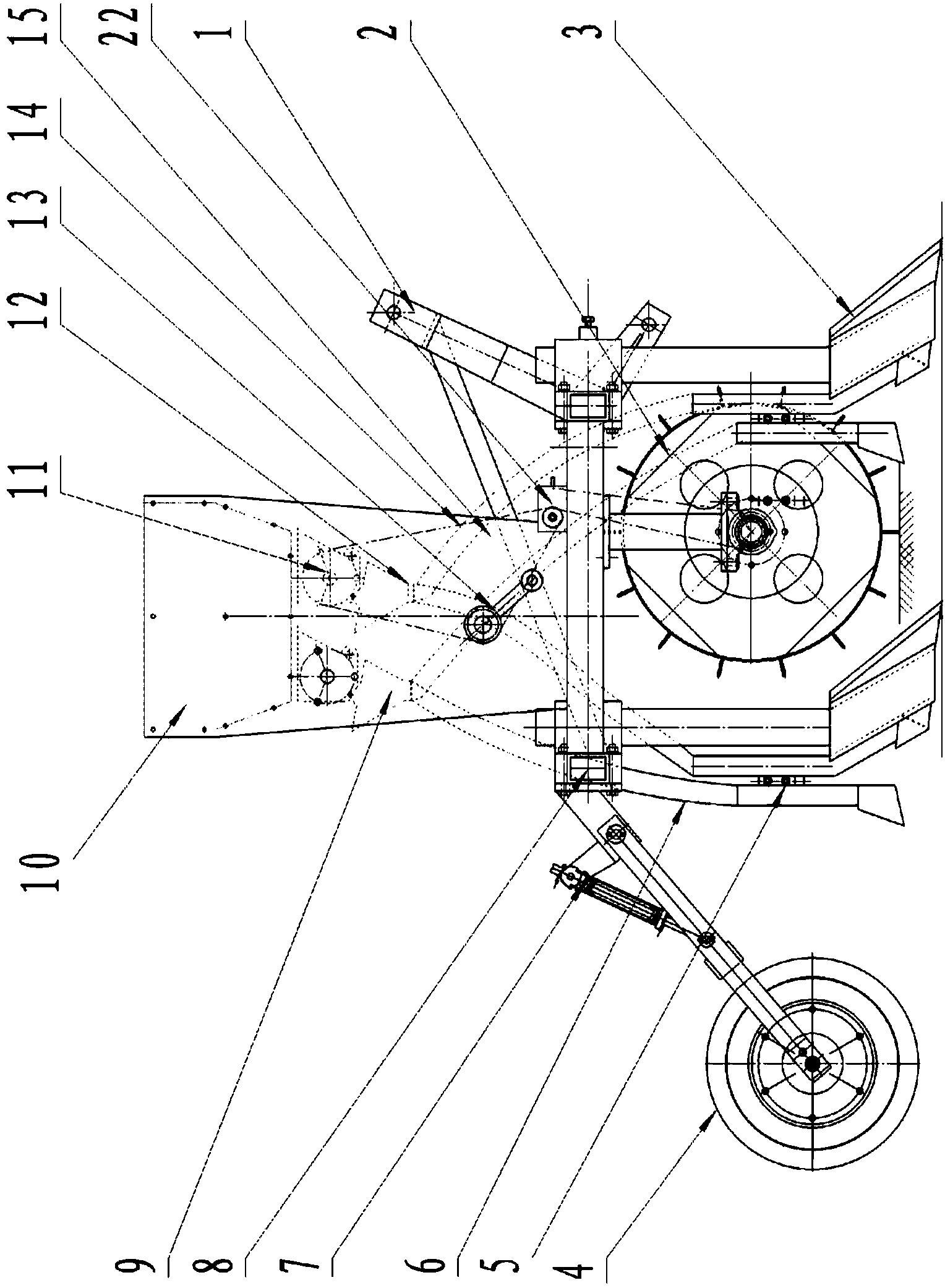

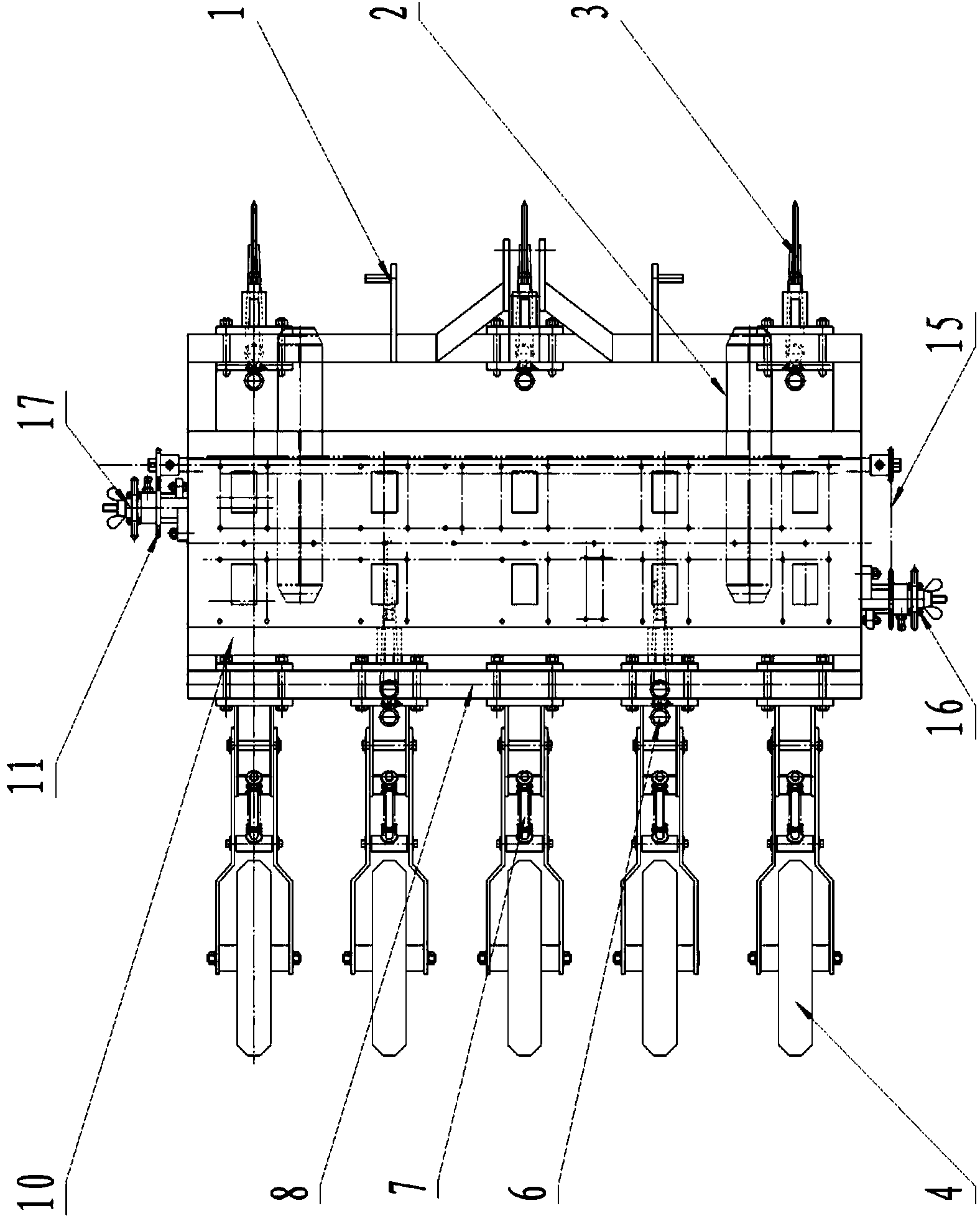

Coarse cereal seeding machine for no-tillage seeding

ActiveCN103444317ASimple structureSimple and fast operationPlantingFurrow making/coveringAgricultural engineeringSoil horizon

The invention discloses a coarse cereal seeding machine for no-tillage seeding. The coarse cereal seeding machine comprises a rack, a fertilizer apparatus, a seed sowing device, a seed manure box, a stubble breaking and ditching device, a suppression mechanism, ground wheels and transmission mechanisms. The machine adopts a stubble breaking, ditching, seed manure applying and seeding single body, a suppression wheel mechanism single body, a high ground clearance and large spacing transverse beam rack and the various transmission mechanisms for intensively changing speeds so as to realize stubble breaking and ditching, seed manure application, and semi-precision no-tillage seeding of wheat, corns, coarse cereals and small-grain pasture seeds. Particularly, the problems of crop stubble winding and blockage, hilling, mixed seed manure application, difficult burying of the ditching device, much disturbance to a soil layer, unevenness of a soil covered ground surface, large traction resistance and the like in the no-tillage seeding process are solved. The machine is simple in structure and easy to operate, has multiple purposes, is low in manufacturing cost and is suitable for specialized households of planting, and small and medium-sized farms to popularize and apply.

Owner:呼和浩特市得利新农机制造有限责任公司

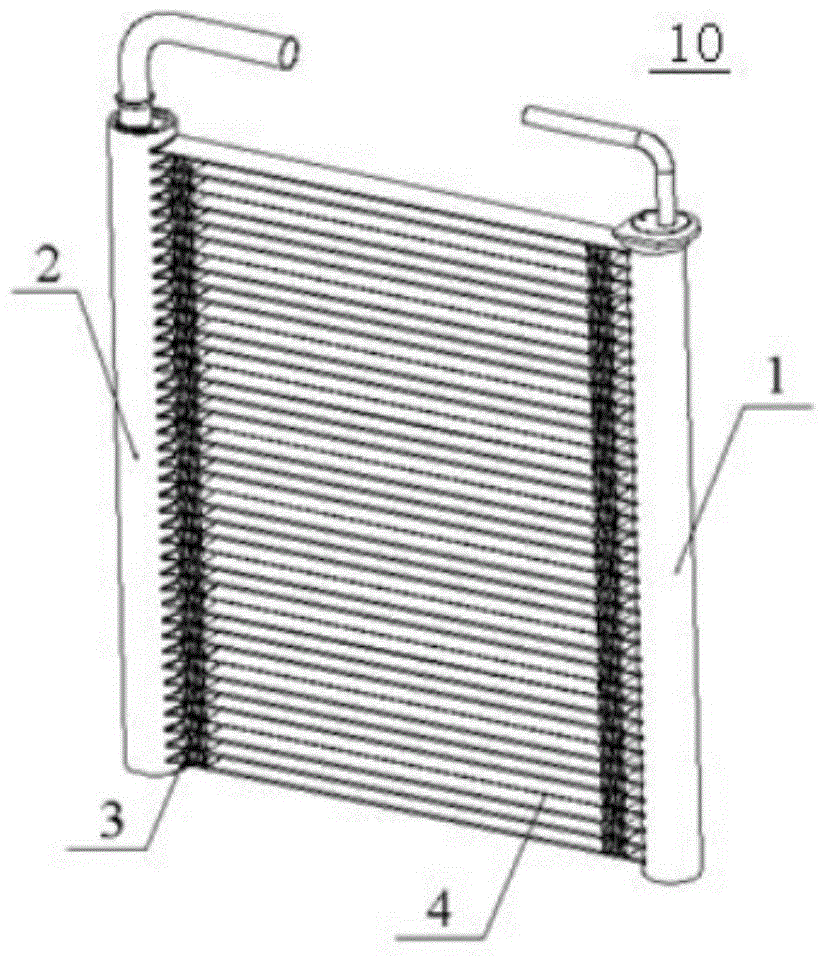

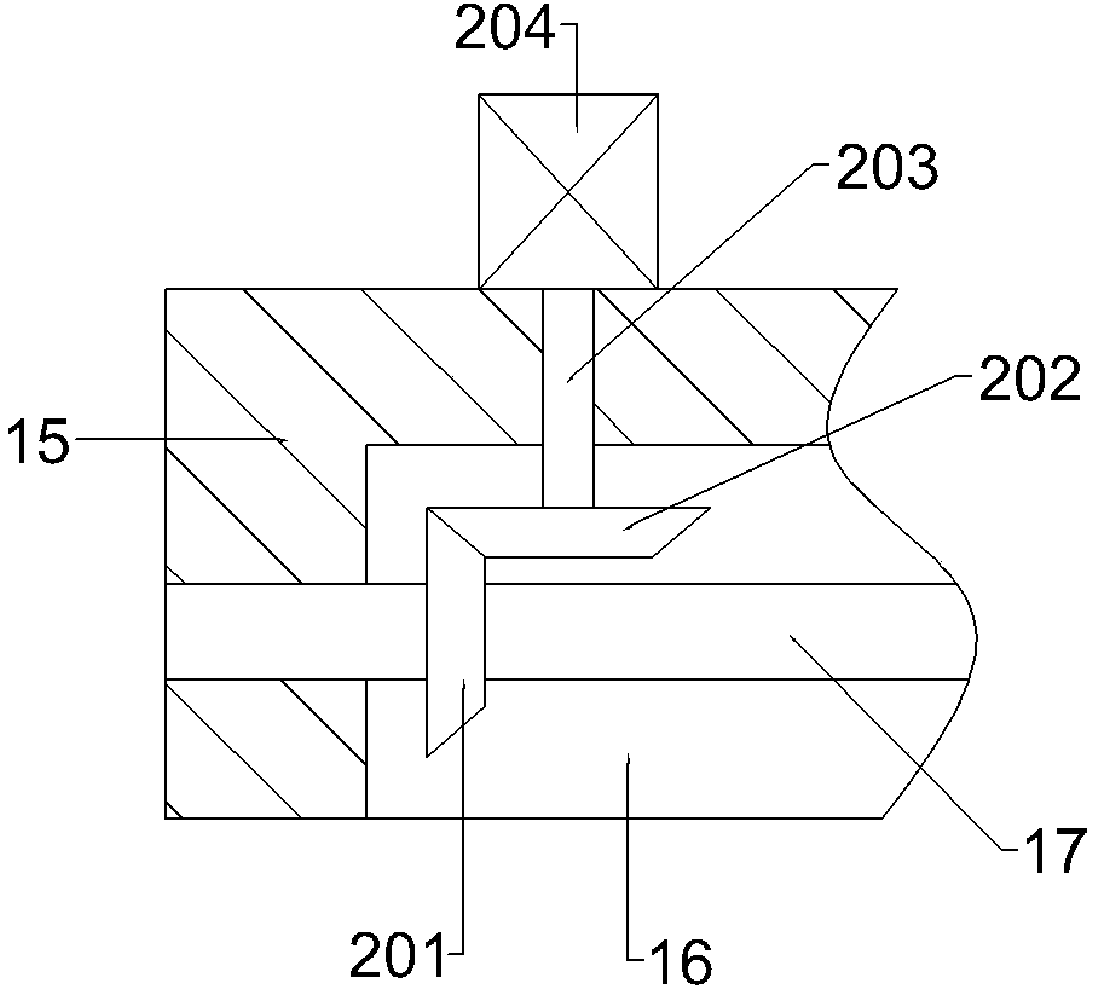

Heat exchanger and internal threaded copper tube thereof

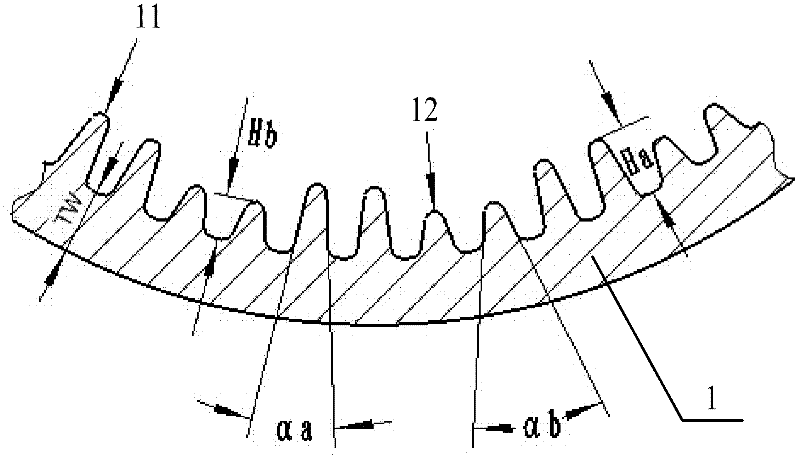

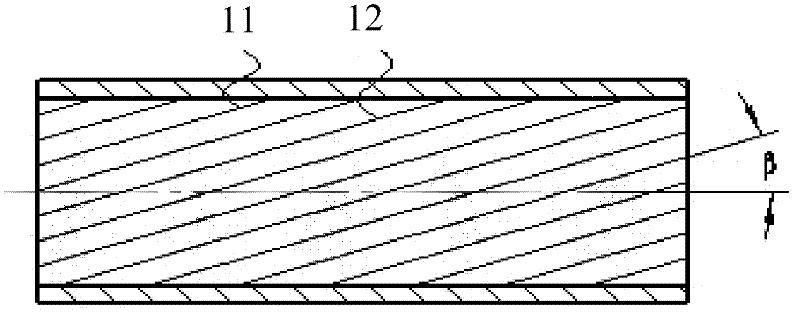

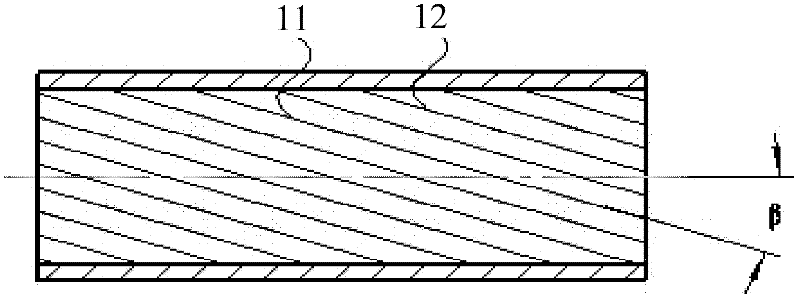

InactiveCN102353296AEnhanced turbulence intensityIncrease disturbanceChemical industryTubular elementsChemical industryHeat transfer efficiency

The invention discloses an internal threaded copper tube. The internal threaded copper tube comprises a tube body (1), wherein internal threaded teeth with different height and various tooth shapes are formed on the inner wall of the tube body (1) and are alternately distributed. Due to the difference of the tooth shapes and the height, the turbulent flow intensity of a coolant is increased, and disturbance on the coolant and heat conduction energy efficiency are improved. In the using process, the tooth shapes of the common internal threaded copper tube are damaged while the tube is expanded, and due to the difference of the tooth shapes and the height, only a part of tooth shapes of the internal threaded copper tube are damaged after the internal threaded copper tube is expanded, and the internal threaded copper tube still has high heat transfer efficiency. By using the optimized design, the weight, production cost and using cost of the tube can be reduced. The internal threaded copper tube is suitable to be widely used in the fields of refrigeration, air conditioning, power generation, sugar making, chemical industry, solar energy and the like.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

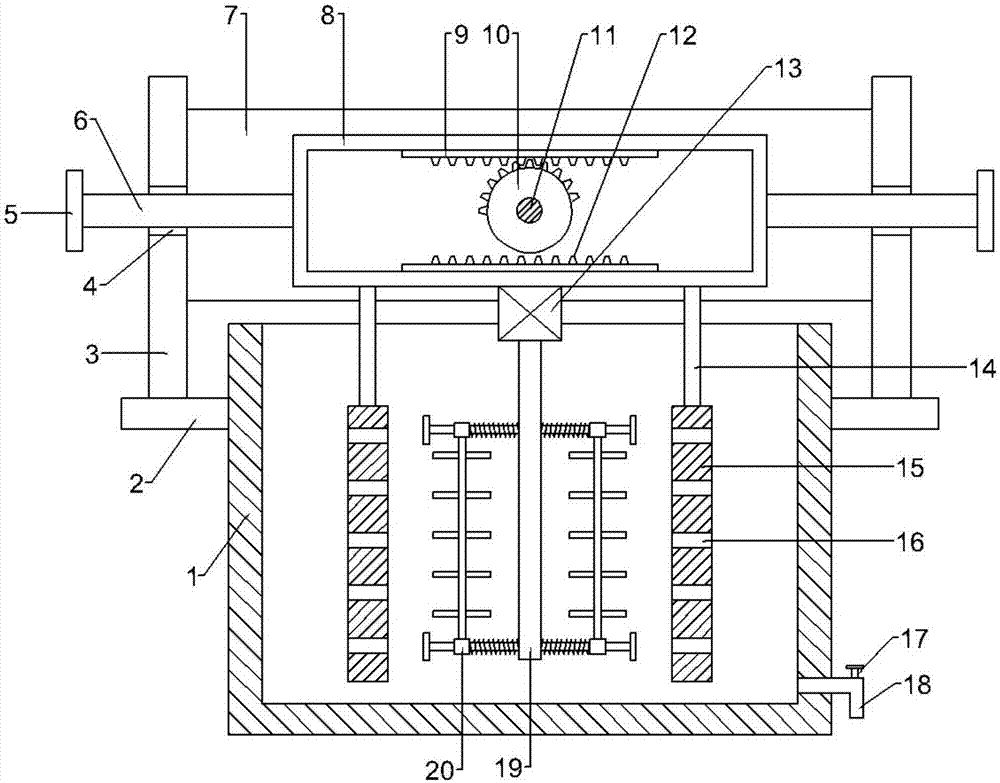

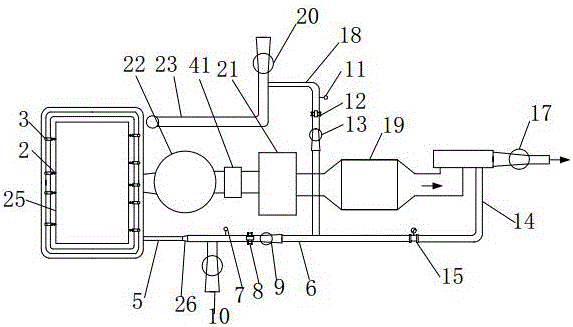

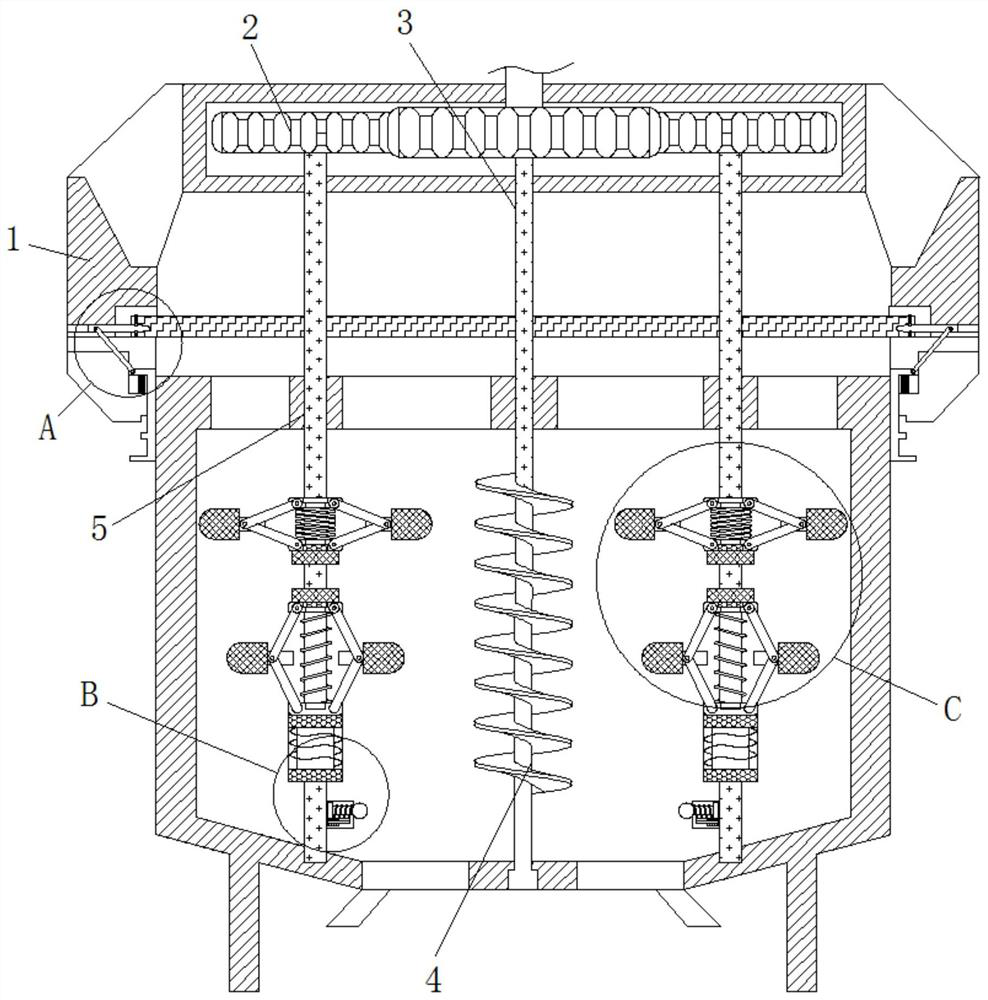

Left-right movable type chemical engineering reaction kettle

InactiveCN107199006AImprove the perturbation effectImprove the mixing effectShaking/oscillating/vibrating mixersTransportation and packagingChinese charactersMovable type

The invention discloses a left-right movable type chemical engineering reaction kettle which comprises a kettle body. Two installation seats are symmetrically and fixedly connected to an outer lateral wall of the kettle body, supporting plates are fixedly connected to the installation seats, through holes are formed in the upper portions of the supporting plates, movable rods are arranged in the through holes, a left-right movable frame is fixedly connected between the two movable rods, the section of the left-right movable frame is in a shape like a Chinese character hui, a half gear is arranged in the left-right movable frame, a half of gear teeth are distributed on the half gear, a first rotating shaft is fixedly connected to the center of the half gear, cover plates are jointly and fixedly connected to the front sides and the rear sides of the two supporting plates, and the first rotating shaft is erected on the cover plates. The left-right movable type chemical engineering reaction kettle disclosed by the invention has the beneficial effects that the left-right movable frame reciprocate left and right to drive a spoiler to move left and right, the spoiler has a perturbation effect on materials, and meanwhile perturbation holes can further improve the perturbation effect on the materials; the left-right movable frame further drives a stirring device to move left and right, a stirring range is changed, and a stirring effect is improved.

Owner:SHENZHEN XINGDINGYUAN TECH CO LTD

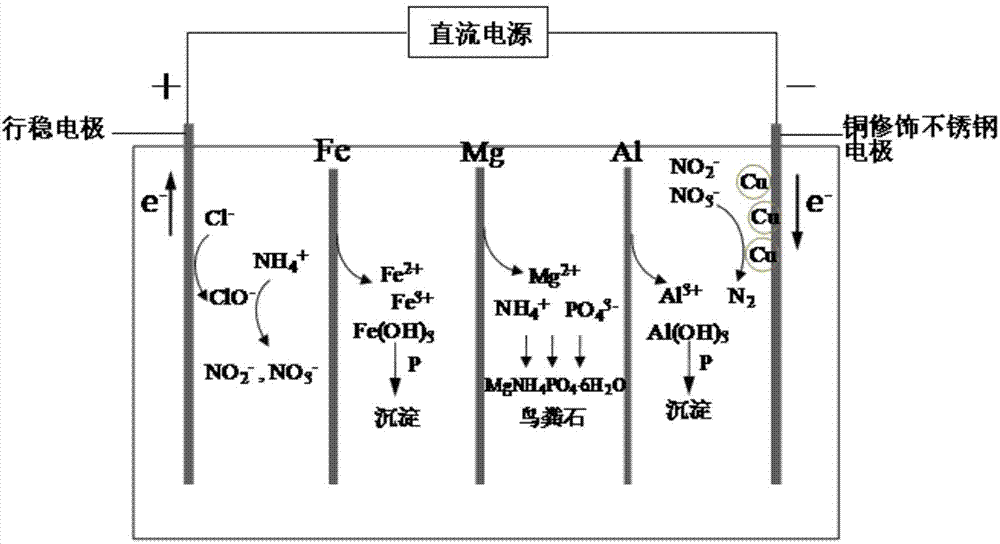

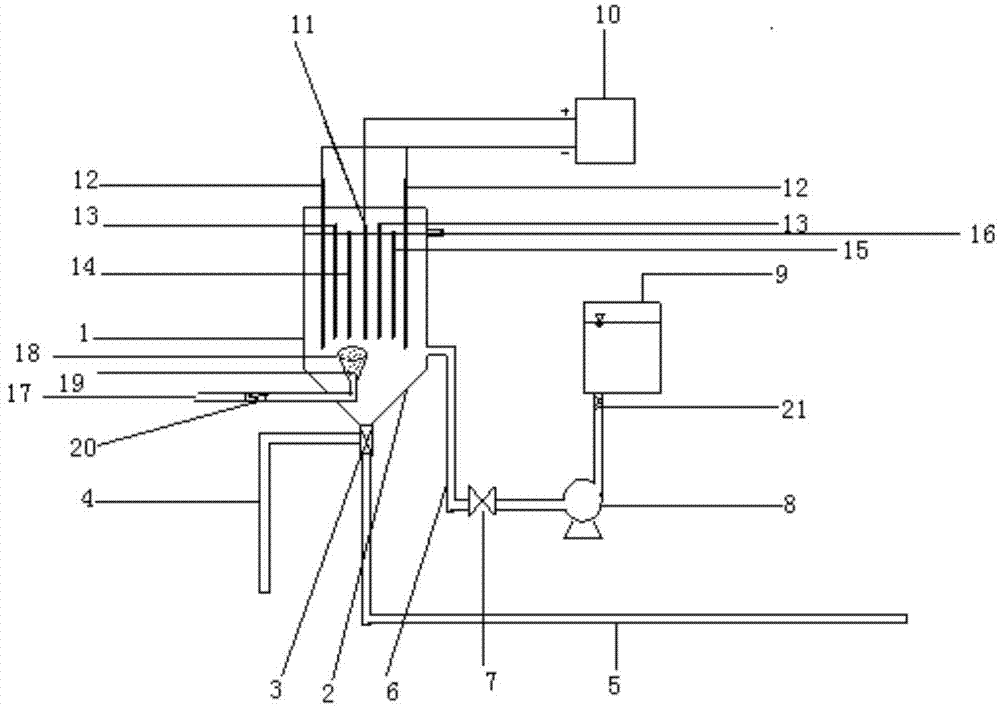

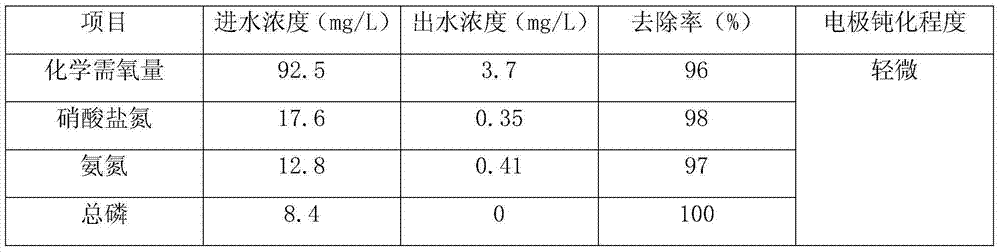

Electrochemical synchronous nitrogen and phosphorus removal apparatus and municipal sewage treatment method

InactiveCN103936106ASimple structureEasy to operateWater/sewage treatment using germicide/oligodynamic-processChemical oxygen demandMaterial resources

The invention discloses an electrochemical synchronous nitrogen and phosphorus removal apparatus and a municipal sewage treatment method, and belongs to the technical field of sewage treatment. A dimensionally stable electrode, an iron electrode, an aluminum electrode, a magnesium electrode and a copper modified stainless steel electrode which are commonly used in an electrochemical water treatment technology are combined to realize the nitrogen and phosphorus removal treatment of the municipal sewage in a same electrolytic cell. The apparatus has the advantages of simple structure, operation convenience, high efficiency, stable indexes of discharged water, and realization of the large-scale automatic sewage treatment. The municipal sewage method has the advantages of simple technology, operation convenience, manpower and material resource saving, low energy consumption, high removal rate of sewage pollution indexes, and realization of the removal rate of each of the municipal sewage indexes comprising the chemical oxygen demand, nitrate nitrogen, ammonia nitrogen and total phosphorus to reach above 92%.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Low-nitrogen combustion technique based on circulating fluidized bed boiler

ActiveCN106051749ASolve the reduction of NOx emissionsSolve the high carbon content of fly ashFluidized bed combustionFluegas recirculationBurning outCirculating fluidized bed boiler

The invention discloses a low-nitrogen combustion technique based on circulating fluidized bed boiler. The circulating fluidized bed boiler comprises a boiler body, a cyclone separator, a deduster, an induced draft fan, a primary air supply system and a secondary air supply system which are connected in sequence. A smoke recirculation pipe is drawn out behind the induced draft fan. The primary air supply system and the secondary air supply system are connected to the smoke recirculation pipe in parallel. A burn-out chamber is arranged at an outlet of the cyclone separator. The low-nitrogen combustion technique based on the circulating fluidized bed boiler comprises the following steps that pulverized coal enters the boiler body under the action of primary air, specifically, the amount of smoke recirculation air in the primary air accounts for 8-10% the total air amount of the primary amount, and the amount of the primary air accounts for 40-45% of the total air amount; secondary air is introduced into the boiler body through the secondary air supply system, specifically, the amount of smoke recirculation air in the secondary air accounts for 12-14% the total air amount of the secondary air; fine flying ash enters the burn-out chamber; and over fire air is introduced into the burn-out chamber. According to the low-nitrogen combustion technique based on the circulating fluidized bed boiler, the burn-out chamber is arranged at the outlet of the separator, and part of smoke is mixed into the primary air and the secondary air, so that generation of NOx is reduced.

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

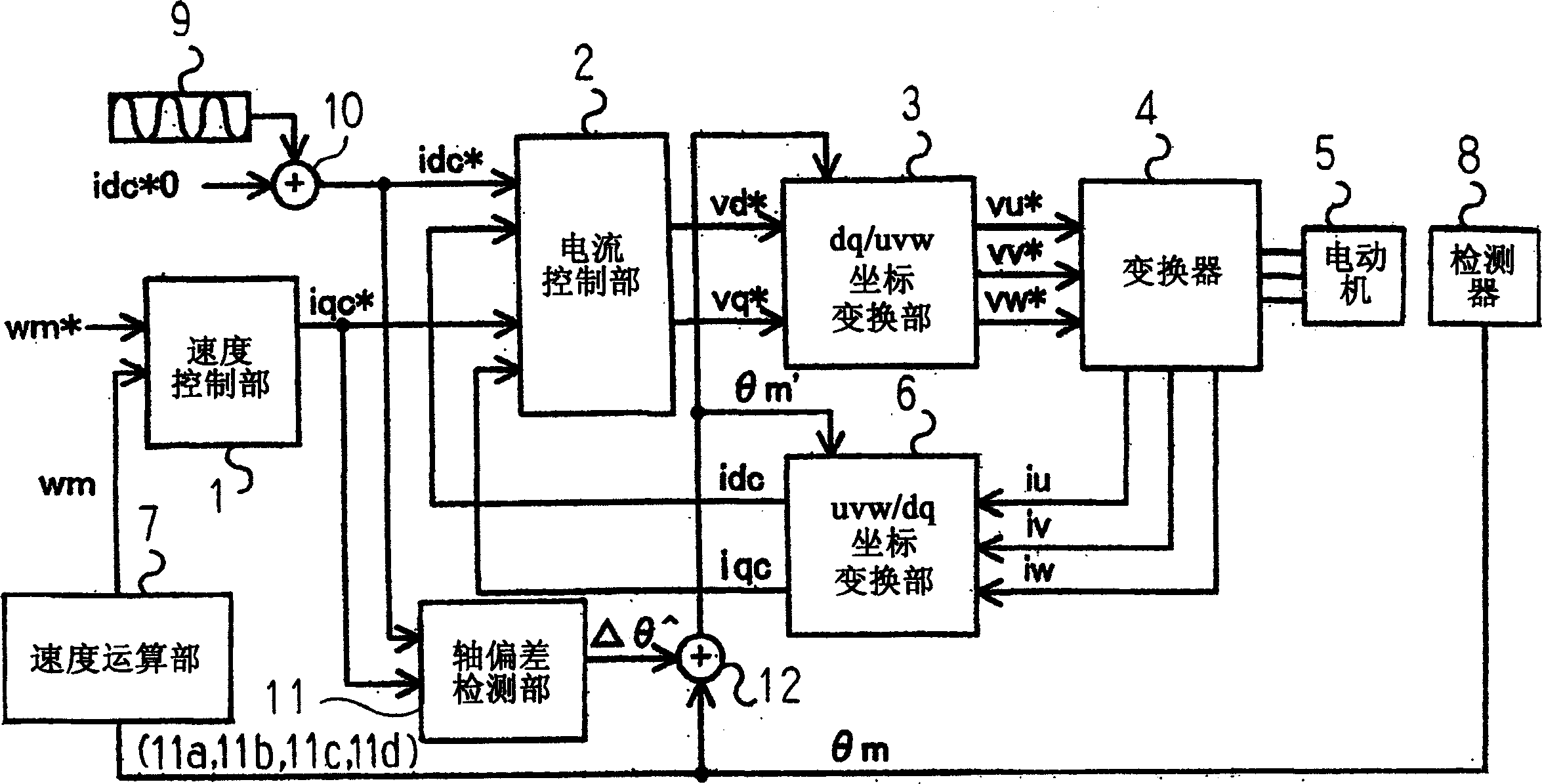

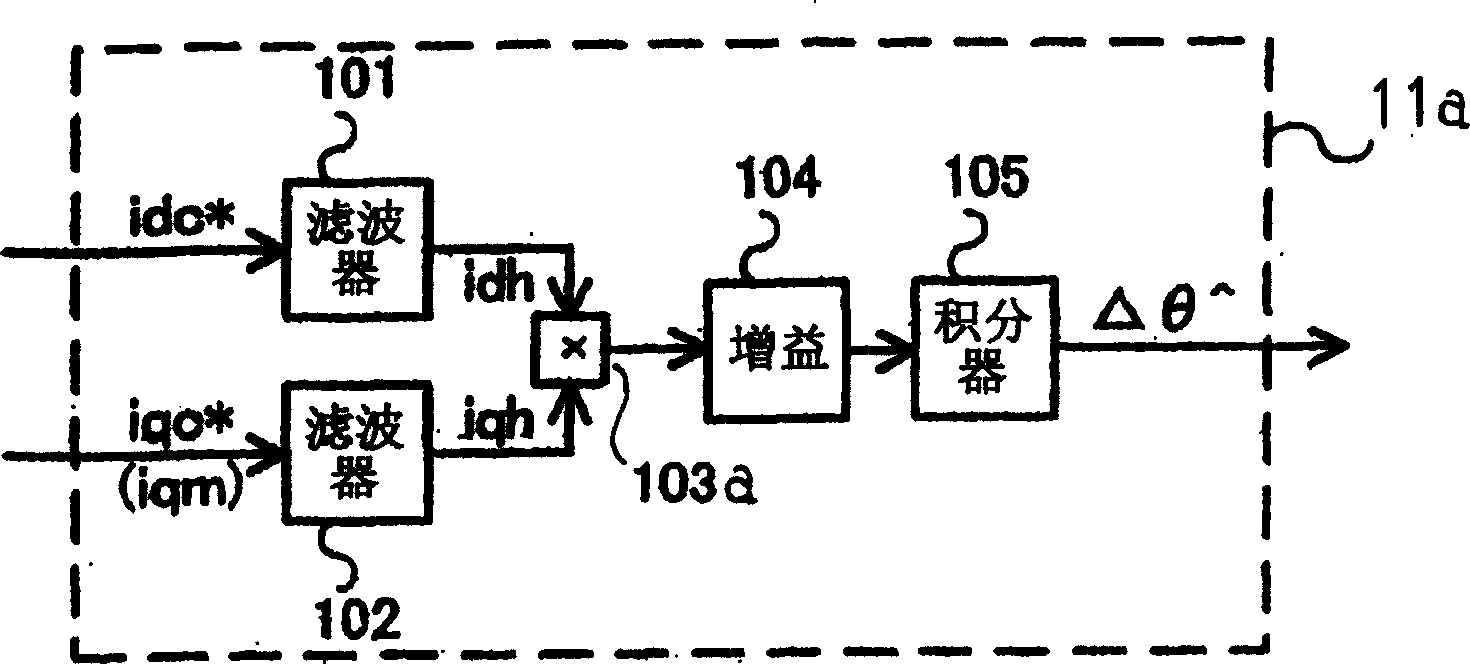

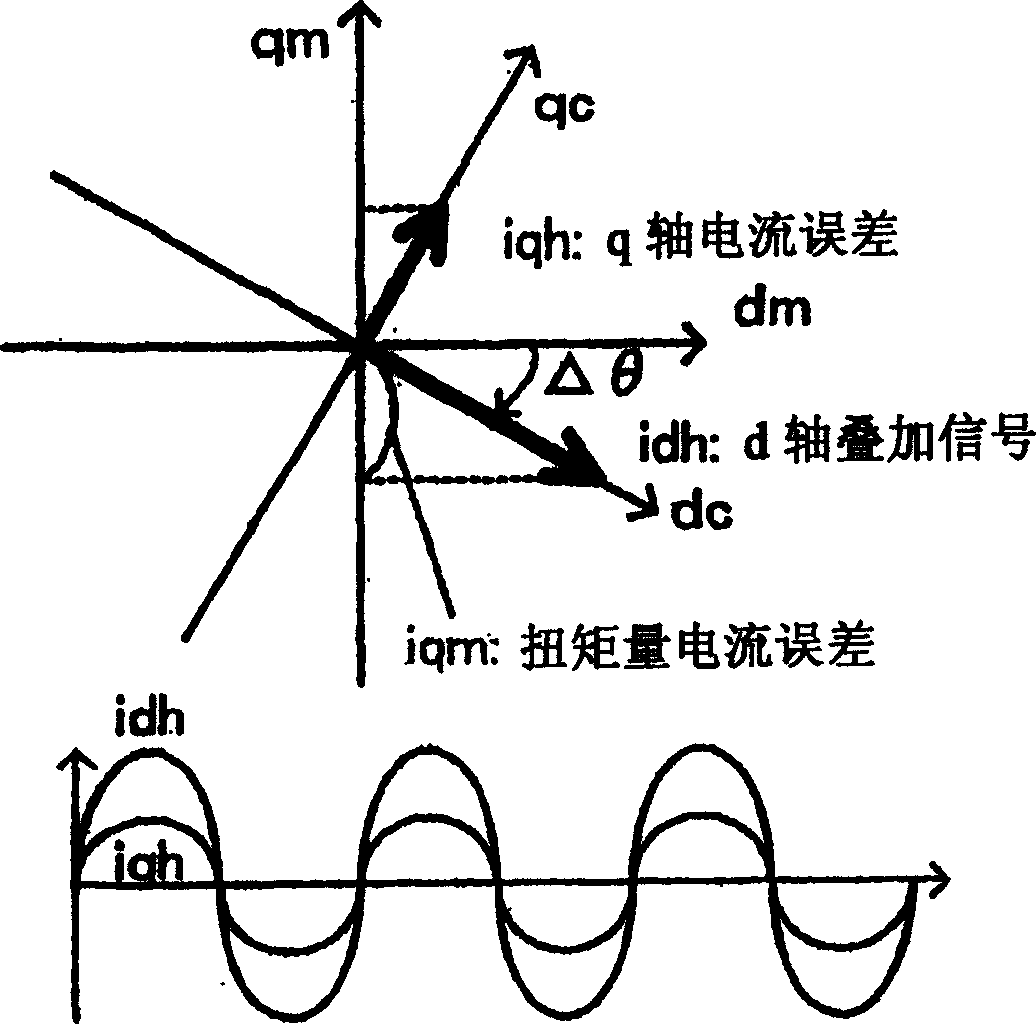

Motor controller

InactiveCN1902813AEasy to operateReal-time correctionVector control systemsSingle motor speed/torque controlMotor speedSuperimposition

A motor controller wherein a superimposition signal generating section outputs a superimposition signal idh of repetitive waveform such as a triangular wave or a sine wave during motor speed control, a d-axis current command generating section adds the superimposition signal idh to a d-axis current command idc*0 to output a d-axis current command idc*, an axis offset detection section receives the d-axis current command idc* and a q-axis current command iqc* to output an axis offset angle estimate deltatheta', an axis offset correction section receives the axis offset angle estimate deltatheta' and an actually detected position thetam to output a corrected position thetam'. The axis offset can be detected and corrected by computation at a given time in real time during normal operation.

Owner:MITSUBISHI ELECTRIC CORP

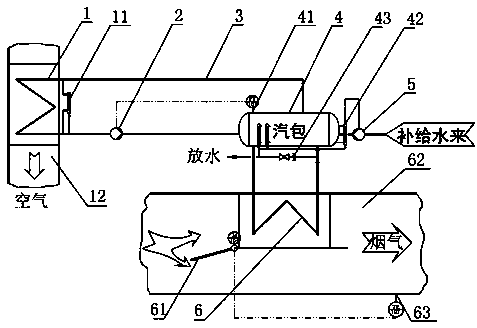

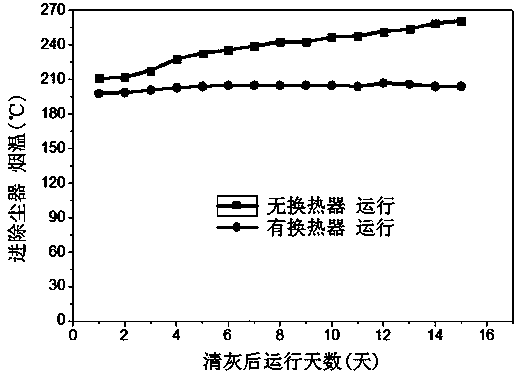

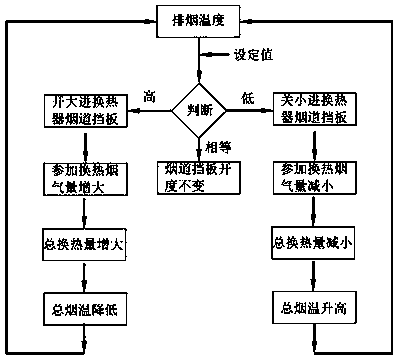

Device and method for waste heat recovery based on control over outlet smoke temperature

ActiveCN104006371AMeet temperature control requirementsSafe and stable operationSteam boilersSteam boilers componentsWaste heat recovery unitSteam pressure

The invention relates to a device for waste heat recovery based on control over outlet smoke temperature. According to the device, a smoke adjusting baffle and a bypass flue are arranged in an original flue and a temperature sensor is arranged in the flue; the bypass flue is communicated with a smoke heat exchanger and the smoke heat exchanger is connected with a steam pocket; the steam pocket is communicated with an air heat exchanger in an air side flue through a saturated steam output pipe and the air heat exchanger is further communicated with the steam pocket through a condensate water input pipeline so that circulation can be formed; a condensate water circulation pump is arranged on the condensate water input pipeline; a liquid level sensor is arranged on the air heat exchanger; the steam pocket is provided with a steam pocket pressure sensor. The outlet smoke temperature is controlled by the adjusting baffle, smoke is shunted by the adjusting baffle, and therefore it is guaranteed that the temperature of the discharged smoke is stabilized at a set value; according to control over the steam pressure of the steam pocket, the backflow speed of condensate water is controlled to control the heat exchange area of a heat exchange system, and therefore control over the heat exchange power of the heat exchangers is achieved.

Owner:常熟浦发热电能源有限公司 +1

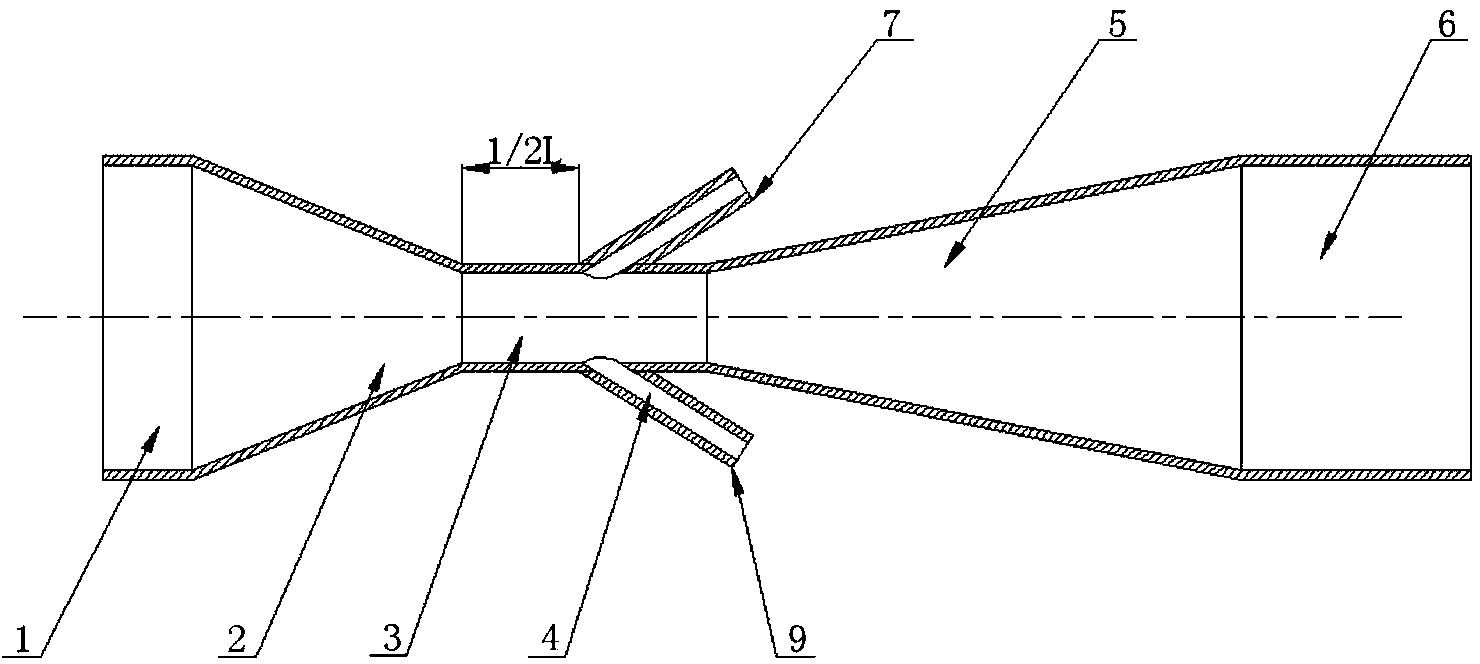

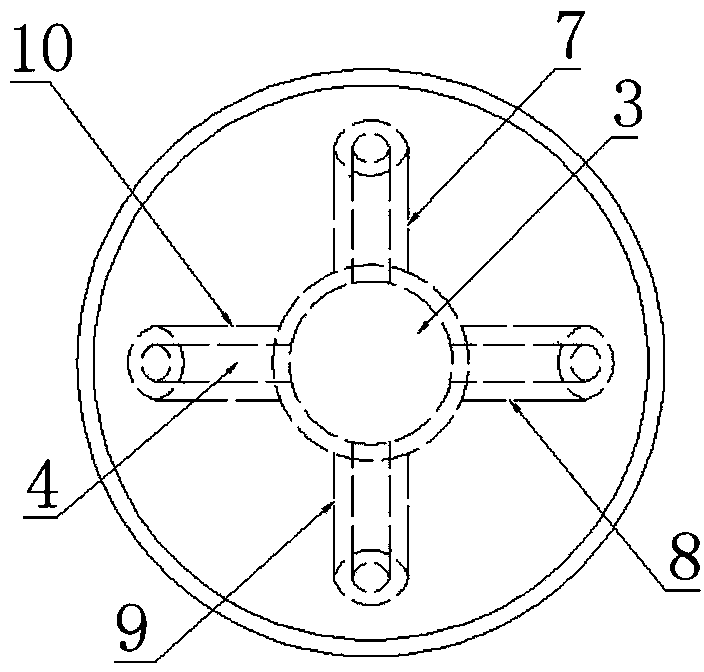

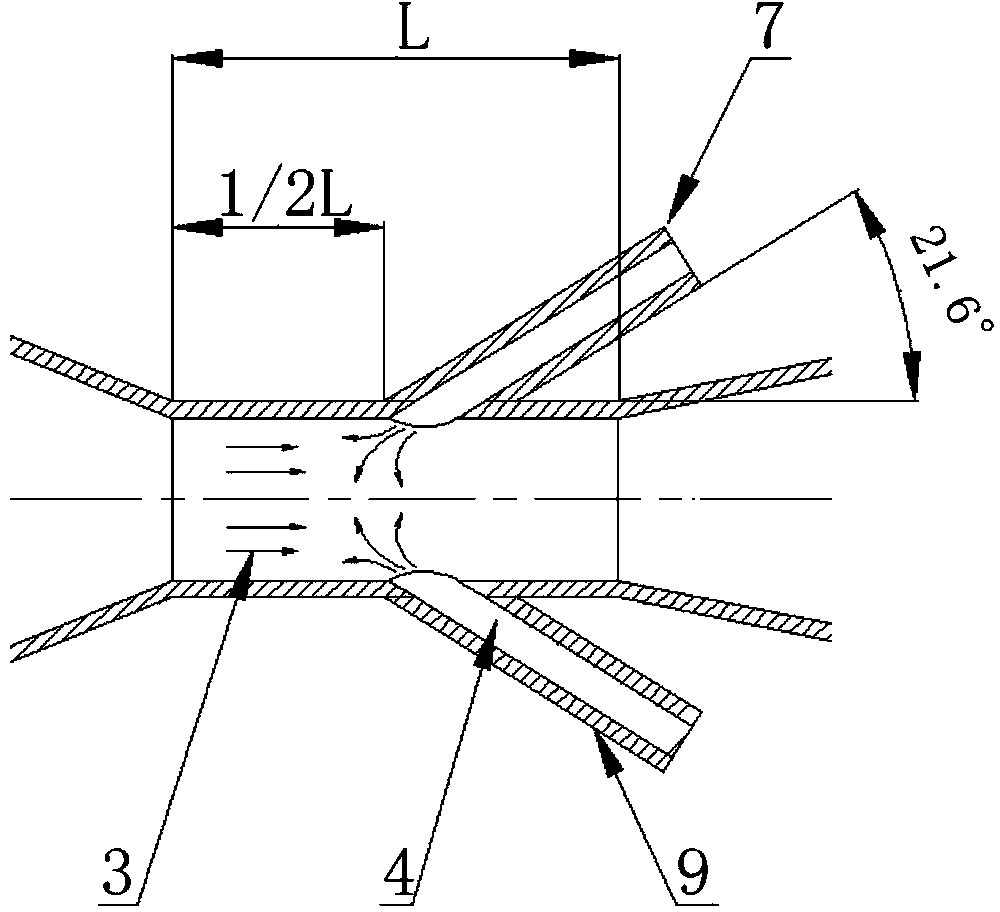

Venturi mixer with symmetrical inlet pipes at throat part

ActiveCN104028132AOvercoming Mixing InefficienciesImprove mixing efficiencyFlow mixersThroatEngineering

The invention discloses a venturi mixer with symmetrical inlet pipes at a throat part. The venturi mixer comprises a mainstream venturi pipe flow-in pipeline, a mainstream venturi pipe tapered section, the mainstream venturi pipe throat part, a mainstream venturi pipe diffusion section and a mainstream venturi pipe flow-out pipeline, wherein the mainstream venturi pipe throat part is symmetrically provided with a first inlet pipe, a second inlet pipe, a third inlet pipe and a fourth inlet pipe which are oblique toward the mainstream venturi pipe diffusion section, are communicated with the mainstream venturi pipe throat part and are centrally provided with open pores in which an inlet fluid flows. Compared with a traditional single inlet mode, the mode disclosed by the invention has the advantages that the inlet fluid can be distributed more uniformly; a mainstream fluid flows through the throat part, and converges with the inlet fluid at the center of the throat part so as to form intense reverse opposite impact, so that the influence to a mixing effect of a boundary layer is reduced fully, the turbulent effect increases, the mixing effect of the mainstream fluid and the inlet fluid nearby the central line is improved, the mixing efficiency is improved effectively, and the using range of the venturi mixer is expanded.

Owner:度测(上海)科技服务中心

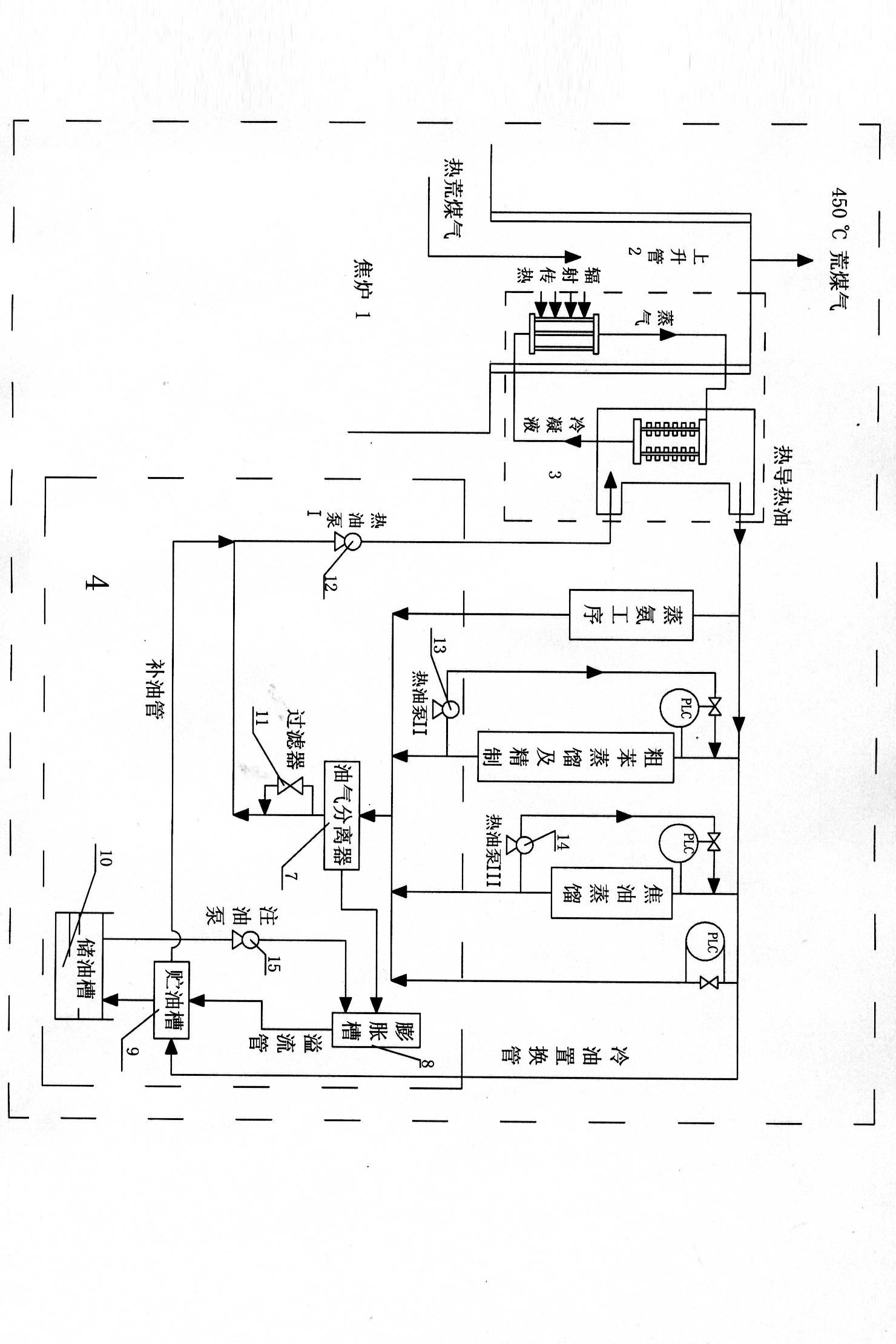

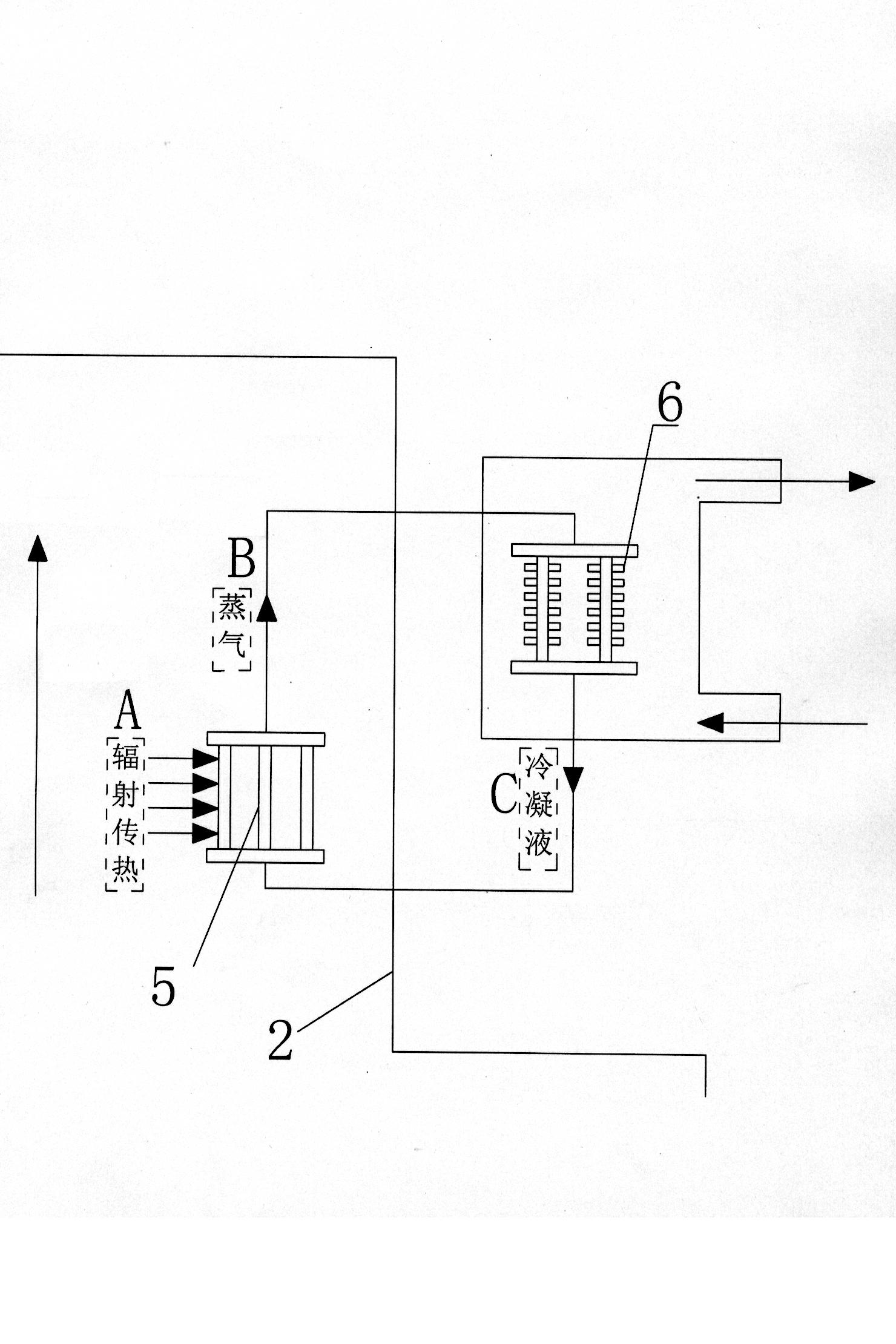

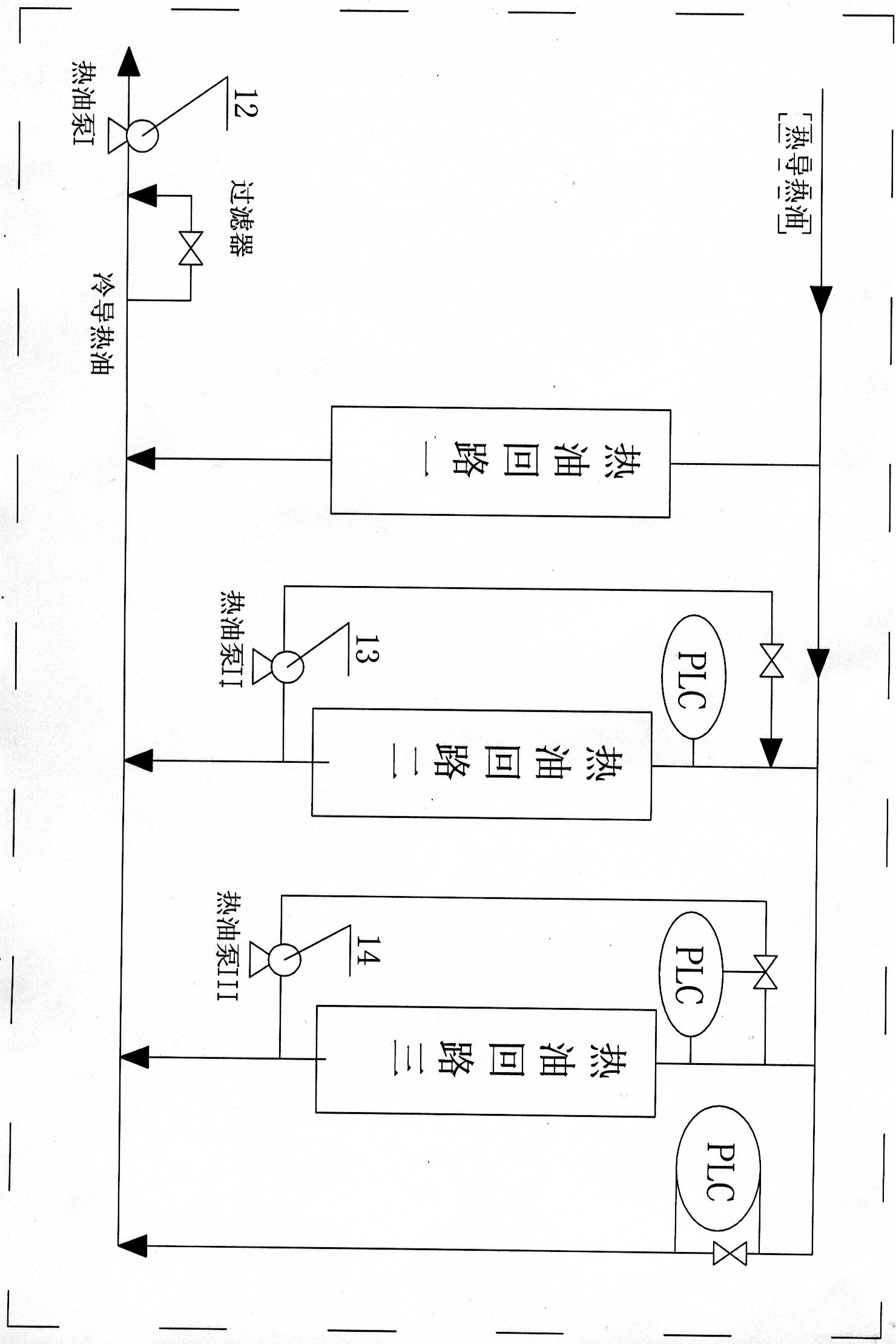

Integrated technique and special equipment for raw gas waste heat recovery and steam replacement with heat transfer soil

ActiveCN102519285AIncrease the heat exchange areaReduce convection heat transfer thermal resistanceEnergy industryIndirect heat exchangersHeating systemDistillation

The invention relates to an integrated technique and special equipment for raw gas waste heat recovery and steam replacement with heat transfer soil. The integrated technique and the special equipment are mainly characterized in that high-temperature separation heat pipes are used to recover latent heat of high-temperature raw gas from a coking chamber, the recovered heat is transmitted to heat transfer oil, the heated transfer oil supplies required heat to various coking procedures of chemical production operational units (an ammonia evaporation procedure, crude benzene distillation and refining procedures, a coke distillation procedure), the heat transfer oil in a whole chemical production system cycles in closed loops, and temperature and flow are regulated and controlled according different requirements of the units on operational heat sources. Compared with the prior art, the integrated technique and the special equipment can be used for efficiently recovering high-quality waste heat of raw coke oven gas, energy consumption of the coking procedure is reduced, consumption of circulating ammonia water in spraying is reduced, heat transfer oil heating systems for the chemical production operational units and addition heat required by the heat transfer oil heating systems are omitted, and closed-loop circulation of the heat transfer soil and cascade use of the waste heat are achieved.

Owner:NORTHEASTERN UNIV

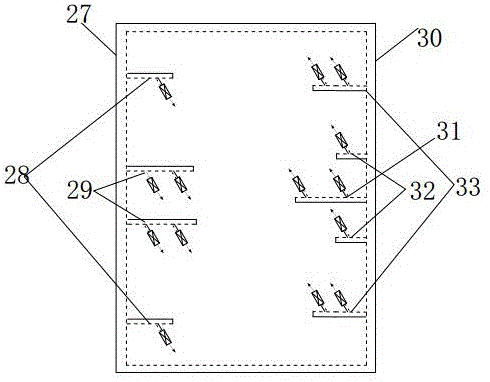

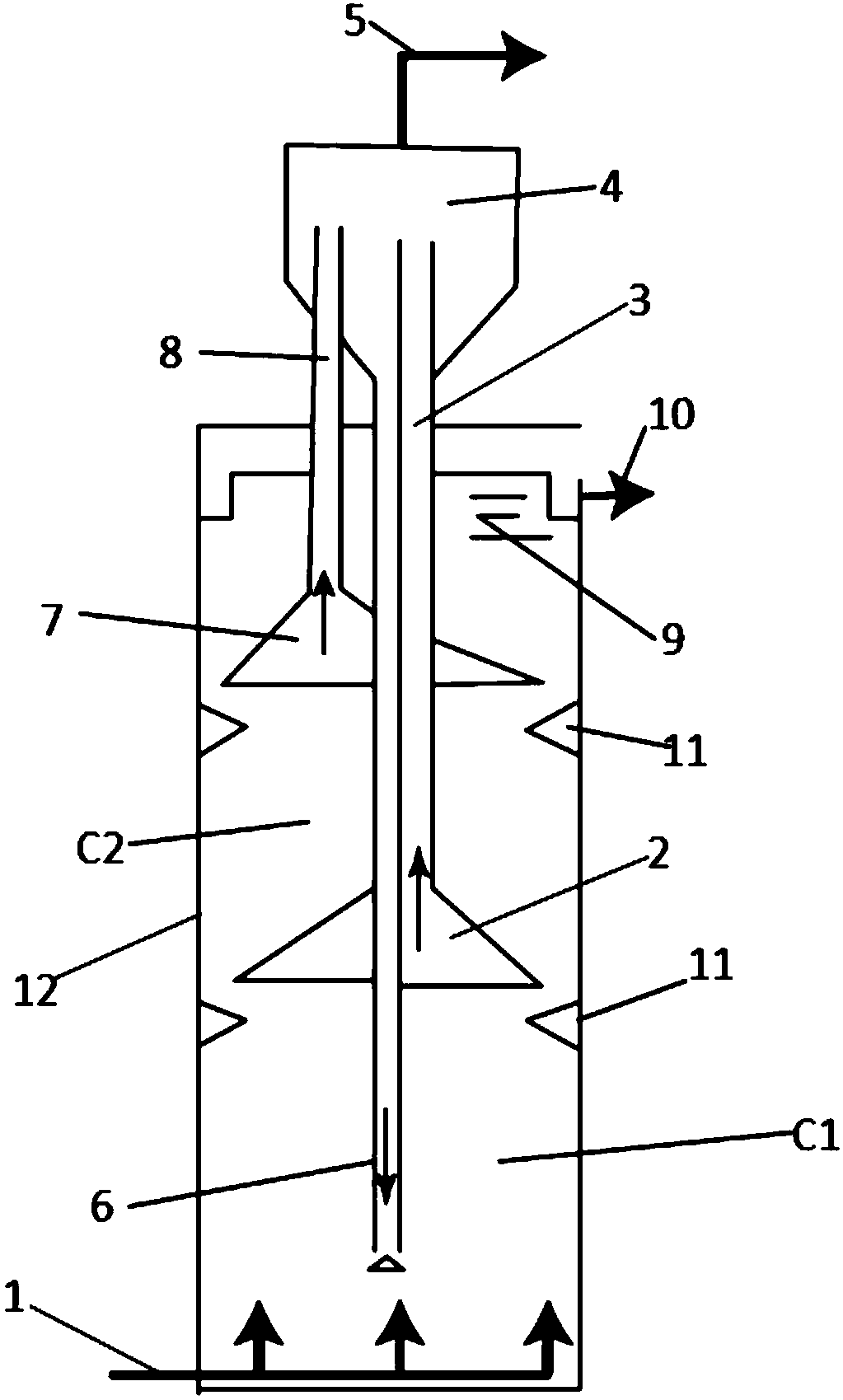

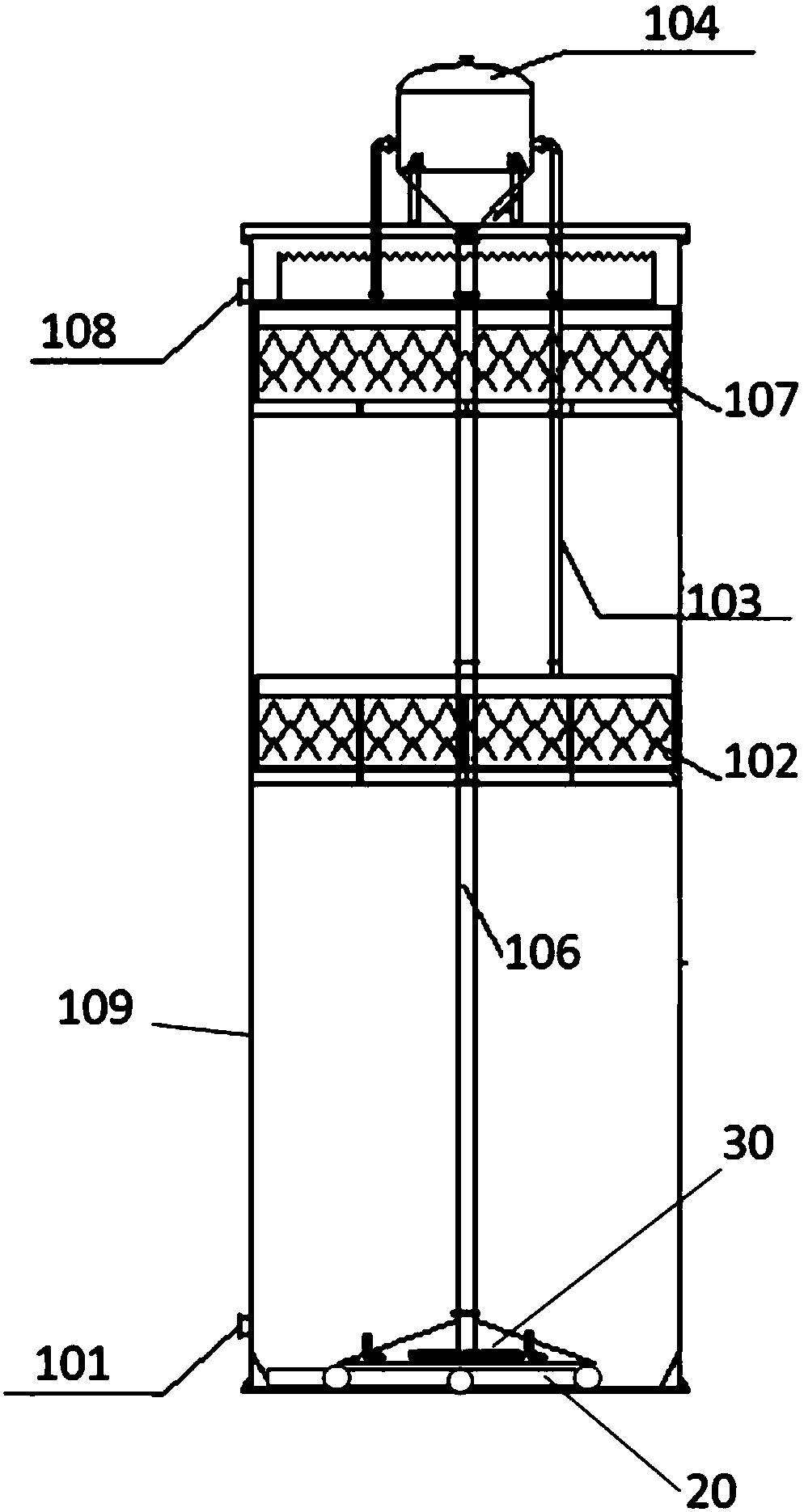

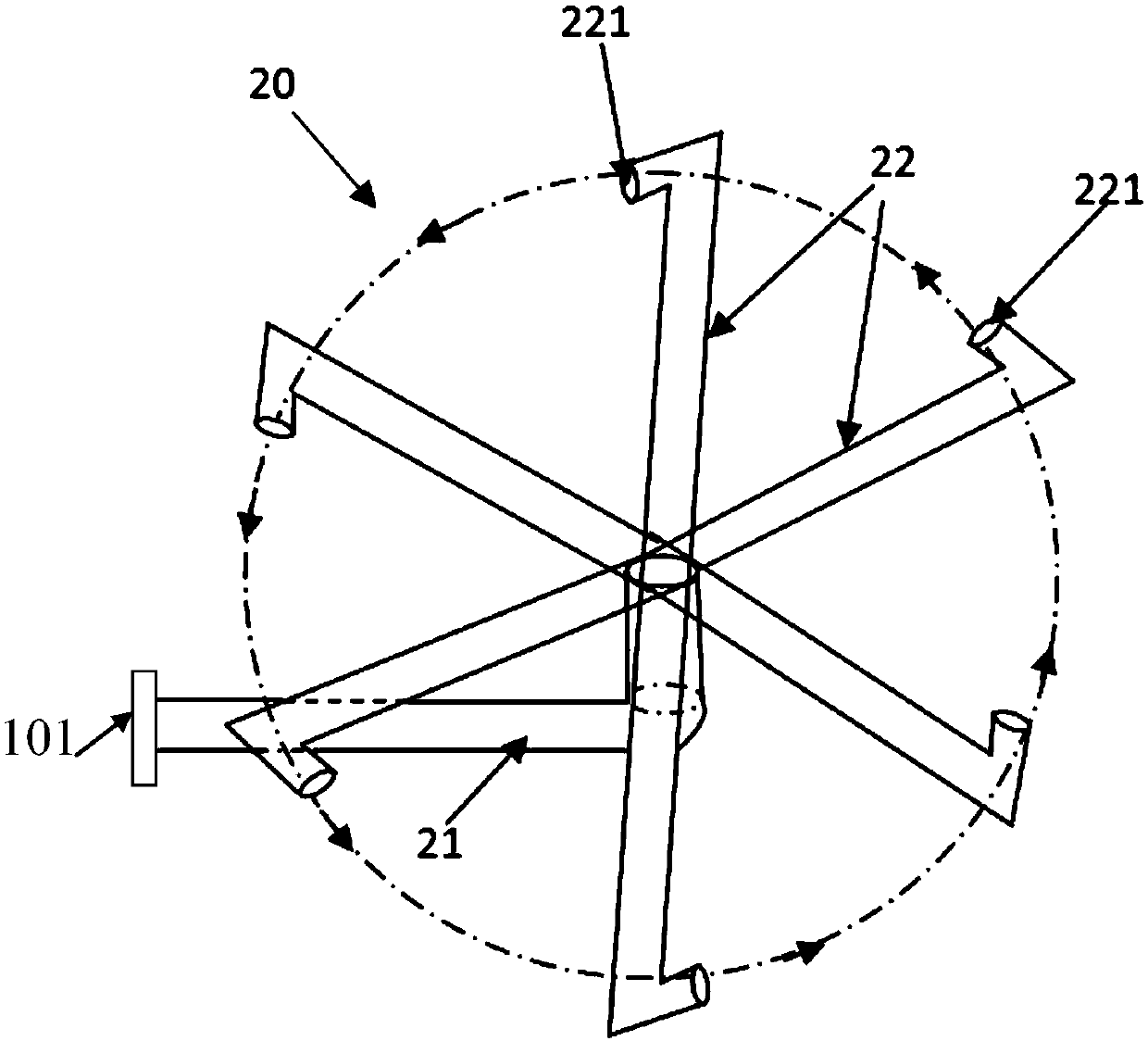

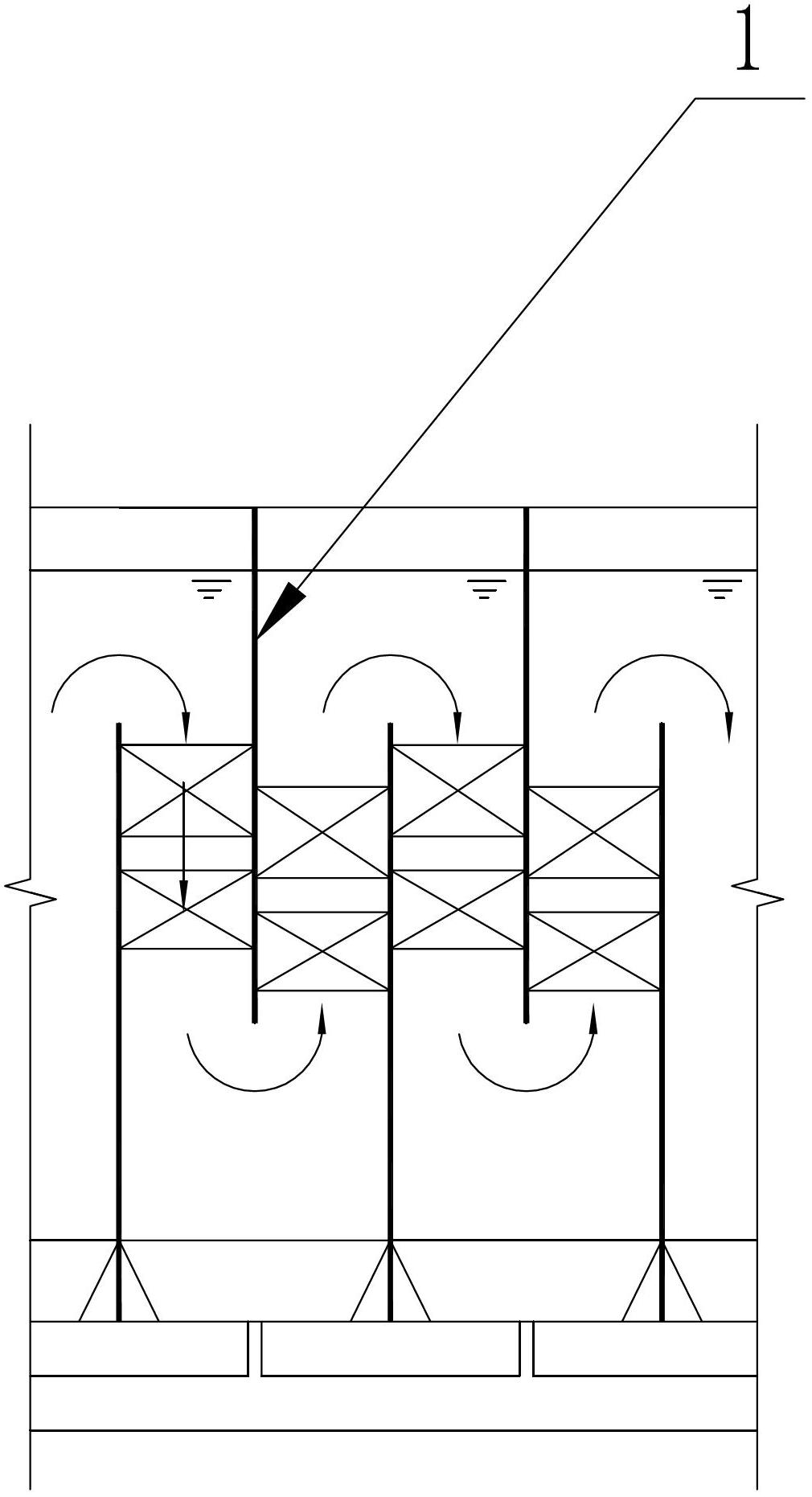

Rotary water-distributing type IC anaerobic reactor

PendingCN107720960AImprove processing efficiencyImprove mass transfer effectBiological treatment apparatusTreatment with anaerobic digestion processesWater dischargeSewage

The invention relates to a rotary water-distributing type IC (internal circulation) anaerobic reactor. The rotary water-distributing type IC anaerobic reactor comprises a reaction tower, wherein the bottom of the reaction tower is provided with a water inlet, a water discharging opening is formed in the upper part of the reaction tower, and a water introducing and distributing device, a reflux water distributing device, an inner reflux pipe, a first three-phase separator, a second three-phase separator and a gas-water separator are arranged in the reaction tower from bottom to top sequentially; the upper end of the inner reflux pipe communicates with the gas-water separator, and the lower end of the inner reflux pipe is arranged towards the bottom of the reaction tower; the upper part of the first three-phase separator and the upper part of the second three-phase separator are each connected with a biogas collecting pipe which communicates with the gas-water separator, and the water inlet is connected with the water introducing and distributing device which comprises a main connecting pipe; and one end of the main connecting pipe is provided with two or more branch pipes which areradially arranged, each branch pipe is provided with a water inlet hole, and the water inlet holes all face to the counter-clockwise direction or the clockwise direction. In the way, sewage which is injected into the water inlet can be mixed with anaerobic bacteria-containing sludge in the tower evenly, so that the effect of mass transfer between the sewage and anaerobic bacteria is improved.

Owner:河南小威环境科技有限公司

Command current extraction method and compensating current generation method for active power filter

InactiveCN102025157AImprove real-time performanceImprove the perturbation effectActive power filteringHarmonic reduction arrangementHysteresisPower flow

The invention discloses a command current extraction method and a compensating current generation method for an active power filter. The command current is extracted by a digital phase-locked loop method and the compensating current is generated by a hysteresis current control method, so that the real time of an active power filtering device is improved, and the capability of the active power filtering device of inhibiting the disturbance in a loop is enhanced and the performance of a system is greatly improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

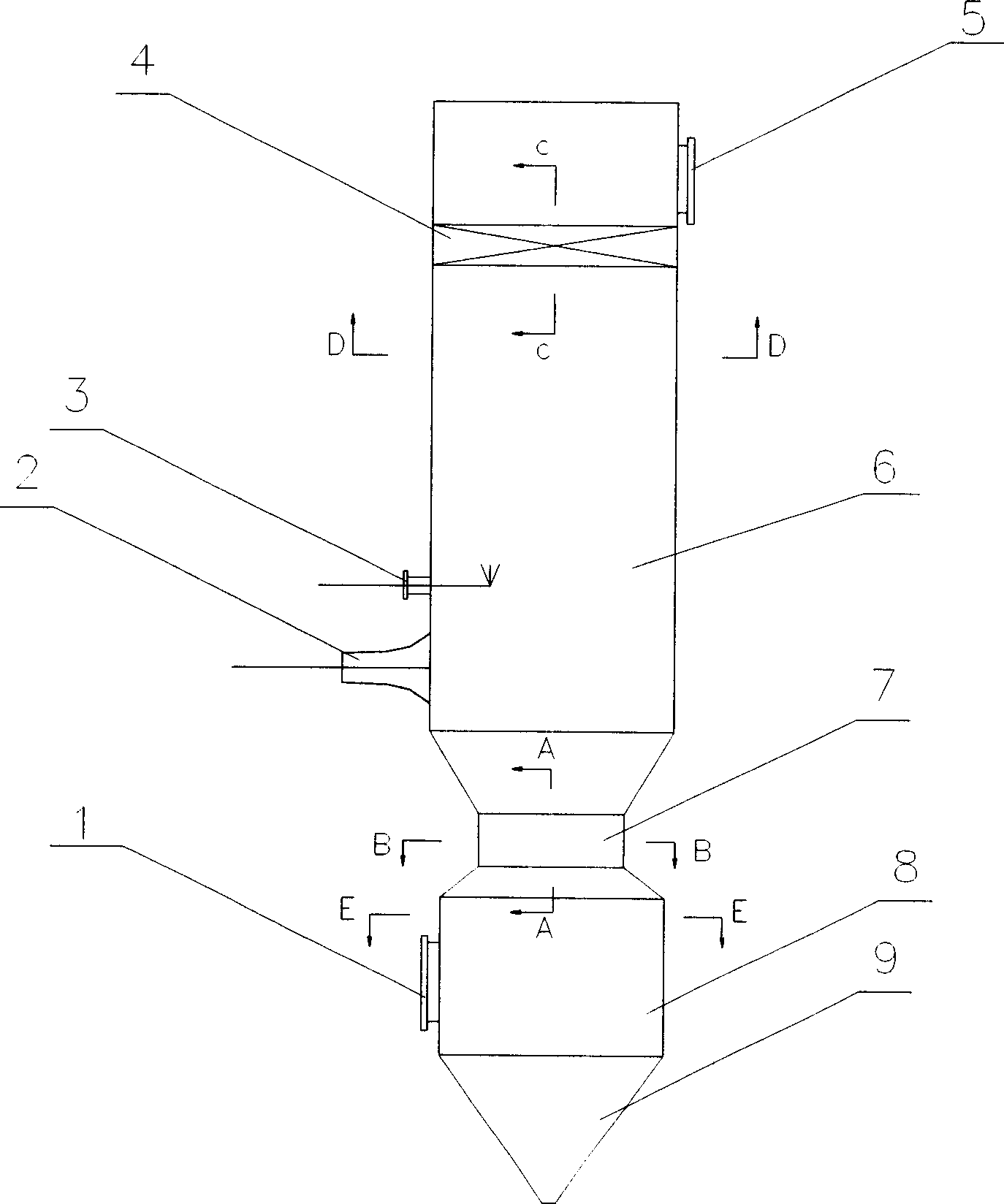

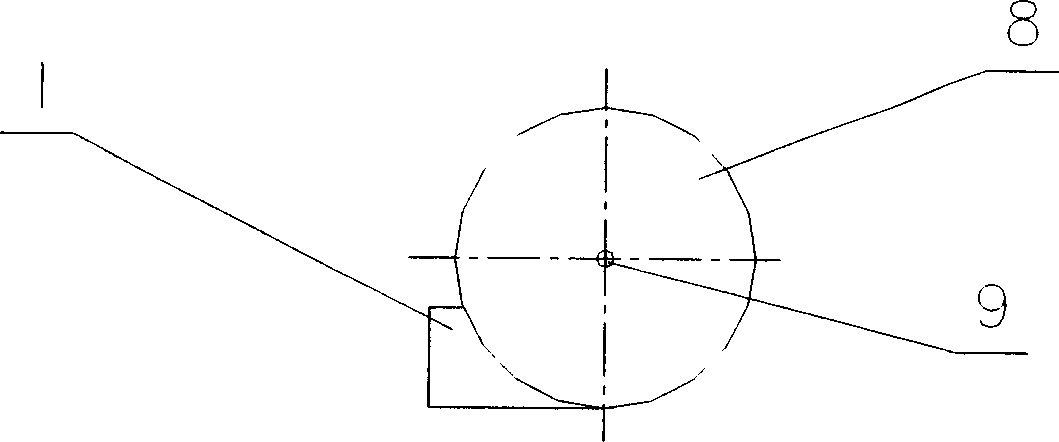

Reaction tower for stack gas desulfurization of dry type circulating fluid bed

ActiveCN1795968ARaise the ratioPre-separation implementationDispersed particle separationFluidized bedFlue gas

The invention relates to a dry circulating fluidized bed flue gas desulfurization reaction tower, belonging to the field of flue gas purification technology. Said invention includes tower body and flue gas inlet, flue gas outlet, spraying water inlet and spraying powder outlet which are connected with the tower body. Said tower body is composed of upper and lower two sections which are connected by means of designed Venturi section. The lower section of said tower body is preseparation chamber with buffer action, the connection form of the preseparation chamber and the described flue gas inlet adopts a tangetial gas-feeding turnable type structure, the bottom portion of preseparation chamber is equipped with a conical ash-falling mouth. The upper section of said tower body is a straight barrel section; the lower portion of said straight barrel section is connected with the described spraying powder inlet and spraying water inlet placed over the spraying powder inlet. In the interior of upper portion of said straight barrel section an internal separation member with inertial separation action is mounted, and the described flue gas outlet is placed over the internal separation member and connected with outer wall of said straight barrel section.

Owner:TSINGHUA UNIV +1

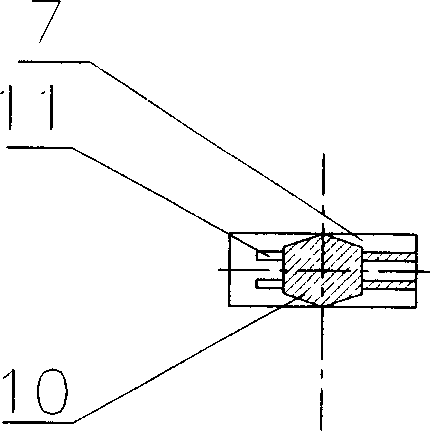

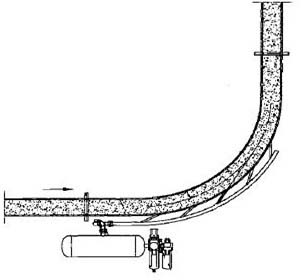

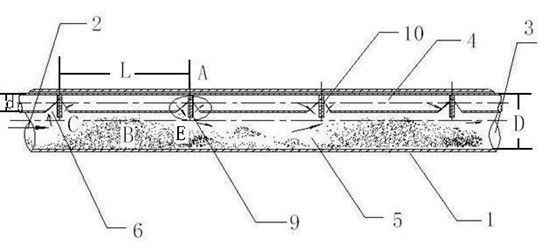

Material conveying pipe

ActiveCN102367103AEffective anti-blocking effectEasy accessBulk conveyorsSolid materialCivil engineering

The invention relates to a solid material conveying pipeline, and in particular relates to a conveying pipeline capable of preventing materials from blocking. The material conveying pipe provided by the invention comprises an external pipe; one end of the external pipe is a feeding port; the other end of the external pipe is a discharging port; the upper pipe wall in the external pipe is fixedly fitted with an internal pipe; a material channel is formed between the external wall of the internal pipe and the internal wall of the external pipe; a plurality of flowing-aided through holes distributed along the length direction of the internal pipe are formed on the pipe wall of the internal pipe towards the material channel; and a flowing-aided plate passing through the flowing-aided through holes and stretching in the material channel is extended downwards from the upper pipe wall in the internal pipe. As the flowing-aided through holes and the flowing-aided plate are adopted, the material conveying pipe provided by the invention can effectively prevent blocking.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

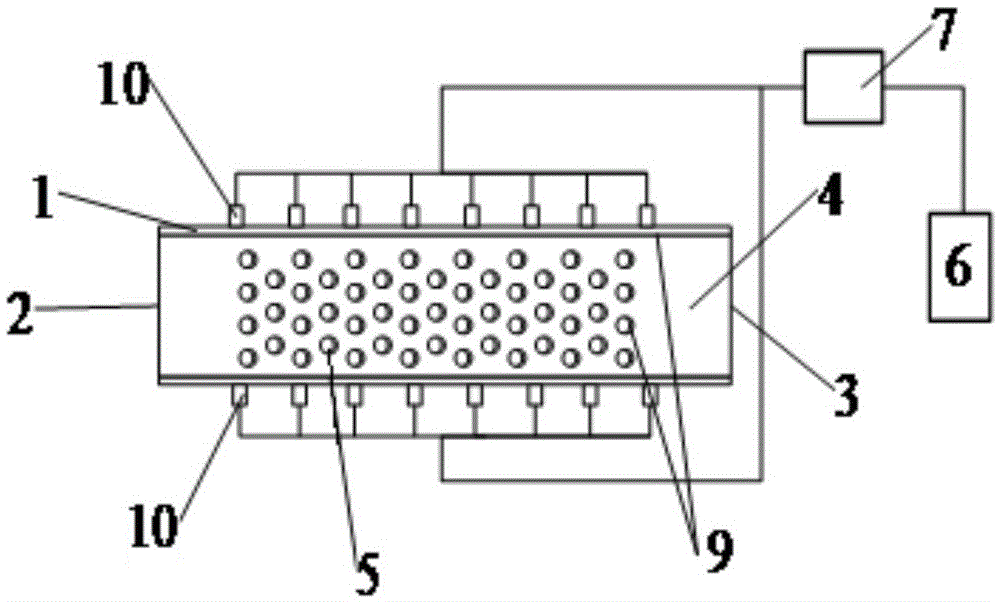

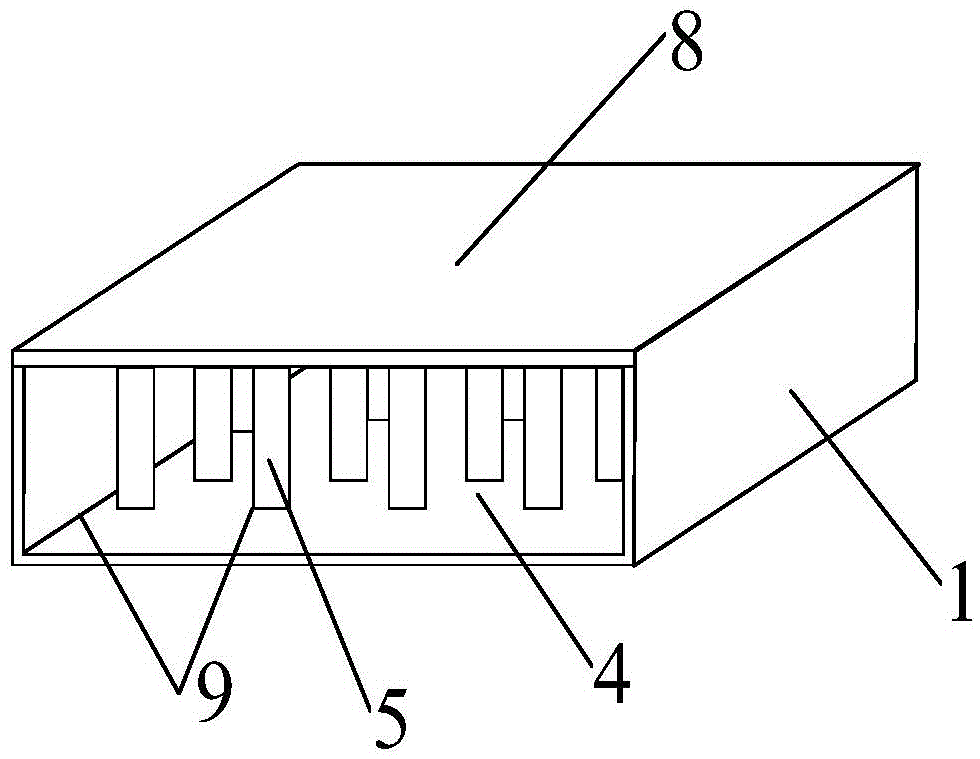

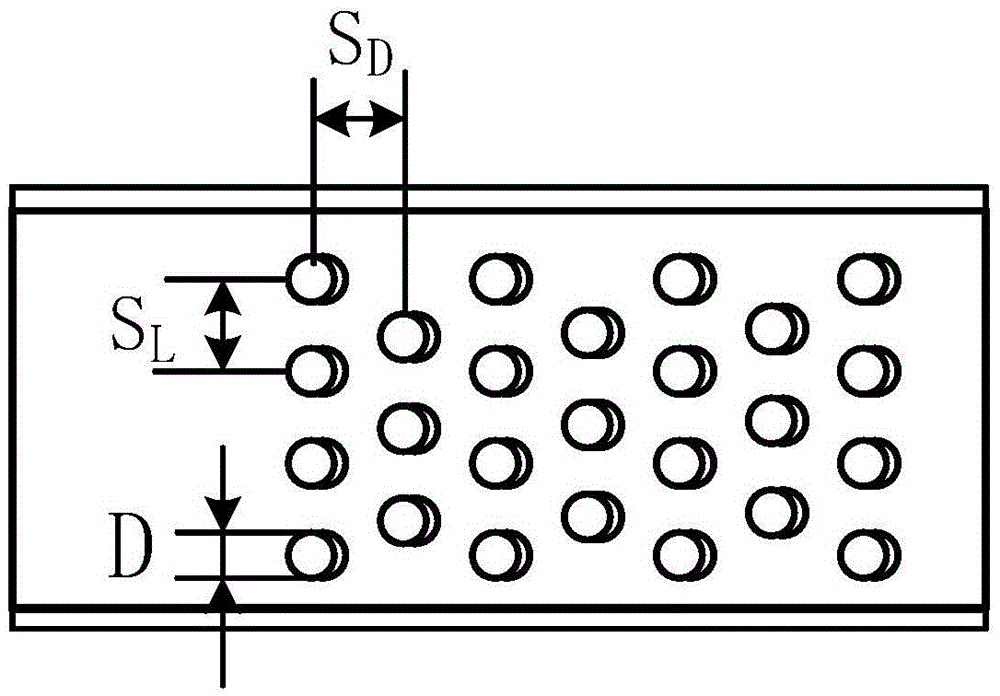

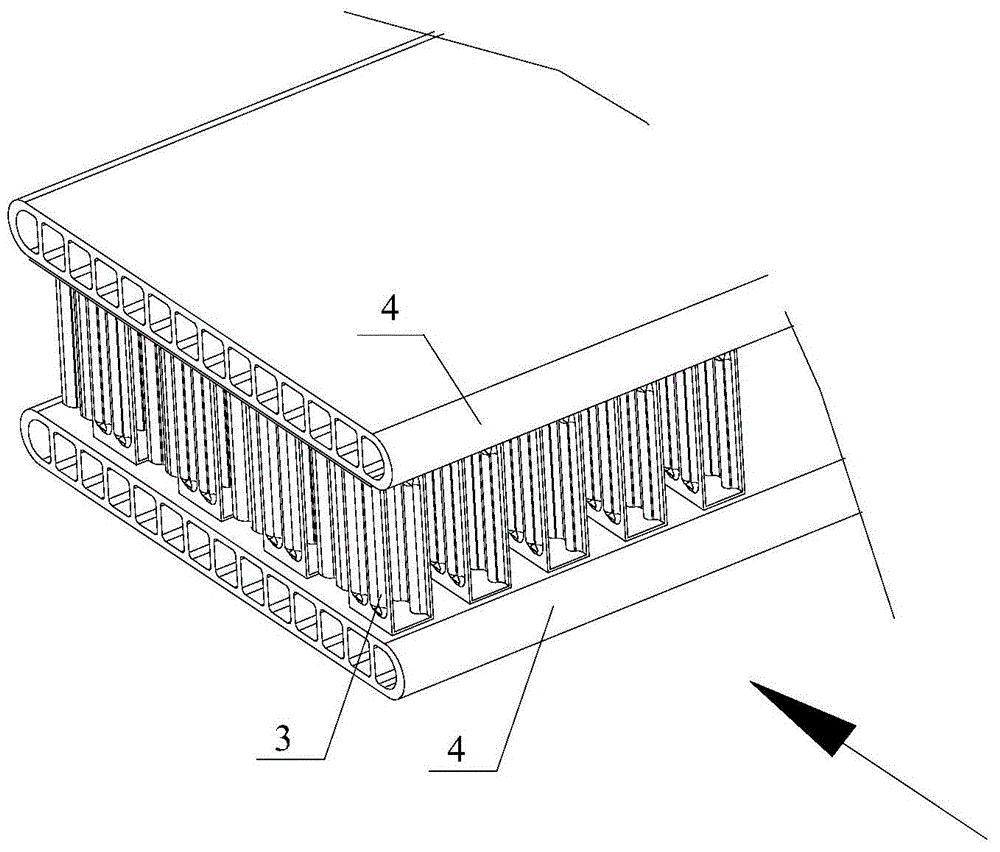

Ultrasonic reinforced micro-channel heat exchanger

InactiveCN105609475AImprove heat transfer effectSlow down the flow of waterSemiconductor/solid-state device detailsSolid-state devicesUltrasonic cavitationPlate heat exchanger

The invention provides an ultrasonic reinforced micro-channel heat exchanger. The heat exchanger comprises a shell, a water-cooling system, micro pin fins, an ultrasonic generator and an ultrasonic transducer, wherein the water-cooling system comprises a cooling water channel, a water inlet and a water outlet; the cooling water channel is arranged in the shell; the water inlet and the water outlet are connected with the cooling water channel to form the water-cooling system; the shell comprises a channel main body and an upper sealing cover; the channel main body and the upper sealing cover are connected in a sealing manner; the micro pin fins and the cooling water channel are arranged in the channel main body; the micro pin fins are arranged along the axial direction of the channel main body; the cooling water channel is formed in the spaces among the micro pin fins, and the spaces between the micro pin fins and the inner wall of the channel main body; ultrasonic transducer oscillators are distributed on the two sides of the channel main body; and the ultrasonic generator is connected with the transducer through a wire. According to the ultrasonic reinforced micro-channel heat exchanger, the ultrasonic generator is adopted to give out high-frequency signals to enable the transducer to generate ultrasonic vibration; an ultrasonic cavitation effect generated by the cooling water is changed into an ultra-turbulent flow state, so that the cooling effect is reinforced; and in addition, dirt in the channel can be cleaned at any time, and the heat transfer resistance is lowered.

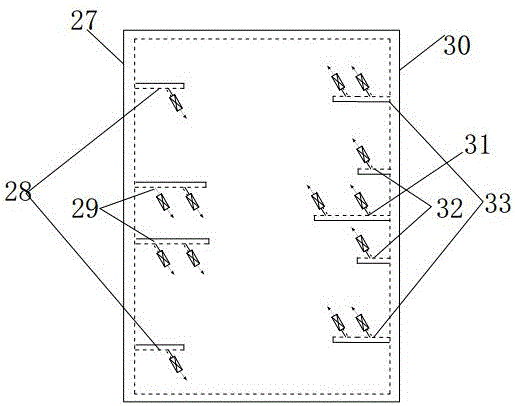

Circulating fluidized bed boiler system for achieving low nitrogen oxide discharge

InactiveCN105805730AImprove fluidization characteristicsWell mixedFluidized bed combustionStaged combustionFlue gasEngineering

The invention discloses a circulating fluidized bed boiler system for achieving low nitrogen oxide discharge. The circulating fluidized bed boiler system comprises a boiler, a cyclone separator, a dust remover and an induced draft fan which are sequentially connected. The circulating fluidized bed boiler system further comprises a primary air supply system and a secondary air supply system. A flue gas recirculation pipe is guided out of the rear portion of the induced draft fan and connected with the primary air supply system and the secondary air supply system in parallel. The secondary air supply system comprises a secondary air fan, a secondary air pipe, a plurality of secondary air vertical pipes arranged on the outer sides of a front wall and a rear wall of the boiler and secondary air nozzles, wherein the secondary air nozzles are arranged on a water cooling wall, connected with the secondary air vertical pipes and arranged in a dilute phase area of the boiler in a layered manner. According to the circulating fluidized bed boiler system, part of flue gas is mixed into primary air, the fluidization characteristic of a dense phase area during low-load running is improved, part of flue gas is mixed into secondary air, the air speed of the secondary air nozzles can be increased easily, a local high-temperature area is avoided, and generated NOx is reduced. By means of the secondary air arrangement manner of the system, the disturbance function of the flue gas in a hearth is increased, fuel is combusted fully, and the generated NOx is reduced.

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

Intelligent stirring equipment based on ceramic material

InactiveCN112169662AAchieve the effect of edge replacement filterImprove practicalityTransportation and packagingRotary stirring mixersSpiral bladeGear wheel

The invention relates to the technical field of ceramic material production equipment, and discloses intelligent stirring equipment based on a ceramic material. The intelligent stirring equipment comprises a shell, the top of the shell is rotatably connected with a gear set, the middle part of the gear set is fixedly connected with a first rotating shaft, and the periphery of the bottom of the first rotating shaft is fixedly connected with spiral blades; and a second rotating shaft is rotationally connected into the gear set, an electromagnet is fixedly connected to the bottom of the second rotating shaft, a supporting base is fixedly connected to the periphery of the middle of the second rotating shaft, and a connecting rod set is hinged to the periphery of the supporting base. Accordingto the intelligent stirring equipment based on the ceramic material, during replacement, a pull rod is pulled up to release locking of a movable block to a filter screen frame to take out a blocked filter screen, the effect of replacing the filter screen at the edge is achieved, the practicability of the equipment is improved, the supporting bases at the top and the bottom are crossed to stretch and fold, the disturbance effect of water is enhanced, and intelligent adjustment makes stirring more uniform; and fine clods are prevented from influencing the surface quality of the ceramic.

Owner:谭尚平

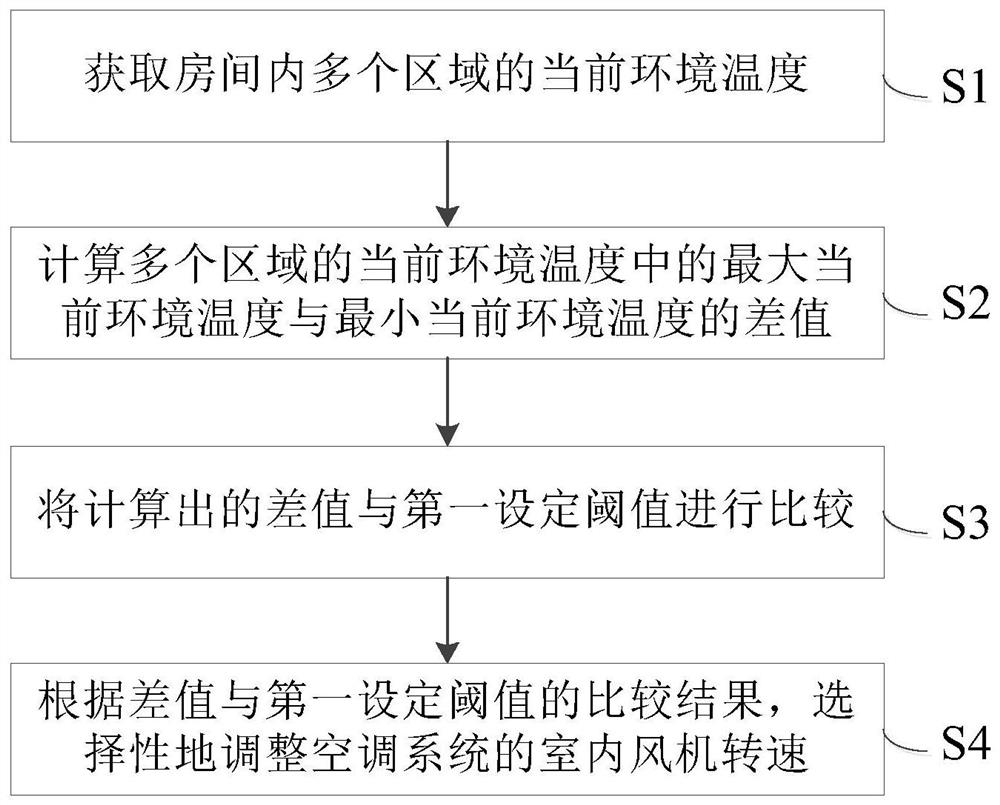

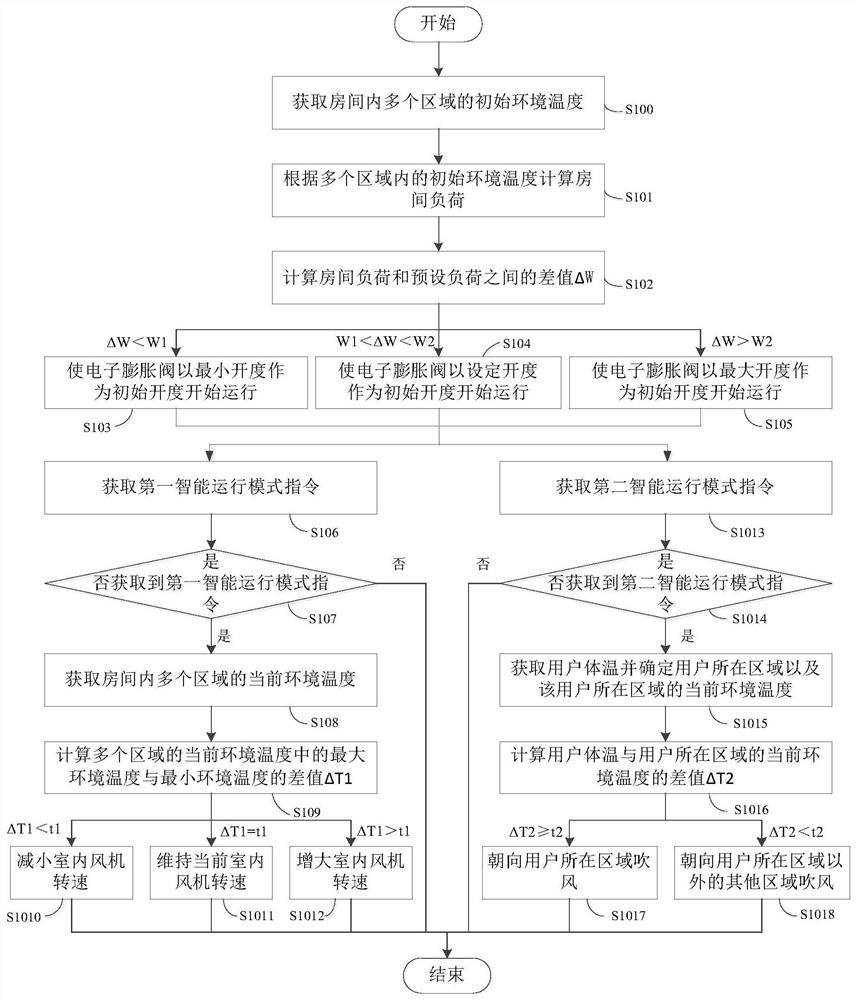

Control method of air conditioning system

ActiveCN112762580AImprove the temperature regulation effectEven and fast regulationMechanical apparatusSpace heating and ventilation safety systemsTemperature conditioningEngineering

The invention belongs to the technical field of heat exchange equipment, and particularly relates to a control method of an air conditioning system. The invention aims to solve the problems that the uniform distribution degree of cold and warm airflow in a room cannot be guaranteed when the indoor temperature is adjusted by the existing air conditioning equipment, and the temperature adjusting effect of each indoor position is not uniform. According to the control method of the air conditioning system, the temperature equalization degree in the room can be determined based on the difference between the maximum temperature value and the minimum temperature value in the current environment temperatures of the multiple areas in the room, so that the rotating speed of an indoor fan is regulated and controlled according to the current temperature equalization degree of the room, and the indoor air supply capacity of the air conditioning system is selectively adjusted, and therefore, the indoor temperature environment can be uniformly and quickly adjusted when the air conditioning system operates, and a good temperature adjusting effect can be achieved in any position in the room, and thus, the overall temperature adjusting effect of the air conditioning system is greatly improved.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +2

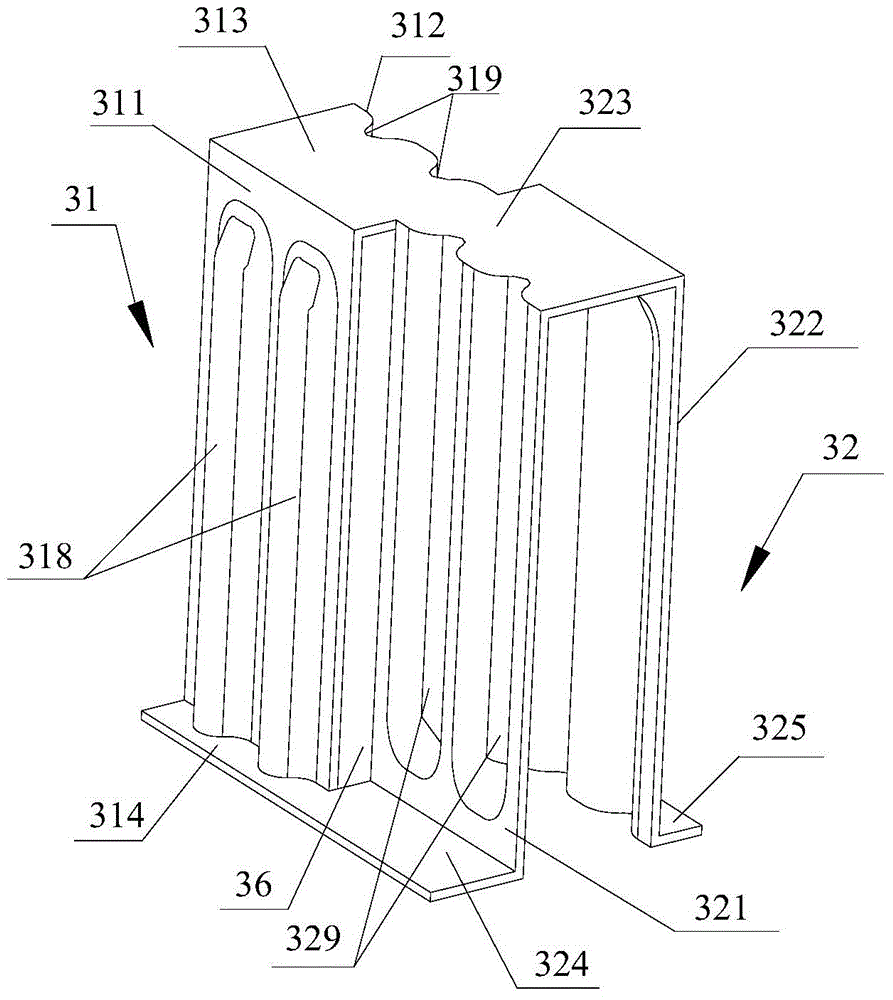

Heat exchanger fin, heat exchanger and manufacturing method of heat exchanger fin

InactiveCN104677162ANot easy to accumulateSpeed up the flowEvaporators/condensersTubular elementsEngineeringMicro heat exchanger

The invention provides a heat exchanger fin. The heat exchanger fin comprises a plurality of fin units which are integrally connected in a certain manner; the sections of the fin units in the circulation direction of an outside fluid are approximately rectangular or trapezoidal; in the length direction of the fin, the adjacent fin units are connected by use of corresponding tops and corresponding first roots and second roots; in addition, the adjacent fin units are arranged in a ladder pattern, and gaps are formed between corresponding first sidewalls and corresponding second sidewalls; in the width direction of the fin, the adjacent fins are connected by use of the corresponding first roots and the corresponding second roots; an reinforcing element serving as a lug and / or a concave portion is integrally formed on one of the first sidewall and the second sidewall, so that the bearing strength of the fin units can be enhanced and the surface heat exchange area of the fin also can be increased; meanwhile, the reinforcing element is matched with the gaps to increase the turbulence between the fin and the fluid, and consequently, the heat exchange efficiency of the heat exchanger with the fin can be improved.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER

Building construction sand sieving equipment with swing function

The invention provides building construction sand sieving equipment with a swing function. The equipment comprises a frame body. A screen is arranged in the frame body. A baffle is fixedly connected to the periphery of the screen. A horizontal rod is fixedly connected to the upper end of the baffle through a vertical rod. Two supporting plates are fixedly connected to the top of the frame body symmetrically. The horizontal rod is connected with the supporting plates in a rotating manner through a rotating shaft. A vertical plate is fixedly connected to the lower side of the other end of the horizontal rod. A rack is arranged on one side of the vertical plate. A supporting frame is arranged on the outer side wall of the frame body. A first rotating shaft is connected to the supporting framein a rotating manner. One end of the first rotating shaft is fixedly connected with an output shaft of a first motor. The other end of the first rotating shaft is fixedly connected with a gear. Halfwheel teeth are arranged on the gear. The gear is meshed with the rack. The equipment has the beneficial effects that when the first motor on the left side works, the first motor can drive the gear onthe left side to rotate, the gear on the left side can drive the rack on the left side to move downwards, thus the horizontal rod rotates around the rotating shaft, and the left end of the screen istilted.

Owner:湖北泰和建设集团有限公司

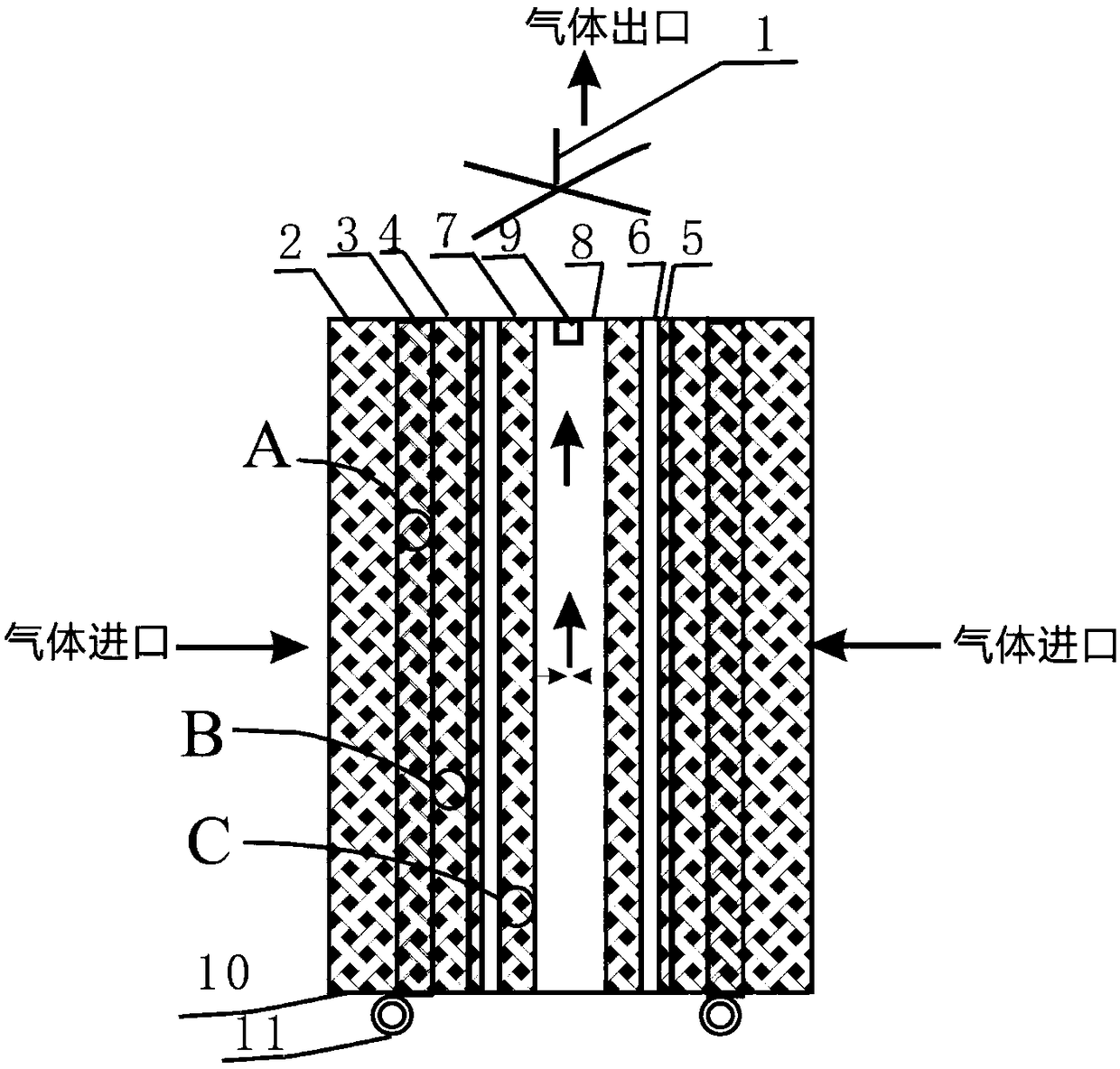

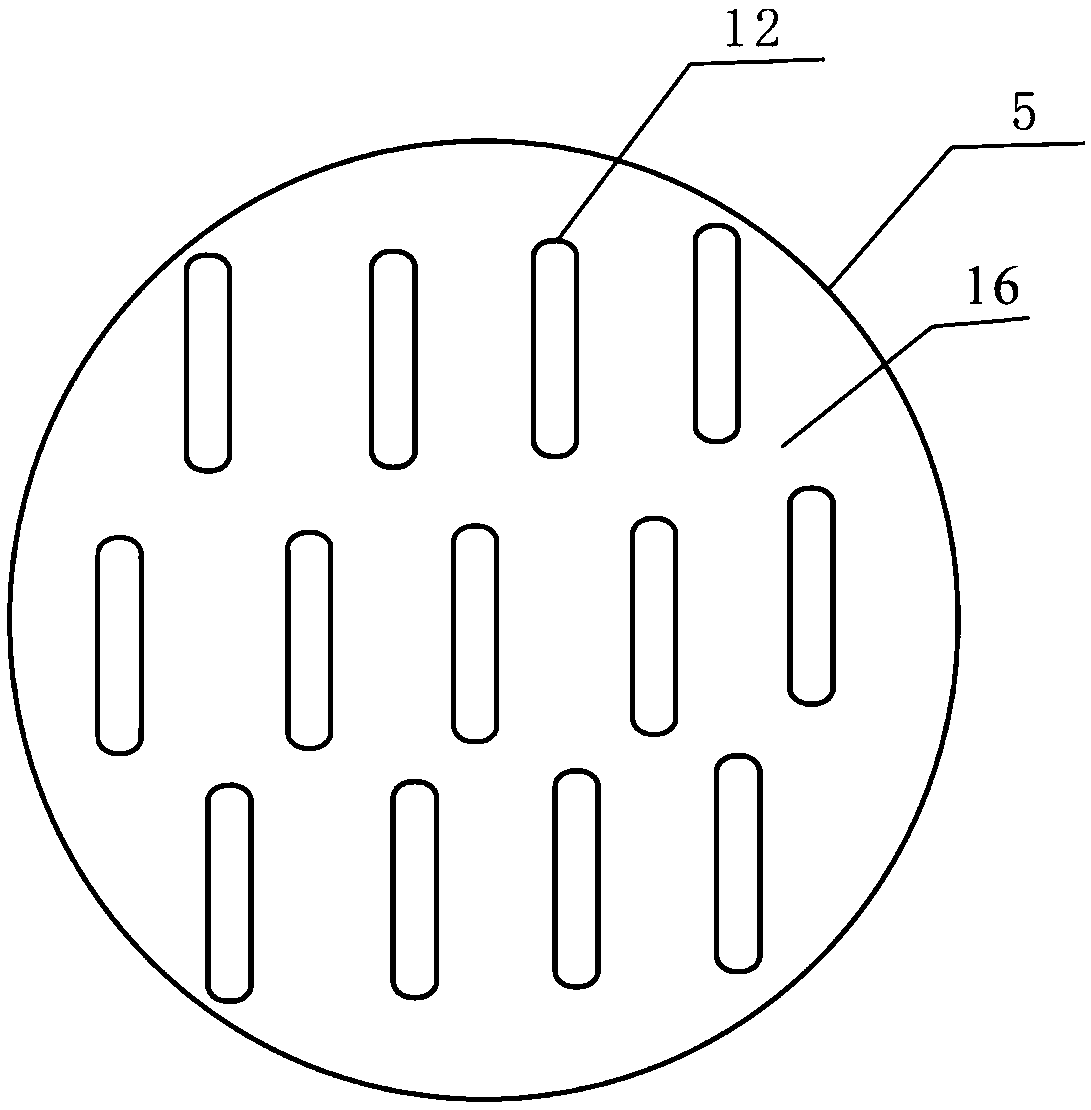

Multi-stage indoor formaldehyde removing device with sterilization effect

InactiveCN109012162ALarge specific surface areaStrong adsorption capacity characteristicsGas treatmentOther chemical processesChemistryActivated carbon

The invention provides a multi-stage indoor formaldehyde removing device with sterilization effect. According to the invention, a high-pass filter screen, a water vapor removing layer, a carbon dioxide removing layer, a steel mesh and a formaldehyde removing layer are sequentially installed between an air inlet and an air outlet; the high-pass filter screen is used for filtering dust particles andPM2.5 particles; the water vapor removing layer is made of a silica gel or molecular sieve, and the silica gel or molecular sieve is grown on activated carbon cotton or high-pass fibers; the carbon dioxide removing layer employs a metal organic framework material growing on the activated carbon cotton or high-pass fibers; the steel mesh is sprayed with nanometer silver ions and is provided with aplurality of uniformly-distributed ultraviolet lamps; and the formaldehyde removing layer is a metal organic framework material growing on the activated carbon cotton or high-pass fibers, and the metal organic framework material is doped with a photocatalyst. The multi-stage indoor formaldehyde removing device of the invention can remove PM2.5, dust, water vapor and CO2 gas step by step, therebyefficiently removing formaldehyde and achieving sterilization effect at the same time.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

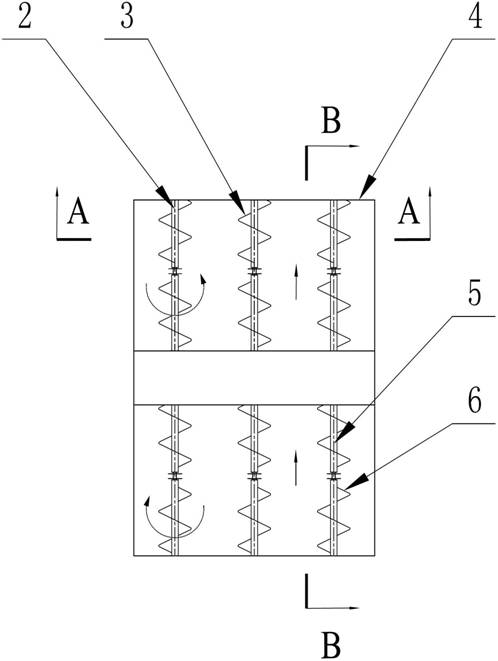

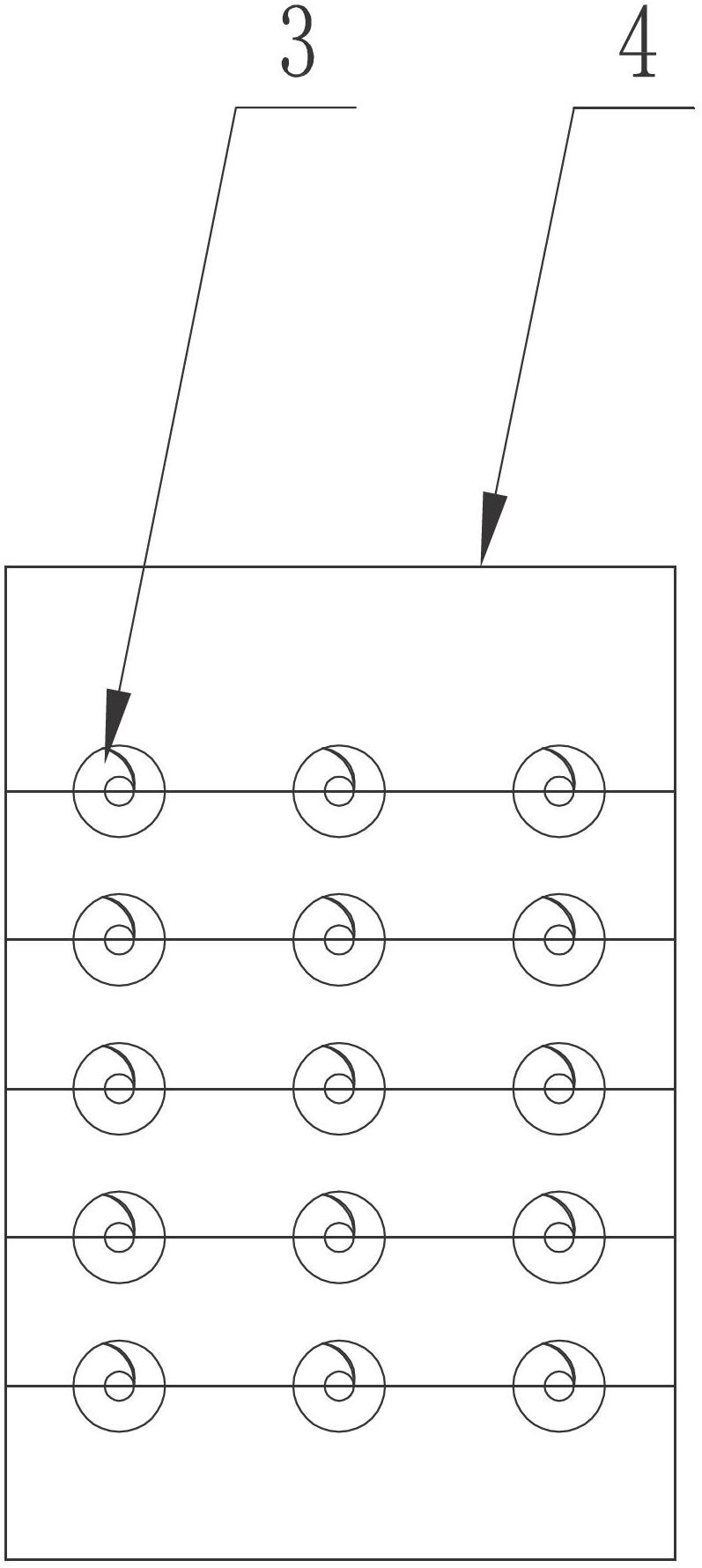

Spiral flocculator and application to folded plate type flocculation reaction tank

ActiveCN102674518AFully disturbedIncrease mixing intensityWater/sewage treatment by flocculation/precipitationSedimentation settling tanksFlocculationWater flow

The invention belongs to water treatment equipment, and particularly relates to a spiral flocculator which comprises a support. At least two spiral plates with opposite turning directions are longitudinally arranged on the support at intervals, the upper end and the lower end of each spiral plate are rotationally assembled on the support, and strip-shaped blades are radially fixed onto outer edges of the spiral plates. The spiral flocculator is mounted between two adjacent partition boards in a folded plate type flocculation reaction tank when applied to the folded plate type flocculation reaction tank. The spiral flocculator solves problems of large application limitation, poor flocculation effect and large occupied area of an existing reaction tank in the prior art, and has the advantages that a disturbance effect to water flow is good, the occupied area of the reaction tank is small, installation is simple, energy is saved, and the like.

Owner:JIACHENG ENVIRONMENTAL PROTECTION ENG CO LTD

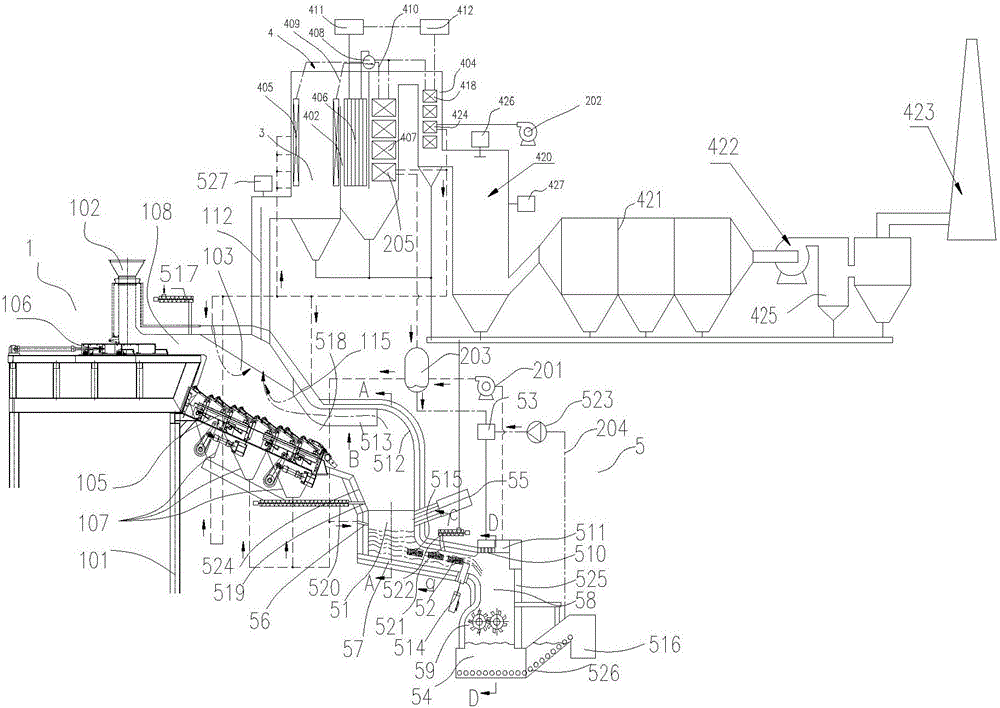

Waste fusing and curing treatment system and method

ActiveCN106524175ARealize continuous gasification and melting processingLarge amount of processingIncinerator apparatusCombustorSlag

The invention discloses a waste fusing and curing treatment system and method. When the waste fusing and curing treatment system and method are used for treating rubbish, the rubbish conveying capacity is higher, the rubbish treating capacity is larger, the thermal loss can be reduced, the heat exchanging efficiency can be improved, the recovery efficiency of heat is relatively high, and the emission load of pollutants can be effectively reduced. The waste fusing and curing treatment system comprises a fusion hearth, a laminar flow channel, a water-cooling breaking system and a water seal deslagging system all of which are sequentially arranged in the feeding direction. A high-temperature burner and a gasifying agent inlet are formed in the side wall of the fusion furnace. The water-cooling breaking system comprises a water-cooling system, a water-cooling cavity and a glass body pulverizer. The method comprises the first step of furnace starting and drying; the second step of enabling residues into the fusion hearth to be fused; the third step of fusing inorganic waste in the laminar flow channel; the fourth step of carrying out water cooling on fusion slag and curing the fusion slag into glass body dregs, and breaking and discharging the dregs; and the fifth step of turning off the waste fusing and curing treatment system after the waste fusion dregs are discharged completely.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

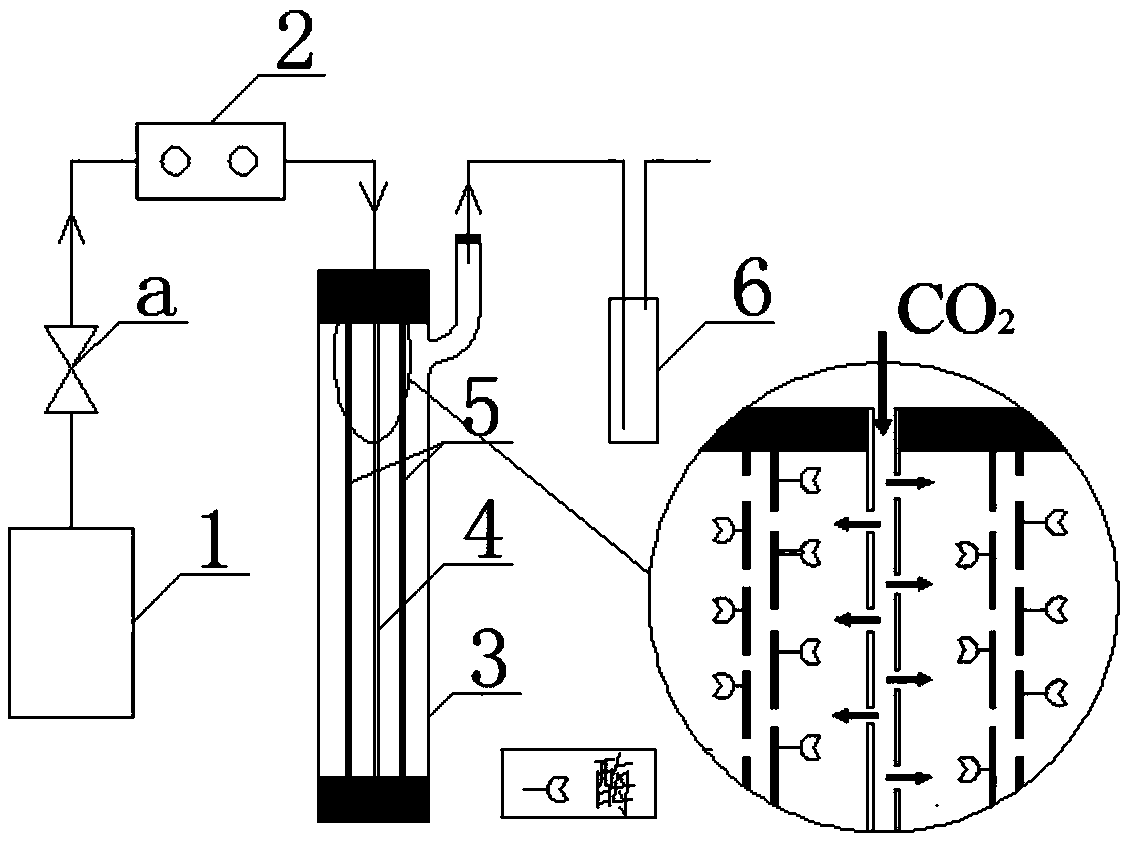

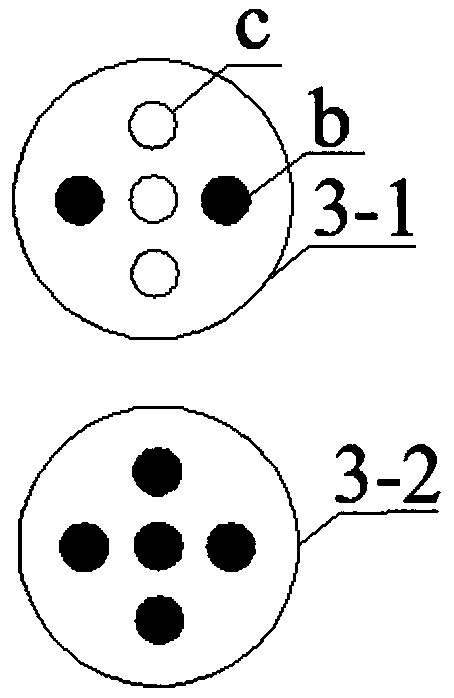

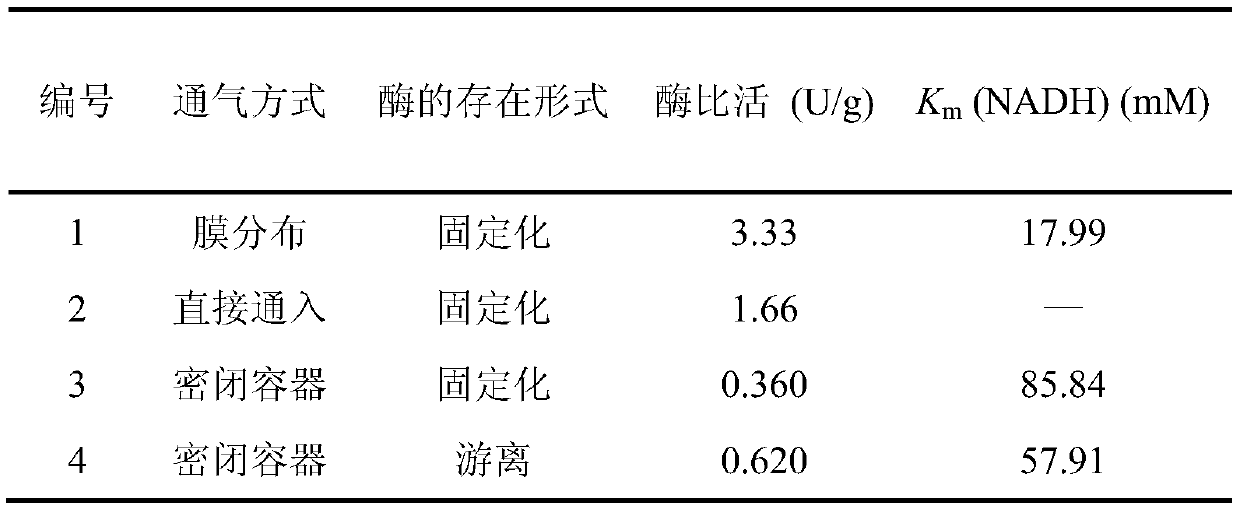

Hollow fibrous membrane reactor integrating gas distribution and enzyme catalysis and application of hollow fibrous membrane reactor

InactiveCN105505770AAffects gas distribution performanceEasy to control separatelyBioreactor/fermenter combinationsBiological substance pretreatmentsGas phaseRetention time

The invention relates to a hollow fibrous membrane reactor integrating a gas distribution function and an enzyme catalysis function and an application method of the reactor. A hollow fibrous membrane is used as a gas distributor, the hollow fibrous membrane for distributing the gas and a hollow fibrous membrane of an immobilized enzyme are assembled into a same component, the bottom end of the membrane component and the bottom ends of all fibrous membranes in the component are sealed, the top end of the membrane component and the top end of the hollow fibrous membrane of the immobilized enzyme are sealed, and the top end of the hollow fibrous membrane for distributing the gas is open and is used for introducing CO2 gas; the hollow fibrous membrane reactor is applied to a formate dehydrogenase (FDH) catalytic CO2 methanoic acid synthetic system, by controlling the upstream gas rate, the number of the hollow fibrous membrane for distributing the gas and the micro-structural parameters of the membrane, the quantity and the size of bubbles, the retention time and space distribution in a solution can be adjusted, so that the gas-liquid contact time and the gas-liquid contact area can be increased, the liquid phase can be effectively disturbed, the rapid and efficient dispersion and mixing between the gas phase and the liquid phase and inside the liquid phase can be realized, and the mass transfer effect can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com